Biogas and Syngas Production from Sewage Sludge: A Sustainable Source of Energy Generation

Abstract

:1. Introduction

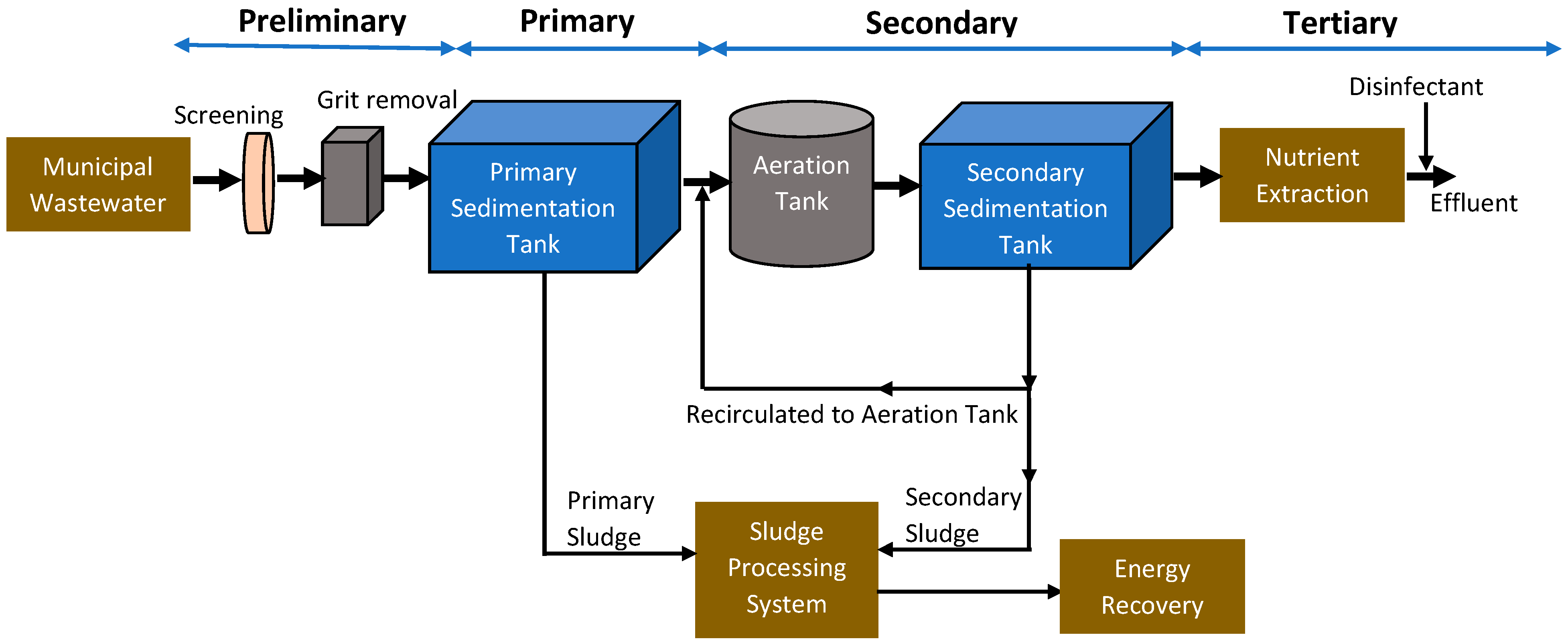

2. Sewage Sludge: A Product of Wastewater

3. Biogas Production from Sewage Sludge through Anaerobic Digestion

4. Sewage Sludge Pretreatment for Enhanced Biogas Quality

5. Syngas Production from Sewage Sludge via Gasification

6. Improvement Measures for the Gasification of Sewage Sludge

7. Application and Economic Feasibility of Anaerobic Digestion and Gasification

8. Limitation of Anaerobic Digestion and Gasification of Sewage Sludge

9. Conclusions and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lorenzo-Toja, Y.; Vázquez-Rowe, I.; Amores, M.J.; Termes-Rifé, M.; Marín-Navarro, D.; Moreira, M.T.; Feijoo, G. Benchmarking wastewater treatment plants under an eco-efficiency perspective. Sci. Total Environ. 2016, 566, 468–479. [Google Scholar] [CrossRef]

- Qi, G.; Li, C.; Mei, Y.; Xu, W.; Shen, Y.; Gao, X. A new strategy for nitrogen containing compounds recovery from gaseous products during sewage sludge pyrolysis under vacuum condition. J. Environ. Chem. Eng. 2020, 8, 104452. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Z.; Li, X.; Liu, Y.J.E.S.; Research, P. Distribution and transformation behaviors of heavy metals and phosphorus during hydrothermal carbonization of sewage sludge. Environ. Sci. Pollut. Res. 2020, 27, 17109–17122. [Google Scholar] [CrossRef] [PubMed]

- Gherghel, A.; Teodosiu, C.; De Gisi, S.J. A review on wastewater sludge valorisation and its challenges in the context of circular economy. J. Clean. Prod. 2019, 228, 244–263. [Google Scholar] [CrossRef]

- Xu, Z.-X.; Song, H.; Zhang, S.; Tong, S.-Q.; He, Z.-X.; Wang, Q.; Li, B.; Hu, X. Co-hydrothermal carbonization of digested sewage sludge and cow dung biogas residue: Investigation of the reaction characteristics. Energy 2019, 187, 115972. [Google Scholar] [CrossRef]

- Gao, N.; Kamran, K.; Quan, C.; Williams, P. Thermochemical conversion of sewage sludge: A critical review. Prog. Energy Combust. Sci. 2020, 79, 100843. [Google Scholar] [CrossRef]

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Djandja, O.S.; Yin, L.-X.; Wang, Z.-C.; Duan, P.-G. From wastewater treatment to resources recovery through hydrothermal treatments of municipal sewage sludge: A critical review. Process. Saf. Environ. Prot. 2021, 151, 101–127. [Google Scholar] [CrossRef]

- Saha, O.; Sultana, A.; Nikkon Sarker, M.; Siddiqui, A.R.; Hossen, F.; Mukharjee, S.K. Biomass as a renewable resource for energy and chemical products. Sci. J. Energy Eng. 2017, 5, 146. [Google Scholar] [CrossRef]

- Nwokolo, N.; Mukumba, P.; Obileke, K.; Enebe, M.J. Waste to energy: A focus on the impact of substrate type in biogas production. Processes 2020, 8, 1224. [Google Scholar] [CrossRef]

- Winkler, M.-K.; Bennenbroek, M.; Horstink, F.; Van Loosdrecht, M.; Van de Pol, G.-J. The biodrying concept: An innovative technology creating energy from sewage sludge. Bioresour. Technol. 2013, 147, 124–129. [Google Scholar] [CrossRef] [PubMed]

- Chrispim, M.C.; Scholz, M.; Nolasco, M.A. A framework for resource recovery from wastewater treatment plants in megacities of developing countries. Environ. Res. 2020, 188, 109745. [Google Scholar] [CrossRef] [PubMed]

- Svardal, K.; Kroiss, H. Energy requirements for waste water treatment. Water Sci. Technol. 2011, 64, 1355–1361. [Google Scholar] [CrossRef]

- Liu, X.; Chang, F.; Wang, C.; Jin, Z.; Wu, J.; Zuo, J.; Wang, K. Pyrolysis and subsequent direct combustion of pyrolytic gases for sewage sludge treatment in China. Appl. Therm. Eng. 2018, 128, 464–470. [Google Scholar] [CrossRef]

- Ferreira, L.; Donoso-Bravo, A.; Nilsen, P.; Fdz-Polanco, F.; Pérez-Elvira, S. Influence of thermal pretreatment on the biochemical methane potential of wheat straw. Bioresour. Technol. 2013, 143, 251–257. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; Liu, X.; Chen, C.; Xiao, X.; Feng, L.; He, Y.; Liu, G. Evaluating methane production from anaerobic mono-and co-digestion of kitchen waste, corn stover, and chicken manure. Energy Fuels 2013, 27, 2085–2091. [Google Scholar] [CrossRef]

- Nhuchhen, D.R.; Salam, P.A. Estimation of higher heating value of biomass from proximate analysis: A new approach. Fuel 2012, 99, 55–63. [Google Scholar] [CrossRef]

- Janke, L.; Leite, A.; Nikolausz, M.; Schmidt, T.; Liebetrau, J.; Nelles, M.; Stinner, W. Biogas production from sugarcane waste: Assessment on kinetic challenges for process designing. Int. J. Mol. Sci. 2015, 16, 20685–20703. [Google Scholar] [CrossRef] [PubMed]

- Contreras, L.; Schelle, H.; Sebrango, C.; Pereda, I. Methane potential and biodegradability of rice straw, rice husk and rice residues from the drying process. Water Sci. Technol. 2012, 65, 1142–1149. [Google Scholar] [CrossRef]

- Shukla, A.; Kumar, S. A comparative study of sugarcane bagasse gasification and direct combustion. Int. J. Appl. Eng. Res. 2017, 12, 14739–14745. [Google Scholar]

- Nanda, S.; Reddy, S.N.; Vo, D.V.N.; Sahoo, B.N.; Kozinski, J.A. Catalytic gasification of wheat straw in hot compressed (subcritical and supercritical) water for hydrogen production. Energy Sci. Eng. 2018, 6, 448–459. [Google Scholar] [CrossRef]

- Kate, G.; Chaurasia, A. Gasification of rice husk in two-stage gasifier to produce syngas, silica and activated carbon. Energy Sources 2018, 40, 466–471. [Google Scholar] [CrossRef]

- Obileke, K.; Mamphweli, S.; Meyer, E.L.; Makaka, G.; Nwokolo, N. Design and fabrication of a plastic biogas digester for the production of biogas from cow dung. J. Eng. 2020, 2020, 1848714. [Google Scholar] [CrossRef]

- Ngan, N.V.C.; Chan, F.M.S.; Nam, T.S.; Van Thao, H.; Maguyon-Detras, M.C.; Hung, D.V.; Cuong, D.M.; Van Hung, N. Anaerobic digestion of rice straw for biogas production. In Sustainable Rice Straw Management; Springer: Cham, Switzerland, 2020; pp. 65–92. [Google Scholar] [CrossRef]

- Atelge, M.; Krisa, D.; Kumar, G.; Eskicioglu, C.; Nguyen, D.D.; Chang, S.W.; Atabani, A.; Al-Muhtaseb, A.H.; Unalan, S.J.W.; Valorization, B. Biogas production from organic waste: Recent progress and perspectives. Waste Biomass-Valorization 2020, 11, 1019–1040. [Google Scholar] [CrossRef]

- Hanum, F.; Yuan, L.C.; Kamahara, H.; Aziz, H.A.; Atsuta, Y.; Yamada, T.; Daimon, H. Treatment of sewage sludge using anaerobic digestion in Malaysia: Current state and challenges. Front. Energy Res. 2019, 7, 19. [Google Scholar] [CrossRef]

- Chow, W.L.; Chong, S.; Lim, J.W.; Chan, Y.J.; Chong, M.F.; Tiong, T.J.; Chin, J.K.; Pan, G.-T. Anaerobic co-digestion of wastewater sludge: A review of potential co-substrates and operating factors for improved methane yield. Processes 2020, 8, 39. [Google Scholar] [CrossRef]

- Nguyen, V.K.; Chaudhary, D.K.; Dahal, R.H.; Trinh, N.H.; Kim, J.; Chang, S.W.; Hong, Y.; La, D.D.; Nguyen, X.C.; Ngo, H. Review on pretreatment techniques to improve anaerobic digestion of sewage sludge. Fuel 2021, 285, 119105. [Google Scholar] [CrossRef]

- Liew, C.S.; Yunus, N.M.; Chidi, B.S.; Lam, M.K.; Goh, P.S.; Mohamad, M.; Sin, J.C.; Lam, S.M.; Lim, J.W.; Lam, S.S. A review on recent disposal of hazardous sewage sludge via anaerobic digestion and novel composting. J. Hazard. Mater. 2022, 423, 126995. [Google Scholar] [CrossRef]

- Kamyab, H.; Yuzir, A.; Ashokkumar, V.; Hosseini, S.E.; Balasubramanian, B.; Kirpichnikova, I. Review of the application of gasification and combustion technology and waste-to-energy technologies in sewage sludge treatment. Fuel 2022, 316, 123199. [Google Scholar]

- Werle, S.; Sobek, S.J.E.S.; Research, P. Gasification of sewage sludge within a circular economy perspective: A Polish case study. Environ. Sci. Pollut. Res. 2019, 26, 35422–35432. [Google Scholar] [CrossRef] [PubMed]

- Bezirgiannidis, A.; Chatzopoulos, P.; Tsakali, A.; Ntougias, S.; Melidis, P. Renewable energy recovery from sewage sludge derived from chemically enhanced precipitation. Renew. Energy 2020, 162, 1811–1818. [Google Scholar] [CrossRef]

- Valipour, A.; Raman, V.K.; Ahn, Y.-H. Effectiveness of domestic wastewater treatment using a bio-hedge water hyacinth wetland system. Water 2015, 7, 329–347. [Google Scholar] [CrossRef]

- Scherson, Y.D.; Criddle, C.S. Recovery of freshwater from wastewater: Upgrading process configurations to maximize energy recovery and minimize residuals. Environ. Sci. Technol. 2014, 48, 8420–8432. [Google Scholar] [CrossRef]

- Oladejo, J.; Shi, K.; Luo, X.; Yang, G.; Wu, T. A review of sludge-to-energy recovery methods. Energies 2018, 12, 60. [Google Scholar] [CrossRef]

- Ramalho, R.S. Introduction to Wastewater Treatment Processes; Elsevier: Amsterdam, The Netherlands, 1983. [Google Scholar]

- Syed-Hassan, S.S.A.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Thermochemical processing of sewage sludge to energy and fuel: Fundamentals, challenges and considerations. Renew. Sustain. Energy Rev. 2017, 80, 888–913. [Google Scholar] [CrossRef]

- Gupta, V.K.; Ali, I.; Saleh, T.A.; Nayak, A.; Agarwal, S. Chemical treatment technologies for waste-water recycling—An overview. RSC Adv. 2012, 2, 6380–6388. [Google Scholar] [CrossRef]

- Luostarinen, S.; Luste, S.; Sillanpää, M. Increased biogas production at wastewater treatment plants through co-digestion of sewage sludge with grease trap sludge from a meat processing plant. Bioresour. Technol. 2009, 100, 79–85. [Google Scholar] [CrossRef]

- Martínez, E.J.; Rosas, J.G.; Sotres, A.; Moran, A.; Cara, J.; Sánchez, M.E.; Gómez, X. Codigestion of sludge and citrus peel wastes: Evaluating the effect of biochar addition on microbial communities. Biochem. Eng. J. 2018, 137, 314–325. [Google Scholar] [CrossRef]

- Chen, J.; Liu, S.; Wang, Y.; Huang, W.; Zhou, J. Effect of different hydrolytic enzymes pretreatment for improving the hydrolysis and biodegradability of waste activated sludge. Water Sci. Technol. 2018, 2017, 592–602. [Google Scholar] [CrossRef] [PubMed]

- Burgess, J.; Meeker, M.; Minton, J.; O’Donohue, M. International research agency perspectives on potable water reuse. Environ. Sci. Water Res. Technol. 2015, 1, 563–580. [Google Scholar] [CrossRef]

- Raheem, A.; Sikarwar, V.S.; He, J.; Dastyar, W.; Dionysiou, D.D.; Wang, W.; Zhao, M. Opportunities and challenges in sustainable treatment and resource reuse of sewage sludge: A review. Chem. Eng. J. 2018, 337, 616–641. [Google Scholar] [CrossRef]

- Cieślik, B.M.; Namieśnik, J.; Konieczka, P. Review of sewage sludge management: Standards, regulations and analytical methods. J. Clean. Prod. 2015, 90, 1–15. [Google Scholar] [CrossRef]

- Samolada, M.; Zabaniotou, A. Comparative assessment of municipal sewage sludge incineration, gasification and pyrolysis for a sustainable sludge-to-energy management in Greece. Waste Manag. 2014, 34, 411–420. [Google Scholar] [CrossRef]

- Ruffino, B.; Campo, G.; Genon, G.; Lorenzi, E.; Novarino, D.; Scibilia, G.; Zanetti, M. Improvement of anaerobic digestion of sewage sludge in a wastewater treatment plant by means of mechanical and thermal pre-treatments: Performance, energy and economical assessment. Bioresour. Technol. 2015, 175, 298–308. [Google Scholar] [CrossRef]

- Zhao, J.; Hou, T.; Wang, Q.; Zhang, Z.; Lei, Z.; Shimizu, K.; Guo, W.; Ngo, H. Application of biogas recirculation in anaerobic granular sludge system for multifunctional sewage sludge management with high efficacy energy recovery. Appl. Energy 2021, 298, 117212. [Google Scholar] [CrossRef]

- Zouagri, R.; Mameri, A.; Tabet, F.; Hadef, A. Characterization of the combustion of the mixtures biogas-syngas at high strain rates. Fuel 2020, 271, 117580. [Google Scholar] [CrossRef]

- Yan, M.; Feng, H.; Zheng, R.; Yu, C.; Hantoko, D.; Zhou, Z.; Zhang, Y.; Kanchanatip, E. Sulfur conversion and distribution during supercritical water gasification of sewage sludge. J. Energy Inst. 2021, 95, 61–68. [Google Scholar] [CrossRef]

- Nwabunwanne, N.; Vuyokazi, T.; Olagoke, A.; Mike, O.; Patrick, M.; Anthony, O. Improving the Solid Fuel Properties of Non-Lignocellulose and Lignocellulose Materials through Torrefaction. Materials 2021, 14, 2072. [Google Scholar] [CrossRef] [PubMed]

- Mei, Z.; Chen, D.; Zhang, J.; Yin, L.; Huang, Z.; Xin, Q. Sewage sludge pyrolysis coupled with self-supplied steam reforming for high quality syngas production and the influence of initial moisture content. Waste Manag. 2020, 106, 77–87. [Google Scholar] [CrossRef]

- Maragkaki, A.; Fountoulakis, M.; Kyriakou, A.; Lasaridi, K.; Manios, T. Boosting biogas production from sewage sludge by adding small amount of agro-industrial by-products and food waste residues. Waste Manag. 2018, 71, 605–611. [Google Scholar] [CrossRef]

- Arthur, R.; Brew-Hammond, A. Potential biogas production from sewage sludge: A case study of the sewage treatment plant at Kwame Nkrumah university of science and technology, Ghana. Int. J. Energy Environ. 2010, 1, 1009–1016. [Google Scholar]

- Demirbas, A.; Taylan, O.; Kaya, D. Biogas production from municipal sewage sludge (MSS). Energy Sources Part A Recovery Util. Environ. Eff. 2016, 38, 3027–3033. [Google Scholar] [CrossRef]

- Choi, H.-J. Acid-fermented fish by-products broth: An influence to sludge reduction and biogas production in an anaerobic co-digestion. J. Environ. Manag. 2020, 262, 110305. [Google Scholar] [CrossRef]

- Suksong, W.; Promnuan, K.; Seengenyoung, J.; Sompong, O. Anaerobic Co-digestion of palm oil mill waste residues with sewage sludge for biogas production. Energy Procedia 2017, 138, 789–794. [Google Scholar] [CrossRef]

- Mu, L.; Zhang, L.; Zhu, K.; Ma, J.; Ifran, M.; Li, A. Anaerobic co-digestion of sewage sludge, food waste and yard waste: Synergistic enhancement on process stability and biogas production. Sci. Total Environ. 2020, 704, 135429. [Google Scholar] [CrossRef]

- Gaur, R.Z.; Suthar, S. Anaerobic digestion of activated sludge, anaerobic granular sludge and cow dung with food waste for enhanced methane production. J. Clean. Prod. 2017, 164, 557–566. [Google Scholar] [CrossRef]

- Thorin, E.; Olsson, J.; Schwede, S.; Nehrenheim, E. Co-digestion of sewage sludge and microalgae–biogas production investigations. Appl. Energy 2018, 227, 64–72. [Google Scholar] [CrossRef]

- Ghosh, P.; Kumar, M.; Kapoor, R.; Kumar, S.S.; Singh, L.; Vijay, V.; Vijay, V.K.; Kumar, V.; Thakur, I.S. Enhanced biogas production from municipal solid waste via co-digestion with sewage sludge and metabolic pathway analysis. Bioresour. Technol. 2020, 296, 122275. [Google Scholar] [CrossRef]

- Vu, H.T.; Min, B. Enhanced methane fermentation of municipal sewage sludge by microbial electrochemical systems integrated with anaerobic digestion. Int. J. Hydrogen Energy 2019, 44, 30357–30366. [Google Scholar] [CrossRef]

- Grosser, A.; Neczaj, E. Enhancement of biogas production from sewage sludge by addition of grease trap sludge. Energy Convers. Manag. 2016, 125, 301–308. [Google Scholar] [CrossRef]

- Scarcelli, P.G.; Serejo, M.L.; Paulo, P.L.; Boncz, M.Á. Evaluation of biomethanization during co-digestion of thermally pretreated microalgae and waste activated sludge, and estimation of its kinetic parameters. Sci. Total Environ. 2020, 706, 135745. [Google Scholar] [CrossRef]

- Ortega-Bravo, J.C.; Ruiz-Filippi, G.; Donoso-Bravo, A.; Reyes-Caniupán, I.E.; Jeison, D. Forward osmosis: Evaluation thin-film-composite membrane for municipal sewage concentration. Chem. Eng. J. 2016, 306, 531–537. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, H.; Guo, G.; Zhang, T.; Qin, Y.; Li, Y.-Y. High solid mono-digestion and co-digestion performance of food waste and sewage sludge by a thermophilic anaerobic membrane bioreactor. Bioresour. Technol. 2020, 310, 123433. [Google Scholar] [CrossRef]

- Dhar, H.; Kumar, P.; Kumar, S.; Mukherjee, S.; Vaidya, A.N. Effect of organic loading rate during anaerobic digestion of municipal solid waste. Bioresour. Technol. 2016, 217, 56–61. [Google Scholar] [CrossRef]

- Tang, J.; Wang, X.C.; Hu, Y.; Pu, Y.; Huang, J.; Ngo, H.H.; Zeng, Y.; Li, Y. Nutrients removal performance and sludge properties using anaerobic fermentation slurry from food waste as an external carbon source for wastewater treatment. Bioresour. Technol. 2019, 271, 125–135. [Google Scholar] [CrossRef] [PubMed]

- Lee, U.; Dong, J.; Chung, J. Experimental investigation of sewage sludge solid waste conversion to syngas using high temperature steam gasification. Energy Convers. Manag. 2018, 158, 430–436. [Google Scholar] [CrossRef]

- Cerón-Vivas, A.; Cáceres, K.T.; Rincón, A.; Cajigas, Á. Influence of pH and the C/N ratio on the biogas production of wastewater. Rev. Fac. Ing. Univ. Antioq. 2019, 92, 70–79. [Google Scholar] [CrossRef]

- Latif, M.A.; Mehta, C.M.; Batstone, D. Influence of low pH on continuous anaerobic digestion of waste activated sludge. Water Res. 2017, 113, 42–49. [Google Scholar] [CrossRef] [PubMed]

- Chua, K.H.; Cheah, W.; Tan, C.; Leong, Y. Harvesting biogas from wastewater sludge and food waste. IOP Conf. Ser. Earth Environ. Sci. 2013, 16, 012118. [Google Scholar] [CrossRef]

- Anukam, A.; Mohammadi, A.; Naqvi, M.; Granström, K. A review of the chemistry of anaerobic digestion: Methods of accelerating and optimizing process efficiency. Processes 2019, 7, 504. [Google Scholar] [CrossRef]

- Mirmasoumi, S.; Ebrahimi, S.; Saray, R.K. Enhancement of biogas production from sewage sludge in a wastewater treatment plant: Evaluation of pretreatment techniques and co-digestion under mesophilic and thermophilic conditions. Energy 2018, 157, 707–717. [Google Scholar] [CrossRef]

- Wang, Q.; Wei, W.; Gong, Y.; Yu, Q.; Li, Q.; Sun, J.; Yuan, Z. Technologies for reducing sludge production in wastewater treatment plants: State of the art. Sci. Total Environ. 2017, 587, 510–521. [Google Scholar] [CrossRef]

- Kondusamy, D.; Kalamdhad, A.S. Pre-treatment and anaerobic digestion of food waste for high rate methane production–A review. J. Environ. Chem. Eng. 2014, 2, 1821–1830. [Google Scholar] [CrossRef]

- Li, C.; Wang, X.; Zhang, G.; Li, J.; Li, Z.; Yu, G.; Wang, Y. A process combining hydrothermal pretreatment, anaerobic digestion and pyrolysis for sewage sludge dewatering and co-production of biogas and biochar: Pilot-scale verification. Bioresour. Technol. 2018, 254, 187–193. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.; Chen, S.; Shi, J.; Wang, S.; Zhu, G. Combination treatment of ultrasound and ozone for improving solubilization and anaerobic biodegradability of waste activated sludge. J. Hazard. Mater. 2010, 180, 340–346. [Google Scholar] [CrossRef]

- Haug, R.T.; Stuckey, D.C.; Gossett, J.M.; McCarty, P.L. Effect of thermal pretreatment on digestibility and dewaterability of organic sludges. J. (Water Pollut. Control Fed.) 1978, 50, 73–85. [Google Scholar]

- Shrestha, B.; Hernandez, R.; Fortela, D.L.B.; Sharp, W.; Chistoserdov, A.; Gang, D.; Revellame, E.; Holmes, W.; Zappi, M.E. A Review of Pretreatment Methods to Enhance Solids Reduction during Anaerobic Digestion of Municipal Wastewater Sludges and the Resulting Digester Performance: Implications to Future Urban Biorefineries. Appl. Sci. 2020, 10, 9141. [Google Scholar] [CrossRef]

- Yi, H.; Han, Y.; Zhuo, Y. Effect of combined pretreatment of waste activated sludge for anaerobic digestion process. Procedia Environ. Sci. 2013, 18, 716–721. [Google Scholar] [CrossRef]

- Deepanraj, B.; Sivasubramanian, V.; Jayaraj, S. Enhancement of biogas production by pretreatment: A review. In Proceedings of the 4th International Conference on Advances in Energy Research, Indian Institute of Technology Bombay, Mumbai, India, 10–12 December 2013. [Google Scholar]

- Xue, Y.; Liu, H.; Chen, S.; Dichtl, N.; Dai, X.; Li, N. Effects of thermal hydrolysis on organic matter solubilization and anaerobic digestion of high solid sludge. Chem. Eng. J. 2015, 264, 174–180. [Google Scholar] [CrossRef]

- Tyagi, V.K.; Lo, S.-L. Application of physico-chemical pretreatment methods to enhance the sludge disintegration and subsequent anaerobic digestion: An up to date review. Rev. Environ. Sci. Bio/Technol. 2011, 10, 215–242. [Google Scholar] [CrossRef]

- Carrère, H.; Dumas, C.; Battimelli, A.; Batstone, D.J.; Delgenes, J.P.; Steyer, J.-P.; Ferrer, I. Pretreatment methods to improve sludge anaerobic degradability: A review. J. Hazard. Mater. 2010, 183, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Akgul, D.; Cella, M.; Eskicioglu, C. Temperature phased anaerobic digestion of municipal sewage sludge: A Bardenpho treatment plant study. Water Pract. Technol. 2016, 11, 569–573. [Google Scholar] [CrossRef]

- Xu, J.; Yuan, H.; Lin, J. Evaluation of thermal, thermal-alkaline, alkaline and electrochemical pretreatments on sludge to enhance anaerobic biogas production. J. Taiwan Inst. Chem. Eng. 2014, 45, 2531–2536. [Google Scholar] [CrossRef]

- Malhotra, M.; Garg, A. Performance of non-catalytic thermal hydrolysis and wet oxidation for sewage sludge degradation under moderate operating conditions. J. Environ. Manag. 2019, 238, 72–83. [Google Scholar] [CrossRef]

- Ariunbaatar, J.; Panico, A.; Esposito, G.; Pirozzi, F.; Lens, P. Pretreatment methods to enhance anaerobic digestion of organic solid waste. Appl. Energy 2014, 123, 143–156. [Google Scholar] [CrossRef]

- Brodeur, G.; Yau, E.; Badal, K.; Collier, J.; Ramachandran, K.; Ramakrishnan, S. Chemical and physicochemical pretreatment of lignocellulosic biomass: A review. Enzym. Res. 2011, 2011, 787532. [Google Scholar] [CrossRef]

- Kim, J.; Yu, Y.; Lee, C. Thermo-alkaline pretreatment of waste activated sludge at low-temperatures: Effects on sludge disintegration, methane production, and methanogen community structure. Bioresour. Technol. 2013, 144, 194–201. [Google Scholar] [CrossRef]

- Cacho Rivero, J.A.; Madhavan, N.; Suidan, M.T.; Ginestet, P.; Audic, J.-M. Enhancement of anaerobic digestion of excess municipal sludge with thermal and/or oxidative treatment. J. Environ. Eng. 2006, 132, 638–644. [Google Scholar] [CrossRef]

- Nabi, M.; Liang, J.; Zhang, P.; Wu, Y.; Fu, C.; Wang, S.; Ye, J.; Gao, D.; Shah, F.A.; Dai, J. Anaerobic digestion of sewage sludge pretreated by high pressure homogenization using expanded granular sludge blanket reactor: Feasibility, operation optimization and microbial community. J. Environ. Chem. Eng. 2021, 9, 104720. [Google Scholar] [CrossRef]

- Yang, G.; Wang, J. Enhancing biohydrogen production from disintegrated sewage sludge by combined sodium citrate-thermal pretreatment. J. Clean. Prod. 2021, 312, 127756. [Google Scholar] [CrossRef]

- Hodaei, M.; Ghasemi, S.; Khosravi, A.; Vossoughi, M. Effect of the ozonation pretreatment on biogas production from waste activated sludge of tehran wastewater treatment plant. Biomass-Bioenergy 2021, 152, 106198. [Google Scholar] [CrossRef]

- Choi, J.-M.; Han, S.-K.; Lee, C.-Y. Enhancement of methane production in anaerobic digestion of sewage sludge by thermal hydrolysis pretreatment. Bioresour. Technol. 2018, 259, 207–213. [Google Scholar] [CrossRef]

- Wang, X.; Gao, C.; Qi, X.; Zhang, Y.; Chen, T.; Xie, Y.; Zhang, A.; Gao, J. Enhancing sludge fermentation and anaerobic digestion by mechanical cutting pretreatment. J. Water Process. Eng. 2021, 40, 101812. [Google Scholar] [CrossRef]

- Yin, Y.; Liu, Y.-J.; Meng, S.-J.; Kiran, E.U.; Liu, Y. Enzymatic pretreatment of activated sludge, food waste and their mixture for enhanced bioenergy recovery and waste volume reduction via anaerobic digestion. Appl. Energy 2016, 179, 1131–1137. [Google Scholar] [CrossRef]

- Mehari, B.B.; Chang, S.; Hong, Y.; Chen, H. Temperature-phased biological hydrolysis and thermal hydrolysis pretreatment for anaerobic digestion performance enhancement. Water 2018, 10, 1812. [Google Scholar] [CrossRef]

- Babu, R.; Capannelli, G.; Comite, A. Effect of Different Pretreatments on Sludge Solubilization and Estimation of Bioenergy Potential. Processes 2021, 9, 1382. [Google Scholar] [CrossRef]

- Siami, S.; Aminzadeh, B.; Karimi, R.; Hallaji, S.M. Process optimization and effect of thermal, alkaline, H2O2 oxidation and combination pretreatment of sewage sludge on solubilization and anaerobic digestion. BMC Biotechnol. 2020, 20, 21. [Google Scholar] [CrossRef] [PubMed]

- Le, T.M.; Vo, P.T.; Do, T.A.; Tran, L.T.; Truong, H.T.; Xuan Le, T.T.; Chen, Y.-H.; Chang, C.-C.; Chang, C.-Y.; Tran, Q.T. Effect of assisted ultrasonication and ozone pretreatments on sludge characteristics and yield of biogas production. Processes 2019, 7, 743. [Google Scholar] [CrossRef]

- Mainardis, M.; Buttazzoni, M.; Gievers, F.; Vance, C.; Magnolo, F.; Murphy, F.; Goi, D. Life cycle assessment of sewage sludge pretreatment for biogas production: From laboratory tests to full-scale applicability. J. Clean. Prod. 2021, 322, 129056. [Google Scholar] [CrossRef]

- Jiang, X.; Lyu, Q.; Bi, L.; Liu, Y.; Xie, Y.; Ji, G.; Huan, C.; Xu, L.; Yan, Z. Improvement of sewage sludge anaerobic digestion through synergistic effect combined trace elements enhancer with enzyme pretreatment and microbial community response. Chemosphere 2022, 286, 131356. [Google Scholar] [CrossRef]

- Yang, G.; Wang, J. Enhancing biohydrogen production from waste activated sludge disintegrated by sodium citrate. Fuel 2019, 258, 116177. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, P.; Zhang, G.; Fan, J.; Zhang, Y. Enhancement of anaerobic sludge digestion by high-pressure homogenization. Bioresour. Technol. 2012, 118, 496–501. [Google Scholar] [CrossRef] [PubMed]

- Wahidunnabi, A.K.; Eskicioglu, C. High pressure homogenization and two-phased anaerobic digestion for enhanced biogas conversion from municipal waste sludge. Water Res. 2014, 66, 430–446. [Google Scholar] [CrossRef] [PubMed]

- Gil, A.; Siles, J.; Martín, M.; Chica, A.; Estévez-Pastor, F.; Toro-Baptista, E. Effect of microwave pretreatment on semi-continuous anaerobic digestion of sewage sludge. Renew. Energy 2018, 115, 917–925. [Google Scholar] [CrossRef]

- De los Cobos-Vasconcelos, D.; Villalba-Pastrana, M.E.; Noyola, A.J. Effective pathogen removal by low temperature thermal pre-treatment and anaerobic digestion for Class A biosolids production from sewage sludge. J. Water Sanit. Hyg. Dev. 2015, 5, 56–63. [Google Scholar] [CrossRef]

- Liao, X.; Li, H.; Zhang, Y.; Liu, C.; Chen, Q. Accelerated high-solids anaerobic digestion of sewage sludge using low-temperature thermal pretreatment. Int. Biodeterior. Biodegrad. 2016, 106, 141–149. [Google Scholar] [CrossRef]

- Montalvo, S.; Huiliñir, C.; Ojeda, F.; Castillo, A.; Lillo, L.; Guerrero, L. Microaerobic pretreatment of sewage sludge: Effect of air flow rate, pretreatment time and temperature on the aerobic process and methane generation. Int. Biodeterior. Biodegrad. 2016, 110, 1–7. [Google Scholar] [CrossRef]

- Kapusta, K. Effect of ultrasound pretreatment of municipal sewage sludge on characteristics of bio-oil from hydrothermal liquefaction process. Waste Manag. 2018, 78, 183–190. [Google Scholar] [CrossRef]

- Gorazda, K.; Tarko, B.; Werle, S.; Wzorek, Z. Sewage sludge as a fuel and raw material for phosphorus recovery: Combined process of gasification and P extraction. Waste Manag. 2018, 73, 404–415. [Google Scholar] [CrossRef]

- Chen, S.; Sun, Z.; Zhang, Q.; Hu, J.; Xiang, W. Steam gasification of sewage sludge with CaO as CO2 sorbent for hydrogen-rich syngas production. Biomass-Bioenergy 2017, 107, 52–62. [Google Scholar] [CrossRef]

- Manara, P.; Zabaniotou, A. Towards sewage sludge based biofuels via thermochemical conversion—A review. Renew. Sustain. Energy Rev. 2012, 16, 2566–2582. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. A comparative overview of hydrogen production processes. Renew. Sustain. Energy Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- Calvo, L.; García, A.; Otero, M. An experimental investigation of sewage sludge gasification in a fluidized bed reactor. Sci. World J. 2013, 2013, 479403. [Google Scholar] [CrossRef] [PubMed]

- Migliaccio, R.; Brachi, P.; Montagnaro, F.; Papa, S.; Tavano, A.; Montesarchio, P.; Ruoppolo, G.; Urciuolo, M. Sewage sludge gasification in a fluidized bed: Experimental investigation and modeling. Ind. Eng. Chem. Res. 2021, 60, 5034–5047. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, R.; Man, Y.; Ren, J. Recent developments of hydrogen production from sewage sludge by biological and thermochemical process. Int. J. Hydrogen Energy 2019, 44, 19676–19697. [Google Scholar] [CrossRef]

- Nipattummakul, N.; Ahmed, I.I.; Kerdsuwan, S.; Gupta, A.K. Hydrogen and syngas production from sewage sludge via steam gasification. Int. J. Hydrogen Energy 2010, 35, 11738–11745. [Google Scholar] [CrossRef]

- Gai, C.; Chen, M.; Liu, T.; Peng, N.; Liu, Z. Gasification characteristics of hydrochar and pyrochar derived from sewage sludge. Energy 2016, 113, 957–965. [Google Scholar] [CrossRef]

- Arjharn, W.; Hinsui, T.; Liplap, P.; Raghavan, G.V. Evaluation of an energy production system from sewage sludge using a pilot-scale downdraft gasifier. Energy Fuels 2013, 27, 229–236. [Google Scholar] [CrossRef]

- De Andres, J.M.; Narros, A.; Rodríguez, M.E. Air-steam gasification of sewage sludge in a bubbling bed reactor: Effect of alumina as a primary catalyst. Fuel Process. Technol. 2011, 92, 433–440. [Google Scholar] [CrossRef]

- Seggiani, M.; Puccini, M.; Raggio, G.; Vitolo, S. Effect of sewage sludge content on gas quality and solid residues produced by cogasification in an updraft gasifier. Waste Manag. 2012, 32, 1826–1834. [Google Scholar] [CrossRef]

- Choi, Y.-K.; Ko, J.-H.; Kim, J.-S. A new type three-stage gasification of dried sewage sludge: Effects of equivalence ratio, weight ratio of activated carbon to feed, and feed rate on gas composition and tar, NH3, and H2S removal and results of approximately 5 h gasification. Energy 2017, 118, 139–146. [Google Scholar] [CrossRef]

- Hantoko, D.; Kanchanatip, E.; Yan, M.; Weng, Z.; Gao, Z.; Zhong, Y. Assessment of sewage sludge gasification in supercritical water for H2-rich syngas production. Process. Saf. Environ. Prot. 2019, 131, 63–72. [Google Scholar] [CrossRef]

- Chen, Y.; Yi, L.; Wei, W.; Jin, H.; Guo, L. Hydrogen production by sewage sludge gasification in supercritical water with high heating rate batch reactor. Energy 2022, 238, 121740. [Google Scholar] [CrossRef]

- Madadian, E.; Orsat, V.; Lefsrud, M. Comparative study of temperature impact on air gasification of various types of biomass in a research-scale down-draft reactor. Energy Fuels 2017, 31, 4045–4053. [Google Scholar] [CrossRef]

- Werle, S. Impact of feedstock properties and operating conditions on sewage sludge gasification in a fixed bed gasifier. Waste Manag. Res. J. Sustain. Circ. Econ. 2014, 32, 954–960. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Chen, M.; Li, Q.; Xing, W. Hydrogen-rich syngas produced from co-gasification of wet sewage sludge and torrefied biomass in self-generated steam agent. Energy 2018, 161, 202–213. [Google Scholar] [CrossRef]

- Phuphuakrat, T.; Nipattummakul, N.; Namioka, T.; Kerdsuwan, S.; Yoshikawa, K. Characterization of tar content in the syngas produced in a downdraft type fixed bed gasification system from dried sewage sludge. Fuel 2010, 89, 2278–2284. [Google Scholar] [CrossRef]

- Karaca, C.; Sözen, S.; Orhon, D.; Okutan, H. High temperature pyrolysis of sewage sludge as a sustainable process for energy recovery. Waste Manag. 2018, 78, 217–226. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Yi, L.; Zhang, Q.; Hu, H.; Lu, G.; Li, A.; Yao, H. Co-production of clean syngas and ash adsorbent during sewage sludge gasification: Synergistic effect of Fenton peroxidation and CaO conditioning. Appl. Energy 2016, 179, 1062–1068. [Google Scholar] [CrossRef]

- Domínguez, A.; Fernández, Y.; Fidalgo, B.; Pis, J.; Menéndez, J. Bio-syngas production with low concentrations of CO2 and CH4 from microwave-induced pyrolysis of wet and dried sewage sludge. Chemosphere 2008, 70, 397–403. [Google Scholar] [CrossRef] [PubMed]

- Deng, W.; Tao, C.; Cobb, K.; Zhou, H.; Su, Y.; Ruan, R. Catalytic oxidation of NO at ambient temperature over the chars from pyrolysis of sewage sludge. Chemosphere 2020, 251, 126429. [Google Scholar] [CrossRef] [PubMed]

- Marin-Batista, J.; Mohedano, A.; Rodríguez, J.; de La Rubia, M. Energy and phosphorous recovery through hydrothermal carbonization of digested sewage sludge. Waste Manag. 2020, 105, 566–574. [Google Scholar] [CrossRef]

- Rahman, T.; Jahromi, H.; Roy, P.; Adhikari, S.; Hassani, E.; Oh, T.-S. Hydrothermal liquefaction of municipal sewage sludge: Effect of red mud catalyst in ethylene and inert ambiences. Energy Convers. Manag. 2021, 245, 114615. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Zhang, Y.; Li, A. Pressurized pyrolysis of sewage sludge: Process performance and products characterization. J. Anal. Appl. Pyrolysis 2019, 139, 205–212. [Google Scholar] [CrossRef]

- Li, M.; Wang, H.; Huang, Z.; Yuan, X.; Tan, M.; Jiang, L.; Wu, Z.; Qin, X.; Li, H. Comparison of atmospheric pressure and gas-pressurized torrefaction of municipal sewage sludge: Properties of solid products. Energy Convers. Manag. 2020, 213, 112793. [Google Scholar] [CrossRef]

- Hu, Q.; Dai, Y.; Wang, C.-H. Steam co-gasification of horticultural waste and sewage sludge: Product distribution, synergistic analysis and optimization. Bioresour. Technol. 2020, 301, 122780. [Google Scholar] [CrossRef]

- Chiang, K.-Y.; Lu, C.-H.; Liao, C.-K.; Ger, R.H.-R. Characteristics of hydrogen energy yield by co-gasified of sewage sludge and paper-mill sludge in a commercial scale plant. Int. J. Hydrogen Energy 2016, 41, 21641–21648. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, Y.; Yang, L.; Zhu, Y. High quality syngas produced from the co-pyrolysis of wet sewage sludge with sawdust. Int. J. Hydrogen Energy 2018, 43, 5463–5472. [Google Scholar] [CrossRef]

- Zuo, Z.; Feng, Y.; Li, X.; Luo, S.; Ma, J.; Sun, H.; Bi, X.; Yu, Q.; Zhou, E.; Zhang, J. Thermal-chemical conversion of sewage sludge based on waste heat cascade recovery of copper slag: Mass and energy analysis. Energy 2021, 235, 121327. [Google Scholar] [CrossRef]

- Fang, S.; Deng, Z.; Lin, Y.; Huang, Z.; Ding, L.; Deng, L.; Huang, H. Investigation of the nitrogen migration characteristics in sewage sludge during chemical looping gasification. Energy 2021, 216, 119247. [Google Scholar] [CrossRef]

- Hantoko, D.; Yan, M.; Kanchanatip, E.; Adnan, M.A.; Mubeen, I.; Hamid, F.S. Supercritical water gasification of sewage sludge and combined cycle for H2 and power production–a thermodynamic study. Int. J. Hydrogen Energy 2019, 44, 24459–24470. [Google Scholar] [CrossRef]

- Ma, J.; Chen, M.; Yang, T.; Liu, Z.; Jiao, W.; Li, D.; Gai, C. Gasification performance of the hydrochar derived from co-hydrothermal carbonization of sewage sludge and sawdust. Energy 2019, 173, 732–739. [Google Scholar] [CrossRef]

- Li, Z.; Gong, M.; Wang, M.; Feng, A.; Wang, L.; Ma, P.; Yuan, S. Influence of AlCl3 and oxidant catalysts on hydrogen production from the supercritical water gasification of dewatered sewage sludge and model compounds. Int. J. Hydrogen Energy 2021, 46, 31262–31274. [Google Scholar] [CrossRef]

- Dong, N.; Huo, R.; Liu, M.; Deng, L.; Deng, Z.; Chang, G.; Huang, Z.; Huang, H. Chemical looping gasification of sewage sludge using copper slag modified by NiO as an oxygen carrier. Chin. J. Chem. Eng. 2021, 29, 335–343. [Google Scholar] [CrossRef]

- Languer, M.P.; Batistella, L.; Alves, J.L.F.; Da Silva, J.C.G.; da Silva Filho, V.F.; Di Domenico, M.; Moreira, R.d.F.P.M.; José, H. Insights into pyrolysis characteristics of Brazilian high-ash sewage sludges using thermogravimetric analysis and bench-scale experiments with GC-MS to evaluate their bioenergy potential. Biomass-Bioenergy 2020, 138, 105614. [Google Scholar] [CrossRef]

- Chen, G.-B.; Wu, F.-H.; Fang, T.-L.; Lin, H.-T.; Chao, Y.-C. A study of Co-gasification of sewage sludge and palm kernel shells. Energy 2021, 218, 119532. [Google Scholar] [CrossRef]

- Weng, Z.; Kanchanatip, E.; Hantoko, D.; Yan, M.; Su, H.; Zhang, S.; Wang, G. Improving supercritical water gasification of sludge by oil palm empty fruit bunch addition: Promotion of syngas production and heavy metal stabilization. Chin. J. Chem. Eng. 2020, 28, 293–298. [Google Scholar] [CrossRef]

- Zheng, X.; Huang, J.; Ying, Z.; Ji, S.; Feng, Y.; Wang, B.; Dou, B. Thermochemical conversion of sewage sludge-derived hydrochars: Volatiles release and char gasification kinetics. J. Anal. Appl. Pyrolysis 2021, 156, 105138. [Google Scholar] [CrossRef]

- Pawlak-Kruczek, H.; Wnukowski, M.; Niedzwiecki, L.; Czerep, M.; Kowal, M.; Krochmalny, K.; Zgóra, J.; Ostrycharczyk, M.; Baranowski, M.; Tic, W.J. Torrefaction as a valorization method used prior to the gasification of sewage sludge. Energies 2019, 12, 175. [Google Scholar] [CrossRef]

- Yang, X.; Tian, S.; Kan, T.; Zhu, Y.; Xu, H.; Strezov, V.; Nelson, P.; Jiang, Y. Sorption-enhanced thermochemical conversion of sewage sludge to syngas with intensified carbon utilization. Appl. Energy 2019, 254, 113663. [Google Scholar] [CrossRef]

- Zheng, X.; Jiang, Z.; Ying, Z.; Song, J.; Chen, W.; Wang, B. Role of feedstock properties and hydrothermal carbonization conditions on fuel properties of sewage sludge-derived hydrochar using multiple linear regression technique. Fuel 2020, 271, 117609. [Google Scholar] [CrossRef]

- Karki, S.; Poudel, J.; Oh, S.C. Thermal pre-treatment of sewage sludge in a lab-scale fluidized bed for enhancing its solid fuel properties. Appl. Sci. 2018, 8, 183. [Google Scholar] [CrossRef]

- Yang, X.; Kan, T.; Kheradmand, A.; Xu, H.; Strezov, V.; Yu, A.; Jiang, Y. Tunable syngas production from two-stage sorption-enhanced steam gasification of sewage sludge. Chem. Eng. J. 2021, 404, 126069. [Google Scholar] [CrossRef]

- Shen, Y.; He, C.; Chen, X.; Lapkin, A.A.; Xiao, W.; Wang, C.-H. Nitrogen removal and energy recovery from sewage sludge by combined hydrothermal pretreatment and CO2 gasification. ACS Sustain. Chem. Eng. 2018, 6, 16629–16636. [Google Scholar] [CrossRef]

- Moon, J.; Mun, T.-Y.; Yang, W.; Lee, U.; Hwang, J.; Jang, E.; Choi, C. Effects of hydrothermal treatment of sewage sludge on pyrolysis and steam gasification. Energy Convers. Manag. 2015, 103, 401–407. [Google Scholar] [CrossRef]

- Peng, C.; Zhai, Y.; Zhu, Y.; Xu, B.; Wang, T.; Li, C.; Zeng, G. Production of char from sewage sludge employing hydrothermal carbonization: Char properties, combustion behavior and thermal characteristics. Fuel 2016, 176, 110–118. [Google Scholar] [CrossRef]

- Zhuang, X.; Zhan, H.; Huang, Y.; Song, Y.; Yin, X.; Wu, C. Conversion of industrial biowastes to clean solid fuels via hydrothermal carbonization (HTC): Upgrading mechanism in relation to coalification process and combustion behavior. Bioresour. Technol. 2018, 267, 17–29. [Google Scholar] [CrossRef]

- Chew, J.J.; Doshi, V. Recent advances in biomass pretreatment–Torrefaction fundamentals and technology. Renew. Sustain. Energy Rev. 2011, 15, 4212–4222. [Google Scholar] [CrossRef]

- Nhuchhen, D.R.; Basu, P.; Acharya, B. A comprehensive review on biomass torrefaction. Int. J. Renew. Energy Biofuels 2014, 2014, 506376. [Google Scholar] [CrossRef]

- Eseyin, A.E.; Steele, P.H.; Pittman, C.U., Jr. Current Trends in the Production and Applications of Torrefied Wood/Biomass-A Review. BioResources 2015, 10, 8812–8858. [Google Scholar] [CrossRef]

- Abdelrahim, A.; Brachi, P.; Ruoppolo, G.; Fraia, S.D.; Vanoli, L. Experimental and numerical investigation of biosolid gasification: Equilibrium-based modeling with emphasis on the effects of different pretreatment methods. Ind. Eng. Chem. Res. 2019, 59, 299–307. [Google Scholar] [CrossRef]

- Qian, L.; Wang, S.; Wang, S.; Zhao, S.; Zhang, B. Supercritical water gasification and partial oxidation of municipal sewage sludge: An experimental and thermodynamic study. Int. J. Hydrogen Energy 2021, 46, 89–99. [Google Scholar] [CrossRef]

- Weijin, G.; Zizheng, Z.; Yue, L.; Qingyu, W.; Lina, G. Hydrogen production and phosphorus recovery via supercritical water gasification of sewage sludge in a batch reactor. Waste Manag. 2019, 96, 198–205. [Google Scholar] [CrossRef]

- Feng, H.; Zhou, Z.; Hantoko, D.; Zhong, L.; Rahim, D.A.; Fang, W.; Yan, M. Effect of alkali additives on desulfurization of syngas during supercritical water gasification of sewage sludge. Waste Manag. 2021, 131, 394–402. [Google Scholar] [CrossRef] [PubMed]

- Schmid, M.; Hafner, S.; Biollaz, S.; Schneebeli, J.; Waizmann, G.; Scheffknecht, G. Steam-oxygen gasification of sewage sludge: Reduction of tar, H2S and COS with limestone as bed additive. Biomass-Bioenergy 2021, 150, 106100. [Google Scholar] [CrossRef]

- Urych, B.; Smoliński, A. Sewage sludge and phytomass co-pyrolysis and the gasification of its chars: A kinetics and reaction mechanism study. Fuel 2021, 285, 119186. [Google Scholar] [CrossRef]

- Schweitzer, D.; Gredinger, A.; Schmid, M.; Waizmann, G.; Beirow, M.; Spörl, R.; Scheffknecht, G. Steam gasification of wood pellets, sewage sludge and manure: Gasification performance and concentration of impurities. Biomass-Bioenergy 2018, 111, 308–319. [Google Scholar] [CrossRef]

- Prussi, M.; Padella, M.; Conton, M.; Postma, E.; Lonza, L. Review of technologies for biomethane production and assessment of Eu transport share in 2030. J. Clean. Prod. 2019, 222, 565–572. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Monforti-Ferrario, F.; Banja, M.; Motola, V. Renewable energy policy framework and bioenergy contribution in the European Union–An overview from National Renewable Energy Action Plans and Progress Reports. Renew. Sustain. Energy Rev. 2015, 51, 969–985. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.F. Technology Development Report Heat and Power from Biomass. In Low Carbon Energy Observatory Deliverable D 2.1.; 2016; p. JRC102407. [Google Scholar]

- Huiru, Z.; Yunjun, Y.; Liberti, F.; Pietro, B.; Fantozzi, F. Technical and economic feasibility analysis of an anaerobic digestion plant fed with canteen food waste. Energy Convers. Manag. 2019, 180, 938–948. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, Y.; Guo, Q.; Zhang, R.; Wang, C.; Yan, B.; Lin, F.; Chen, G. Evaluation on energetic and economic benefits of the coupling anaerobic digestion and gasification from agricultural wastes. Renew. Energy 2021, 176, 494–503. [Google Scholar] [CrossRef]

- Hu, M.; Ye, Z.; Zhang, H.; Chen, B.; Pan, Z.; Wang, J. Thermochemical conversion of sewage sludge for energy and resource recovery: Technical challenges and prospects. Environ. Pollut. Bioavailab. 2021, 33, 145–163. [Google Scholar] [CrossRef]

- Ramos, A.; Monteiro, E.; Silva, V.; Rouboa, A. Co-gasification and recent developments on waste-to-energy conversion: A review. Renew. Sustain. Energy Rev. 2018, 81, 380–398. [Google Scholar] [CrossRef]

- Rittmann, B.E.; McCarty, P.L. Environmental Biotechnology: Principles and Applications; McGraw-Hill Education: New York, NY, USA, 2001. [Google Scholar]

- Di Capua, F.; Spasiano, D.; Giordano, A.; Adani, F.; Fratino, U.; Pirozzi, F.; Esposito, G. High-solid anaerobic digestion of sewage sludge: Challenges and opportunities. Appl. Energy 2020, 278, 115608. [Google Scholar] [CrossRef]

- Duan, N.; Dong, B.; Wu, B.; Dai, X. High-solid anaerobic digestion of sewage sludge under mesophilic conditions: Feasibility study. Bioresour. Technol. 2012, 104, 150–156. [Google Scholar] [CrossRef]

- Krakat, N.; Demirel, B.; Anjum, R.; Dietz, D. Methods of ammonia removal in anaerobic digestion: A review. Water Sci. Technol. 2017, 76, 1925–1938. [Google Scholar] [CrossRef]

- Yuan, H.; Zhu, N. Progress in inhibition mechanisms and process control of intermediates and by-products in sewage sludge anaerobic digestion. Renew. Sustain. Energy Rev. 2016, 58, 429–438. [Google Scholar] [CrossRef]

- Westerholm, M.; Moestedt, J.; Schnürer, A. Biogas production through syntrophic acetate oxidation and deliberate operating strategies for improved digester performance. Appl. Energy 2016, 179, 124–135. [Google Scholar] [CrossRef]

- Hu, M.; Gao, L.; Chen, Z.; Ma, C.; Zhou, Y.; Chen, J.; Ma, S.; Laghari, M.; Xiao, B.; Zhang, B.; et al. Syngas production by catalytic in-situ steam co-gasification of wet sewage sludge and pine sawdust. Energy Convers. Manag. 2016, 111, 409–416. [Google Scholar] [CrossRef]

- Hu, M.; Wang, X.; Chen, J.; Yang, P.; Liu, C.; Xiao, B.; Guo, D. Kinetic study and syngas production from pyrolysis of forestry waste. Energy Convers. Manag. 2017, 135, 453–462. [Google Scholar] [CrossRef]

- Liu, S.; Wei, M.; Qiao, Y.; Yang, Z.; Gui, B.; Yu, Y.; Xu, M.J.P.o.t.C.I. Release of organic sulfur as sulfur-containing gases during low temperature pyrolysis of sewage sludge. Proc. Combust. Inst. 2015, 35, 2767–2775. [Google Scholar] [CrossRef]

| C/N | COD | VS | TS | pH | SS Type | Reference |

|---|---|---|---|---|---|---|

| - | 41.5–44.2 g/L | 20.7–21 g/L | 29.4–30.5 g/L | 6.9–7.3 | Primary sludge from municipal sewage treatment plant At 35 °C | [52] |

| - | 38.32 mg/L | 57.74 mg/L or 64.7% | 89.28 mg/L or 9.1% | 6.8 | Primary sludge At 28 °C | [53] |

| - | 13.65 g/L | 8.25 g/L | 11.93 g/L | 7.17 | Chemically enhanced primary treated sludge At 35 °C | [32] |

| - | - | - | - | 7.1–8.2 | Municipal sewage sludge | [54] |

| 6.44 | 27.5 g/L | 13.4 g/L | 18.3 g/L | 7.5 | Secondary sludge At 35 °C for 30 days | [55] |

| 51.7 | - | 17.10% | 32.6% | 7.5 | Sewage biological sludge at 35 °C for 45–50 days | [56] |

| 7.0 | - | 12.30% | 15.2% | 8.0 | Sewage chemical sludge | [56] |

| 6.8 | - | 9.7% | 16.9% | - | Primary Sludge | [57] |

| - | 15.7 g/kg or g/L With MC of 74.4% | 1.71% | 3.77% | 7.3 | Waste-activated sludge | [58] |

| 14 | - | 78% | 4.8% Or 48 g/L | - | - | [59] |

| 17.1 | MC of 93.2% | 84.11 vs. (%TS) | 6.8% 68 g/L | - | Sewage sludge from sewage treatment plant | [60] |

| - | 30,633.24 mg/L | 16.16 g/L | - | 5.4 | Untreated secondary sewage sludge | [61] |

| - | - | 1.65–3.5% | 2.15–4.51% 21.5–45.1 g/L | 5.04–7.04 | Primary + waste-activated sludge | [62] |

| 1.2 g/L | 27 g/L | 34.4 g/L | 6.8 | Waste-activated sludge | [63] | |

| 275 mg/L | - | 603 mg/L | 7.3 | Primary SS | [64] | |

| 64.6 g/L | 38.2 g/L | 45.9 g/L | 5.74 | Primary SS + excess sludge from municipal wastewater treatment plant | [65] |

| Pretreatment Techniques | Substrate Type | Impact of Pretreatment | Reference |

|---|---|---|---|

| Mechanical—high-pressure homogenization (HPH) at 20, 40 and 60 MPa | Domestic Sewage | Cumulative biogas production increased by 27%, 73% and 82% for HPH of 20, 40 and 60 Mpa, respectively. | [92] |

| Chemical—with addition of 0.3 g/g-SS of sodium citrate and stirred for 1 h at 150 rpm | Waste-activated sludge | Improved biohydrogen yield with increase ratio of 157.8%. | [93] |

| Thermal—heated at 121 °C for 30 min | Waste-activated sludge | Increase in biohydrogen productivity by 79.7%. | [93] |

| Chemical + Thermal—with addition of sodium citrate and heated at 121 °C for 30 min | Waste-activated sludge | Improved biohydrogen yield with increase ratio of 346.9%. | [93] |

| Chemical—ozonation using two doses of 0.05 g and 0.1 g of O3 per total solid | Waste-thickened activated sludge | Cumulative biogas production increased by 169% for 0.05 g dose and 140% for 0.1 g dose. | [94] |

| Thermal hydrolysis at 180 °C for 76 min | Sewage sludge | 340% increase in methane production was obtained. | [95] |

| Mechanical—high-pressure homogenization at 40 Mpa | Sewage sludge | Biogas production increased by 12%, methane content in biogas by 5%, total chemical oxygen demand (TCOD) by 12% and volatile solid removal by 8%. | [92] |

| Mechanical—cutting at a speed of 35,000 rpm for 6, 8 and 10 min using a high-speed blender | Waste-activated sludge | The cumulative biogas production for pre-treated waste-activated sludge was 2.86, 3.06 and 2.91 (for 6, 8 and 10 min respectively) times more than untreated sludge. | [96] |

| Biological—enzymatic pretreatment using Fungal mash | Waste-activated sludge | Yielded a 52% increase in net methane production. | [97] |

| Biological—temperature-phased biological hydrolysis at 55 °C | Municipal wastewater sludge | Led to a 20% increase in methane production and 324% increase in sCOD. | [98] |

| Chemical + Thermal—5 M of NaOH was added and stirred for 1 h at 200 rpm before heating at 75 °C | Waste-activated sludge | Led to TS solubilization of 9.6% and VS solubilization of 17.2%. | [99] |

| Triple—heated at 90 °C for 5 h, followed by the addition of NaOH to obtain pH of 12 (alkaline) and, lastly, hydrogen peroxide (30 mg H2O2/g TS) was added | Waste-activated sludge | It gave rise to 96% higher methane production and increase in COD solubilization of 30.37% | [100] |

| Chemical—with the addition of 60 mg of H2O2/g TS and stirred for 24 h at 150 rpm | Waste-activated sludge | 14.01% increase in methane production with 9.05% solubilization of COD was recorded | [100] |

| Mechanical—ultrasonic irradiation of sludge at a frequency of 37 kHz and 250 W power | Sludge | Biogas yield increased by 32.3% with organic compound biodegradability index of 50.9%. | [101] |

| Biological—lysozyme, protease, and α-amylase pretreatment | Waste-activated sludge | When compared to protease and -amylase, lysozymes increased sCOD concentration in the sludge by 2.23 and 2.15 times, respectively, and improved sludge flocculation disintegration. | [41] |

| Thermal—low-temperature heating between 65 °C and 85 °C | Municipal and industrial sludge | Enhancement in sludge solubilization and methane yield up to 110%. | [102] |

| Biological + Chemical—addition of enzyme cocktail at 400 U/g dosage followed by trace element enhancer at a concentration of 1.24% | Sewage sludge | Cumulative methane production increased by 45.29% and daily methane yield by 84.7%, respectively. | [103] |

| VM | FC | MC | Ash | Type of SS Feedstock | Ref. |

|---|---|---|---|---|---|

| 44.30 | 21.8 | 1.74 | 33.91 | SS | [119] |

| 36.87 | 4.89 | nr | 58.18 | SS | [129] |

| 54.96 | - | - | 35.39 | Raw SS | [111] |

| 39.3 | 19.40 | 11.20 | 30.10 | Industrial SS | [130] |

| 55.10 | 7.10 | 7.9 | 37.9 | SS from Oakland California | [116] |

| 54.3 | 5.1 | 10.0 | 30.60 | Municipal SS from Italy collected in January | [117] |

| 60.9 | 4.8 | 10.0 | 24.30 | Same but collected in April | [117] |

| 55.5 | 9.0 | 6.0 | 35.5 | Dried sludge | [131] |

| 52.10 | 5.96 | - | 41.94 | Raw sludge from Wuhan, China | [132] |

| 62.3 | 6.5 | 71.0 | 31.2 | Aerobically digested sludge | [133] |

| 54.7 | 7.2 | 81.0 | 38.1 | Anaerobically digested | [133] |

| 59.7 | 6.5 | 80 | 31.2 | Dewatered SS from Shanghai, China | [134] |

| 54.7 | 4.4 | 83.5 | 40.9 | Dewatered SS from Centra, Spain | [135] |

| 52.9 | 17.3 | 82.4 | 29.8 | Municipal SS from Alabama, USA | [136] |

| 71.57 | 9.27 | 4.60 | 19.16 | Dried SS from Dalian, China | [137] |

| 49.77 | 5.42 | 2.54 | 42.27 | Municipal SS | [138] |

| 59.72 | 7.70 | 6.33 | 26.17 | Dried SS from Ocala, Florida | [68] |

| 15.60 | 15.90 | 78.00 | 68.50 | Wet SS from Wuhan, China | [139] |

| 57.78 | 11.46 | - | 30.76 | Municipal raw sewage from Beijing | [120] |

| 9.78 | 1.84 | 80.07 | 8.31 | Municipal sewage sludge from Taiwan | [140] |

| 31.52 | 5.25 | 79.00 | 63.23 | Wet SS from Nanjing, China | [141] |

| 61.63 | 9.41 | 84.0 | 28.96 | Shaanxi, China | [126] |

| 56.59 | 4.17 | 5.63 | 33.61 | SS from Qingdao, China | [142] |

| 46.24 | 4.59 | 0.05 | 49.12 | SS from Guangdong, China | [143] |

| 35.14 | 2.29 | - | 62.57 | Hangzhou, China | [144] |

| 55.00 | 3.20 | - | 41.80 | SS from | [145] |

| 51.51 | 1.20 | 86.21 | 47.29 | Dewatered sewage sludge from Hefei Anhui, China | [146] |

| 46.24 | 4.59 | 0.05 | 49.12 | SS from Foshan | [147] |

| 53.90 | 3.10 | 8.70 | 43.0 | Anaerobic sewage sludge from Brazil | [148] |

| 64.9 | 7.60 | 18.40 | 27.50 | Aerobic sewage sludge from Brazil | [148] |

| 57.65 | 13.49 | - | 28.86 | SS from Singapore | [139] |

| 52.31 | 18.51 | 8.98 | 29.18 | ||

| 49.01 | 10.71 | 6.94 | 40.28 | SS from Taiwan | [149] |

| 55.1 | 7.10 | 7.9 | 37.9 | SS from California | [116] |

| 48.22 | 7.07 | - | 44.71 | SS from China | [76] |

| Carbon | Hydrogen | Nitrogen | Sulphur | Oxygen | HHV (MJ/kg) | Ref. |

|---|---|---|---|---|---|---|

| 45.79 | 2.99 | 1.49 | 1.11 | 14.70 | 16.34 | [119] |

| 56.20 | 8.99 | 9.19 | 1.38 | 24.23 | - | [129] |

| 34.52 | 4.98 | 8.80 | 1.2 | 15.16 | 14,230 kJ/kg | [111] |

| 40.93 | 5.01 | 3.85 | 0.88 | 49.33 | - | [51] |

| 69.20 | 4.60 | 2.20 | 1.70 | 22.30 | - | [130] |

| 36.20 | 4.50 | 5.60 | 1.10 | 14.70 | 15.40 | [116] |

| 49.16 | 8.50 | 6.06 | 1.18 | 35.02 | 10.60 | [117] |

| 51.75 | 7.91 | 6.70 | 1.37 | 26.64 | 14.8 | [117] |

| 34.08 | 4.33 | 5.34 | 0.98 | 19.69 | 14.435 | [131] |

| 28.27 | 4.43 | 5.36 | 1.14 | - | 11,337 kJ/kg | [132] |

| 52.3 | 8.0 | 6.7 | 0.7 | 32.3 | 16.70 | [133] |

| 49.1 | 7.3 | 8.1 | 1.5 | 34.0 | 14.0 | [133] |

| 35.7 | 5.5 | 4.5 | 1.0 | 19.5 | - | [134] |

| 32.7 | 4.9 | 5.1 | 1.0 | 15.4 | - | [135] |

| 33.1 | 5.5 | 5.0 | 0.7 | 25.9 | 14.1 | [136] |

| 41.28 | 6.55 | 7.60 | Nr | 25.41 | 18.25 | [137] |

| 28.71 | 4.66 | 5.01 | 0.5 | 18.82 | 12.82 | [138] |

| 35.76 | 6.10 | 6.34 | 0.52 | 25.12 | 16.01 | [68] |

| 12.90 | 2.54 | 2.37 | 0.05 | 16.30 | 14.89 | [139] |

| 33.98 | 6.02 | 6.24 | 0.92 | 52.84 | 13.17 | [120] |

| 6.27 | 1.09 | 0.77 | 0.28 | 3.20 | 678 kcal/kg | [140] |

| 20.95 | 8.66 | 3.47 | 0.9 | 2.79 | - | [141] |

| 38.18 | 3.40 | 4.67 | 1.05 | 23.74 | 14.63 | [126] |

| 45.74 | 5.62 | 1.03 | 1.23 | 42.8 | 11,000 kJ/kg | [142] |

| 26.05 | 4.29 | 4.12 | 0.67 | 15.70 | 11.05 | [143] |

| 18.94 | 2.21 | 2.89 | 0.60 | 12.79 | 5.89 | [144] |

| 21.86 | 3.37 | 3.83 | 0.64 | 28.50 | 10.98 | [145] |

| 25.93 | 4.13 | 4.58 | 0.75 | 17.33 | 11.77 | [146] |

| 26.05 | 4.29 | 4.12 | 0.67 | 15.70 | - | [147] |

| 16.11 | 1.88 | 2.46 | 0.51 | 16.47 | 6.34 kJ/g | [150] |

| 23.70 | 4.95 | 3.15 | 3.44 | 21.42 | 14.00 | [148] |

| 33.90 | 6.30 | 5.88 | 0.67 | 25.5 | 16.60 | [148] |

| 36.17 | 5.28 | 5.58 | 0.81 | 23.30 | - | [139] |

| 51.58 | 8.23 | 8.79 | Nr | 31.40 | 15.04 | [129] |

| 28.40 | 5.29 | 4.65 | 2.66 | 25.58 | 11.38 | [149] |

| 36.2 | 4.5 | 5.60 | 1.1 | 14.7 | 15.4 | [116] |

| 24.67 | 4.65 | 4.51 | 0.95 | 20.52 | 11.61 | [76] |

| Pretreatment Technique | Substrate Type | Impact of Pretreatment | Reference |

|---|---|---|---|

| Chemical—Fenton peroxidation (Fe2+/H2O2) and CaO conditioning. | Raw sewage sludge | Hydrogen yield almost doubled and s slight increase in CO and CO2 was observed. In addition, carbon-conversion efficiency was enhanced by 43.7%, 42.2% and 30.4%. | [132] |

| Chemical—Raw sludge was mixed with CaO under magnetic stirring at room temperature, dried at 105 °C for 16 h and used to form pellets. | Raw sludge | Improved the carbon utilization efficiency of sewage sludge to as much as 20.4%, resulting in higher yields of CO. Secondly, syngas with separated H2- and CO-rich streams was produced. | [153] |

| Chemical—Hydrothermal carbonization at a temperature of 220 °C and retention time of 1 h | Municipal sewage sludge | It improved gasification reactivity as well as interactions between the carbon surface and hydrogen bonding, hence leading to higher yield of hydrogen. | [120] |

| Chemical—Addition of activated carbon with coconut shell base at 2–8 wt.%, | Sewage sludge | At 8 wt.% activated carbon and 400 °C, syngas production and cold gas efficiency significantly increased from 2.98% to 6.44% and 11.15% to 27.93%, respectively. | [125] |

| Thermal—Torrefaction of SS sample at varying temperature (240–320 °C) and constant residence time of 40 min under an inert atmosphere. | Sewage sludge | Enhanced the removal of about 33.3% of N and 52.8% of S from sewage sludge, which reduces precursor emissions of NOx and SOx. | [154] |

| Thermal—Co-hydrothermal carbonization of sewage sludge and saw dust at 220 °C for 60 min | Sewage Sludge | The produced syngas had a higher carbon monoxide content compared to raw sludge due to increased gasification reactivity and aromatization degree. | [145] |

| Mechanical—Ultrasonication of SS at a frequency of 24 kHz, power of 300 W and input energy of 4500 kJ/kg of solid sludge | Fermented sludge (anaerobically stabilized sludge) | The gas by product yield increased from 26.7 wt% to 55.0 wt% at a process temperature of 360 C. | [111] |

| Thermal—Torrefaction of SS at temperature levels of 200, 250, 300 and 350 °C and residence time of 0–50 min. | Raw sewage sludge | The overall value of chemical exergy increased as the torrefaction temperature increased. In addition, the volatile fraction of the SS decreased as torrefaction temperature increased, which caused an increase in fixed carbon and ash content. | [155] |

| Thermal/Chemical—Gasification of varying mass ratios of Cao-SS pellets in a two-stage sorption-enhanced steam gasification system (SESG) | Municipal sewage sludge | The Cao/SS mass ratio of 3:7 yielded a H2-rich gas stream of 72 vol% at first stage and CO-rich gas stream of 60.5 vol% at the second stage. | [156] |

| Thermal—Torrefaction of SS at 391.9 °C | Sewage sludge | The torrefied sewage sludge resulted in producer gas with higher energy value (LHV) of 17.51 MJ/m3 compared to LHV of 13.51 MJ/m3 reported for raw SS. A 7.4% decrease in the concentration of the condensable compounds. | [152] |

| Chemical—Hydrothermal Carbonization conversion of sewage sludge with CO2 co-gasification of hydrochar | Sewage sludge | The hydrothermal carbonization of the SS resulted in the removal of about 50% of nitrogen contained in the sludge | [157] |

| Hydrothermal treatment of SS | Sewage sludge | Increased the lignin content of the SS, which translated to more methane concentration in the product gas after steam gasification. | [158] |

| S/N | Anaerobic Digestion | Gasification |

|---|---|---|

| Technology | ||

| 1 | Long retention time | Dewatering/drying to >50 wt% solids content required |

| 2 | Low conversion efficiency | Complex reaction |

| 3 | High organic pollutants from process | Technology use still in its infancy |

| 4 | Ammonia toxicity leading to anaerobic digester failure | Extensive syngas cleaning required |

| Social and Environment | ||

| 5 | Appropriate treatment required after digestion to avoid health hazards to the public | Emission of heavy organic pollutants |

| 6 | Polluting odour in the vicinity | Formation of tars |

| 7 | Formation of NOx and SOx precursors | |

| Economics | ||

| 8 | High capital and maintenance costs | High investment and operational costs |

| 9 | High energy requirements | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enebe, N.L.; Chigor, C.B.; Obileke, K.; Lawal, M.S.; Enebe, M.C. Biogas and Syngas Production from Sewage Sludge: A Sustainable Source of Energy Generation. Methane 2023, 2, 192-217. https://doi.org/10.3390/methane2020014

Enebe NL, Chigor CB, Obileke K, Lawal MS, Enebe MC. Biogas and Syngas Production from Sewage Sludge: A Sustainable Source of Energy Generation. Methane. 2023; 2(2):192-217. https://doi.org/10.3390/methane2020014

Chicago/Turabian StyleEnebe, Nwabunwanne Lilian, Chinyere Blessing Chigor, KeChrist Obileke, Mohammed Shariff Lawal, and Matthew Chekwube Enebe. 2023. "Biogas and Syngas Production from Sewage Sludge: A Sustainable Source of Energy Generation" Methane 2, no. 2: 192-217. https://doi.org/10.3390/methane2020014

APA StyleEnebe, N. L., Chigor, C. B., Obileke, K., Lawal, M. S., & Enebe, M. C. (2023). Biogas and Syngas Production from Sewage Sludge: A Sustainable Source of Energy Generation. Methane, 2(2), 192-217. https://doi.org/10.3390/methane2020014