Particle Size Distribution and Its Impacts on Ash Deposition and Radiative Transfer during Oxy-Combustion of Rice Husk–Natural Gas

Abstract

:1. Introduction

- Can the effects of fly-ash PKE on the measured deposition/shedding rates be modeled based on available data? Since the OXY70 scenarios investigated by Wu et al. [1] and Wang et al. [2] were associated with a three-fold reduction in volumetric flow rates in comparison to the AIR scenario, the implications of this may extend beyond designing second-generation oxy-combustion systems to optimizing load-following operations involving biomass firing that are also associated with a significant (60–70%) reduction in combustor flue gas flow rates when compared to baseload operation.

- Can a PKE-critical viscosity-based criterion be employed to model the capture/deposition of RH fly-ash given the widespread variability in its composition and properties [17]? While recent efforts have focused on predicting deposition propensities based on an equilibrium-based approach that uses fly-ash compositions and temperature to estimate the melt fractions and liquidus temperatures of the fly-ash [1,18], the potential for using a PKE-critical viscosity criterion for biomass fly-ashes has been shown by Schulze et al. [19]. During this process, we also attempted to identify an appropriate model for the particle viscosity, µP, in our calculations.

- Given our current lack of knowledge regarding the relative importance of gas and particle radiation in second-generation atmospheric pressure oxy-combustion systems (cf. Table 1), we also wanted to quantify the contribution of fly-ash on the radiative transfer processes given that its concentrations would be higher at these greatly reduced flue gas volumetric flow rates. In addition to the higher particle concentrations, the generation of coarser fly-ash particles (in comparison to firing in air) may further magnify its radiation contribution.

2. Results and Discussion

2.1. Carbon Burnout

2.2. Gas Temperature

2.3. Radiant Fractions

2.4. Ash Deposition Rates Using Shrinking Core and Shrinking Sphere Methodologies

2.5. Ash Deposition Rate Predictions from Measured Fly-Ash PSD

3. Materials and Methods

4. Conclusions

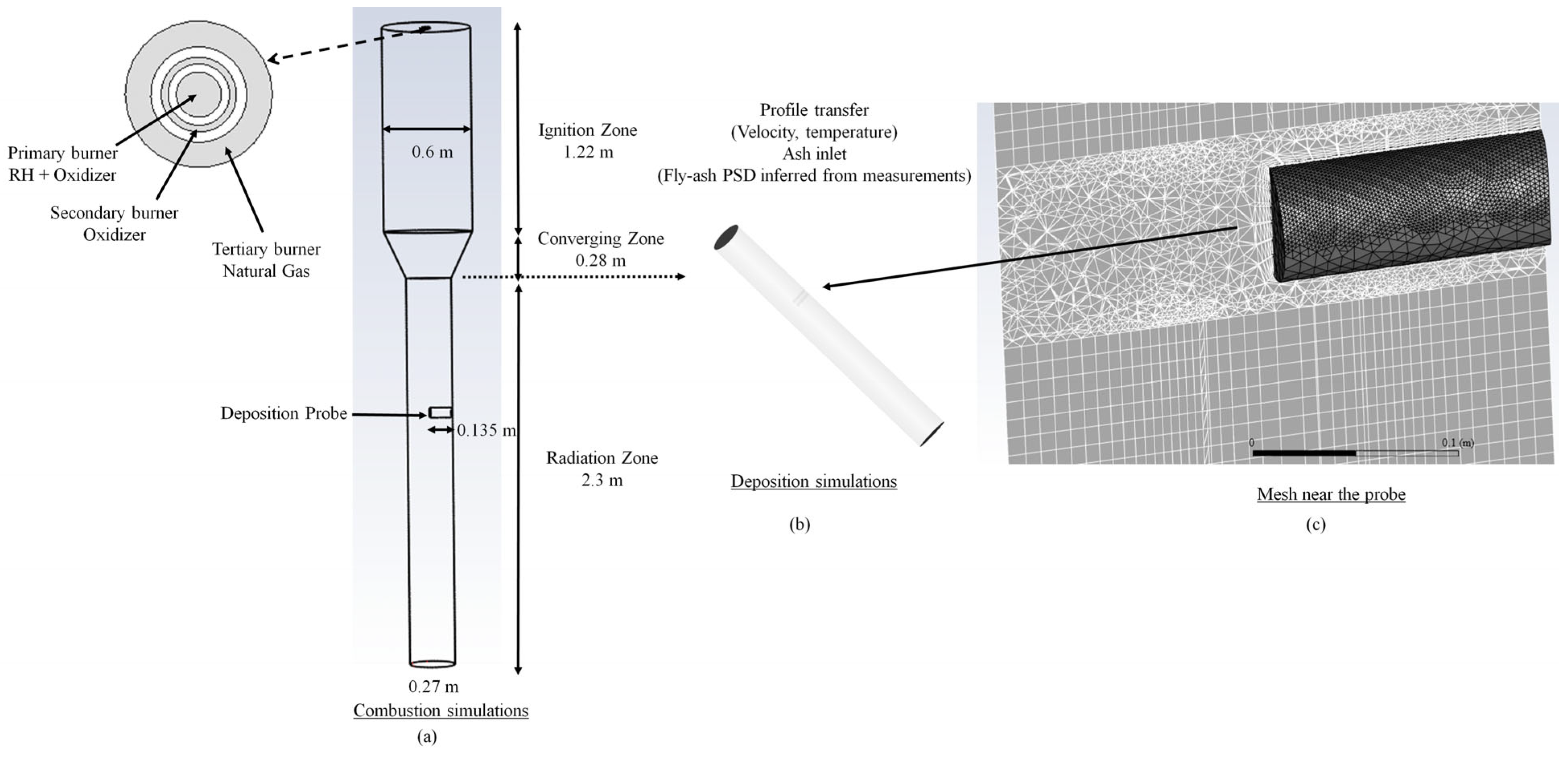

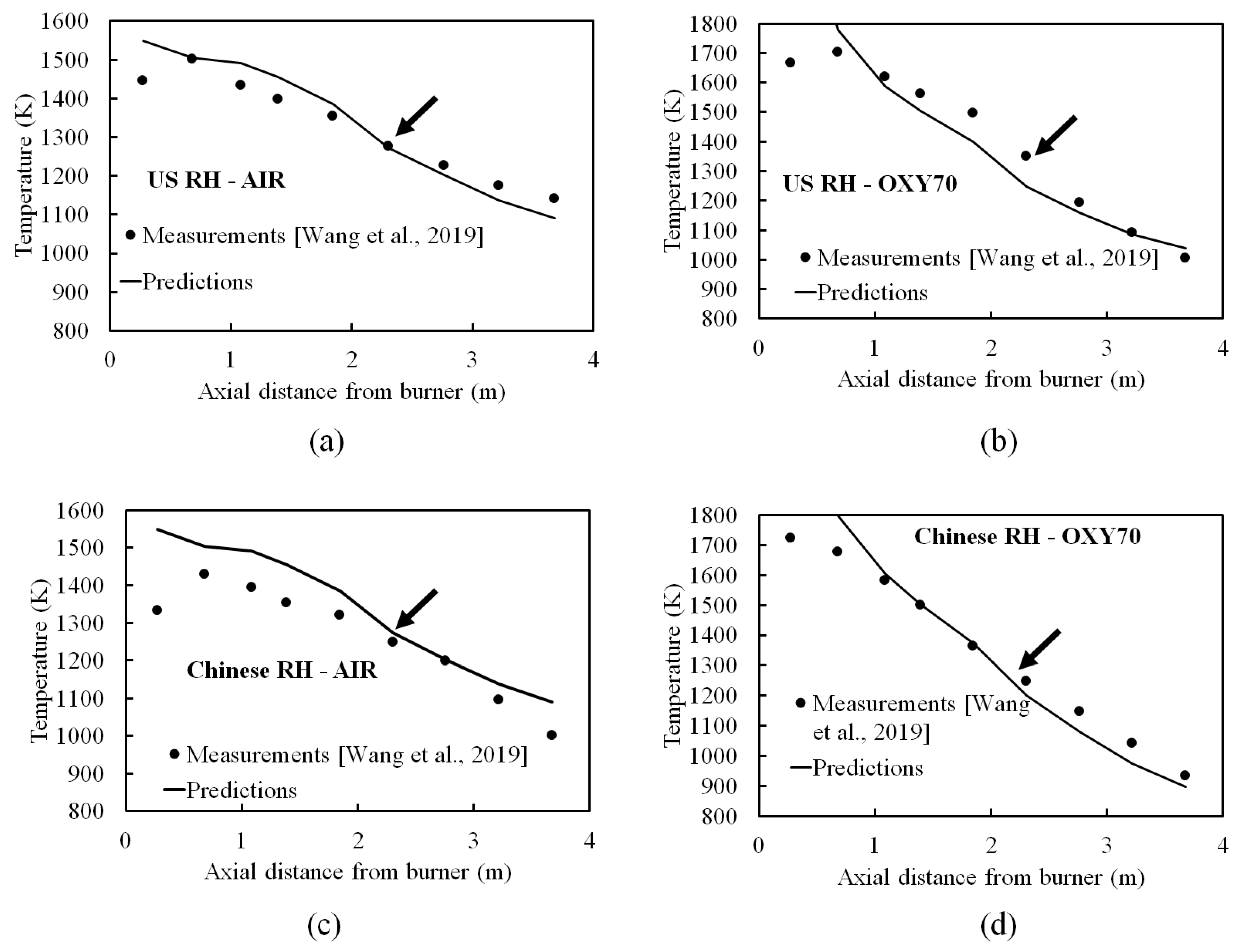

- The predicted temperature profiles along the combustor and particularly near the deposit probe agreed well with the measurements across the four scenarios, demonstrating the adequacy of our combustion modeling procedure. Concurring with experimental observations involving the combustion of several different fuels within this combustor, the simulations also showed that complete carbon burnout occurred prior to the ash deposition at the probe. In spite of the higher oxidizer content in the OXY70 scenario, the gas temperatures near the probe ranged from 1250–1350 K, which is characteristic of gas temperatures near the super heater region in full-scale boilers. Furthermore, the OXY70 scenarios were associated with a 60–70% reduction in the volumetric flow rates. Therefore, the results from this study may provide valuable insights into ash deposition characteristics under load-following operational scenarios (e.g., 35–50% of the base load) where lower velocities but approximately similar temperatures to that of the base load may be encountered.

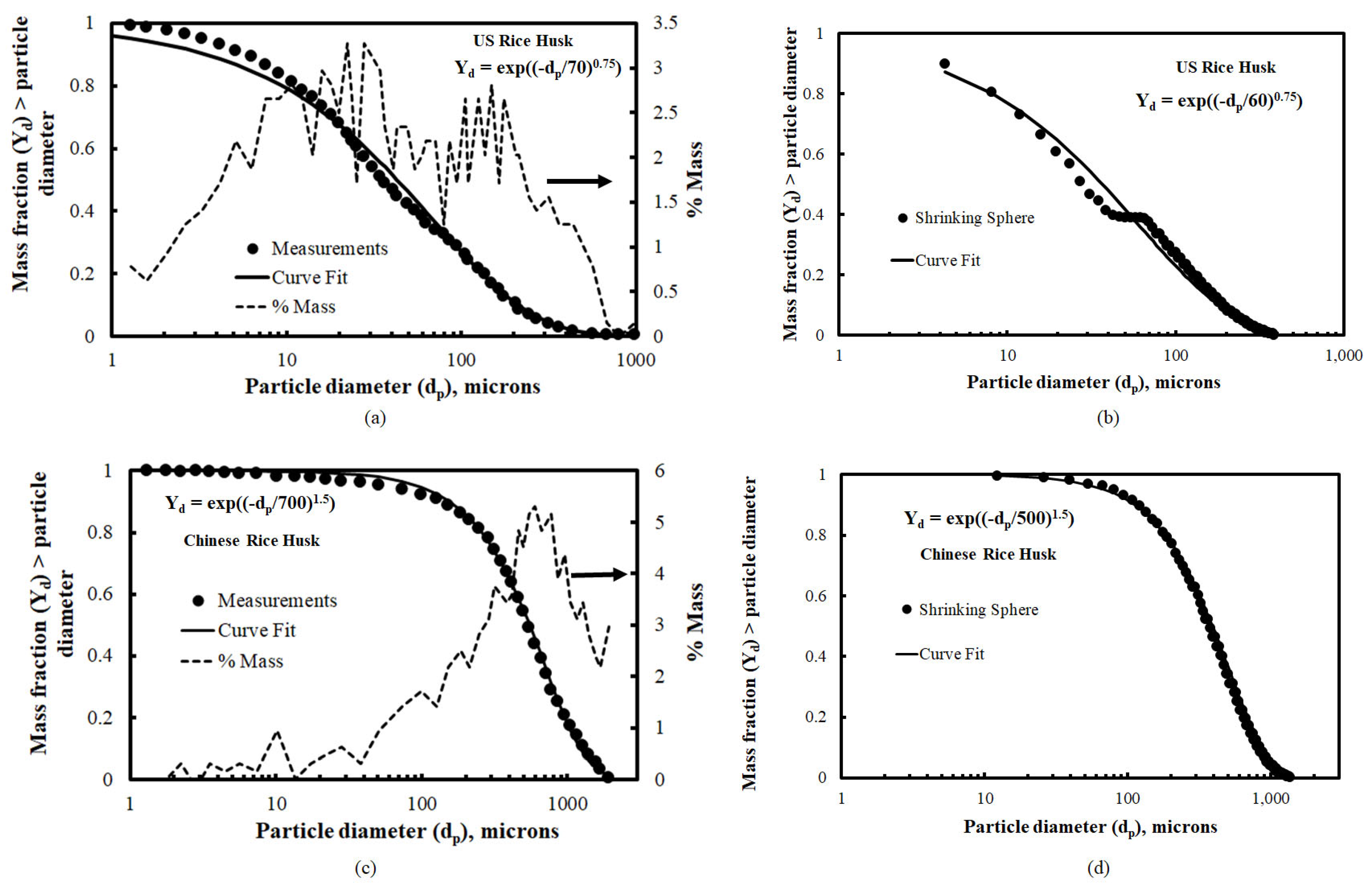

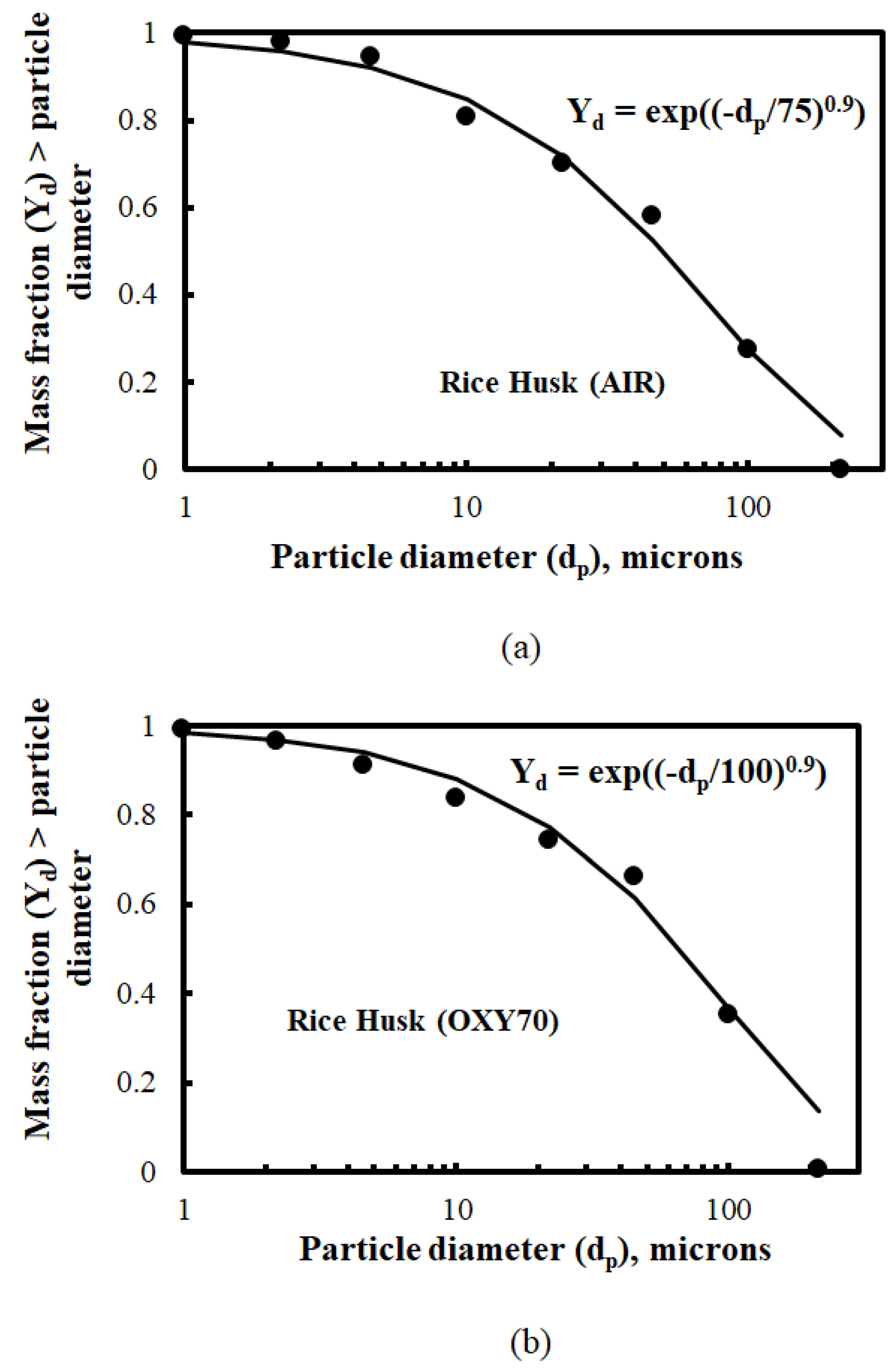

- A shrinking core modeling methodology, where the PSD stays invariant from that of the parent fuel throughout the combustion process, and a shrinking sphere methodology, where the density is held constant while the PSD varies, were adopted to assess the particle impacts on the radiation and heat extraction characteristics. Despite the wide PSD variation between the two fuels and the two methodologies, gases dominated the radiative transfer in these configurations. Radiation accounted for 80% and 95% of the overall heat transfer in the AIR and OXY70 firing scenarios, respectively.

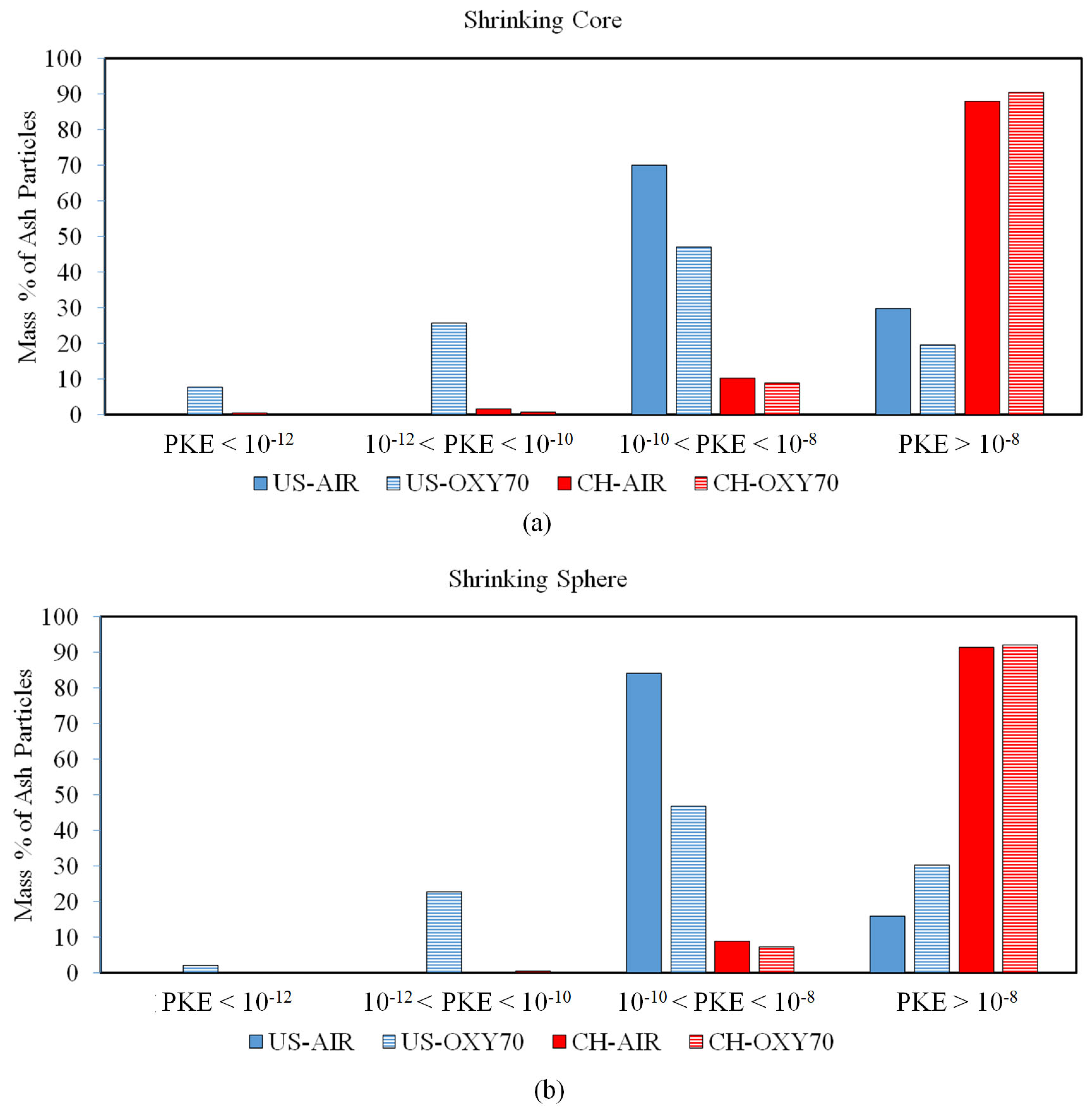

- A well-resolved boundary layer grid was employed near the deposit probe to represent the particle impaction characteristics accurately. In spite of the velocities in the OXY70 scenario being 60–70% lower, the ratios of the impaction rates (OXY70/AIR) were in the range of 1.5–2.0-times for the US RH and in the range 1.1–1.3-times for the Chinese RH when employing conventional char combustion methodologies (shrinking core and shrinking sphere). Since identical parent fuel PSDs were employed for both the AIR and OXY70 scenarios, the fly-ash PSDs near the deposit surface would also be identical near the deposit surface (following complete burnout). Therefore, the surprisingly higher impaction rates associated with the OXY70 scenario points to complex flow features near the probe along with the local segregation of larger sized particles.

- Based on viscosity measurements in similar silica-rich RH ashes, the temperature-dependent viscosity correlations proposed by Senior and Srinivasachar [23] were deemed to be sufficiently accurate to estimate the ash particle viscosity across the temperature range of interest in this study. However, the predicted deposition rates were grossly under-estimated when employing the PKE-critical viscosity-based ash capture criterion in conjunction with conventional char combustion methodologies (shrinking core and shrinking sphere) pointing to either a need for accurate fly-ash PSD information near the probe or a shortcoming of the capture criterion itself.

- To identify the source of the discrepancy, measured fly-ash PSDs near the deposit surface (that were only available for the Chinese RH) were employed in the calculations. This improved the deposition rate predictions significantly. The predictions improved further when a simple erosion model (that took the PKE and particle surface tension into account) was employed in conjunction with the capture criterion.

- When more accurate or representative fly-ash PSDs were employed in these scenarios, the impaction rates were similar in both the AIR and OXY70 conditions. However, the OXY70 scenarios showed higher ash-capturing propensities due to the lower PKE. Conversely, higher erosion rates (due to the larger PKE) were predicted in the AIR firing scenarios. Both these effects may help explain the higher deposition rates measured in OXY70 for both RHs.

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AP | Particle surface area, m2 |

| d | Diameter, m |

| E | Energy, J |

| k | Extinction coefficient, 1/m |

| PKE | Particle kinetic energy, J |

| Q | Extinction efficiency |

| Re | Reynolds number |

| Stk | Stokes Number |

| T | Temperature, K |

| u | Velocity, m/s |

| V | Particle volume, m3 |

| Greek Symbols | |

| γ | Surface tension, N/m |

| η | Efficiency |

| ρ | Density, kg/m3 |

| µ | Viscosity, kg/m-s |

| Subscripts | |

| p | Denotes particle |

References

- Wu, J.; Wang, Y.; Han, J.; Li, X.; Yu, D.; Xu, M.; Wendt, J.O.L. Ash Formation and Deposition in Oxy-fuel Combustion of Rice Husk, Coal, and Their Blend with 70% Inlet O2. Energy Fuels 2019, 34, 890–899. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Li, X.; Han, J.; Yu, D.; Xu, M.; Wendt, J.O.L. Comparison Study of Ash Partitioning and Deposition Behavior between Two Rice Husk Fuels under a 100 kW Combustor. Energy Fuels 2019, 33, 11968–11975. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Wendt, J.O.L. Ash Aerosol and Deposition Formation Mechanisms during Air/Oxy-combustion of Rice Husks in a 100 kW Combustor. Energy Fuels 2018, 32, 4391–4398. [Google Scholar] [CrossRef]

- Kleinhans, U.; Wieland, C.; Frandsen, F.J.; Spliethoff, H. Ash formation and deposition in coal and biomass fired combustion systems: Progress and challenges in the field of ash particle sticking and rebound behavior. Prog. Energy Combust. Sci. 2018, 68, 65–168. [Google Scholar] [CrossRef]

- Black, S.; Szuhánszki, J.; Pranzitelli, A.; Ma, L.; Stanger, P.J.; Ingham, D.B.; Pourkashanian, M. Effects of firing coal and biomass under oxy-fuel conditions in a power plant boiler using CFD modelling. Fuel 2013, 113, 780–786. [Google Scholar] [CrossRef]

- Seidel, T.; Krishnamoorthy, G.; Seames, W.S. Characterizing flame stability and radiative heat transfer in non-swirling oxy-coal flames using different multiphase modeling frameworks. Fuel 2019, 256, 115948. [Google Scholar] [CrossRef]

- Andersson, K.; Johansson, R.; Hjärtstam, S.; Johnsson, F.; Leckner, B. Radiation intensity of lignite-fired oxy-fuel flames. Exp. Therm. Fluid Sci. 2008, 33, 67–76. [Google Scholar] [CrossRef]

- Krishnamoorthy, G.; Sami, M.; Orsino, S.; Perera, A.; Shahnam, M.; Huckaby, E.D. Radiation modelling in oxy-fuel combustion scenarios. Int. J. Comput. Fluid Dyn. 2010, 24, 69–82. [Google Scholar] [CrossRef]

- Nakod, P.; Krishnamoorthy, G.; Sami, M.; Orsino, S. A comparative evaluation of gray and non-gray radiation modeling strategies in oxy-coal combustion simulations. Appl. Therm. Eng. 2013, 54, 422–432. [Google Scholar] [CrossRef]

- Krishnamoorthy, G.; Wolf, C. Assessing the Role of Particles in Radiative Heat Transfer during Oxy-Combustion of Coal and Biomass Blends. J. Combust. 2015, 2015, 1–15. [Google Scholar] [CrossRef]

- Zhang, J.; Ito, T.; Ito, S.; Riechelmann, D.; Fujimori, T. Numerical investigation of oxy-coal combustion in a large-scale furnace: Non-gray effect of gas and role of particle radiation. Fuel 2015, 139, 87–93. [Google Scholar] [CrossRef]

- Yang, X.; Clements, A.; Szuhánszki, J.; Huang, X.; Moguel, O.F.; Li, J.; Gibbins, J.; Liu, Z.; Zheng, C.; Ingham, D.; et al. Prediction of the radiative heat transfer in small and large scale oxy-coal furnaces. Appl. Energy 2018, 211, 523–537. [Google Scholar] [CrossRef]

- Adams, B.R.; Hosler, T.R. Pressure and particle property impacts on radiation in oxy-coal combustion. Fuel 2019, 239, 667–676. [Google Scholar] [CrossRef]

- Kez, V.; Consalvi, J.-L.; Liu, F.; Gronarz, T.; Ströhle, J.; Kneer, R.; Epple, B. Investigation of gas and particle radiation modelling in wet oxy-coal combustion atmospheres. Int. J. Heat Mass Transf. 2019, 133, 1026–1040. [Google Scholar] [CrossRef]

- Guo, J.; Hu, F.; Jiang, X.; Li, P.; Liu, Z. Effects of gas and particle radiation on IFRF 2.5 MW swirling flame under oxy-fuel combustion. Fuel 2019, 263, 116634. [Google Scholar] [CrossRef]

- Johansson, R.; Gronarz, T.; Kneer, R. Influence of Index of Refraction and Particle Size Distribution on Radiative Heat Transfer in a Pulverized Coal Combustion Furnace. J. Heat Transf. 2017, 139, 042702. [Google Scholar] [CrossRef]

- Chaloupková, V.; Ivanova, T.; Hutla, P.; Špunarová, M. Ash melting behavior of rice straw and calcium additives. Agriculture 2021, 11, 1282. [Google Scholar] [CrossRef]

- Atallah, E.; Defoort, F.; Pisch, A.; Dupont, C. Thermodynamic equilibrium approach to predict the inorganic interactions of ash from biomass and their mixtures: A critical assessment. Fuel Process. Technol. 2022, 235, 107369. [Google Scholar] [CrossRef]

- Schulze, K.; Hofmeister, G.; Joeller, M.; Scharler, R.; Obernberger, I.; Korbee, R.; Cieplik, M. Development and evaluation of a flexible model for CFD simulation of ash deposit formation in biomass fired boilers. In Proceedings of the International Conference “Impacts of Fuel Quality on Power Production”, EPRI Report (No. 1014551), Snowbird, UT, USA, 29 October–3 November 2007; pp. 7–95. [Google Scholar]

- Krishnamoorthy, G. A new weighted-sum-of-gray-gases model for oxy-combustion scenarios. Int. J. Energy Res. 2013, 37, 1752–1763. [Google Scholar] [CrossRef]

- Krishnamoorthy, G. Aerodynamic influences on the outer ash deposition rates during oxy-coal combustion. Clean. Chem. Eng. 2022, 3, 100057. [Google Scholar] [CrossRef]

- Krishnamoorthy, G.; Kuznia, M.E.; Smith, K.M.; Seames, W.S.; Wang, Y.; Wendt, J.O. Aerodynamic effects on outer ash deposition rates in second generation atmospheric pressure oxy-coal combustion systems. Fuel 2021, 303, 121217. [Google Scholar] [CrossRef]

- Senior, C.L.; Srinivasachar, S. Viscosity of Ash Particles in Combustion Systems for Prediction of Particle Sticking. Energy Fuels 1995, 9, 277–283. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, H.; Li, L.; Zhou, B. Ash Deposit Shedding during Co-combustion of Coal and Rice Hull Using a Digital Image Technique in a Pilot-Scale Furnace. Energy Fuels 2013, 27, 7126–7137. [Google Scholar] [CrossRef]

- Dizaji, H.B.; Zeng, T.; Hölzig, H.; Bauer, J.; Klöß, G.; Enke, D. Ash transformation mechanism during combustion of rice husk and rice straw. Fuel 2022, 307, 121768. [Google Scholar] [CrossRef]

- Krishnamoorthy, G. Modeling Ash Deposition and Shedding during Oxy-Combustion of Coal/Rice Husk Blends at 70% Inlet O2. Int. J. Coal Sci. Technol. 2023. accepted. [Google Scholar] [CrossRef]

- Weber, R.; Schaffel-Mancini, N.; Mancini, M.; Kupka, T. Fly ash deposition modelling: Requirements for accurate predictions of particle impaction on tubes using RANS-based computational fluid dynamics. Fuel 2013, 108, 586–596. [Google Scholar] [CrossRef]

- ANSYS, Inc. ANSYS Fluent Theory Guide; Release 21.1; ANSYS, Inc.: Canonsburg, PA, USA, 2021. [Google Scholar]

- Bäckström, D.; Gall, D.; Pushp, M.; Johansson, R.; Andersson, K.; Pettersson, J.B. Particle composition and size distribution in coal flames–The influence on radiative heat transfer. Exp. Therm. Fluid Sci. 2015, 64, 70–80. [Google Scholar] [CrossRef]

- Ates, C.; Selçuk, N.; Kulah, G. Influence of fly ash composition on non-gray particle radiation in combusting systems. J. Quant. Spectrosc. Radiat. Transf. 2018, 215, 25–40. [Google Scholar] [CrossRef]

- Jiayu, L.; Xiaobing, G. Influence of Particle Morphology on High-Temperature Heat Flux to Combustor Walls. J. Thermophys. Heat Transf. 2019, 33, 574–579. [Google Scholar] [CrossRef]

- Schiemann, M.; Gronarz, T.; Graeser, P.; Gorewoda, J.; Kneer, R.; Scherer, V. A correlation between char emissivity and temperature. Fuel 2019, 256, 115889. [Google Scholar] [CrossRef]

- Pörtner, L.; Gu, Y.; Schiemann, M. Investigation of Pulverized Biomass and Coal Char Emissivity. Energies 2020, 13, 4620. [Google Scholar] [CrossRef]

- Doner, N.; Topal, H.; Aygahoglu, A.; Sen, F.; Karimi-Maleh, H. Study on particle radiative properties of lignite, hard coal and biomass fly ashes in the infrared wavelength range. Chemosphere 2021, 291, 132719. [Google Scholar] [CrossRef]

- Zhou, H.; Hu, S. Numerical simulation of ash deposition behavior with a novel erosion model using dynamic mesh. Fuel 2020, 286, 119482. [Google Scholar] [CrossRef]

| Reference | Summary |

|---|---|

| K. Andersson et al. [7] | OXY 25–29 scenarios were investigated in a 100 kW furnace. A large fraction of the radiation was emitted by particles (assumed to be soot). An increase in the CO2 concentration in the OXY scenarios did not impact the radiative fluxes if the temperature was identical to combustion in air. A wavelength-dependent complex index of refraction was employed for soot, and its volume fraction was modeled (not measured). |

| G. Krishnamoorthy et al. [8] | Dry- and wet-recycle scenarios were investigated at lab- and full-scale (300 MW) geometries. Particle radiation dominated at small scales, and inaccuracies in the gas radiation modeling did not impact the predictions at this scale. Fuel-conversion-dependent particle radiative properties were employed. However, gas radiation became more important at larger scales, thereby requiring the use of accurate emissivity models corresponding to the H2O/CO2 ratios within the boiler. |

| P. Nakod et al. [9] | Dry- and wet-recycle scenarios were investigated at lab- and full-scale (300 MW) geometries. Particle radiation dominated at small scales, and no differences were found when employing either a gray or non-gray radiation model for the gas phase. However, gas radiation became more important at larger scales, and employing an accurate non-gray model for gas radiative properties was deemed necessary. Particle radiative properties were modeled based on fuel conversion. |

| G. Krishnamoorthy and C. Wolf [10] | Simulations of air and oxy-combustion of coal/biomass blends in a 0.5 MW combustion test facility were carried out. Accounting for the fuel-conversion-dependent particle radiative property variations was determined to be important as opposed to employing constant particle radiative properties. The lower gas flow rates through the furnace during oxy-combustion resulted in higher particle concentrations and particle extinction coefficients when compared against combustion in air. The resolution of the particle PSD and changes to PSD due to particle swelling had an impact on the incident radiative fluxes. Isotropic and forward scattering phase functions resulted in identical radiative fluxes. |

| J. Zhang et al. [11] | Simulations of a prototypical furnace as well as a front-wall-fired 100 MW boiler were carried out. Contrary to a previous study [9], the wall radiative fluxes in the boiler were relatively insensitive with either the gray or non-gray gas property model. This suggested that the particle temperature could be employed to calculate the non-gray weighting factors for particle emission. |

| X. Yang et al. [12] | In a small-scale furnace (250 kW), both gas and particle radiation were deemed to be important. A higher particle emission was predicted when employing constant radiative properties. However, gas radiation dominated at larger scales (35 MW). The scattering efficiencies were in the range 0.1–0.4 based on the Mie theory. |

| B.R. Adams and T.R. Hosler [13] | Smaller ash particles, by virtue of their higher concentrations, could increase the scattering and heat fluxes. Forward scattering was a reasonable first approximation, but the phase function became more important at smaller sizes. An accurate representation of the particle size distribution was important in calculating the absorption and scattering coefficients. However, a Sauter mean diameter could be used with reasonable accuracy for radiation calculations if a single particle size must be used to represent a poly-disperse particle distribution. |

| V. Kez et al. [14] | Radiative transfer calculations were carried out in a prototypical 2D geometry representative of wet oxy-combustion. Temperature, specie, coal and ash concentration profiles were represented as functional forms. Particle radiation accounted for 50% of the radiative transfer. The choice of the complex refractive index for ash particles strongly impacted the results. |

| J. Guo et al. [15] | In a 2.5 MW furnace, radiation in the flame zone was dominated by particle contributions, whereas the burnout region was dominated by gas. Particle property variation with burnout was important, otherwise the particle radiation was over-estimated during oxy-fuel combustion. |

| Physics Being Modeled | Modeling Option |

|---|---|

| Particle devolatilization (heterogeneous) | Constant rate (50, 1/s) |

| Char oxidation (heterogeneous) | Kinetic/diffusion-limited: shrinking core (PSD remains unchanged from that of parent fuel), shrinking sphere * (density fixed at 1700 kg/m3 and PSD varies depending on mass consumption) |

| Volatile combustion (homogeneous) to form products: CO, H2O, N2, SO2 | Finite rate/eddy dissipation |

| CO oxidation to form CO2 (homogeneous) | Finite rate/eddy dissipation |

| Turbulence | Realizable k-epsilon |

| Particle drag law | Morsi–Alexander |

| Model describing radiative transport | Discrete ordinates |

| Particle radiative property | Particle-burnout-dependent absorption (Qabs) and scattering efficiencies (Qscat) [10] * |

| Particle scattering phase function | Anisotropic (forward scattering) |

| Gas-phase radiative property | Non-gray weighted sum of gray gases [20] * |

| Ash capture/deposition | Particle-kinetic-energy-critical viscosity-based criterion [21] * |

| Ash shedding | Particle-kinetic-energy-based criterion * |

| Radiative Fraction (Gas + Particle) | Radiative Fraction Gas Only (Without Particle Radiation) | |

|---|---|---|

| US RH AIR | 81 | 80 |

| Chinese RH AIR | 83 | 82 |

| US RH OXY70 | 95 | 95 |

| Chinese RH OXY70 | 95 | 95 |

| Units: g/m2-h | Measured Deposition Rates | Predicted Deposition Rates (Shrinking Core) | Predicted Deposition Rates (Shrinking Sphere) | Predicted Impaction Rates (Shrinking Core) () | Predicted Impaction Rates (Shrinking Sphere) |

|---|---|---|---|---|---|

| US RH AIR | 160 ± 70 | 0 | 0 | 250 (16) | 307 (19) |

| US RH OXY70 | 220 | 13 | 17 | 475 (30) | 484 (30) |

| CH RH AIR | 30 * | 1 | 1 | 489 (68) | 466 (65) |

| CH RH OXY70 | 160 * | 1 | 2 | 542 (75) | 600 (83) |

| Units: g/m2-h | Measured Deposition Rates | Predicted Impaction Rates | Predicted Deposition Rates (Without Erosion) | Predicted Erosion Rates | Predicted Deposition Rates (With Erosion) | Predicted Capture Efficiency | Predicted Erosion Efficiency |

|---|---|---|---|---|---|---|---|

| CH RH AIR | 30 * | 117 (16) | 86 | 24 | 62 | 74 | 28 |

| CH RH OXY70 | 160 * | 124 (17) | 105 | 12 | 93 | 85 | 12 |

| (Mean Diameter, Spread) | Predicted Impaction Rates g/m2-h | Predicted Deposition Rates (Without Erosion) g/m2-h | Predicted Erosion Rates g/m2-h | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (35, 1.1) | (50, 1.1) | (50, 0.9) | (35, 1.1) | (50, 1.1) | (50, 0.9) | (35, 1.1) | (50, 1.1) | (50, 0.9) | |

| US RH AIR | 166 (23) | 234 (15) | 225 (14) | 67 (41) | 69 (30) | 60 (26) | 5 (7) | 18 (25) | 27 (46) |

| US RH OXY70 | 176 (25) | 238 (15) | 230 (14) | 134 (76) | 152 (64) | 133 (58) | 0 (0) | 3 (2) | 7 (5) |

| Proximate Analysis (wt. %) | Ultimate Analysis (wt.%, Dry Ash Free) | |||

|---|---|---|---|---|

| US RH | Fixed Carbon | 9.22 | C | 28.47 |

| Volatiles | 48.96 | H | 4.15 | |

| Ash | 33.67 | N | 1.05 | |

| Moisture | 8.16 | S | 0.1 | |

| HHV(kJ/kg) | 11551 | O | 24.42 | |

| Chinese RH | Fixed Carbon | 13.75 | C | 35.78 |

| Volatiles | 60.76 | H | 5.08 | |

| Ash | 15.08 | N | 0.44 | |

| Moisture | 10.41 | S | 0.082 | |

| HHV(kJ/kg) | 14576 | O | 33.13 | |

| US RH AIR | US RH OXY70 | Chinese RH AIR | Chinese RH OXY70 | |

|---|---|---|---|---|

| RH mass flow rate (kg/h) | 0.86 | 0.86 | 0.86 | 0.86 |

| Natural gas mass flow rate (kg/h) (tertiary burner) | 2.0 | 2.0 | 2.0 | 2.0 |

| Primary burner oxidizer mass flow rate (kg/h) | 10.8 | 10.8 | 10.8 | 10.8 |

| Primary burner species concentrations (mol%) | ||||

| O2 | 21 | 21 | 21 | 21 |

| N2 | 79 | 0 | 79 | 0 |

| CO2 | 0 | 79 | 0 | 79 |

| Secondary burner oxidizer mass flow rate (kg/h) | 30.6 | 7.2 | 30.6 | 7.2 |

| Secondary burner species concentrations (mol%) | ||||

| O2 | 21 | 100 | 21 | 100 |

| N2 | 79 | 0 | 79 | 0 |

| CO2 | 0 | 0 | 0 | 0 |

| Reference | Summary |

|---|---|

| Bäckström et al. [29] | Qabs of coal and ash particles of size 10 µm were approximately 1 and 0.5, respectively, in the IR region of 1–3 µm. The corresponding Qscat were 1.5 at this size range but increased to as high as 4 for smaller ash particles (1 µm). |

| Ates et al. [30] | Five different complex index of refraction models were compared across five ash composition variations. In the IR region of 3–10 µm, Qabs was between 0 and 1 across all the particles sizes between 10–200 µm. Qscat values were approximately 1.5 across this size range but increased to as high as 4 for smaller ash particles (1 µm). In conditions representative of a PC fired furnace, kscat was greater than kabs. |

| Jiayu and Xiaobing [31] | At particle volume fractions that were representative of the combustion zone of boilers (~10−5), Qabs and Qscat of the coal and fly-ash particles were estimated to be about 1.0 and 1.5, respectively, for the particle size parameters (x = πd/λ) of interest in this study. However, the heat fluxes seemed to be more dependent on the phase function and more significant for smaller-sized particles |

| Schiemann et al. [32] | Spectrally averaged emissivity of particles was reported in specific sizes. The total emissivity was shown to decrease with decreasing the particle size and increasing the temperature. A simple linear correlation between emissivity and temperature was proposed. |

| Pörtner et al. [33] | The total emissivity of both coal and biomass char were shown to decrease with increasing the temperature. A simple linear correlation between emissivity and temperature was proposed. |

| Doner et al. [34] | Absorbance characteristics of lignite coal, biomass and hard coal were investigated and reported. For Sauter mean diameters in the range of 5–10 µm, Qabs and Qscat values of 1.0 and 1.5, respectively, seemed to be good approximations in the IR region of interest. The study highlighted the importance of determining the k index of the complex index of refraction. |

| Qabs | Qscat | Qscat/Qabs | |

|---|---|---|---|

| Parent fuel | 1.13 | 1.3 | 1.15 |

| Char | 0.59 | 1.5 | 2.54 |

| Ash | 0.05 | 1.7 | 34.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krishnamoorthy, G. Particle Size Distribution and Its Impacts on Ash Deposition and Radiative Transfer during Oxy-Combustion of Rice Husk–Natural Gas. Methane 2023, 2, 218-240. https://doi.org/10.3390/methane2020015

Krishnamoorthy G. Particle Size Distribution and Its Impacts on Ash Deposition and Radiative Transfer during Oxy-Combustion of Rice Husk–Natural Gas. Methane. 2023; 2(2):218-240. https://doi.org/10.3390/methane2020015

Chicago/Turabian StyleKrishnamoorthy, Gautham. 2023. "Particle Size Distribution and Its Impacts on Ash Deposition and Radiative Transfer during Oxy-Combustion of Rice Husk–Natural Gas" Methane 2, no. 2: 218-240. https://doi.org/10.3390/methane2020015

APA StyleKrishnamoorthy, G. (2023). Particle Size Distribution and Its Impacts on Ash Deposition and Radiative Transfer during Oxy-Combustion of Rice Husk–Natural Gas. Methane, 2(2), 218-240. https://doi.org/10.3390/methane2020015