Utilization of Hydrothermally Treated Flours in Gluten-Free Doughs †

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Hydrothermal Processes

2.3. Hydration Properties of Hydrothermally Treated Flours

2.4. Textural Properties of Dough

2.5. Statistical Analysis

3. Results and Discussion

3.1. Gel Hydration Properties (WAI and WSI) and Subjective Water Absorption Capacity (SWAC)

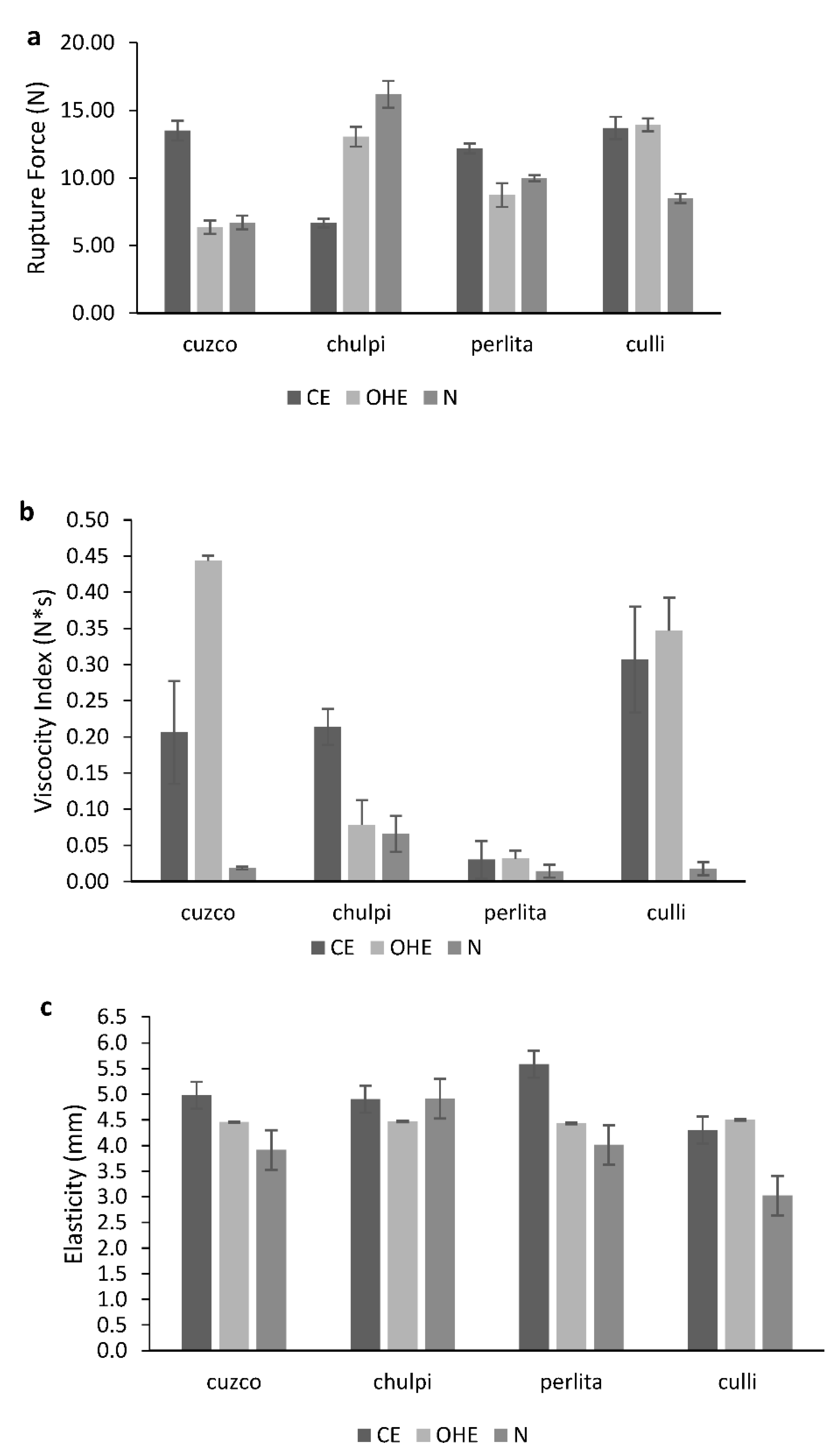

3.2. Textural Properties of Dough

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramos, R.S.; Hilgert, N.I.; Lambaré, D.A. Agricultura Tradicional y Riqueza de Maíces (Zea mays); Estudio de Caso en Caspalá: Provincia de Jujuy, Argentina, 2013. (In Spanish) [Google Scholar]

- Giménez, M.A.; Segundo, C.N.; Lobo, M.O.; Sammán, N.C. Physicochemical and Techno-Functional Characterization of Native Corn Reintroduced in the Andean Zone of Jujuy, Argentina. Proceedings 2020, 53, 7. [Google Scholar] [CrossRef]

- Bello Pérez, A.B.; Díaz, P.O.; Acevedo, E.A.; Santiago, C.N.; López, O.P. Propiedades químicas, fisicoquímicas y reológicas de masas y harinas de maíz nixtamalizado. Agrociencia 2002, 36, 319–328. (In Spanish) [Google Scholar]

- Martínez, M.M.; Pico, J.; Gómez, M. Physicochemical modification of native and extruded wheat flours by enzymatic amylolysis. Food Chem. 2015, 167, 447–453. [Google Scholar] [CrossRef] [PubMed]

- Enríquez-Castro, C.M.; Torres-Chávez, P.I.; Ramírez-Wong, B.; Quintero-Ramos, A.; Ledesma-Osuna, A.I.; López-Cervantes, J.; Gerardo-Rodríguez, J.E. Physicochemical, rheological, and morphological characteristics of products from traditional and extrusion nixtamalization processes and their relation to starch. Int. J. Food Sci. 2020, 2020, 5927670. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Singh, J.; Kaur, L.; Sodhi, N.S.; Gill, B.S. Morphological, thermal and rheological properties of starches from different botanical sources. Food Chem. 2003, 81, 219–231. [Google Scholar] [CrossRef]

- Gaytán-Martínez, M.; Figueroa, J.D.C.; Vázquez-Landaverde, P.; Morales-Sánchez, E.; Martínez-Flores, H.E.; Reyes-Vega, M.L. Caracterización fisicoquímica, funcional y química de harinas nixtamalizadas de maíz obtenidas por calentamiento óhmico y proceso tradicional. CyTA-J. Food 2012, 10, 182–195. [Google Scholar] [CrossRef]

- Salvador-Reyes, R.; Rebellato, A.P.; Pallone, J.A.L.; Ferrari, R.A.; Clerici, M.T.P.S. Kernel characterization and starch morphology in five varieties of Peruvian Andean maize. Food Res. Int. 2021, 140, 110044. [Google Scholar] [CrossRef] [PubMed]

- Topete-Betancourt, A.; Santiago-Ramos, D.; Figueroa-Cárdenas, J.D.D. Relaxation tests and textural properties of nixtamalized corn masa and their relationships with tortilla texture. Food Biosci. 2020, 33, 100500. [Google Scholar] [CrossRef]

| Race | Process | WAI (%) | WSI (*) (g/g) | SWAC (mL/g) |

|---|---|---|---|---|

| Cuzco | CE | 3.80b ** | 0.05b ** | 0.93b ** |

| OHE | 4.46c ** | 0.06c ** | 0.96b ** | |

| N | 2.65a ** | 0.03a ** | 0.84a ** | |

| Chulpi | CE | 3.16b ** | 0.115a ** | 0.74a ** |

| OHE | 2.62a ** | 0.18b ** | 0.84b ** | |

| N | 3.61c ** | 0.205c ** | 0.93c ** | |

| Perlita | CE | 3.68b ** | 0.065a ** | 0.89c ** |

| OHC | 3.24a ** | 0.08c ** | 0.86b ** | |

| N | 3.09a ** | 0.05b ** | 0.81a ** | |

| Culli | CE | 4.15b ** | 0.055a ** | 0.85b ** |

| OHC | 3.57ab ** | 0.055a ** | 0.90c ** | |

| N | 3.21a ** | 0.045a ** | 0.81a ** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gimenez, M.A.; Segundo, C.N.; Dominguez, N.E.; Samman, N.C.; Lobo, M.O. Utilization of Hydrothermally Treated Flours in Gluten-Free Doughs. Biol. Life Sci. Forum 2022, 17, 5. https://doi.org/10.3390/blsf2022017005

Gimenez MA, Segundo CN, Dominguez NE, Samman NC, Lobo MO. Utilization of Hydrothermally Treated Flours in Gluten-Free Doughs. Biology and Life Sciences Forum. 2022; 17(1):5. https://doi.org/10.3390/blsf2022017005

Chicago/Turabian StyleGimenez, Maria A., Cristina N. Segundo, Natalia E. Dominguez, Norma C. Samman, and Manuel O. Lobo. 2022. "Utilization of Hydrothermally Treated Flours in Gluten-Free Doughs" Biology and Life Sciences Forum 17, no. 1: 5. https://doi.org/10.3390/blsf2022017005

APA StyleGimenez, M. A., Segundo, C. N., Dominguez, N. E., Samman, N. C., & Lobo, M. O. (2022). Utilization of Hydrothermally Treated Flours in Gluten-Free Doughs. Biology and Life Sciences Forum, 17(1), 5. https://doi.org/10.3390/blsf2022017005