The Particle Size to Modulate the Techno-Functional Properties of Fava Bean Pod Powder

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Obtaining Powdered Fava Bean Pods

2.3. Characterization of Fava Bean Pod Powder

2.4. Statistical Analysis

3. Results and Discussion

3.1. Powdered Fava Bean Pod Particle Size Distribution

3.2. Proximate Composition of Fava Bean Pod

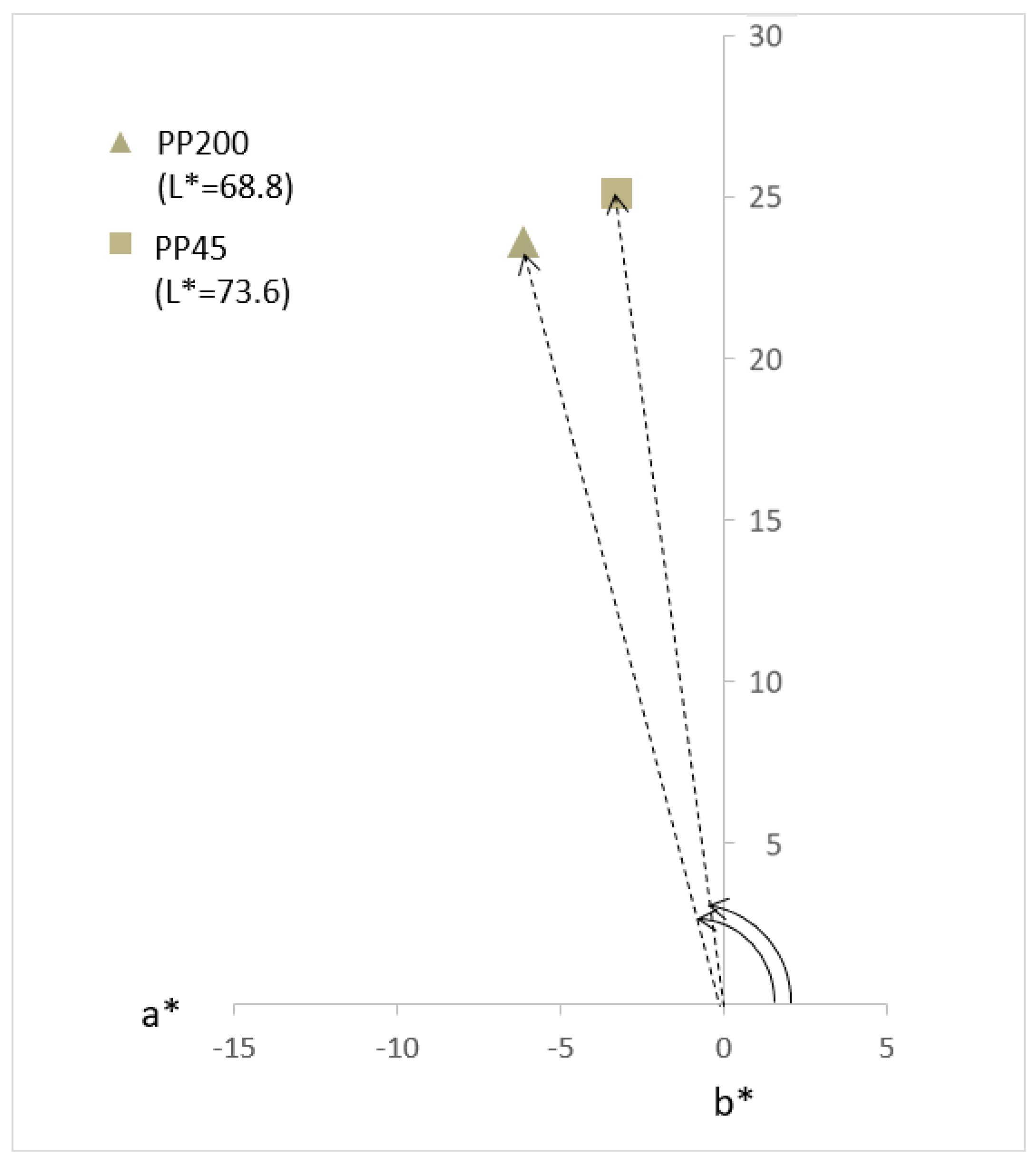

3.3. Color of Powdered Fava Bean Pods

3.4. Powder Flowability

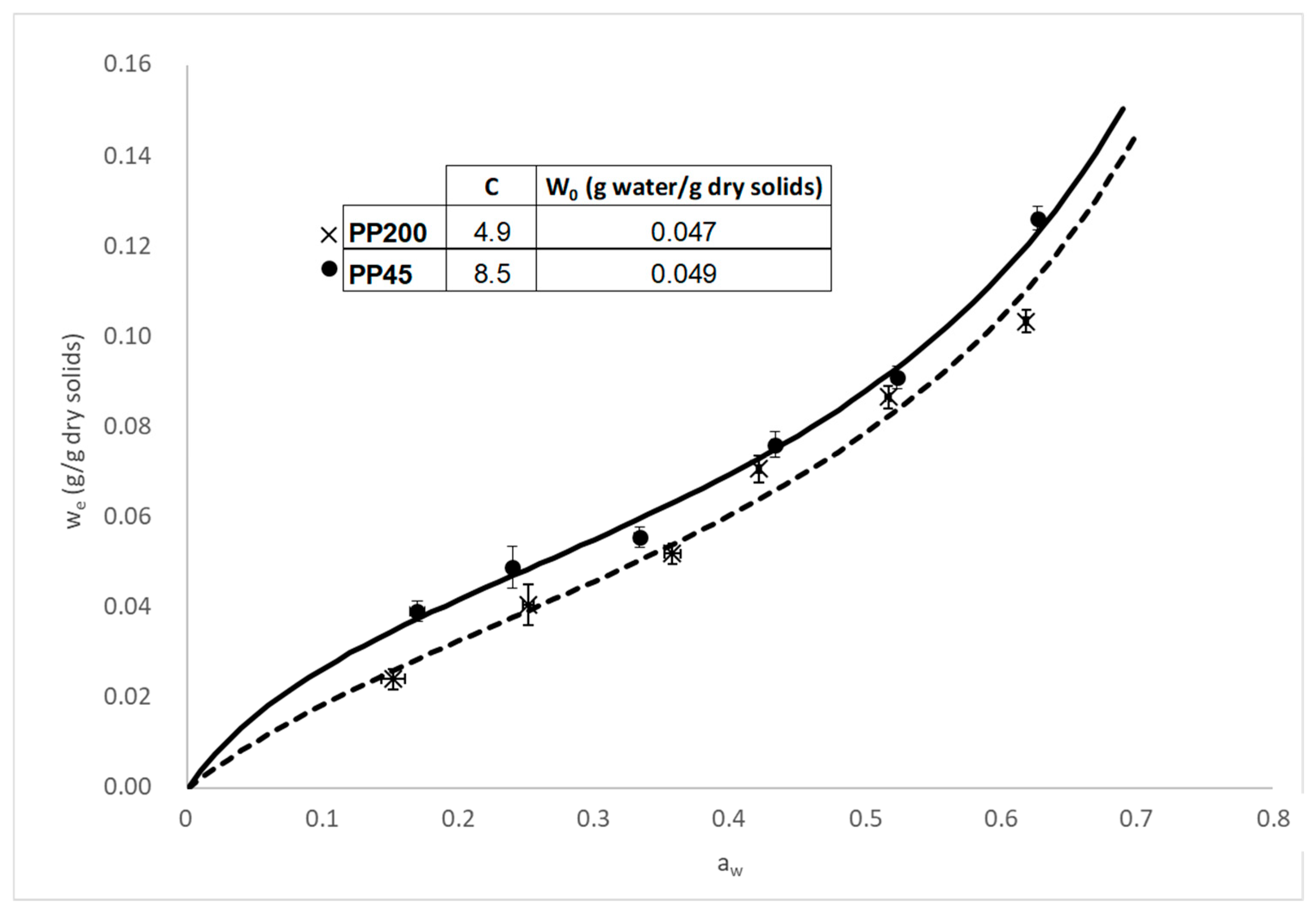

3.5. Properties Related to the Interaction of Powder with Water and with Oil

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PP200 | Powdered pod sample with 200 µm particle size |

| PP45 | Powdered pod sample with 45 µm particle size |

| SDF | Soluble dietary fiber |

| IDF | Insoluble dietary fiber |

| TDF | Total dietary fiber |

| A | Angle of repose |

| εb | Porosity of the bulk samples |

| εt | Porosity of tapped samples |

| HR | Hausner ratio |

| CI | Carr index |

| WRC | Water retention capacity |

| ORC | Oil retention capacity |

| FC | Foaming capacity |

| FS | Foam stability |

| L* | Luminosity |

| h* | Hue angle |

| C* | Chroma or saturation |

| ∆E | Color difference |

References

- FAO, Crops and Livestock Products. Food and Agriculture Organization of the United Nations. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 15 April 2025).

- Renna, M.; De Cillis, F.; Leoni, B.; Acciardi, E.; Santamaria, P. Preliminary Evaluation of Fresh Fava Hulls Highlights Richness in L-Dopa and Low Content of Anti-Nutritional Factor. Foods 2020, 9, 159. [Google Scholar] [CrossRef] [PubMed]

- Stenmarck, A.; Jensen, C.; Quested, T.; Moates, G. Estimates of European Food Waste Levels. Fusion. Reducing Food Waste Through Social Innovation. Technical Report European Commission. 2016. Available online: https://edepot.wur.nl/378674 (accessed on 11 May 2025).

- Singh, B.; Singh, J.P.; Kaur, A.; Singh, N. Phenolic composition, antioxidant potential and health benefits of citrus peel. Food Res. Int. 2020, 132, 109114. [Google Scholar] [CrossRef]

- Szabo, K.; Cătoi, A.F.; Vodnar, D.C. Bioactive Compounds Extracted from Tomato Processing by-products as a Source of Valuable Nutrients. Plant Foods Hum. Nutr. 2018, 73, 268–277. [Google Scholar] [CrossRef] [PubMed]

- Mateos-Aparicio, I.; Redondo-Cuenca, A.; Villanueva-Suárez, M.J.; Zapata-Revilla, M.A.; Tenorio-Sanz, M.D. Pea pod, broad bean pod and okara, potential sources of functional compounds. LWT Food Sci. Tech. 2021, 43, 1467–1470. [Google Scholar] [CrossRef]

- Mejri, F.; Selmi, S.; Martins, A.; Benkhoud, H.; Baati, T.; Chaabane, H.; Njim, L.; Serralheiro, L.M.; Rauter, A.P.; Hosni, K. Broad bean (Vicia faba L.) pods: A rich source of bioactive ingredients with antimicrobial, antioxidant, enzyme inhibitory, anti-diabetic and health-promoting properties. Food Funct. 2018, 9, 2051–2069. [Google Scholar] [CrossRef]

- Kalili, A.; El Ouafi, R.; Aboukhalaf, A.; Naciri, K.; Tbatou, M.; Essaih, S.; Belahyan, A.; Belahsen, R. Chemical composition and antioxidant activity of extracts from Moroccan fresh fava beans pods (Vicia faba L.). Rocz. Panstw. Zakl. Hig. 2022, 73, 79–86. [Google Scholar] [CrossRef] [PubMed]

- Dilucia, F.; Lacivita, V.; Conte, A.; Del Nobile, M.A. Sustainable Use of Fruit and Vegetable By-Products to Enhance Food Packaging Performance. Foods 2020, 9, 857. [Google Scholar] [CrossRef]

- Cuq, B.; Gaiani, C.; Turchiuli, C.; Galet, L.; Scher, J.; Jeantet, R.; Ruiz, T. Advances in food powder agglomeration engineering. Adv. Food Nutr. Res. 2013, 69, 41–103. [Google Scholar]

- Bhatta, S.; Janezic, T.S.; Ratti, C. Freeze-drying of plant-based foods. Foods 2020, 9, 87. [Google Scholar] [CrossRef]

- Jiang, G.; Ramachandraiah, K.; Wu, Z.; Li, S.; Eun, J.B. Impact of ball-milling time on the physical properties, bioactive compounds, and structural characteristics of onion peel powder. Food Biosci. 2020, 36, 100630. [Google Scholar] [CrossRef]

- Qin, X.; Dong, X.; Tang, J.; Chen, Y.; Xie, J.; Cheng, Y.; Zheng, B.; Hu, X.; Yu, Q. Comparative analysis of dietary fibers from grapefruit peel prepared by ultrafine grinding: Structural properties, adsorption capacities, in vitro prebiotic activities. Food Biosci. 2023, 56, 103163. [Google Scholar] [CrossRef]

- Camacho, M.M.; Zago, M.; García-Martínez, E.; Martínez-Navarrete, N. Free and Bound Phenolic Compounds Present in Orange Juice By-Product Powder and Their Contribution to Antioxidant Activity. Antioxidants 2022, 11, 1748. [Google Scholar] [CrossRef]

- Jayadeep, A.; Singh, V.; Rao, B.V.; Srinivas, A.; Ali, S.Z. Effect of physical processing of commercial de-oiled rice bran on particle size distribution, and content of chemical and bio-functional components. Food Bioproc. Tech. 2009, 2, 57–67. [Google Scholar] [CrossRef]

- Alam, S.A.; Järvinen, J.; Kirjoranta, S.; Jouppila, K.; Poutanen, K.; Sozer, N. Influence of particle size reduction on structural and mechanical properties of extruded rye bran. Food Bioproc. Tech. 2014, 7, 2121–2133. [Google Scholar] [CrossRef]

- Bender, A.B.B.; Speroni, C.S.; Moro, K.I.B.; Morisso, F.; dos Santos, D.; da Silva, L.P.; Penna, N. Effects of micronization on dietary fiber composition, physicochemical properties, phenolic compounds, and antioxidant capacity of grape pomace and its dietary fiber concentrate. LWT 2020, 117, 108652. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Liu, F.; Pan, S. Effect of grinding methods on structural, physicochemical, and functional properties of insoluble dietary fiber from orange peel. Int. J. Polym. Sci. 2016, 2016, 6269302. [Google Scholar] [CrossRef]

- Zhu, F.; Du, B.; Xu, B. Superfine grinding improves functional properties and antioxidant capacities of bran dietary fibre from Qingke (hull-less barley) grown in Qinghai-Tibet Plateau, China. J. Cereal Sci. 2015, 65, 43–47. [Google Scholar] [CrossRef]

- Goh, H.P.; Heng, P.W.S.; Liew, C.V. Comparative evaluation of powder flow parameters with reference to particle size and shape. Int. J. Pharm. 2018, 547, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Lv, G.; Zhang, Z.; Pan, H.; Fan, R. Effect of physical modification of mushroom (A. chaxingu) powders on their physical and chemical properties. Food Sci. Tech. Res. 2014, 20, 731–738. [Google Scholar] [CrossRef]

- Zhong, C.; Zu, Y.; Zhao, X.; Li, Y.; Ge, Y.; Wu, W.; Zhang, Y.; Li, Y.; Guo, D. Effect of superfine grinding on physicochemical and antioxidant properties of pomegranate peel. Int. J. Food Sci. Tech. 2016, 51, 212–221. [Google Scholar] [CrossRef]

- AOAC. Official methods of analysis. In Association of Official Analytical Chemists; Herrich, K., Ed.; AOAC: Arlington, VA, USA, 1990. [Google Scholar]

- ISO 10520:1997; ISO, Native Starch. Determination of Starch Content. Ewers Polarimetric Method. International Organization for Standardization: Geneva, Switzerland, 1997.

- Camacho, M.M.; Silva-Espinoza, M.A.; Martinez-Navarrete, N. Flowability, Rehydration Behaviour and bioactive Compounds of an Orange Powder Product as Affected by Particle Size. Food Bioproc. Tech. 2022, 15, 683–692. [Google Scholar] [CrossRef]

- García-Martínez, E.; Camacho, M.M.; Martínez-Navarrete, N. In vitro Bioaccesibilty of Bioactive Compounds of Freeze-dried Orange Juice Co-Product Formulated with Gum Arabic and Modified Starch. Molecules 2023, 28, 810. [Google Scholar] [CrossRef]

- Uscanga, M.A.; Camacho, M.M.; Salgado, M.A.; Martínez-Navarrete, N. Influence of an Orange Product Composition on the Characteristics of the Obtained Freeze-dried Cake and Powder as Related to Their Consumption Pattern. Food Bioproc. Tech. 2020, 13, 1368–1379. [Google Scholar] [CrossRef]

- Camacho, M.M.; Silva-Espinoza, M.A.; Martínez-Navarrete, M. Sorption Behavior, Glass Transition and Flowability of Powdered Orange Co-product. Mater. Circ. Econ. 2021, 3, 17. [Google Scholar] [CrossRef]

- Raghavendra, S.N.; Rastogi, N.K.; Raghavarao, K.S.M.S.; Tharanathan, R.N. Dietary fiber from coconut residue: Effects of different treatments and particle size on the hydration properties. Eur. Food Res. Technol. 2004, 218, 563–567. [Google Scholar] [CrossRef]

- Martínez-Navarrete, N.; García-Martínez, E.; Camacho, M.M. Characterization of the Orange Juice Powder Co-Product for Its Valorization as a Food Ingredient. Foods 2023, 12, 97. [Google Scholar] [CrossRef] [PubMed]

- Camacho, M.M.; Martínez-Lahuerta, J.J.; Ustero, I.; García-Martínez, E.; Martínez-Navarrete, N. Composition of Powdered Freeze-Dried Orange Juice Co-Product as Related to Glucose Absorption in Vitro. Foods 2023, 12, 1127. [Google Scholar] [CrossRef]

- Fendri, L.B.; Chaari, F.; Maaloul, M.; Kallel, F.; Abdelkafi, L.; Ellouz, S.; Ghribi-Aydi, D. Wheat bread enrichment by pea and broad bean pods fibers: Effect on dough rheology and bread quality. LWT Food Sci. Tech. 2016, 73, 584–591. [Google Scholar] [CrossRef]

- Muhoza, B.; Harimana, Y.; Kayitesi, E.; Uriho, A.; Liu, Q. Insight into the Effect of Extraction and Spray Drying Conditions on the Nutritional and Techno-Functional Properties of Legume Protein Powder: A Review. Food Bioproc. Technol. 2025, 18, 1141–1159. [Google Scholar] [CrossRef]

- Russin, T.A.; Arcand, Y.; Boye, J.I. Particle size effect on soy protein isolate extraction. J. Food Process Preserv. 2007, 31, 308–319. [Google Scholar] [CrossRef]

- Jeganathan, B.; Gao, J.; Vasanthan, T.; Temelli, F. Potential of sequential pearling to explore macronutrient distribution across faba beans (Vicia faba L.) for chemical-free hybrid fractionation. J. Food Compos. Anal. 2022, 112, 104695. [Google Scholar] [CrossRef]

- Maja, L.; Krenz, M.; Grebenteuch, S.; Zocher, K.; Rohn, S.; Pleissner, D. Valorization of faba bean (Vicia faba) by-products. Biomass Convers. Biorefin. 2023, 1, 3. [Google Scholar]

- De Moraes, T.; Jablonski, A.; de Oliveira Rios, A.; Rech, R.; Flôres, S.H. Dietary fiber from orange byproducts as a potential fat replacer. LWT Food Sci. Tech. 2013, 53, 9–14. [Google Scholar] [CrossRef]

- Grigelmo-Miguel, N.; Martín-Belloso, O. Characterization of dietary fiber from orange juice extraction. Food Res. Int. 1998, 31, 355–361. [Google Scholar] [CrossRef]

- Peña, M.M.; Odriozola-Serrano, I.; Oms-Oliu, G.; Martín-Belloso, O. Dietary Fiber in Fruits and Vegetables. In Science and Technology of Fibers in Food Systems; Food Engineering Series; Welti-Chanes, J., Serna-Saldívar, S., Campanella, O., Tejada-Ortigoza, V., Eds.; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Timm, M.; Offringa, L.C.; Van Klinken, B.J.W.; Slavin, J. Beyond Insoluble Dietary Fiber: Bioactive Compounds in Plant Foods. Nutrients 2023, 15, 4138. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, J.; Alazemi, A.; Ponnumani, P.; Soliman, M.; Emmanuval, L.; Thomas, N.M. Transformation of quinoa seeds to nanoscale flour by ball milling: Influence of ball diameter and milling time on the particle sizing, microstructure, and rheology. J. Food Eng. 2024, 379, 112127. [Google Scholar] [CrossRef]

- Rodríguez, I.F.; Pérez, M.J.; Cattaneo, F.; Zampini, I.C.; Cuello, A.S.; Mercado, M.I.; Ponessa, G.; Isla, M.I. Morphological, histological, chemical and functional characterization of Prosopis alba flours of different particle sizes. Food Chem. 2019, 274, 583–591. [Google Scholar] [CrossRef] [PubMed]

- Benlloch-Tinoco, M.; Kaulmann, A.; Corte-Real, J.; Rodrigo, D.; Martínez-Navarrete, N.; Bohn, T. Chlorophylls and carotenoids of kiwifruit puree are affected similarly or less by microwave than by conventional heat processing and storage. Food Chem. 2015, 187, 254–262. [Google Scholar] [CrossRef]

- Gao, W.; Chen, F.; Wang, X.; Meng, Q. Recent advances in processing food powders by using superfine grinding techniques: A review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2222–2255. [Google Scholar] [CrossRef]

- Krapfenbauer, G.; Kinner, M.; Gossinger, M.; Schonlechner, R.; Berghofer, E. Effect of thermal treatment on the quality of cloudy apple juice. J. Agric. Food Chem. 2006, 54, 5453–5460. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Ortega-Rivas, E.; Juliano, P.; Yan, H. Physical Properties, Processing, and Functionality, Food Powders; Springer: New York, NY, USA, 2005; pp. 71–75. [Google Scholar]

- Alavi, S.; Caussat, B. Experimental study on fluidization of micronic powders. Powder Technol. 2005, 157, 114–120. [Google Scholar] [CrossRef]

- Fitzpatrick, J. Powder properties in food production systems. In Handbook of Food Powders: Processes and Properties; Bhandari, B., Bansal, N., Zhang, M., Schuck, P., Eds.; Woodhead Publishing: Sawston, UK, 2013; pp. 285–308. [Google Scholar]

- Bhusari, S.N.; Muzaffar, K.; Kumar, P. Effect of carrier agents on physical and microstructural properties of spray dried tamarind pulp powder. Powder Technol. 2014, 266, 354–364. [Google Scholar] [CrossRef]

- O’Donoghue, L.T.; Haque, M.K.; Kennedy, D.; Laffir, F.R.; Hogan, S.A.; O’Mahony, J.A.; Murphy, E.G. Influence of particle size on the physicochemical properties and stickiness of dairy powders. Int. Dairy. J. 2019, 98, 54–63. [Google Scholar] [CrossRef]

- Schuck, P.; Jeantet, R.; Dolivet, A. Analytical Methods for Food and Dairy Powders; John Wiley & Sons: Oxford, UK, 2012. [Google Scholar]

- Noguerol, A.T.; Igual, M.; Pagán, M.J. Developing psyllium fibre gel-based foods: Physicochemical, nutritional, optical and mechanical properties. Food Hydrocoll. 2022, 122, 107108. [Google Scholar] [CrossRef]

- Femenia, A.; Lefebvre, A.C.; Thebaudin, J.Y.; Robertson, J.A.; Bourgeois, C.M. Physical and sensory properties of model foods supplemented with cauliflower fiber. J. Food Sci. 1997, 62, 635–639. [Google Scholar] [CrossRef]

- Chubert, H.S. Food particle technology. Part I: Properties of particles and particulate food systems. J. Food Eng. 1987, 6, 1–32. [Google Scholar] [CrossRef]

- Shittu, T.A.; Lawal, M.O. Factors affecting instant properties of powdered cocoa beverages. Food Chem. 2007, 100, 91–98. [Google Scholar] [CrossRef]

- Ji, J.; Fitzpatrick, J.; Cronin, K.; Maguire, P.; Zhang, H.; Miao, S. Rehydration behaviours of high protein dairy powders: The influence of agglomeration on wettability, dispersibility and solubility. Food Hydrocoll. 2016, 58, 194–203. [Google Scholar] [CrossRef]

- Selomulya, C.; Fang, Y. Food-powder-rehydration. In Handbook of Food Powders: Processes and Properties; Bhandari, B., Bansal, N., Zhang, M., Schuck, P., Eds.; Woodhead Publishing: Sawston, UK, 2013. [Google Scholar]

- Gaiani, C.; Ehrhardt, J.J.; Scher, J.; Hardy, J.; Desobry, S.; Banon, S. Surface composition of dairy powders observed by X-ray photoelectron spectroscopy and effects on their rehydration properties. Colloids Surf. B Biointerfaces 2006, 49, 71–78. [Google Scholar] [CrossRef]

- Yin, Z.; Wang, Z.; He, Z.; Zeng, M.; Qin, F.; Chen, J. Effect of particle size and microstructure on the physical properties of soybean insoluble dietary fiber in aqueous solution. Food Biosci. 2021, 41, 100898. [Google Scholar] [CrossRef]

- Auffret, A.; Ralet, M.C.; Guillon, F.; Barry, J.L.; Thibault, J.F. Effect of Grinding and Experimental Conditions on the Measurement of Hydration Properties of Dietary Fibres. LWT Food Sci. Technol. 1994, 27, 166–172. [Google Scholar] [CrossRef]

- Lan, G.; Chen, H.; Chen, S.; Tian, J. Chemical composition and physicochemical properties of dietary fiber from Polygonatum odoratum as affected by different processing methods. Food Res. Int. 2012, 49, 406–410. [Google Scholar] [CrossRef]

- Mokhtar, S.M.; Swailam, H.M.; Embaby, H.E.S. Physicochemical properties, nutritional value and techno-functional properties of goldenberry (Physalis peruviana) waste powder concise title: Composition of goldenberry juice waste. Food Chem. 2018, 248, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Thebaudin, J.Y.; Lefebvre, A.C.; Harrington, M.; Bourgeois, C.M. Dietary fibers: Nutritional and Tecnological Interest. Trends Food Sci. Tech. 1997, 8, 41–47. [Google Scholar] [CrossRef]

| PP200 | PP45 | |

|---|---|---|

| Protein | 16.77 ± 0.7 (a) | 20.40 ± 0.04 (b) |

| Fat | 0.89 ± 0.10 (b) | 0.532 ± 0.07 (a) |

| Ash | 6.3 ± 0.2 (a) | 8.3 ± 0.2 (b) |

| Total Dietetic Fiber | 33.5 ± 1.4 (a) | 34.4 ± 0.3 (a) |

| Soluble Dietetic Fiber | 9.7 ± 0.9 (a) | 14.6 ± 0.5 (b) |

| Insoluble Dietetic Fiber | 23.8 ± 1.7 (b) | 19.9 ± 0.3 (a) |

| Starch | 16.7 ± 0.4 (a) | 17.4 ± 0.8 (a) |

| Sugar | 25.84 ± 0.6 (b) | 18.9 ± 0.9 (a) |

| Total phenols | 0.0519 ± 0.0001 (a) | 0.070 ± 0.004 (b) |

| PP200 | PP45 | |

|---|---|---|

| α (°) | 38.4 ± 0.3 (a) | 37.5 ± 1.4 (a) |

| HR | 1.09 ± 0.03 (a) | 1.119 ± 0.006 (a) |

| CI (%) | 9 ± 2 (a) | 10.7 ± 0.5 (a) |

| ρb (g/cm3) | 0.350 ± 0.010 (b) | 0.299 ± 0.008 (a) |

| ρt (g/cm3) | 0.389 ± 0.007 (b) | 0.335 ± 0.009 (a) |

| εb (%) | 74.8 ± 0.7 (a) | 78.5 ± 0.6 (b) |

| εt (%) | 72.0 ± 0.5 (a) | 75.9 ± 0.7 (b) |

| PP200 | PP45 | |

|---|---|---|

| Higroscopicity | 2.4 ± 0.7 (a) | 5.4 ± 0.7 (b) |

| Wettability | 192 ±12 (a) | 1532 ±33 (b) |

| Dispersibility | 9.1 ± 1.0 (a) | 58.8 ± 1.5 (b) |

| Solubility | 27.8 ± 0.4 (a) | 33.4 ± 0.7 (b) |

| Water retention capacity | 6.3 ± 0.2 (b) | 5.55 ± 0.19 (a) |

| Swelling capacity | 4.7 ± 0.6 (b) | 2.3 ± 0.6 (a) |

| Foam capacity | 15.0 ± 1.5 (a) | 12 ± 3 (a) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barrial-Lujan, A.I.; Camacho, M.d.M.; García-Martínez, E.; Yuste, A.; Martínez-Navarrete, N. The Particle Size to Modulate the Techno-Functional Properties of Fava Bean Pod Powder. Powders 2025, 4, 14. https://doi.org/10.3390/powders4020014

Barrial-Lujan AI, Camacho MdM, García-Martínez E, Yuste A, Martínez-Navarrete N. The Particle Size to Modulate the Techno-Functional Properties of Fava Bean Pod Powder. Powders. 2025; 4(2):14. https://doi.org/10.3390/powders4020014

Chicago/Turabian StyleBarrial-Lujan, Abel I., María del Mar Camacho, Eva García-Martínez, Alberto Yuste, and Nuria Martínez-Navarrete. 2025. "The Particle Size to Modulate the Techno-Functional Properties of Fava Bean Pod Powder" Powders 4, no. 2: 14. https://doi.org/10.3390/powders4020014

APA StyleBarrial-Lujan, A. I., Camacho, M. d. M., García-Martínez, E., Yuste, A., & Martínez-Navarrete, N. (2025). The Particle Size to Modulate the Techno-Functional Properties of Fava Bean Pod Powder. Powders, 4(2), 14. https://doi.org/10.3390/powders4020014