Amount of Fill Product Residues in Plastic Packagings for Recycling

Abstract

:1. Introduction

1.1. Recycling of Disposable Packaging in Germany

1.2. Relevance of Impurities and Residues for Sorting

1.3. Emptying Behaviour of Packagings

1.4. Intention of the Study

2. Materials and Methods

2.1. Sampling

2.2. Measurement of Weights

2.3. Data Processing

3. Results

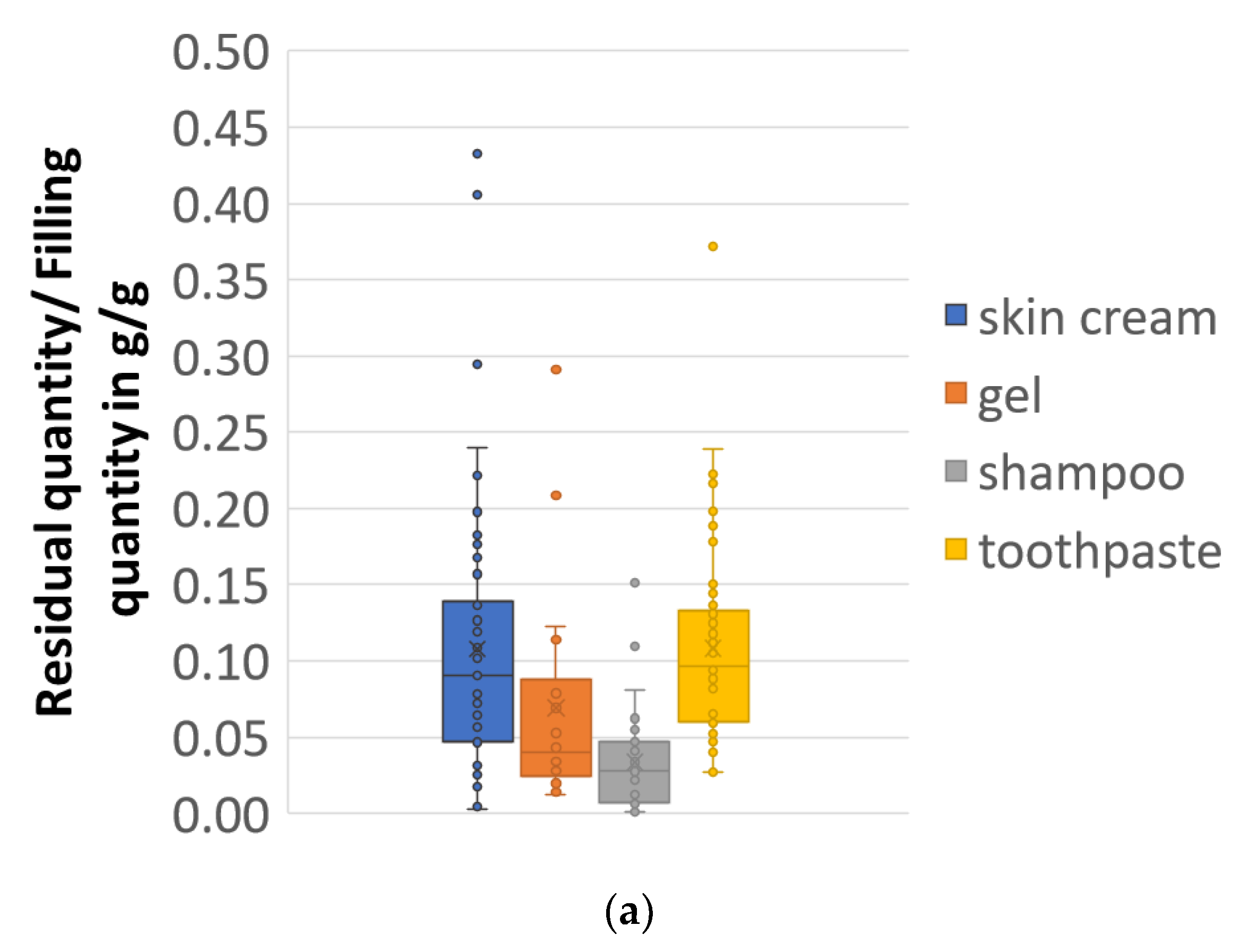

3.1. Tubes Composed of PE

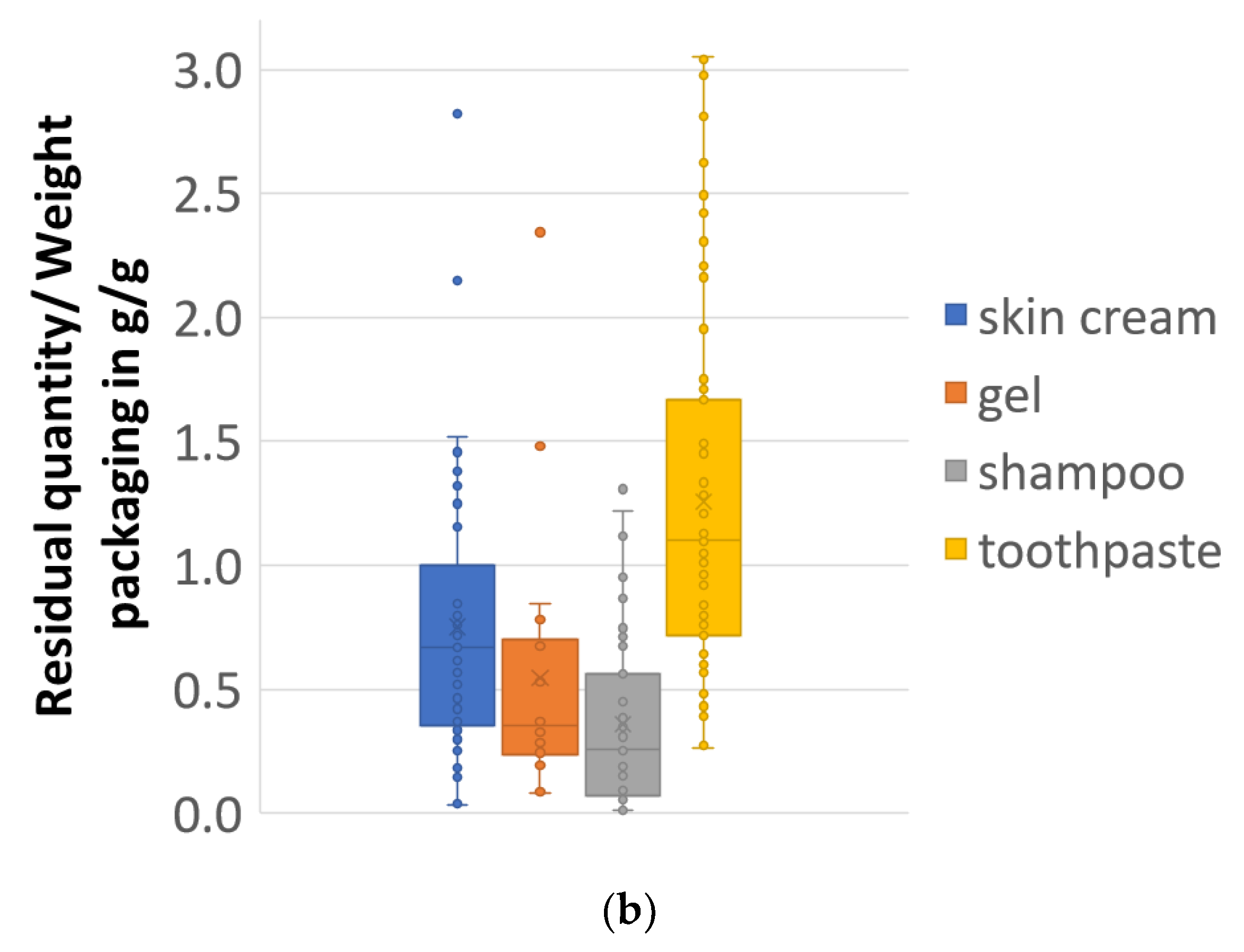

3.2. Cups Composed of PP

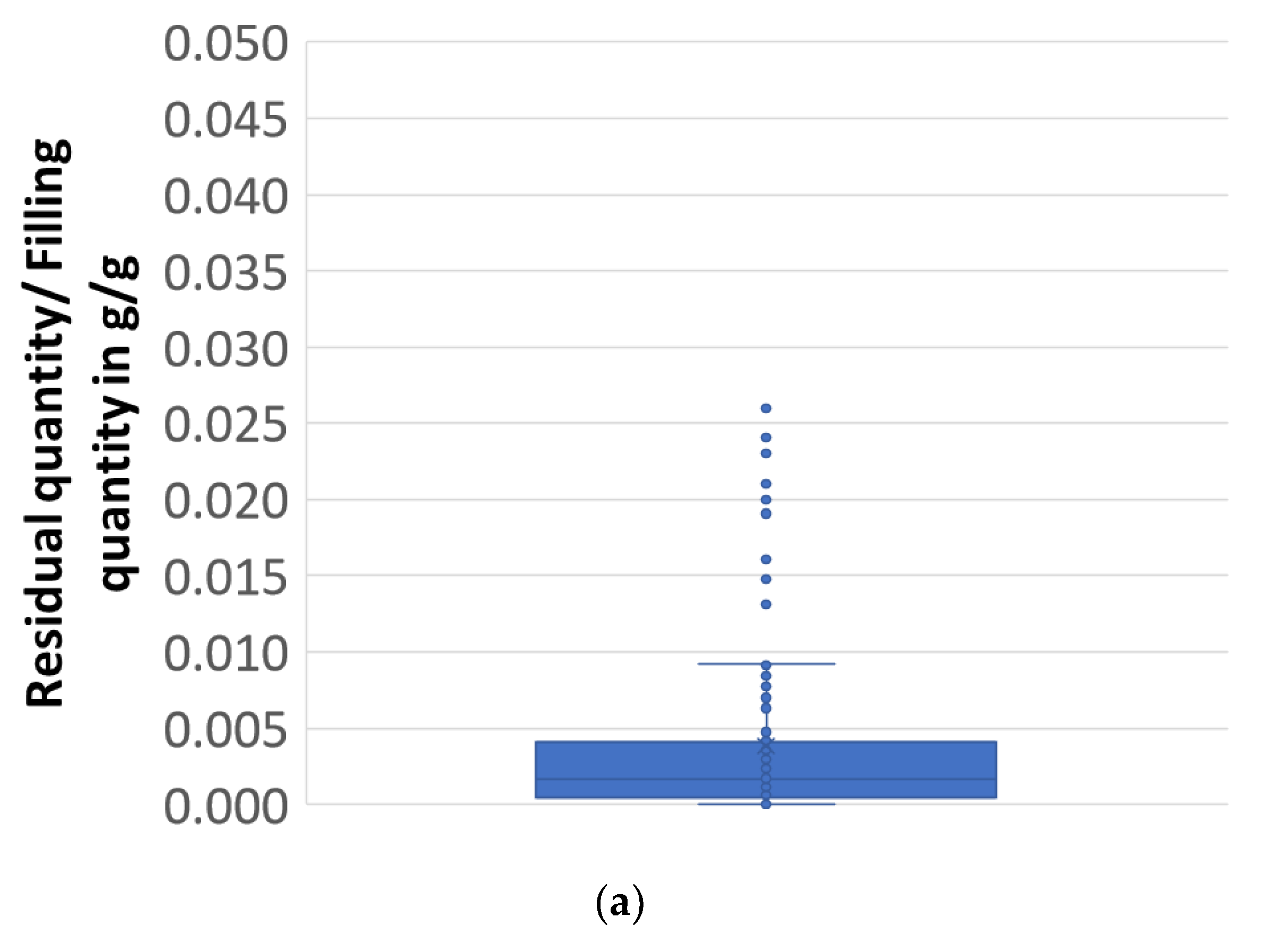

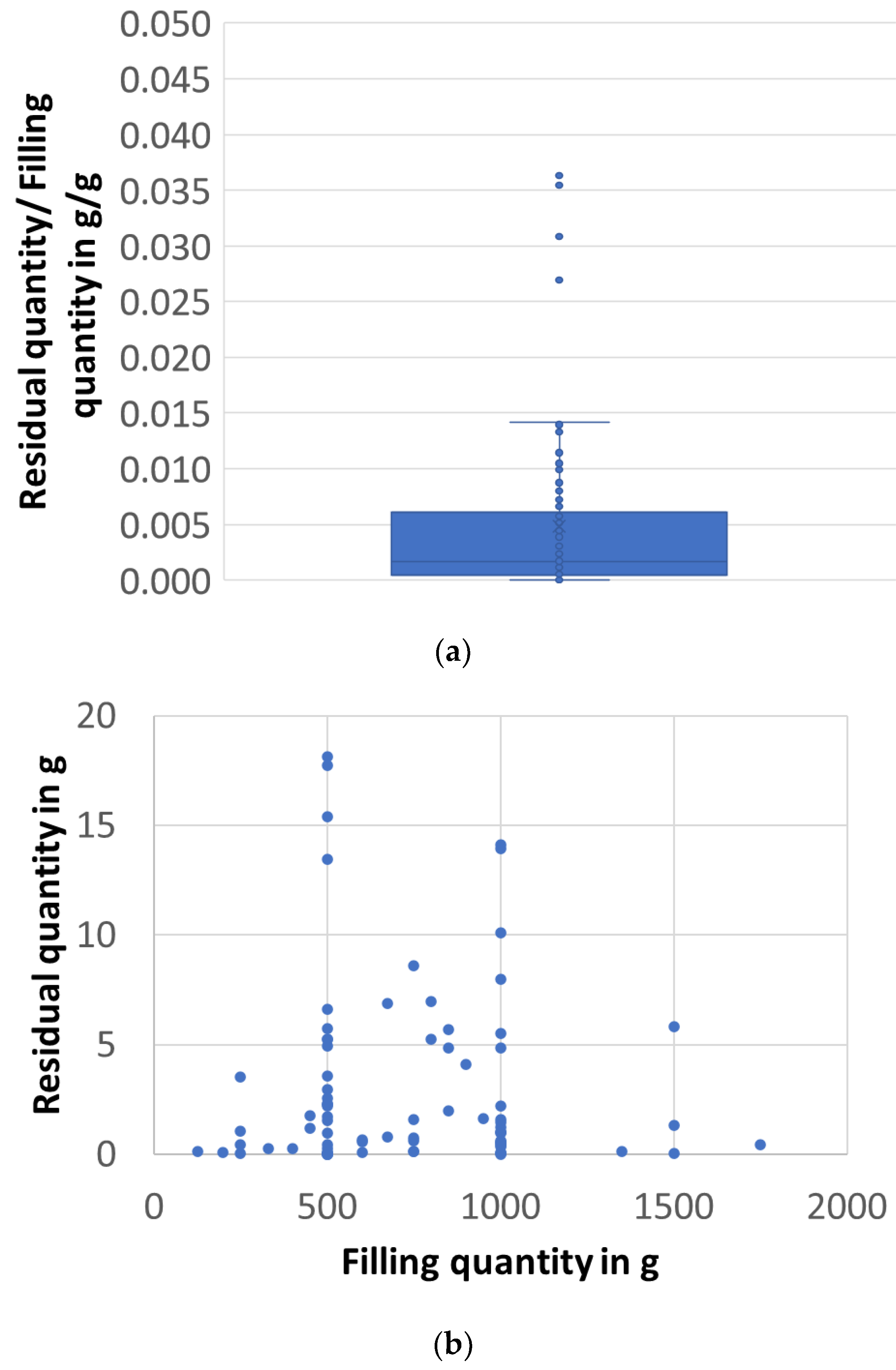

3.3. Bottles Composed of PP and PE-HD

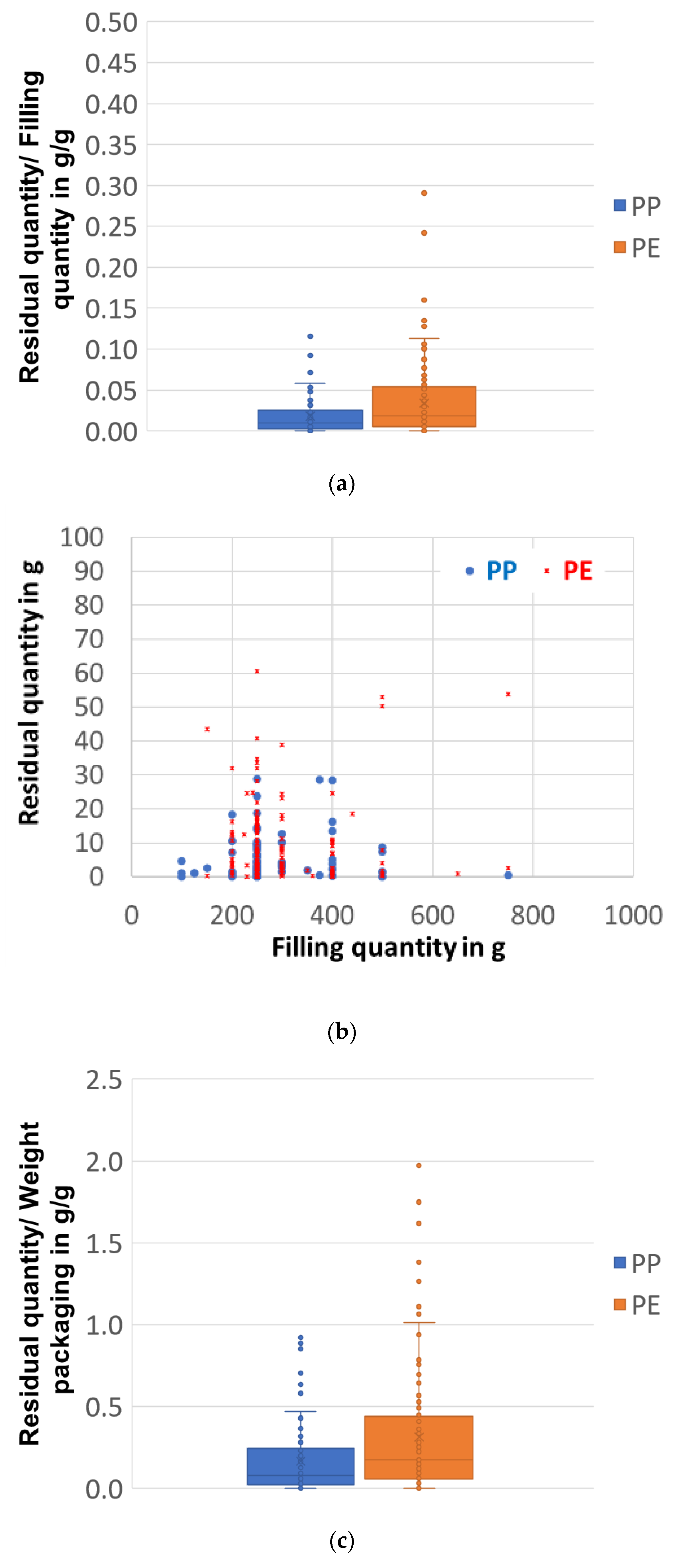

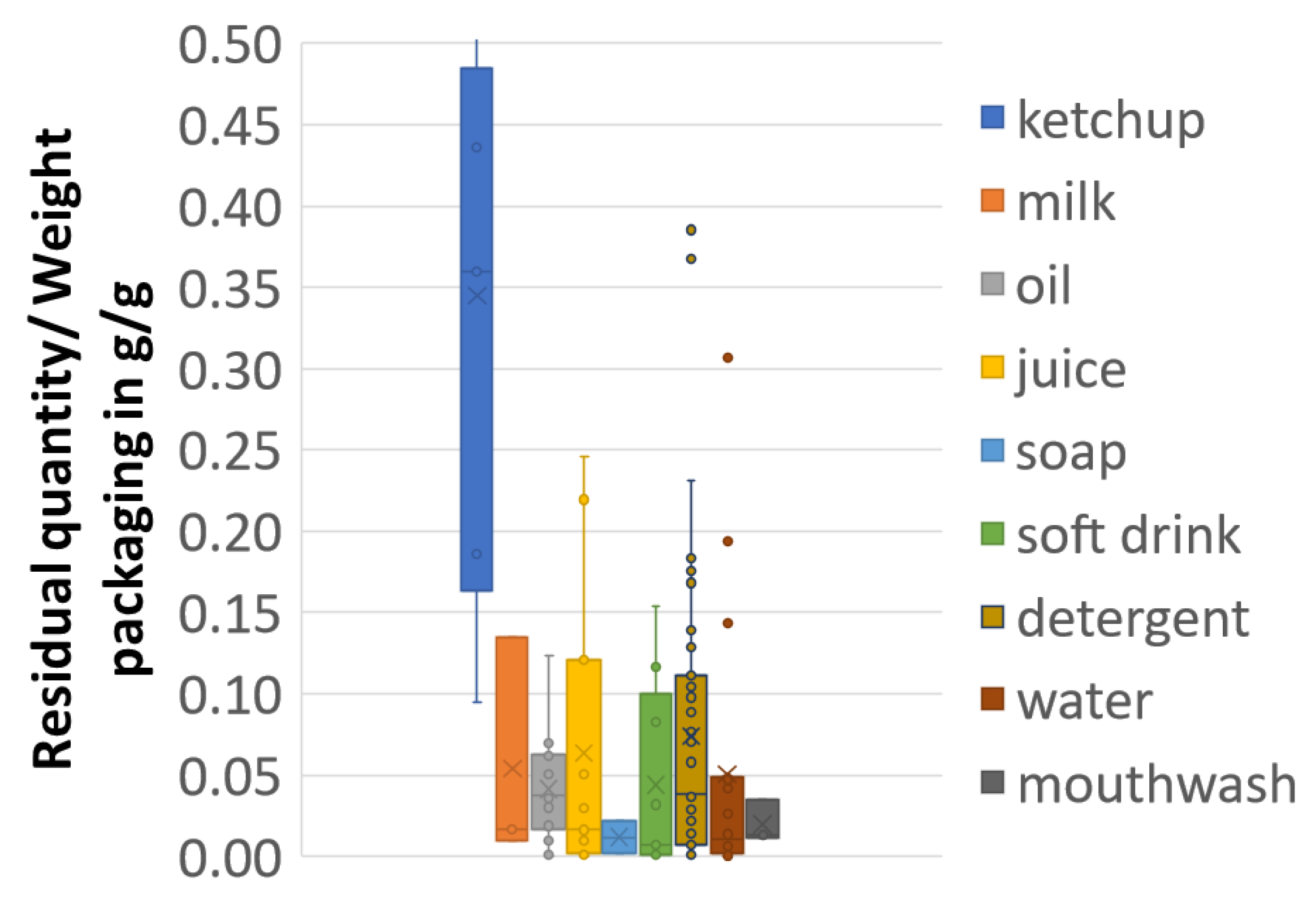

3.4. PET Bottles

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Snell, H.; Nassour, A.; Nelles, M. Qualitative comparison of polyethylene terephthalate flakes from various collection systems in Germany. Waste Manag. Res. 2017, 35, 163–171. [Google Scholar] [CrossRef]

- Picuno, C.; Alassali, A.; Chong, Z.K.; Kuchta, K. Flows of post-consumer plastic packaging in Germany: An MFA-aided case study. Resour. Conserv. Recycl. 2021, 169, 105515. [Google Scholar] [CrossRef]

- Dehio, J.; Janßen-Timmen, R.; Rothgang, M. Regulating markets for post-consumer recycling plastics: Experiences from Germany’s Dual System. Resour. Conserv. Recycl. 2023, 196, 107048. [Google Scholar] [CrossRef]

- Rudolph, N.; Kiesel, R.; Aumnate, C. Plastic Waste around the World: Increasing Potential of Recycling. In Understanding Plastics Recycling; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2020; pp. 97–115. ISBN 978-1-56990-846-4. [Google Scholar]

- Orth, P.; Bruder, J.; Rink, M. Kunststoffe im Kreislauf: Vom Recycling zur Rohstoffwende, 1st ed.; Springer Vieweg: Wiesbaden, Germany, 2022; ISBN 9783658378141. [Google Scholar]

- Lase, I.S.; Bashirgonbadi, A.; van Rhijn, F.; Dewulf, J.; Ragaert, K.; Delva, L.; Roosen, M.; Brandsma, M.; Langen, M.; De Meester, S. Material flow analysis and recycling performance of an improved mechanical recycling process for post-consumer flexible plastics. Waste Manag. 2022, 153, 249–263. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Kroell, N.; Hofmann, B.; Schlögl, S.; Greiff, K. Improving drum sieve performance in lightweight packaging waste recycling by automatic parameter adjustment through 3D laser triangulation-based process monitoring. Resour. Conserv. Recycl. 2023, 192, 106924. [Google Scholar] [CrossRef]

- Voet, V.; Folkersma, R.; Jager, J. Plastics in the Circular Economy; Walter de Gruyter GmbH: Berlin, Germany, 2021; ISBN 9783110666762. [Google Scholar]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of Polymer-Based Multilayer Packaging: A Review. Recycling 2018, 3, 1. [Google Scholar] [CrossRef]

- Picuno, C.; van Eygen, E.; Brouwer, M.T.; Kuchta, K.; Thoden van Velzen, E.U. Factors Shaping the Recycling Systems for Plastic Packaging Waste—A Comparison between Austria, Germany and The Netherlands. Sustainability 2021, 13, 6772. [Google Scholar] [CrossRef]

- Chen, X.; Kroell, N.; Althaus, M.; Pretz, T.; Pomberger, R.; Greiff, K. Enabling mechanical recycling of plastic bottles with shrink sleeves through near-infrared spectroscopy and machine learning algorithms. Resour. Conserv. Recycl. 2023, 188, 106719. [Google Scholar] [CrossRef]

- Chen, X.; Kroell, N.; Wickel, J.; Feil, A. Determining the composition of post-consumer flexible multilayer plastic packaging with near-infrared spectroscopy. Waste Manag. 2021, 123, 33–41. [Google Scholar] [CrossRef]

- Feil, A.; Pretz, T. Chapter 11—Mechanical recycling of packaging waste. In Plastic Waste and Recycling; Letcher, T.M., Ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 283–319. ISBN 978-0-12-817880-5. [Google Scholar]

- Koinig, G.; Friedrich, K.; Rutrecht, B.; Oreski, G.; Barretta, C.; Vollprecht, D. Influence of reflective materials, emitter intensity and foil thickness on the variability of near-infrared spectra of 2D plastic packaging materials. Waste Manag. 2022, 144, 543–551. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Möllnitz, S.; Küppers, B.; Curtis, A.; Khodier, K.; Sarc, R. Influence of pre-screening on down-stream processing for the production of plastic enriched fractions for recycling from mixed commercial and municipal waste. Waste Manag. 2021, 119, 365–373. [Google Scholar] [CrossRef] [PubMed]

- Kroell, N.; Chen, X.; Greiff, K.; Feil, A. Optical sensors and machine learning algorithms in sensor-based material flow characterization for mechanical recycling processes: A systematic literature review. Waste Manag. 2022, 149, 259–290. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Wu, H.; Cai, M.; Zhou, Y.; Guo, C.; Han, Y.; Zhang, L. Valorization of Biomass-Derived Polymers to Functional Biochar Materials for Supercapacitor Applications via Pyrolysis: Advances and Perspectives. Polymers 2023, 15, 2741. [Google Scholar] [CrossRef] [PubMed]

- Schmiemann, A.; Amici, M.; Schröder, T.; van Roost, H.; Jahnke, E.; Nießner, N.; Mangold, H.; Beyer, C.; Leadbitter, J.; Wilhelmus, B. Mechanical Recycling. In Recycling of Plastics; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2022; pp. 275–433. ISBN 978-1-56990-856-3. [Google Scholar]

- Strangl, M.; Lok, B.; Breunig, P.; Ortner, E.; Buettner, A. The challenge of deodorizing post-consumer polypropylene packaging: Screening of the effect of washing, color-sorting and heat exposure. Resour. Conserv. Recycl. 2021, 164, 105143. [Google Scholar] [CrossRef]

- Lange, J.-P. Managing Plastic Waste—Sorting, Recycling, Disposal, and Product Redesign. ACS Sustain. Chem. Eng. 2021, 9, 15722–15738. [Google Scholar] [CrossRef]

- Strangl, M.; Schlummer, M.; Maeurer, A.; Buettner, A. Comparison of the odorant composition of post-consumer high-density polyethylene waste with corresponding recycled and virgin pellets by combined instrumental and sensory analysis. J. Clean. Prod. 2018, 181, 599–607. [Google Scholar] [CrossRef]

- Strangl, M.; Ortner, E.; Fell, T.; Ginzinger, T.; Buettner, A. Odor characterization along the recycling process of post-consumer plastic film fractions. J. Clean. Prod. 2020, 260, 121104. [Google Scholar] [CrossRef]

- Strangl, M.; Ortner, E.; Buettner, A. Evaluation of the efficiency of odor removal from recycled HDPE using a modified recycling process. Resour. Conserv. Recycl. 2019, 146, 89–97. [Google Scholar] [CrossRef]

- Gall, M.; Freudenthaler, P.J.; Fischer, J.; Lang, R.W. Characterization of Composition and Structure–Property Relationships of Commercial Post-Consumer Polyethylene and Polypropylene Recyclates. Polymers 2021, 13, 1574. [Google Scholar] [CrossRef]

- Strangl, M.; Fell, T.; Schlummer, M.; Maeurer, A.; Buettner, A. Characterization of odorous contaminants in post-consumer plastic packaging waste using multidimensional gas chromatographic separation coupled with olfactometric resolution. J. Sep. Sci. 2017, 40, 1500–1507. [Google Scholar] [CrossRef]

- Ladhari, A.; Kucukpinar, E.; Stoll, H.; Sängerlaub, S. Comparison of Properties with Relevance for the Automotive Sector in Mechanically Recycled and Virgin Polypropylene. Recycling 2021, 6, 76. [Google Scholar] [CrossRef]

- Küppers, B.; Schloegl, S.; Oreski, G.; Pomberger, R.; Vollprecht, D. Influence of surface roughness and surface moisture of plastics on sensor-based sorting in the near infrared range. Waste Manag. Res. 2019, 37, 843–850. [Google Scholar] [CrossRef]

- Schmidt, M.C.; Loibl, F.; Muller, M.; Oehr, C.; Hirth, T. The Emptying Behavior of Highly Viscous Liquids. Part I: Polymeric Surfaces and Plasma Coatings. J. Adhes. Sci. Technol. 2012, 26, 2449–2467. [Google Scholar] [CrossRef]

- Schmidt, M.C.; Müller, M.; Oehr, C.; Hirth, T. Influence of semi-solid fluid’s surface tension and rheological properties on the residues at packaging materials. J. Food Eng. 2012, 108, 211–215. [Google Scholar] [CrossRef]

- Liu, X.; Wang, L.; Qiao, Y.; Sun, X.; Ma, S.; Cheng, X.; Qi, W.; Huang, W.; Li, Y. Adhesion of liquid food to packaging surfaces: Mechanisms, test methods, influencing factors and anti-adhesion methods. J. Food Eng. 2018, 228, 102–117. [Google Scholar] [CrossRef]

- Cragnell, C.; Hansson, K.; Andersson, T.; Jönsson, B.; Skepö, M. Underlying mechanisms behind adhesion of fermented milk to packaging surfaces. J. Food Eng. 2014, 130, 52–59. [Google Scholar] [CrossRef]

- Go, N. Beitrag zum Recyclingpotential von PET- und PS-Kunststoffverpackungsabfällen; Shaker Verlag: Düren, Germany, 2020; ISBN 9783844077261. [Google Scholar]

- Wohner, B. The Relationship between Packaging and Food Waste and Its Consideration in Sustainability Assessments. Ph.D. Thesis, TU Wien, Vienna, Austria, 2020. [Google Scholar]

- Loibl, F.; Holtz, C.; Langowski, H.-C. Improving the Emptying Behaviour of Packaging via Coating their Surfaces with Plasma-Polymerized Nanoscale Layers. In Proceedings of the 51st Annual Technical Conference, Society of Vacuum Coaters, Chicago, IL, USA, 19–24 April 2008; pp. 554–558. [Google Scholar]

- Michalski, M.-C.; Desobry, S.; Hardy, J. Food materials adhesion: A review. Crit. Rev. Food Sci. Nutr. 1997, 37, 591–619. [Google Scholar] [CrossRef]

- Adhikari, B.; Howes, T.; Bhandari, B.R.; Truong, V. Stickiness in Foods: A Review of Mechanisms and Test Methods. Int. J. Food Prop. 2001, 4, 1–33. [Google Scholar] [CrossRef]

- Loibl, F.; Schmidt, M.C.; Auer-Seidl, A.; Kirchner, C.; Holtz, C.; Miiller, K.; Stramm, C.; Langowski, H.-C. The Emptying Behaviour of Highly Viscous Liquids. Part II: Development of Test Methods and Evaluation of Untreated and Coated Films. J. Adhes. Sci. Technol. 2012, 26, 2469–2503. [Google Scholar] [CrossRef]

- Müller, K.; Bugnicourt, E.; Latorre, M.; Jorda, M.; Echegoyen Sanz, Y.; Lagaron, J.M.; Miesbauer, O.; Bianchin, A.; Hankin, S.; Bölz, U.; et al. Review on the Processing and Properties of Polymer Nanocomposites and Nanocoatings and Their Applications in the Packaging, Automotive and Solar Energy Fields. Nanomaterials 2017, 7, 74. [Google Scholar] [CrossRef] [PubMed]

- Meurer, I.R.; Lange, C.C.; Hungaro, H.M.; Valenzuela Bell, M.J.; Carvalho dos Anjos, V. de; Antonio de Sá Silva, Cleuber; Aparecida de Oliveira Pinto, Miriam. Quantification of whole ultra high temperature UHT milk waste as a function of packages type and design. J. Clean. Prod. 2017, 153, 483–490. [Google Scholar] [CrossRef]

- Wohner, B.; Gabriel, V.H.; Krenn, B.; Krauter, V.; Tacker, M. Environmental and economic assessment of food-packaging systems with a focus on food waste. Case study on tomato ketchup. Sci. Total Environ. 2020, 738, 139846. [Google Scholar] [CrossRef] [PubMed]

- Wohner, B.; Schwarzinger, N.; Gürlich, U.; Heinrich, V.; Tacker, M. Technical emptiability of dairy product packaging and its environmental implications in Austria. PeerJ 2019, 7, e7578. [Google Scholar] [CrossRef] [PubMed]

- Lasprilla-Botero, J.; Torres-Giner, S.; Pardo-Figuerez, M.; Álvarez-Láinez, M.; M. Lagaron, J. Superhydrophobic Bilayer Coating Based on Annealed Electrospun Ultrathin Poly(ε-caprolactone) Fibers and Electrosprayed Nanostructured Silica Microparticles for Easy Emptying Packaging Applications. Coatings 2018, 8, 173. [Google Scholar] [CrossRef]

- Schmidt, M.C. Untersuchung und Verbesserung des Entleerungsverhaltens von Füllgut-Verpackungssystemen; University of Stuttgart: Stuttgart, Germany, 2011. [Google Scholar]

- Smith, J.D.; Dhiman, R.; Anand, S.; Reza-Garduno, E.; Cohen, R.E.; McKinley, G.H.; Varanasi, K.K. Droplet mobility on lubricant-impregnated surfaces. Soft Matter 2013, 9, 1772–1780. [Google Scholar] [CrossRef]

- Solomon, B.R.; Khalil, K.S.; Varanasi, K.K. Drag Reduction using Lubricant-Impregnated Surfaces in Viscous Laminar Flow. Langmuir 2014, 30, 10970–10976. [Google Scholar] [CrossRef]

- Loibl, F.; Langowski, H.-C. Improved emptying behaviour of packaging coated with plasma-polymerized nanoscale layers. In VDI Berichte (2027); VDI Fachmedien GmbH & Co. KG: Düsseldorf, Germany, 2008; pp. 133–136. [Google Scholar]

- Dahlén, L.; Lagerkvist, A. Methods for household waste composition studies. Waste Manag. 2008, 28, 1100–1112. [Google Scholar] [CrossRef]

- Kostic, D.; Hoffmann, U.; Fürtauer, S.; Fell, T.; Yilmaz, C.; Burth, D.; Sängerlaub, S. Packaging Weight, Filling Ratio and Filling Efficiency of Yogurt and Relevant Packagings Depending on Commercial Packaging Design, Material, Packaging Type and Filling Quantity. Dairy 2022, 3, 46. [Google Scholar] [CrossRef]

- Braun, J. Technische Strömungsmechanik: Lehrbuch für Ingenieurstudiengänge; BoD—Books on Demand: Norderstedt, Germany, 2015; ISBN 9783735723482. [Google Scholar]

- Herwig, H. Das seltsame Verhalten einiger Flüssigkeiten im Haushalt. In Ach, So Ist Das!: 50 Thermofluiddynamische Alltagsphänomene Anschaulich und Wissenschaftlich Erklärt; Herwig, H., Ed.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2014; pp. 3–7. ISBN 978-3-658-05630-8. [Google Scholar]

| Packaging | Fill Product | n | Fill Quantity | Residual Quantity in g | Residual Quantity/Fill Quantity in g/g | Packaging Weight (Body) in g | Weight Closure in g | Weight Label in g | Residual Quantity/Weight Packaging in g/g | Sample | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Median | Min | Max | u. q. | l. q. | ||||||||||

| PE tube | toothpaste | 30 | 50–125 mL | 10.4 | 0.127 | 3.8–7.7 | 1.6–6.5 | none | 1.10 | 0.26 | 3.05 | 1.67 | 0.72 | s.p. |

| PE tube | hair gel | 42 | 30–200 mL | 11.3 | 0.069 | 4.6–14.5 | 2.4–10.0 | none | 0.36 | 0.08 | 0.84 | 0.7 | 0.24 | s.p. |

| PE tube | shampoo | 16 | 50–200 mL | 8.2 | 0.033 | 2.8–9.8 | 5.8–16.8 | none | 0.26 | 0.01 | 1.22 | 0.56 | 0.07 | s.p. |

| PE tube | crème | 30 | 50–250 mL | 6.5 | 0.113 | 3.9–16.2 | 1.5–10.6 | none | 0.67 | 0.03 | 1.52 | 1 | 0.35 | s.p. |

| PP cup | mostly dairy products | 100 | 50–500 mL | 0.8 | 0.004 | 3.8–13.5 | n.a. | none | 0.056 | 0 | 0.29 | 0.13 | 0.015 | s.p. |

| PP cup | various dairy products | 3 | 184–245 g | 0.95–3.07 | 0.007–0.010 | 8.2–13.9 (all) | n.a. | n.a. | 0.11–0.22, m | i.p. [34,42] | ||||

| PS cup | various dairy products | 3 | 130–251 g | 1.19–1.94 | 0.007–0.013 | 7.47–9.35 (all) | n.a. | n.a. | 0.13–0.34, m | i.p. [34,42] | ||||

| PS cup | curd | 37 | 500 g | 0.3 | 0.001 | 5.7–9.3 | ≤0.56 | none | 0.08 | 0 | 0.29 | 0.15 | 0.04 | s.p. [33] |

| PS cup | yoghurt | 29 | 500 mL | 0.5 | 0.001 | 11.1–17.1 | ≤1.54 | ≤0.62 | 0.036 | 0 | 0.09 | 0.05 | 0.019 | s.p. [33] |

| PS cup | yoghurt | 36 | <500 mL | 0.3 | 0.001 | 3.0–5.7 | ≤0.52 | none | 0.05 | 0 | 0.3 | 0.14 | 0.02 | s.p. [33] |

| PS cup | yoghurt, dessert | 39 | 50–200 g | 0.1 | n.a. | 2.2–14.5 | ≤0.56 | none | 0.028 | 0.001 | 0.07 | 0.04 | 0.01 | s.p. [33] |

| PS cup | yoghurt with corner | 30 | 150 g | 0.5 | 0.003 | 7.5–17.2 | ≤0.49 | none | 0.04 | 0.01 | 0.097 | 0.059 | 0.023 | s.p. [33] |

| PS cup | milk rice | 29 | 200 g | 0.2 | 0.001 | 5.7–15.1 | ≤1.82 | 0.94 | 0.02 | 0.009 | 0.09 | 0.05 | 0.018 | s.p. [33] |

| PS cup | butter milk | 20 | 500 g | 0.3 | 0.001 | 9.4–13.1 | ≤0.84 | none | 0.02 | 0.004 | 0.07 | 0.04 | 0.013 | s.p. [33] |

| PS cup | butter milk drink | 17 | 500 g | 0.3 | 0.001 | 19.7–21.2 | ≤3.1 | 1.68 | 0.01 | 0 | 0.12 | 0.05 | 0.007 | s.p. [33] |

| PS cup | butter milk dessert | 15 | 100–300 g | 0.2 | n.a. | 4.4–13.1 | ≤0.96 | none | 0.02 | 0 | 0.11 | 0.05 | 0.006 | s.p. [33] |

| PS cup | sour cream | 10 | 200 g | 0.2 | 0.001 | 5.3–7.9 | ≤14 | none | 0.025 | 0.009 | 0.07 | 0.04 | 0.019 | s.p. [33] |

| PS cup | whipped cream | 30 | 200 mL | 0.1 | 0.001 | 4.7–5.6 | ≤0.62 | none | 0.02 | 0.005 | 0.055 | 0.04 | 0.01 | s.p. [33] |

| PS cup | grainy cream cheese | 11 | 200 g | 0.3 | 0.002 | 5.8–7.1 | ≤0.88 | none | 0.04 | 0.018 | 0.089 | 0.06 | 0.026 | s.p. [33] |

| PE-HD bottle | shower gel | 157 | 150–750 mL | 9.2 | 0.034 | 16.8–60.0 | none | 0.64–2.24 | 0.17 | 0 | 1.01 | 0.44 | 0.06 | s.p. |

| PP bottle | shower gel | 109 | 100–750 mL | 4.7 | 0.018 | 12.8–49.1 | none | 0.37–1.53 | 0.08 | 0 | 0.47 | 0.24 | 0.02 | s.p. |

| PP bottle | tomato ketchup | 6 | 380–550 g | 25.3–108.5 | 0.051–0.29 | 22.3–31.0 | 4.7–11.1 | 0.63–1.27 | 0.67–3.94, m | s.p. [34,41] | ||||

| PET bottle | ketchup | 6 | 500 mL | 12.3 | 0.025 | 28.0–42.9 | n.a. | n.a. | 0.36 | 0.09 | 0.63 | 0.49 | 0.16 | s.p. |

| PET bottle | milk | 3 | 500–1000 mL | 1.3 | 0.001 | 20.3–29.0 | n.a. | n.a. | 0.02 | 0 | 0.14 | 0.14 | 0.01 | s.p. |

| PET bottle | oil | 14 | 250–1000 mL | 1.1 | 0.005 | 16.4–56.1 | n.a. | n.a. | 0.06 | 0 | 0.12 | 0.06 | 0 | s.p. |

| PET bottle | juice | 11 | 330–1350 mL | 2.1 | 0.002 | 17.8–50.6 | n.a. | n.a. | 0.02 | 0 | 0.25 | 0.12 | 0 | s.p. |

| PET bottle | liquid soap | 2 | 250 mL | 0.6 | 0.002 | 22.5–49.2 | n.a. | n.a. | 0.01 | 0 | 0.02 | 0.02 | 0 | s.p. |

| PET bottle | soft drink | 9 | 250–1000 mL | 1.8 | 0.003 | 14.5–76.4 | n.a. | n.a. | 0.01 | 0 | 0.15 | 0.1 | 0 | s.p. |

| PET bottle | hand washing detergent | 47 | 125–1000 mL | 3.0 | 0.004 | 24.7–60.1 | n.a. | n.a. | 0.04 | 0 | 0.23 | 0.11 | 0.01 | s.p. |

| PET bottle | mouthwash | 3 | 600 mL | 0.9 | 0.001 | 40.0–51.5 | n.a. | n.a. | 0.01 | 0.01 | 0.03 | 0.03 | 0.01 | s.p. |

| PET bottle | various dairy products | 3 | 126–750 g | 1.8–20.3 | 0.005–0.06 | 7.2–31 (all) | 0.1–0.81, m | i.p. [34,42] | ||||||

| PET bottle | water | 16 | 500–1500 mL | 1.7 | 0.003 | 13.9–54.2 | n.a. | n.a. | 0.01 | 0 | 0.06 | 0.05 | 0 | s.p. |

| PET bottle | water | 16–29, v | 500 mL | 0.5–2.5 | 0.001–0.005 | 10.8–28.4 | 1.68–2.18 | 0.27–0.62 | 0.015–0.15 | 0–0.01 | 0.05–0.62 | 0.08–0.32 | 0.002–0.07 | i.p. [33] |

| PET bottle | water | 23 | 750 mL | 2.2 | 0.003 | 21.8–21.9 | 4.65–5.0 | 0.45 | 0.08 | 0.03 | 0.16 | 0.1 | 0.04 | i.p. [33] |

| PET bottle | water | 17–27, v | 1000 mL | 0.8–2.2 | 0.002–0.008 | 26.7–30.6 | 1.63–2.83 | 0.31–0.54 | 0.02–0.067 | 0–0.01 | 0.14–0.23 | 0.11–0.12 | 0.016–0.045 | i.p. [33] |

| PET bottle | water | 16–29, v | 1500 mL | 0.4–2.5 | 0.001–0.002 | 21.8–32.1 | 0.87–2.95 | 0.4–0.65 | 0.01–0.09 | 0–0.03 | 0.018–0.26 | 0.014–0.16 | 0.011–0.07 | i.p. [33] |

| PET bottle | water | 18 | 1750 mL | 2.8 | 0.002 | 35.9–35.1 | 1.65–1.83 | 0.77 | 0.07 | 0 | 0.11 | 0.09 | 0.02 | i.p. [33] |

| PET bottle | lemonade | 15–23, v | 500 mL | 1.2–1.9 | 0.002–0.004 | 13.0–26.8 | 1.65–1.91 | 0.27–0.66 | 0.05–0.12 | 0.005–0.02 | 0.1–0.34 | 0.086–0.23 | 0.035–0.09 | i.p. [33] |

| PET bottle | lemonade | 15–20, v | 1000 mL | 2.3–3.8 | 0.002–0.004 | 34.7–36.0 | 2.57–2.69 | 1.27 | 0.07–0.097 | 0.06–0.084 | 0.087–0.13 | 0.082–0.107 | 0.064–0.088 | i.p. [33] |

| PET bottle | ice tea | 15 | 500 mL | 3.1 | 0.006 | 41.9–42.1 | 2.85–2.93 | 6.0 | 0.05 | 0.03 | 0.11 | 0.07 | 0.039 | i.p. [33] |

| PET bottle | ice tea | 26–30, v | 1500 mL | 4.1–4.2 | 0.003 | 36.1–37.1 | 2.98–3.27 | 1.06–1.29 | 0.09–0.092 | 0–0.043 | 0.151–0.21 | 0.11–0.13 | 0.06–0.07 | i.p. [33] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schinkel, K.; Küppers, B.; Reichenbach, S.; Rohrmeier, T.; Müller, K.; Fell, T.; Sängerlaub, S. Amount of Fill Product Residues in Plastic Packagings for Recycling. Waste 2023, 1, 901-918. https://doi.org/10.3390/waste1040052

Schinkel K, Küppers B, Reichenbach S, Rohrmeier T, Müller K, Fell T, Sängerlaub S. Amount of Fill Product Residues in Plastic Packagings for Recycling. Waste. 2023; 1(4):901-918. https://doi.org/10.3390/waste1040052

Chicago/Turabian StyleSchinkel, Konstantin, Bastian Küppers, Sven Reichenbach, Teresa Rohrmeier, Kajetan Müller, Tanja Fell, and Sven Sängerlaub. 2023. "Amount of Fill Product Residues in Plastic Packagings for Recycling" Waste 1, no. 4: 901-918. https://doi.org/10.3390/waste1040052

APA StyleSchinkel, K., Küppers, B., Reichenbach, S., Rohrmeier, T., Müller, K., Fell, T., & Sängerlaub, S. (2023). Amount of Fill Product Residues in Plastic Packagings for Recycling. Waste, 1(4), 901-918. https://doi.org/10.3390/waste1040052