Abstract

Plant by-products are undervalued as they are an important source of nutrients and bioactive compounds with potential health benefits, which also contribute to aroma and color. Therefore, their use in human food is a challenging field of study that deserves to be explored. This study proposes the conversion of fava bean pods into a powdered product as a high-quality, stable, and easy-to-handle food ingredient, thus contributing to the sustainability of the food industry within the framework of the circular economy. The powdered product was obtained by freeze-drying and grinding. As the particle size of powders is a determinant of their quality and functionality, some properties of two bean pod powder samples with mean particle sizes of 102.9 and 45.3 μm, obtained by sieving at 200 and 45 μm, respectively, are compared. The results obtained indicate good flowability of both powders. However, the sample with the largest size showed, in addition to a greener tone, lower interparticle porosity related to a better packing capacity, lower hygroscopicity, and much better wettability, along with its higher swelling capacity and water and oil retention capacity. Nevertheless, in this case, the extraction of proteins and phenols decreased by 18% and 25%, respectively, without compromising the total fiber content. Considering the use of fava bean pod powder as a versatile food ingredient, the largest size of those studied, 102.9 μm, is recommended. Only if the objective is to obtain a healthy food supplement would it be more desirable to grind it to a smaller particle size.

1. Introduction

In recent years, broad bean (Vicia faba L.) cultivation, belonging to the Fabaceae family, has been extended in terms of production. The global average production of this pulse between 2015 and 2022 exceeded 5.9 million tons, with the European Union being the second-largest producer after China [1]. The production of broad bean generates a large volume of by-products, mainly the pod that surrounds the seeds, which accounts for 70–75% of the fresh pod’s weight [2]. To overcome this problem, and considering the interesting nutritional composition of bean pod, it seems advisable to explore the possibility of converting it into a food ingredient. This would expand the options for its reuse, including from households, where around 50% of food waste is generated [3].

The valorization of agri-food by-products has gained increasing interest in recent years due to its potential to reduce waste, improve sustainability, and promote the circular economy. Various plant-derived by-products, such as citrus peels and tomato skins, have been studied for their content of dietary fiber and bioactive compounds. In this sense, while citrus peels are rich in flavonoids and pectin [4], and tomato skins provide lycopene and fiber [5], fava bean pods combine high levels of dietary fiber with substantial amounts of protein, minerals (such as potassium, magnesium, and calcium), and polyphenolic compounds, including flavonoids and phenolic acids [6,7]. Due to their fiber content, the intake of fava bean pods can support intestinal motility, contribute to blood glucose regulation, and aid in cholesterol reduction. Protein can serve as an alternative protein source. Additionally, their bioactive compounds exhibit antioxidant, anti-inflammatory, and antimicrobial activities [8]. This unique combination of macronutrients and bioactives positions fava bean pods as a particularly valuable by-product, justifying their transformation into a co-product for use as an ingredient in human food products. Such an approach could contribute to the development of functional foods with health-promoting properties, aligned with sustainable development goals and the principles of a circular economy. This would also make it possible to contribute to the achievement of some of the SDGs described by the United Nations in the 2030 Agenda. However, due to the high water content of vegetable by-products, they are unstable in terms of their physical, chemical, and biochemical properties, with a high risk of growth of micro-organisms [9]. One way to extend its useful life is by drying. Specifically, offering this dehydrated by-product in powdered form as a food ingredient would confer stability, ease of handling, and logistical advantages [10]. Freeze-drying (FD) is a drying method often used to obtain high-quality products, especially when processing raw materials with thermolabile and oxidation-sensitive compounds, such as those of vegetable origin [11]. The FD process protects the structural integrity of the product, minimizes volume reduction, and preserves bioactive compounds. Additionally, FD products are easy to rehydrate, which is an important factor in food ingredient application [11]. For all these reasons, despite the use of FD is expensive and there are alternative more economical drying methods, this process was selected in this study to obtain the bean pod powder.

Grinding is another crucial step in producing powdered food ingredients. The size and shape of the obtained particles are of critical importance with respect to the functional, reconstitution, and handling properties of the powder and its functionality when mixed with any other foodstuff. Particulate products increase their surface area, improving their dispersibility, solubility, and water-holding capacity, in addition to the bioavailability, distribution, and absorption of bioactive compounds [12,13]. The degree of grinding can be proposed as a green and user-friendly method for producing powders with adequate properties. Nevertheless, these properties are not always affected in the same way, and contradictory results can be found in this respect [14]. In some cases, this may be due to the method used to obtain the powdered product. Grinding and separation of different fractions by sieving can lead to compositional variations between the different fractions, which may be responsible for differences in powder properties [15,16]. Some technologies, such as superfine grinding, may also be responsible for compositional changes, especially those related to different fiber fractions [17,18,19]. However, even when milling is not expected to lead to changes in product composition, size does not always affect powder behavior in the same way. In this sense, larger and more rounded particles are generally associated with freer flowability than smaller or irregular particles [20,21]. However, some authors have justified an inverse relationship [22]. Therefore, it seems that the powder properties depend not only on the type of product and its moisture content but also on the size range considered. For these reasons, product-specific studies are necessary.

To ensure the success of the proposed powdered fava bean pod as a food ingredient, which could be extended to other by-products of plant origin, it seems appropriate to know some properties of interest from a technological point of view, such as its ability to remain as a free-flowing powder without agglomeration, allowing easy handling, or its ability to mix with water or oil. The results obtained may help to understand the viability of the ingredient and recommend the best applications for it. As these properties can be affected by the particle size of the powder, this study analyzed the influence of particle size on the color and some techno-functional properties related to powder flowability, such as the angle of repose, bulk density, porosity, Hausner ratio, and Carr index, as well as others related to their interaction with water and oil, such as hygroscopicity, wettability, dispersibility, solubility, swelling capacity, water and oil retention capacity, foaming capacity, and stability of the foam formed. In addition, the impact of processing on the nutritive and phenolic compounds has been considered.

2. Materials and Methods

2.1. Materials

In this study, the raw material used was fava bean (Vicia fava) of the criolla variety, which was acquired from a local market in Valencia (Spain) in January 2023. The beans were selected according to their degree of commercial maturity and absence of apparent physical damage and stored under refrigeration until processing (maximum 4 days).

2.2. Obtaining Powdered Fava Bean Pods

The pods were manually separated from the seeds and cleaned before being blanched (98 °C, 60 s) in batches of about 350 g. The blanched pods were crushed in an emulsifier with a serrated blade (Robot Coupe Blixer 2, Vincennes, France) at 3000 rpm. The puree obtained was distributed in aluminum trays of 25 cm in diameter, with a thickness of 0.5 cm, and frozen for at least 48 h in a freezer cabinet (Liebherr LGT 2325, Baden-Wurtemberg, Germany) at −45 °C. The frozen samples were freeze-dried (Telstar Lyoquest-55 L, Terrasa, Barcelona, Spain) at −50 °C in the condenser, at a pressure of 0.05 mbar, and with the trays heated to 50 °C for 7 h. The freeze-dried product was ground in a food processor at 3700 rpm (Thermomix TM 21, Vorwerk, Valencia, Spain) for 20 s in batches of 40 g of product and sieved using a sieving machine (AMPO.40 CISA, Cedacería Industrial S.L, Lliça de Vall, Barcelona, Spain) for 5 min at a power of 50 Hz and an amplitude of 2.5 mm.

To obtain powdered pods with two different sizes, one part of the ground product was passed through a 200 µm mesh and the other through a 45 µm mesh sieve (samples PP200 and PP45, respectively), as described in Section 2.3. The particles that did not pass through the sieve were re-ground using a grinder (Taurus, Valencia, Spain) for 20 s in 20 g batches and re-sieved. This process was repeated as many times as necessary to obtain as much sample as possible with a particle size smaller than desired, and in the shortest possible time to avoid overheating and wetting of the sample. The product that finally did not pass the sieve (3.25% and 6.80% for PP200 and PP45, respectively) was added to the sample to be analyzed to ensure that the composition of the bean pod was not changed. The obtained powder was weighed and stored under refrigeration until use for the different tests. The proposed particle sizes correspond to those encountered in any household using conventional equipment.

2.3. Characterization of Fava Bean Pod Powder

To obtain the particle size distribution of PP200 and PP45, two sets of sieves were used (CISA Cedacería Industrial, Lliça de Vall, Barcelona, Spain): series 1 with a diameter of 200 mm and height of 50 mm and series 2 with a diameter of 100 mm and height of 23 mm, with 40 or 20 g of sample, respectively. For PP200, series 1 sieves were used with mesh sizes of 300, 200, and 150 μm, and for the 2 series with mesh sizes of 100, 63, 45, 32, and 25 μm. For the PP45 sample, only sieves of series 2 were used, with mesh sizes of 100, 63, 45, 32, and 25 µm. In both cases, the top and bottom were used and sieved for 5 min at a power of 50 Hz and an amplitude of 2.5 mm (AMP0.40 CISA sieve shaker, Lliça de Vall, Barcelona, Spain). The sieves were weighed with and without the retained powder to calculate the proportion of the sample retained on each sieve (relative frequency, Equation (1)) and the mean particle size (Equation (2)).

where, ms: weight of powder that has been collected in each sieve (g); m: sum of all powder weights collected on the different sieves (g), DMs: mean sieve mesh = mean of the mesh size of the sieve on which the retained sample is retained and the previous one (μm).

The water content of the powdered samples was determined by coulometric titration (Karl Fischer, Compact coulometric titrator C10S, Mettler Toledo, Columbus, OH, USA). For the proximate analysis of the raw material, the water, protein, fat, starch, fiber, and ash contents of the bean pod powder were determined. Proteins were quantified using the Kjeldahl method 955.04/90 [23] and the factor 6.25 for the conversion of nitrogen to crude protein. For fats, direct Soxhlet extraction 920.39c was used [23]. Starch was determined by polarimetry, using the Ewers method ISO 10520:1997 [24]. For dietary fiber, the soluble (SDF) and insoluble (IDF) fractions were quantified, and the total dietary fiber (TDF) was calculated as the sum. The enzymatic gravimetric method was applied using an enzymatic kit (Sigma-Aldrich 1.12979.0001, Darmstadt, Germany). For ashes, the gravimetric method 942.05/90 was used [23]. Sugar content was calculated by difference.

To extract the total phenolic compounds (TP), a mixture of MeOH and H2O was used [25]. The phenolic content was quantified using the spectrophotometric Folin–Ciocalteu assay with some modifications, as described previously [26]. Gallic acid was used to construct the calibration curve, and the data were expressed as mg of gallic acid (GA)/g dry basis (ds).

A Minolta CM 2600D spectrophotometer (Minolta Co. Ltd., Tokyo, Japan) was used to measure the color of the samples. The reflectance of the samples placed in cylindrical aluminum containers of standardized dimensions was measured (100 mm × 50 mm). Color coordinates in CIE L*a*b* space were obtained using the illuminant D65 and observer 10° as a reference, and from these, the color attributes luminosity (L*), hue angle (h*, Equation (3)), chroma or saturation (C*, Equation (4)), and color difference (∆E, Equation (5)) were calculated.

To evaluate the flowability of the powder, the angle of repose (α) and porosity of the bulk and tapped samples (εb and εt, respectively) were measured. Porosity values were used to calculate the Hausner ratio (HR) and Carr index (CI). The procedures described by Uscanga et al. [27] were followed.

In order to determine the ability of the powder to interact with water and oil, the water sorption capacity [28], swelling capacity [29], hygroscopicity [30], solubility, wettability, dispersibility, water retention capacity (WRC), in addition to its oil retention capacity (ORC), foaming capacity (FC) and foam stability (FS) of the samples were determined according to the methodology described by Martínez-Navarrete et al. [30].

2.4. Statistical Analysis

To analyze the influence of particle size on the properties studied, significant differences between the two bean pod powder samples, PP200 and PP45, were compared using a one-way analysis of variance (ANOVA) at a 95% confidence level (p-value < 0.05). Prior to performing ANOVA, the normality of the data was assessed using the Shapiro–Wilk test. All statistical analyses were carried out using Statgraphics Centurion XIX-X64 (StatPoint Technologies, Inc., Madrid, Spain).

3. Results and Discussion

3.1. Powdered Fava Bean Pod Particle Size Distribution

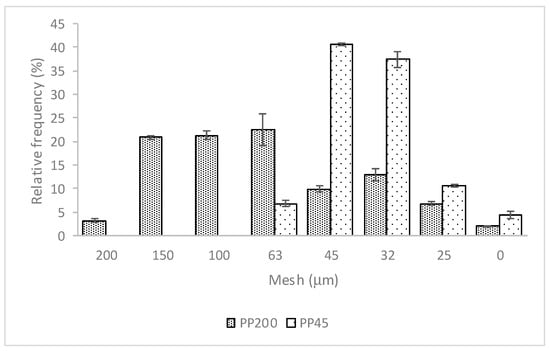

Figure 1 shows the particle size distributions of the two samples. As can be noted, in both cases, some of the powder was retained on the sieves used for particle sieving, 200 and 45 µm. This was because, although the material that did not pass through these sieves was re-ground, it was not possible to reduce the size of some of the particles sufficiently, and, as mentioned above, this larger powder was not discarded. The higher resistance of some particles to crushing could be related to their different composition, may be with a higher fiber content making them harder. Therefore, as the aim of this work was to obtain two different particle sizes without modifying the composition of the pod with respect to that of the powder obtained from it, it was decided to incorporate it into the sample to be characterized. The corresponding mean particle sizes were 102.9 ± 0.3 and 45.254 ± 0.002 µm. The mode, which is the size that accumulates the most particles, was 81.5 and 54 µm for samples PP200 and PP45, respectively, and the median was 115.6 ± 1.7 µm and 56.85 ± 0.10 µm, a parameter indicating the size above which 50% of the particles of powder are found in each case. The statistical analysis results allow us to assume that two samples with different particle sizes were obtained (p < 0.05).

Figure 1.

Particle size distribution of samples (PP200 and PP45) as a percentage of the sample retained on each sieve (relative frequency).

3.2. Proximate Composition of Fava Bean Pod

The water content of the fava bean powders was 0.033 and 0.035 g water/g sample for PP200 and PP45, respectively. Table 1 shows the solute composition of the two samples studied on a dry basis. The major components were carbohydrates, followed by proteins, with fat being a minor component. Carbohydrates include sugars, starch, and dietary fiber. These results can be compared with those obtained by other authors [6,7], who also analyzed the composition of freeze-dried fava bean pods. In general, the protein content, around 3–5% higher than that reported by the authors mentioned above, is high compared to other vegetable by-products such as pea pods (10.8% db, [4]) or orange juice by-products (4.5% db, [31]). Because of their high protein and fiber content, fava bean pods can be considered an interesting ingredient for increasing the nutritional value of other foods. In this sense, its use has been described together with flour for bread or pastry making [32], which could also be of interest for the design of plant-based foods.

Table 1.

Proximate composition and total phenols of powdered fava bean pod samples (PP200 and PP45) (g/100 g dry matter). Results are expressed as ± σ.

Samples with smaller particle sizes showed higher protein content (p < 0.05), probably because the larger surface area increases protein accessibility, which favors the extraction yield [33]. Russin et al. [34] also observed a better recovery of soy proteins when the particle size of the raw material was smaller, without affecting the quality. For total fiber, no significant differences were observed according to pod size in our samples. The values obtained were 6.6% and 13.5% lower than those reported by Mateos-Aparicio et al. [6] and Mejri et al. [7], respectively. Such variations are likely attributable to differences in cultivar, growing conditions, and geographic origins. For instance, Mejri et al. [7] highlighted that Spanish broad bean tends to contain lower fiber levels than other regional varieties, suggesting a potential varietal or environmental influence on fiber content. The fava bean pod used in this study was found to have the same amount of fiber as the orange juice by-product (38.1% db, [31]), although less than the pea pod (58.6% db, [6]). Compared to bean seeds, the pods have a much lower content of protein and starch and a higher content of sugars and fiber, with these values for the skinned seed being around 30, 45, 5, and 10%, respectively [35,36]. The highest fraction of dietary fiber in the fava bean pod for both PP200 and PP45 was the insoluble one (Table 1, 71% and 58%), although a non-negligible content of soluble dietary fiber was found (Table 1, 29% and 42%). The latter fraction represents a higher content than that found in other fruits, such as grapefruit or lemon (7.3–15.3 g/100 g, [37]). Grigelmo-Miguel et al. [38] indicated that soluble fiber is associated with a reduction in glycemic response and blood cholesterol levels, among other effects, and the insoluble fiber contributes to the proper functioning of the intestinal tract. In addition, other factors, such as viscosity, fermentability, and changes in gut microbiota, have recently been given more weight in the physiological impact of fiber, related to the high presence of both fractions [39,40]. The sample with the smallest particle size had a 35% higher phenol content (p < 0.05), which may be attributed to the higher extraction of these compounds because of the higher surface/volume ratio reached in this case. The larger contact surface of the smaller particles allows for greater interaction with the solvent, increasing the extraction efficiency. This same trend has been observed in other studies by Ahmed et al. [41] and Rodriguez et al. [42], who showed that the total phenol content is dependent on particle size in quinoa and Proposis alba flour, respectively.

3.3. Color of Powdered Fava Bean Pods

The color of processed foods is an important characteristic of commercial quality and provides significant information regarding their properties. Chlorophylls are among the main pigments that contribute to the characteristic bright green color of some vegetables. The natural green color of food can be altered by the degradation of chlorophyll into pheophytins, pyropheophytins, chlorophyllides, and pheophorbides, and the cis-trans isomerization of carotenoids and formation of epoxides, furanoids, and other degradation products of these compounds [43]. According to these authors, color change is common during cooking, canning, blanching, exposure to gamma radiation to eradicate micro-organisms, acidic environments, and even during storage.

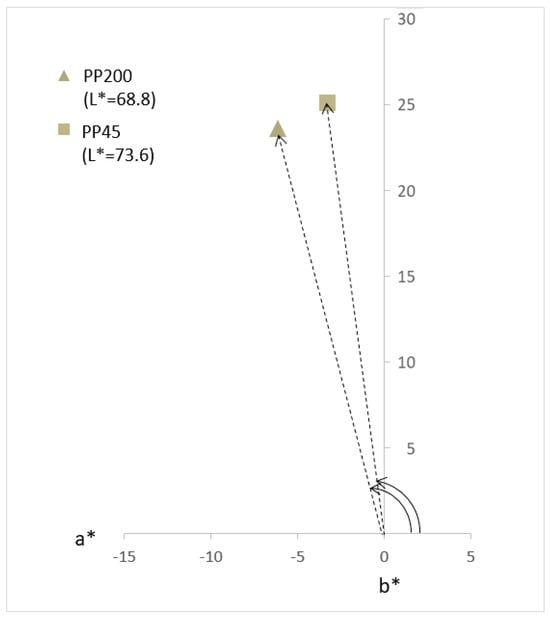

Figure 2 shows the values of the color coordinates for the PP200 and PP45 samples. The coordinate L* represents luminosity and varies from 0 for black to 100 for white. The values of a* and b* indicate the predominant color tones in the different samples. The a* coordinate had negative values in both cases, which were associated with green colors. The b* coordinate has positive values related to yellowish tones. All three coordinates showed significant differences between the PP200 and PP 45 samples (p < 0.05). The chroma and hue angle calculated from these coordinates also showed significant differences between the two samples (p < 0.05, Figure 2), with C = 24.4 ± 0.4 and h* = 104.5 ± 0.4 for PP200 and C = 25.3 ± 0.4, h* = 97.5 ± 0.2 for PP45. These values indicate that the smaller the particle size, the more luminous and saturated the color of the powder, and the more yellowish its green tone. The higher surface area when the particles are smaller and the higher presence of air between the smaller particles (Table 2) could justify a higher light reflection [44], explaining the observed differences.

Figure 2.

Chromatic a* and b* color coordinates of the two studied samples (PP200 and PP45). The hue angle and chroma are indicated by continuous and discontinuous arrows, respectively.

Table 2.

Mean values of angle of repose (α), Hausner ratio (HR), Carr index (CI), bulk and tapped densities (ρb and ρt), and porosity of bulk and tapped powder (εb and εt) of fava bean pod powder for the two particle sizes studied.

The ability to visually distinguish between two colors depends on the color itself and the eye that observes it. Although a trained eye is able to differentiate between two colors when ΔE < 2, an average viewer can notice this difference only when ΔE > 3.5 [45]. In our case, judging by the opinion of a few researchers but not as a result of a strict sensory study, which has not yet been implemented, the differences in color between the two samples were perceptible, which is consistent with the calculated color difference between them calculated from the color coordinate values (∆E, Equation (5)), which was 5.75. From this point of view, powder particle size must be properly fitted, considering that color plays a very important role in the consumer’s choice of food. In this case, PP 200 powder, with a more intense green color, may be more likely to be perceived as fresh and appetizing.

3.4. Powder Flowability

When comparing the parameters analyzed for the two particle sizes studied (Table 2), no significant differences (p > 0.05) were detected for α, CI, and HR, but there were for the bulk and tapped densities, and therefore for both porosities (p < 0.05). The flowability of a powder is related to the friction between the particles, as well as to the water content, and may be classified according to α, CI, and HR, although these classifications are not unique [46,47,48]. Based on these classifications, the α value of the two samples considered in this study, as well as the CI and HR values (Table 2), these being around 38°, 5–15%, and <1.25, respectively, and the absence of significant differences between them (p > 0.05), the bean pod flour behaves as a powder with intermediate to high fluidity.

The true density of the powdered bean pod, calculated on the basis of its composition [27], was 1.389 g cm−3. The bulk density of a powdered product can provide a general idea of the ability of its constituent particles to pack. This property depends on the degree of pre-packaging of the powder itself and its handling. In this sense, it is possible to refer to the bulk density of the discharged powder and the tapped density of the compacted powder under standardized conditions. As is evident, compaction of the powdered product results in a decrease in the volume it occupies and, thus, an increase in the corresponding bulk density. On the other hand, the volume of air enclosed by a given volume of the powdered sample, which is its porosity, can be calculated from the real and bulk or tapped densities (Section 2.3). As shown in Table 2, these two densities were higher, and consequently, the porosities were lower, with increasing particle size (p < 0.05). These results present the same relationship as those reported by Gao et al. [44] in a review of different food powders. This could be due to the different shapes of the powder particles generated after processing and the different particle size distributions. In this case, sample PP200 showed greater particle size diversity (Figure 1), which could favor better packing of the powder, thus decreasing the porosity. In contrast, in the PP45 powder, 78% of the particles had an average particle size between 38.5 and 54 µm, and 15% had a smaller particle size, leaving less opportunity for the latter to fill the remaining voids.

3.5. Properties Related to the Interaction of Powder with Water and with Oil

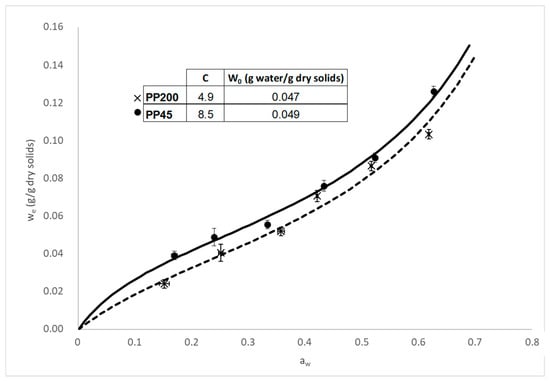

Figure 3 shows the water sorption isotherm of the two studied samples, in which the higher water gain capacity of PP45 can be observed. The experimental procedure used to obtain these data, which was the equilibration of the samples in environments with different relative humidity, lasted for 5 months, thus allowing the long-term hygroscopicity of the powder to be evaluated. This behavior is useful for determining the degree of interaction between water and the surface of food and optimizing storage conditions.

Figure 3.

Water content (We)—water activity (aw) relationships of samples (PP200 and PP45). Experimental data (points) and predicted behavior from the BET-fitted model (lines). Wo and C are BET model parameters.

The experimental sorption data were well-fitted to the BET model (Ec. 6), obtaining the parameter values shown in Figure 3. In this model, Wo is the monolayer water content, and C is related to the sorption heat released when water molecules adsorb to the substrate surface, forming the monolayer. In the case of sample PP45, compared with PP200, the slightly greater Wo reflects the greater specific surface available for water sorption, and the higher C value may be related to the higher accessibility of insoluble proteins and the lower amount of insoluble fiber analyzed, the former having a greater interaction force with water than the latter.

where we and aw are the water content (g water/g dry solids) and water activity of the sample after reaching equilibrium with the environment; Wo (g water/g dry solids) and C are BET model parameters.

Hygroscopicity is based on the ability of a material to gain water from the environment with high relative humidity [49], as measured in this case within 90 min. As moisture occurs mainly on the surface of the particles, the particle size can affect this property. The hygroscopicity values obtained were not high in any case (Table 3), although there were significant differences between the samples (p < 0.05). This was greater for PP45, probably due to the smaller particle size and, thus, the larger specific surface area, which favors water absorption and the formation of liquid bridges between them. This higher water absorption may also be due to the greater amount of hygroscopic components, such as sugars, proteins, and minerals, present in the smaller fractions [50]. According to the classification by Schuck et al. [51], it can be stated that PP200 is a non-hygroscopic powder (≤4.5) while PP45 is slightly hygroscopic (4.6–8.0). This hygroscopicity is much lower than that of some plant fibers (14–35%, [52]). This was also lower than that found, for example, for freeze-dried orange by-products (6.5%, [18]), in relation to the lower sugar content of the by-products, especially bean pods.

Table 3.

Mean values ± standard deviation of hygroscopicity (g water gained/100 g dry solids), wettability (s), dispersibility (g soluble solutes sieved/100 g soluble solutes in the sample), solubility (g soluble solutes/100 g total solutes), water retention capacity (g water/100 g dry residue), swelling capacity (mL/g), foam capacity (mL/100 mL), and foam stability (mL/100 mL).

Rehydration properties are mainly related to the amount and characteristics of polysaccharides and are influenced by porosity and particle size [53]. The rehydration process is mostly associated with three events: wettability, dispersibility, and solubilization. Wettability generally improves with an increase in the particle size. This was observed in this case, with PP200 showing a much shorter wetting time than PP45 (p < 0.05). In this case, the decrease in the particle surface area would decrease the adhesion forces among the particles, decreasing the tendency to agglomerate on the surface of the liquid [54].

Dispersibility refers to the ease with which powders are distributed as individual particles in the liquid phase [55]. This indicates the ability of a powder to interact with water without the formation of lumps. The particles absorb water during the wetting step, and this swelling process leads to an increase in the particle size in the first stage of dispersion [56]. In this study, the sample PP45 was more dispersible (p < 0.05, Table 3), which is consistent with the observations of Selomulya and Fang [57] and Gaiani et al. [58]. The lower mean particle size, greater porosity (Table 2), and lower swelling capacity (Table 3) of this sample would facilitate the passage of hydrated particles through the sieve mesh. Despite the particle size, the solubility was low, probably due to the high TDF content, especially IDF [59]. The increase in solubility with decreasing size could be due to the increased solubility of proteins due to the decrease in sulfhydryl groups and carbohydrates [44]. In view of the above, the poor wettability of the PP45 sample was the most limiting factor for this powder rehydration.

The swelling capacity is often evaluated in this type of product for the satiating effect it can provide during the digestive process in the stomach. This property also appears to be related to the WRC, which determines the water retained after an external force. The WRC values of the studied samples were in the range obtained by Grigelmo-Miguel and Martín-Belloso [38] for the by-products of the orange processing industry (6–10%). The lowest swelling capacity and WRC obtained for PP45 (p < 0.05) could be attributed to the damage to the fiber matrix and pore collapse during grinding [60]. The authors concluded that grinding not only reduces particle size but may also be related to profound structural modifications of the fiber. However, the fact that no significant differences were found in the foaming capacity or foam stability indicates that the grinding applied in this case did not affect the structural conformation of the proteins (p > 0.05, Table 3).

Similarly, the ORC was lower in samples with the smallest particle size (p < 0.05), being 1.47 ± 0.03 and 2.03 ± 0.02 for PP45 and PP200, respectively. This is in line with what has been described by other authors, such as Lan et al. [61], who indicated that a larger particle size is related to a better ability to bind oil and water. The ORC values were lower than those of WRC, which could be due to the presence of a high number of hydrophilic groups capable of binding to water molecules and soluble fibers that have a high capacity to absorb water. However, the presence of protein, which is composed of hydrophobic and hydrophilic parts, is the main factor affecting the oil absorption rate, despite IDF also contributing to oil retention [62,63].

4. Conclusions

The high protein and fiber content of bean pods makes them suitable for human consumption. The powder format appears to be suitable because of its stability and handling advantages. In this case, it is important to define the most desirable degree of grinding for the ingredient. The two particle sizes considered in this study for fava bean pod powder, 102.9 and 45.3 μm, did not affect its flowability, behaving as a powder with intermediate to high fluidity, but did affect other techno-functional properties studied. A larger particle size imparts a visibly greener shade to the powder, promotes particle packing, reduces hygroscopicity, and, above all, significantly shortens the wetting time. It also confers a greater swelling capacity and increases the water and oil retention capacity. Nevertheless, from a nutritional and functional point of view, the extraction of proteins and phenols, and therefore their availability, is slightly hindered in the larger particle size powder without compromising the total fiber content. For all these reasons, and considering the use of fava bean pod powder as a versatile food ingredient, under the tested conditions, the largest size of those studied is recommended. A smaller particle size is desirable only when using the powder as the basis for the preparation of a nutritional supplement. In this case, the health benefits would be related to the higher availability of phenolic compounds and, therefore, to the higher potential antioxidant capacity of the supplement.

Author Contributions

Conceptualization: M.d.M.C., E.G.-M. and N.M.-N.; Data curation: A.I.B.-L., E.G.-M., M.d.M.C. and N.M.-N.; Formal analysis: M.d.M.C. and N.M.-N.; Funding acquisition: N.M.-N., M.d.M.C., A.Y. and E.G.-M.; Investigation: A.I.B.-L., E.G.-M., M.d.M.C. and N.M.-N.; Methodology: A.I.B.-L., E.G.-M., A.Y., M.d.M.C. and N.M.-N.; Project administration: E.G.-M., M.d.M.C. and N.M.-N.; Supervision, M.d.M.C. and N.M.-N.; Writing—original draft: A.I.B.-L., E.G.-M., M.d.M.C. and N.M.-N.; Writing—review and editing: E.G.-M., M.d.M.C. and N.M.-N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [PID2022-139711OB-C21] R&D&i project, funded by Ministerio de Ciencia e Innovación/Agencia Estatal de Investigación/10.13039/501100011033/; and “Fondo Europeo de Desarrollo Regional Una manera de hacer Europa”.

Institutional Review Board Statement

Not applicable for studies not involving humans or animals.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| PP200 | Powdered pod sample with 200 µm particle size |

| PP45 | Powdered pod sample with 45 µm particle size |

| SDF | Soluble dietary fiber |

| IDF | Insoluble dietary fiber |

| TDF | Total dietary fiber |

| A | Angle of repose |

| εb | Porosity of the bulk samples |

| εt | Porosity of tapped samples |

| HR | Hausner ratio |

| CI | Carr index |

| WRC | Water retention capacity |

| ORC | Oil retention capacity |

| FC | Foaming capacity |

| FS | Foam stability |

| L* | Luminosity |

| h* | Hue angle |

| C* | Chroma or saturation |

| ∆E | Color difference |

References

- FAO, Crops and Livestock Products. Food and Agriculture Organization of the United Nations. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 15 April 2025).

- Renna, M.; De Cillis, F.; Leoni, B.; Acciardi, E.; Santamaria, P. Preliminary Evaluation of Fresh Fava Hulls Highlights Richness in L-Dopa and Low Content of Anti-Nutritional Factor. Foods 2020, 9, 159. [Google Scholar] [CrossRef] [PubMed]

- Stenmarck, A.; Jensen, C.; Quested, T.; Moates, G. Estimates of European Food Waste Levels. Fusion. Reducing Food Waste Through Social Innovation. Technical Report European Commission. 2016. Available online: https://edepot.wur.nl/378674 (accessed on 11 May 2025).

- Singh, B.; Singh, J.P.; Kaur, A.; Singh, N. Phenolic composition, antioxidant potential and health benefits of citrus peel. Food Res. Int. 2020, 132, 109114. [Google Scholar] [CrossRef]

- Szabo, K.; Cătoi, A.F.; Vodnar, D.C. Bioactive Compounds Extracted from Tomato Processing by-products as a Source of Valuable Nutrients. Plant Foods Hum. Nutr. 2018, 73, 268–277. [Google Scholar] [CrossRef] [PubMed]

- Mateos-Aparicio, I.; Redondo-Cuenca, A.; Villanueva-Suárez, M.J.; Zapata-Revilla, M.A.; Tenorio-Sanz, M.D. Pea pod, broad bean pod and okara, potential sources of functional compounds. LWT Food Sci. Tech. 2021, 43, 1467–1470. [Google Scholar] [CrossRef]

- Mejri, F.; Selmi, S.; Martins, A.; Benkhoud, H.; Baati, T.; Chaabane, H.; Njim, L.; Serralheiro, L.M.; Rauter, A.P.; Hosni, K. Broad bean (Vicia faba L.) pods: A rich source of bioactive ingredients with antimicrobial, antioxidant, enzyme inhibitory, anti-diabetic and health-promoting properties. Food Funct. 2018, 9, 2051–2069. [Google Scholar] [CrossRef]

- Kalili, A.; El Ouafi, R.; Aboukhalaf, A.; Naciri, K.; Tbatou, M.; Essaih, S.; Belahyan, A.; Belahsen, R. Chemical composition and antioxidant activity of extracts from Moroccan fresh fava beans pods (Vicia faba L.). Rocz. Panstw. Zakl. Hig. 2022, 73, 79–86. [Google Scholar] [CrossRef] [PubMed]

- Dilucia, F.; Lacivita, V.; Conte, A.; Del Nobile, M.A. Sustainable Use of Fruit and Vegetable By-Products to Enhance Food Packaging Performance. Foods 2020, 9, 857. [Google Scholar] [CrossRef]

- Cuq, B.; Gaiani, C.; Turchiuli, C.; Galet, L.; Scher, J.; Jeantet, R.; Ruiz, T. Advances in food powder agglomeration engineering. Adv. Food Nutr. Res. 2013, 69, 41–103. [Google Scholar]

- Bhatta, S.; Janezic, T.S.; Ratti, C. Freeze-drying of plant-based foods. Foods 2020, 9, 87. [Google Scholar] [CrossRef]

- Jiang, G.; Ramachandraiah, K.; Wu, Z.; Li, S.; Eun, J.B. Impact of ball-milling time on the physical properties, bioactive compounds, and structural characteristics of onion peel powder. Food Biosci. 2020, 36, 100630. [Google Scholar] [CrossRef]

- Qin, X.; Dong, X.; Tang, J.; Chen, Y.; Xie, J.; Cheng, Y.; Zheng, B.; Hu, X.; Yu, Q. Comparative analysis of dietary fibers from grapefruit peel prepared by ultrafine grinding: Structural properties, adsorption capacities, in vitro prebiotic activities. Food Biosci. 2023, 56, 103163. [Google Scholar] [CrossRef]

- Camacho, M.M.; Zago, M.; García-Martínez, E.; Martínez-Navarrete, N. Free and Bound Phenolic Compounds Present in Orange Juice By-Product Powder and Their Contribution to Antioxidant Activity. Antioxidants 2022, 11, 1748. [Google Scholar] [CrossRef]

- Jayadeep, A.; Singh, V.; Rao, B.V.; Srinivas, A.; Ali, S.Z. Effect of physical processing of commercial de-oiled rice bran on particle size distribution, and content of chemical and bio-functional components. Food Bioproc. Tech. 2009, 2, 57–67. [Google Scholar] [CrossRef]

- Alam, S.A.; Järvinen, J.; Kirjoranta, S.; Jouppila, K.; Poutanen, K.; Sozer, N. Influence of particle size reduction on structural and mechanical properties of extruded rye bran. Food Bioproc. Tech. 2014, 7, 2121–2133. [Google Scholar] [CrossRef]

- Bender, A.B.B.; Speroni, C.S.; Moro, K.I.B.; Morisso, F.; dos Santos, D.; da Silva, L.P.; Penna, N. Effects of micronization on dietary fiber composition, physicochemical properties, phenolic compounds, and antioxidant capacity of grape pomace and its dietary fiber concentrate. LWT 2020, 117, 108652. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Liu, F.; Pan, S. Effect of grinding methods on structural, physicochemical, and functional properties of insoluble dietary fiber from orange peel. Int. J. Polym. Sci. 2016, 2016, 6269302. [Google Scholar] [CrossRef]

- Zhu, F.; Du, B.; Xu, B. Superfine grinding improves functional properties and antioxidant capacities of bran dietary fibre from Qingke (hull-less barley) grown in Qinghai-Tibet Plateau, China. J. Cereal Sci. 2015, 65, 43–47. [Google Scholar] [CrossRef]

- Goh, H.P.; Heng, P.W.S.; Liew, C.V. Comparative evaluation of powder flow parameters with reference to particle size and shape. Int. J. Pharm. 2018, 547, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Lv, G.; Zhang, Z.; Pan, H.; Fan, R. Effect of physical modification of mushroom (A. chaxingu) powders on their physical and chemical properties. Food Sci. Tech. Res. 2014, 20, 731–738. [Google Scholar] [CrossRef]

- Zhong, C.; Zu, Y.; Zhao, X.; Li, Y.; Ge, Y.; Wu, W.; Zhang, Y.; Li, Y.; Guo, D. Effect of superfine grinding on physicochemical and antioxidant properties of pomegranate peel. Int. J. Food Sci. Tech. 2016, 51, 212–221. [Google Scholar] [CrossRef]

- AOAC. Official methods of analysis. In Association of Official Analytical Chemists; Herrich, K., Ed.; AOAC: Arlington, VA, USA, 1990. [Google Scholar]

- ISO 10520:1997; ISO, Native Starch. Determination of Starch Content. Ewers Polarimetric Method. International Organization for Standardization: Geneva, Switzerland, 1997.

- Camacho, M.M.; Silva-Espinoza, M.A.; Martinez-Navarrete, N. Flowability, Rehydration Behaviour and bioactive Compounds of an Orange Powder Product as Affected by Particle Size. Food Bioproc. Tech. 2022, 15, 683–692. [Google Scholar] [CrossRef]

- García-Martínez, E.; Camacho, M.M.; Martínez-Navarrete, N. In vitro Bioaccesibilty of Bioactive Compounds of Freeze-dried Orange Juice Co-Product Formulated with Gum Arabic and Modified Starch. Molecules 2023, 28, 810. [Google Scholar] [CrossRef]

- Uscanga, M.A.; Camacho, M.M.; Salgado, M.A.; Martínez-Navarrete, N. Influence of an Orange Product Composition on the Characteristics of the Obtained Freeze-dried Cake and Powder as Related to Their Consumption Pattern. Food Bioproc. Tech. 2020, 13, 1368–1379. [Google Scholar] [CrossRef]

- Camacho, M.M.; Silva-Espinoza, M.A.; Martínez-Navarrete, M. Sorption Behavior, Glass Transition and Flowability of Powdered Orange Co-product. Mater. Circ. Econ. 2021, 3, 17. [Google Scholar] [CrossRef]

- Raghavendra, S.N.; Rastogi, N.K.; Raghavarao, K.S.M.S.; Tharanathan, R.N. Dietary fiber from coconut residue: Effects of different treatments and particle size on the hydration properties. Eur. Food Res. Technol. 2004, 218, 563–567. [Google Scholar] [CrossRef]

- Martínez-Navarrete, N.; García-Martínez, E.; Camacho, M.M. Characterization of the Orange Juice Powder Co-Product for Its Valorization as a Food Ingredient. Foods 2023, 12, 97. [Google Scholar] [CrossRef] [PubMed]

- Camacho, M.M.; Martínez-Lahuerta, J.J.; Ustero, I.; García-Martínez, E.; Martínez-Navarrete, N. Composition of Powdered Freeze-Dried Orange Juice Co-Product as Related to Glucose Absorption in Vitro. Foods 2023, 12, 1127. [Google Scholar] [CrossRef]

- Fendri, L.B.; Chaari, F.; Maaloul, M.; Kallel, F.; Abdelkafi, L.; Ellouz, S.; Ghribi-Aydi, D. Wheat bread enrichment by pea and broad bean pods fibers: Effect on dough rheology and bread quality. LWT Food Sci. Tech. 2016, 73, 584–591. [Google Scholar] [CrossRef]

- Muhoza, B.; Harimana, Y.; Kayitesi, E.; Uriho, A.; Liu, Q. Insight into the Effect of Extraction and Spray Drying Conditions on the Nutritional and Techno-Functional Properties of Legume Protein Powder: A Review. Food Bioproc. Technol. 2025, 18, 1141–1159. [Google Scholar] [CrossRef]

- Russin, T.A.; Arcand, Y.; Boye, J.I. Particle size effect on soy protein isolate extraction. J. Food Process Preserv. 2007, 31, 308–319. [Google Scholar] [CrossRef]

- Jeganathan, B.; Gao, J.; Vasanthan, T.; Temelli, F. Potential of sequential pearling to explore macronutrient distribution across faba beans (Vicia faba L.) for chemical-free hybrid fractionation. J. Food Compos. Anal. 2022, 112, 104695. [Google Scholar] [CrossRef]

- Maja, L.; Krenz, M.; Grebenteuch, S.; Zocher, K.; Rohn, S.; Pleissner, D. Valorization of faba bean (Vicia faba) by-products. Biomass Convers. Biorefin. 2023, 1, 3. [Google Scholar]

- De Moraes, T.; Jablonski, A.; de Oliveira Rios, A.; Rech, R.; Flôres, S.H. Dietary fiber from orange byproducts as a potential fat replacer. LWT Food Sci. Tech. 2013, 53, 9–14. [Google Scholar] [CrossRef]

- Grigelmo-Miguel, N.; Martín-Belloso, O. Characterization of dietary fiber from orange juice extraction. Food Res. Int. 1998, 31, 355–361. [Google Scholar] [CrossRef]

- Peña, M.M.; Odriozola-Serrano, I.; Oms-Oliu, G.; Martín-Belloso, O. Dietary Fiber in Fruits and Vegetables. In Science and Technology of Fibers in Food Systems; Food Engineering Series; Welti-Chanes, J., Serna-Saldívar, S., Campanella, O., Tejada-Ortigoza, V., Eds.; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Timm, M.; Offringa, L.C.; Van Klinken, B.J.W.; Slavin, J. Beyond Insoluble Dietary Fiber: Bioactive Compounds in Plant Foods. Nutrients 2023, 15, 4138. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, J.; Alazemi, A.; Ponnumani, P.; Soliman, M.; Emmanuval, L.; Thomas, N.M. Transformation of quinoa seeds to nanoscale flour by ball milling: Influence of ball diameter and milling time on the particle sizing, microstructure, and rheology. J. Food Eng. 2024, 379, 112127. [Google Scholar] [CrossRef]

- Rodríguez, I.F.; Pérez, M.J.; Cattaneo, F.; Zampini, I.C.; Cuello, A.S.; Mercado, M.I.; Ponessa, G.; Isla, M.I. Morphological, histological, chemical and functional characterization of Prosopis alba flours of different particle sizes. Food Chem. 2019, 274, 583–591. [Google Scholar] [CrossRef] [PubMed]

- Benlloch-Tinoco, M.; Kaulmann, A.; Corte-Real, J.; Rodrigo, D.; Martínez-Navarrete, N.; Bohn, T. Chlorophylls and carotenoids of kiwifruit puree are affected similarly or less by microwave than by conventional heat processing and storage. Food Chem. 2015, 187, 254–262. [Google Scholar] [CrossRef]

- Gao, W.; Chen, F.; Wang, X.; Meng, Q. Recent advances in processing food powders by using superfine grinding techniques: A review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2222–2255. [Google Scholar] [CrossRef]

- Krapfenbauer, G.; Kinner, M.; Gossinger, M.; Schonlechner, R.; Berghofer, E. Effect of thermal treatment on the quality of cloudy apple juice. J. Agric. Food Chem. 2006, 54, 5453–5460. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Ortega-Rivas, E.; Juliano, P.; Yan, H. Physical Properties, Processing, and Functionality, Food Powders; Springer: New York, NY, USA, 2005; pp. 71–75. [Google Scholar]

- Alavi, S.; Caussat, B. Experimental study on fluidization of micronic powders. Powder Technol. 2005, 157, 114–120. [Google Scholar] [CrossRef]

- Fitzpatrick, J. Powder properties in food production systems. In Handbook of Food Powders: Processes and Properties; Bhandari, B., Bansal, N., Zhang, M., Schuck, P., Eds.; Woodhead Publishing: Sawston, UK, 2013; pp. 285–308. [Google Scholar]

- Bhusari, S.N.; Muzaffar, K.; Kumar, P. Effect of carrier agents on physical and microstructural properties of spray dried tamarind pulp powder. Powder Technol. 2014, 266, 354–364. [Google Scholar] [CrossRef]

- O’Donoghue, L.T.; Haque, M.K.; Kennedy, D.; Laffir, F.R.; Hogan, S.A.; O’Mahony, J.A.; Murphy, E.G. Influence of particle size on the physicochemical properties and stickiness of dairy powders. Int. Dairy. J. 2019, 98, 54–63. [Google Scholar] [CrossRef]

- Schuck, P.; Jeantet, R.; Dolivet, A. Analytical Methods for Food and Dairy Powders; John Wiley & Sons: Oxford, UK, 2012. [Google Scholar]

- Noguerol, A.T.; Igual, M.; Pagán, M.J. Developing psyllium fibre gel-based foods: Physicochemical, nutritional, optical and mechanical properties. Food Hydrocoll. 2022, 122, 107108. [Google Scholar] [CrossRef]

- Femenia, A.; Lefebvre, A.C.; Thebaudin, J.Y.; Robertson, J.A.; Bourgeois, C.M. Physical and sensory properties of model foods supplemented with cauliflower fiber. J. Food Sci. 1997, 62, 635–639. [Google Scholar] [CrossRef]

- Chubert, H.S. Food particle technology. Part I: Properties of particles and particulate food systems. J. Food Eng. 1987, 6, 1–32. [Google Scholar] [CrossRef]

- Shittu, T.A.; Lawal, M.O. Factors affecting instant properties of powdered cocoa beverages. Food Chem. 2007, 100, 91–98. [Google Scholar] [CrossRef]

- Ji, J.; Fitzpatrick, J.; Cronin, K.; Maguire, P.; Zhang, H.; Miao, S. Rehydration behaviours of high protein dairy powders: The influence of agglomeration on wettability, dispersibility and solubility. Food Hydrocoll. 2016, 58, 194–203. [Google Scholar] [CrossRef]

- Selomulya, C.; Fang, Y. Food-powder-rehydration. In Handbook of Food Powders: Processes and Properties; Bhandari, B., Bansal, N., Zhang, M., Schuck, P., Eds.; Woodhead Publishing: Sawston, UK, 2013. [Google Scholar]

- Gaiani, C.; Ehrhardt, J.J.; Scher, J.; Hardy, J.; Desobry, S.; Banon, S. Surface composition of dairy powders observed by X-ray photoelectron spectroscopy and effects on their rehydration properties. Colloids Surf. B Biointerfaces 2006, 49, 71–78. [Google Scholar] [CrossRef]

- Yin, Z.; Wang, Z.; He, Z.; Zeng, M.; Qin, F.; Chen, J. Effect of particle size and microstructure on the physical properties of soybean insoluble dietary fiber in aqueous solution. Food Biosci. 2021, 41, 100898. [Google Scholar] [CrossRef]

- Auffret, A.; Ralet, M.C.; Guillon, F.; Barry, J.L.; Thibault, J.F. Effect of Grinding and Experimental Conditions on the Measurement of Hydration Properties of Dietary Fibres. LWT Food Sci. Technol. 1994, 27, 166–172. [Google Scholar] [CrossRef]

- Lan, G.; Chen, H.; Chen, S.; Tian, J. Chemical composition and physicochemical properties of dietary fiber from Polygonatum odoratum as affected by different processing methods. Food Res. Int. 2012, 49, 406–410. [Google Scholar] [CrossRef]

- Mokhtar, S.M.; Swailam, H.M.; Embaby, H.E.S. Physicochemical properties, nutritional value and techno-functional properties of goldenberry (Physalis peruviana) waste powder concise title: Composition of goldenberry juice waste. Food Chem. 2018, 248, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Thebaudin, J.Y.; Lefebvre, A.C.; Harrington, M.; Bourgeois, C.M. Dietary fibers: Nutritional and Tecnological Interest. Trends Food Sci. Tech. 1997, 8, 41–47. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).