Dielectric Performance of UHMWPE-MgFe2O4 Composites Depending on Polymer Crystallinity, and the Concentration and Size of Mechanochemically Synthesized Ferrite Particles

Abstract

1. Introduction

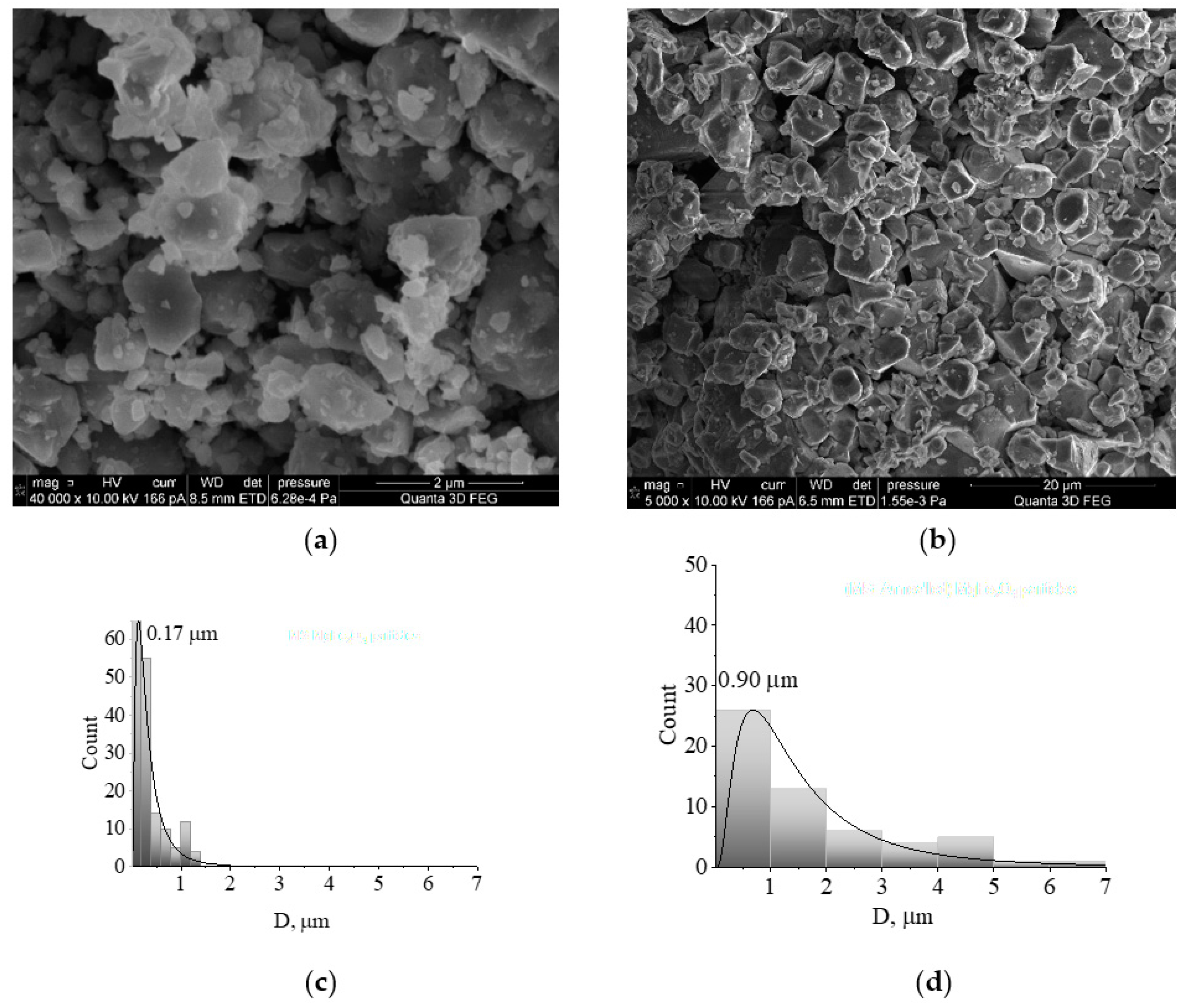

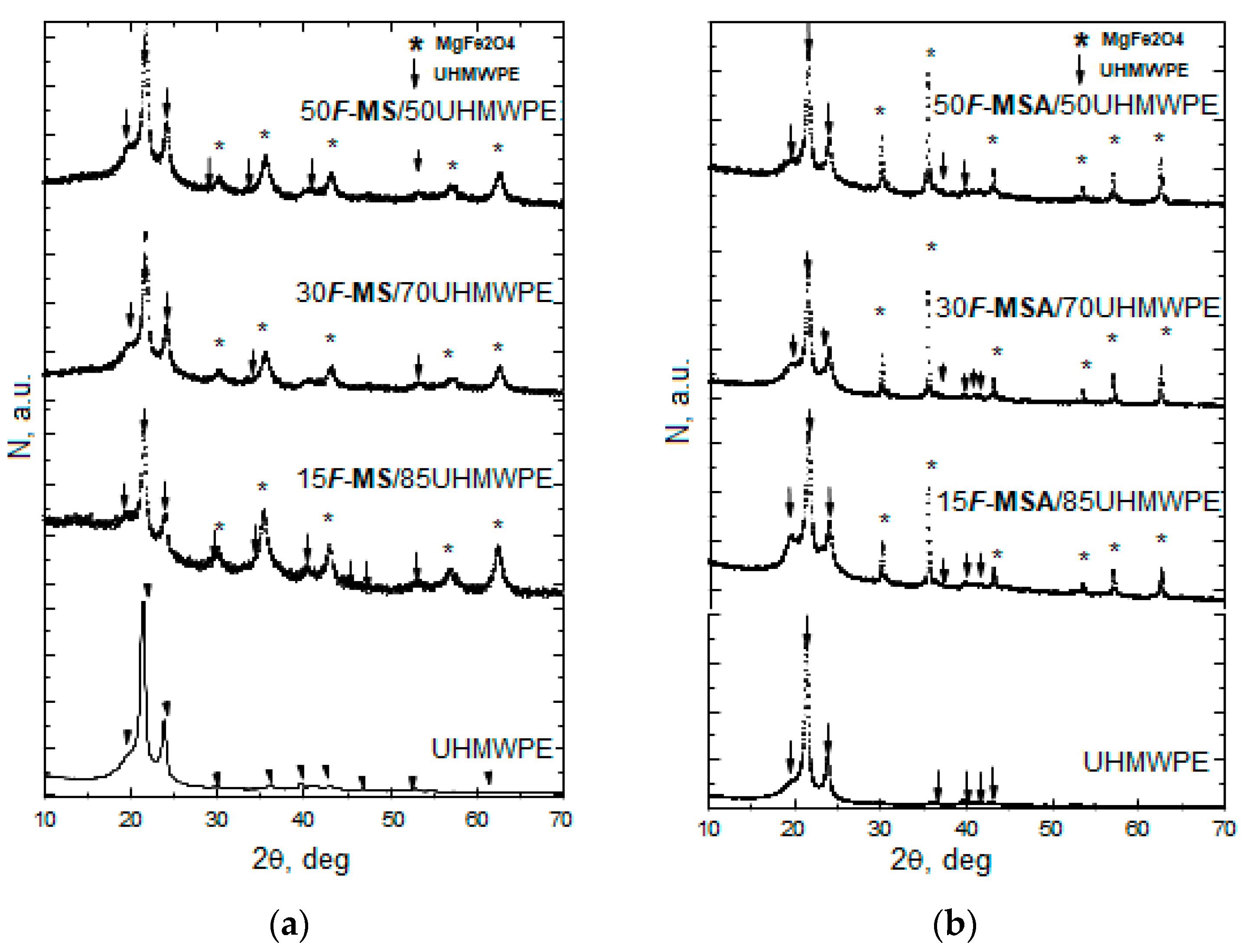

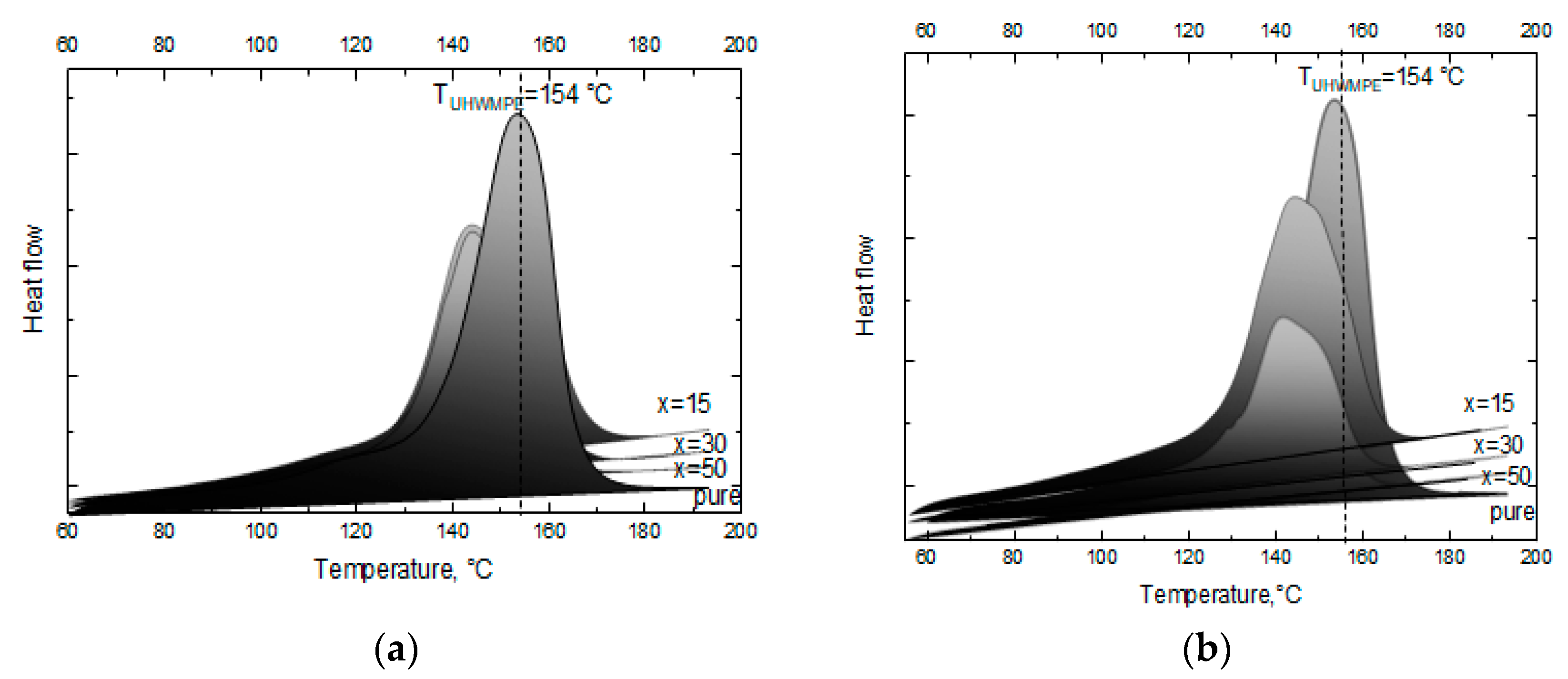

2. Materials and Methods

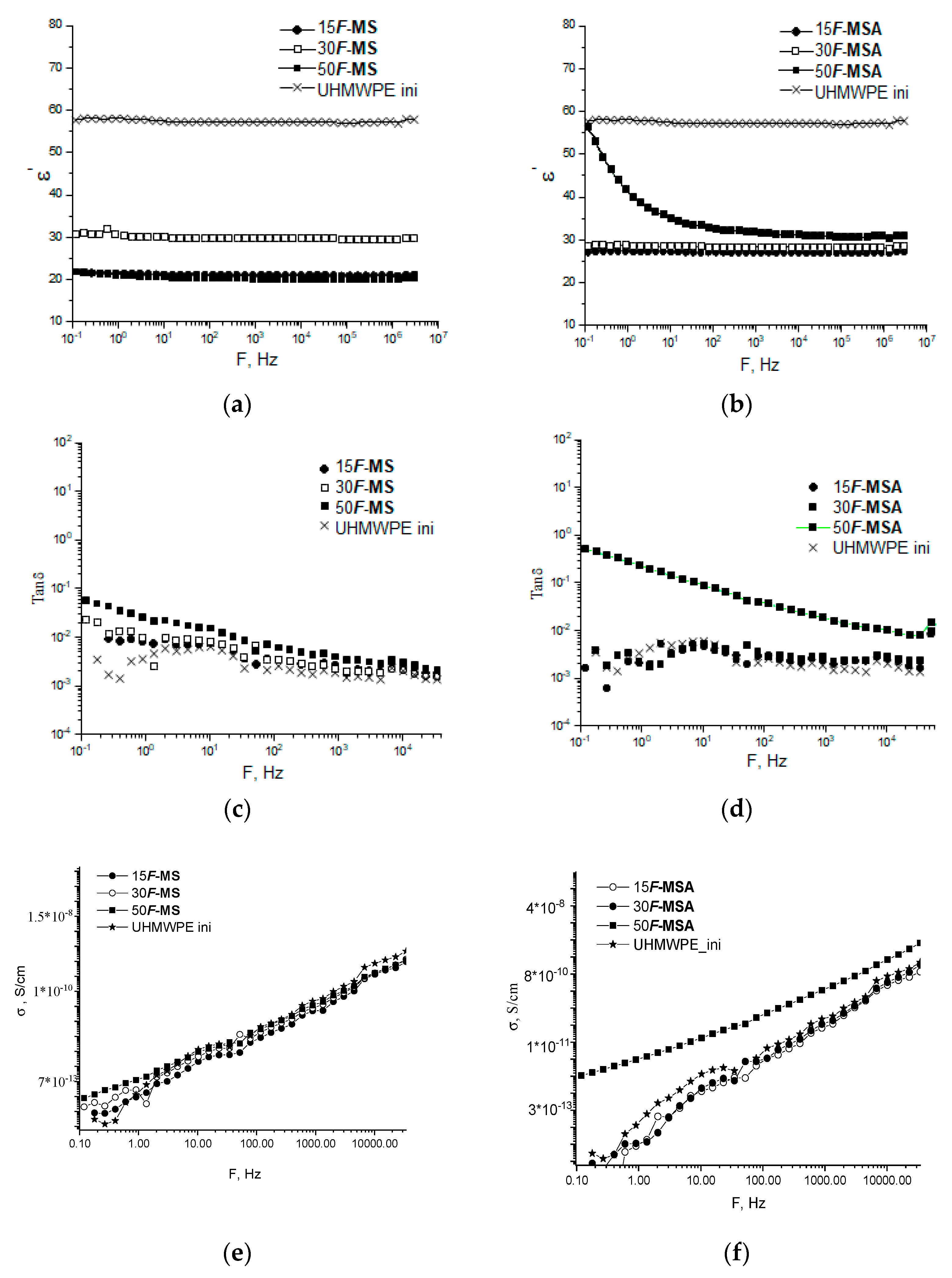

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- González, M.; Pozuelo, J.; Baselga, J. Electromagnetic Shielding Materials in GHz Range. Chem. Rec. 2018, 18, 1000–1009. [Google Scholar] [CrossRef]

- McCrum, N.; Buckley, C.; Bucknall, C. Principles of Polymer Engineering; Oxford Science: Oxford, NY, USA, 1996; p. 464. [Google Scholar]

- Rocha, M.; Mansur, A.; Mansur, H. Characterization and Accelerated Ageing of UHMWPE Used in Orthopedic Prosthesis by Peroxide. Materials 2009, 2, 562–576. [Google Scholar] [CrossRef]

- Kurtz, S.M. The UHMWPE Handbook: Ultra-High Molecular Weight Polyethylene in Total Joint Replacement; Elsevier Academic Press: New York, NY, USA, 2004; p. 379. [Google Scholar]

- Peacock, A.J. Handbook of Polyethylene: Structure, Properties and Applications; Marcel Dekker: New York, NY, USA, 2000; p. 536. [Google Scholar]

- Selyutin, G.E.; Gavrilov, Y.U.; Voskresenskaya, E.N.; Zakharov, V.A.; Nikitin, V.E.; Poluboyarov, V.A. Composite Materials Based on Ultra High Molecular Polyethylene: Properties, Application prospects. Chem. Sustain. Dev. 2010, 18, 301–314. [Google Scholar]

- Okhlopkova, A.; Nikiforov, L.; Borisova, R.; Okhlopkova, T. Polymer Nanocomposites Exploited Under the Arctic Conditions. KnE Mater. Sci. 2016, 1, 122. [Google Scholar] [CrossRef]

- Hussain, M.; Naqvi, R.A.; Abbas, N.; Khan, S.M.; Nawaz, S.; Hussain, A.; Zahra, N.; Khalid, M.W. Ultra-High-Molecular-Weight-Polyethylene (UHMWPE) as a Promising Polymer Material for Biomedical Applications: A Concise Review. Polymers 2020, 12, 323. [Google Scholar] [CrossRef]

- Bracco, P.; Bellare, A.; Bistolfi, A.; Affatato, S. Ultra-High Molecular Weight Polyethylene: Influence of the Chemical, Physical and Mechanical Properties on the Wear Behavior. A Review. Materials 2017, 10, 791. [Google Scholar] [CrossRef]

- Nambiar, S.; Yeow, J.T.W. Polymer-Composite Materials for Radiation Protection. ACS Appl. Mater. Interfaces 2012, 4, 5717–5726. [Google Scholar] [CrossRef]

- Tsepelev, A.B.; Kiseleva, T.Y.; Zholudev, S.I.; Kovaleva, S.A.; Grigoryeva, T.F.; Ivanenko, I.P.; Devyatkina, E.T.; Ilyushin, A.S.; Lyakhov, N.Z. Electron irradiation resistance of the composite material structure based on ultra-high molecular polyethylene and boron carbide. J. Phys. Conf. Ser. 2019, 1347, 012028. [Google Scholar] [CrossRef]

- Manu, K.M.; Soni, S.; Murthy, V.R.K.; Sebastian, M.T. Ba(Zn1/3Ta2/3)O3 ceramics reinforced high density polyethylene for microwave applications. J. Mater. Sci. Mater. Electron. 2013, 24, 2098–2105. [Google Scholar] [CrossRef]

- Kim, E.S.; Jeon, C.J. Dependence of dielectric properties on the crystallinity of ceramic/polymer composites. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2011, 58, 1939–1946. [Google Scholar] [CrossRef]

- Garzón, A.O.; Landínez, D.A.; Roa-Rojas, J.; Fajardo-Tolosa, F.E.; Peña-Rodríguez, G.; Parra-Vargas, C.A. Production and structural, electrical and magnetic characterization of a composite material based on powdered magnetite and high density polyethylene. Rev. Acad.Colomb. Cienc. Ex. Fis. Nat. 2017, 41, 154–167. [Google Scholar] [CrossRef][Green Version]

- Yurkov, G.; Gubin, S.P.; Pankratov, D.A.; Koksharov, Y.A.; Kozinkin, A.V.; Spichkin, Y.I.; Nedoseikina, T.I.; Pirog, I.V.; Vlasenko, V.G. Iron(III) Oxide Nanoparticles in a Polyethylene Matrix. Inorg. Mater. 2002, 38, 137–145. [Google Scholar] [CrossRef]

- Xue, Q. The influence of particle shape and size on electric conductivity of metal–polymer composites. Eur. Polym. J. 2004, 40, 323–327. [Google Scholar] [CrossRef]

- Lu, S.-H.; Liang, G.-Z.; Zhou, Z.-W.; Li, F. Structure and properties of UHMWPE fiber/carbon fiber hybrid composites. J. Appl. Polym. Sci. 2006, 101, 1880–1884. [Google Scholar] [CrossRef]

- Dayyoub, T.; Maksimkin, A.V.; Kaloshkin, S.; Kolesnikov, E.; Chukov, D.; Dyachkova, T.P.; Gutnik, I. The Structure and Mechanical Properties of the UHMWPE Films Modified by the Mixture of Graphene Nanoplates with Polyaniline. Polymers 2018, 11, 23. [Google Scholar] [CrossRef]

- Kovaleva, S.A.; Zhornik, V.I.; Grigoreva, T.F.; Belotserkovskiy, M.A.; Vityaz, P.A.; Dubinchuk, A.D.; Lyakhov, N.Z. Modification of ultra high weight polyethylene by nanostructural composites B4C/W by intense mechanical activation. Chem. Sustain. Dev. 2018, 26, 489–494. [Google Scholar] [CrossRef]

- Shukla, V. Review of electromagnetic interference shielding materials fabricated by iron ingredients. Nanoscale Adv. 2019, 1, 1640–1671. [Google Scholar] [CrossRef]

- Hamciuc, C.; Asandulesa, M.; Hamciuc, E.; Roman, T.; Olariu, M.A.; Pui, A. Novel Polyimide/Copper-Nickel Ferrite Composites with Tunable Magnetic and Dielectric Properties. Polymers 2021, 13, 1646. [Google Scholar] [CrossRef]

- Markevich, I.A.; Selyutin, G.E.; Drokin, N.A.; Selyutin, A.G. Electrical and Mechanical Properties of the High-Permittivity Ultra-High-Molecular-Weight Polyethylene-Based Composite Modified by Carbon Nanotubes. Tech. Phys. 2020, 65, 1106–1113. [Google Scholar] [CrossRef]

- Anh, T.T.; Vanga-Bouanga, C.; David, E.; Frechette, M. AC conductivity and dielectric properties modification of UHMWPE by graphene fillers. In Proceedings of the 016 IEEE International Conference on Dielectrics (ICD), Montpellier, France, 3–7 July 2016; Volume 1, pp. 68–71. [Google Scholar] [CrossRef]

- Maharramov, A.M.; Ismayilova, R.S.; Nuriyev, M.A.; Nabiyev, A.A. Dielectric properties of nanocomposites based on ul-tra-high molecular weight polyethylene and a-SiO2. Plast. Massy 2019, 1–2, 6–8. (In Russian) [Google Scholar]

- Drakopoulos, S.X.; Psarras, G.C.; Forte, G.; Martin-Fabiani, I.; Ronca, S. Entanglement dynamics in ultra-high molecular weight polyethylene as revealed by dielectric spectroscopy. Polymer 2018, 150, 35–43. [Google Scholar] [CrossRef]

- Collins, T.J. ImageJ for microscopy. Biotechniques 2007, 43 (Suppl. S1), S25–S30. [Google Scholar] [CrossRef]

- Wunderlich, B. Macromolecular Physics. Crystal Nucleation, Growth, Annealing; Academic Press: New York, NY, USA, 1976; p. 560. [Google Scholar]

- Flory, P.J. Principles of Polymer Chemistry; Cornell University Press: Ithaca, NY, USA; London, UK, 1953; p. 690. [Google Scholar]

- Egorov, V.M.; Boiko, Y.M.; Marikhin, V.A.; Myasnikova, L.P.; Radovanova, E.I. A study of ultra-strength polymer fibers via calorimetry. Phys. Solid State 2016, 58, 1622–1626. [Google Scholar] [CrossRef]

| Samples | Tonset, °C ±0.5 | Tmax, °C ±0.5 | Tend, °C ±0.5 | ΔHm0, J g−1 ±0.5 | ν ±13 | L, nm ±3 | XDSC, % ±10 |

|---|---|---|---|---|---|---|---|

| UHMWPE initial | 117.5 | 154.4 | 180.3 | 175.5 | 160 | 20 | 69 |

| 15F-MS/85UHMWPE | 129.7 | 148.7 | 178.1 | 136.2 | 204 | 25 | 53 |

| 30F-MS/70UHMWPE | 128.5 | 146.7 | 167.2 | 98.8 | 253 | 31 | 47 |

| 50F-MS/50UHMWPE | 129.7 | 143.4 | 165.1 | 90.4 | 272 | 34 | 35 |

| 15F-MSA/85UHMWPE | 129.1 | 153.6 | 181.4 | 133.2 | 194 | 24 | 52 |

| 30F-MSA/70UHMWPE | 130.1 | 146.2 | 173.5 | 101.2 | 225 | 28 | 39 |

| 50F-MSA/50UHMWPE | 130.2 | 144.3 | 171.9 | 85.3 | 232 | 29 | 33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiseleva, T.; Grigoreva, T.; Kovaliova, S.; Il’in, M.; Yakuta, E.; Devyatkina, E.; Malyshkina, I.; Ivanenko, I.; Vosmerikov, S.; Lyakhov, N. Dielectric Performance of UHMWPE-MgFe2O4 Composites Depending on Polymer Crystallinity, and the Concentration and Size of Mechanochemically Synthesized Ferrite Particles. Powders 2023, 2, 578-587. https://doi.org/10.3390/powders2030036

Kiseleva T, Grigoreva T, Kovaliova S, Il’in M, Yakuta E, Devyatkina E, Malyshkina I, Ivanenko I, Vosmerikov S, Lyakhov N. Dielectric Performance of UHMWPE-MgFe2O4 Composites Depending on Polymer Crystallinity, and the Concentration and Size of Mechanochemically Synthesized Ferrite Particles. Powders. 2023; 2(3):578-587. https://doi.org/10.3390/powders2030036

Chicago/Turabian StyleKiseleva, Tatiana, Tatiana Grigoreva, Svetlana Kovaliova, Maxim Il’in, Ekaterina Yakuta, Evgeniya Devyatkina, Inna Malyshkina, Ilya Ivanenko, Sergey Vosmerikov, and Nikolay Lyakhov. 2023. "Dielectric Performance of UHMWPE-MgFe2O4 Composites Depending on Polymer Crystallinity, and the Concentration and Size of Mechanochemically Synthesized Ferrite Particles" Powders 2, no. 3: 578-587. https://doi.org/10.3390/powders2030036

APA StyleKiseleva, T., Grigoreva, T., Kovaliova, S., Il’in, M., Yakuta, E., Devyatkina, E., Malyshkina, I., Ivanenko, I., Vosmerikov, S., & Lyakhov, N. (2023). Dielectric Performance of UHMWPE-MgFe2O4 Composites Depending on Polymer Crystallinity, and the Concentration and Size of Mechanochemically Synthesized Ferrite Particles. Powders, 2(3), 578-587. https://doi.org/10.3390/powders2030036