Abstract

The aim of this work was to introduce the by-products generated by the sea bream processing industry as a new ingredient in the production of fish and seafood burgers. Fish by-product flour was obtained and added in the preparation of sea bream and shrimp burgers. The formulations selected from a sensory evaluation with semi-trained assessors were burgers with sea bream and shrimp (C) and the same sample with 10% of by-product flour (BP10). These formulations were subjected to sensory evaluation with consumers using hedonic scales. Both samples had a good acceptability, although the presence of by-products had a negative impact on the colour, resulting in a slight decrease in the global acceptance. It would be interesting to use a natural ingredient that could improve the colour of the product or use the by-product flour in battered products where the colour could be masked.

1. Introduction

Global aquaculture production has been on an upward trend in recent years, and in 2022, it surpassed capture fishery production for the first time. Although the utilisation and processing of aquatic products continue to improve, with 89% being used for human consumption, a significant volume is destined for non-food uses, mainly to produce fish meal and fish oil for feed [1]. The fish-processing industry generates more than 60% of by-products as waste [2,3], which is a serious pollution and disposal problem worldwide [3]. The use of these by-products in human food could reduce the magnitude of these problems.

All the healthy compounds present in the fish meal are also part of its by-products [4]. Specifically, sea bream (Sparus aurata) is one of the most important fish species farmed in the Mediterranean area [5], which has demonstrated constant and continuous growth [6]. Research is being carried out on the use of different by-products, allowing for their valuation, as it has been proven that they are rich in proteins and have high levels of essential amino acids, omega-3 fatty acids and macro and microelements, especially calcium and phosphorus in the head, bone and gills and iron and zinc in the liver [4]. In the case of sea bream by-products, they have been found to be rich in protein (10–25%) and fat (17–35%). These discards have high levels of essential amino acids (41–49% of total amino acids), omega-3 fatty acids (about 13% of total fatty acids) and macro and microelements, especially calcium and phosphorous in fishbone [4]. Therefore, the use of sea bream by-products as ingredients in different types of food could improve their nutritional profile.

Today, the population is concerned about the environment and sustainability, so it is expected that the introduction of by-products in food will be well received [7]. The aim of this work was to introduce the by-products generated by the sea bream-processing industry as a new ingredient in the production of fish and seafood burgers, which are accepted by consumers, allowing for the improvement of the sustainability of this sector.

2. Materials and Methods

2.1. Raw Materials

The raw materials used for the preparation of the burgers were sea bream (Sparus aurata) and white shrimp (Litopenaeus vannamei), purchased in a supermarket in Valencia. The sea bream was gutted and filleted, using the muscle of the fish to make the product, while the remains from the filleting (bones, attached muscle and fins) were used to obtain the by-product flour. The shrimps were peeled, separating the head and the exoskeleton from the muscle, the latter being used to make the burgers. The muscles obtained from the sea bream were cut by knife into pieces of approximately 1 × 1 cm (width × length), and those from the shrimps were minced at speed 1 for 10 s using a Braun MultiPractic 3 CH3011BK (Braun GmbH, Kronberg, Germany). These ingredients were stored at −18 °C.

2.2. Obtention of the By-Product Flour

The methodology described by de Souza et al. (2022) [8] with some modifications was followed to obtain the flour. The by-products obtained from the sea bream filleting, (bones, attached muscle and fins) were first cooked in a pressure cooker for 7 min, in a ratio of by-products:water 1:3 (w/v). The cooked by-products were then pressed with the help of gauze to remove part of the water, and this residue was ground with a grinder (KOENIC Meat grinder, KMG 4151B, Imtron GmbH, Ingolstadt, Germany), reducing the size of the bone fragments and facilitating subsequent drying. This minced mass was spread on aluminum trays and dried in a BinderTM ED Classic.Line Series drying chamber (BINDER GmbH, Tuttlingen, Germany) at 60 °C for 22 h. Finally, the dried by-products were ground using an electric grinder (GOLDENWALL, High-speed Multifunction Grinder, Boston, MA, USA) and the final flour was sieved to remove the larger particles, resulting in a fine powder (<0.710 mm of particles). The boiling process is important for the reduction of the microbial load of the by-products. The drying step is an important phase in the process to obtain the by-product flour with 7% moisture and a water activity value of 0.42, which avoids the rapid growth of bacteria and mold, thus ensuring the quality of the product. Finally, sieving is another significant phase in order to obtain a safe product free of oversized particles that could be harmful when the product is ingested.

2.3. Preparation of the Burgers

Four formulations were prepared by mixing different proportions of sea bream, shrimp muscle and salt, some of them with seaweed mix (sea spaghetti, kombu, nori and wakame), spirulina and/or by-product flour (Table 1). The four formulations tested were sample with sea bream and shrimp muscle (control sample or C), the same sample + 10% by-product flour (BP10), samples with sea bream and shrimp muscle + 7% by-product flour + seaweed mix (BP7Sw) and samples with sea bream and shrimp muscle + 7% by-product flour + spirulina (BP7S). Sea bream and shrimp muscles were thawed at 4 °C and ground separately. The ingredients belonging to each formulation were placed in a Thermomix and homogenised for 1 min at speed 4. The dough obtained was divided into portions of 15 g each and shaped into a circular, flattened mould. The formulated burgers were stored at 6 °C and then cooked in a frying pan with olive oil for 4 min on each side.

Table 1.

Formulations of burgers. C, BP10, BP7Sw and BP7S are the codes of the samples.

2.4. Sensory Evaluation

Initially, a sensory evaluation of the four types of samples was carried out with a panel of semi-trained assessors belonging to the Instituto Universitario de Ingeniería de Alimentos FoodUPV. This evaluation was carried out by a total of 10 assessors (seven women and three men) in a session where a consensus was reached on the suitability of the four formulations (C, BP10, BP7Sw and BP7S) in terms of appearance, colour, odour, flavour and texture parameters.

To evaluate the acceptance of the selected samples (C and BP10) by the consumers, a sensory analysis was carried out in compliance with the Helsinki Declaration, first providing the participant with information about the project and then the informed consent that the participant had to sign. This study was approved by the Ethics Committee of the Universitat Politècnica de València (P08_29_05_2023).

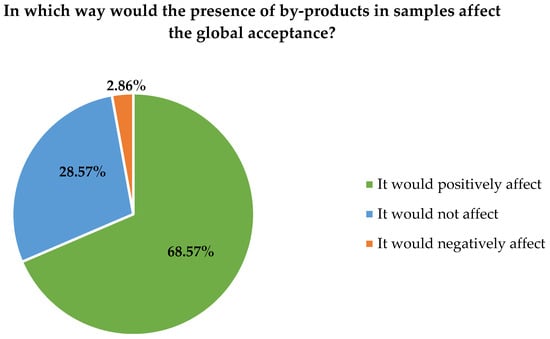

A total of 70 consumers participated in this evaluation. The participants evaluated the degree of acceptability of colour, appearance, odour, texture, taste and global acceptance in structured nine-point scales where the extreme values corresponded from: 9 ‘I like very much’ to 1 ‘I dislike very much’. The frequency of the consumption of fish burgers or similar products and the degree of liking for this type of product were also recorded. In addition, the purchase intention of each sample was asked using a structured five-point scale, where 1 corresponded to ‘Definitely not’ and 5 to ‘Definitely yes’. Finally, the respondents were asked whether the addition of by-product flour would positively, negatively or neutrally affect their level of acceptance of the product.

2.5. Statistical Analysis

To evaluate the existence of significant differences in the sensory analysis of the samples, a Student’s t-test was performed. All data analyses described in this section were carried out with the statistical programme XLSTAT (Addinsoft, Long Island, NY, USA).

3. Results and Discussion

3.1. Selection of the Best Formulations

To assess the potential acceptability of the burgers, a sensory evaluation of all formulations (C, BP10, BP7Sw and BP7S) was first carried out with a semi-trained panel, as mentioned above. In this session, formulations BP7Sw and BP7S were discarded as being particularly intense in taste and colour for most assessors, with formulations C and BP10 presenting a better balance in all the attributes evaluated. Therefore, the sensory analysis with consumers was carried out with C and BP10 formulations.

3.2. Sensory Evaluation of the Selected Formulations

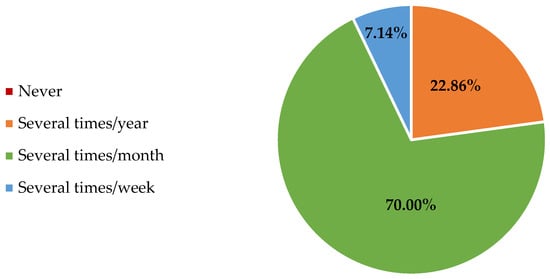

A total of 70 consumers participated in this sensory evaluation. Regarding the frequency of the consumption of burgers, 7.14% of the participants consumed these products weekly and 70% monthly, as shown in Figure 1.

Figure 1.

Frequency of consumption of burgers or similar products.

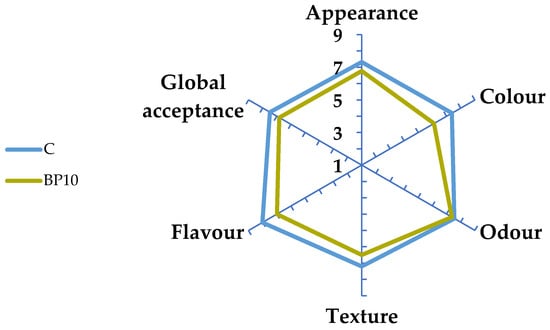

The mean values of the scores given by consumers to the attributes assessed in the burger samples are shown in Figure 2. The control burgers showed the highest scores, with values above 7 in all attributes. No significant differences in odour was found between both samples. Although the flavour of the sample with by-products showed significant differences from the control sample (p < 0.05), a high score was also obtained for BP10 (score of 7). The colour was the attribute that showed a lower score in BP10, with significant differences from sample C. In addition, the global acceptance was slightly lower than 7 for the sample with by-products. The decrease in global acceptance was mainly due to the colour attribute. The presence of by-product flour causes a darkening of the colour of the samples, which has a negative effect on the perception of the consumers. The burgers BP10 had a greyish colour as opposed to the reddish colour of the C burgers. The colour attribute showed significant differences between both samples, this attribute being the worst valued by consumers in the BP10 sample. Therefore, it would be necessary to reduce the percentage of by-product flour or to use natural ingredients to improve the colour of the burger, such as Calanus oil or vegetable extracts that provide a red colour that could improve the acceptance. The inclusion of this by-product flour in battered products where the colour would not be appreciated could also be a good alternative.

Figure 2.

Mean values of the scores given by consumers to the attributes assessed in the burger samples.

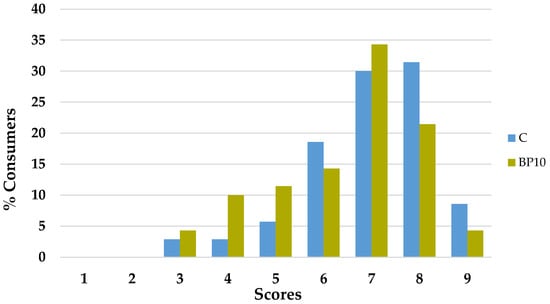

The percentages of the scores given by the consumers for the attribute global acceptance are shown in Figure 3. For both formulations C and BP10, a higher number of responses were clustered in scores 7 and 8.

Figure 3.

Distribution of the scores given by the consumers to the global acceptance of the burger samples.

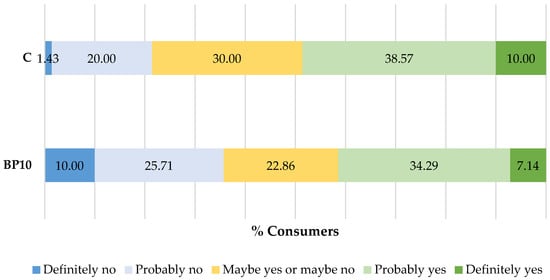

Regarding the results on consumers’ purchase intention (Figure 4), 48.57% and 41.43% of consumers stated that they would buy or probably buy sample C and BP10, respectively. Although there was a high percentage of negative responses (‘Definitely not’ or ‘Probably not’) for BP10 samples, no significant differences were found between both formulations (p > 0.05).

Figure 4.

Percentage of responses on the purchase intention of the burger samples.

Finally, consumers were asked in which way the fact of using by-products in the burgers would affect the global acceptance of the product. Figure 5 shows how the highest percentage of participants stated that their perception of the product would improve, followed by consumers for whom the presence of by-products would not affect global acceptance. Only 2.9% of participants stated that the presence of by-products in the samples would negatively affect their global acceptance. According to these results, the presence of by-products could be considered an added value for most consumers in the study, demonstrating the potential of by-product utilisation for human consumption.

Figure 5.

Percentage of responses on consumers’ opinion about the presence of by-products in burger samples.

Due to the characteristics of this product (soft texture, tasty flavour and convenience) and its nutritional value, it would be a very suitable food for consumption by the general population, being particularly interesting for children, given that most of them do not like fish, and these products could encourage their consumption.

The main obstacle to producing burgers made from sea bream by-products is that a manufacturing plant is needed to obtain the flour, although it is a relatively simple process. In addition, obtaining flour from sea bream by-products involves a cost that would be reflected in the final price of the burgers. However, consumers are increasingly concerned about the environment and the reuse of by-products could provide added value when making purchases. An economic study would be necessary to assess the viability of this new ingredient, as well as the willingness of consumers to pay a little more for a sustainable product.

4. Conclusions

The sea bream and shrimp burgers developed in this study had good acceptance by consumers. The presence of by-products obtained from the sea bream filleting in the burgers had a negative effect on colour, resulting in a slight decrease in global acceptance. The use of natural ingredients that mask the effect of the colour of by-products could solve this problem. A large proportion of consumers could be considered potential consumers of both products, according to the responses in terms of purchase intention. In addition, the information about the presence of by-products as a new ingredient would have a positive impact on global acceptance. This study demonstrates the high potential of the use of sea bream by-products in fish and seafood products.

The inclusion of sea bream by-products into food products would reduce waste in the aquaculture sector, promoting a circular and sustainable economy.

Public administrations and associations in the aquaculture sector should carry out information campaigns to raise consumer awareness of the importance of reusing fish by-products, which, in addition to having a positive effect on environmental sustainability, are a very valuable source of nutrients.

Author Contributions

Conceptualization, I.F.-S. and A.F.; methodology, I.F.-S.; formal analysis, S.P.-E. and A.F.; investigation, S.P.-E. and M.I.M.; data curation, I.F.-S. and A.F.; writing-original draft preparation, S.P.-E.; writing-review and editing A.F., supervision I.F.-S.; funding acquisition I.F.-S. and J.M.B.-B. All authors have read and agreed to the published version of the manuscript.

Funding

This study was developed within the ThinkInAzul Program financed by the MCIN with funds from the European Union NextGenerationEU (PRTR-C17.I1) and by the Generalitat Valenciana (GVA-THINKINAZUL/2021/004).

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by Ethics Committee of Instituto Universitario de Ingeniería de Alimentos FoodUPV (protocol code P08_29_05_2023 and date of approval 29 May 2023).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- FAO. The State of World Fisheries and Aquaculture 2024; FAO: Rome, Italy, 2024; ISBN 978-92-5-138763-4. [Google Scholar]

- Dekkers, E.; Raghavan, S.; Kristinsson, H.G.; Marshall, M.R. Oxidative Stability of Mahi Mahi Red Muscle Dipped in Tilapia Protein Hydrolysates. Food Chem. 2011, 124, 640–645. [Google Scholar] [CrossRef]

- Malaweera, B.O.; Wijesundara, W.M.N.M. Use of Seafood Processing By-Products in the Animal Feed Industry. In Seafood Processing By-Products: Trends and Applications; Springer: New York, NY, USA, 2013; pp. 315–339. [Google Scholar] [CrossRef]

- Pateiro, M.; Munekata, P.E.S.; Domínguez, R.; Wang, M.; Barba, F.J.; Bermúdez, R.; Lorenzo, J.M. Nutritional Profiling and the Value of Processing By-Products from Gilthead Sea Bream (Sparus aurata). Mar. Drugs 2020, 18, 101. [Google Scholar] [CrossRef] [PubMed]

- Firmino, J.; Furones, M.D.; Andree, K.B.; Sarasquete, C.; Ortiz-Delgado, J.B.; Asencio-Alcudia, G.; Gisbert, E. Contrasting Outcomes of Vibrio harveyi Pathogenicity in Gilthead Seabream, Sparus aurata and European Seabass, Dicentrachus labrax. Aquaculture 2019, 511, 734210. [Google Scholar] [CrossRef]

- Sanches-Fernandes, G.M.M.; Sá-Correia, I.; Costa, R. Vibriosis Outbreaks in Aquaculture: Addressing Environmental and Public Health Concerns and Preventive Therapies Using Gilthead Seabream Farming as a Model System. Front. Microbiol. 2022, 13, 904815. [Google Scholar] [CrossRef] [PubMed]

- Aspevik, T.; Oterhals, Å.; Rønning, S.B.; Altintzoglou, T.; Wubshet, S.G.; Gildberg, A.; Afseth, N.K.; Whitaker, R.D.; Lindberg, D. Valorization of Proteins from Co- and By-Products from the Fish and Meat Industry. In Chemistry and Chemical Technologies in Waste Valorization; Lin, C.S.K., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 123–150. ISBN 978-3-319-90653-9. [Google Scholar]

- de Souza, M.L.R.; Gasparino, E.; dos Reis Goes, E.S.; Coradini, M.F.; Vieira, V.I.; Oliveira, G.G.; Matiucci, M.A.; de Castro, A.C.V.J.; Siemer, S.; Fernandes, V.R.T.; et al. Fish Carcass Flours from Different Species and Their Incorporation in Tapioca Cookies. Future Foods 2022, 5, 100132. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).