Processing of Aluminum Alloy 6182 with High Scanning Speed in LPBF by In-Situ Alloying with Zr and Ti Powder

Abstract

1. Introduction

2. Material and Methods

2.1. Materials and Processing

2.2. Characterization of the LPBF Parts

3. Results and Discussion

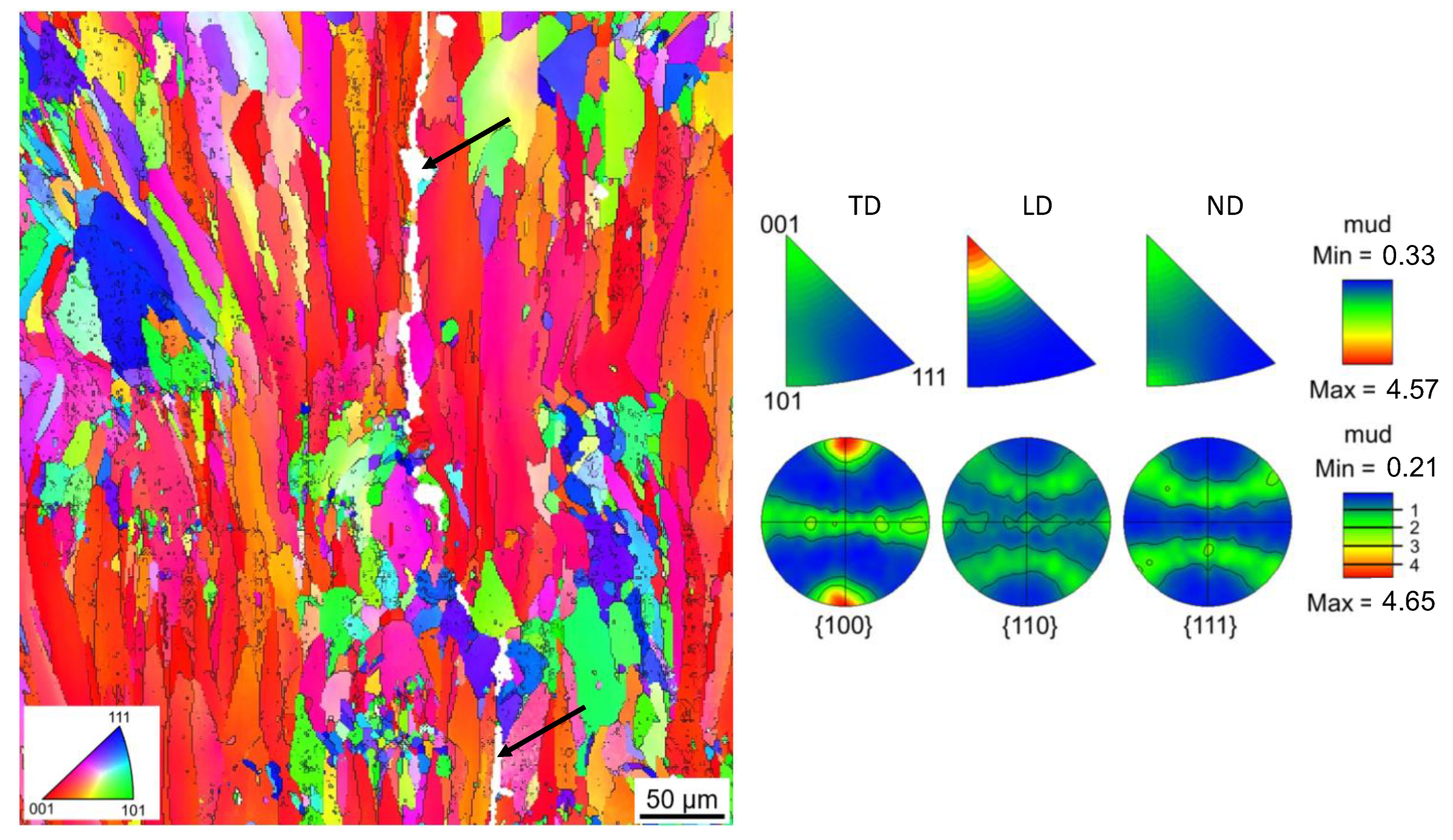

3.1. Status Quo: Microstructural Analysis of the Printed Parts Manufactured with Pre-Alloyed 6182 Powder

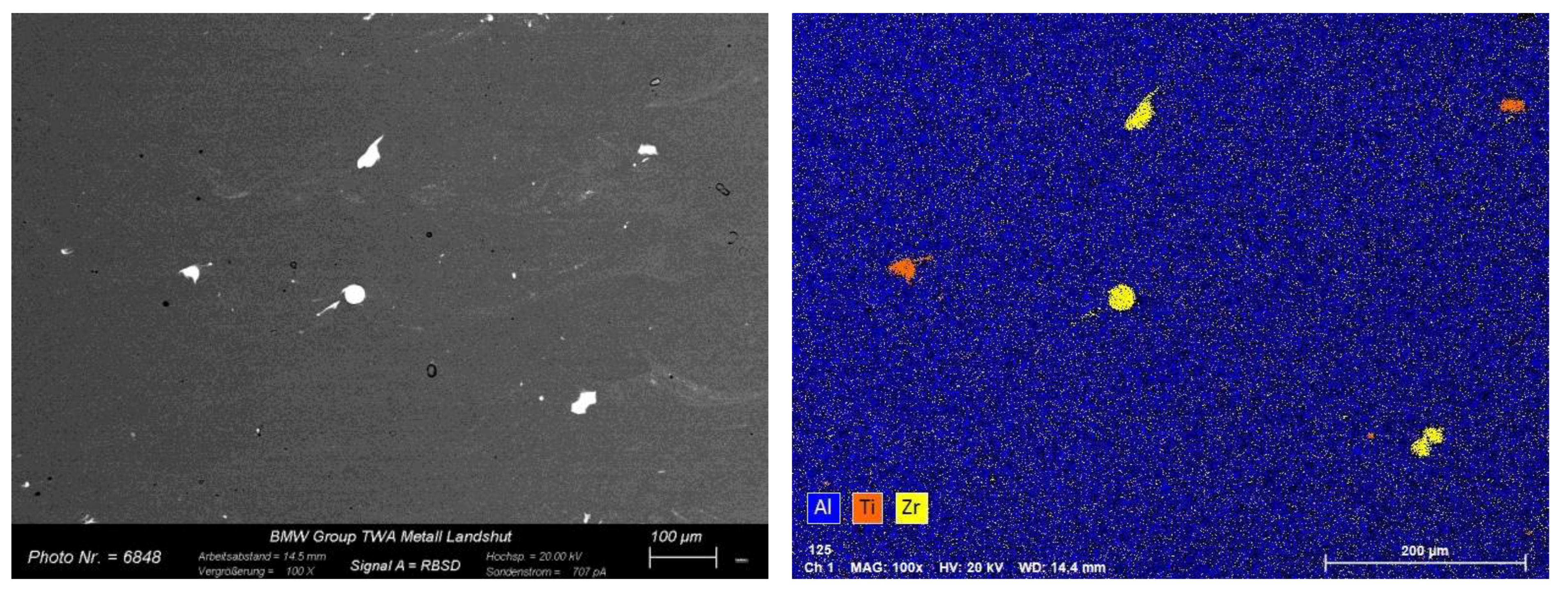

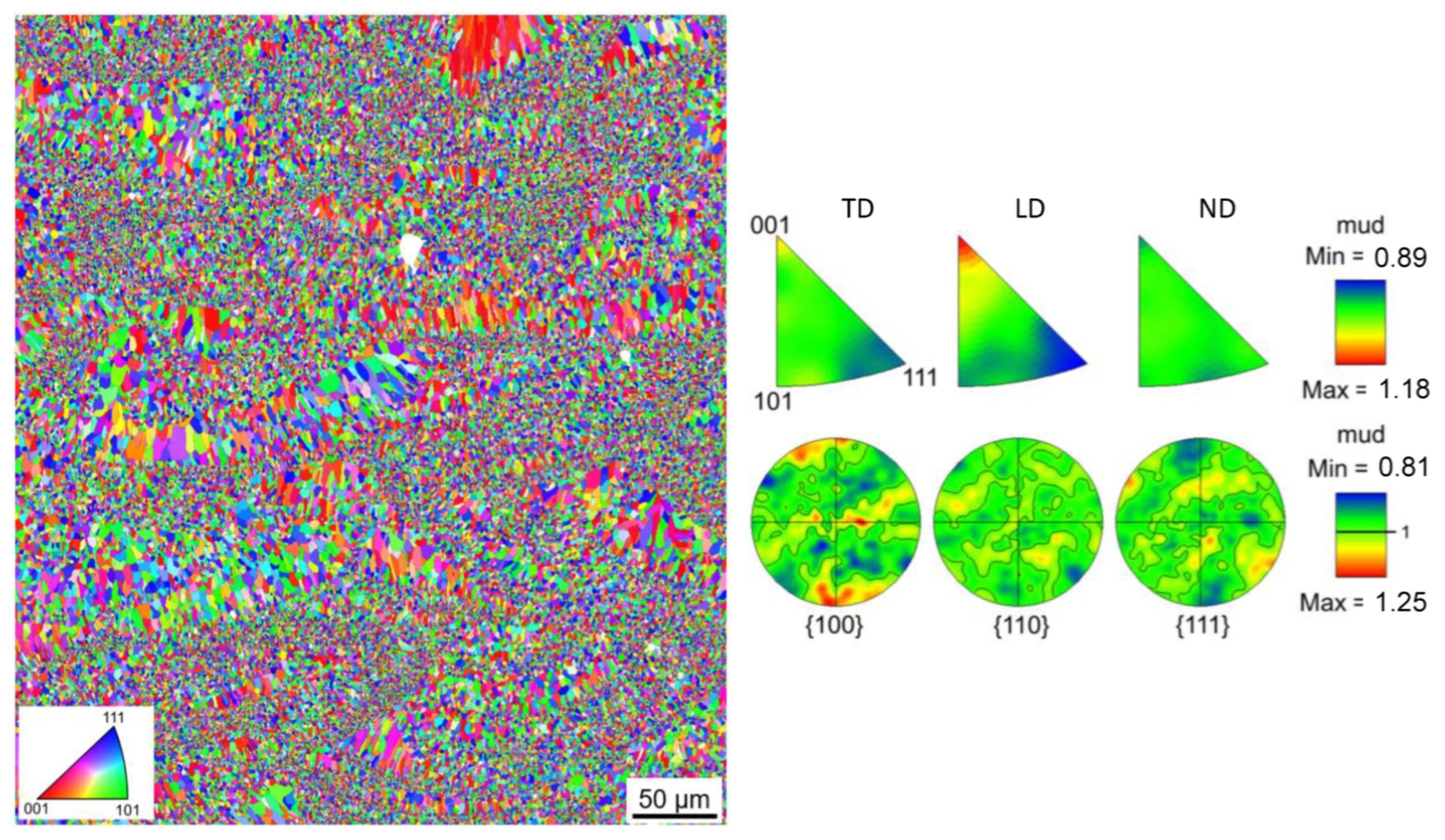

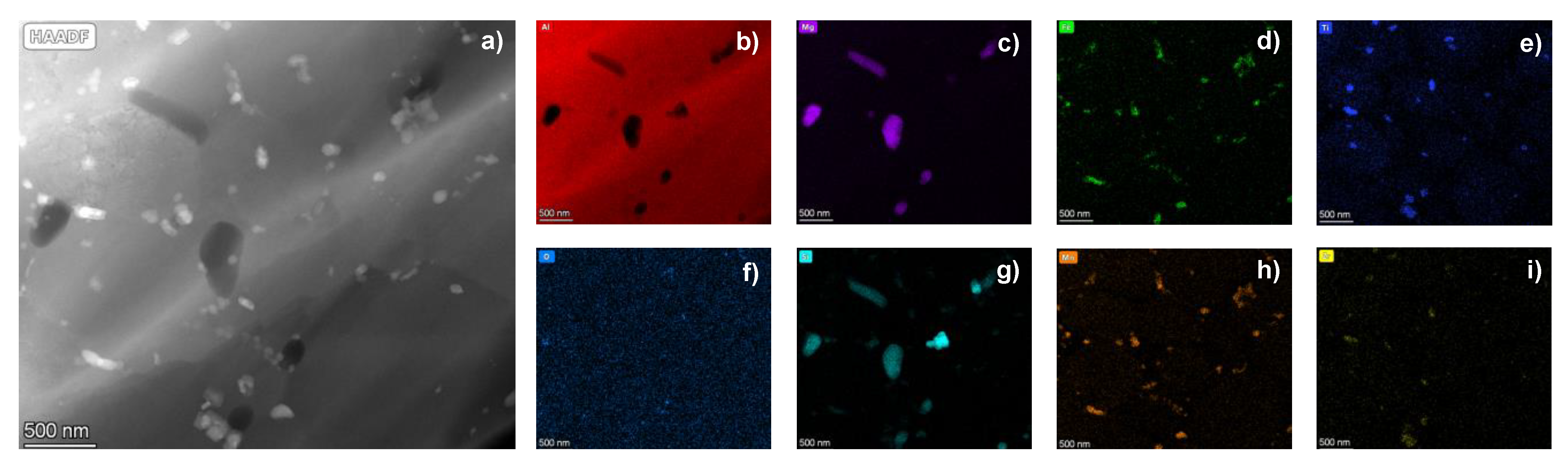

3.2. Characterization of the Printed Parts, Manufactured with the Powder Mixture

4. Conclusions

- LPBF parts made of pre-alloyed 6182 powder (with 0.2 wt.-% each of Zr and Ti) reveals a columnar, epitaxially grown grain structure permeated with hot cracks;

- The powder mixture containing 0.7 wt.-% each of Zr and Ti was processed using LPBF. A crack-free microstructure was achieved, showing a relative density of 99.95 ± 0.05%;

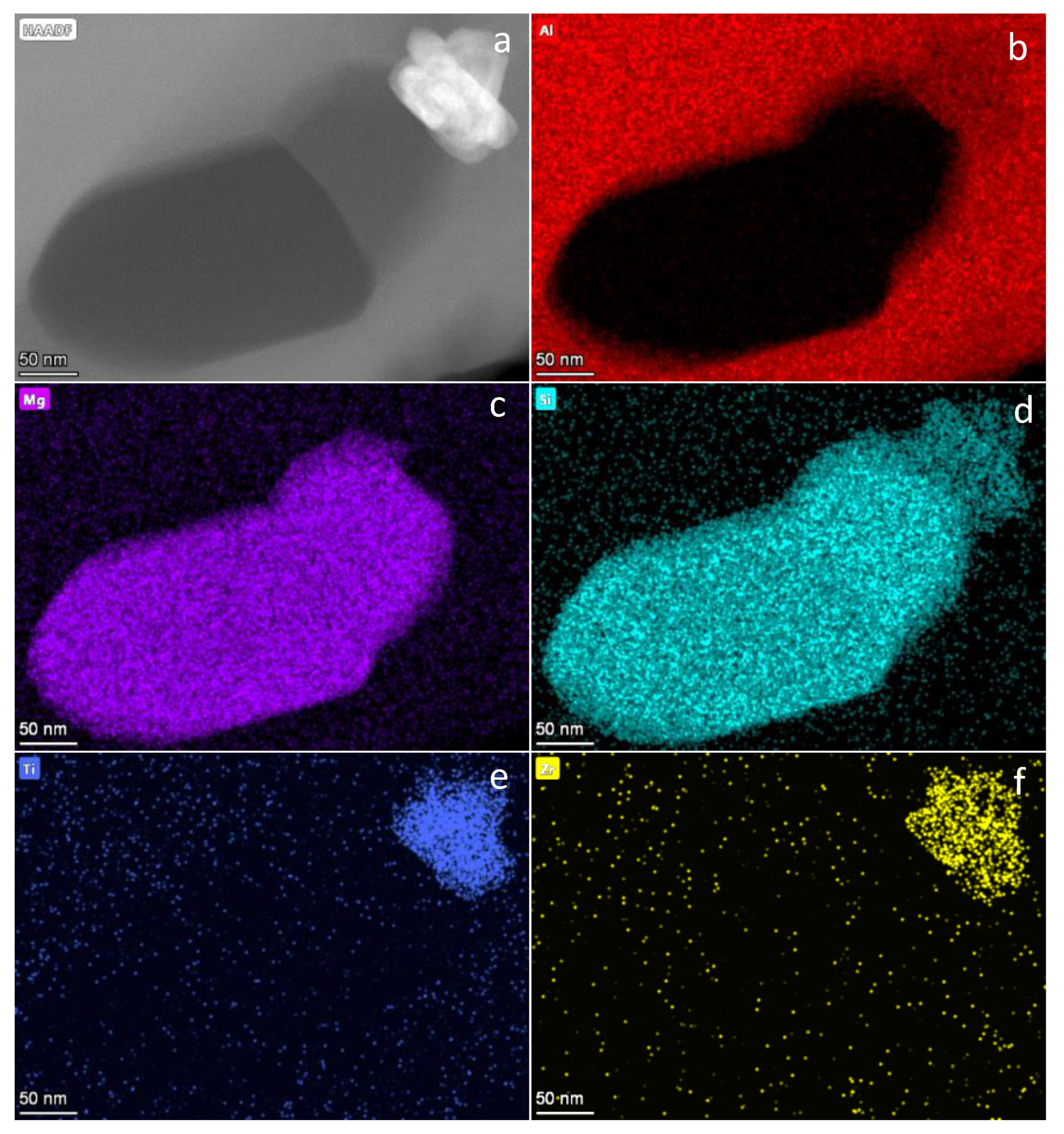

- Unmolten or only partially molten Zr and Ti particles remain in the microstructure;

- An equiaxed microstructure with a grain size of 1.2 µm on the average was obtained in the as-built specimen;

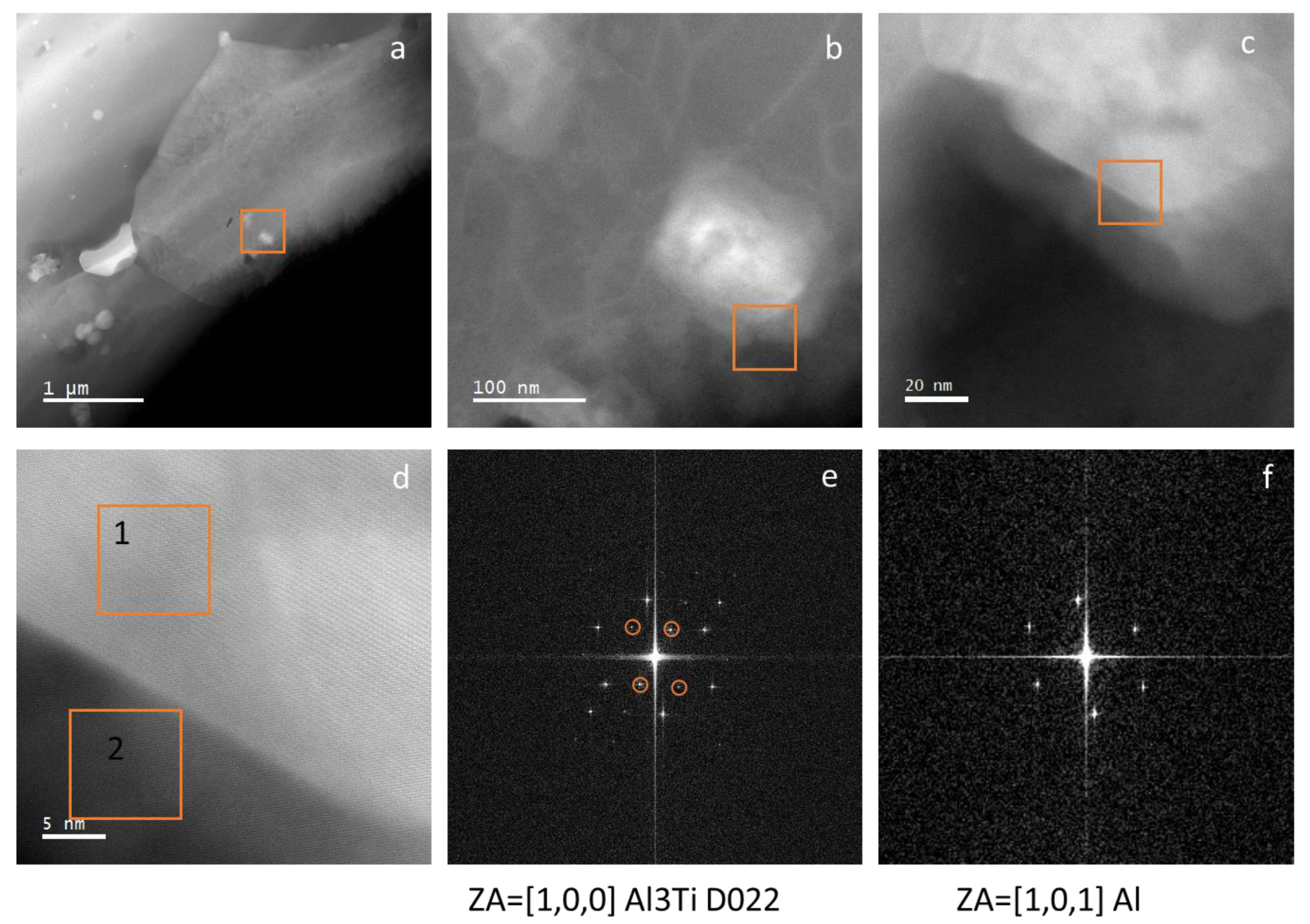

- Orthorhombic D022 Al3(Ti,Zr) particles work effectively as an heterogeneous grain refiner for α-Al, evidenced by the coherent interface that was found between D022 particles and α-Al;

- In the as-built condition, the material exhibits an average yield strength of 155 ± 5 MPa with an elongation at break of 25.1 ± 1.8 %. After T6 heat treatment, an average yield strength of 294 ± 2 MPa with an elongation at break of 11.4 ± 0.9 % can be achieved.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Poprawe, R.; Hinke, C.; Meiners, W.; Schrage, J.; Bremen, S.; Risse, J.; Merkt, S. Disruptive Innovation Through 3D Printing. In Supply Chain Integration Challenges in Commercial Aerospace; Richter, K., Walther, J., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 73–87. [Google Scholar]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the Selective Laser Melting (SLM) of the AlSi10Mg Alloy: Process, Microstructure, and Mechanical Properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef] [PubMed]

- Santos Macías, J.G.; Douillard, T.; Zhao, L.; Maire, E.; Pyka, G.; Simar, A. Influence on microstructure, strength and ductility of build platform temperature during laser powder bed fusion of AlSi10Mg. Acta Mater. 2020, 201, 231–243. [Google Scholar] [CrossRef]

- Hyer, H.; Zhou, L.; Park, S.; Gottsfritz, G.; Benson, G.; Tolentino, B.; McWilliams, B.; Cho, K.; Sohn, Y. Understanding the Laser Powder Bed Fusion of AlSi10Mg Alloy. Met. Microstruct. Anal. 2020, 9, 484–502. [Google Scholar] [CrossRef]

- Riener, K.; Oswald, S.; Winkler, M.; Leichtfried, G.J. Influence of storage conditions and reconditioning of AlSi10Mg powder on the quality of parts produced by laser powder bed fusion (LPBF). Addit. Manuf. 2021, 39, 101896. [Google Scholar] [CrossRef]

- Yang, T.; Liu, T.; Liao, W.; MacDonald, E.; Wei, H.; Zhang, C.; Chen, X.; Zhang, K. Laser powder bed fusion of AlSi10Mg: Influence of energy intensities on spatter and porosity evolution, microstructure and mechanical properties. J. Alloy. Compd. 2020, 849, 156300. [Google Scholar] [CrossRef]

- Lathabai, S. Additive Manufacturing of Aluminium-Based Alloys and Composites. In Fundamentals of Aluminium Metallurgy; Elsevier: Amsterdam, The Netherlands, 2018; pp. 47–92. [Google Scholar]

- Galy, C.; Le Guen, E.; Lacoste, E.; Arvieu, C. Main defects observed in aluminum alloy parts produced by SLM: From causes to consequences. Addit. Manuf. 2018, 22, 165–175. [Google Scholar] [CrossRef]

- Li, L.; Li, R.; Yuan, T.; Chen, C.; Zhang, Z.; Li, X. Microstructures and tensile properties of a selective laser melted Al–Zn–Mg–Cu (Al7075) alloy by Si and Zr microalloying. Mater. Sci. Eng. A 2020, 787, 139492. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Su, Y.; Wang, H.; Enz, J.; Ebel, T.; Yan, M. Selective laser melting additive manufacturing of 7xxx series Al-Zn-Mg-Cu alloy: Cracking elimination by co-incorporation of Si and TiB2. Addit. Manuf. 2020, 36, 101458. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Spierings, A.B.; Dawson, K.; Heeling, T.; Uggowitzer, P.J.; Schäublin, R.; Palm, F.; Wegener, K. Microstructural features of Sc- and Zr-modified Al-Mg alloys processed by selective laser melting. Mater. Des. 2017, 115, 52–63. [Google Scholar] [CrossRef]

- Mair, P.; Kaserer, L.; Braun, J.; Weinberger, N.; Letofsky-Papst, I.; Leichtfried, G. Microstructure and mechanical properties of a TiB2-modified Al–Cu alloy processed by laser powder-bed fusion. Mater. Sci. Eng. A 2021, 799, 140209. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Mertens, R.; Vanmeensel, K.; Vleugels, J.; van Humbeeck, J.; Kruth, J.-P. In situ alloying and reinforcing of Al6061 during selective laser melting. Procedia CIRP 2018, 74, 39–43. [Google Scholar] [CrossRef]

- Mertens, R.; Baert, L.; Vanmeensel, K.; van Hooreweder, B. Laser powder bed fusion of high strength aluminum. Mat. Des. Process. Comms. 2021, 3, e161. [Google Scholar] [CrossRef][Green Version]

- Riener, K.; Pfalz, T.; Funcke, F.; Leichtfried, G. Processability of high-strength aluminum 6182 series alloy via laser powder bed fusion (LPBF). Int. J. Adv. Manuf. Technol. 2022, 119, 4963–4977. [Google Scholar] [CrossRef]

- Ivanovic, J. Scandium (Sc): Why Is Everyone Talking about It and How It Affects the Australian Industry? Available online: http://ozscience.com/chemistry-2/scandium-sc-everyone-talking-affects-australian-industry/ (accessed on 5 November 2020).

- Horovitz, C.T. Scandium Its Occurrence, Chemistry Physics, Metallurgy, Biology and Technology; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Costantino, N.; Pellegrino, R. Choosing between single and multiple sourcing based on supplier default risk: A real options approach. J. Purch. Supply Manag. 2010, 16, 27–40. [Google Scholar] [CrossRef]

- Zeng, F.-L.; Wei, Z.-L.; Li, J.-F.; Li, C.-X.; Tan, X.; Zhang, Z.; Zheng, Z.-Q. Corrosion mechanism associated with Mg2Si and Si particles in Al–Mg–Si alloys. Trans. Nonferrous Met. Soc. China 2011, 21, 2559–2567. [Google Scholar] [CrossRef]

- Knight, S.P.; Birbilis, N.; Muddle, B.C.; Trueman, A.R.; Lynch, S.P. Correlations between intergranular stress corrosion cracking, grain-boundary microchemistry, and grain-boundary electrochemistry for Al–Zn–Mg–Cu alloys. Corros. Sci. 2010, 52, 4073–4080. [Google Scholar] [CrossRef]

- Wang, P.; Gebert, A.; Yan, L.; Li, H.; Lao, C.; Chen, Z.; Kosiba, K.; Kühn, U.; Scudino, S. Corrosion of Al-3.5Cu-1.5 Mg–1Si alloy prepared by selective laser melting and heat treatment. Intermetallics 2020, 124, 106871. [Google Scholar] [CrossRef]

- Zou, Y.; Liu, Q.; Jia, Z.; Xing, Y.; Ding, L.; Wang, X. The intergranular corrosion behavior of 6000-series alloys with different Mg/Si and Cu content. Appl. Surf. Sci. 2017, 405, 489–496. [Google Scholar] [CrossRef]

- Zhan, H.; Mol, J.M.C.; Hannour, F.; Zhuang, L.; Terryn, H.; de Wit, J.H.W. The influence of copper content on intergranular corrosion of model AlMgSi(Cu) alloys. Mater. Corros. 2008, 59, 670–675. [Google Scholar] [CrossRef]

- Blanc, C.; Lavelle, B.; Mankowski, G. The role of precipitates enriched with copper on the susceptibility to pitting corrosion of the 2024 aluminium alloy. Corros. Sci. 1997, 39, 495–510. [Google Scholar] [CrossRef]

- Buha, J.; Lumley, R.N.; Crosky, A.G.; Hono, K. Secondary precipitation in an Al–Mg–Si–Cu alloy. Acta Mater. 2007, 55, 3015–3024. [Google Scholar] [CrossRef]

| 6182 | Powder Mixture | |

|---|---|---|

| Si (wt.-%) | 1.05 | 1.04 |

| Mg (wt.-%) | 1.08 | 1.07 |

| Mn (wt.-%) | 0.60 | 0.59 |

| Fe (wt.-%) | 0.13 | 0.13 |

| Ti (wt.-%) | 0.19 | 0.69 |

| Zr (wt.-%) | 0.20 | 0.70 |

| Al (wt.-%) | bal. | bal. |

| 6182 | Ti | Zr | |

|---|---|---|---|

| d10 (µm) | 22.6 | 20.2 | 24.4 |

| d50 (µm) | 37.8 | 39.9 | 42.4 |

| d90 (µm) | 57.0 | 51.9 | 52.0 |

| Substrate plate temperature (°C) | 300 |

| Laser power (W) | 520 |

| Scanning speed (mm/sec) | 1600 |

| Hatch distance (mm) | 0.13 |

| Laser spot diameter (µm) | 105 |

| Layer thickness (µm) | 50 |

| Scanning strategy | Stripes in zig-zag pattern, 67° rotation between adjacent layers |

| Hardness (HV3) | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation at Break (%) | |

|---|---|---|---|---|

| As-Built | 62 ± 3 | 155 ± 5 | 191 ± 2 | 25.1 ± 1.8 |

| T6 | 117 ± 1 | 294 ± 2 | 329 ± 4 | 11.4 ± 0.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riener, K.; Nagler, A.; Letofsky-Papst, I.; Leichtfried, G. Processing of Aluminum Alloy 6182 with High Scanning Speed in LPBF by In-Situ Alloying with Zr and Ti Powder. Alloys 2022, 1, 277-287. https://doi.org/10.3390/alloys1030018

Riener K, Nagler A, Letofsky-Papst I, Leichtfried G. Processing of Aluminum Alloy 6182 with High Scanning Speed in LPBF by In-Situ Alloying with Zr and Ti Powder. Alloys. 2022; 1(3):277-287. https://doi.org/10.3390/alloys1030018

Chicago/Turabian StyleRiener, Kirstin, Alexander Nagler, Ilse Letofsky-Papst, and Gerhard Leichtfried. 2022. "Processing of Aluminum Alloy 6182 with High Scanning Speed in LPBF by In-Situ Alloying with Zr and Ti Powder" Alloys 1, no. 3: 277-287. https://doi.org/10.3390/alloys1030018

APA StyleRiener, K., Nagler, A., Letofsky-Papst, I., & Leichtfried, G. (2022). Processing of Aluminum Alloy 6182 with High Scanning Speed in LPBF by In-Situ Alloying with Zr and Ti Powder. Alloys, 1(3), 277-287. https://doi.org/10.3390/alloys1030018