Abstract

The effects of milling on the anaerobic degradability of wheat straw and corn stover were investigated. Pretreatment was carried out by an industrial-scale device, able to process over one ton per hour. After 28 days of digestion under mesophilic conditions, the cumulative methane production from the pretreated straw (250 Nm3 t−1 of volatile solids) was 49.2% greater than that from the raw material. Pretreated stover reached a cumulative methane yield of 219.8 Nm3 t−1 of volatile solids, gaining 10.1% as compared to the feedstock. The specific electrical energy requirements for pretreatment were 66.6 kWh t−1 for processed straw and 64.8 kWh t−1 for stover; these consumptions were not significantly different. With reference to biomethane production, the impact of raw material on the production cost decreased from EUR 0.418 Nm−3 to EUR 0.328 Nm−3 for pretreated straw, whereas it increased by 5.8% for corn stover, whose pretreatment, therefore, was not economically feasible.

1. Introduction

As part of the transition towards net-zero emissions, the European Commission has planned to achieve a 55% reduction in greenhouse gas emissions by 2030, compared to 1990 levels [1]. Biogas and biomethane play an important role in attaining these objectives. In particular, the EU Methane Strategy [2] suggests use of efficient biogas solutions to decrease GHG emissions from waste, agriculture activities, and energy production. Furthermore, the Energy System Integration Strategy [3] promotes the use of waste for substitution of fossil gas by renewable gases.

Biogas represents a useful alternative to fossil-based energy, because the production process is relatively simple, robust, and cost effective [4]. The European Union is the world’s leading producer of biomethane for use as a vehicle fuel or for injection into the natural gas grid, with a total of 1322 biomethane-producing facilities by April 2023, which in 2022 produced 3.5 billion cubic meters of biomethane [5]. Energy crops and agricultural waste are the most widely used raw materials, accounting for more than 70% of the feedstock utilized in Germany, Italy, Austria, Latvia, and Hungary.

In the European Union, agricultural activities generate around 200 million tons of residues every year [6]. They are mostly composed of wheat straw and corn stover, whose potential—after consideration of sustainability constraints, as well as consumption from existing activities—is estimated at 46 and 31 million tons, respectively [7]. Biomethane from straw is expected to cause 80 to 90% less greenhouse gas emissions compared with natural gas [8].

However, cereal straws are scarcely used for methane production due to their low biodegradability since they have a high content of structural carbohydrates and lignin, whose physical and chemical associations make it difficult for anaerobic bacteria to utilize [9,10]. Pretreatment is therefore required to weaken the lignocellulosic structure, make available the anaerobically digestible compounds, and increase the surface area for enzymatic attack.

Several pretreatment techniques have been used to improve the anaerobic degradability of both wheat straw and corn stover.

Among chemical pretreatments, inorganic acid ones are already in use in industry. They effectively dissolve a portion of hemicellulose, but have some drawbacks with regard to anaerobic digestion due to the formation of inhibitor compounds from sugar degradation, resulting in low biogas production [11]. A study on the effects of steam pretreatment of corn stalks [12] confirmed that the addition of sulfuric acid caused methanogenic inhibition. Dilute acid pretreatment can prevent the aforementioned drawbacks. A severe treatment with dilute sulfuric acid (120 °C for 2 h) increased the methane production only by 15% [13]. A milder treatment (60 °C for 3 h) reduced the methane yield of corn stover, whereas it increased up to 45% using dilute phosphoric acid [14].

Alkali pretreatments are often preferred to acidic ones, due to their effectiveness in altering the structure of lignin and increasing the enzymatic accessibility of cellulose and hemicelluloses [15].

An alkaline pretreatment of wheat straw with 10% (w/w) sodium hydroxide, with a 24 h residence time at 40 °C, produced a 43% increase in the methane yield compared to that of the untreated substrate; the cumulative methane production was 293 Nm3 tTS−1. Shorter residence times (30 min) and higher temperatures (100 °C) produced a 67% increase [15].

Wheat straw anaerobic degradation was also enhanced by treatment with potassium hydroxide (KOH), which also improves the fertilizer value of the digestate. Using 6% KOH (w/wTS) and a residence time of 72 h at room temperature produced a biomethane yield of 258 Nm3 tVS−1, resulting in a gain of 41% compared to that of feedstock [16]. The cumulative methane yield of KOH-treated corn stover improved with increasing KOH concentration from 0.5% to 1.5%, and then it declined as the concentration was increased to 2%; the residence time was 12 h, and the temperature was 20 °C [17]. The maximum methane production was 208 Nm3 tVS−1, achieving a 45% gain over that of the untreated stover.

Ethanol organosolv pretreatment at 180 °C for 1 h enhanced the cumulative methane production of wheat straw by 15% compared to that of the raw material [18].

Physicochemical pretreatments reduce the use of chemicals and thus improve the environmental sustainability. Wet explosion of wheat straw (heating at 180 °C and 10 bar pressure with H2O2 as oxidizing agent) resulted in a slight reduction in methane production [19], most likely due to the formation of inhibitory compounds.

Biological pretreatment has the great advantages of low toxicity and economic input as compared to physical and chemical pretreatments. Inoculating wheat straw with Plerotus Ostreatus for 60 days provided a 21% increase in biogas yield [20]. A 25% increase in methane yield of corn stover was observed after 24 h of enzymatic pretreatment with laccase [21], whereas a combination of yeast, cellulolytic, and lactic acid bacteria increased the methane production by 35% and 75% after 5 and 15 days of pretreatment, respectively [22].

Among physical methods, steam explosion has been extensively used to enhance the degradability of both straw and stover. Pretreatment of corn stover at 160 °C for 2 min improved the methane yield by 22%. Harsher pretreatment conditions led to lower methane yields [23]. Residence at 187 °C for 5 min produced a methane yield of 206 Nm3 tVS−1, which increased to 237 Nm3 tVS−1 for 10 min, which was 55.2% more than that of the untreated material; the yield decreased to 199 Nm3 tVS−1 as the residence time increased to 20 min [17]. With regard to straw pretreatment, at optimal conditions, an increase in the methane potential of straw from 20 to 41% was achieved [24]. For more severe conditions, the biodegradability decreased due to the formation of inhibitory compounds.

Microwave heating has produced differing results. According to some authors, it did not improve the anaerobic degradation of several cereal straws [25], whereas other researchers found a strong increase in the methane yield of the substrates, but the process was not sustainable because of the high demand for electric energy [26].

Size reduction pretreatment, or comminution, has the goal of increasing the specific surface area of the feedstock, thus facilitating the exchange of mass and heat and the action of anaerobic microorganisms, and of reducing the fiber crystallinity [27]. Its main drawback is the high demand for electrical energy, which is mostly dissipated into heat. Despite this, the great advantages represented by the process speed and the absence of any effluent and inhibitory compounds drive the search for effective and energy-efficient mechanical pretreatments. Moreover, a size reduction step is almost always necessary upstream of other pretreatment systems.

Compared to mechanical methods, chemical pretreatments can modify the lignocellulosic structure, but have several drawbacks, such as long treatment times, possible formation of inhibitory compounds (for the acid ones), expensive operation and maintenance costs, and environmental toxicity. Steam explosion is cost effective, and environmentally friendly, but can form inhibitors and requires more complex plant engineering than purely mechanical systems. Biological pretreatments, whether based on microorganisms or enzymes, require low energy inputs, but have the major disadvantage of long treatment times. In addition, those based on enzymes have high economic costs.

In the field of size reduction devices, ball mills can significantly increase the conversion of carbohydrates; however, because of their enormous electrical energy consumption (up to 30,000 kWh t−1), these devices are not suited for commercial installations [28,29].

Several studies have highlighted that particle size has a significant impact on the methane production of wheat straw by anaerobic digestion under mesophilic conditions. Particularly, it was shown that production increases roughly with a quadratic law as particle size decreases [30]. The biomethane yield increased from 160 to 230 Nm3 tVS−1 as the particle size decreased from 30 to 6 mm, reaching a maximum of 250 Nm3 tVS−1 as the particle size was reduced to 0.4 mm. No further increase was observed by reducing the particle size to 80 µm [31]. Another study [32] confirmed that micronization from 790 to 48 µm did not improve the methane yield, which was about 280 Nm3 tVS−1, but had a positive effect on the biodegradation kinetics down to a threshold size of approximately 200 µm.

Unlike straw, maize stalks did not show any significant improvement in methane yield after milling from 50 mm to about 2 mm [33], whereas other authors measured a yield gain of about 10% following disk refining [34]. Milling of corn straw silage to a median particle size of about 1 mm produced an improvement in the methane yield of about 8.3% [35]. All these studies were conducted on laboratory devices.

In summary, size reduction pretreatment produced a yield gain not greater than 55% for wheat straw and had a poor effect on corn stover, but these results were obtained from laboratory-scale devices and the electric energy demand for pretreatment was not assessed or has no utility in an industrial context, since it is known that the specific energy consumption strongly depends on the mill size and the mass flow rate at which it is operated [36].

Due to the lack of data on industrial-scale devices, some authors believe that milling is not economically feasible due to its high energy requirements and lower methane yield compared to other types of pretreatments [37].

In the present study, the effectiveness of milling straw and corn stover by an industrial-scale device was evaluated. To the best of our knowledge, an industrial-scale comminution device has never been used to pretreat corn stover, while there are no reliable data on the energy performance of devices used for straw pretreating.

The methane yield of both untreated and pretreated materials was determined together with the specific energy consumption of the mill. Finally, we evaluated the energy balance of pretreatment to allow the operators of commercial AD plants to understand whether the adoption of the studied pretreatment should be considered or not.

2. Materials and Methods

2.1. Raw Materials

Straw from a soft wheat and corn stover containing corn cobs without grain were harvested in central Italy in summer and fall 2022, respectively.

The above-mentioned feedstocks were chopped by a knife mill to an average length of about 20 mm, which is a common size used in commercial anaerobic digestion plants. Portions of these materials were used as a reference and named WS (wheat straw) and CS (corn stover).

2.2. Pretreatment

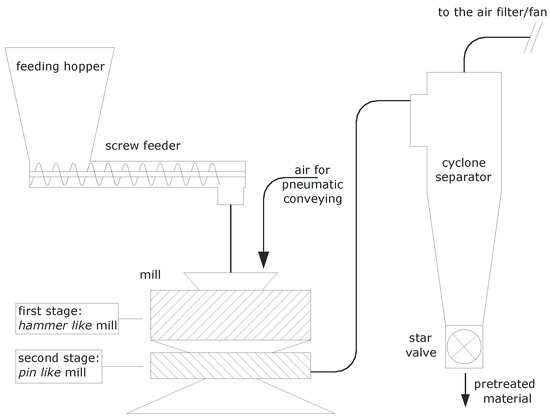

Comminution was carried out by a two-stage, industrial-scale mill, especially suitable to process feedstock with a high dry matter content (>70%). It comprises two milling stages (Figure 1): the first stage acts like a hammer mill, equipped with an interchangeable semicircular screen through which the milled material is pneumatically transported to the second stage. Peripheral fins are used for improving its energy efficiency by both reducing the energy loss due to the high-speed circular motion of the processed material at the periphery of the milling chamber and maximizing the number of shocks, in order to increase breakage due to fatigue. The second stage acts like a pin mill, with close shearing surfaces between the outer pins and the inner, cylindrical surface of the stator. The inside diameter of the milling chambers is about 900 mm.

Figure 1.

Scheme of the pretreatment device.

Two samples of chips of the raw materials, 50 kg each, were processed in the described mill. A screw conveyer fed the mill at a constant mass flow rate of 900 kg h−1, which was approximately 75% of the minimum mass flow rate which caused an overload shut off of the 75 kW electric motor.

From here on out, the products will be named WSMP (wheat straw mechanically pretreated) and CSMP (corn stover mechanically pretreated).

The electrical power absorbed by the device was monitored by means of a wattmeter (MTME-485, ABB-SACE, Italy); power, supply voltage, and current were acquired at time intervals of one second. The energy required for milling (kWh) was determined by integrating the area under the power demand curve for the total time required to grind the samples. The specific energy demand (kWh kg−1) was then calculated by dividing the energy required for milling by the mass of the processed sample.

2.3. Chemical Composition Analysis

The raw, processed materials and the inoculum were analyzed for total and volatile solids (TS and VS, respectively) according to the method described by APHA [38]. The contents of NDF, ADF, and ADL (neutral detergent fiber, acid detergent fiber, and acid detergent lignin, respectively) were also determined according to the van Soest method [39]. The tests were performed in three replicates.

2.4. Particle Size Distribution

The particle size distribution of the materials was determined according to the ASABE standard S319.3 [40]. A sieve analyzer used twelve ISO sieves, from 1.400 mm down to 0.075 mm. Each time, a sample of 150 g was sieved for 15 min.

2.5. Anaerobic Digestion

Biogas production tests were carried out in triplicate on samples of both the raw and the processed materials to evaluate the biogas and methane production. Two controls with inoculum sludge were also used to determine the biomethane production of the inoculum, which was then subtracted from the production of the feedstocks. The experiments were performed in batch anaerobic reactors with a working volume of 2 L operated under mesophilic conditions (38 °C) and equipped with mixing and thermostating systems. Anaerobic sludge from a mesophilic digester was used as inoculum and the substrate/inoculum ratio was in the range of 0.504–0.507 on a VS basis, whereas the final loading was in the range of 49–50 gTS/L.

The generation of biogas was assessed every 1 or 2 days, depending on the volume of accumulated gas, by means of a Ritter Drum-type gas volume meter (TG05, Ritter Apparatebau GmbH & Co. KG, Bochum, Germany). The methane content in the biogas was measured using an SG06IOMX6 portable automatic analyzer (B.A.G.G.I. srl, Milan, Italy).

The experiments were terminated after 28 days, when the daily biogas production was <1.2% of the cumulative biogas volume for all the samples.

3. Results

3.1. Characterization of the Biomasses

Pretreatment resulted in a reduction in the masses of WSMP and CSMP compared to the raw materials, which amounted to 1.1% and 2.0%, respectively, which was due to both reduction in the moisture content and processing losses.

The processed wheat straw showed a median particle size (d50) of about 300 μm, whereas it was about 250 μm for the CSMP.

The results of the chemical analysis are reported in Table 1. No statistically significant differences in the chemical compositions of the processed materials were observed compared to those of the feedstocks.

Table 1.

Chemical analysis of the raw and pretreated materials.

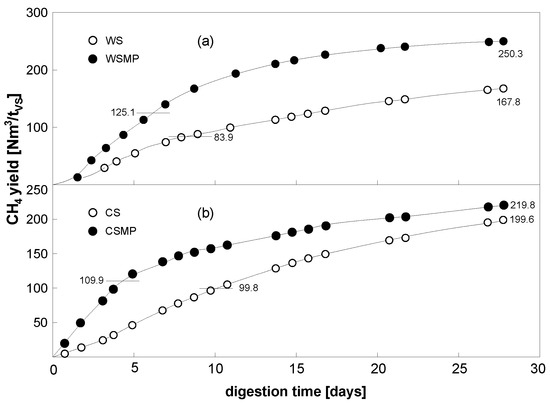

3.2. Methane Yield and Biogas Composition

WS reached a methane yield of 167.8 (±4.0) Nm3 tVS−1, which increased to 250.3 (±5.2) Nm3 tVS−1 for the pretreated material; the yield gain was 49.1% (±6.6%) (Table 2). The methane yield of the processed corn stover reached 219.8 (±4.2) Nm3 tVS−1, which was 10.1% greater than that of the raw material.

Table 2.

Methane yield and biogas composition.

The methane concentration in biogas was significantly greater in WSMP (52.2%) than in the raw material (49.3%), whereas no statistically significant differences in the biogas composition were observed for corn stover.

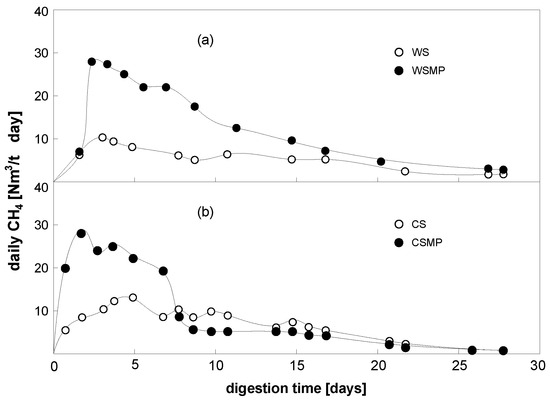

As depicted in Figure 2 and Figure 3, pretreatment enhanced the kinetics of the process. WS and CS reached 50% of the cumulative production on the 8th and 11th days after the beginning of the assay, respectively. Whereas it took about 6 days for WSMP and only 4 days for CSMP, whose digestion suddenly slowed down from day 6 onwards.

Figure 2.

Cumulative methane yield for wheat straw (a) and corn stover (b).

Figure 3.

Daily methane production for wheat straw (a) and corn stover (b).

3.3. Specific Energy Requirement

The overall energy consumption, including the need for the feeding conveyer and the pneumatic transport of the processed material, was 3.330 (±0.090) kWh for WSMP, which leads to a specific energy requirement of 66.6 (±1.8) kWh t−1. Corn stover processing required a similar amount of electrical energy, 3.241 (±0.115) kWh, leading to 64.8 (±2.3) kWh t−1.

3.4. Energy Data Analysis

The primary energy (EP) potentially obtainable by the samples upstream of the upgrading process to obtain biomethane, expressed as kWh t−1 of raw material (WS and CS), was calculated using Equations (1) and (2) for the untreated and pretreated materials, respectively:

where Y is the methane yield of the samples, expressed in Nm3 t−1; the LHV (lower heating value) is assumed to be 9.94 kWh Nm−3 (35.7 MJ Nm−3), and mU and mP are the masses of the processed sample before and after pretreatment, respectively.

EP = Y ∙ LHV

EP = Y ∙ LHV

The primary energy consumed to pretreat the raw materials was calculated using Equation (3):

where EC is the electric energy used for pretreatment, expressed in kWh t−1 and f is the coefficient that enables the transformation of electric energy into primary energy, set equal to 1.86 kWh kWh−1 for the Italian electric grid [41]. The primary energy gain was obtained by subtracting the sum of the primary energy obtained from the raw material and the primary energy consumed for pretreatment from the energy produced by the pretreated material. The results are shown in Table 3.

EP = EC ∙ f

Table 3.

Energy performance.

4. Discussion

As already discussed in the Introduction, studies carried out on industrial-scale pretreatment devices are rare in the literature, and data concerning the used devices and operating conditions are often largely incomplete. This research was conducted on a full-scale mill, and it is therefore expected that the data presented, with particular reference to energy consumption, can be conveniently used for the operation of commercial digesters.

A limitation of the present study is that, although it was carried out on a full-scale pretreatment device, the anaerobic digestion process was studied at the laboratory scale using BMP (biochemical methane potential) tests in 2 L batch reactors. This methodology is useful and effective for the determination of optimal pretreatment conditions, and it has already been extensively used in studies concerning pretreatment of wheat straw and corn stover. However, as a matter of principle, it is risky to extrapolate the results of BMP tests to full-scale continuous anaerobic digesters. This is because the batch digestion tests are carried out under optimal conditions, due to the excess of inoculum, which contains the active microflora, essential nutrients, and buffering capacity. Furthermore, BMP data do not take into account some important parameters of an industrial, continuous digestion plant, such as the organic loading rate and the hydraulic retention time (HRT). Experiments carried out in continuous stirred tank, lab-scale reactors (CSTRs) can take into account these parameters and provide information about the stability of the process and the specific methane yield (SMY) of the feedstock. A recent study [42] compared the result of BMP tests carried out on corn straw with the specific methane yield evaluated in CSTR devices. The SMY did not change significantly as HRT increased from 40 to 60 days and was not significantly different from the yield obtained in BMP tests. Moreover, several studies carried out in full-scale plants have demonstrated that the results of tests can provide a good prediction of actual biogas production, especially where mechanical pretreatments are concerned. Straw-based horse manure was pretreated by a comminution device and the effectiveness of pretreatment was investigated both by BMP tests and by monitoring a full-scale, CSRT biogas plant over a period of 160 days. The plant was operated under mesophilic conditions with an HRT of about 78 days. The differences between the batch digestion test and the full-scale actual specific methane production were negligible [43]. Similar results were also found by studying the effects of a full-scale hydrodynamic cavitation pretreatment in a 725 KWe agricultural biogas plant, whose HRT was 35 days [44]. When untreated material was digested, the daily methane production measured at the full-scale biogas plant was almost 93% of the daily theoretical methane production calculated from the BMP tests; it increased to 105% when the pretreated material was used in the feeding mix. Schievano et al. [45] studied, for a one-year period, a full-scale CSTR plant operating under wet conditions. The plant, whose HRT was 57 days, used swine and cow manure as liquid substrate, enriching the feeding mixture by various energy crops and agricultural residues. It was found that the specific methane yield measured from the plant was 93% of the yield obtained by the BMP test.

In light of the above, since the aim of the present work is not to design an industrial AD plant, but only provide information about the effectiveness and the efficiency of a pre-treatment methodology, it can be assumed that the batch methane yields presented in this study can be used to give a sufficiently accurate prediction of the SMY from the same materials in full-scale operation.

As discussed in the Introduction, size reduction by milling the feedstock up to a few microns achieved a methane yield gain not larger than 55% for wheat straw and had no effect on corn stover. The results of the present study confirm that milling carried out at industrial scale strongly enhances the cumulative methane yield from wheat straw (+49.1%), whereas the yield from corn stover is poorly improved (+10.1%).

Other authors also highlighted the poor effectiveness of milling in increasing the specific methane yield of corn straw silage (+8.3%) [35] and corn stover (+9.9%) [34]. The authors of the first study proposed that this was due to the limited susceptibility of maize straw silage to comminution, since 45.6% of the processed material showed a particle size larger than 1.25 mm. This conclusion is not supported by the results of the present study, since the median particle size of the processed corn stover (250 µm) was smaller than that of the pretreated wheat straw (300 µm). Furthermore, as already pointed out in the Introduction, the increase in anaerobic degradability of wheat straw is already appreciable for particle sizes around 5 mm [31,32]. The authors of the second study observed a lag time in methane production from pretreated stover, thus indicating a limited adaptability of anaerobic microorganisms to that feedstock. Such behavior was not observed in the present study, in which the digestion of the pretreated stover was immediate and effective, but suddenly declined from day six onwards.

From an economic point of view, assuming a straw supply cost of EUR 58.8 t−1 [46], the incidence of raw material on the production cost is EUR 0.418 Nm−3. This cost is reduced to EUR 0.328 Nm−3 for the pretreated material, taking into account the cost for electric energy at an average purchase price of EUR 0.15 kWh−1 [47]. Using the same parameters, the incidence of feedstock on the production cost for pretreated corn stover (EUR 0.365 Nm−3) would exceed that of raw material (EUR 0.345 Nm−3).

It is worth noting that annual costs due to maintenance and capital depreciation are an order of magnitude lower than wheat straw costs. In fact, based on the data summarized in Table 4, annual maintenance costs amount to EUR 0.022 Nm−3, while capital depreciation is estimated at EUR 0.02 Nm−3. This indicates that the process—in economical terms—could easily be sustained on an industrial level.

Similar results in pretreatment of corn stover were obtained by a small-scale (10 kW of electric power) single-screw extruder [48]. The cumulative methane production was enhanced by 10%, but the energy balance of pretreatment was negative, due to the high electric energy consumption, 200–300 kWh t−1.

Table 4.

Parameters for estimating maintenance and depreciation costs.

Table 4.

Parameters for estimating maintenance and depreciation costs.

| Pretreatment equipment cost | EUR 75,000 |

| Installation [49] | 32% of capital cost |

| Maintenance [49] | 18% of capital cost |

| Working period | 2000 h/y |

| Pretreated straw | 2400 t/y |

| Capital depreciation period | 15 y |

| Interest rate | 6% |

Coupling impregnation with acidogenesis liquid digestate (5 h, 1:10 solid–liquid ratio) and disk refining, a biomethane yield gain of about 47% was achieved [34], but electric energy consumption was once again considerable, approximately 300 kWh t−1.

Considering pretreatment methods other than mechanical, for the thermoalkaline pretreatment of wheat straw cited in the Introduction [15], the authors estimated an additional operational cost—due to the purchase of the chemicals—equal to EUR 0.041 kWh−1 and EUR 0.299 kWh−1 for NaOH concentrations of 1% and 10%, respectively. It is evident that only the treatment carried out at the lower concentration of the chemical agent seems to be compatible with the selling price of the electric energy. Furthermore, the additional operating costs for milling the feedstock to a median particle size of about 1 mm and heating the mixture to 100 °C should be considered, but they were not estimated by the authors. In conclusion, the incidence of raw material on the production cost is estimated at EUR 0.418 Nm−3 for the pretreated material, which is approximately 31% higher than that estimated for the pretreatment under consideration in this study. This incidence takes into account the costs for electric energy and chemicals, to which the cost of heating should be further added.

Similar results were obtained by KOH pretreatment [16]. When operating at room temperature with a KOH concentration of 6% (w/wTS), the additional operating cost due to the chemical agent was EUR 0.175 Nm−3. Even in this case, the additional operating costs for milling the feedstock should be taken into account, leading to an estimated impact of raw material on the production cost of about EUR 0.471 Nm−3, which is approximately 44% higher than that for mechanical pretreatment.

The thermal-expansionary pretreatment of wheat straw discussed in the Introduction [18] obtained the best performance after cooking at 170 °C for 20 min; the methane yield of processed wheat straw was 360 Nm3 tTS−1, which was 41% greater than that of the untreated feedstock. The net electric energy gain was 346.8 kWh t−1, estimated at about 1.6 times the net gain achieved by the process investigated in the present study, but the thermal-expansionary pretreatment required a large amount (510 kWh t−1) of additional thermal energy.

These results suggest that mechanical pretreatment of wheat straw can be successful for use in anaerobic digesters. In fact, the working capacity investigated in the present study—up to 1.2 t h−1—can meet the requirements of medium- and large-scale biogas plants. Moreover, the additional operating cost—due to the electric energy consumption—is moderate and to be regarded as accurate. The optimal organic loading rates and HRTs should be evaluated in CSTR experiments, both at the laboratory and full scales. Last, the present study confirmed that mechanical pretreatment of corn stover is poorly effective and inefficient. Alkali pretreatment seems to be the best option for enhancing the anaerobic digestion of corn stover.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author/s.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- European Commission. Communication from the Commission to the European Parliament, the Council and the European Economic and Social Committee of the Regions—The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council and the European Economic and Social Committee of the Regions on an EU Strategy to Reduce Methane Emissions; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council and the European Economic and social Committee of the Regions—Powering a Climate-Neutral Economy: An EU strategy for energy system integration; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Deublein, D.; Steinhauser, A. Biogas from Waste and Renewable Resources: An Introduction; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- European Biomethane Association. EBA Statistical Report 2023. Available online: https://www.europeanbiogas.eu/eba-statistical-report-2023/ (accessed on 14 May 2024).

- de Wit, M.; Faaij, A. European biomass resource potential and costs. Biomass Bioenerg. 2010, 34, 188–202. [Google Scholar] [CrossRef]

- Thorenz, A.; Wietsche, L.; Stind, D.; Tuma, A. Assessment of agroforestry residue potentials for the bioeconomy in the European Union. J. Clean. Prod. 2018, 176, 348–359. [Google Scholar] [CrossRef] [PubMed]

- Cherubini, F.; Ulgiati, S. Crop residues as raw materials for biorefinery systems—A LCA case study. Appl. Energy 2010, 87, 47–57. [Google Scholar] [CrossRef]

- Adani, F.; Papa, G.; Schievano, A.; Cardinale, G.; D’Imporzano, G.; Tambone, F. Nanoscale structure of the cell wall protecting cellulose from enzyme attack. Environ. Sci. Technol. 2022, 45, 1107–1113. [Google Scholar] [CrossRef]

- Li, Y.; Merrettig-Bruns, U.; Strauch, S.; Kabasci, S.; Chen, H. Optimization of ammonia pretreatment of wheat straw for biogas production. J. Chem. Technol. Biotechnol. 2015, 90, 130–138. [Google Scholar] [CrossRef]

- Palmqvist, E.; Hahn-Hägerdal, B. Fermentation of lignocellulosic hydrolysates. II: Inhibitors and mechanisms of inhibition. Bioresour. Technol. 2000, 74, 25–33. [Google Scholar] [CrossRef]

- Venturin, B.; Camargo, A.F.; Scapini, T.; Mulinar, J.; Bonatto, C.; Bazoti, S.; Steinmetz, R.L.R. Effect of pretreatments on corn stalk chemical properties for biogas production purposes. Bioresour. Technol. 2018, 266, 116–124. [Google Scholar] [CrossRef]

- Taherdanak, M.; Zilouei, H.; Karimi, K. The influence of dilute sulfuric acid pretreatment on biogas production from wheat plant. Int. J. Green Energy 2016, 13, 1129–1134. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, H.; Mi, X.; Wang, L.; Zhang, L.; Ai, Y. Research on anaerobic digestion of corn stover enhanced by dilute acid pretreatment: Mechanism study and potential utilization in practical application. J. Renew. Sustain. Energy 2016, 8, 023103. [Google Scholar] [CrossRef]

- Sambusiti, C.; Monlau, F.; Ficara, E.; Carrère, H.; Malpei, F. A comparison of different pre-treatments to increase methane production from two agricultural substrates. Appl. Energy 2013, 104, 62–70. [Google Scholar] [CrossRef]

- Jaffar, M.; Pang, Y.; Yuan, H.; Zou, D.; Liu, Y.; Zhu, B.; Korai, R.M.; Li, X. Wheat straw pretreatment with KOH for enhancing biomethane production and fertilizer value in anaerobic digestion. Chin. J. Chem. Eng. 2016, 24, 404–409. [Google Scholar] [CrossRef]

- Li, J.; Zhang, R.; Siddhu, M.A.; Wang, W.; Li, Y.; Liu, G. Enhancing methane production of corn stover through a novel way: Sequent pretreatment of potassium hydroxide and steam explosion. Bioresour. Technol. 2015, 181, 345–350. [Google Scholar] [CrossRef] [PubMed]

- Mancini, G.; Papirio, S.; Lens, P.N.L. Anaerobic digestion of lignocellulosic materials using ethanol-organosolv pretreatment. Environ. Eng. Sci. 2018, 35, 953–960. [Google Scholar] [CrossRef]

- Wang, G.; Gavala, H.N.; Skiadas, I.; Ahring, B.K. Wet explosion of wheat straw and codigestion with swine manure:Effect on the methane productivity. Waste Manag. 2009, 29, 2830–2835. [Google Scholar] [CrossRef]

- Yadav, M.; Paritosh, K.; Pareek, N.; Vivekanand, V. Coupled treatment of lignocellulosic agricultural residues for augmented biomethanation. J. Clean. Prod. 2019, 213, 75–88. [Google Scholar] [CrossRef]

- Schroyen, M.; Vervaeren, H.; Van Hulle, S.W.; Raes, K. Impact of enzymatic pretreatment on corn stover degradation and biogas production. Bioresour. Technol. 2014, 173, 59–66. [Google Scholar] [CrossRef]

- Zhong, W.; Zhang, Z.; Luo, Y.; Sun, S.; Qiao, W.; Xiao, M. Effect of biological pretreatments in enhancing corn straw biogas production. Bioresour. Technol. 2011, 102, 11177–11182. [Google Scholar] [CrossRef]

- Lizasoain, J.; Trulea, A.; Gittinger, J.; Kral, I.; Piringer, G.; Schedl, A.; Bauer, A. Corn stover for biogas production: Effect of steam explosion pretreatment on the gas yields and on the biodegradation kinetics of the primary structural compounds. Bioresour. Technol. 2017, 244, 949–956. [Google Scholar] [CrossRef]

- Kratky, L.; Jirout, T. The effect of process parameters during the thermal-expansionary pretreatment of wheat straw on hydrolysate quality and on biogas yield. Renew. Energy 2015, 77, 250–258. [Google Scholar] [CrossRef]

- Sapci, Z. The effect of microwave pretreatment on biogas production from agricultural straws. Bioresour. Technol. 2013, 128, 487–494. [Google Scholar] [CrossRef]

- Jackowiak, D.; Bassard, A.; Pauss, T. Optimisation of a microwave pretreatment of wheat straw for methane production. Bioresour. Technol. 2011, 102, 6750–6756. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Cheng, J. Hydrolysis of lignocellulosic materials for ethanol production: A review. Bioresour. Technol. 2002, 83, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Koullas, D.P.; Christakopoulos, P.; Kekos, D.; Macris, B.J.; Koukios, E.G. Correlating the effect of pretreatment on the enzymatic hydrolysis of straw. Biotechnol. Bioeng. 1999, 39, 13–116. [Google Scholar] [CrossRef] [PubMed]

- Kratky, L.; Jirout, T. Biomass Size Reduction Machines for Enhancing Biogas Production. Chem. Eng. Technol. 2011, 234, 391–399. [Google Scholar] [CrossRef]

- Andersen, L.F.; Parsin, S.; Lüdtke, O.; Kaltschmitt, M. Biogas production from straw—The challenge feedstock pretreatment. Biomass Convers. Biorefinery 2011, 12, 379–402. [Google Scholar] [CrossRef]

- Sharma, S.K.; Mishra, I.M.; Sharma, M.P.; Saini, J.S. Effect of particle size on biogas generation from biomass residues. Biomass 1998, 17, 251–263. [Google Scholar] [CrossRef]

- Dumas, C.; Ghizzi Damasceno, G.S.; Barakat, A.; Carrère, H.; Steyera, J.P.; Rouau, X. Effects of grinding processes on anaerobic digestion of wheat straw. Ind. Crops Prod. 2015, 74, 450–456. [Google Scholar] [CrossRef]

- Menardo, S.; Airoldi, G.; Balsari, P. The effect of particle size and thermal pre-treatment on the methane yield of four agricultural by-products. Bioresour. Technol. 2012, 104, 708–714. [Google Scholar] [CrossRef]

- Ma, S.; Wang, H.; Li, L.; Gu, X.; Zhu, W. Enhanced biomethane production from corn straw by a novel anaerobic digestion strategy with mechanochemical pretreatment. Renew. Sustain. Energy Rev. 2021, 146, 111099. [Google Scholar] [CrossRef]

- Witaszek, K.; Pilarski, K.; Niedbała, G.; Pilarska, A.A.; Herkowiak, M. Energy efficiency of comminution and extrusion of maize substrates subjected to methane fermentation. Energies 2020, 13, 1887. [Google Scholar] [CrossRef]

- Bianchini, L.; Costa, P.; Dell’Omo, P.P.; Colantoni, A.; Cecchini, M.; Monarca, D. An industrial scale, mechanical process for improving pellet quality and biogas production from Hazelnut and Olive pruning. Energies 2021, 14, 1600. [Google Scholar] [CrossRef]

- Khan, M.U.; Usman, M.; Ashraf, M.A.; Dutta, N.; Luo, G.; Zhang, S. A review of recent advancements in pretreatment techniques of lignocellulosic materials for biogas production: Opportunities and Limitations. Chem. Eng. J. Adv. 2022, 10, 100263. [Google Scholar] [CrossRef]

- Rice, E.V.; Baird, R.B.; Eaton, A.D. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; APHA (American Public Health Association): Washington, DC, USA, 2017. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef] [PubMed]

- ANSI/ASABE S319.3: Method of Determining and Expressing Fineness of Feed Materials by Sieving, ASABE Standards; ASABE (American Society of Agricultural and Biological Engineers): St Joseph, MI, USA, 2006; p. 602.

- ENEA (Agenzia nazionale per le nuove tecnologie, l’energia e lo sviluppo economico sostenibile). Piano d’Azione Italiano per l’Efficienza Energetica. ENEA: 00196–ROMA Italia. 2014. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/2014_neeap_it_italy.pdf (accessed on 8 March 2020).

- Steindl, M.; Dandikas, V.; Lichti, F.; Höcherl, S.; Koch, K. A comprehensive study on the consequences of substituting energy crops by alternative substrates for biogas production in Germany. Renew. Energy 2023, 219, 119541. [Google Scholar] [CrossRef]

- Monch-Tegeder, M.; Lemmer, A.; Oechsner, H. Enhancement of methane production with horse manure supplement and pretreatment in a full-scale biogas process. Energy 2014, 73, 523e30. [Google Scholar] [CrossRef]

- Garuti, M.; Langone, M.; Fabbri, C.; Piccinini, S. Monitoring of full-scale hydrodynamic cavitation pretreatment in agricultural biogas plant. Bioresour. Technol. 2018, 247, 599–609. [Google Scholar] [CrossRef]

- Schievano, A.; D’Imporzano, G.; Orzi, V.; Adani, F. On-field study of anaerobic digestion full-scale plants (Part II): New approaches in monitoring and evaluating process efficiency. Bioresour. Technol. 2011, 102, 8814–8819. [Google Scholar] [CrossRef]

- Karras, T.; Thrän, D. The Costs of Straw in Germany: Development of Regional Straw Supply Costs between 2010 and 2020. Waste Biomass Valorization 2024, 15, 5369–5385. [Google Scholar] [CrossRef]

- European Commission. Report from the Commission to the European Parliament, the Council, the European Economic and Social Commitee and the Commitee of the Regions—Energy Prices and Costs in Europe; European Commission: Brussels, Belgium, 2024; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2024%3A136%3AFIN&qid=1711266005450 (accessed on 10 July 2024).

- Raud, M.; Orupõld, K.; Rocha-Meneses, L.; Rooni, V.; Träss, O.; Kikas, T. Biomass pretreatment with the Szego Mill™ for bioethanol and biogas production. Processes 2020, 8, 1327. [Google Scholar] [CrossRef]

- Sultana, A.; Kumar, A.; Harfield, D. Development of agri-pellet production cost and optimum size. Bioresour. Technol. 2010, 101, 5609–5621. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).