Modeling and Forecasting of Coal Bed Methane Reservoir from Raniganj Coalfield, India

Abstract

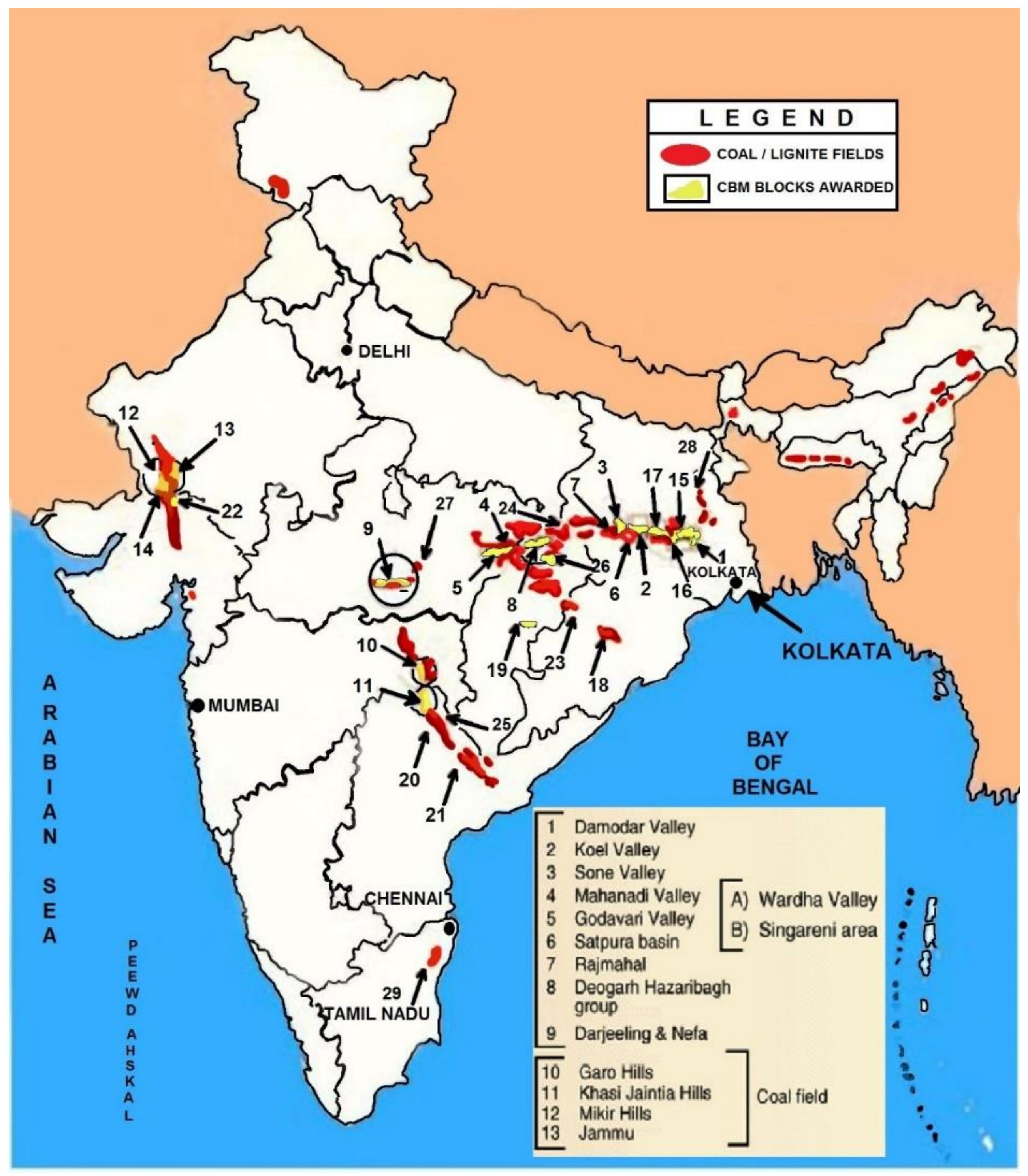

1. Introduction:

2. Methodology

2.1. Numerical Modeling of CBM Process

2.2. Controlling Equations Used in Modeling

2.3. The Assumptions Used for the Development of the Model

- (a)

- There is no thermal change occurring during the gas production from the reservoir.

- (b)

- The reservoir contains two phases: methane and water.

- (c)

- Methane is not soluble in water.

- (d)

- The flow of fluid inside the cleats or fracture system is assumed as laminar flow according to Darcy’s law [58] and flow measurement is done through relative permeability.

- (e)

- All matrix blocks are homogeneous; however, the matrix block is in equilibrium with the fracture system.

- (f)

- The thickness of the seam is alleged to be uniform.

- (g)

- Pseudo steady-state flow condition existed in between the matrix and fractures.

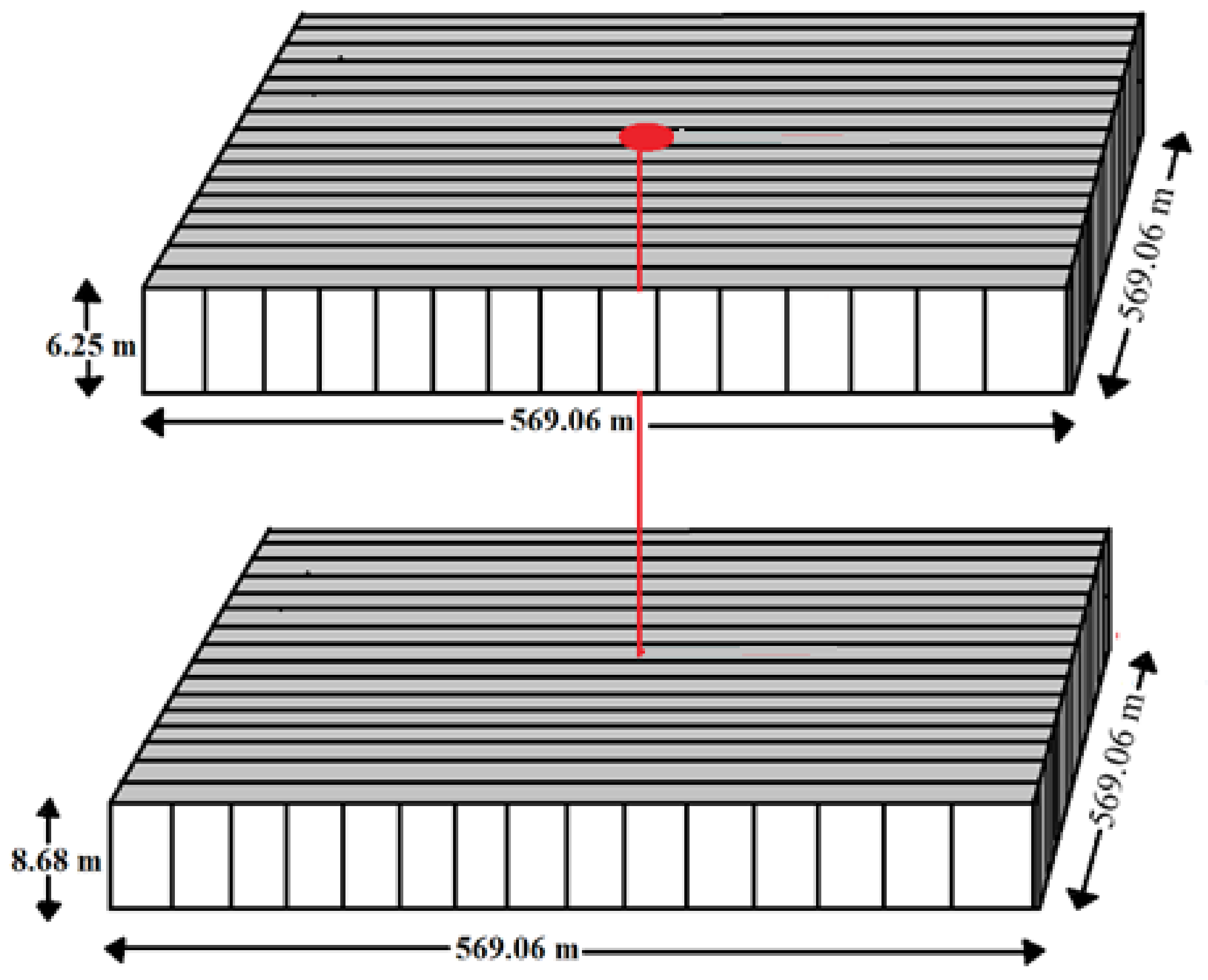

2.4. Model Development

3. Results and Discussions

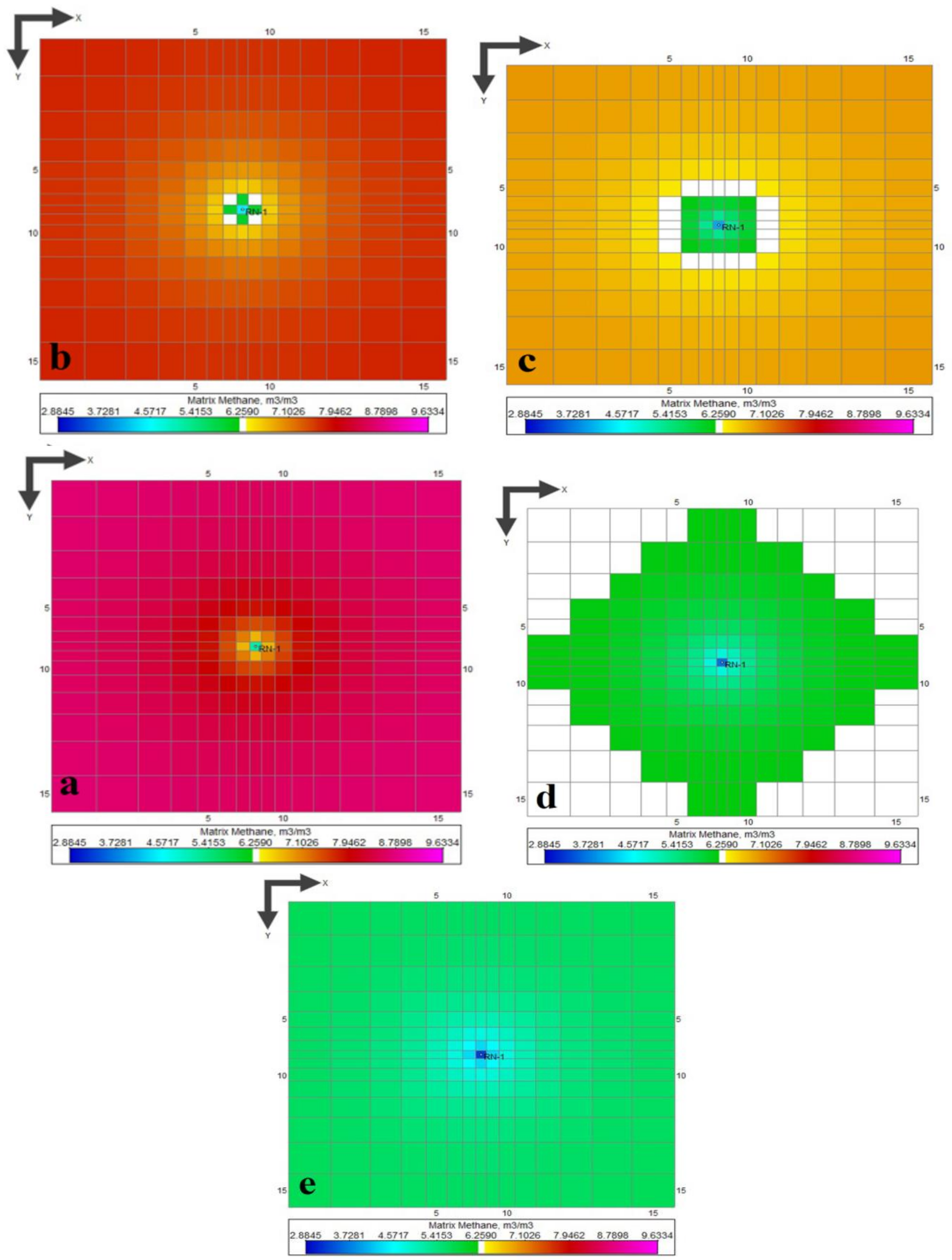

3.1. Matrix Methane Concentration

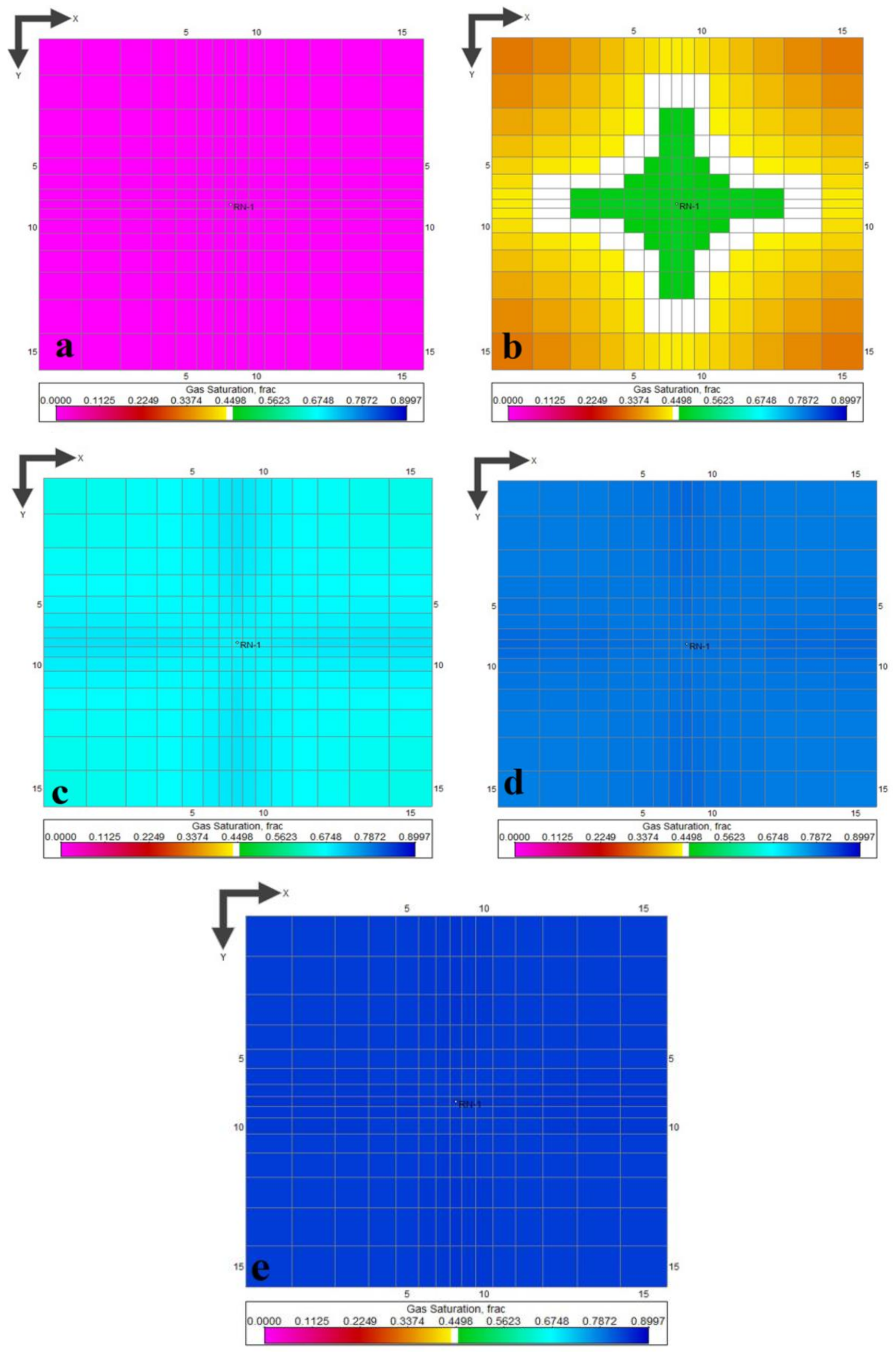

3.2. Fracture Gas Saturation

3.3. Water Production

3.4. Scope for Future

4. Conclusions

- (a)

- This study illustrates that the chosen coal seams of the Sitarampur block can produce an expected 18.60 MCM of methane and 22,117.30 m3 of water over a period of 9125 days.

- (b)

- These coals desorbed methane slowly and attain a peak value of the gas production rate of 2713.2 m3/d in 1948 days, which shows that the gas desorption rate is low in both coal seams.

- (c)

- The fracture gas concentration increases with time, and it is observed that fractures are fully saturated with gas in 3000 days. The gas concentration is high near the production well due to a quick diffusion rate of gas and water production.

- (d)

- This study concludes that approximately 70% of gas recovery can be achieved by this method over a period of 9125 days.

- (e)

- A simulation study demonstrates that the extraction of methane can prevent 372 MCM equivalent CO2 emissions.

- (f)

- The desorption study of coal samples shows that the gas content of coal samples increases with depth.

List of Abbreviation

| CBM | Coal Bed Methane |

| VCBM | Virgin Coal Bed Methane |

| VAM | Ventilation Air Methane |

| CMM | Coal Mine Methane |

| ECBM | Enhanced Coal Bed Methane |

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Park, S.Y.; Liang, Y. Biogenic methane production from coal: A review on recent research and development on microbially enhanced coalbed methane (MECBM). Fuel 2016, 166, 258–267. [Google Scholar] [CrossRef]

- Robbins, S.J.; Evans, P.N.; Esterle, J.S.; Golding, S.D.; Tyson, G.W. The effect of coal rank on biogenic methane potential and microbial composition. Int. J. Coal Geol. 2016, 154, 205–212. [Google Scholar] [CrossRef]

- Guo, H.; Cheng, Y.; Huang, Z.; Urynowicz, M.A.; Liang, W.; Han, Z.; Liu, J. Factors affecting co-degradation of coal and straw to enhance biogenic coalbed methane. Fuel 2019, 244, 240–246. [Google Scholar] [CrossRef]

- Ritter, D.; Vinson, D.; Barnhart, E.; Akob, D.M.; Fields, M.W.; Cunningham, A.B.; Orem, W.; McIntosh, J.C. Enhanced microbial coalbed methane generation: A review of research, commercial activity, and remaining challenges. Int. J. Coal Geol. 2015, 146, 28–41. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Ruiz, F.A.; Cotè, M.; Phipps, S. Coal mine methane: A review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int. J. Coal Geol. 2011, 86, 121–156. [Google Scholar] [CrossRef]

- Zhou, F.; Xia, T.; Wang, X.; Zhang, Y.; Sun, Y.; Liu, J. Recent developments in coal mine methane extraction and utilization in China: A review. J. Nat. Gas Sci. Eng. 2016, 31, 437–458. [Google Scholar] [CrossRef]

- Limbri, H.; Gunawan, C.; Rosche, B.; Scott, J. Challenges to developing methane biofiltration for coal mine ventilation air: A review. Water Air Soil Pollut. 2013, 224, 1566. [Google Scholar] [CrossRef]

- Ali, M.; Paul, S.; Chatterjee, R. Cleat orientation from ground mapping and image log studies for in situ stress analysis: Coal bed methane exploration in South Karanpura Coalfield, India. Energy Fuels 2017, 31, 6812–6824. [Google Scholar] [CrossRef]

- Chatterjee, R.; Paul, S. Classification of coal seams for coal bed methane exploitation in central part of Jharia coalfield, India–A statistical approach. Fuel 2013, 111, 20–29. [Google Scholar] [CrossRef]

- Garg, A.; Kankal, B.; Shukla, P. Methane emissions in India: Sub-regional and sectoral trends. Atmos. Environ. 2011, 45, 4922–4929. [Google Scholar] [CrossRef]

- Paul, S.; Chatterjee, R. Determination of in-situ stress direction from cleat orientation mapping for coal bed methane exploration in south-eastern part of Jharia coalfield, India. Int. J. Coal Geol. 2011, 87, 87–96. [Google Scholar] [CrossRef]

- Gao, L.; Mastalerz, M.; Schimmelmann, A. The origin of coalbed methane. In Coal Bed Methane; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–34. [Google Scholar]

- Mastalerz, M.; Drobniak, A. Coalbed Methane: Reserves, Production, and Future Outlook. In Future Energy; Elsevier: Amsterdam, The Netherlands, 2020; pp. 97–109. [Google Scholar]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Akanksha Singh, A.; Mohanty, D.; Jena, H.; Panwar, D.S. Prospective evaluation of hydrocarbon generation potential of Umarsar lignite, India. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 664–675. [Google Scholar] [CrossRef]

- Panwar, D.; Saxena, V.; Rani, A.; Singh, A.; Kumar, V. Source rock evaluation of the Gondwana coals in Raniganj coalfield, India. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 1395–1402. [Google Scholar] [CrossRef]

- Panwar, D.; Saxena, V.; Singh, A.; Prashant, Y.; Yadav, A. Seam quality and gas resource estimation in kulti block of Raniganj coal field West Bengal India. Int. J. Eng. Res. Sci. Technol. 2016, 5, 1–9. [Google Scholar]

- Panwar, D.; Saxena, V.; Suman, S.; Kumar, V.; Singh, A. Physicochemical study of coal for CBM extraction in Raniganj coal field, India. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 1182–1189. [Google Scholar] [CrossRef]

- Panwar, D.S.; Saxena, V.K.; Chaurasia, R.C.; Singh, A.K. Prospective evaluation of coal bed methane in Raniganj coal field, India. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 946–954. [Google Scholar] [CrossRef]

- Panwar, D.S.; Saxena, V.K.; Yadav, A.M.; Singh, A.K. Natural Gas Recovery: A Case Study of Field Scale Development in Raniganj Coal Field West Bengal, India. Int. J. Eng. Res. Sci. Technol. 2016, 5, 51–57. [Google Scholar]

- Panwar, D.S.; Suman, S.; Singh, A.; Saxena, V.; Chaurasia, R.C. Assessment of hydrocarbon generation potential of bituminous coal from Raniganj Basin, India. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 824–834. [Google Scholar] [CrossRef]

- Panwar, D.; Chaurasia, R.C.; Saxena, V.; Singh, A.K. Geochemical investigation of hydrocarbon generation potential of coal from Raniganj Basin, India. J. Pet. Explor. Prod. Technol. 2021, 11, 3627–3636. [Google Scholar] [CrossRef]

- Panwar, D.S.; Chaurasia, R.C.; Akansha Jena, S.S. Hydrocarbon generation and gasification study of Valia lignite, Gujrat, India. Energy Sources Part A Recovery Util. Environ. Eff. 2021. [Google Scholar] [CrossRef]

- Aydın, G.; Karakurt, I.; Aydıner, K. Investigating the effects of methane drainage on the operating performances of mines. In Proceedings of the 3rd Balkan Mining Congress, Izmir, Turkey, 1–3 October 2009; pp. 575–583. [Google Scholar]

- Mallett, C.; Su, S. Progress in developing ventilation air methane mitigation and utilisation technologies. In Proceedings of the 3rd International Methane & Nitrous Oxide Mitigation Conference, Beijing, China, 17–21 November 2003. [Google Scholar]

- Lei, J.; Niu, R.; Wang, S.; Li, J. The Pd/Na-ZSM-5 catalysts with different Si/Al ratios on low concentration methane oxidation. Solid State Sci. 2020, 101, 106097. [Google Scholar] [CrossRef]

- Nadaraju, F.; Maddocks, A.; Zanganeh, J.; Moghtaderi, B. Ventilation air methane: A simulation of an optimised process of abatement with power and cooling. Min. Technol. 2020, 129, 9–21. [Google Scholar] [CrossRef]

- Su, S.; Agnew, J.J.F. Catalytic combustion of coal mine ventilation air methane. Fuel 2006, 85, 1201–1210. [Google Scholar] [CrossRef]

- Yang, X.; Li, Z.; Zhang, C.; Wang, H.; Zhang, E.; Xing, Y.; Xiao, P.; Yang, R.T.; Liu, Y.; Webley, P.A. Practical separation performance evaluation of coal mine methane upgrading with carbon molecular sieves. Chem. Eng. J. 2019, 367, 295–303. [Google Scholar] [CrossRef]

- Carothers, P.; Deo, M. Technical and Economic Assessment: Mitigation of Methane Emissions from Coal Mine Ventilation Air; Environmental Protection Agency, Climate Protection Division: Washington, DC, USA, 2000. [Google Scholar]

- Karakurt, I.; Aydin, G.; Aydiner, K. The effect of geologic features on methane emissions at underground coal mines. In Proceedings of the 2nd National Workers Health Occupational Safety in Mining, Adana, Turkey, 1–3 October 2009; pp. 151–158. [Google Scholar]

- Bibler, C.J.; Marshall, J.S.; Pilcher, R.C. Status of worldwide coal mine methane emissions and use. Int. J. Coal Geol. 1998, 35, 283–310. [Google Scholar] [CrossRef]

- Cheng, Y.-P.; Wang, L.; Zhang, X.-L. Environmental impact of coal mine methane emissions and responding strategies in China. Int. J. Greenh. Gas Control. 2011, 5, 157–166. [Google Scholar] [CrossRef]

- Gao, J.; Guan, C.; Zhang, B. China’s CH4 emissions from coal mining: A review of current bottom-up inventories. Sci. Total Environ. 2020, 725, 138295. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Warwick, P.D. Assessment of coal mine methane (CMM) and abandoned mine methane (AMM) resource potential of longwall mine panels: Example from Northern Appalachian Basin, USA. Int. J. Coal Geol. 2019, 208, 37–53. [Google Scholar] [CrossRef]

- Kholod, N.; Evans, M.; Pilcher, R.C.; Roshchanka, V.; Ruiz, F.; Coté, M.; Collings, R. Global methane emissions from coal mining to continue growing even with declining coal production. J. Clean. Prod. 2020, 256, 120489. [Google Scholar] [CrossRef]

- Sinha, S.K.; Panigrahi, D. Leveraging Coal Mine Methane/Ventilation Air Methane for Improving Ventilation Standards in Indian Underground Coal Mines and to Reduce Its Carbon Footprints. In Proceedings of the 11th International Mine Ventilation Congress; Springer: Berlin/Heidelberg, Germany, 2019; pp. 355–363. [Google Scholar]

- Su, S.; Beath, A.; Guo, H.; Mallett, C. An assessment of mine methane mitigation and utilisation technologies. Prog. Energy Combust. Sci. 2005, 31, 123–170. [Google Scholar] [CrossRef]

- Su, S.; Chen, H.; Teakle, P.; Xue, S. Characteristics of coal mine ventilation air flows. J. Environ. Manag. 2008, 86, 44–62. [Google Scholar] [CrossRef]

- Hamawand, I.; Yusaf, T.; Hamawand, S.G. Coal seam gas and associated water: A review paper. Renew. Sustain. Energy Rev. 2013, 22, 550–560. [Google Scholar] [CrossRef]

- Feng, R.; Chen, S.; Bryant, S. Investigation of Anisotropic Deformation and Stress-Dependent Directional Permeability of Coalbed Methane Reservoirs. Rock Mech. Rock Eng. 2020, 53, 625–639. [Google Scholar] [CrossRef]

- Jing, Z.; Balucan, R.D.; Underschultz, J.R.; Pan, S.; Steel, K.M. Chemical stimulation for enhancing coal seam permeability: Laboratory study into permeability variation and coal structure examination. Int. J. Coal Geol. 2020, 219, 103375. [Google Scholar] [CrossRef]

- Laubach, S.E.; Marrett, R.A.; Olson, J.E.; Scott, A.R. Characteristics and origins of coal cleat: A review. Int. J. Coal Geol. 1998, 35, 175–207. [Google Scholar] [CrossRef]

- Tian, L.; Cao, Y.; Liu, S.; Shi, B.; Liu, J.; Elsworth, D. Coalbed methane reservoir fracture evaluation through the novel passive microseismic survey and its implications on permeable and gas production. J. Nat. Gas Sci. Eng. 2020, 76, 103181. [Google Scholar] [CrossRef]

- Laubach, S.E.; Olson, J.E.; Gross, M.R. Mechanical and fracture stratigraphy. AAPG Bull. 2009, 93, 1413–1426. [Google Scholar] [CrossRef]

- Laxminarayana, C.; Crosdale, P.J. Role of coal type and rank on methane sorption characteristics of Bowen Basin, Australia coals. Int. J. Coal Geol. 1999, 40, 309–325. [Google Scholar] [CrossRef]

- Levine, J.R. Coalification: The Evolution of Coal as Source Rock and Reservoir Rock for Oil and Gas: Chapter 3; AAPG: Tulsa, OK, USA, 1993. [Google Scholar]

- Rani, S.; Padmanabhan, E.; Prusty, B.K. Review of gas adsorption in shales for enhanced methane recovery and CO2 storage. J. Pet. Sci. Eng. 2019, 175, 634–643. [Google Scholar] [CrossRef]

- Chattaraj, S.; Mohanty, D.; Kumar, T.; Halder, G.; Mishra, K. Comparative study on sorption characteristics of coal seams from Barakar and Raniganj formations of Damodar Valley Basin, India. Int. J. Coal Geol. 2019, 212, 103202. [Google Scholar] [CrossRef]

- Fang, H.; Sang, S.; Liu, S. A Methodology for Characterizing the Multiscale Pores and Fractures in Anthracite and Semi-Anthracite Coals and Its Application in Analysis of the Storage and Permeable Capacity of Coalbed Methane. SPE Reserv. Eval. Eng. 2020, 23, 177–186. [Google Scholar] [CrossRef]

- Scott, A.R. Hydrogeologic factors affecting gas content distribution in coal beds. Int. J. Coal Geol. 2002, 50, 363–387. [Google Scholar] [CrossRef]

- Feng, Q.; Tian, M.; Huang, Z.; Zeng, M.; Wang, T.; Zhang, W.; Wang, X.; Wang, J. Study on Reservoir Properties’ Varying Laws and Production Features of CBM Wells. In Proceedings of the International Field Exploration and Development Conference 2018; Je, L., Ed.; Springer: Singapore, 2020; pp. 304–315. [Google Scholar]

- Liu, T.; Liu, S.; Lin, B.; Fu, X.; Zhu, C.; Yang, W.; Zhao, Y. Stress response during in-situ gas depletion and its impact on permeability and stability of CBM reservoir. Fuel 2020, 266, 117083. [Google Scholar] [CrossRef]

- Peng, Z.; Li, X.; Sun, Z. A relative permeability model for CBM reservoir. Oil Gas Sci. Technol.—Rev. D’ifp Energ. Nouv. 2020, 75, 2. [Google Scholar] [CrossRef]

- Talapatra, A.; Karim, M. The influence of moisture content on coal deformation and coal permeability during coalbed methane (CBM) production in wet reservoirs. J. Pet. Explor. Prod. Technol. 2020, 10, 1907–1920. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, X.; Ma, G.; Feng, D. Experimental and theoretical study on influencing factor of fracture width in coalbed methane reservoir. Arab. J. Geosci. 2019, 12, 558. [Google Scholar] [CrossRef]

- Zhang, K.; Du, F.; Nojabaei, B. Effect of Pore Size Heterogeneity on Hydrocarbon Fluid Distribution and Transport in Nanometer-Sized Porous Media. In Proceedings of the SPE Eastern Regional Meeting, Charleston, WV, USA, 21–23 October 2019. [Google Scholar]

- Darcy, H.P.G. Les Fontaines Publiques de la Ville de Dijon. Exposition et Application des Principes à Suivre et des Formules à Employer dans les Questions de Distribution D’eau, etc; Dalamont: Dijon, France, 1856. [Google Scholar]

- Warren, J.E.; Root, P.J. The Behavior of Naturally Fractured Reservoirs. SPE J. 1963, 3, 245–255. [Google Scholar] [CrossRef]

| Parameter | Value | |

|---|---|---|

| Seam-I | Seam-II | |

| Reservoir temperature (°C) | 61.72 | 64.94 |

| Depth (m) | 657.98 | 755 |

| Permeability (mD) | 1.84 | 1.25 |

| Density of coal (kg/m3) | 1280 | 1320 |

| Cleat porosity (%) | 0.50 | 0.50 |

| Thickness (m) | 6.25 | 8.68 |

| Sorption time (days) | 1.42 | 0.21 |

| Initial matrix content (m3/t) | 7.12 | 7.67 |

| Fracture spacing (m) | 2.54 × 10−3 | 2.54 × 10−3 |

| Langmuir volume for methane (m3/t) | 17.98 | 21.82 |

| Langmuir pressure for methane (atm) | 44.76 | 40.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panwar, D.S.; Chaurasia, R.C.; Saxena, V.K.; Singh, A.K. Modeling and Forecasting of Coal Bed Methane Reservoir from Raniganj Coalfield, India. Methane 2022, 1, 229-242. https://doi.org/10.3390/methane1040019

Panwar DS, Chaurasia RC, Saxena VK, Singh AK. Modeling and Forecasting of Coal Bed Methane Reservoir from Raniganj Coalfield, India. Methane. 2022; 1(4):229-242. https://doi.org/10.3390/methane1040019

Chicago/Turabian StylePanwar, Deepak Singh, Ram Chandra Chaurasia, Vinod Kumar Saxena, and Ajay Kumar Singh. 2022. "Modeling and Forecasting of Coal Bed Methane Reservoir from Raniganj Coalfield, India" Methane 1, no. 4: 229-242. https://doi.org/10.3390/methane1040019

APA StylePanwar, D. S., Chaurasia, R. C., Saxena, V. K., & Singh, A. K. (2022). Modeling and Forecasting of Coal Bed Methane Reservoir from Raniganj Coalfield, India. Methane, 1(4), 229-242. https://doi.org/10.3390/methane1040019