Floater Assembly and Turbine Integration Strategy for Floating Offshore Wind Energy: Considerations and Recommendations

Abstract

1. Introduction—Finding the Best Construction Strategy

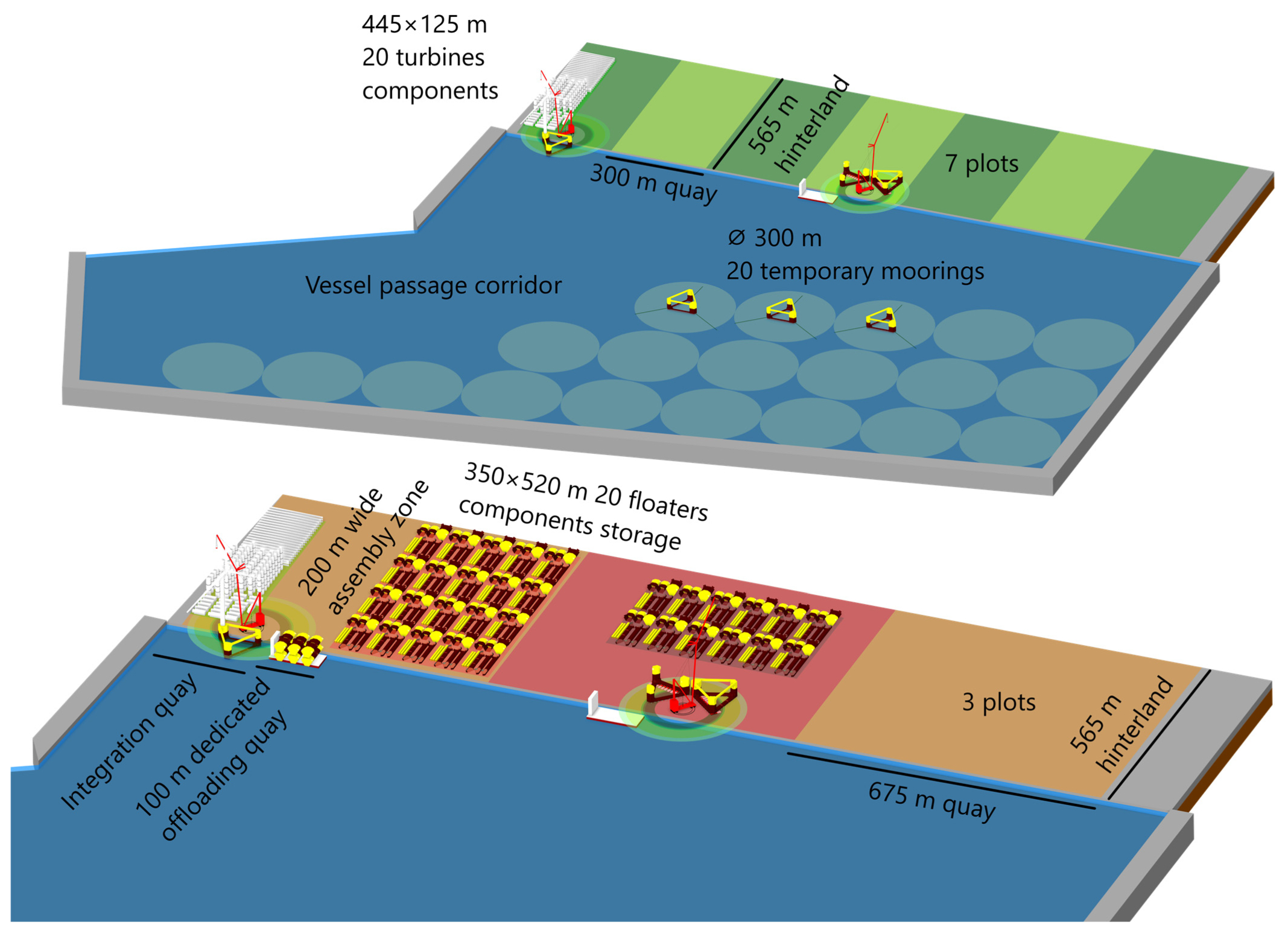

2. Port Operations and Crane Types

- Floater—floater hull assembly port;

- Turbine—turbine integration port;

- F+T—floater assembly and turbine integration port;

- Moor—mooring and service base port;

- All—all-in-one hub port.

| Floater | Turbine | F + T | Mooring | All | Operation Types | Quay Depth, m | Crane Capacity, t | Storage, km2 |

|---|---|---|---|---|---|---|---|---|

| Components offloading | 4–10 | <1000 | 0.02 | |||||

| Turbine assembly | - | <1600 | 0.03 | |||||

| Turbine integration | 8–12 | <3200 | 0.05 | |||||

| Turbine comp. storage | - | - | 0.06 | |||||

| Floater comp. storage | - | - | 0.2 | |||||

| Floater assembly | - | <1600 | 0.03 | |||||

| Floater launch | 8–12 | - | 0.02 | |||||

| Mooring comp. storage | - | <200 | 0.04 | |||||

| Anchor Handling Base | 4–8 | <200 | - | |||||

| Service Vessel base | 4–8 | <200 | - | |||||

| Spare parts storage | - | <200 | 0.04 |

3. Floater Block Assembly and Launching

- The floater will be transported to a semi-submersible barge and lowered to the water, then moored at the quayside and the turbine installed.

- The turbine will be installed on the floater onshore, and the assembly will be moved to a barge and lowered to the water.

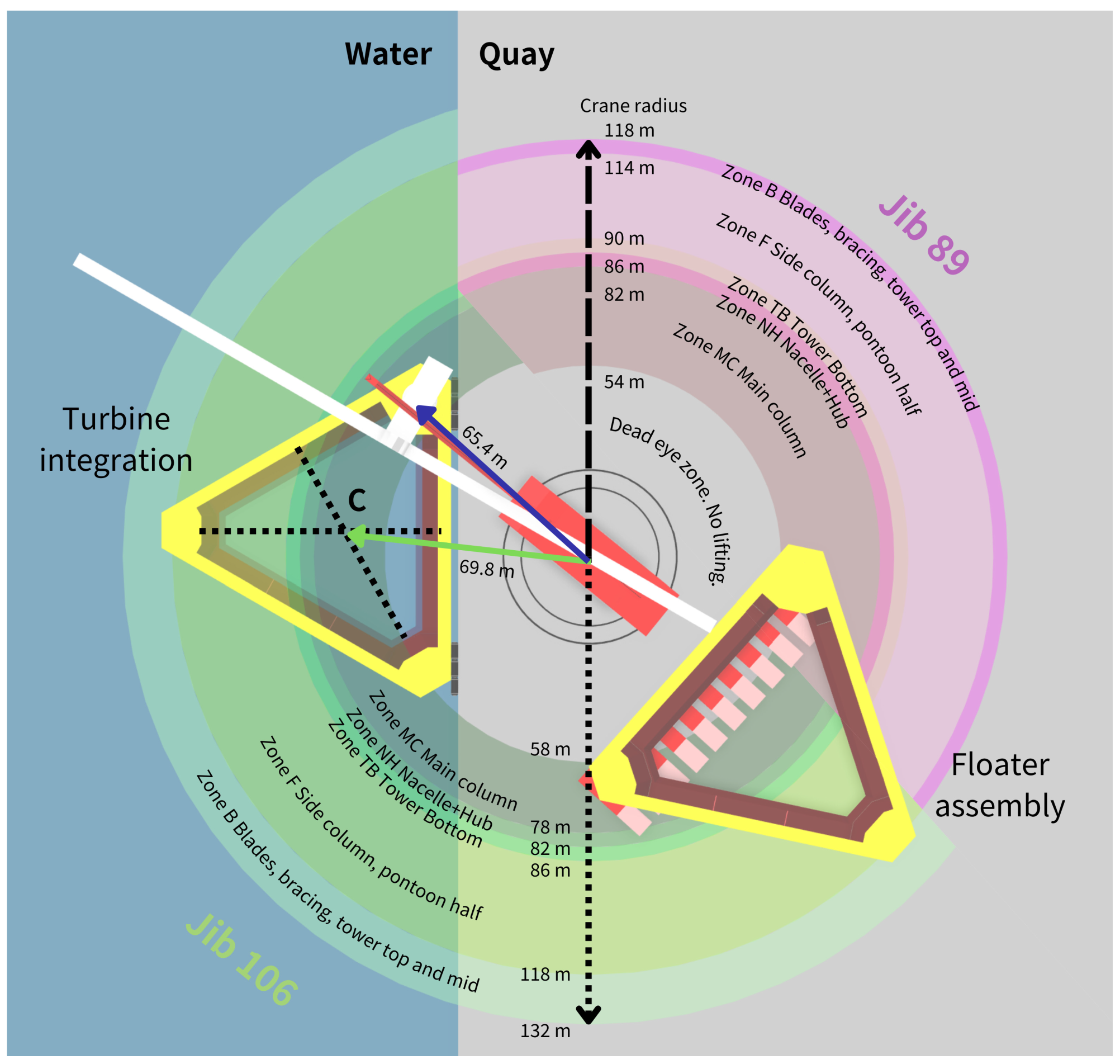

4. Cranes for Turbine Assembly

5. Turbine Integration with Floater

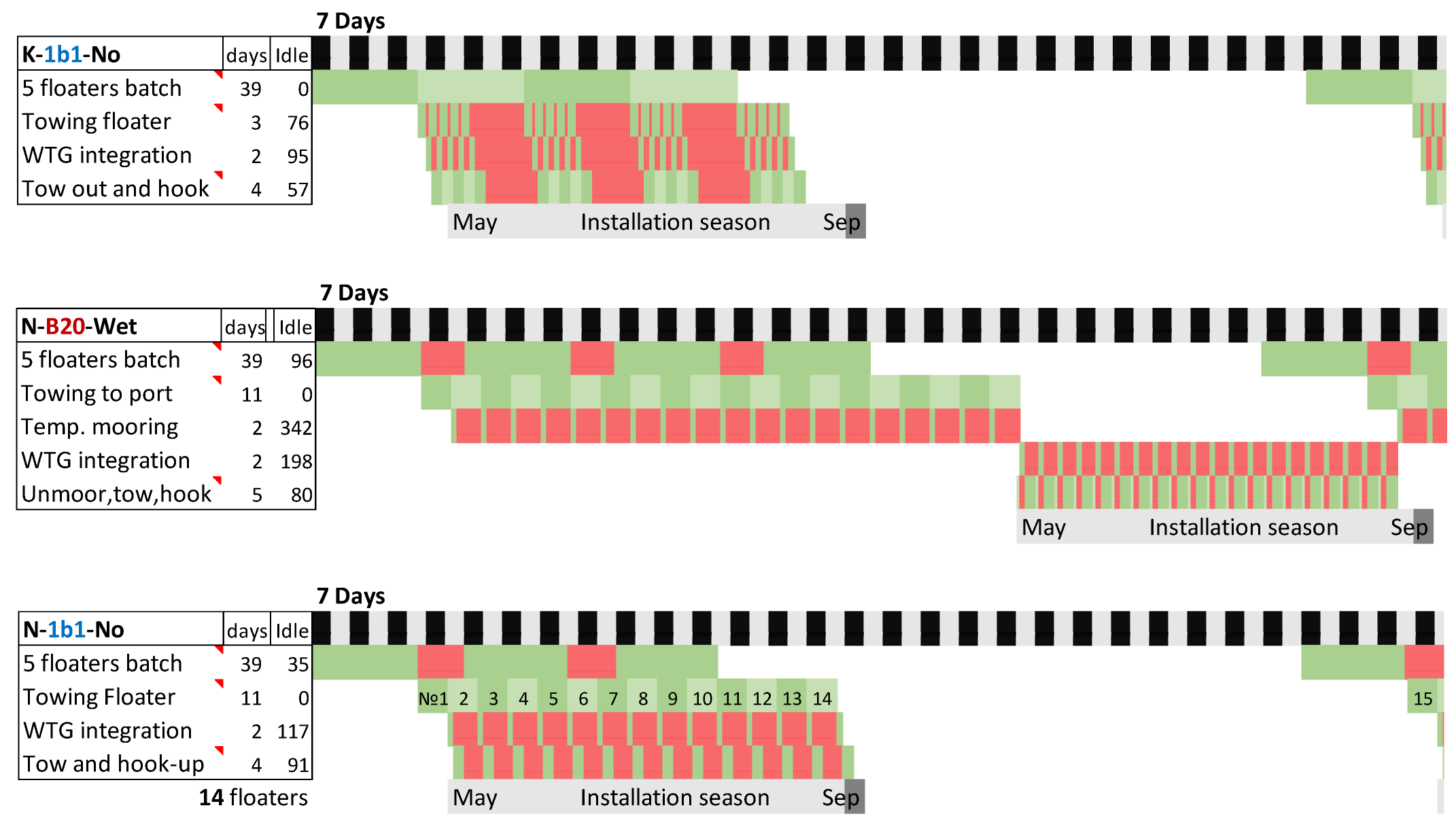

- One-by-one (1b1): Install the turbine as soon as a floater is ready and then pay for the crane’s idle time before the next installation.

- Batches of 20 (B20): Wait for a batch of 20 floaters to be ready for integration in one season to minimise the crane idle time.

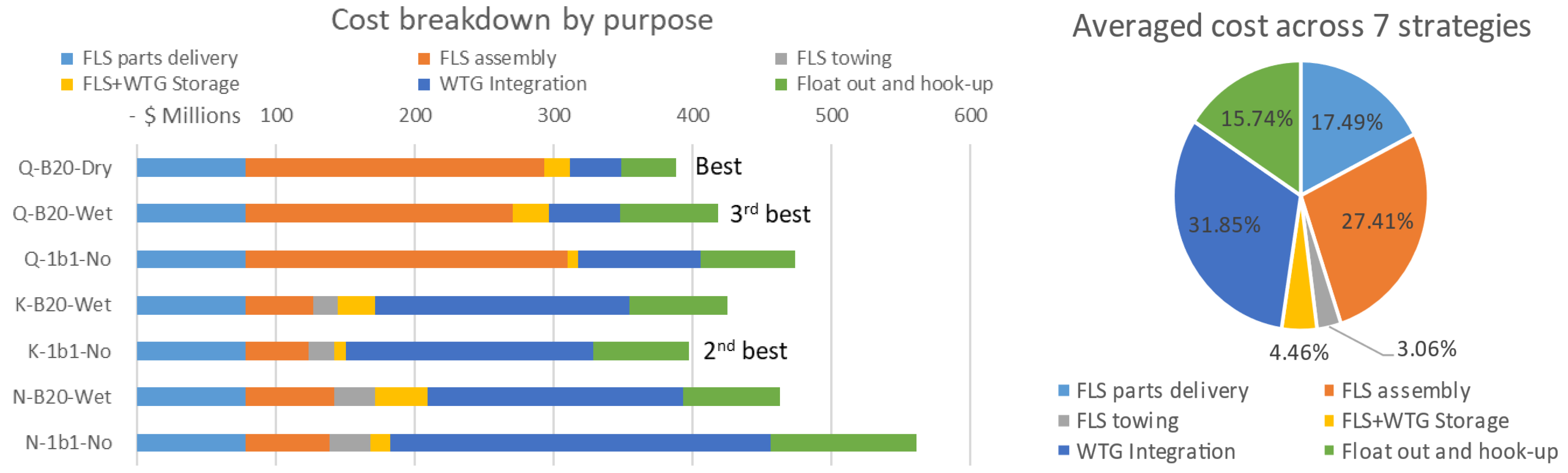

| Strategies No. | 1 Q-B20-Dry | 2 Q-B20-Wet | 3 Q-1b1-No | 4 K-B20-Wet | 5 K-1b1-N | 6 N-B20-Wet | 7 N-1b1-No |

|---|---|---|---|---|---|---|---|

| Floater Construction | On-quay | On-quay | On-quay | Kaohsiung | Kaohsiung | Nagasaki | Nagasaki |

| Turbine Integration | Batches of 20 | Batches of 20 | One-by-one | Batches of 20 | One-by-one | Batches of 20 | One-by-one |

| Storage | Dry | Wet | (n/a) | Wet | (n/a) | Wet | (n/a) |

- Strategy No. 1, Q-B20-Dry (Taichung quay, batch 20 and dry storage), gives the lowest overall cost. Its low cost mainly comes from the lowest turbine integration cost due to its high crane time efficiency, as the components are located conveniently on-site.

- Dry dock and towing costs balance out crane costs. Thus, dry dock assembly has a similar cost as an on-quay assembly. The duration is also similar. If a cheaper crane solution can be found (buy second-hand, share, etc.), on-quay assembly can be made significantly cheaper.

- On-quay assembly and immediate turbine integration are as good as on-quay assembly and dry storage, giving choice flexibility based on other factors.

- When it comes to wet storage, it is cost-ineffective if paired with on-quay assembly or if the drydock is close by (Kaohsiung). However, it can be slightly beneficial if the drydock is far (Nagasaki). Combined with a limited wet storage area in the harbour, wet storage is the worst choice overall.

- Comparing batch vs one-by-one turbine integration, waiting for a batch helps save costs due to the reduced crane hire time, but just-in-time turbine integration generally allows the fastest project execution overall.

| Floaters Installed | ||||||||||

| Welding | Crane | Tugs | AHT | Semi-sub | SMPT | Quay | Dock | 40 pcs | 100 pcs | |

| Days | Days | Days | Days | Days | Days | Days | Days | Days | Days | |

| Q-B20-Dry | 700 | 390 | - | 400 | 390 | 1,090 | 1,624 | - | 616 | 1,624 |

| Q-B20-Wet | 700 | 390 | 675 | 700 | 665 | 700 | 1,624 | - | 616 | 1,624 |

| Q-1b1-No | 700 | 675 | - | 685 | 670 | 700 | 1,491 | - | 483 | 1,491 |

| K-B20-Wet | 975 | 695 | 1,315 | 700 | - | - | 1,773 | 780 | 678 | 1,773 |

| K-1b1-No | 780 | 675 | 680 | 685 | - | - | 1,641 | 780 | 546 | 1,641 |

| N-B20-Wet | 1,295 | 695 | 2,155 | 700 | - | - | 1,905 | 1,020 | 762 | 1,905 |

| N-1b1-No | 1,064 | 1,036 | 1,100 | 1,050 | - | - | 2,754 | 1,030 | 929 | 2,754 |

| Welders | Crane | Tugs | AHT | Semi-sub | SMPT | Quay | Dry dock | Total | ||

| $ mil. | $ mil. | $ mil. | $ mil. | $ mil. | $ mil. | $ mil. | $ mil. | $ mil. | ||

| Q-B20-Dry | 10.75 | 103.07 | - | 40.00 | 106.58 | 109.21 | 18.58 | - | 388 |  |

| Q-B20-Wet | 10.75 | 103.07 | 18.23 | 70.00 | 134.08 | 73.89 | 8.26 | - | 418 | |

| Q-1b1-No | 10.75 | 178.40 | - | 68.50 | 134.58 | 73.89 | 7.58 | - | 474 | |

| K-B20-Wet | 14.98 | 183.68 | 35.51 | 70.00 | 67.58 | 10.49 | 9.02 | 33.38 | 425 | |

| K-1b1-No | 11.98 | 178.40 | 18.36 | 68.50 | 67.58 | 10.49 | 8.34 | 33.38 | 397 | |

| N-B20-Wet | 19.89 | 183.68 | 58.19 | 70.00 | 67.58 | 10.49 | 9.69 | 43.66 | 463 | |

| N-1b1-No | 16.35 | 273.73 | 29.70 | 105.00 | 67.58 | 10.49 | 14.00 | 44.08 | 561 | |

6. Discussion

7. Conclusions and Recommendations

- Floater on-quay assembly in Taichung Port may be the most cost-effective compared to remote drydock assembly. After a cost evaluation under several assumptions, the integration strategy (Q-B20-Dry) using Taichung quay, a batch of 20 floaters and dry storage gives the lowest overall cost. Its low cost mainly comes from the lowest turbine integration cost due to its high crane time efficiency, as the components are located conveniently on-site.

- A complete list of possible port operations with necessary equipment is summarized for a FOWT project. Regarding selecting a floater launching method, the most viable method may be using a semi-submersible barge (e.g., a floating dock). This is based on the assumption that the hull assembly work will be carried out at Taichung Port in an ideal situation. This launching method avoids the long-distance wet tow from a shipyard with a drydock to the port.

- A very large crane (e.g., a ring crane) is needed even for floater designs with a turbine on the side column. A large crane may be enough to install the turbine in both central and side columns, making the argument that a side-column turbine may not gain too much advantage. However, the side-column location could show its advantage if the large crane is impossible to procure due to short supply. In that situation, a tandem of two smaller crawler cranes could install the turbine.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stehly, T.; Beiter, P.; Duffy, P. 2019 Cost of Wind Energy Review; National Renewable Energy Lab (NREL): Golden, CO, USA, 2020. Available online: https://www.nrel.gov/docs/fy21osti/78471.pdf (accessed on 28 August 2024).

- Hong, S.; McMorland, J.; Zhang, H.; Collu, M.; Halse, K.H. Floating offshore wind farm installation, challenges and opportunities: A comprehensive survey. Ocean Eng. 2024, 304, 117793. [Google Scholar] [CrossRef]

- Torres, E.S.; Thies, P.R.; Lawless, M. Offshore Logistics: Scenario Planning and Installation Modeling of Floating Offshore Wind Projects. ASME Open J. Eng. 2023, 2, 021013. [Google Scholar] [CrossRef]

- Díaz, H.; Guedes Soares, C. Approach for Installation and Logistics of a Floating Offshore Wind Farm. J. Mar. Sci. Eng. 2023, 11, 53. [Google Scholar] [CrossRef]

- BVG Associates. Guide to a Floating Offshore Wind Farm; Offshore Renewable Energy Catapult: Blyth, UK, 2023. [Google Scholar]

- Zhou, S.; Müller, K.; Li, C.; Xiao, Y.; Cheng, P.W. Global sensitivity study on the semisubmersible substructure of a floating wind turbine: Manufacturing cost, structural properties and hydrodynamics. Ocean Eng. 2021, 221, 108585. [Google Scholar] [CrossRef]

- Ferri, G.; Marino, E. Site-specific optimizations of a 10 MW floating offshore wind turbine for the Mediterranean Sea. Renew. Energy 2023, 202, 921–941. [Google Scholar] [CrossRef]

- Hsu, I.-J.; Ivanov, G.; Ma, K.-T.; Huang, Z.-Z.; Wu, H.-T.; Huang, Y.-T.; Chou, M. Optimization of Semi-Submersible Hull Design for Floating Offshore Wind Turbines. In Proceedings of the 41st International Conference on Offshore Mechanics and Arctic Engineering (OMAE 2022), Hamburg, Germany, 5–11 June 2022. [Google Scholar]

- Ivanov, G.; Hsu, I.-J.; Ma, K.-T. Design Considerations on Semi-Submersible Columns, Bracings and Pontoons for Floating Wind. J. Mar. Sci. Eng. 2023, 11, 1663. [Google Scholar] [CrossRef]

- Lai, Z.-Y.; Ivanov, G.; Chen, J.-C.; Chen, D.; Ma, K.-T. Mooring Anchor radius and Spread-angle Optimization for a 2 MW Semi-Submersible Floating Wind Turbine in Taiwan Strait. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering (OMAE 2024), Singapore, 9–14 June 2024. [Google Scholar]

- Chen, C.-A.; Chen, K.-H.; Igarashi, Y.; Chen, D.; Ma, K.-T.; Lai, Z.-Y. Design Of Mooring System for a 15mw Semi-Submersible, Taidafloat, in Taiwan Strait. In Proceedings of the 42nd International Conference on Ocean, Offshore and Arctic Engineering, Melbourne, Australia, 11–16 June 2023. [Google Scholar]

- Wu, K.-Y.; Ivanov, G.; Hsu, I.-J.; Ma, K.-t.; Chiang, M.-H. Technology Development of a Floating Offshore Wind Turbine, “TaidaFloat”. In Proceedings of the Taiwan Wind Energy Conference 2023, Taipei, Taiwan, 18–20 October 2023. [Google Scholar]

- Gaertner, E.; Rinker, J.; Sethuraman, L.; Zahle, F.; Anderson, B.; Barter, G.E.; Abbas, N.J.; Meng, F.; Bortolotti, P.; Skrzypinski, W. IEA Wind TCP Task 37: Definition of the IEA 15-Megawatt Offshore Reference Wind Turbine; National Renewable Energy Lab (NREL): Golden, CO, USA, 2020. [Google Scholar]

- Jensen, M.B.; Kofoed-Hansen, H.; Hansen, A.; Christensen, L.M.; Hess, M.; Jørgensen, A.; Hsu, M. Offshore Wind Port Feasibility Study of Taichung Harbor, Taiwan. 2016. Available online: https://www.academia.edu/33881798/Offshore_Wind_Port_Feasibility_Study_of_Taichung_Harbor_Taiwan_Taichung (accessed on 9 August 2024).

- Taiwan International Ports Corporation. Port Layouts. 2024. Available online: https://www.twport.com.tw/en/cp.aspx (accessed on 9 August 2024).

- Terex. Terex CC9800 Crawler Crane Specification. 2009. Available online: https://storage.bigge.com/webstorage/crane-charts/Demag-CC9800.pdf (accessed on 28 August 2024).

- Liebherr. Technical Data—LR 13000. 2024. Available online: https://www.liebherr.com/en/int/products/mobile-and-crawler-cranes/crawler-cranes/lr-crawler-cranes/lr-13000.html (accessed on 28 August 2024).

- Liebherr. Game Changer for Tomorrow's Energy. LR12500-1.0 Crawler Crane. 2023. Available online: https://www.liebherr.com/external/products/products-assets/68260ca3-3e8d-4366-9019-5413e68d6bf1-10/liebherr-281-lr-12500-1.0-281-00-defisr10-2023.pdf (accessed on 28 August 2024).

- Mammoet. Mammoet-Giant JV Supports Manufacturing of Taiwan’s First Wind Turbine Jacket Foundations. Available online: https://www.mammoet.com/news/mammoet-giant-jv-supports-manufacturing-of-taiwans-first-wind-turbine-jacket-foundations/ (accessed on 23 May 2024).

- Mammoet. MAMMOET PTC 200-DS Dimensions. 2015. Available online: https://www.mammoet.com/equipment/cranes/ring-cranes/ptc-200-ds/ (accessed on 28 August 2024).

- Mammoet. SPMT Scheuerle Dimensions and Specifications. 2015. Available online: https://www.mammoet.com/siteassets/06-equipment/transport/self-propelled-modular-transporter/datasheet-SPMT-Scheuerle/ (accessed on 28 August 2024).

- Tayyar, G.T. Welding in Shipbuilding; Martin Leduc. 2008. Available online: https://www.dieselduck.info/machine/04%20auxiliary/2008%20Ship%20Welding.pdf (accessed on 28 August 2024).

- Scheid, P. Sailing Cargo Ship|Shipyard Vietnam—Hull Block Heavy Lift & installation|Dop Peter Scheid. YouTube. 2023. Available online: https://www.youtube.com/watch?v=speTKU4Bkcg (accessed on 28 August 2024).

- Ocergy. About OCG-Wind. Available online: https://www.ocergy.com/ocg-wind (accessed on 23 May 2024).

- Stiesdal. Tetra Offshore Foundations for Any Water Depth. Available online: https://www.stiesdal.com/offshore/tetra-offshore-foundations-for-any-water-depth/ (accessed on 23 May 2024).

- Ivanov, G. Ukraine—Taiwan Offshore Wind Joint Venture. Promising Cooperation for Achieving Energy Independence. Int. J. Bus. 2024, 29. [Google Scholar] [CrossRef]

- National Development Council (Taiwan). 2021–2023 Annual Survey and Estimation of Talent Supply and Demand in Key Industries; Taiwan. 2021. Available online: https://ws.ndc.gov.tw/Download.ashx?u=LzAwMS9hZG1pbmlzdHJhdG9yLzE4L3JlbGZpbGUvNjAzNy85NTEwLzkxN2I0ZDk4LTRkNzAtNDk0OC1hNDM3LTVhMmI4MGVkNDQ0Ni5wZGY%3D&n=MTEwLTExMuW5tOmHjem7nueUoualreS6uuaJjeS%2Bm%2BmcgOiqv%2BafpeWPiuaOqOS8sCgxMDnlubTovqbnkIbmiJDmnpzlvZnmlbTloLHlkYopLnBkZg%3D%3D&icon=..pdf (accessed on 28 August 2024).

- van der Kaaij, I. Evaluating the workability of On-Site Assembly of a 15MW Wind Turbine Blade on a Semi-Submersible Floating Wind Turbine Using a Crane Vessel. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2023. [Google Scholar]

- Vestas. Building the V236-15.0 MW™ Offshore Turbine Prototype|Episode 3: The Installation. YouTube. 2023. Available online: https://www.youtube.com/watch?v=xRqwEnb8K68 (accessed on 28 August 2024).

- Bigge. Operated & Maintained Crane Rental Rates. Available online: https://www.bigge.com/crane-rental/operated-and-maintained/ (accessed on 23 May 2024).

- Ralls, M.L.; Newman, R. Introduction on Use of Self Propelled Modular Transporters (SPMTs) to Move Bridges; National Highway Institute: Vienna, VA, USA, 2008. [Google Scholar]

- Shandong Panda Mechanical Co. For Sale: 150 ton 10 Axle 12 Axle Line Spmt Self Propelled Modular Transporter Trailer. 2024. Available online: https://www.alibaba.com/product-detail/150-ton-10-axle-12-axle_1600987143384.html?spm=a2700.7724857.0.0.44cd4d58LXp6Ei (accessed on 4 June 2024).

- Crowle, A.; Thies, P. Floating offshore wind turbines port requirements for construction. Proc. Inst. Mech. Eng. Part M: J. Eng. Marit. Environ. 2022, 236, 1047–1056. [Google Scholar] [CrossRef]

- Hasumi, T.; Yokoi, T.; Haneda, K.; Chujo, T.; Fujiwara, T. Estimation For Efficiency of Offshore Installation Process of Floating Offshore Wind Turbines in Japan. In Proceedings of the 42nd International Conference on Ocean, Offshore and Arctic Engineering, Melbourne, Australia, 11–16 June 2023. [Google Scholar]

- Buljan, A. Floaters for French Pilot Wind Farm Taking Shape. offshoreWind.biz. 2022. Available online: https://www.offshorewind.biz/2022/07/14/floaters-for-french-pilot-wind-farm-taking-shape/ (accessed on 28 August 2024).

- Chitteth Ramachandran, R.; Desmond, C.; Judge, F.; Serraris, J.J.; Murphy, J. Floating wind turbines: Marine operations challenges and opportunities. Wind Energ. Sci. 2022, 7, 903–924. [Google Scholar] [CrossRef]

- Arvesen, A.; Birkeland, C.; Hertwich, E.G. The Importance of Ships and Spare Parts in LCAs of Offshore Wind Power. Environ. Sci. Technol. 2013, 47, 2948–2956. [Google Scholar] [CrossRef] [PubMed]

- Ferry, T. Offshore Wind Industry Struggles with Localisation. In Euroview; European Chamber of Commerce Taiwan: Taipei City, Taiwan, 2022; Available online: https://euroview.ecct.com.tw/category-inside.php?id=412 (accessed on 28 August 2024).

- Uttley, E.; Martin-Venner, K.; Scott, M.; Williams, S.B. Port and Manufacturing Infrastructure Investment Models. In Offshore Renewable Energy Catapult; Floating Offshore Wind Centre of Excellence: Aberdeen, Scotland, 2024; Available online: https://fowcoe.co.uk/wp-content/uploads/2024/03/FOW-CoE-PR50-Port-Infrastructure-and-Manufacturing-Investment-Models.pdf (accessed on 28 August 2024).

- Metal Industry Intelligence. The Supply Chain Study of Offshore Wind Industry in Taiwan. 2022. Available online: https://www.bcctaipei.com/sites/default/files/2022-03/Taiwan%20Offshore%20Wind%20Supply%20Chain%20Report%200322.pdf (accessed on 28 August 2024).

- Smith, B.M.; Ongley, J.; Angeloudis, A.; Thies, P.R. Mitigation of assembly constraints for floating offshore wind turbines using discrete event simulation. J. Phys. Conf. Ser. 2023, 2626, 012044. [Google Scholar] [CrossRef]

- Pronoza, P. Ukraine shipbuilding and world: Features and trends. Econ. Manag. Law: Probl. Prospect. 2015, 215, 102. [Google Scholar]

| Using PTC 200-DS 140 Crane | Crane Radius, m | ||||

|---|---|---|---|---|---|

| 15 MW IEA Turbine | Quantity | Mass, t | Jib 106 | Jib 101 | Jib 89 |

| Tower top | 1 | 213 | 132 | 132 | 118 |

| Tower mid | 1 | 252 | 132 | 132 | 118 |

| Tower bot | 1 | 796 | 86 | 86 | 90 |

| Nacelle+Hub | 1 | 822 | 82 | 86 | 86 |

| Blade 1x | 3 | 65 | 208 | 200 | 118 |

| Total | 2280 | ||||

| TaidaFloat(ver. 4.1.6A) | |||||

| Main Column | 1 | 883 | 78 | 82 | 82 |

| Side Column | 2 | 492 | 122 | 118 | 114 |

| Pontoon half | 6 | 521 | 118 | 118 | 114 |

| Brace | 3 | 152 | 132 | 132 | 118 |

| Total | 5448 | ||||

| No. | Assembly Procedure | Thickness, mm | Seam Length, m | Time, h |

|---|---|---|---|---|

| 1 | Pontoon 1 lift | 30 | 5.0 | |

| 2 | Pontoon 1 middle weld | 30 | 50.6 | 189.2 |

| 3 | Pontoon 1 butt weld 1 | 30 | 87.7 | 327.8 |

| 4 | Pontoon 1 butt weld 2 | 30 | 87.7 | 327.8 |

| 5 | Pontoon 2 lift | 30 | 5.0 | |

| 6 | Pontoon 2 middle weld | 30 | 50.6 | 189.2 |

| 7 | Pontoon 2 butt weld 1 | 30 | 87.7 | 327.8 |

| 8 | Pontoon 2 butt weld 2 | 30 | 87.7 | 327.8 |

| 9 | Pontoon 3 lift | 30 | 5.0 | |

| 10 | Pontoon 3 middle weld | 30 | 50.6 | 189.2 |

| 11 | Pontoon 3 butt weld 1 | 30 | 87.7 | 327.8 |

| 12 | Pontoon 3 butt weld 2 | 30 | 87.7 | 327.8 |

| 13 | MC lift 1 | 30 | 5.0 | |

| 14 | MC bottom weld | 30 | 170 | 634.0 |

| 15 | MC lift 2 | 30 | 5.0 | |

| 16 | MC mid weld | 30 | 142 | 529.2 |

| 17 | SC 1 lift | 30 | 5.0 | |

| 18 | SC 1 weld | 30 | 124 | 462.1 |

| 19 | SC 2 lift | 30 | 5.0 | |

| 20 | SC 2 weld | 30 | 124 | 462.1 |

| 21 | Bracing 1 lift | 20 | 53.0 | |

| 22 | Bracing 1 weld 1 | 20 | 30 | 52.2 |

| 23 | Bracing 1 weld 2 | 20 | 30 | 52.2 |

| 24 | Bracing 2 lift | 20 | 53.0 | |

| 25 | Bracing 2 weld 1 | 20 | 30 | 52.2 |

| 26 | Bracing 2 weld 2 | 20 | 30 | 52.2 |

| 27 | Bracing 3 lift | 20 | 53.0 | |

| 28 | Bracing 3 weld 1 | 20 | 30 | 52.2 |

| 29 | Bracing 3 weld 2 | 20 | 30 | 52.2 |

| 30 | Internal systems outfitting | 72.0 | ||

| 31 | Transportation to barge | 24.0 | ||

| 32 | Towing to quay | 12.0 | ||

| Total | Manhours | 5237 |

| Electro Gas Manual Welding | ||||||

|---|---|---|---|---|---|---|

| Thickness, mm | 10 | 15 | 20 | 25 | 30 | 35 |

| Hours to weld 5 m | 6.8 | 7.6 | 8.7 | 10.3 | 13.1 | 18.7 |

| Hours to weld 1 m | 1.36 | 1.52 | 1.74 | 2.06 | 2.62 | 3.74 |

| Weld area preparation, h | 2 | 2 | 2 | 2 | 2 | 2 |

| Month | Mean Speed (m/s) | Max. Wind Speed/Direction | Wind Speed < 5 m/s (%) | Wind Speed 5–10 m/s (%) | Wind Speed 10–15 m/s (%) | Wind Speed > 15 m/s (%) | Direction N-E (%) | Direction E-S (%) | Direction S-W (%) | Direction W-N (%) | Wind Speed < 10 m/s | Days | Workable Days |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Jan | 13.8 | 28.4/NE | 7.3 | 19.5 | 24.9 | 48.3 | 90.9 | 2.3 | 1.1 | 5.7 | 27% | 31 | 8 |

| Feb | 11.7 | 27.8/N | 18.8 | 22.1 | 24.1 | 35 | 82.8 | 3.8 | 6.1 | 7.1 | 41% | 29 | 12 |

| Mar | 10.5 | 32.4/NE | 25.2 | 23.9 | 23.5 | 27.5 | 76 | 5 | 10.6 | 8 | 49% | 31 | 15 |

| Apr | 7.9 | 30.1/NNE | 32.6 | 37.8 | 18.4 | 11.3 | 58.9 | 7.8 | 22.5 | 10.6 | 70% | 30 | 21 |

| May | 7 | 27.6/NE | 35.1 | 44.3 | 15.6 | 5 | 50.5 | 7 | 32.4 | 9.9 | 79% | 31 | 25 |

| Jun | 7.1 | 21.1/SW | 28.8 | 51.5 | 17.2 | 2.5 | 27.4 | 10 | 54.9 | 7.6 | 80% | 30 | 24 |

| Jul | 6.6 | 37.5/NNE | 34.8 | 53.4 | 8.7 | 3.2 | 21.1 | 10.3 | 54.3 | 14.2 | 88% | 31 | 27 |

| Aug | 5.7 | 35.5/NNE | 52.6 | 36 | 8 | 3.4 | 24.5 | 15.3 | 43.4 | 16.6 | 89% | 30 | 27 |

| Sep | 7.6 | 36.3/N | 40.4 | 31.8 | 15.8 | 12.1 | 61.4 | 9.5 | 16.6 | 11.2 | 72% | 31 | 22 |

| Oct | 12.4 | 40.0/NNE | 15.9 | 21.9 | 21.8 | 40.4 | 88.6 | 3 | 4.2 | 4.1 | 38% | 30 | 11 |

| Nov | 12.1 | 32.2/NNE | 19.9 | 19.5 | 19.9 | 40.8 | 87 | 4.3 | 4.1 | 4.7 | 39% | 31 | 12 |

| Dec | 12.8 | 30.3/NNE | 16 | 17.3 | 27.1 | 39.7 | 92.2 | 3 | 1.5 | 3.3 | 33% | 30 | 10 |

| Mean | 9.6 | 31.6/NNE | 27.3 | 31.6 | 18.7 | 22.4 | 63.4 | 6.8 | 21 | 8.6 | 59% | 365 | 215 |

| Floater Storage | Dry + Wet | Dry + No | Wet + No |

|---|---|---|---|

| Dry storage | 3 | 1 | 0 |

| Wet storage | 1 | 1 | 1 |

| No storage | 0 | 4 | 6 |

| Total projects | 4 | 6 | 7 |

| Daily Cost, USD | |

|---|---|

| Crane | 264,293 |

| SPMT 100 (20) lines | 90,566 (18,113) |

| 3 Tugs | 27,000 |

| AHT | 100,000 |

| Semi-sub barge | 100,000 |

| Quay 1 m2 | 0.03 |

| Dry dock 1 m2 | 1 |

| 60 assemblers | 15,360 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivanov, G.; Ma, K.-T. Floater Assembly and Turbine Integration Strategy for Floating Offshore Wind Energy: Considerations and Recommendations. Wind 2024, 4, 376-394. https://doi.org/10.3390/wind4040019

Ivanov G, Ma K-T. Floater Assembly and Turbine Integration Strategy for Floating Offshore Wind Energy: Considerations and Recommendations. Wind. 2024; 4(4):376-394. https://doi.org/10.3390/wind4040019

Chicago/Turabian StyleIvanov, Glib, and Kai-Tung Ma. 2024. "Floater Assembly and Turbine Integration Strategy for Floating Offshore Wind Energy: Considerations and Recommendations" Wind 4, no. 4: 376-394. https://doi.org/10.3390/wind4040019

APA StyleIvanov, G., & Ma, K.-T. (2024). Floater Assembly and Turbine Integration Strategy for Floating Offshore Wind Energy: Considerations and Recommendations. Wind, 4(4), 376-394. https://doi.org/10.3390/wind4040019