Optimization Study of the Electrical Microgrid for a Hybrid PV–Wind–Diesel–Storage System in an Island Environment

Abstract

1. Introduction

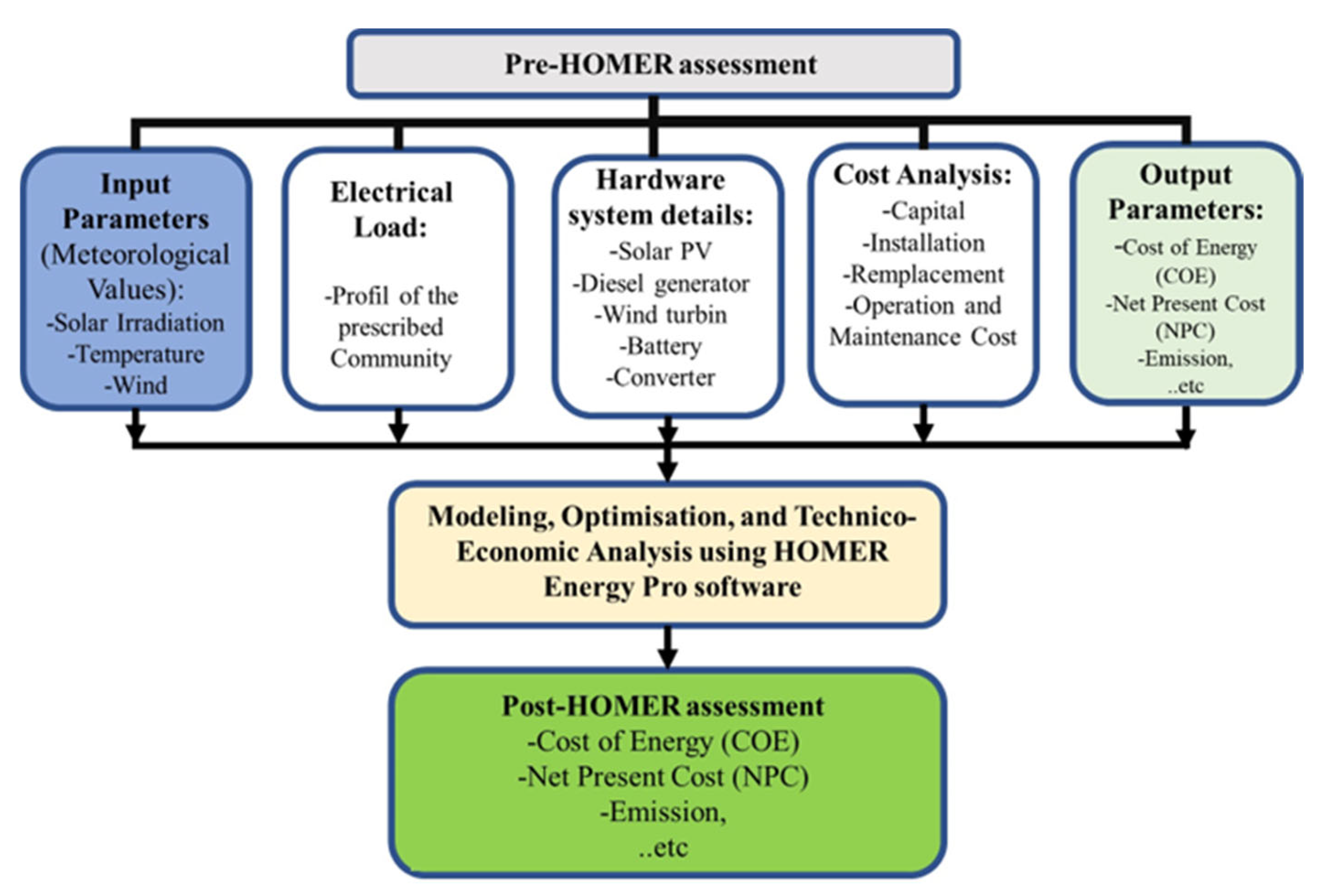

2. Materials and Methods

- Modeling data collection;

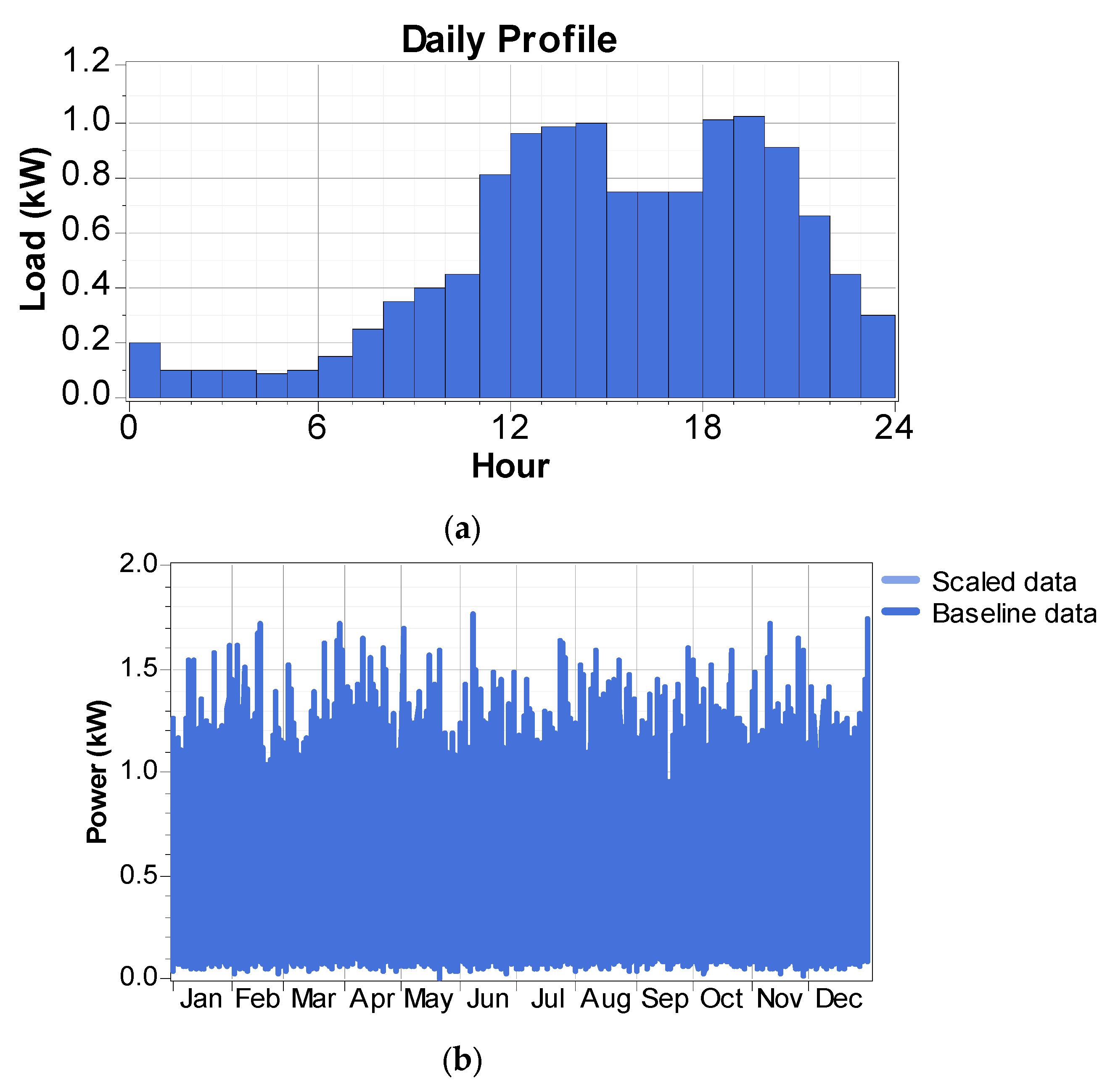

- Average daily electricity demand;

- Daily solar irradiance and daylight index;

- Average wind speed;

- Daily ambient temperature;

- System architecture definition: optimal combination of different renewable and conventional technologies.

2.1. Site Characterization and Load Profile

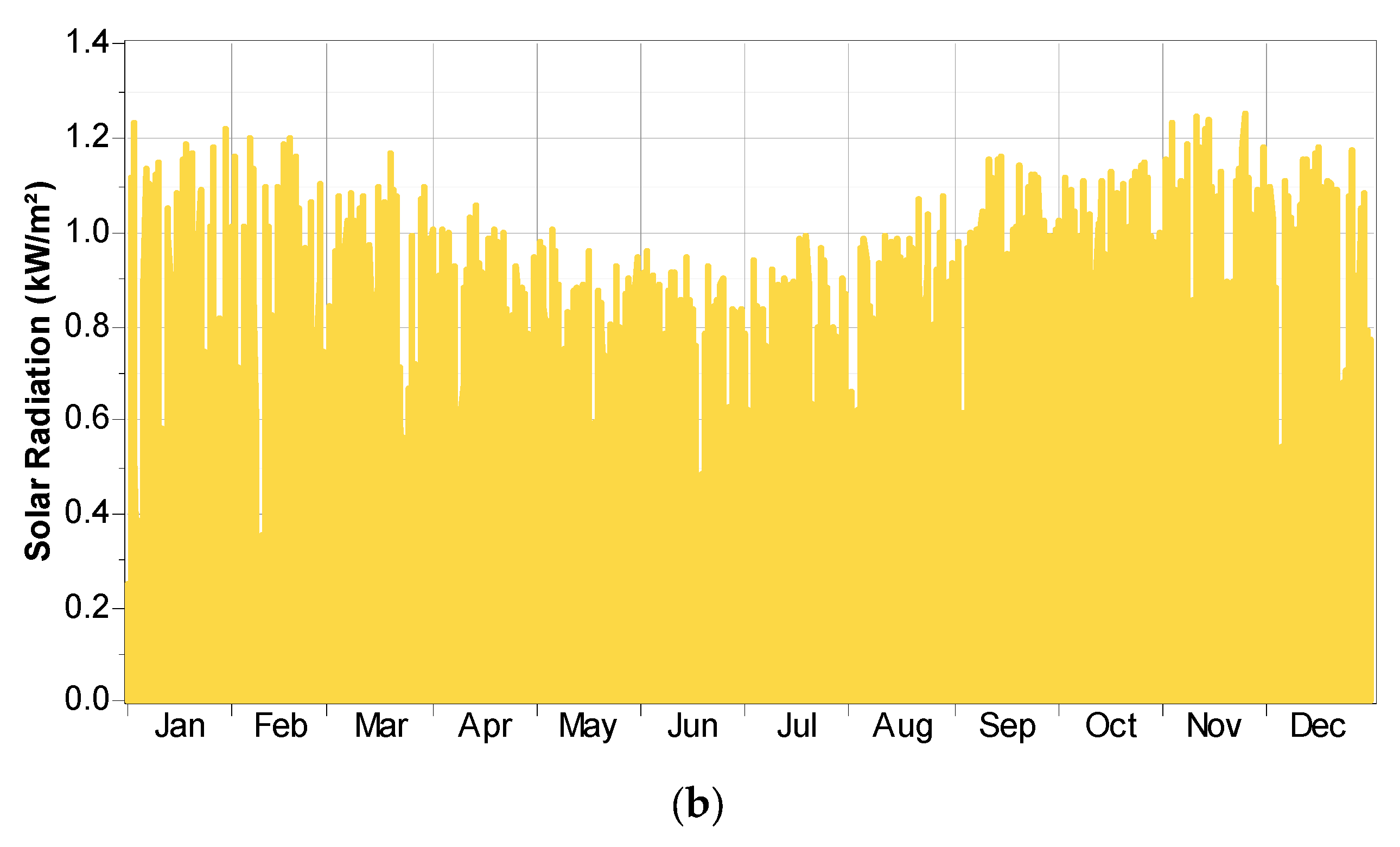

2.1.1. Solar Resources

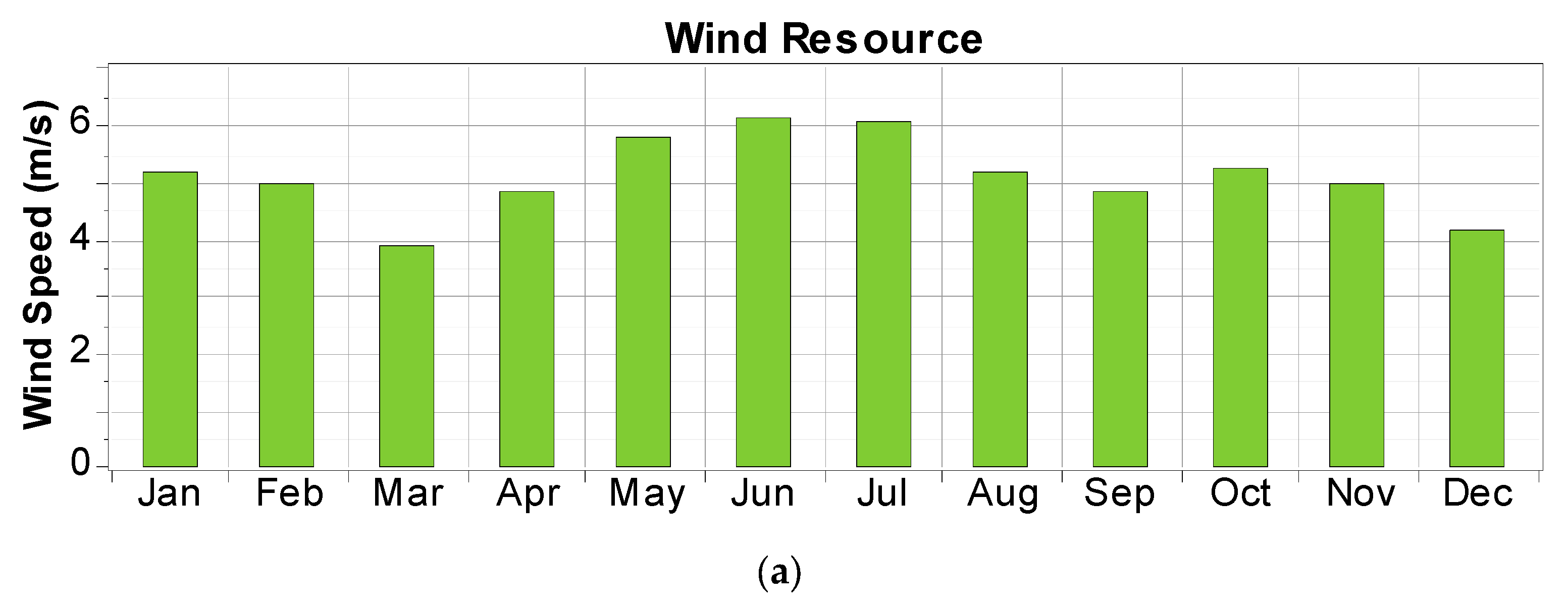

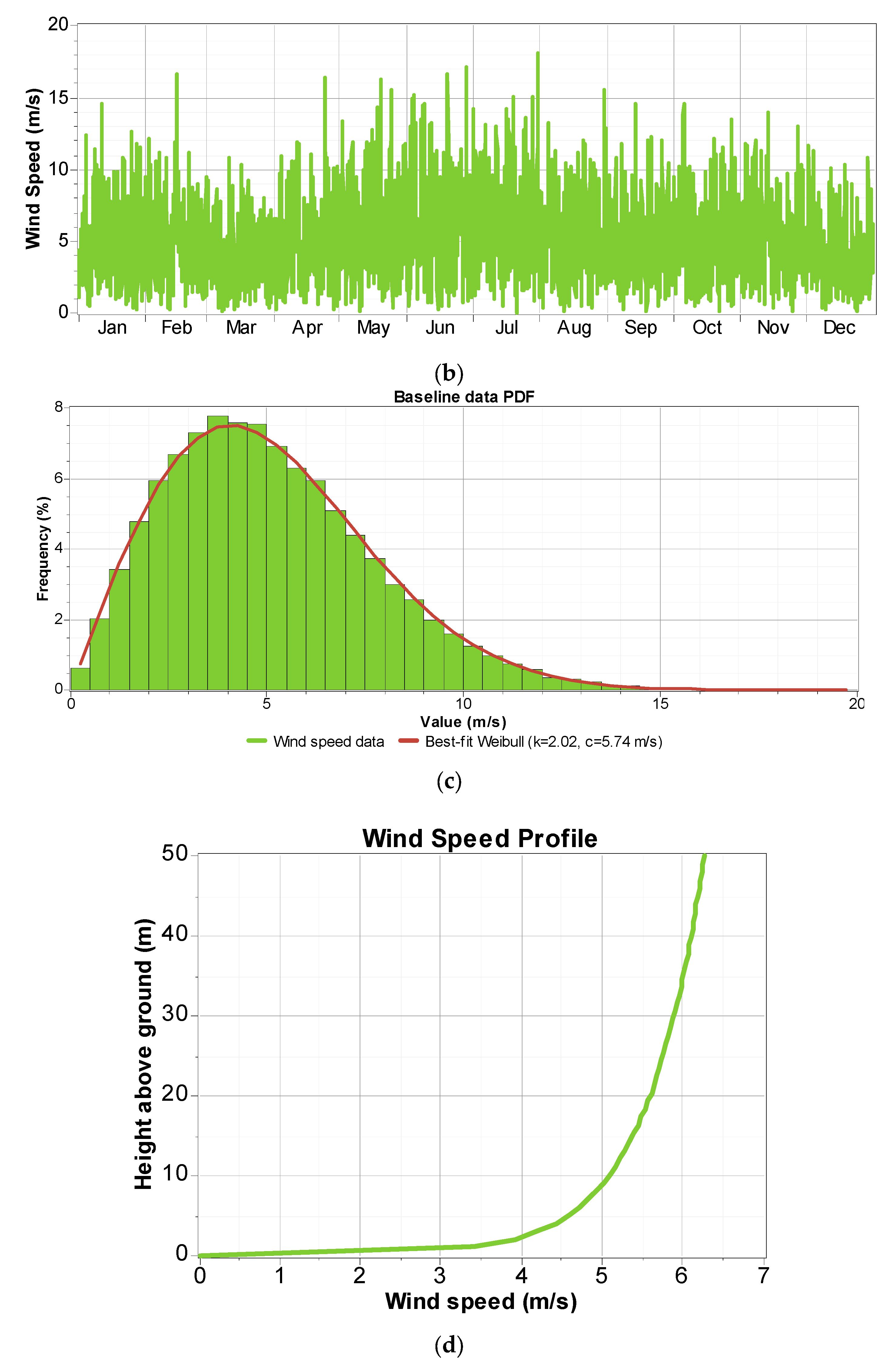

2.1.2. Wind Resource

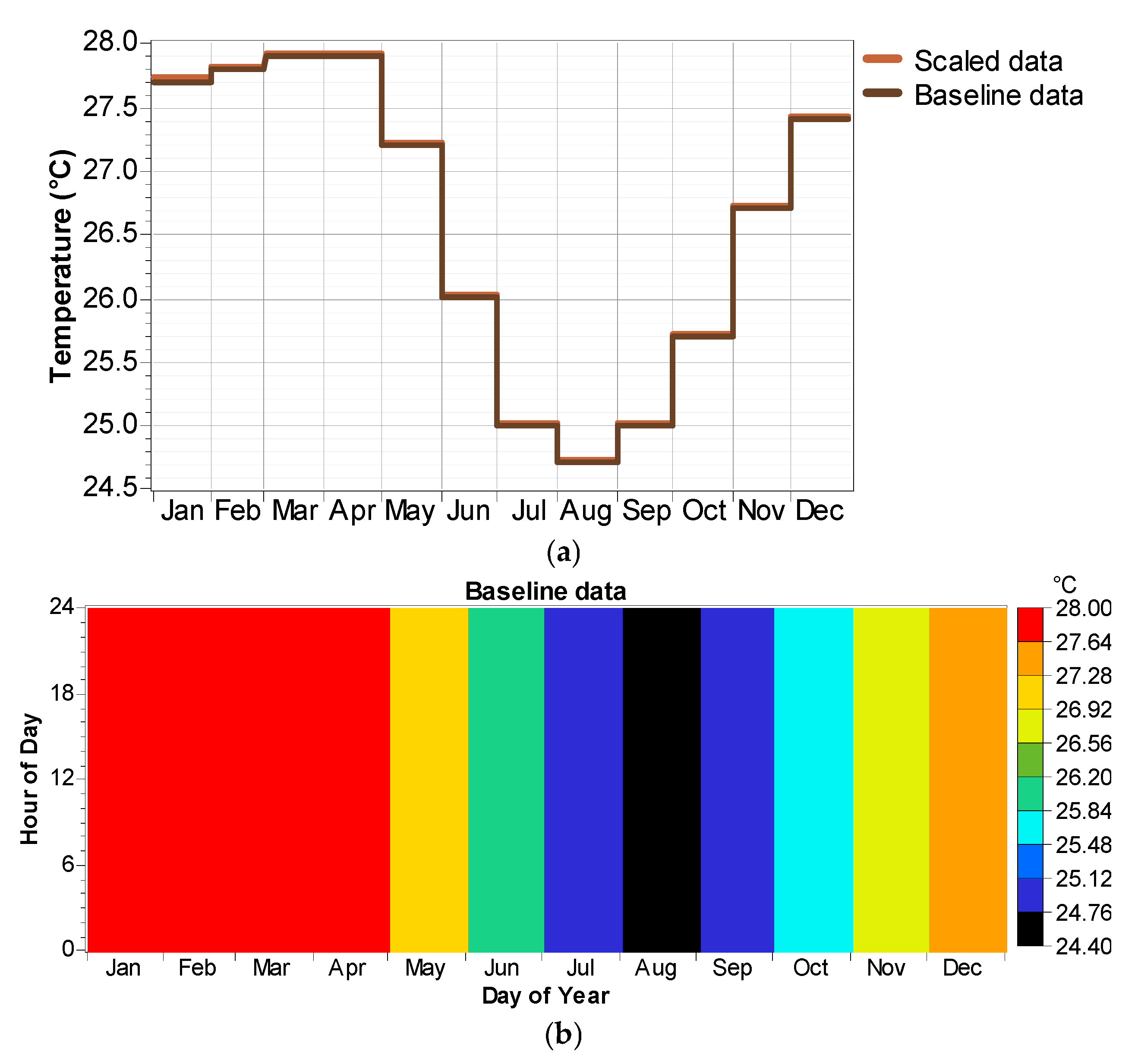

2.1.3. Ambient Temperature

2.1.4. Diesel Fuel Characteristics

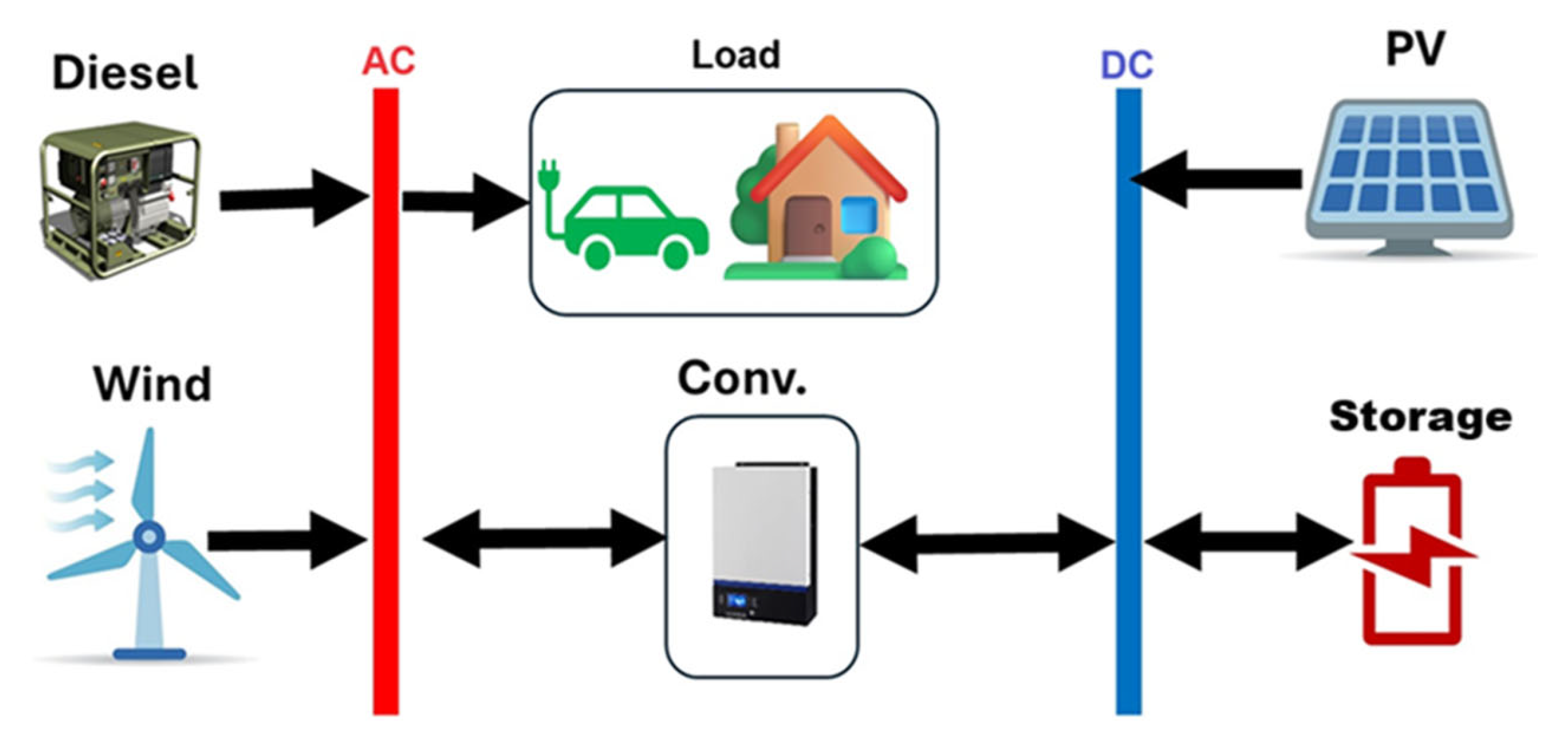

2.1.5. Microgrid Architecture and Load Profile

2.2. Simulation Tool and Assumptions

- An economic assessment based on the levelized cost of energy (COE), the net levelized cost (NPC), and the renewable fraction.

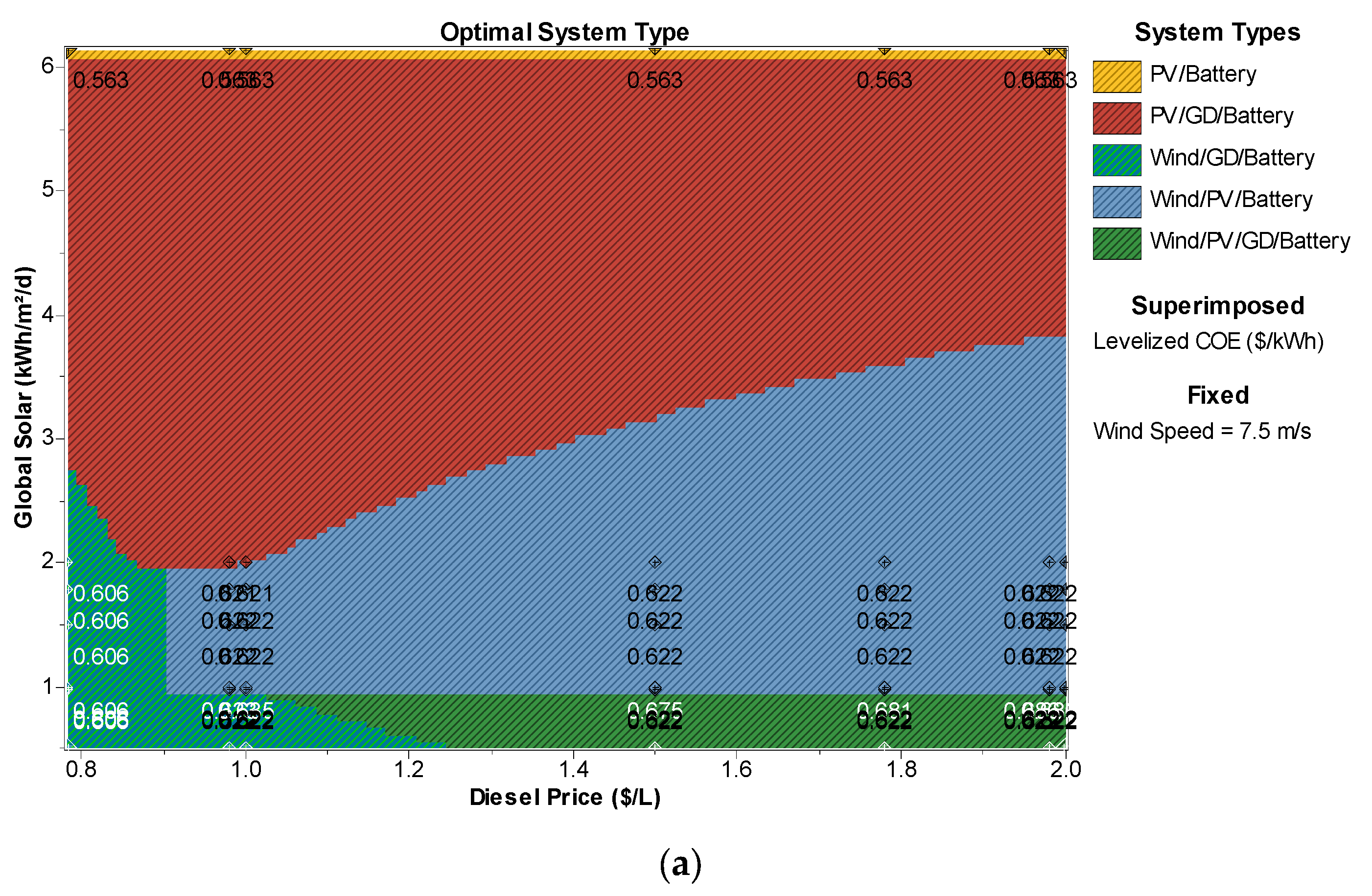

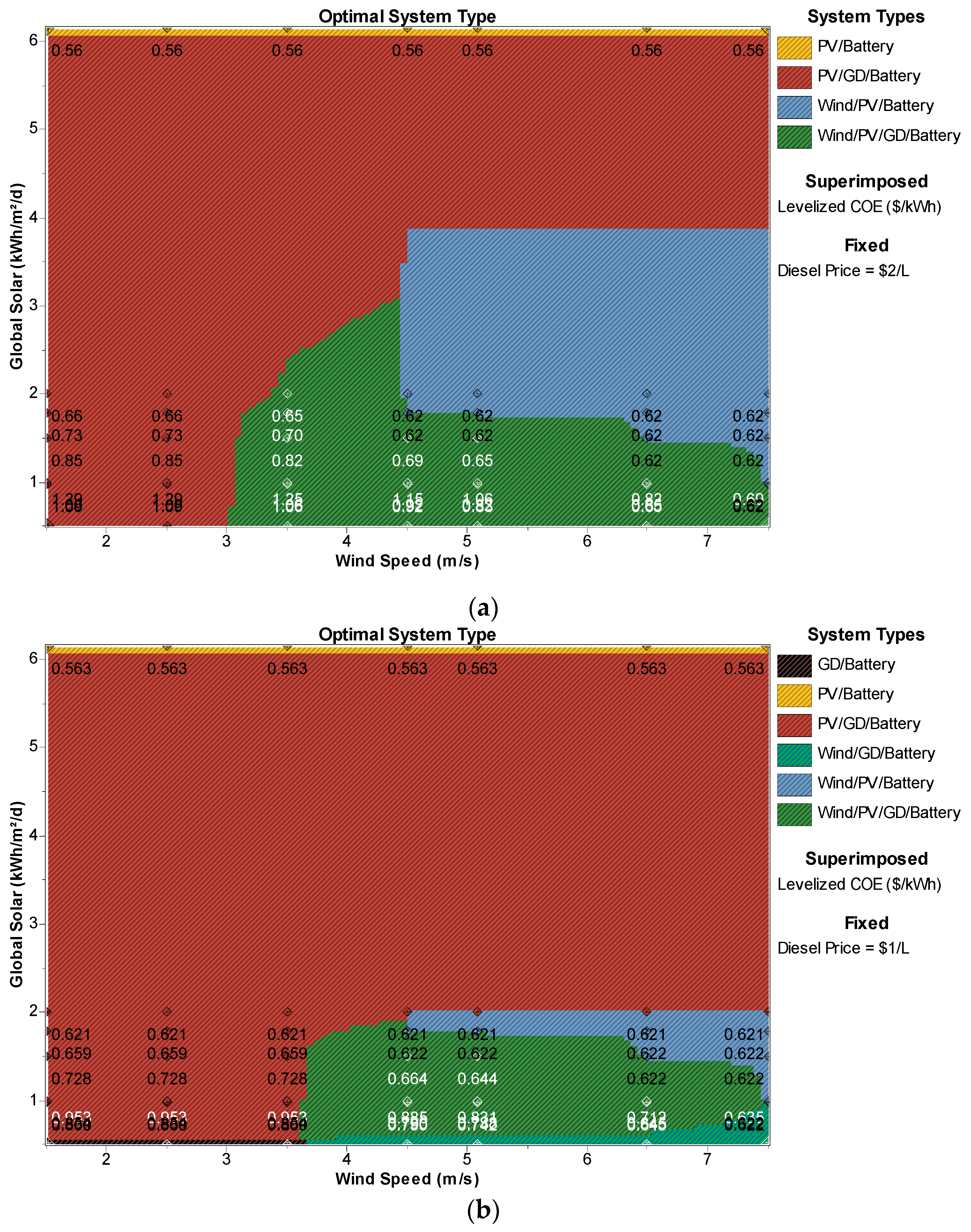

- A sensitivity analysis on variations in solar resources, wind speed, and fuel costs.

2.3. Microgrid Architecture Modeling

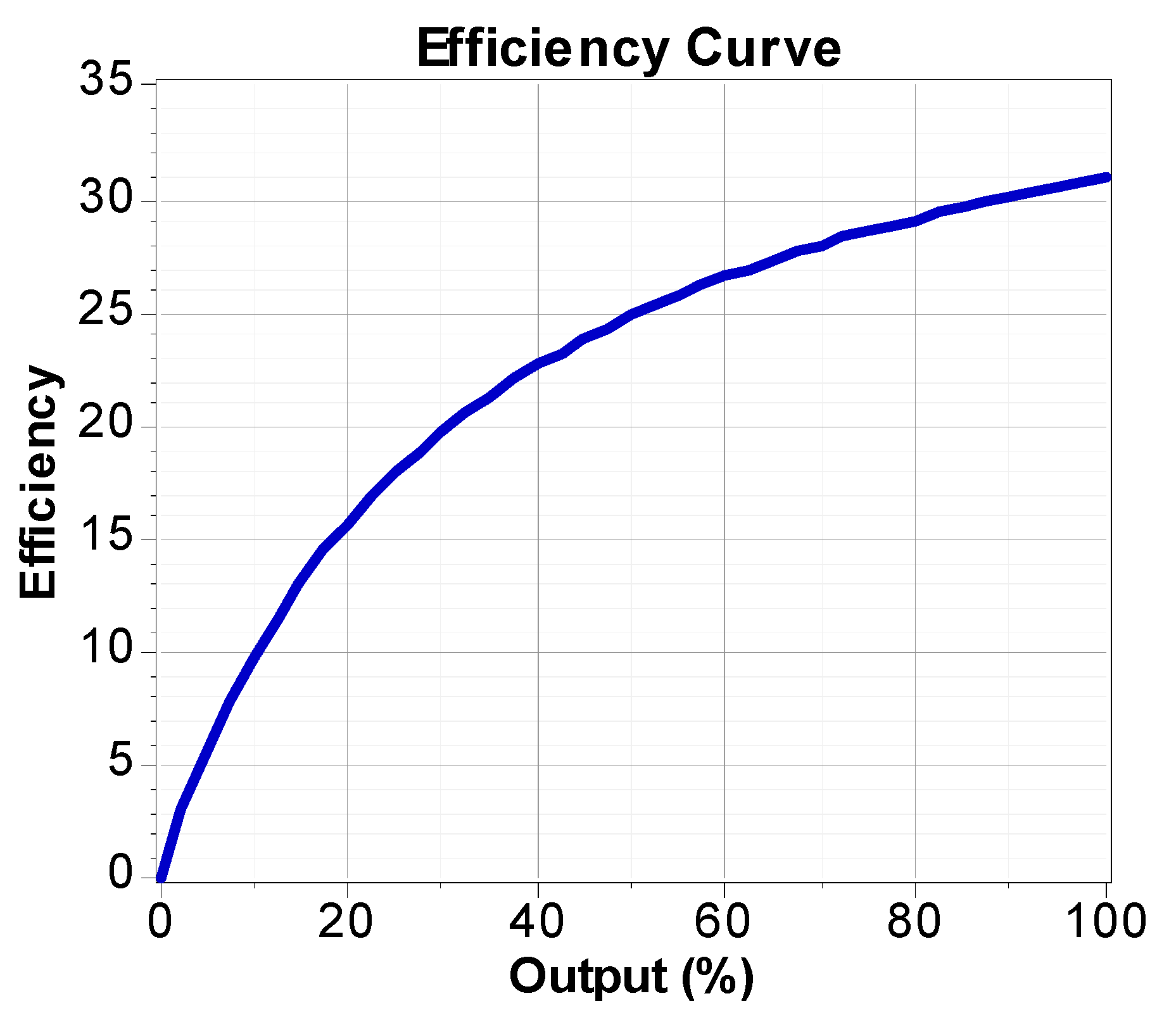

2.3.1. Modeling of the Diesel Generator Set and Fuel

2.3.2. Photovoltaic Solar Panels Modeling

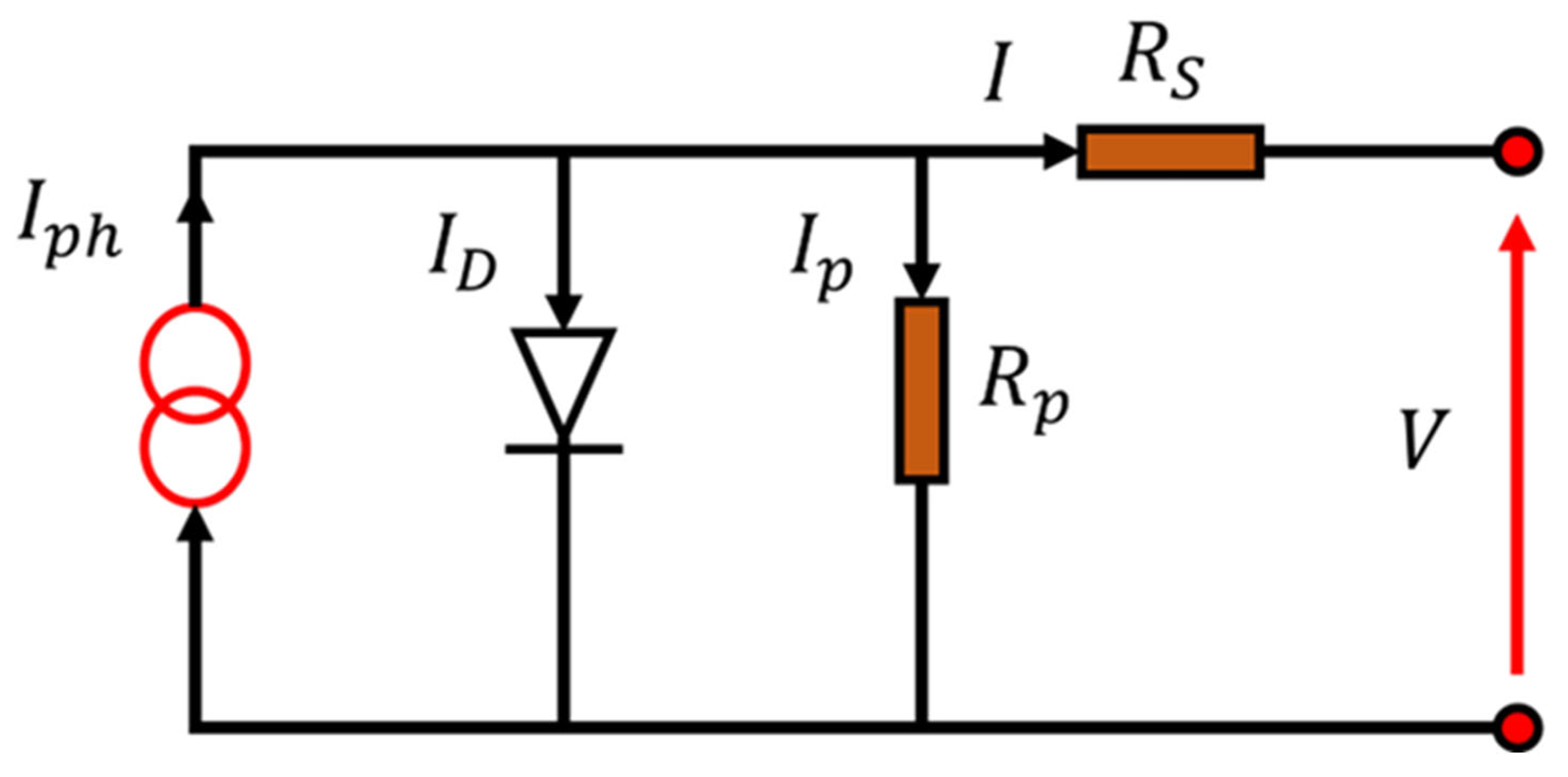

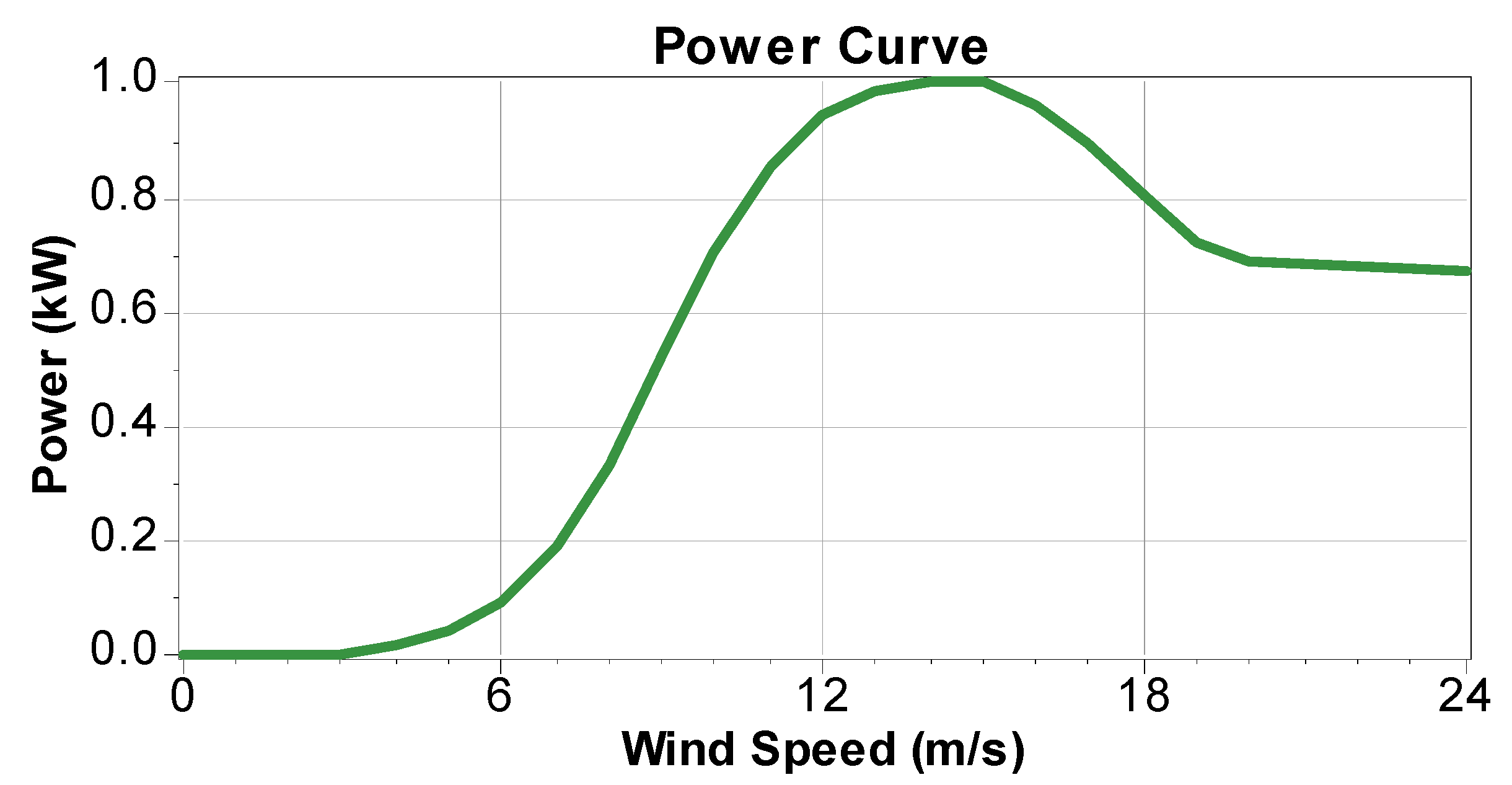

2.3.3. Modeling of Wind Production

- Logarithm method:

- Power law method:

2.3.4. Converter Modeling

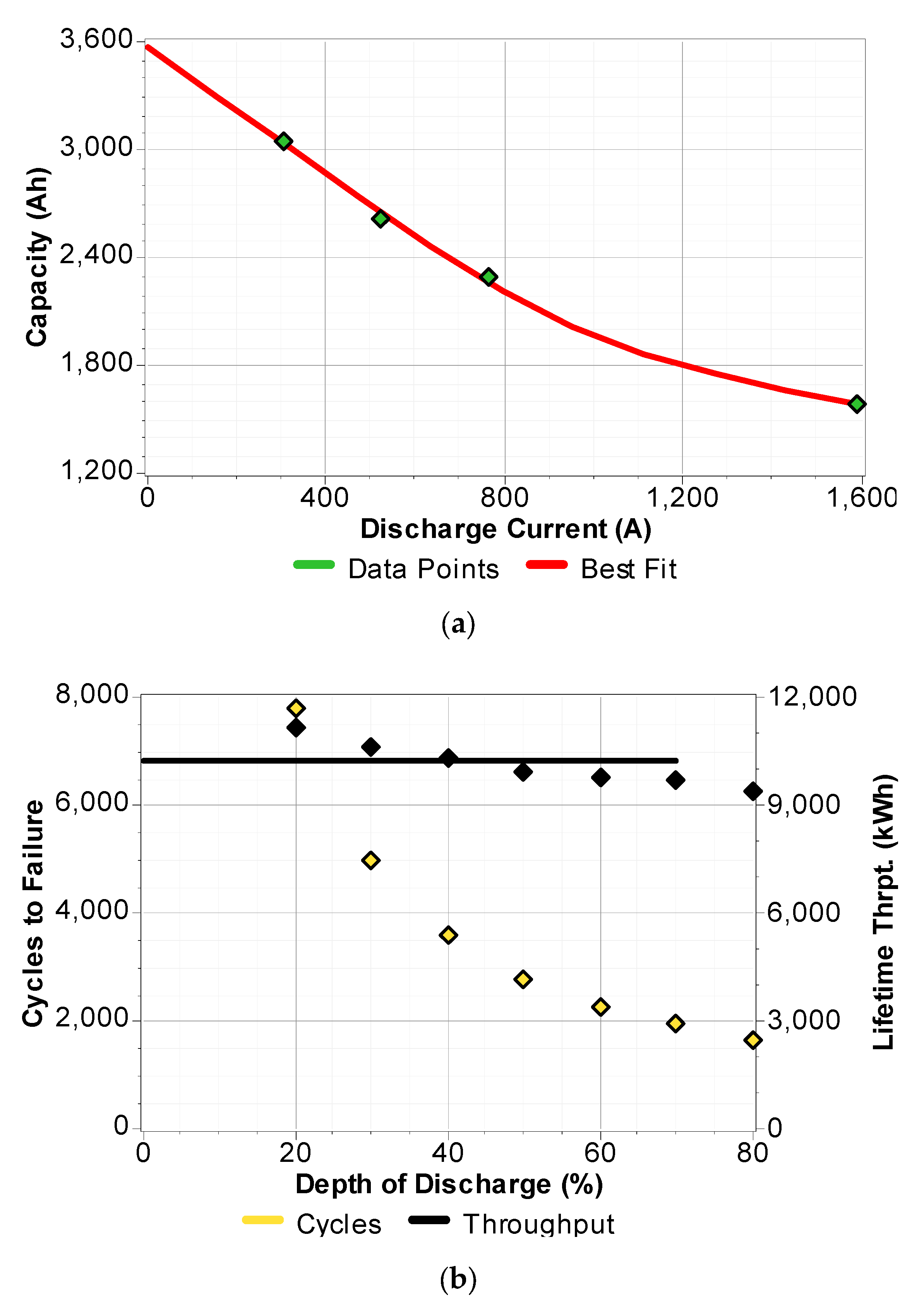

2.3.5. Modeling of Battery Storage

- A fixed efficiency;

- Charge/discharge rate limits;

- A maximum energy transfer capacity before replacement.

3. Results

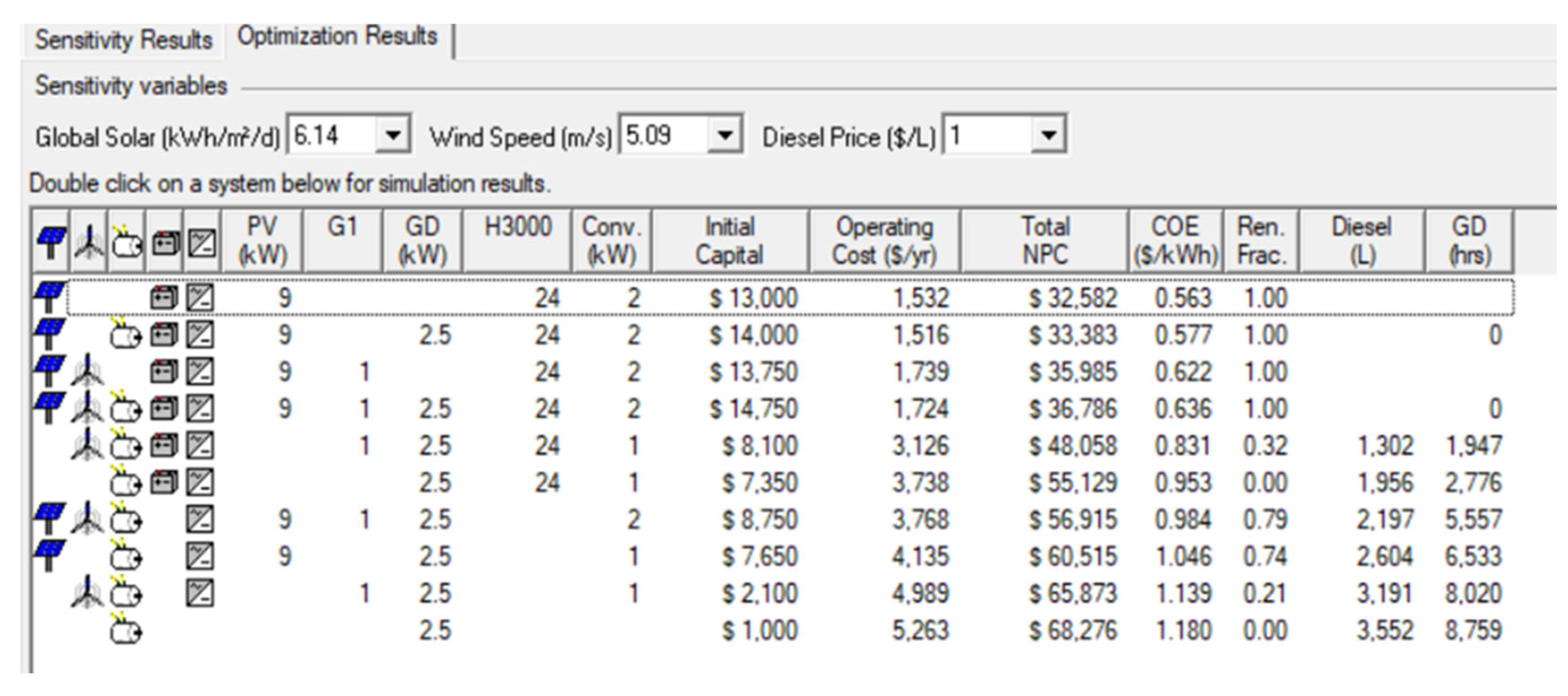

3.1. Optimization Result

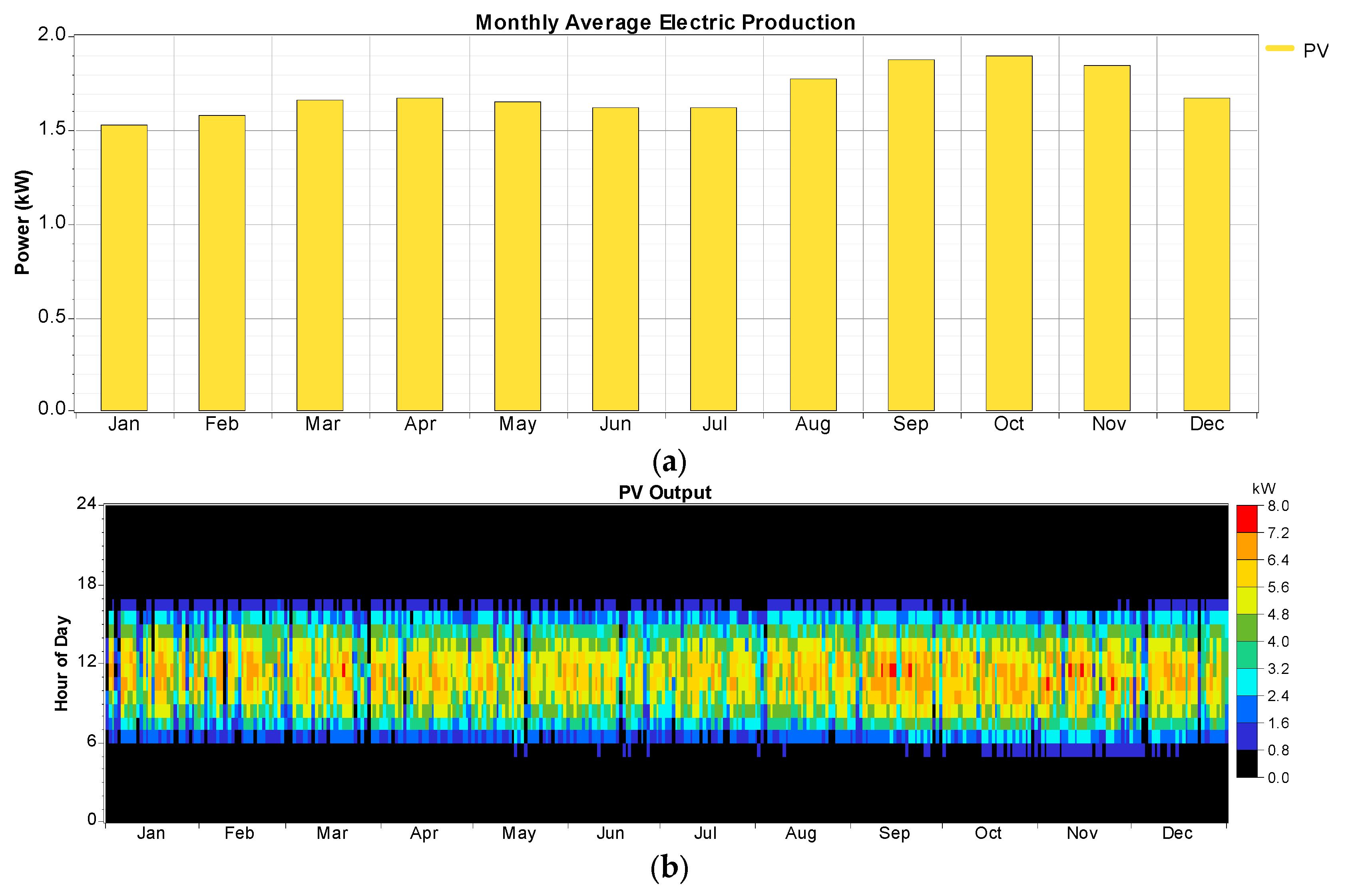

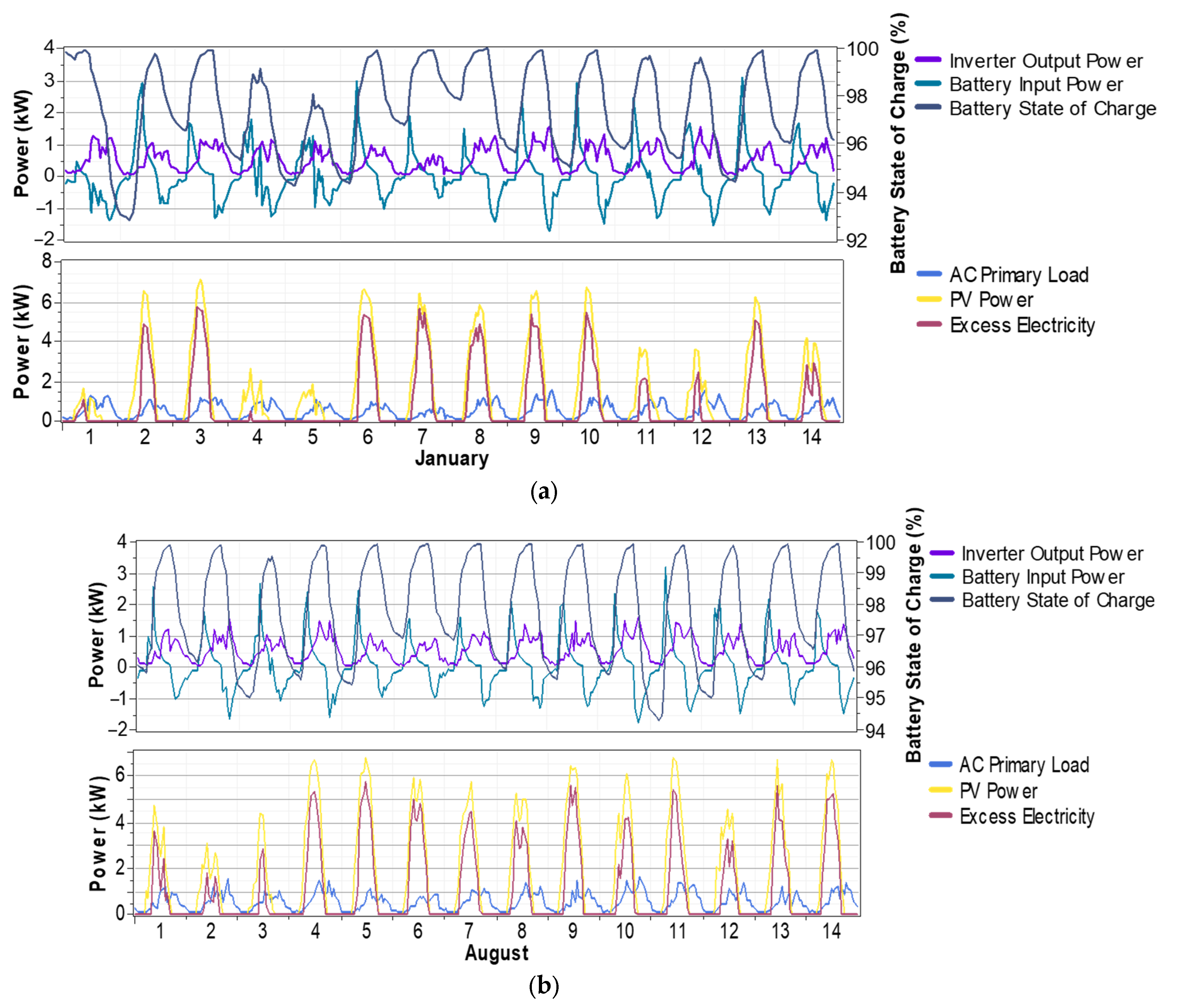

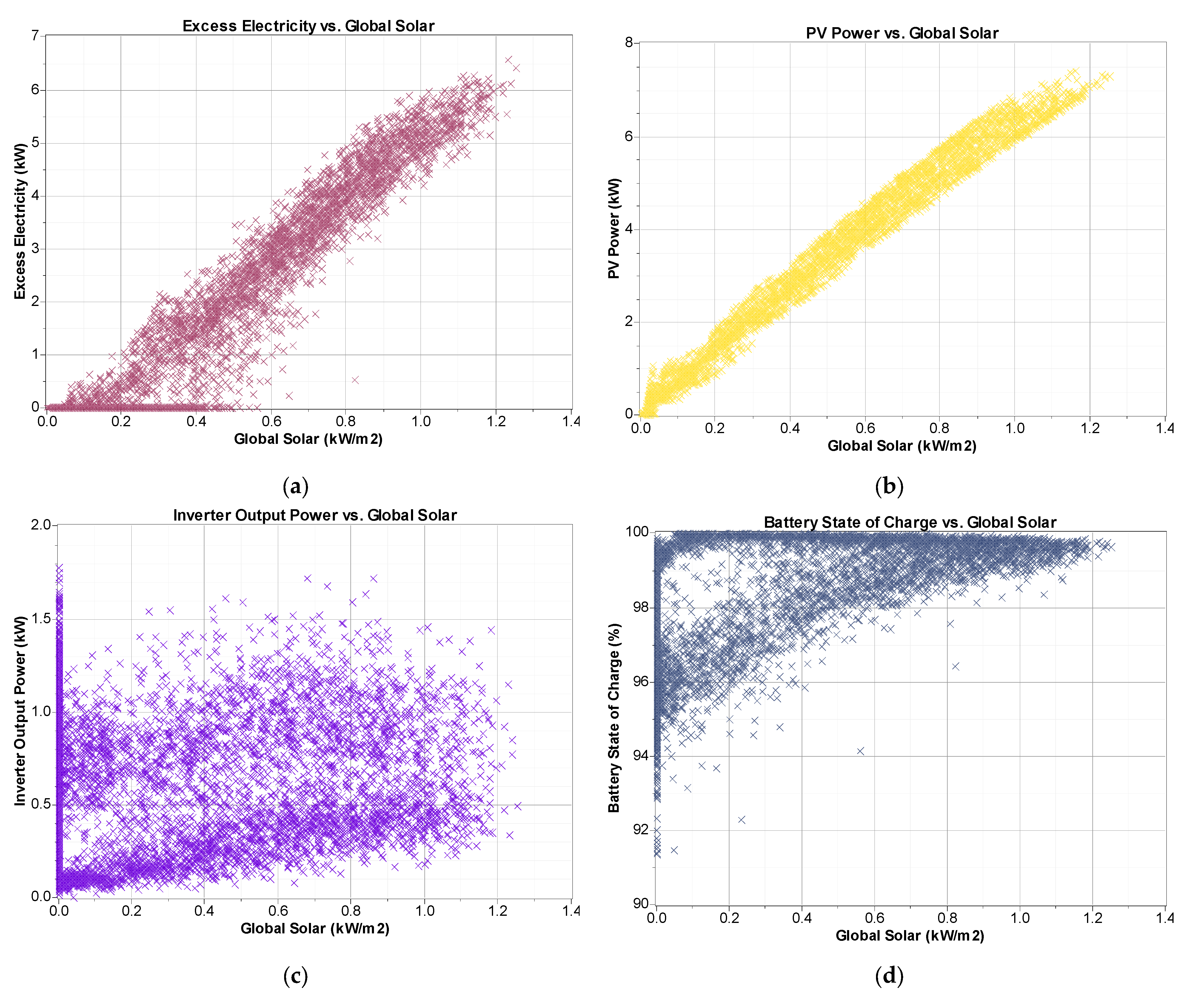

3.1.1. Energy Production

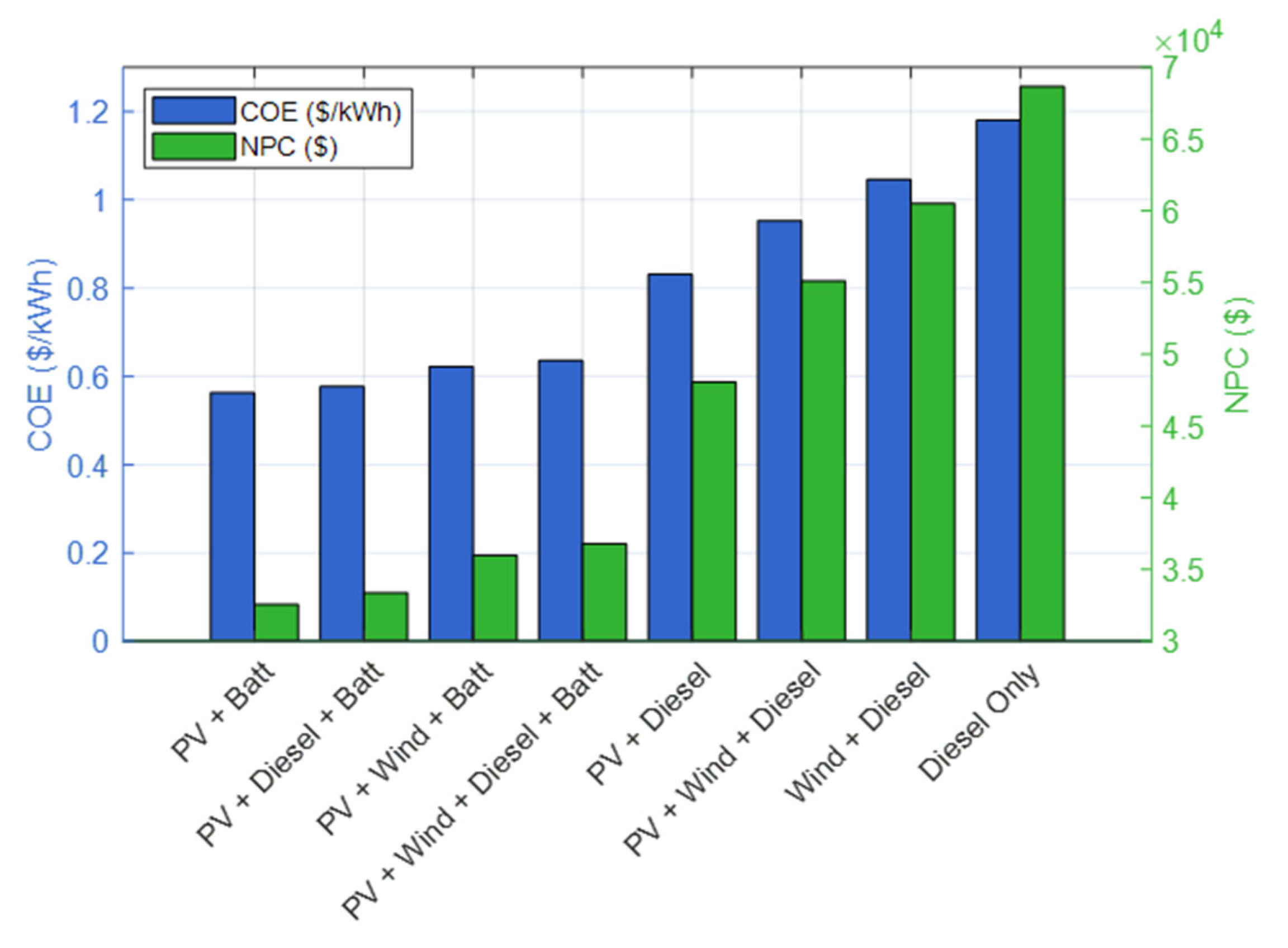

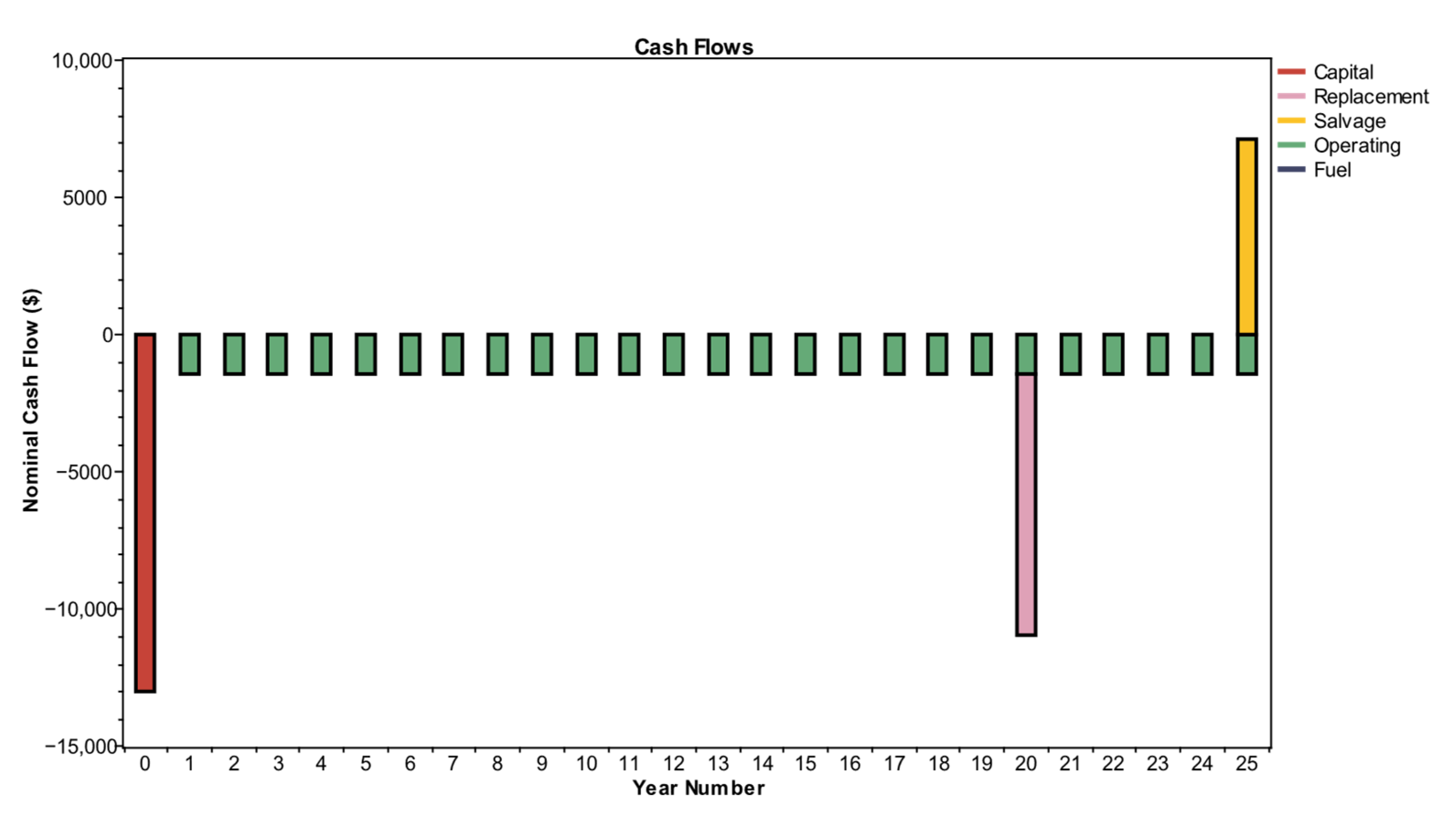

3.1.2. Economic Analysis

3.1.3. Gas Emissions

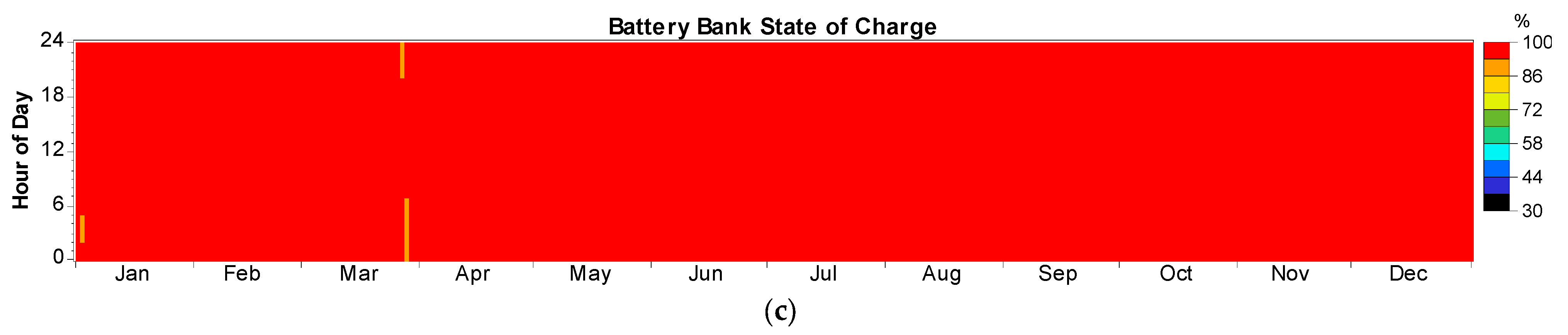

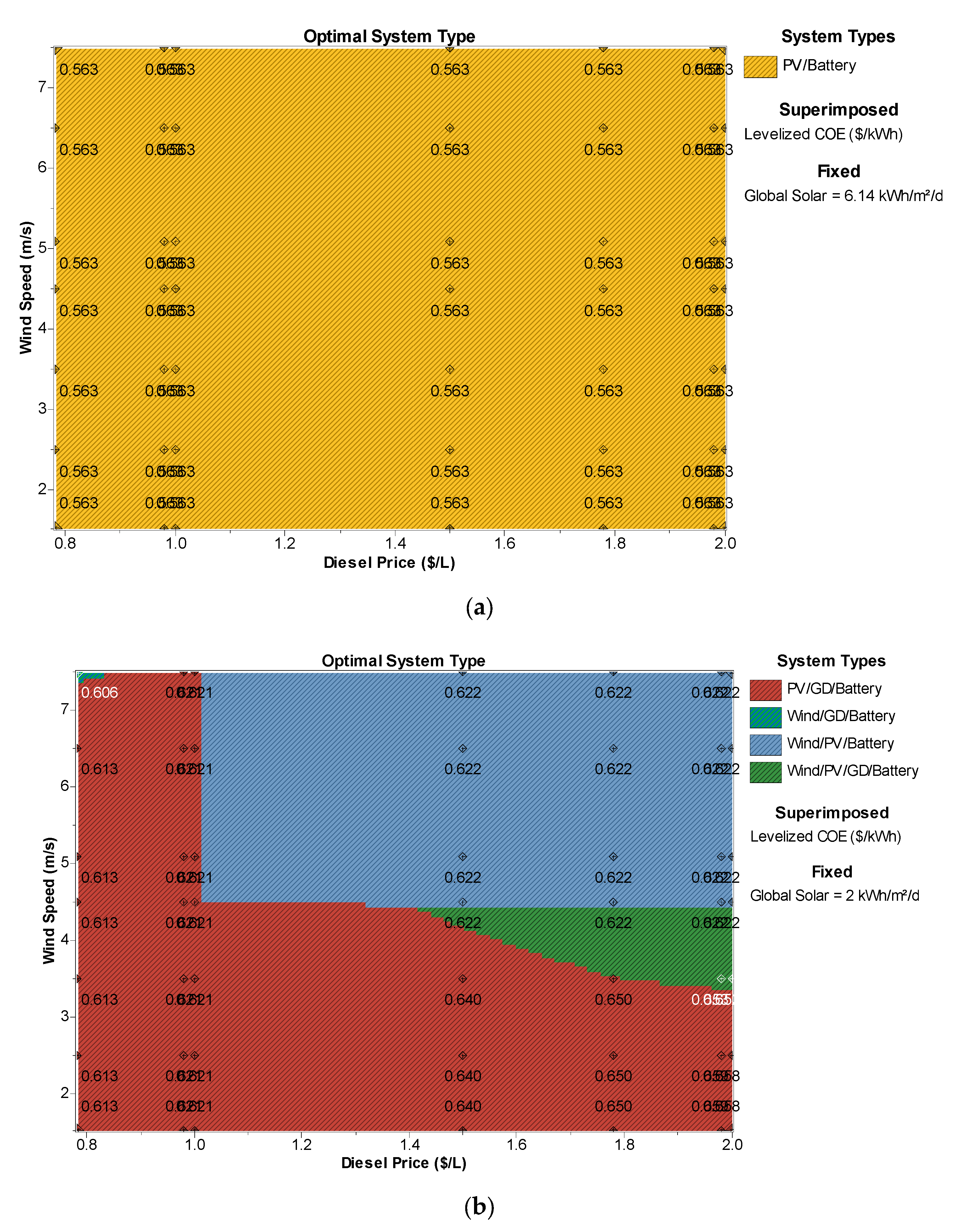

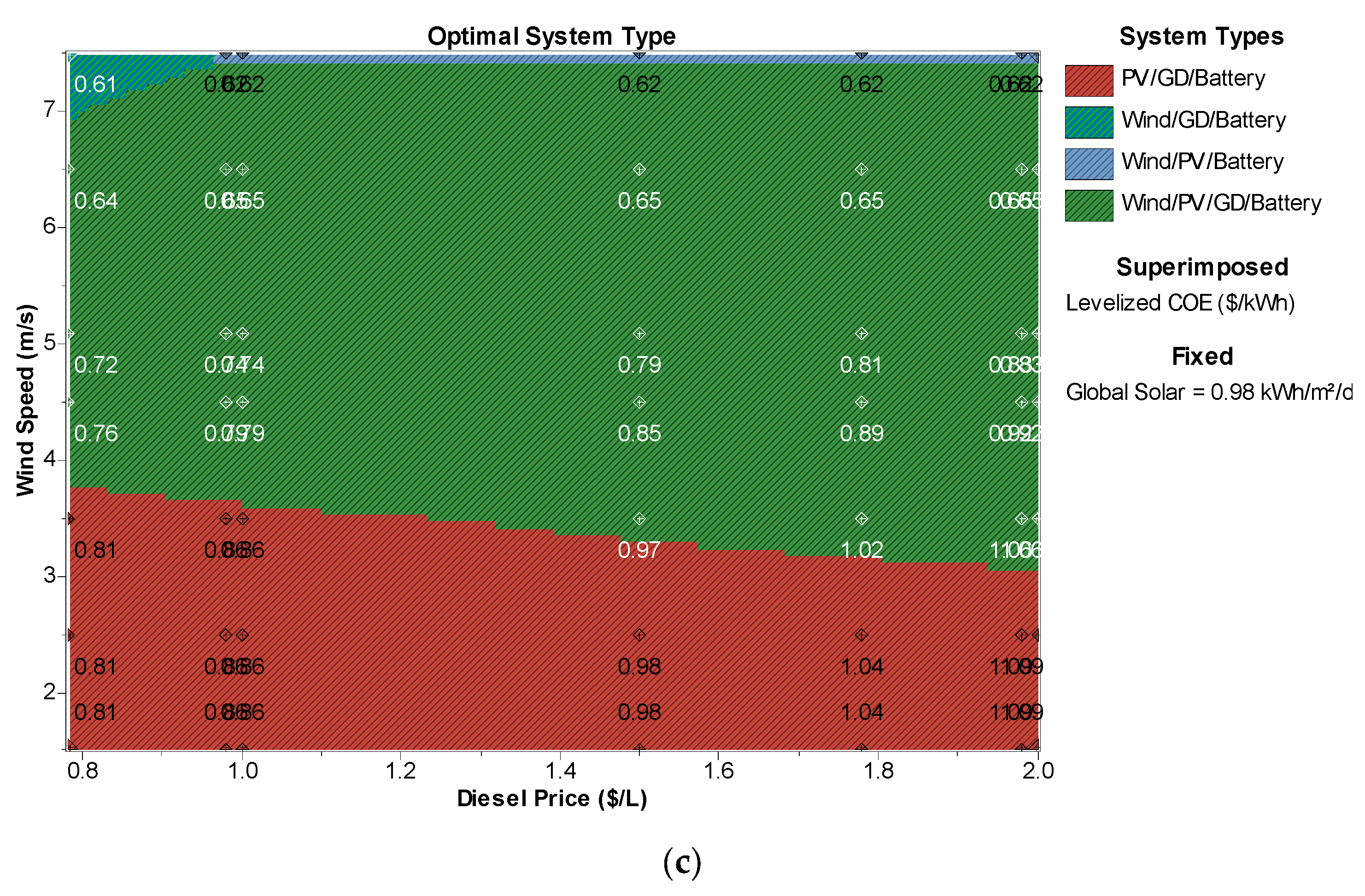

3.2. Microgrid Configuration with Sentience Parameters

4. Discussion

- A quantified evaluation of surplus energy and its potential applications;

- A robust sensitivity analysis of technical and economic variables;

- A contextualized discussion tailored to insular and off-grid environments.

5. Conclusions

- Full energy autonomy based entirely on renewable resources;

- A competitive levelized cost of electricity at 0.563 USD/kWh;

- Zero emissions of greenhouse gases or other pollutants;

- A 63.7% surplus of generated electricity, representing a strategic reserve for future development or community-scale applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviation/Acronym | Meaning | Unit |

| PV | Photovoltaic | kW, kWh |

| SOC | State of Charge (battery charge level) | % |

| COE | Cost of Energy | USD/kWh |

| NPC | Net Present Cost | USD |

| LCOE | Levelized Cost of Energy | USD/kWh |

| HOMER | Hybrid Optimization Model for Electric Renewables | — |

| HRES | Hybrid Renewable Energy System | — |

| AC | Alternating Current | kWh/year |

| DC | Direct Current | — |

| kW | Kilowatt (power) | kW |

| kWh | Kilowatt-hour (energy) | kWh |

| USD | US Dollar | $ |

| CAPEX | Capital Expenditure (initial investment) | USD |

| OPEX | Operating Expenditure (annual operating cost) | USD/year |

| RES | Renewable Energy Sources | — |

| %Ren | Renewable fraction in total electricity production | % |

References

- Ma, W.W.; Rasul, M.G.; Liu, G.; Li, M.; Tan, X.H. Climate Change Impacts on Techno-Economic Performance of Roof PV Solar System in Australia. Renew. Energy 2016, 88, 430–438. [Google Scholar] [CrossRef]

- Vidal, Y.; Acho, L.; Luo, N.; Zapateiro, M.; Pozo, F. Power Control Design for Variable-Speed Wind Turbines. Energies 2012, 5, 3033–3050. [Google Scholar] [CrossRef]

- Touili, S.; Alami Merrouni, A.; El Hassouani, Y.; Amrani, A.; Rachidi, S. Analysis of the Yield and Production Cost of Large-Scale Electrolytic Hydrogen from Different Solar Technologies and under Several Moroccan Climate Zones. Int. J. Hydrogen Energy 2020, 45, 26785–26799. [Google Scholar] [CrossRef]

- Perspectives Énergétiques mondiales 2019. World Energy Outlook–Topics. Available online: https://www.iea.org/topics/world-energy-outlook (accessed on 1 April 2022).

- Perspectives Énergétiques mondiales 2020. World Energy Outlook–Topics. Available online: https://www.iea.org/topics/world-energy-outlook (accessed on 1 April 2022).

- Norouzi, N.; Bozorgian, A.; Dehghani, M.A. Best Option of Investment in Renewable Energy: A Multicriteria Decision-Making Analysis for Iranian Energy Industry. J. Environ. Assmt. Pol. Mgmt. 2020, 22, 2250001. [Google Scholar] [CrossRef]

- Norouzi, N. The Pahlev Reliability Index: A Measurement for the Resilience of Power Generation Technologies versus Climate Change. Nucl. Eng. Technol. 2021, 53, 1658–1663. [Google Scholar] [CrossRef]

- Blanco, M.I. The Economics of Wind Energy. Renew. Sustain. Energy Rev. 2009, 13, 1372–1382. [Google Scholar] [CrossRef]

- Aguilar, M.M. Production de biobutanol à partir de lignocellulose: Un nouveau procédé thermochimique. J. Power Energy Eng. 2024, 12, 5. [Google Scholar]

- Aguilar-Jiménez, J.A.; Hernández-Callejo, L.; Alonso-Gómez, V.; Velázquez, N.; López-Zavala, R.; Acuña, A.; Mariano-Hernández, D. Techno-Economic Analysis of Hybrid PV/T Systems under Different Climate Scenarios and Energy Tariffs. Sol. Energy 2020, 212, 191–202. [Google Scholar] [CrossRef]

- Mohd Noor, M.S.; Adzis, Z.; Arief, Y.Z.; Muhamad, N.A. Feasibility Analysis of Stand-Alone Renewable Energy Supply for Telecommunication Tower Using Homer. Appl. Mech. Mater. 2016, 818, 223–227. [Google Scholar] [CrossRef]

- Gonzalez-Salazar, M.; Poganietz, W.R. Evaluating the Complementarity of Solar, Wind and Hydropower to Mitigate the Impact of El Niño Southern Oscillation in Latin America. Renew. Energy 2021, 174, 453–467. [Google Scholar] [CrossRef]

- Yao, Y.; Xu, J.-H.; Sun, D.-Q. Untangling Global Levelised Cost of Electricity Based on Multi-Factor Learning Curve for Renewable Energy: Wind, Solar, Geothermal, Hydropower and Bioenergy. J. Clean. Prod. 2021, 285, 124827. [Google Scholar] [CrossRef]

- Thirunavukkarasu, M.; Sawle, Y. A Comparative Study of the Optimal Sizing and Management of Off-Grid Solar/Wind/Diesel and Battery Energy Systems for Remote Areas. Front. Energy Res. 2021, 9, 752043. [Google Scholar] [CrossRef]

- Rachid, A.; Korkut, T.B.; Cardot, J.-S.; Kébé, C.M.F.; Ndiaye, A.; Sinsin, L.M.; Fifatin, F.X. Optimizing Solar-Integrated Microgrid Design for Sustainable Rural Electrification: Insights from the LEOPARD Project. Solar 2025, 5, 9. [Google Scholar] [CrossRef]

- Olatomiwa, L.; Mekhilef, S.; Ismail, M.S.; Moghavvemi, M. Energy Management Strategies in Hybrid Renewable Energy Systems: A Review. Renew. Sustain. Energy Rev. 2016, 62, 821–835. [Google Scholar] [CrossRef]

- Maoulida, F.; Rabah, D.; Ganaoui, M.E.; Aboudou, K.M. PV-Wind-Diesel System for Energy Supply on Remote Area Applied for Telecommunication Towers in Comoros. Open J. Energy Effic. 2021, 10, 50–72. [Google Scholar] [CrossRef]

- Fahad, M.; Kassim, M.; Djedjig, R.; Ganaoui, M. Feasibility Study for a Hybrid Power Plant (PV-Wind-Diesel-Storage) Connected to the Electricity Grid. Fluid Dyn. Mater. Process. 2022, 18, 1607–1617. [Google Scholar] [CrossRef]

- Garg, V.K.; Sharma, S. Techno-Economic Analysis of a Microgrid for a Small Community; Springer: Singapore, 2021; Available online: https://link.springer.com/chapter/10.1007/978-981-16-1048-6_40 (accessed on 22 January 2023).

- Kassim, M.; Fahad, M.; El Ganaoui, M. Pv-Wind Hybrid Energy System for Application of Building in Rural Areas in Comorspv-Wind Hybrid Energy System for Application of Building in Rural Areas in Comors. Proceedings of the International Conference on Materials and Energy (ICOME’2018), San Sebastian, Spain, 30 April–4 May 2018, 2020. [Google Scholar]

- Fahad, M.; Kassim, M.; Rakoto, J.; El Ganaoui, M. Dimensionnement d’un Système Hybride Pv/Générateur Diesel Pour l’alimentation Électrique d’un Pylône de Télécommunication Aux Comores. In Proceedings of the CIFEM 2018—Conférence Internationale Francophone en Énergie, Mécanique et Thermique, Antananarivo, Madagascar, 23–24 April 2018. [Google Scholar]

- Aboudou, K.M.; Ganaoui, M.E. Design of a Hybrid System for Rural Area Electricity Supply in Comoros. J. Power Energy Eng. 2019, 7, 59–78. [Google Scholar] [CrossRef]

- Kassim, M.; El Ganaoui, M. Design of Hybrid Power System for a Power Supply in Rural Areas in Comoros. In Proceedings of the 3rd Southern African Solar Energy Conference, SASEC 2015, Skukuza, South Africa, 11–13 May 2015. [Google Scholar]

- World Energy Transitions Outlook: 1.5 °C Pathway; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021.

- Skandalos, N.; Kocher-Oberlehner, G. Impact of Surface Modification on Performance of Solar Concentrators. Solar 2025, 5, 17. [Google Scholar] [CrossRef]

- Nasir, M.; Iqbal, S.; Khan, H.A.; Vasquez, J.C.; Guerrero, J.M. Sustainable Rural Electrification Through Solar PV DC Microgrids—An Architecture-Based Assessment. Processes 2020, 8, 1417. [Google Scholar] [CrossRef]

- Sanfilippo, S.; Hernández Cabrera, J.J.; Évora, J.; Kébé, C.M.F.; Kremers, E.; Péchiné, B.; Cardot, J.S.; Rachid, A.; Tossa, A.K.; Lekoto, J.; et al. Microgrid Design Optimization in Benin within the LEOPARD Project: Evaluating the Impact of Inaccurate Load Profile Estimation. In Proceedings of the 2023 3rd International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Tenerife, Spain, 19–21 July 2023; pp. 1–6. [Google Scholar]

- Aziz, A.S.; Tajuddin, M.F.N.; Adzman, M.R.; Ramli, M.A.M.; Mekhilef, S. Energy Management and Optimization of a PV/Diesel/Battery Hybrid Energy System Using a Combined Dispatch Strategy. Sustainability 2019, 11, 683. [Google Scholar] [CrossRef]

- Almutairi, K.; Hosseini Dehshiri, S.S.; Hosseini Dehshiri, S.J.; Mostafaeipour, A.; Issakhov, A.; Techato, K. Use of a Hybrid Wind—Solar—Diesel—Battery Energy System to Power Buildings in Remote Areas: A Case Study. Sustainability 2021, 13, 8764. [Google Scholar] [CrossRef]

- Al Garni, H.Z.; Abubakar Mas’ud, A.; Wright, D. Design and Economic Assessment of Alternative Renewable Energy Systems Using Capital Cost Projections: A Case Study for Saudi Arabia. Sustain. Energy Technol. Assess. 2021, 48, 101675. [Google Scholar] [CrossRef]

- Hasan, S.M.N.; Ahmad, S.; Liaf, A.F.; Mustayen, A.G.M.B.; Hasan, M.M.; Ahmed, T.; Howlader, S.; Hassan, M.; Alam, M.R. Techno-Economic Performance and Sensitivity Analysis of an Off-Grid Renewable Energy-Based Hybrid System: A Case Study of Kuakata, Bangladesh. Energies 2024, 17, 1476. [Google Scholar] [CrossRef]

- Gerlici, J.; Shavolkin, O.; Kravchenko, O.; Shvedchykova, I.; Haman, Y. Improvement of the Hybrid Renewable Energy System for a Sustainable Power Supply of Transportation Infrastructure Objects. Future Transp. 2025, 5, 61. [Google Scholar] [CrossRef]

- Jarso, A.K.; Jin, G.; Ahn, J. Hybrid Genetic Algorithm-Based Optimal Sizing of a PV–Wind–Diesel–Battery Microgrid: A Case Study for the ICT Center, Ethiopia. Mathematics 2025, 13, 985. [Google Scholar] [CrossRef]

- Bouchekara, H.R.E.H.; Sha’aban, Y.A.; Shahriar, M.S.; Abdullah, S.M.; Ramli, M.A. Sizing of Hybrid PV/Battery/Wind/Diesel Microgrid System Using an Improved Decomposition Multi-Objective Evolutionary Algorithm Considering Uncertainties and Battery Degradation. Sustainability 2023, 15, 11073. [Google Scholar] [CrossRef]

- Żołądek, M.; Kafetzis, A.; Figaj, R.; Panopoulos, K. Energy-Economic Assessment of Islanded Microgrid with Wind Turbine, Photovoltaic Field, Wood Gasifier, Battery, and Hydrogen Energy Storage. Sustainability 2022, 14, 12470. [Google Scholar] [CrossRef]

- Belboul, Z.; Toual, B.; Kouzou, A.; Mokrani, L.; Bensalem, A.; Kennel, R.; Abdelrahem, M. Multiobjective Optimization of a Hybrid PV/Wind/Battery/Diesel Generator System Integrated in Microgrid: A Case Study in Djelfa, Algeria. Energies 2022, 15, 3579. [Google Scholar] [CrossRef]

- Halabi, L.M.; Mekhilef, S.; Olatomiwa, L.; Hazelton, J. Performance Analysis of Hybrid PV/Diesel/Battery System Using HOMER: A Case Study Sabah, Malaysia. Energy Convers. Manag. 2017, 144, 322–339. [Google Scholar] [CrossRef]

- Riayatsyah, T.M.I.; Geumpana, T.A.; Fattah, I.M.R.; Mahlia, T.M.I. Techno-Economic Analysis of Hybrid Diesel Generators and Renewable Energy for a Remote Island in the Indian Ocean Using HOMER Pro. Sustainability 2022, 14, 9846. [Google Scholar] [CrossRef]

- Mehallou, A.; M’hamdi, B.; Amari, A.; Teguar, M.; Rabehi, A.; Guermoui, M.; Alharbi, A.H.; El-kenawy, E.-S.M.; Khafaga, D.S. Optimal Multiobjective Design of an Autonomous Hybrid Renewable Energy System in the Adrar Region, Algeria. Sci. Rep. 2025, 15, 4173. [Google Scholar] [CrossRef] [PubMed]

- Murtza Qamar, H.G.; Guo, X.; Seif Ghith, E.; Tlija, M.; Siddique, A. Assessment of Energy Management and Power Quality Improvement of Hydrogen Based Microgrid System through Novel PSO-MWWO Technique. Sci. Rep. 2025, 15, 863. [Google Scholar] [CrossRef] [PubMed]

- Yamegueu, D.; Nelson, H.T.; Boly, A.S. Improving the Performance of PV/Diesel Microgrids via Integration of a Battery Energy Storage System: The Case of Bilgo Village in Burkina Faso. Energy Sustain. Soc. 2024, 14, 48. [Google Scholar] [CrossRef]

- Putri, S.A.; Ge, X.; Khazaei, J. Economic Dispatch and Power Flow Analysis for Microgrids. arXiv 2024, arXiv:2411.19279. [Google Scholar]

- Toms, A.M.; Li, X.; Rajashekara, K. Optimal Microgrid Sizing of Offshore Renewable Energy Sources for Offshore Platforms and Coastal Communities. arXiv 2025, arXiv:2505.053052025. [Google Scholar]

- Dufo-López, R.; Bernal-Agustín, J.L. Design and Control Strategies of PV-Diesel Systems Using Genetic Algorithms. Sol. Energy 2005, 79, 33–46. [Google Scholar] [CrossRef]

- Chao, J. Experts’ Predictions for Future Wind Energy Costs Drop Significantly. Available online: https://newscenter.lbl.gov/2021/04/15/experts-predictions-for-future-wind-energy-costs-drop-significantly/ (accessed on 22 January 2023).

- Homer Energy HOMER-Logiciel de Conception de Systèmes de Génération Hybrides Renouvelables et Distribués. Available online: https://www.homerenergy.com/ (accessed on 28 June 2021).

- Belboul, Z.; Toual, B.; Bensalem, A.; Ghenai, C.; Khan, B.; Kamel, S. Techno-Economic Optimization for Isolated Hybrid PV/Wind/Battery/Diesel Generator Microgrid Using Improved Salp Swarm Algorithm. Sci. Rep. 2024, 14, 2920. [Google Scholar] [CrossRef]

- Manmadharao, S.; Chaitanya, S.N.V.S.K.; Venkateswara rao, B.; Srinivasarao, G. Design and Optimization of Grid Integrated Solar Energy System Using HOMER GRID Software. In Proceedings of the 2019 Innovations in Power and Advanced Computing Technologies (i-PACT), Vellore, India, 22–23 March 2019; Volume 1, pp. 1–5. [Google Scholar]

- Ghatak, A.; Alfred, R.B.; Singh, R.R. Optimization for Electric Vehicle Charging Station Using Homer Grid. In Proceedings of the 2021 Innovations in Power and Advanced Computing Technologies (i-PACT), Kuala Lumpur, Malaysia, 27–29 November 2021; pp. 1–7. [Google Scholar]

- Sen, R.; Bhattacharyya, S.C. Off-Grid Electricity Generation with Renewable Energy Technologies in India: An Application of HOMER. Renew. Energy 2014, 62, 388–398. [Google Scholar] [CrossRef]

- Shahzad, M.K.; Zahid, A.; ur Rashid, T.; Rehan, M.A.; Ali, M.; Ahmad, M. Techno-Economic Feasibility Analysis of a Solar-Biomass off Grid System for the Electrification of Remote Rural Areas in Pakistan Using HOMER Software. Renew. Energy 2017, 106, 264–273. [Google Scholar] [CrossRef]

- Bahramara, S.; Moghaddam, M.P.; Haghifam, M.R. Optimal Planning of Hybrid Renewable Energy Systems Using HOMER: A Review. Renew. Sustain. Energy Rev. 2016, 62, 609–620. [Google Scholar] [CrossRef]

- Ahmad, J.; Imran, M.; Khalid, A.; Iqbal, W.; Ashraf, S.R.; Adnan, M.; Ali, S.F.; Khokhar, K.S. Techno Economic Analysis of a Wind-Photovoltaic-Biomass Hybrid Renewable Energy System for Rural Electrification: A Case Study of Kallar Kahar. Energy 2018, 148, 208–234. [Google Scholar] [CrossRef]

- Homer energy pro How HOMER Creates the Generator Efficiency Curve. Available online: https://www.homerenergy.com/products/pro/docs/latest/how_homer_creates_the_generator_efficiency_curve.html (accessed on 22 January 2023).

- Maoulida, F. Développement D’Un Système Hybride de Génération D’éNergie en Site Isolé Pour la Télécommunication ET Réalisation D’Un Régulateur de Charge Solaire. Master’s Thesis, d’Ingénierie en Énergies Renouvelables, Université d’Antananarivo, Antananarivo, Madagascar, 2020. [Google Scholar]

- Homer Energy pro How HOMER Calculates the PV Array Power Output. Available online: https://www.homerenergy.com/products/pro/docs/3.14/how_homer_calculates_the_pv_array_power_output.html (accessed on 21 January 2023).

- Brihmat, F.; Mekhtoub, S. PV Cell Temperature/PV Power Output Relationships Homer Methodology Calculation. Int. J. Sci. Res. Eng. Technol. 2014, 1, 33–45. [Google Scholar]

- Haffaf, A.; Lakdja, F.; Meziane, R.; Abdeslam, D.O. Study of Economic and Sustainable Energy Supply for Water Irrigation System (WIS). Sustain. Energy Grids Netw. 2021, 25, 100412. [Google Scholar] [CrossRef]

- Homer Energy Pro How HOMER Calculates Wind Turbine Power Output. Available online: https://www.homerenergy.com/products/pro/docs/3.10/how_homer_calculates_wind_turbine_power_output.html (accessed on 11 April 2023).

- Delannoy, L.; Puri, S.; Perera, A.T.D.; Coccolo, S.; Mauree, D.; Scartezzini, J.-L. Climate Impact and Energy Sustainability of Future European Neighborhoods. In Proceedings of the 2018 5th International Symposium on Environment-Friendly Energies and Applications (EFEA), Rome, Italy, 24–26 September 2018; pp. 1–6. [Google Scholar]

| Study/Reference | Location | Tool | LCOE (USD/kWh) | Math Modeling | Sensitivity Analysis | Surplus Energy | Island Context |

|---|---|---|---|---|---|---|---|

| Nasir et al. [26] | Pakistan | HOMER | ≈0.5 | ✗ | ✓ | ✗ | ✗ |

| Sanfilippo et al. [27] | Benin | HOMER | 0.6–1.2 | ✗ | ✗ | ✗ | Partial |

| Aziz et al. [28] | Iran | HOMER | – | ✗ | ✓ | ✗ | ✗ |

| Almutairi et al. [29] | Iran | HOMER | ≈1.06 | ✗ | ✓ | ✓ | ✓ |

| Al Garni et al. [30] | Saudi Arabia | HOMER | – | ✗ | ✓ | ✗ | ✗ |

| Hasan et al. [31] | Bangladesh | HOMER | – | ✗ | ✓ | ✗ | ✗ |

| Gerlici et al. [32] | Europe | Math modeling | – | ✓ | ✗ | ✗ | ✗ |

| Jarso et al. [33] | Ethiopia | Math modeling | – | ✓ | – | ✗ | ✗ |

| Present study Comoros real-case PV + Battery | Comoros | HOMER + Math model | 0.563 | ✓ | ✓ | ✓ (~64%) | ✓ |

| Component | Description | Power (kW) |

|---|---|---|

| Solar Production | Photovoltaic Panels (PV) | 9.0 |

| Wind Production | Generic Wind Turbine | 1.0 |

| Thermal Production | Backup diesel generator | 2.5 |

| Storage | 24 storage battery of type H3000 | — |

| Conversion | Bidirectional AC/DC Converter | 2.0 |

| Total installed power | Solar + Wind + Diesel | 12.5 |

| Parameters | Hypothesis Retained |

|---|---|

| Solar resources | Average irradiation: 6.14 kWh/m2/day—Clarity index: 0.623 |

| Wind resources | Average annual wind speed: 5.087 m/s (at 10 m in height) |

| Ambient temperature | Average annual temperature: 26.6 °C |

| Diesel prices | 1.0 USD/L—PCI: 43.2 MJ/kg—Density: 820 kg/m3 |

| Fuel Property | Value |

|---|---|

| Lower calorific value (PCI) | 43.2 MJ/kg |

| Density | 820 kg/m3 |

| Carbon content | 88% |

| Sulfur content | 0.4% |

| Maximum fuel cost | USD 1 |

| Minimum fuel cost | USD 0.98 |

| Source/Consumption | Quantity (kWh/an) | Percentage (%) |

|---|---|---|

| Production—PV array | 14,892 | 100 |

| Total production | 14,892 | 100 |

| AC load consumption | 4526 | 100 |

| Total consumption | 4526 | 100 |

| Indicator | Quantity (kWh/an) | Percentage (%) |

|---|---|---|

| Excess electricity | 9490 | 63.7 |

| Unsatisfied portion of the charge | 0.0000174 | 0 |

| Capacity shortage | 0 | 0 |

| Renewable fraction | - | 0 |

| Indicator | Quantity | Price |

| Net Present cost (NPC) | 32,582 | USD |

| Cost of Energy (COE) | 0.563 | USD/kWh |

| Annual operating cost | 1532 | USD/an |

| Indicator | Value | Unit Value |

|---|---|---|

| Nominal power | 9.00 | kW |

| Average power produced | 1.70 | kW |

| Average daily energy | 40.8 | kWh/d |

| Capacity factor | 18.9 | % |

| Total annual production | 14,892 | kWh/an |

| Indicator | Value | Unit Value |

|---|---|---|

| Input energy | 2705 | kWh/yr |

| Output energy | 2333 | kWh/yr |

| Deep dumps | 6 | times/year |

| Energy losses | 367 | kWh/yr |

| Annual flow rate | 2515 | kWh/yr |

| Wear cost per kWh | 0.016 | USD/kWh |

| Average cost of energy | 0.000 | USD/kWh |

| Indicator | Inverter | Rectifier | Unit Value |

|---|---|---|---|

| Capacity | 2.00 | 2.00 | kW |

| Average power | 0.52 | 0.00 | kW |

| Minimum power | 0.00 | 0.00 | kW |

| Maximum power | 1.77 | 0.00 | kW |

| Capacity factor | 25.8 | 0.0 | % |

| Parameter | Unit | Variation Range | Purpose/Impact Analyzed |

|---|---|---|---|

| Solar irradiation | kWh/m2/day | 0.50–2.00 | Evaluate system reliability with fluctuating solar resource |

| Wind speed | m/s | 1.50–7.50 | Assess wind turbine viability and its potential contribution |

| Diesel fuel price | USD/L | 0.78–2.00 | Examine the cost impact of fossil fuel usage and competitiveness of diesel |

| Aspect | Indicator | Value/Performance |

|---|---|---|

| Energy Production and Use | Annual PV production | 14,892 kWh/year (100%) |

| Annual AC load consumption | 4526 kWh/year (100%) | |

| Energy Surplus | Surplus electricity (unused energy) | 9490 kWh/year (≈63.7% of production) |

| Economic Indicators | Possible applications of surplus | Public lighting, water pumping, economic activities |

| Cost of energy (COE) | 0.563 USD/kWh | |

| Net present cost (NPC) | USD 32,582 | |

| Annual operating cost | 1532 USD/year | |

| PV System Performance | Nominal power | 9.0 kW |

| Capacity factor | 18.9% | |

| Average daily production | 40.8 kWh/day | |

| Battery Storage | Number of batteries | 24 (H3000 type) |

| Useful capacity | 101 kWh | |

| Roundtrip efficiency | 86% | |

| Converter | Rated power (inverter/rectifier) | 2.0 kW/2.0 kW |

| Inverter efficiency | 89% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maoulida, F.; Aboudou, K.M.; Djedjig, R.; El Ganaoui, M. Optimization Study of the Electrical Microgrid for a Hybrid PV–Wind–Diesel–Storage System in an Island Environment. Solar 2025, 5, 39. https://doi.org/10.3390/solar5030039

Maoulida F, Aboudou KM, Djedjig R, El Ganaoui M. Optimization Study of the Electrical Microgrid for a Hybrid PV–Wind–Diesel–Storage System in an Island Environment. Solar. 2025; 5(3):39. https://doi.org/10.3390/solar5030039

Chicago/Turabian StyleMaoulida, Fahad, Kassim Mohamed Aboudou, Rabah Djedjig, and Mohammed El Ganaoui. 2025. "Optimization Study of the Electrical Microgrid for a Hybrid PV–Wind–Diesel–Storage System in an Island Environment" Solar 5, no. 3: 39. https://doi.org/10.3390/solar5030039

APA StyleMaoulida, F., Aboudou, K. M., Djedjig, R., & El Ganaoui, M. (2025). Optimization Study of the Electrical Microgrid for a Hybrid PV–Wind–Diesel–Storage System in an Island Environment. Solar, 5(3), 39. https://doi.org/10.3390/solar5030039