Deposition: A DPM and PBM Approach for Particles in a Two-Phase Turbulent Pipe Flow

Abstract

1. Introduction

2. Methods

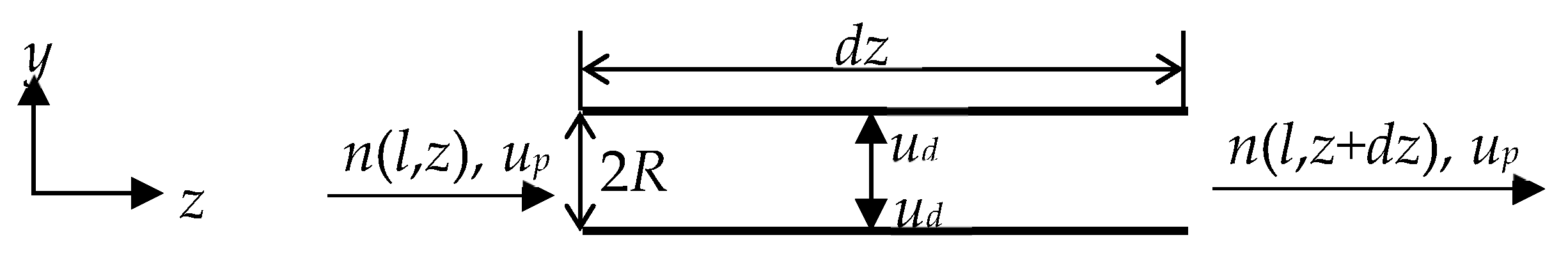

2.1. Geometry, Meshing, and Physical Properties

2.2. Deposition Constant and Velocity

2.3. The Average Particle Velocity in Axial Direction and the Peclet Number in Radial Direction

2.3.1. The Average Particle Velocity in Axial Direction

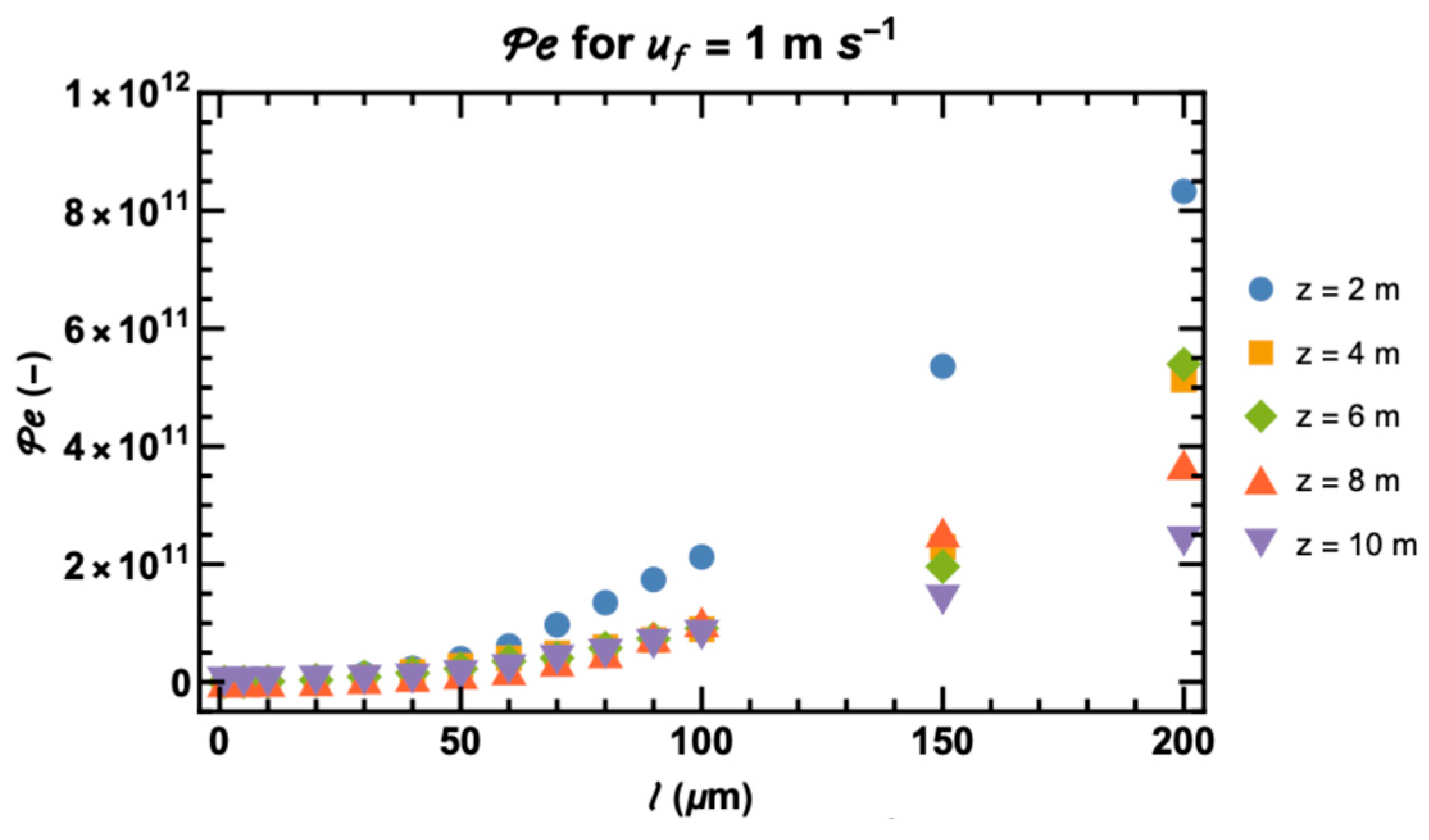

2.3.2. The Peclet Number of Particles in Radial Direction

2.4. The Population Balance Equations

2.4.1. The PBE for Particles in Flow

2.4.2. The PBE for Particles Depositing on the Pipe Wall

2.5. Thickness of the Deposit

2.6. The Particle Size Range, Their Initial Distribution, and the Velocity of the Continuous Phase

2.6.1. Size Range of the Particles

2.6.2. The Initial Particle Size Distribution

2.6.3. Velocity of the Continuous Phase, Length of the Pipe, and Time for PBM

3. Results and Discussion

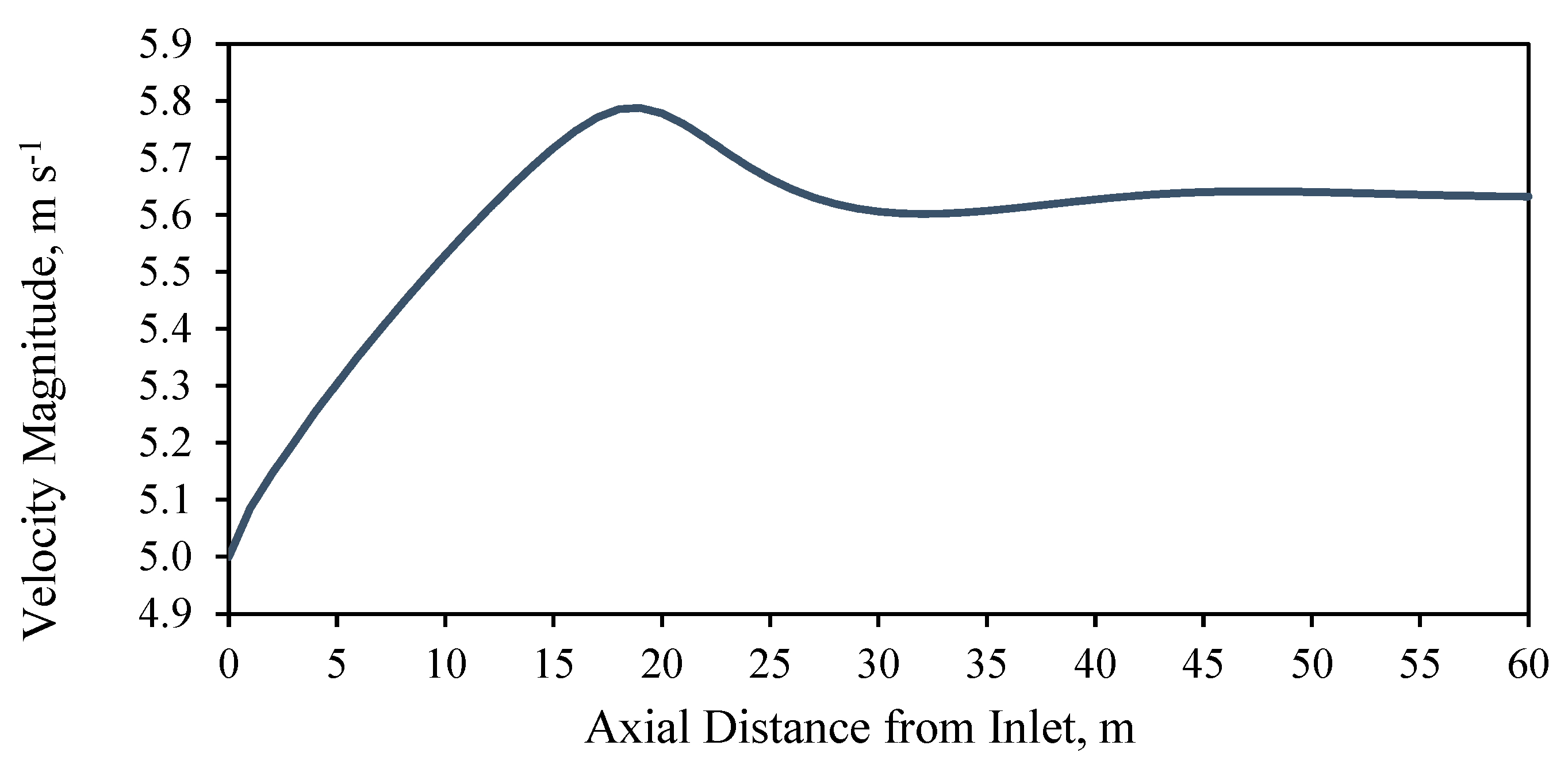

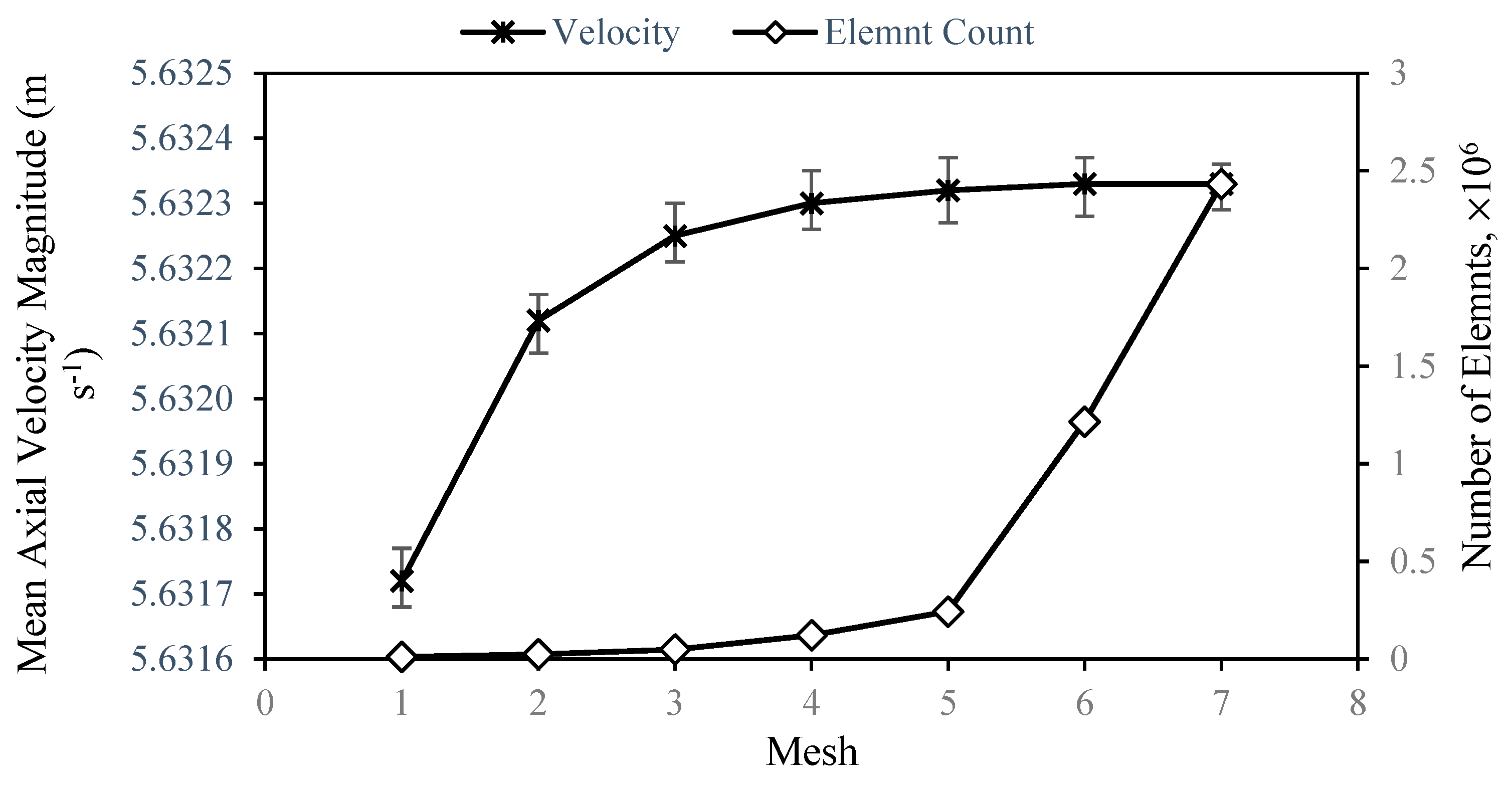

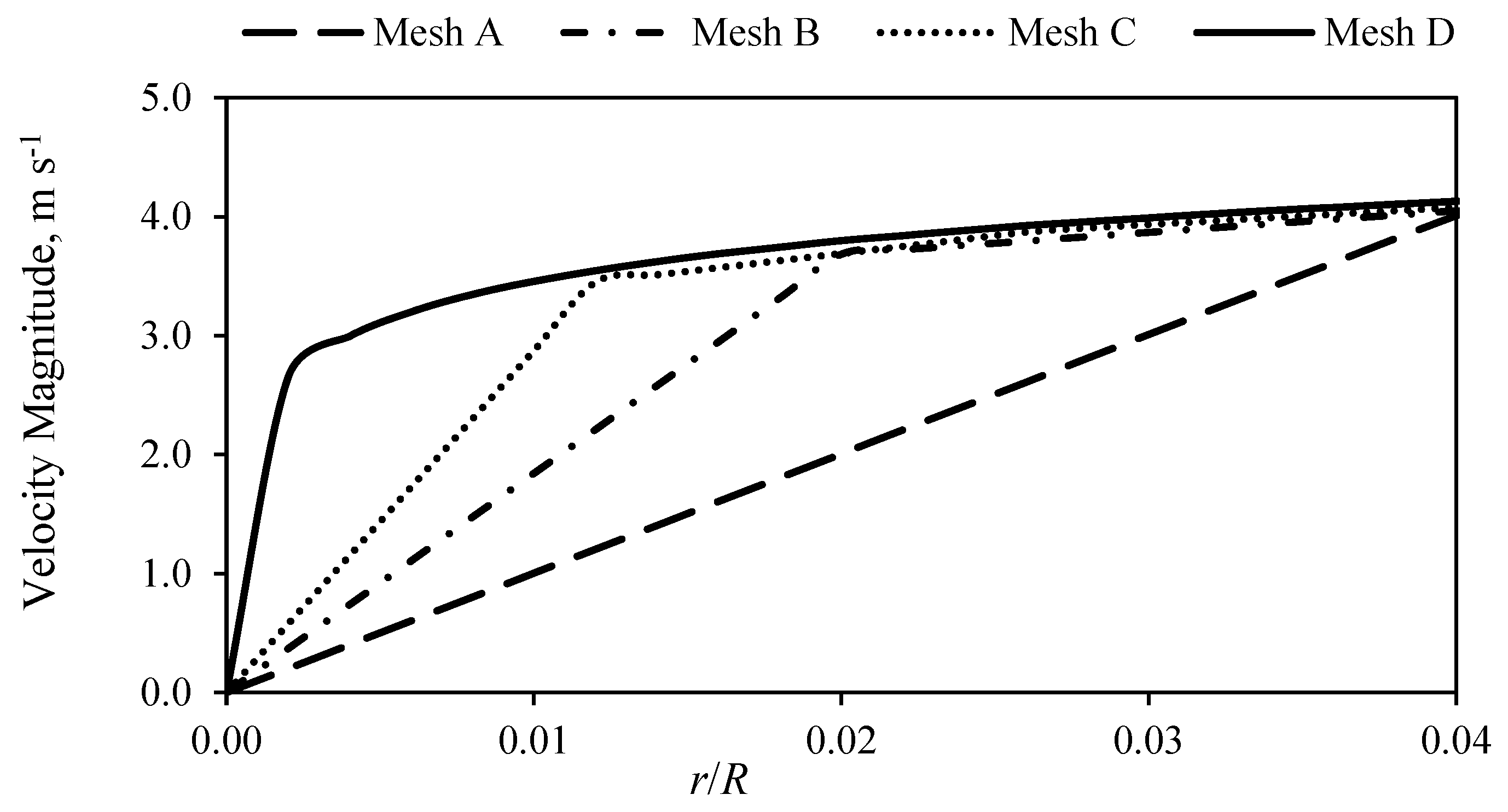

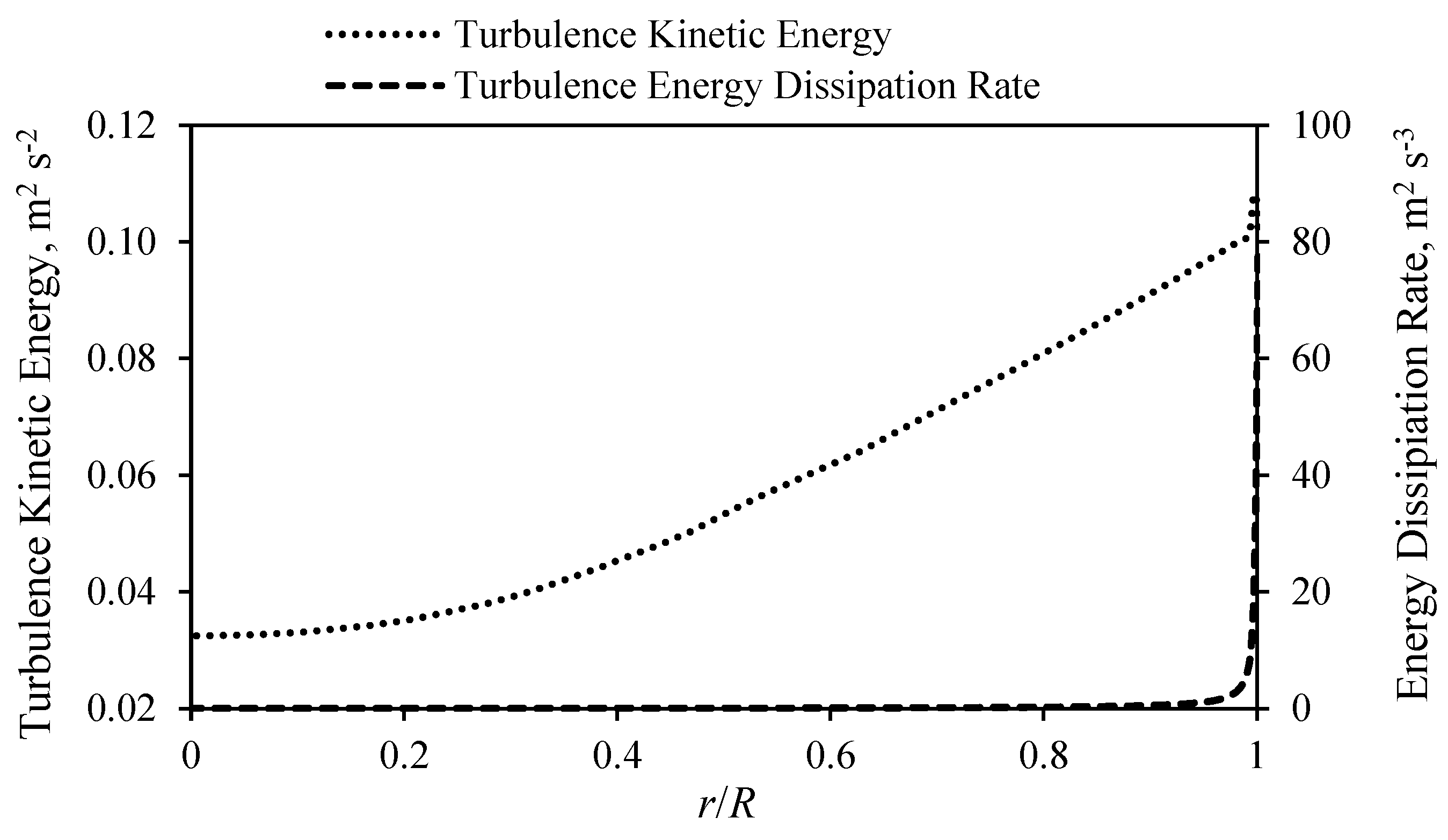

3.1. Mesh Sensitivity

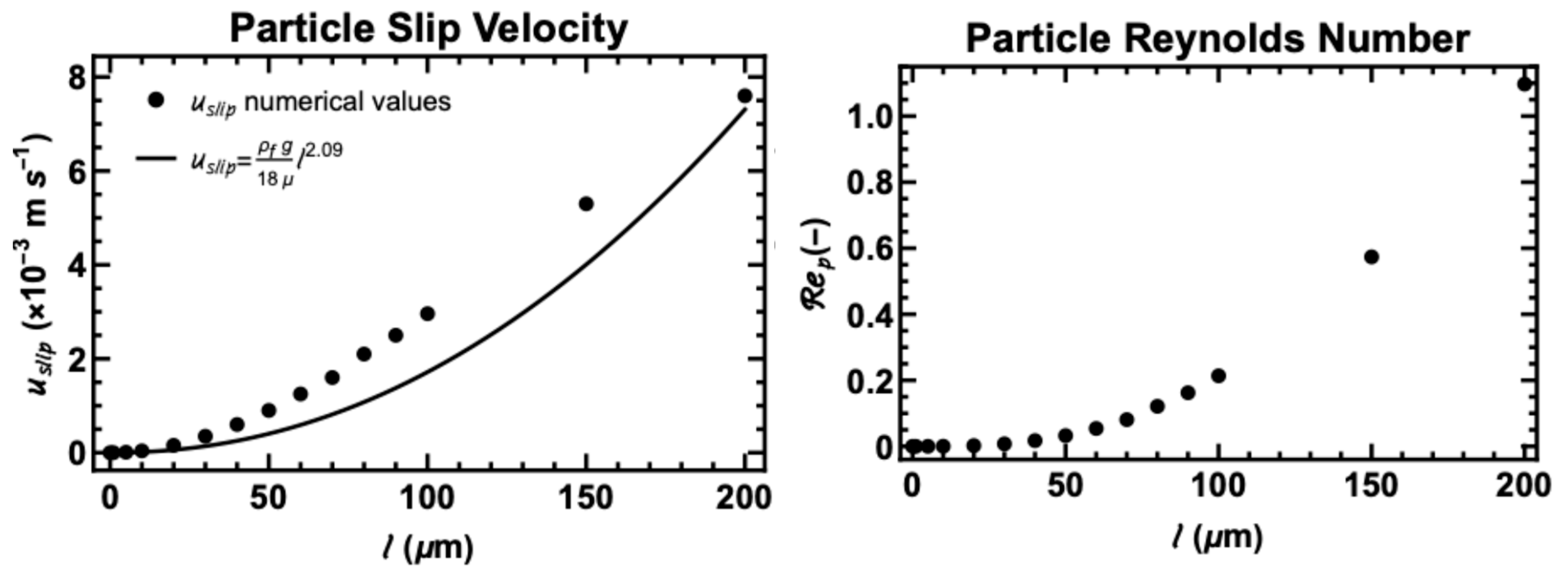

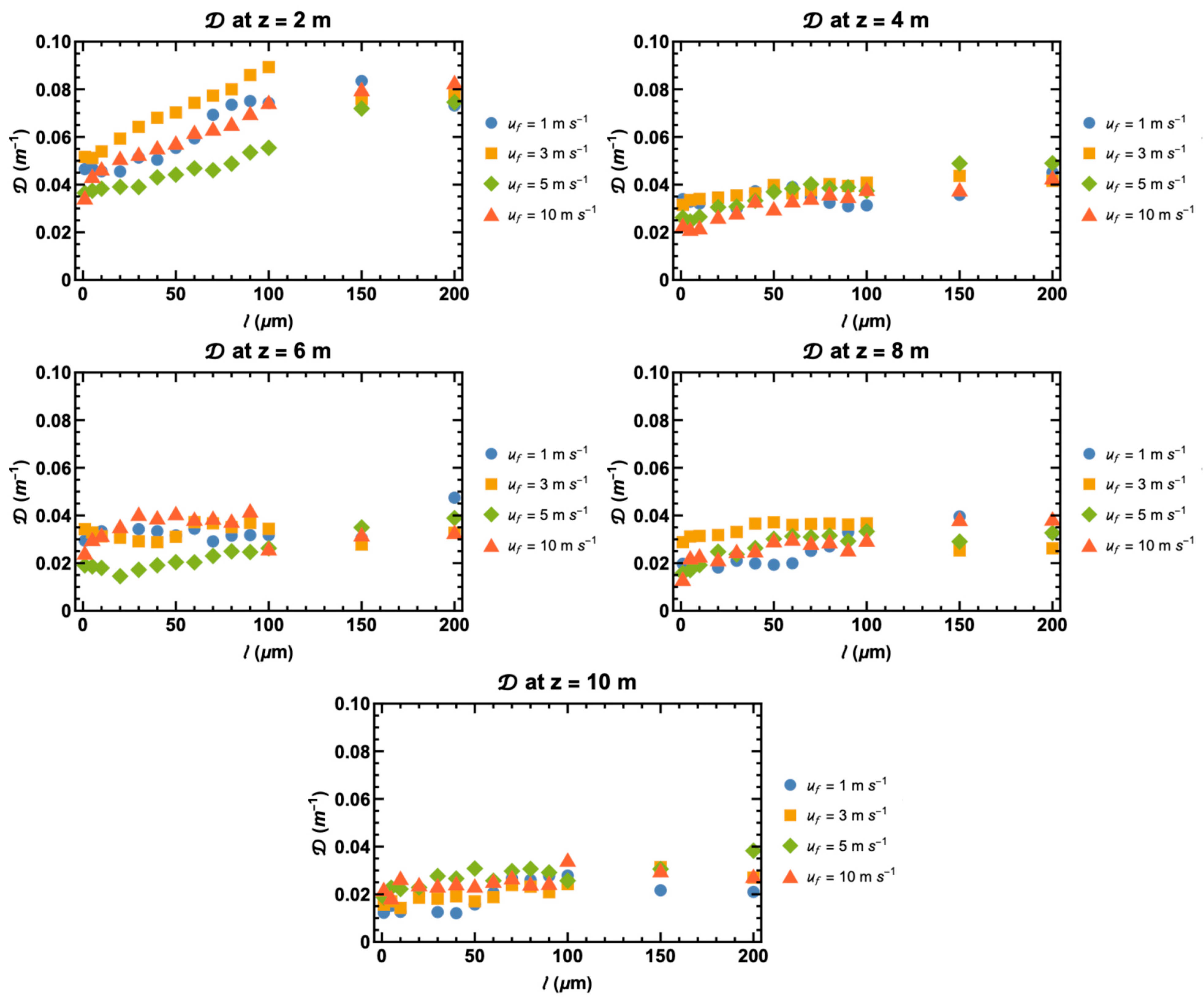

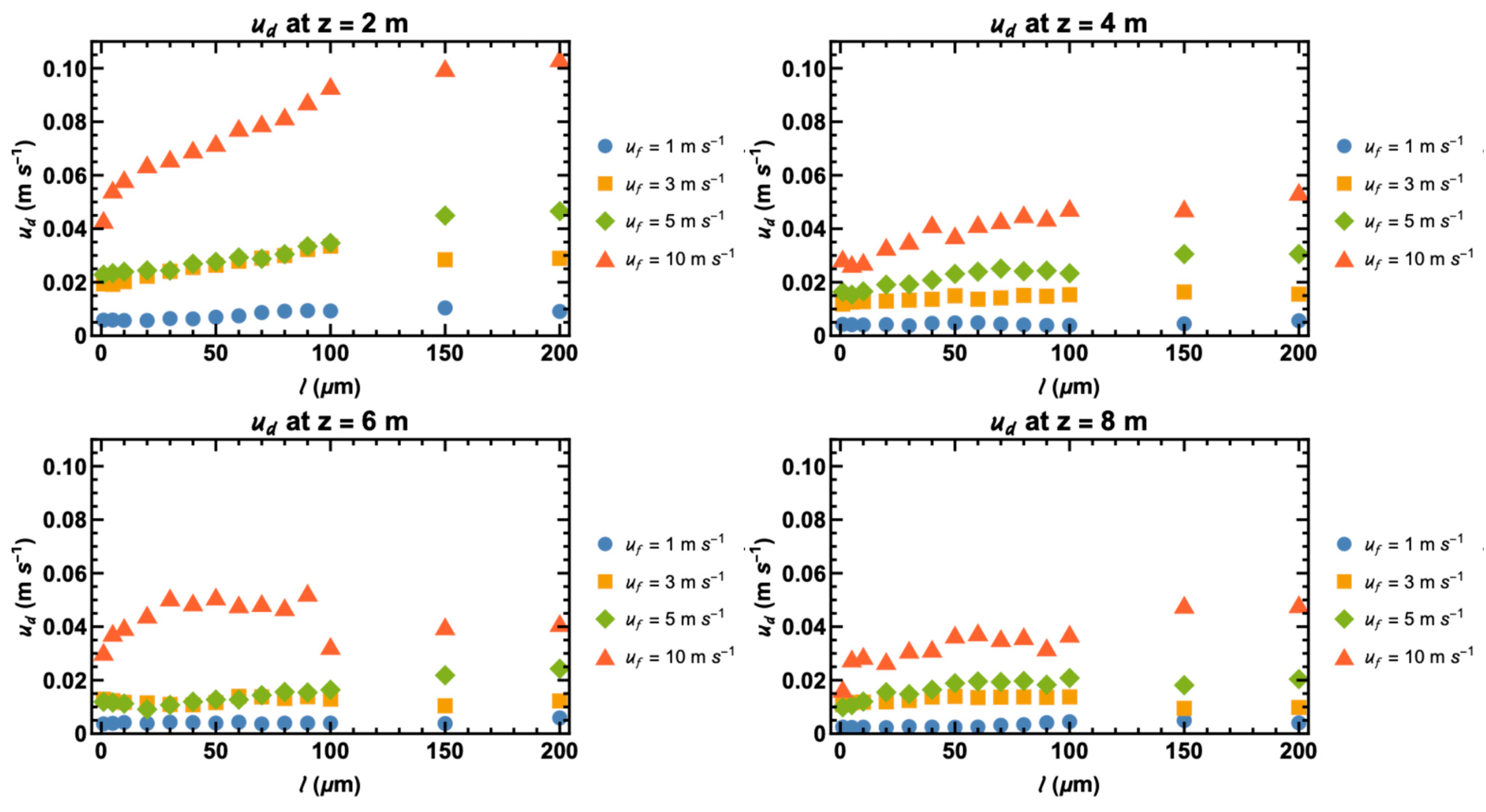

3.2. Slip Velocity, Deposition Constant, and Deposition Velocity

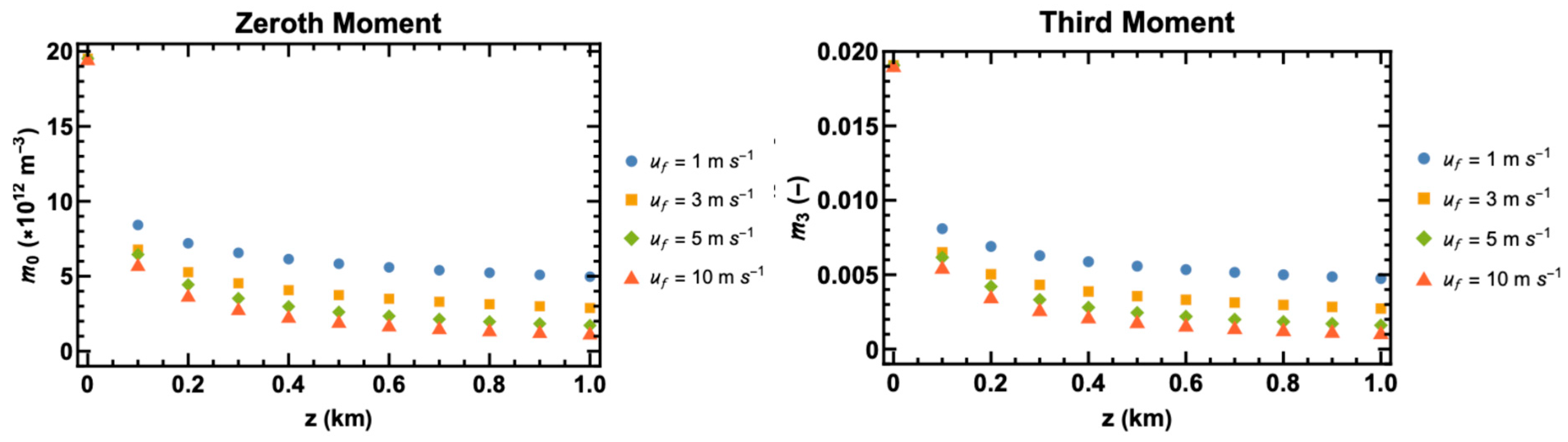

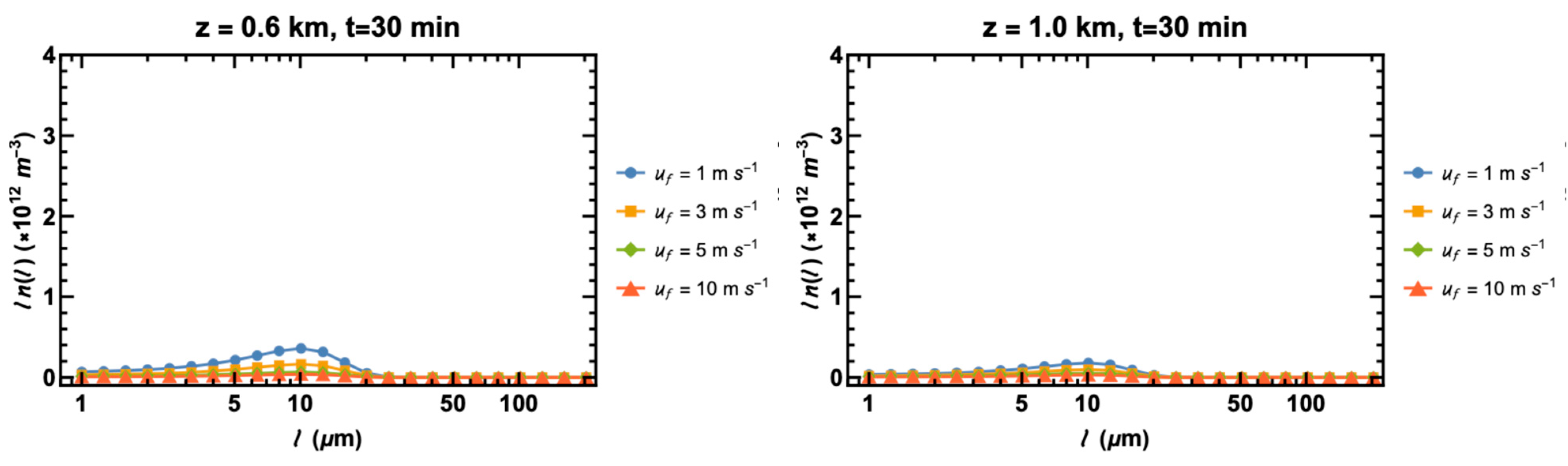

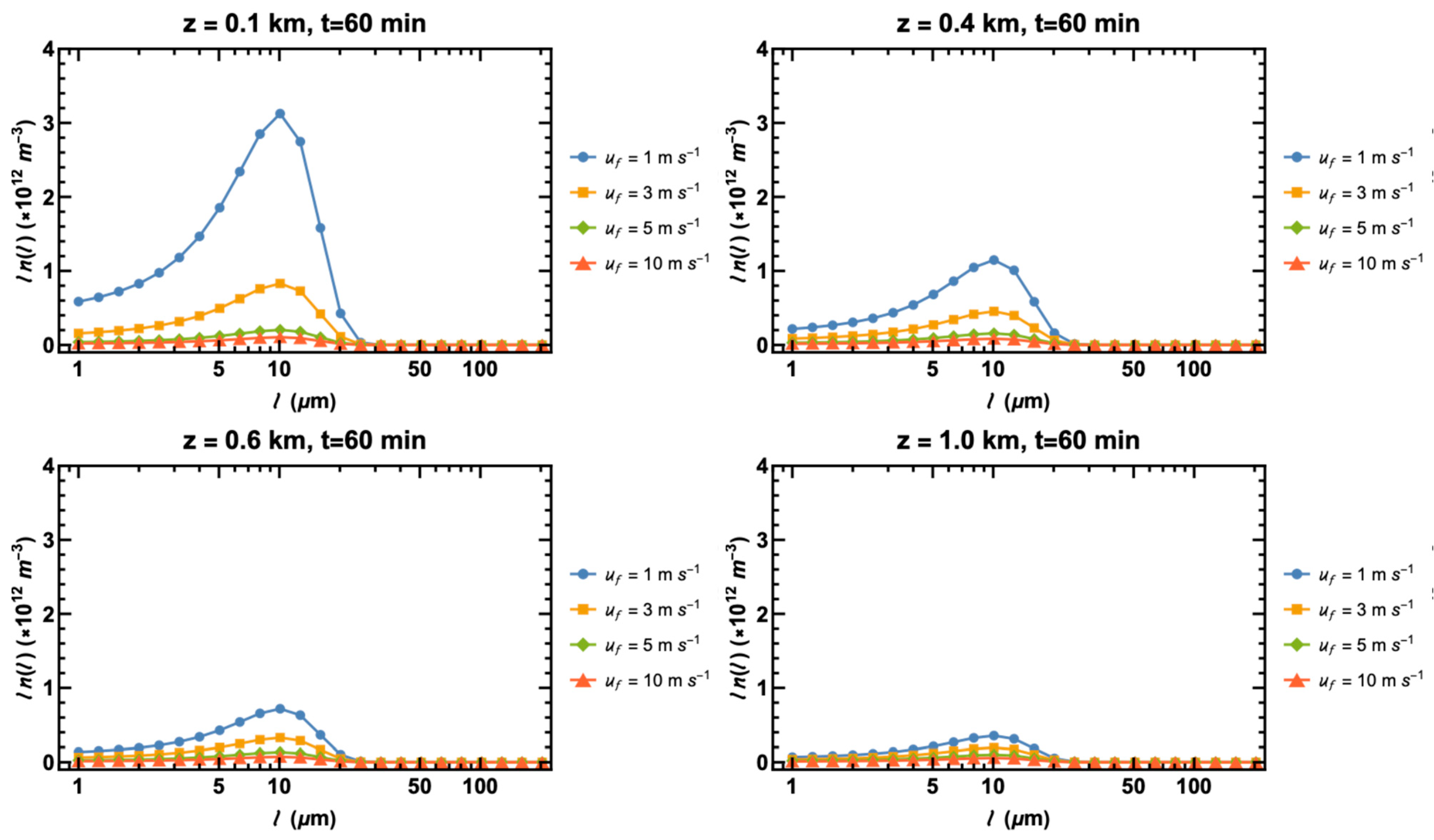

3.3. Size Distribution and Moments of Particles in the Flow

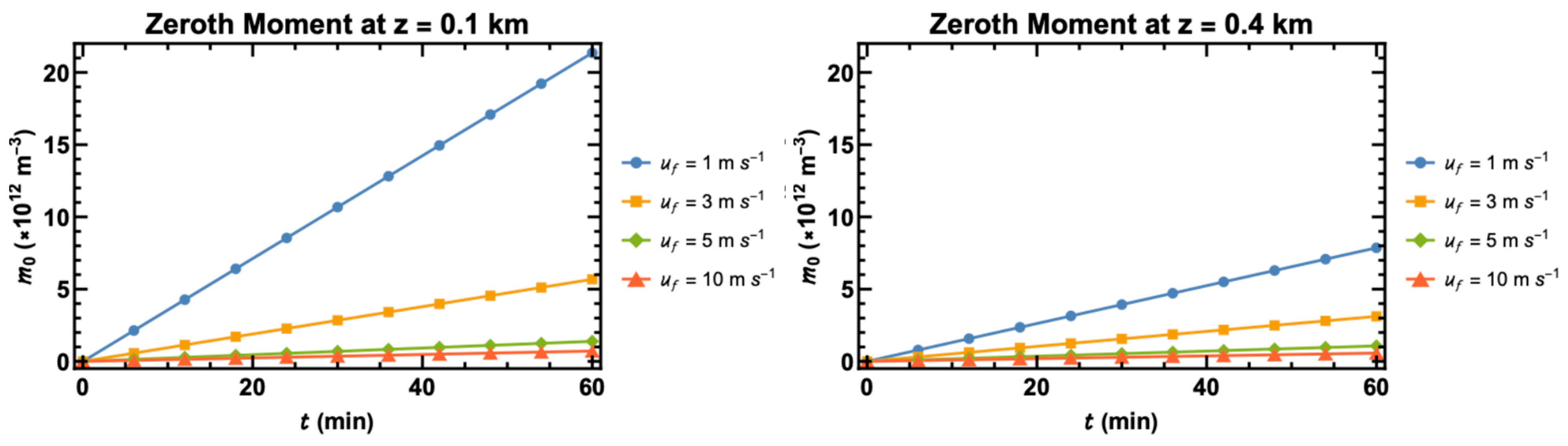

3.4. Size Distribution and Moments for Particles on the Internal Pipe Wall

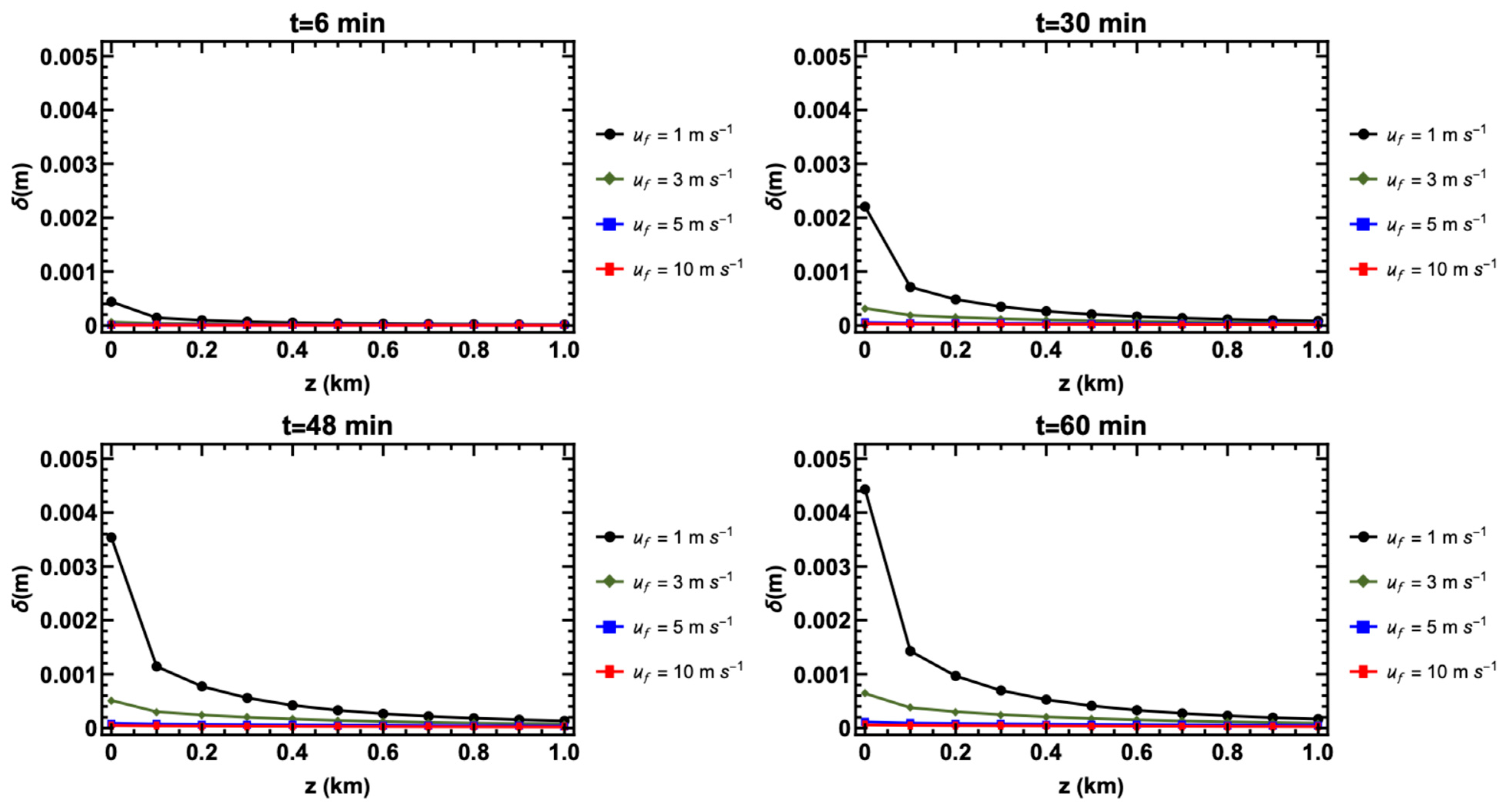

3.5. Thickness of the Deposits

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fissan, H.; Opiolka, S. Particle Deposition in High Capacity Preseparators. Part. Part. Syst. Charact. 1985, 2, 133–136. [Google Scholar] [CrossRef]

- Elimelech, M.; Gregory, J.; Jia, X.; Williams, R.A.F. (Eds.) Particle Deposition and Aggregation: Measurement, Modelling and Simulation; Butterworth-Heinemann: Oxford, UK, 1998. [Google Scholar]

- Pantusheva, M.; Mitkov, R.; Hristov, P.O.; Petrova-Antonova, D. Air Pollution Dispersion Modelling in Urban Environment Using CFD: A Systematic Review. Atmosphere 2022, 13, 1640. [Google Scholar] [CrossRef]

- Longest, P.W.; Bass, K.; Dutta, R.; Rani, V.; Thomas, M.L.; El-Achwah, A.; Hindle, M. Use of computational fluid dynamics deposition modeling in respiratory drug delivery. Expert Opin. Drug Deliv. 2019, 16, 7–26. [Google Scholar] [CrossRef]

- Ding, Y.; Chen, T.; Tian, H.; Shu, G.; Zhang, H. Experimental and numerical investigation of soot deposition on exhaust heat exchanger tube banks. Therm. Sci. Eng. Prog. 2023, 39, 101699. [Google Scholar] [CrossRef]

- Song, J.; Wei, Y.; Sun, G.; Chen, J. Experimental and CFD study of particle deposition on the outer surface of vortex finder of a cyclone separator. Chem. Eng. J. 2017, 309, 249–262. [Google Scholar] [CrossRef]

- Li, Y.; Liu, D.; Cui, B.; Lin, Z.; Zheng, Y.; Ishnazarov, O. Studying particle transport characteristics in centrifugal pumps under external vibration using CFD-DEM simulation. Ocean Eng. 2024, 301, 117538. [Google Scholar] [CrossRef]

- Tandon, P.; Adewumi, M.A. Particle deposition from turbulent flow in a pipe. J. Aerosol Sci. 1998, 29, 141–156. [Google Scholar] [CrossRef]

- Buenrostro-Gonzalez, E.; Lira-Galeana, C.; Gil-Villegas, A.; Wu, J. Asphaltene precipitation in crude oils: Theory and experiments. AIChE J. 2004, 50, 2552–2570. [Google Scholar] [CrossRef]

- Jia, W.; Okuno, R. Modeling of asphaltene and water associations in petroleum reservoir fluids using cubic-plus-association EOS. AIChE J. 2018, 64, 3429–3442. [Google Scholar] [CrossRef]

- Vegendla, S.N.P.; Heynderickx, G.J.; Marin, G.B. Comparison of Eulerian–Lagrangian and Eulerian–Eulerian method for dilute gas–solid flow with side inlet. Comput. Chem. Eng. 2011, 35, 1192–1199. [Google Scholar] [CrossRef]

- Emani, S.; Ramasamy, M.; Shaari, K.Z.K. Discrete phase-CFD simulations of asphaltenes particles deposition from crude oil in shell and tube heat exchangers. Appl. Therm. Eng. 2019, 149, 105–118. [Google Scholar] [CrossRef]

- Bayat, M.; Aminian, J.; Bazmi, M.; Shahhosseini, S.; Sharifi, K. CFD modeling of fouling in crude oil pre-heaters. Energy Convers. Manag. 2012, 64, 344–350. [Google Scholar] [CrossRef]

- Han, Z.; Xu, Z.; Yu, X. CFD modeling for prediction of particulate fouling of heat transfer surface in turbulent flow. Int. J. Heat Mass Transf. 2019, 144, 118428. [Google Scholar] [CrossRef]

- Zhang, J.; Li, A. CFD simulation of particle deposition in a horizontal turbulent duct flow. Chem. Eng. Res. Des. 2008, 86, 95–106. [Google Scholar] [CrossRef]

- Chaumeil, F.; Crapper, M. Using the DEM-CFD method to predict Brownian particle deposition in a constricted tube. Particuology 2014, 15, 94–106. [Google Scholar] [CrossRef]

- Akermann, K.; Renze, P. Numerical study of turbulent heat transfer and particle deposition in enhanced pipes with helical roughness. Int. J. Multiph. Flow 2024, 176, 104827. [Google Scholar] [CrossRef]

- Akter, F.; Saha, S. Deposition of aerosol particles and characteristics of turbulent flow inside wavy pipe using Eulerian-Lagrangian approach. Chem. Eng. Process.—Process Intensif. 2024, 205, 109971. [Google Scholar] [CrossRef]

- Azimifar, M.; Moradian, A.; Jafarian, A. A numerical investigation on the dynamics of particle deposition and fouling on a vertical falling film pipe. J. Water Process Eng. 2024, 66, 105990. [Google Scholar] [CrossRef]

- Balakin, B.V.; Hoffmann, A.C.; Kosinski, P. Experimental study and computational fluid dynamics modeling of deposition of hydrate particles in a pipeline with turbulent water flow. Chem. Eng. Sci. 2011, 66, 755–765. [Google Scholar] [CrossRef]

- Haghshenasfard, M.; Hooman, K. CFD modeling of asphaltene deposition rate from crude oil. J. Pet. Sci. Eng. 2015, 128, 24–32. [Google Scholar] [CrossRef]

- Valus, M.G.; Fontoura, D.V.R.; Serfaty, R.; Nunhez, J.R. Computational fluid dynamic model for the estimation of coke formation and gas generation inside petrochemical furnace pipes with the use of a kinetic net. Can. J. Chem. Eng. 2017, 95, 2286–2292. [Google Scholar] [CrossRef]

- Eskin, D.; Ratulowski, J.; Akbarzadeh, K.; Pan, S. Modelling asphaltene deposition in turbulent pipeline flows. Can. J. Chem. Eng. 2011, 89, 421–441. [Google Scholar] [CrossRef]

- Seyyedbagheri, H.; Mirzayi, B. CFD modeling of high inertia asphaltene aggregates deposition in 3D turbulent oil production wells. J. Pet. Sci. Eng. 2017, 150, 257–264. [Google Scholar] [CrossRef]

- Boyd, F.E.; Joseph, W.W.; Earl, E.S. Dynamics of falling raindrops. Eur. J. Phys. 2001, 22, 113. [Google Scholar] [CrossRef]

- Putnam, A. Integratable Form of Droplet Drag Coefficient. ARS J. 1961, 31, 1467–1468. [Google Scholar]

- Shiller, L.; Naumann, A. A Drag Coefficient Correlation1935. Z. Des Ver. Dtsch. Ingenieure 1935, 77, 318–320. [Google Scholar]

- Smoluchowski, M.V. Drei Vortrage uber Diffusion, Brownsche Bewegung und Koagulation von Kolloidteilchen. Z. Fur Phys. 1916, 17, 557–585. [Google Scholar]

- Mumtaz, H.S.; Hounslow, M.J. Aggregation during precipitation from solution: An experimental investigation using Poiseuille flow. Chem. Eng. Sci. 2000, 55, 5671–5681. [Google Scholar] [CrossRef]

- Liew, T.L.; Barrick, J.P.; Hounslow, M.J. A Micro-Mechanical Model for the Rate of Aggregation during Precipitation from Solution. Chem. Eng. Technol. 2003, 26, 282–285. [Google Scholar] [CrossRef]

- Hulburt, H.M.; Katz, S. Some problems in particle technology: A statistical mechanical formulation. Chem. Eng. Sci. 1964, 19, 555–574. [Google Scholar] [CrossRef]

- Serra, T.; Casamitjana, X. Effect of the shear and volume fraction on the aggregation and breakup of particles. AIChE J. 1998, 44, 1724–1730. [Google Scholar] [CrossRef]

- Tandon, P.; Diamond, S.L. Hydrodynamic effects and receptor interactions of platelets and their aggregates in linear shear flow. Biophys. J. 1997, 73, 2819–2835. [Google Scholar] [CrossRef]

- Liu, L. Kinetic theory of aggregation in granular flow. AIChE J. 2011, 57, 3331–3343. [Google Scholar] [CrossRef]

- Liu, L. Aggregation of silica nanoparticles in an aqueous suspension. AIChE J. 2015, 61, 2136–2146. [Google Scholar] [CrossRef]

- Liu, L. Effects of aggregation on the kinetic properties of particles in fluidised bed granulation. Powder Technol. 2015, 271, 278–291. [Google Scholar] [CrossRef]

- Hounslow, M.J.; Ryall, R.L.; Marshall, V.R. A discretized population balance for nucleation, growth, and aggregation. AIChE J. 1988, 34, 1821–1832. [Google Scholar] [CrossRef]

| ρ (kg m−3) | μ (Pa s) | l (μm) | |

|---|---|---|---|

| Continuous phase (liquid) | 866 | 0.0012 | |

| Dispersed phase (solids) | 1200 | 1–200 |

| l (μm) | 1 | 5 | 10 | 20 | 30 | 40 | 50 |

| 60 | 70 | 80 | 90 | 100 | 150 | 200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saad, A.B.; Obianagha, E.; Liu, L. Deposition: A DPM and PBM Approach for Particles in a Two-Phase Turbulent Pipe Flow. Powders 2025, 4, 20. https://doi.org/10.3390/powders4030020

Saad AB, Obianagha E, Liu L. Deposition: A DPM and PBM Approach for Particles in a Two-Phase Turbulent Pipe Flow. Powders. 2025; 4(3):20. https://doi.org/10.3390/powders4030020

Chicago/Turabian StyleSaad, Alkhatab Bani, Edward Obianagha, and Lande Liu. 2025. "Deposition: A DPM and PBM Approach for Particles in a Two-Phase Turbulent Pipe Flow" Powders 4, no. 3: 20. https://doi.org/10.3390/powders4030020

APA StyleSaad, A. B., Obianagha, E., & Liu, L. (2025). Deposition: A DPM and PBM Approach for Particles in a Two-Phase Turbulent Pipe Flow. Powders, 4(3), 20. https://doi.org/10.3390/powders4030020