Gluten-Free Breadmaking with Extruded Whole-Grain Andean Maize Flours †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Extruded Material Characterization

2.3. Bread Preparation

2.4. Textural Properties of Gluten-Free Dough and Bread

2.5. Statistical Analysis

3. Results and Discussion

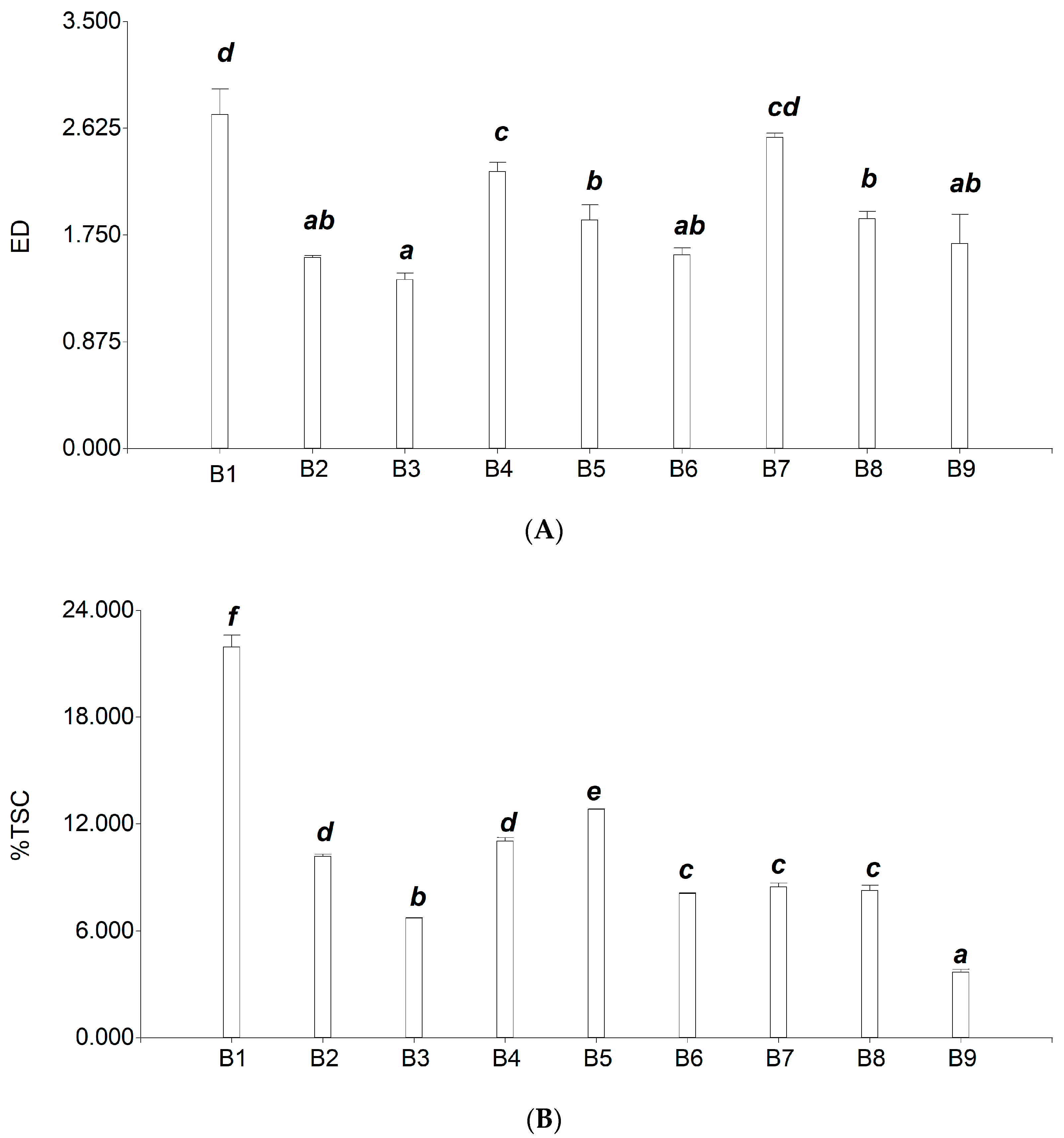

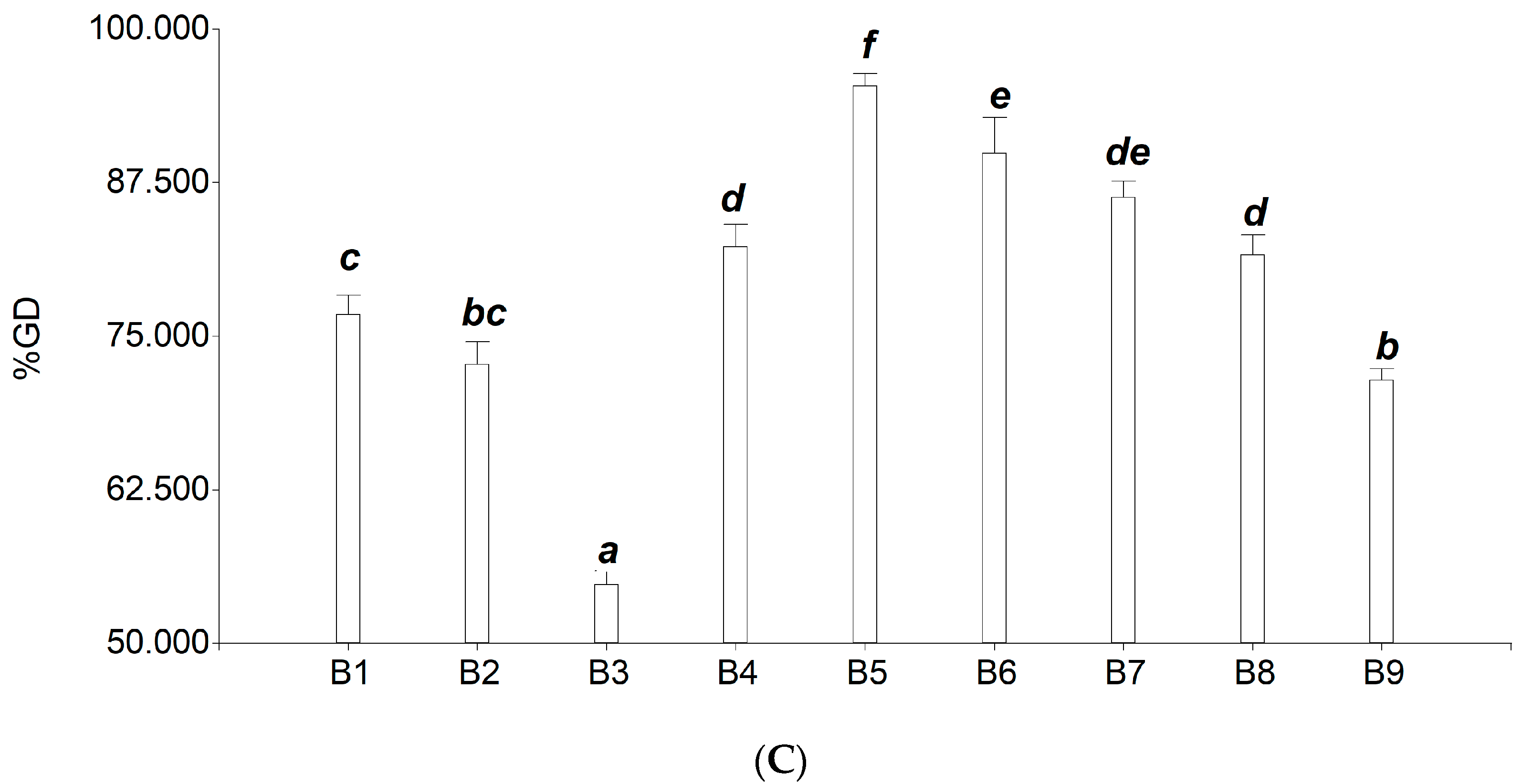

3.1. Properties Physical and Physicochemical of the Extruded Material

3.2. Textural Characteristics of the Doughs and Bread Gluten Free

4. Conclusions

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Giménez, M.A.; Gámbaro, A.; Miraballes, M.; Roascio, A.; Amarillo, M.; Sammán, N.; Lobo, M. Sensory evaluation and acceptability of gluten-free Andean maize spaghetti. J. Sci. Food Agric. 2015, 95, 186–192. [Google Scholar] [CrossRef] [PubMed]

- Sciarini, L.S.; Steffolani, M.E.; León, A.E. El rol del gluten en la panificación y el desafío de prescindir de su aporte en la elaboración de pan. AgriScientia 2016, 33, 61–74. [Google Scholar] [CrossRef]

- Mir, S.A.; Shah, M.A.; Naik, H.R.; Zargar, I.A. Influence of hydrocolloids on dough handling and technological properties of gluten-free breads. Trends Food Sci. Technol. 2016, 51, 49–57. [Google Scholar] [CrossRef]

- Tsatsaragkou, Κ.; Protonotariou, S.; Mandala, I. Structural role of fibre addition to increase knowledge of non-gluten bread. J. Cereal Sci. 2016, 67, 58–67. [Google Scholar] [CrossRef]

- Gómez, M.; Martínez, M.M. Changing flour functionality through physical treatments for the production of gluten-free baking goods. J. Cereal Sci. 2016, 67, 68–74. [Google Scholar] [CrossRef]

- Byars, J.A.; Singh, M. Properties of extruded chia-maize meal puffs. LWT 2015, 62, 506–510. [Google Scholar] [CrossRef]

- Al Loman, A.; Islam, S.M.; Li, Q.; Ju, L.K. Enzyme recycle and fed-batch addition for high-productivity soybean flour processing to produce enriched soy protein and concentrated hydrolysate of fermentable sugars. Bioresour. Technol. 2017, 241, 252–261. [Google Scholar] [CrossRef] [PubMed]

- Baks, T.; Ngene, I.S.; van Soest, J.J.G.; Janssen, A.E.M.; Boom, R.M. Comparison of methods to determine the degree of gelatinisation for both high and low starch concentrations. Carbohydr. Polym. 2007, 67, 481–490. [Google Scholar] [CrossRef]

- Sarifudin, A.; Assiry, A.M. Some physicochemical properties of dextrin produced by extrusion process. J. Saudi Soc. Agric. Sci. 2014, 13, 100–106. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miranda, R.M.; Amaya, A.A.; Lobo, M.O.; Sammán, N.C. Gluten-Free Breadmaking with Extruded Whole-Grain Andean Maize Flours. Biol. Life Sci. Forum 2021, 8, 5. https://doi.org/10.3390/blsf2021008005

Miranda RM, Amaya AA, Lobo MO, Sammán NC. Gluten-Free Breadmaking with Extruded Whole-Grain Andean Maize Flours. Biology and Life Sciences Forum. 2021; 8(1):5. https://doi.org/10.3390/blsf2021008005

Chicago/Turabian StyleMiranda, Rita M., Argentina A. Amaya, Manuel O. Lobo, and Norma C. Sammán. 2021. "Gluten-Free Breadmaking with Extruded Whole-Grain Andean Maize Flours" Biology and Life Sciences Forum 8, no. 1: 5. https://doi.org/10.3390/blsf2021008005

APA StyleMiranda, R. M., Amaya, A. A., Lobo, M. O., & Sammán, N. C. (2021). Gluten-Free Breadmaking with Extruded Whole-Grain Andean Maize Flours. Biology and Life Sciences Forum, 8(1), 5. https://doi.org/10.3390/blsf2021008005