Abstract

Bacterial diseases are a major constraint to aquaculture productivity, driving extensive antibiotic use and raising concerns over antimicrobial resistance, environmental contamination, and food safety. Curcumin, a polyphenolic compound from Curcuma longa, exhibits broad-spectrum antimicrobial and immunomodulatory activities but is limited by poor water solubility, instability, and low bioavailability. This review was conducted through a literature search of Scopus, PubMed, Web of Science, and Google Scholar using targeted keywords, including curcumin nanoparticles, antibacterial, aquatic pathogens, nanotechnology, synthesis, and disease control. Titles and abstracts were screened for relevance, followed by full-text evaluation of selected studies. Key findings were critically analyzed and incorporated into the review. Findings from the literature indicate that curcumin nanoparticles, synthesized via milling, anti-solvent precipitation, ionic gelation, emulsification, spray drying, and metal/polymer nanocomposite formation, exhibit enhanced antibacterial activity against aquatic pathogens, including Aeromonas hydrophila, Vibrio parahaemolyticus, Escherichia coli, and Staphylococcus aureus. Optimally engineered curcumin nanoparticles (<100 nm, being mostly spherical, highly negatively charged) can penetrate bacterial membranes, disrupt biofilms, lower minimum inhibitory concentrations, and improve in vivo fish survival. Practical applications include dietary supplementation to boost fish immunity and growth, water disinfection to reduce pathogen loads, immersion therapy for external infections, and antimicrobial coatings for aquaculture equipment and surfaces, resulting in reduced infections and outbreaks, reduced mortality, improved water quality, and decreased antibiotic dependence. In conclusion, curcumin nanoparticles and curcumin-based nanocomposites present a versatile, eco-friendly approach to sustainable aquaculture disease management. However, further field-scale validation, safety assessment, and cost-effective production methods are necessary to enable commercial adoption.

1. Introduction

Aquaculture has become the fastest-growing food production sector globally, contributing nearly 50% of fish consumed worldwide and providing essential nutrition, income, and employment, especially in low- and middle-income countries [1]. To meet rising demand, aquaculture has intensified, adopting high-density farming systems that, while boosting productivity, also increase the risk of infectious disease outbreaks [2]. A variety of pathogens threaten aquaculture, causing economic losses, reduced efficiency, and trade limitations. Bacterial pathogens such as Aeromonas spp., Vibrio spp., Edwardsiella spp., Flavobacterium spp., Streptococcus spp., and Acinetobacter spp. are particularly troublesome, often causing rapid disease spread and high mortality [3]. Environmental stress, poor water quality, and weak biosecurity further promote pathogen persistence and transmission [4].

Antibiotics have been widely used to control infections. However, their frequent and indiscriminate application has led to antimicrobial resistance (AMR) in aquatic pathogens [5]. AMR reduces treatment efficacy and raises public health concerns due to the potential transfer of resistance genes to human pathogens [6]. Moreover, antimicrobial residues in aquaculture products and ecosystems pose food safety and environmental risks [7]. Consequently, many countries now restrict antibiotic use, highlighting the urgent need for safer, sustainable alternatives for disease prevention and control [8]. In response to these challenges, there is growing interest in the development of natural, plant-based therapeutics with antimicrobial potential.

Curcumin, a polyphenolic compound derived from the rhizomes of Curcuma longa (turmeric), has attracted considerable attention for its broad-spectrum antimicrobial, antioxidant, anti-inflammatory, and immunomodulatory properties [9,10]. However, its application in aquaculture has been limited by poor water solubility, low bioavailability, and chemical instability under physiological conditions [11,12]. Recent advances in nanotechnology have opened new avenues for enhancing the functional performance of curcumin through nanoparticle-based formulations. Curcumin nanoparticles (CurNPs) offer improved aqueous dispersibility, enhanced cellular uptake, greater chemical stability, and controlled release properties, which together contribute to superior antimicrobial efficacy compared to native curcumin [13,14,15]. This nanoformulation approach represents a promising and environmentally friendly strategy for managing bacterial diseases in aquaculture.

This review details the antimicrobial efficacy of CurNPs against bacterial pathogens crucial to aquaculture. The review commences by critically outlining the substantial impact of bacterial diseases on global aquaculture productivity and sustainability, alongside a detailed discussion of the growing challenges and environmental consequences of reliance on conventional antimicrobial interventions, particularly the escalating threat of antimicrobial resistance. It then discusses the scientific rationale for investigating CurNPs as a viable and sustainable alternative therapeutic. Emphasis is placed on their documented broad-spectrum antibacterial properties, enhanced bioavailability compared to native curcumin, and potentially reduced ecotoxicological footprint. The scope extends to a comprehensive examination of the various synthesis techniques, detailed physicochemical properties, and the demonstrated in vitro and in vivo antibacterial efficacy of CurNPs against a range of relevant aquaculture bacterial pathogens. Practical applications and their implications for aquatic animal health are also explored. Through the critical synthesis of contemporary research, this review seeks to identify key knowledge gaps, inform the design of future studies, and ultimately champion the strategic integration of advanced nanotechnology-derived natural product therapeutics into a robust and sustainable aquaculture disease management paradigm.

2. Curcumin: Source, Biological Activity, and Bioavailability Challenges

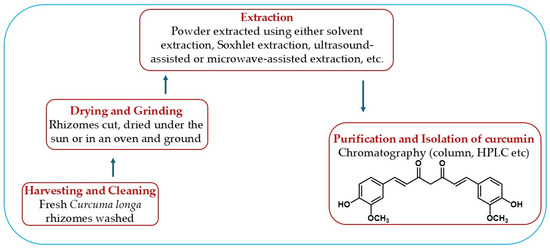

Curcumin is the principal bioactive curcuminoid extracted from the rhizome of Curcuma longa L., commonly known as turmeric, a perennial herbaceous plant belonging to the Zingiberaceae (ginger) family [9]. Turmeric has been valued for centuries in traditional medicinal systems, particularly in Ayurveda and Traditional Chinese Medicine, for its wide range of therapeutic properties, including anti-inflammatory, antimicrobial, hepatoprotective, and wound-healing effects [10]. Figure 1 illustrates the stepwise process of extracting and isolating curcumin from Curcuma longa rhizomes.

Figure 1.

Illustration of the steps in the extraction and isolation of curcumin from Curcuma longa.

Curcumin is one of three major naturally occurring curcuminoids in turmeric, alongside demethoxycurcumin and bisdemethoxycurcumin. These polyphenolic compounds share a common structural motif; however, curcumin is the most extensively studied due to its diverse and potent pharmacological activities [10,16].

Extensive in vitro, in vivo, and clinical studies have shown that curcumin possesses diverse biological activities. Among its most notable properties is its antioxidant capacity. Curcumin acts as a potent scavenger of reactive oxygen species (ROS) and reactive nitrogen species (RNS), thereby protecting biomolecules such as lipids, proteins, and nucleic acids from oxidative damage [17,18]. In addition, it enhances the body’s endogenous antioxidant defense mechanisms by upregulating key enzymes, including superoxide dismutase (SOD), catalase, and glutathione peroxidase. These antioxidant effects are crucial in mitigating the progression of oxidative stress-related diseases, including aging, neurodegenerative disorders, and cardiovascular conditions [19,20]. For example, curcumin has been shown to effectively enhance the antioxidant system of Crassostrea gigas oyster larvae by activating the nuclear factor erythroid-2-related factor 2 (Nrf2) pathway (a key cellular redox regulator responsible for oxidative stress defense), increasing glutathione levels, and reducing ROS, thereby improving their overall antioxidant capacity and resistance to oxidative stressors [21].

Curcumin also exerts significant anti-inflammatory activity, making it a promising agent for managing chronic inflammation-driven conditions [22]. It inhibits pro-inflammatory transcription factors such as nuclear factor-kappa B (NF-κB) and suppresses the expression of enzymes like cyclooxygenase-2 (COX-2). Furthermore, it downregulates pro-inflammatory cytokines, including tumor necrosis factor-alpha (TNF-α), interleukin-1β (IL-1β), and interleukin-6 (IL-6), thereby reducing inflammation at the molecular level [22,23,24]. For instance, a study identified octahydrocurcumin, a curcumin-related compound, with potent anti-inflammatory properties. Octahydrocurcumin inhibited COX-2 in vitro, reduced inflammation in lipopolysaccharide-stimulated zebrafish (Danio rerio), and showed strong COX-2 binding affinity through molecular docking, confirming its selective and concentration-dependent anti-inflammatory activity [25].

Curcumin also exhibits broad-spectrum antimicrobial properties, demonstrating efficacy against a variety of pathogenic microorganisms. It has been shown to inhibit both Gram-positive bacteria and Gram-negative bacteria [26]. In a study involving over 100 clinical isolates from 19 microbial species, comprising six Gram-positive bacteria (Enterococcus faecalis, Staphylococcus aureus, S. epidermidis, S. haemolyticus, Streptococcus agalactiae, and S. pyogenes), nine Gram-negative bacteria (Acinetobacter baumannii, A. lwoffii, Escherichia coli, Klebsiella oxytoca, K. pneumoniae, Proteus mirabilis, Pseudomonas aeruginosa, Serratia marcescens, and Stenotrophomonas maltophilia), and four yeast-like fungi (Candida albicans, C. glabrata, C. tropicalis, and Saccharomyces cerevisiae), curcumin’s antimicrobial activity was assessed using the broth microdilution method. Results revealed markedly higher sensitivity in Gram-positive bacteria, particularly Streptococcus pyogenes and S. aureus, with a median minimum inhibitory concentration (MIC) of 500 µg/mL, compared to 2000 µg/mL for Gram-negative bacteria. In contrast, multidrug-resistant strains and yeast-like fungi, including Candida species, exhibited poor sensitivity [27]. These findings show curcumin’s selective antimicrobial potential and highlight the importance of targeted application and formulation enhancement to improve its clinical relevance. Curcumin’s mechanisms of action include disruption of microbial membranes, inhibition of quorum sensing, and interference with biofilm formation, positioning it as a promising candidate in the fight against resistant bacterial infections [28].

In cancer-related research, curcumin has shown potential as an anticancer agent by modulating key molecular pathways associated with tumor development and progression. Studies indicate that curcumin can induce apoptosis, inhibit abnormal cell proliferation, and suppress angiogenesis and metastasis [29]. It also interferes with conserved oncogenic signaling pathways, including PI3K/Akt, MAPK, and Wnt/β-catenin, which are involved in cellular growth and survival [30]. Although most evidence comes from mammalian models, emerging research using fish models like zebrafish suggests similar mechanisms may be active in aquatic species [31], supporting curcumin’s potential role in aquatic cancer-related research and disease management.

Curcumin also provides neuroprotective benefits relevant to neurodegenerative disorders. Its effects stem from reducing oxidative stress and neuroinflammation while modulating apoptotic and survival pathways in neuronal cells, thereby supporting cognitive function and preserving nerve cell health [32]. For example, in zebrafish models exposed to benzo[a]pyrene (B[a]P), curcumin significantly reduced lipid peroxidation, restored glutathione (GSH) levels, and stabilized redox homeostasis. It also lowered pyknotic neuron counts in the optic tectum, reflecting reduced neurodegeneration. Furthermore, curcumin alleviated B[a]P-induced anxiety-like behaviors in Light-Dark Box and Novel Tank Diving tests [33], showing its potential as a natural therapeutic agent against environmentally induced neurotoxicity in aquatic organisms.

In metabolic and cardiovascular health, curcumin has demonstrated antidiabetic and cardioprotective effects. It improves insulin sensitivity, lowers fasting blood glucose levels, reduces lipid peroxidation, and inhibits the formation of atherosclerotic plaques. Additionally, it modulates lipid metabolism and endothelial function, contributing to the overall maintenance of cardiovascular health [18,34].

Despite its remarkable pharmacological potential, the clinical use of curcumin remains limited due to its poor bioavailability. This challenge arises from several factors, including its low water solubility, poor absorption in the gastrointestinal tract, rapid metabolism in the liver and intestinal wall, and quick systemic elimination [11]. These factors result in minimal plasma and tissue concentrations after oral administration, reducing its therapeutic effectiveness.

To overcome these barriers, significant research has focused on advanced formulation strategies [35], with nanosizing emerging as one of the most promising approaches. Transforming curcumin into nanoscale forms, such as NPs, nanocrystals, and nanoemulsions, greatly enhances its aqueous solubility, chemical stability, and cellular uptake. These nanoformulations also increase curcumin’s antimicrobial activity by improving its interaction with microbial membranes and promoting better intracellular delivery [36]. As a result, nanosizing not only improves curcumin’s pharmacokinetic properties but also helps realize its full antimicrobial and therapeutic potential.

3. Curcumin Nanoparticles: Synthesis and Properties

Nanosizing curcumin offers several significant advantages that help overcome the major limitations of its native form, including poor water solubility, rapid metabolic degradation, and low bioavailability. These challenges have restricted curcumin’s clinical utility despite its potent antimicrobial properties [12]. When curcumin is reduced to the nanoscale, its bioavailability increases substantially, leading to more efficient absorption and higher therapeutic concentrations at sites of infection. This is largely due to the higher surface area-to-volume ratio of CurNPs, which improves interaction with bacterial membranes and enhances antimicrobial activity through membrane disruption [37,38].

One of the most important outcomes of nanosizing is enhanced aqueous dispersion. Unlike bulk curcumin, which is hydrophobic and poorly soluble, CurNPs can remain evenly dispersed in biological fluids, allowing for better access to bacterial cells in both localized and systemic infections [14]. This property also facilitates their incorporation into a wide range of delivery platforms, such as injectable formulations, topical gels, sprays, and antimicrobial surface coatings.

Moreover, nanosized curcumin allows for sustained and controlled release, which is crucial in antimicrobial applications. Encapsulation within nanocarriers, such as liposomes, solid lipid NPs, or biodegradable polymers, enables curcumin to be released gradually, maintaining longer contact with pathogens and enhancing antibacterial efficacy [13,14,15]. This extended exposure helps minimize dosing frequency, reduce side effects, and limit the emergence of bacterial resistance.

In addition, CurNPs have shown improved ability to penetrate bacterial biofilms, which are often resistant to conventional treatments. By disrupting the protective extracellular matrix, CurNPs can reach embedded bacteria more effectively, making them valuable for treating persistent infections [39]. To realize these benefits, a range of formulation strategies have been employed to produce CurNPs with optimal particle size, surface stability, and biological activity.

3.1. Nanoparticle Formulation Strategies

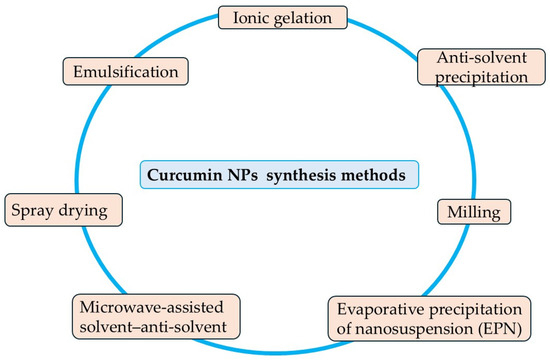

To enhance curcumin’s therapeutic efficacy and overcome its poor solubility and stability, various formulation strategies have been developed, some of which are shown in Figure 2. These approaches focus on reducing particle size to the nanoscale, thereby significantly improving its aqueous dispersibility, bioavailability, and biological performance [13].

Figure 2.

Curcumin nanoparticles synthesis methods.

3.1.1. Milling Method

The milling method, particularly wet milling, is widely used for the synthesis of CurNPs, where mechanical forces are applied to reduce bulk curcumin crystals into the nanoscale [40]. In this process, curcumin powder is suspended in an aqueous medium containing a stabilizer to prevent aggregation. The suspension is then processed in a bead mill or planetary ball mill containing grinding media such as zirconia or stainless-steel beads. Through high-speed rotation and agitation, the media generate shear, impact, and attrition forces that break down curcumin particles to a nanosize [41,42]. The nanosuspension is then separated from the beads and may be used directly or dried via freeze-drying or spray-drying to yield a stable powder. For example, pure curcumin powder was processed using a planetary ball mill fitted with a 150 mL agate jar and 2 mm alumina balls. The milling was conducted at 350 rpm with 5 min intervals between every 5 min of operation to prevent overheating. This effectively reduced the particle size, yielding NPs with an average diameter ranging from 100 to 140 nm [41]. Wet milling is especially favored in pharmaceuticals for producing nanocrystals of poorly soluble drugs like curcumin due to its scalability, efficiency, and ability to enhance aqueous solubility and bioavailability. Unlike dry milling, which often results in particles above 3 µm and risks thermal degradation, wet milling achieves finer particle sizes with minimal structural alteration [43].

3.1.2. Anti-Solvent Precipitation

The anti-solvent precipitation method for curcumin nanoparticle synthesis relies on reducing the solubility of curcumin by introducing it into a non-solvent (anti-solvent), resulting in rapid precipitation and nanoparticle formation [44]. First, curcumin is dissolved in an organic solvent such as acetone, ethanol, or dichloromethane. This solution is then added dropwise or injected into water or an aqueous surfactant solution, acting as the anti-solvent, under vigorous stirring or sonication. Since curcumin is poorly soluble in water, this leads to immediate precipitation, with rapid nucleation and limited crystal growth producing uniform NPs [45,46]. Stabilizers are often added to prevent aggregation and improve colloidal stability. The resulting nanoparticle suspension is then centrifuged to collect the particles, which are subsequently freeze-dried or spray-dried to yield a stable curcumin nanoparticle powder [47]. It should be noted, however, that in instances where ultrasonication is employed to assist the anti-solvent precipitation process, the method is in some articles referred to as wet milling [48,49,50]. While this terminology may be used, it is important to clarify that the process does not involve traditional mechanical grinding media, such as milling beads [40] as described in Section 3.1.1. Instead, the probe sonicator generates intense cavitation forces that promote particle deagglomeration, facilitate nucleation, and contribute to size reduction, effectively mimicking the disintegration effect of conventional milling systems.

3.1.3. Evaporative Precipitation of Nanosuspension

The evaporative precipitation of nanosuspension (EPN) method combines anti-solvent precipitation with rapid solvent evaporation to produce uniformly sized CurNPs. EPN is based on the principle of supersaturation-induced precipitation, followed by quick solvent removal to prevent particle growth and aggregation [45,51]. In this process, curcumin is first dissolved in a volatile organic solvent like ethanol, acetone, or dichloromethane. A non-solvent, typically n-hexane, in which curcumin has low solubility, is rapidly added under constant stirring. This sudden solvent shift creates a supersaturated state, initiating nucleation and the formation of nanosized curcumin particles. The resulting nanosuspension is immediately subjected to vacuum-assisted evaporation (e.g., using a rotary evaporator), which helps fix the particle size by minimizing further growth or agglomeration [45]. The final product is then freeze-dried to remove residual solvents and obtain a stable nanopowder. In a study by Kanwal et al. (2023), curcumin dissolved in ethanol (5 mg/mL) was added to n-hexane in a 1:15 ratio under stirring. This produced a nanosuspension that, after evaporation and freeze-drying, yielded NPs with a mean size of 65.3 nm and a significantly improved water solubility of 74.0 mg/mL, compared to 0.98 mg/mL for unprocessed curcumin [52]. These results highlight the effectiveness of EPN in enhancing curcumin’s functional properties, particularly its solubility, through size reduction.

3.1.4. Microwave-Assisted Solvent–Antisolvent Method

This method combines anti-solvent precipitation with microwave irradiation to rapidly produce CurNPs [53]. Curcumin is first dissolved in a volatile organic solvent such as ethanol, then rapidly introduced into water, which serves as the anti-solvent [44,52]. The mixture is exposed to microwave energy, resulting in rapid and uniform heating via dielectric heating, which accelerates solvent evaporation and promotes supersaturation. This triggers instantaneous nucleation and nanonization, forming NPs efficiently [53,54]. In the study by Nayak et al. (2019), this approach yielded spherical CurNPs ~160 nm in diameter with significantly improved dispersibility and water solubility compared to the bulk compound [53].

3.1.5. Emulsification Method

The emulsification method is a widely adopted technique for synthesizing CurNPs, particularly in the form of nanoemulsions. It is especially effective for lipophilic and poorly water-soluble compounds like curcumin, as it significantly improves their solubility, stability, and bioavailability [55]. This method involves forming a thermodynamically or kinetically stable dispersion of oil droplets in water (oil-in-water, o/w). The oil phase contains curcumin dissolved in a suitable oil, while the aqueous phase includes surfactants and co-surfactants that stabilize the system (prevent droplet aggregation). When the oil phase is introduced into the aqueous phase under agitation or ultrasonication, the curcumin-loaded oil droplets are broken down into nanoscale droplets, spontaneously forming a uniform nanoemulsion [56,57]. The nanoemulsion can be administered as a liquid or dried via spray-drying or freeze-drying to obtain CurNPs in solid form. For instance, a curcumin nanoemulsion was prepared using coconut oil as the oil phase, Tween 80 and Tween 85 as surfactants, and ethanol as the co-surfactant. Curcumin was initially dissolved in the coconut oil, followed by the gradual addition of surfactants, co-surfactant, and distilled water. The mixture was stirred continuously at 100 rpm for 2 h to ensure uniform emulsification. The resulting NPs were spherical, with an average diameter of 30 nm and a zeta potential of −37 mV, indicating strong colloidal stability of the nanoemulsion [58]. Nanoemulsions offer improved curcumin dispersion, enhanced absorption, and protection from degradation, making them ideal for oral or topical antimicrobial formulations.

3.1.6. Ionic Gelation Method

The ionic gelation method is a promising and environmentally friendly technique for synthesizing CurNPs, particularly suited for aquaculture applications. This method enables the encapsulation of curcumin into biodegradable and biocompatible polymers, typically chitosan, thereby improving its solubility, bioavailability, and targeted delivery [59] in aquatic organisms. The process is based on the electrostatic interaction between a positively charged polymer, such as chitosan, and a negatively charged crosslinker like sodium tripolyphosphate (TPP), which leads to spontaneous nanoparticle formation under stirring without the need for heat or organic solvents [60,61]. For example, curcumin (5 mg), pre-dissolved in ethanol to ensure even dispersion, was added to 10 mL of a 0.5% chitosan solution, which had been prepared by dissolving chitosan in dilute acetic acid to create a cationic polymer matrix. A 0.125% sodium tripolyphosphate (TPP) solution was then added dropwise under continuous stirring at 800 rpm for 1 h. This step initiated ionic crosslinking between the positively charged ammonium groups of chitosan and the negatively charged phosphate groups of TPP, resulting in the spontaneous formation of curcumin-loaded NPs [62]. This method offers several advantages for aquaculture, including enhanced delivery of curcumin through improved solubility, better gastrointestinal absorption, and sustained release. CurNPs synthesized by ionic gelation have demonstrated antioxidant, anti-inflammatory, antimicrobial, and growth-promoting effects in fish and shrimp [63]. Moreover, the use of natural polymers like chitosan ensures the process is safe and sustainable, aligning well with eco-friendly aquaculture practices.

3.1.7. Spray Drying Method

Spray drying is a widely used NP formulation technique that converts liquids into dry powders by rapidly drying them with a hot gas. In this method, a solution, suspension, or emulsion containing curcumin and carrier materials is atomized into fine droplets through a nozzle into a heated chamber. The droplets quickly lose moisture due to hot air, forming solid NPs collected as a dry powder [64]. Advantages of spray drying include scalability for industrial production, control over particle size and morphology, and the ability to encapsulate heat-sensitive compounds by optimizing inlet temperature and feed rate. This technique produces stable, free-flowing powders with improved shelf life and dispersibility, making it ideal for pharmaceuticals and food [65].

These synthesis methods highlight the versatility of CurNP production, each offering unique benefits depending on the application. Other promising approaches include supercritical fluid technology, coacervation, solvent evaporation, and ultrasonication-assisted nanoprecipitation.

For aquaculture, ideal curcumin nanoformulations should prioritize biocompatibility, sustained release, scalability, and environmental safety. Ionic gelation with chitosan and anti-solvent precipitation are especially promising, producing stable NPs with high encapsulation efficiency and enhanced antimicrobial activity. Chitosan adds biodegradability and membrane-targeting properties, while anti-solvent precipitation improves dispersibility. Spray drying facilitates large-scale production and easy incorporation into feed, supporting cost-effective and eco-friendly disease management in aquaculture.

3.2. Physicochemical Properties of Curcumin Nanoparticles and Their Role in Antimicrobial Activity

The physicochemical properties of CurNPs, including particle size, shape, surface charge (zeta potential), and colloidal stability, play a crucial role in determining their antimicrobial performance and biological interaction with pathogens.

3.2.1. Effect of Particle Size

Reducing curcumin to the nanoscale significantly increases its surface area-to-volume ratio, which enhances solubility, dissolution rate, and cellular uptake [66]. NPs in the range of 50–150 nm are especially effective in antimicrobial applications, as their small size allows them to penetrate microbial membranes more efficiently and interact with intracellular targets. This facilitates disruption of microbial processes, including cell wall integrity and metabolic pathways, ultimately inhibiting growth or inducing cell death. The improved membrane penetration and intracellular delivery also contribute to enhanced bioavailability and therapeutic efficacy [28]. For example, a curcumin nanoemulsion, with a particle size of 82.7 ± 11.1 nm, significantly improved disease resistance in European seabass fingerlings challenged with Vibrio parahaemolyticus. Nanosizing enhanced curcumin’s solubility, bioavailability, and antimicrobial activity. Improved morphology and surface properties promoted better interaction with pathogens, while enhanced antioxidant capacity and immune responses supported overall fish health. As a result dietary inclusion of the curcumin nanoemulsion significantly reduced mortality, demonstrating its potential aquaculture disease management [67].

3.2.2. Effect of Shape

The shape of NPs plays a critical role in influencing their biological interactions, pharmacokinetics, and antimicrobial performance [28]. Particle shape affects how CurNPs circulate in the bloodstream, reach sites of infection, interact with bacterial cell walls, and are internalized by host or microbial cells [14]. Among the various morphologies, spherical CurNPs are the most extensively studied due to their synthetic simplicity and favorable physicochemical properties. They are readily produced using methods such as nanoprecipitation, emulsion–solvent evaporation, and polymeric encapsulation, which inherently yield spherical NPs [52,58,62]. Spherical CurNPs are thermodynamically stable, possess a uniform size distribution that promotes reproducibility, and exhibit high cellular uptake efficiency via endocytosis in both mammalian and microbial cells [68]. Their symmetrical geometry also facilitates uniform surface functionalization with targeting ligands or stabilizers, enhancing antimicrobial delivery and retention. As a result, spherical CurNPs are well-suited for general antibacterial applications, including inhibition of bacterial growth and mild biofilm disruption.

However, anisotropic shapes such as nanorods, nanostars, and nanocubes, though not so common for CurNPs, have emerged as promising alternatives for more aggressive or targeted antibacterial strategies. These non-spherical particles exhibit greater surface area-to-volume ratios compared to spherical NPs of the same volume. However, both shape and particle size influence antimicrobial efficacy; smaller particles, regardless of shape, offer greater specific surface area, enabling stronger adhesion to bacterial membranes and facilitating more direct physical membrane disruption. This interaction often results in increased membrane permeability, leakage of intracellular contents, and ultimately, bacterial cell death [69]. Studies suggest that rod-shaped NPs, in particular, can maintain prolonged circulation and display improved targeting of infection sites due to altered hydrodynamic behavior and reduced macrophage uptake while spherical NPs may be more readily taken up by macrophages [70]. Moreover, the shape of NPs may influence their interaction with bacterial surface receptors and transport mechanisms, thereby modulating their release kinetics and enhancing intracellular antimicrobial action [71]. The design and optimization of CurNP morphology represent a crucial step toward maximizing their therapeutic potential and expanding their application in combating both acute and chronic bacterial infections.

3.2.3. Effect of Surface Charge (Zeta Potential) and Colloidal Stability

Surface charge, typically measured as zeta potential, is a crucial parameter influencing the colloidal stability and biological activity of NPs. Zeta potential represents the electrostatic potential of a particle in suspension and reflects the net surface charge that governs interparticle interactions. Values below ±5 mV often indicate poor stability leading to rapid aggregation, between ±10 and ±30 mV indicate moderate stability, while those above ±30 mV indicate strong electrostatic repulsion and good colloidal stability [72]. Colloidal stability, the ability of NPs to remain well-dispersed without aggregation, is essential for maintaining bioavailability and functional integrity in biological systems. It is determined by zeta potential, steric hindrance from surface coatings, van der Waals forces, and environmental factors such as pH, ionic strength, and solvent composition. Stable NPs retain their nanoscale size, ensuring maximum surface area for interaction with biological targets, including bacteria [73,74].

The surface charge of NPs also strongly affects their antibacterial activity. Cationic NPs interact readily with negatively charged bacterial membranes, promoting adhesion, membrane disruption, and leakage of intracellular contents [28]. Although anionic NPs interact more weakly, they can still exert antimicrobial effects through mechanisms such as reactive oxygen species (ROS) generation and biofilm penetration. For example, CurNPs with a zeta potential of −21.7 mV demonstrated measurable antibacterial activity against fish pathogens such as Aeromonas hydrophila (zone of inhibition [ZOI] 17.6 mm; minimum inhibitory concentration [MIC] 45.0 µg/mL) and E. coli (MIC 47.5 µg/mL). Despite the relatively moderate surface charge, these particles remained bioactive due to their good colloidal stability [75]. NPs with good colloidal stability remain bioavailable and avoid aggregation-related loss of activity.

CurNPs typically exhibit a negative zeta potential ranging from −20 to −40 mV, which contributes to their colloidal stability. However, the zeta potential can be modulated by formulation parameters such as the choice of surfactants, stabilizers (such as Tween 80, polyethylene glycol [PEG], lecithin, chitosan), pH, and temperature [76,77]. These factors influence not only surface charge but also the hydrophilicity and interaction of CurNPs with bacterial cells. For instance, nonionic surfactants like Tween 80 may reduce the zeta potential magnitude by partially neutralizing surface charges, while cationic agents such as chitosan can shift the zeta potential to positive values, enhancing electrostatic attraction to negatively charged bacterial membranes, thereby improving antimicrobial efficacy [78]. Optimizing surface charge through appropriate formulation strategies not only stabilizes the nanoparticle suspension but also enhances microbial interactions. Therefore, tuning zeta potential is essential for the rational design of curcumin-based nanotherapeutics for antimicrobial applications.

3.2.4. Effect of pH

Curcumin’s stability, solubility, and degradation are significantly influenced by pH. The antimicrobial efficacy of CurNPs as a result is influenced by the pH of their environment. Acidic conditions (pH ~5–6) enhance curcumin solubility and stability [79], which in turn increases antimicrobial activity through better interaction with bacterial membranes and biofilm penetration. Additionally, the controlled release behavior of curcumin is pH-sensitive; acidic environments often trigger faster or more complete release of curcumin from nanocarriers, prolonging effective pathogen exposure [80]. For example, Chen et al. (2021) reported that curcumin release from poly(lactide–glycolide) (PLGA)/chitosan (CT) nanofibers is strongly pH-dependent, with markedly faster and higher cumulative release at pH 2.0 than at pH 7.4. At neutral pH, release followed Fickian diffusion (n < 0.45) as non-ionized chitosan limits fluid penetration. In acidic conditions, protonated chitosan induced matrix swelling and erosion, enabling non-Fickian release (0.45 < n < 0.89). All profiles showed an initial burst within 60 min, followed by sustained release up to 24 h. Acidic pH also caused fiber erosion, unlike at pH 7.4 [81]. This protonation-driven, pH-responsive behavior enhances curcumin’s bioactivity in acidic microenvironments. In contrast, alkaline pH conditions tend to reduce curcumin solubility and accelerate its degradation [79,82], resulting in diminished release rates and lower antimicrobial efficacy. Understanding and leveraging this pH-responsive release profile is critical for designing curcumin-based nanotherapeutics that target acidic infection sites or biofilms, enabling sustained, localized antimicrobial action while minimizing premature drug loss.

3.3. Antimicrobial Efficacy of Curcumin Nanoparticles and Nanocomposites Against Aquatic Bacterial Pathogens

CurNPs have been widely reported to exhibit broad-spectrum antibacterial activity against both Gram-positive and Gram-negative aquatic pathogens [83,84]. However, their efficacy is highly variable and largely influenced by both nanoparticle-specific physicochemical properties, such as size, shape, and surface charge, and structural or adaptive features of the target bacterial species [66]. Table 1 presents data on the properties and activity of CurNPs against a variety of aquatic bacterial pathogens, including both Gram-positive and Gram-negative species.

Table 1.

Physicochemical properties of CurNPs and their antibacterial activity against aquatic bacterial pathogens.

A primary determinant of CurNP efficacy is the bacterial cell wall architecture. Gram-negative bacteria such as E. coli, K. pneumoniae, and P. aeruginosa possess a thin peptidoglycan layer (2–7 nm) covered by an outer membrane rich in lipopolysaccharides (LPSs), which restricts the penetration of many antimicrobials [94]. Nevertheless, CurNPs with small diameters (<50 nm) and strongly negative zeta potentials (typically between −24 and −30 mV) can overcome this barrier via electrostatic interactions with LPSs, enabling membrane disruption, oxidative stress induction, and cytoplasmic leakage [77].

For instance, E. coli showed a zone of inhibition (ZOI) up to 32.7 mm at 20 mg/mL with CurNPs sized 42.64 nm [88], while CurNPs with zeta potentials around −24.7 mV achieved a ZOI of 31 mm [76]. Similarly, K. pneumoniae exhibited MIC values as low as 7.825 µg/mL with CurNPs sized 0.5–4.5 nm and a zeta potential of −26 mV [77], highlighting the importance of nanoscale dimensions and surface charge in penetrating Gram-negative defenses. The ZOI reported were measured using standard antimicrobial susceptibility assays, including well diffusion, disc diffusion, and the standardized Kirby–Bauer method, which together provide reliable indicators of antimicrobial potency.

In contrast, Gram-positive bacteria such as S. aureus lack an outer membrane but possess a thick peptidoglycan wall (20–80 nm), which can delay nanoparticle penetration. Despite this, CurNPs demonstrate potent activity against S. aureus, likely due to their ability to generate reactive oxygen species (ROS) and interact with essential membrane-associated proteins. One study reported a ZOI of 35 mm with CurNPs having a zeta potential of −24.7 mV [76], and another observed 29.91 mm ZOI using particles around 87 nm [39], underscoring the effectiveness of CurNPs even in the presence of thick structural barriers.

Some aquatic pathogens exhibit moderate susceptibility, which is often attributed to intermediate levels of membrane protection, biofilm formation, or adaptive uptake limitations. For example, Aeromonas hydrophila exhibited a ZOI of 17.6 ± 1.7 mm and MIC of 45.0 µg/mL with CurNPs bearing a zeta potential of −21.7 mV [75]. In Vibrio parahaemolyticus, dietary administration of nano-curcumin significantly improved fish survival, from 30% in controls to 75% at 60 mg/kg, illustrating both direct antibacterial effects and potential immunomodulatory benefits [67].

By contrast, some species exhibit low susceptibility or resistance. E. faecalis demonstrated a relatively low ZOI of 12.5 mm and a high MIC of 50 mg/mL, reflecting its robust peptidoglycan layer and intrinsic resistance traits [87]. Similarly, F. columnare, known for its dense biofilm formation, showed a minimum bactericidal concentration (MBC) of 811.18 mg/mL with CurNPs sized between 34 and 359.4 nm [90]. These findings emphasize the challenges posed by structural defenses like EPS-rich biofilms, which hinder nanoparticle diffusion and oxidative stress penetration.

In addition to the cell wall structure, bacterial surface charge plays a key role in CurNP interaction. Although bacterial surfaces (due to teichoic acids or LPS) and CurNPs both tend to carry negative charges, binding is still facilitated through localized charge differentials, hydrophobic interactions, or membrane protein-mediated uptake [95]. Zeta potential influences these interactions: for example, CurNPs with a zeta potential of −30.7 mV showed notable efficacy against M. marinum [93].

The antimicrobial efficacy of CurNPs is strongly influenced by the interplay between NP characteristics and bacterial structural defenses. Optimally engineered CurNPs, characterized by small size (typically <50 nm), spherical shape, and high surface negativity, show enhanced interactions with bacterial surfaces, better penetration, and stronger intracellular effects [83]. However, their efficacy can be reduced against pathogens possessing structural complexities such as thick peptidoglycan layers, robust biofilms, or active efflux mechanisms that limit nanoparticle access or retention [95].

To address these limitations and further enhance antibacterial performance, curcumin nanocomposites (CurNCs) have emerged as more potent alternatives to plain CurNPs. Table 2 shows a summary of the antibacterial activity of Cur-NCs against various aquatic bacterial pathogens.

Table 2.

Antibacterial activity of curcumin nanocomposites against aquatic pathogens.

Cur-NCs’ superiority is demonstrated by consistently larger ZOIs and significantly lower MICs across a wide range of aquatic pathogens, indicating improved therapeutic potential and broader spectrum activity [102,110]. E. coli and S. aureus, for example, are highly susceptible to Cur–AgNCs and Cur-AgNCs-Niosomes, with MICs as low as 5–6.25 µg/mL and ZOIs exceeding 24 mm [100,110]. Aeromonas hydrophila and P. aeruginosa also respond well to Cur- selenium NC, Cur-CuO NC, and Cur-Falcaria vulgaris extract NCs [75,97,105]. Bioactive carriers such as aloe vera and polymeric matrices like mPEG-PCL further enhance delivery, bioavailability, and biofilm inhibition, critical for persistent infections in aquaculture [101,102].

The superior performance of Cur-NCs arises from their optimized physicochemical properties. Spherical and quasi-spherical particles are most used and provide consistent antibacterial effects, while more complex shapes like nanoflowers or nanoflakes (e.g., Cur–SnO2 NC and Cur–copper hybrids NC) offer increased surface area and enhanced membrane interactions. Smaller Cur-NCs (≤50 nm) show stronger antimicrobial effects due to better penetration and reactivity. For example, 25 nm Cur–AgNCs achieved an MIC of 5 mg/L against E. coli, and molybdenum disulfide–Cur-NCs (~13 nm) achieved an MIC < 0.125 µg/mL against K. pneumoniae. Larger particles (~197.5 nm), though less penetrative, can maintain strong efficacy when embedded in targeted delivery systems like niosomes.

Zeta potential remains a crucial factor. Cur-NCs with highly negative zeta potentials (−30 to −42 mV) display greater antimicrobial activity by destabilizing bacterial membranes, while formulations with near-neutral charges (e.g., −1.07 mV) are less effective. When compared to unmodified CurNPs, Cur-NCs offer consistently lower MICs, broader pathogen coverage, and superior biofilm inhibition. For instance, Cur–AgNPs lowered the MIC against E. coli from >30 mg/mL (CurNPs) to just 5 mg/L. Similarly, Cur-ZnONCs and Cur-PCL/PLA NCs performed better against biofilm-forming P. aeruginosa. These enhancements are attributed to the synergistic effects of embedded materials, metals like Ag, Cu, or Zn contribute oxidative stress and membrane damage, while polymers and biological carriers improve targeting, stability, and controlled release. Collectively, Cur-NCs provide a powerful strategy to overcome microbial resistance and structural barriers.

The composition of the nanocarrier matrix critically influences biological performance and therapeutic efficacy, especially in curcumin-based formulations. Key factors such as material type, surface chemistry, hydrophobicity, biodegradability, particle size, and surface charge, affect drug loading, stability, controlled release, cellular uptake, and interaction with bacterial cells [113]. For example, nano-in-micro hydrogels composed of chitosan and κ-carrageenan encapsulating curcumin-loaded rhamnosomes (116 ± 7 nm, −24.5 ± 9.4 mV) demonstrated significant antibacterial activity by effectively reducing P. aeruginosa populations both in vitro and infected animal models. The cationic nature of chitosan promotes electrostatic attraction to the negatively charged bacterial membranes, disrupting membrane integrity and enhancing curcumin uptake. The κ-carrageenan network provides structural support and allows controlled, sustained curcumin release, prolonging antibacterial exposure and preventing regrowth [109]. Similar formulations also substantially reduced S. aureus loads. Additionally, curcumin-loaded copper-based metal–organic frameworks (~200 nm, 19.6 ± 1.7 mV) incorporated into hydrogels markedly improved antibacterial efficacy and strongly inhibited biofilm formation. Copper ions contribute to bacterial killing by generating reactive oxygen species and disrupting enzymatic systems, while the hydrogel maintains local drug concentration and moisture [111]. These examples illustrate how nanocarrier composition and surface properties critically influence antibacterial mechanisms and therapeutic effectiveness.

The data from Table 1 and Table 2 confirm that curcumin nanocomposites or nanoformulations exhibit superior antimicrobial activity over CurNPs. These advantages arise from optimized physicochemical properties, such as smaller size and enhanced surface charge, as well as the functional synergy achieved by integrating metals, polymers, biological agents, or nanocarriers. Formulating curcumin into structurally and chemically tailored nanocomposites presents a promising and sustainable strategy for combating aquatic bacterial pathogens, reducing antibiotic reliance, and enhancing biosecurity in aquaculture systems.

4. Applications in Aquaculture

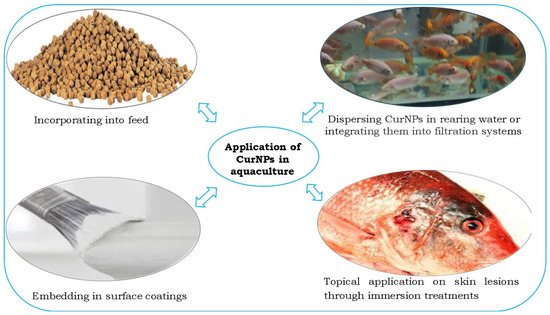

Antimicrobial CurNPs can be strategically applied in aquaculture systems to prevent bacterial contamination by targeting both the external environment and the internal defense mechanisms of aquatic animals, as illustrated in Figure 3.

Figure 3.

Illustration of how antimicrobial CurNPs can be applied in aquaculture systems to prevent bacterial contamination.

4.1. Incorporating into Feed

One of the most effective strategies for utilizing CurNPs in aquaculture is their direct incorporation into fish or shrimp feed. This prophylactic approach not only helps prevent internal bacterial infections but also strengthens the innate and adaptive immune responses of aquatic organisms [114], helping to mitigate the impact of bacterial exposure. CurNPs contribute to the reduction in gut colonization by pathogenic bacteria such as Aeromonas and Vibrio species, supporting intestinal barrier integrity and promoting the competitive exclusion of harmful microbes. For instance, CurNPs demonstrated inherent antibacterial activity against Aeromonas veronii in infected African catfish (Clarias gariepinus); however, their most pronounced effect occurred when combined with florfenicol, significantly enhancing disease resistance and reducing mortality [86]. This synergy highlights the potential of CurNPs to minimize the overuse of conventional antibiotics and reduce the risk of developing antimicrobial resistance in aquaculture systems. In addition to their antimicrobial benefits, CurNPs also promote overall fish health and performance. A study on Nile tilapia (Oreochromis niloticus) fingerlings showed that dietary supplementation with CurNPs significantly improved growth performance, whole-body composition, blood biochemical and hematological parameters, digestive enzyme activities, and antioxidant and immune responses compared to unsupplemented controls [115]. These findings demonstrate that Cur-NP-fortified diets can simultaneously boost productivity, enhance disease resistance, and promote sustainable aquaculture practices using safe, natural feed additives.

4.2. Dispersing CurNPs in Rearing Water or Integrating Them into Filtration Systems

Another promising application is the use of CurNPs in water treatment and system disinfection. Dispersing NPs in rearing water or integrating them into filtration systems can effectively lower microbial loads and prevent the spread of waterborne pathogens. Their ability to inactivate free-living bacteria and disrupt biofilms in tanks, pipes, and nets makes them valuable for maintaining water quality [116]. For example, antibacterial polysulfone (PSF) nanocomposite membranes for ultrafiltration were developed by incorporating varying concentrations of curcumin-enriched sodium dodecylbenzenesulfonate (Cur-NaDBS) NPs into a PSF polymer matrix. The incorporation of Cur-NaDBS NPs significantly enhanced water permeability, improved resistance to membrane fouling, and imparted strong antibacterial activity against S. aureus. These combined effects demonstrate the potential of Cur-NaDBS NPs-incorporated membranes as an effective and sustainable solution for addressing biofouling challenges in water treatment applications [117]. Slow-release formulations can further extend the antimicrobial activity, ensuring sustained pathogen suppression.

4.3. Topical Application Through Immersion Treatments

Bath or immersion treatments using CurNP suspensions provide an effective approach for managing external bacterial infections in aquaculture. For example, topical application of CurNPs lotion led to a 98.8% reduction in wound area and nearly complete elimination of P. aeruginosa viable counts by the fifteenth day post-injury, compared to the control group [118]. These results show the potent antibacterial activity of CurNPs and their potential clinical utility as effective topical antimicrobials and wound healing agents. Short-duration immersion treatments can effectively disinfect the skin, fins, and gills before pathogens penetrate tissues. Such interventions might be valuable during periods of increased stress, such as handling or transport, when fish are more vulnerable to infection.

4.4. Embedding in Surface Coatings

Surface coatings containing CurNPs on aquaculture materials like nets, tanks, and biofilters inhibit biofilm formation by disrupting quorum sensing, reducing contamination and cleaning frequency. Embedding CurNPs into biodegradable nanocomposite gear, such as enclosures and harvest tools, offers localized, sustained antimicrobial protection through controlled curcumin release [28]. For example, a study demonstrated that polyethylene terephthalate (PET) surfaces covalently immobilized with a curcumin derivative (PET-Cur) exhibit significant antibacterial activity. The PET-Cur surfaces effectively inhibited the growth of E. coli, S. aureus, and S. epidermidis. A marked reduction in turbidity at 24 and 48 h confirmed the suppression of bacterial proliferation. Furthermore, PET-Cur samples showed a substantial decrease in viable colony-forming units (CFUs/mL) compared to unmodified PET, indicating a strong bactericidal effect [119]. These findings highlight the potential of covalently bonded curcumin derivatives in creating antimicrobial surface coatings. These applications help maintain low bacterial pressure in high-contact zones, enhancing hygiene and animal health. Overall, Cur-NP integration offers a sustainable, multifunctional strategy for bacterial control in aquaculture, supporting safer and more efficient production.

5. Conclusions and Future Perspectives

CurNPs represent a promising antimicrobial strategy for combating the escalating threat of bacterial diseases in aquaculture. Their enhanced physicochemical properties, such as improved solubility, stability, surface charge modulation, and targeted delivery have significantly increased efficacy against a broad spectrum of aquatic pathogens. Cur-NCs further demonstrate the potential of integrating curcumin with metals, polymers, bioactive agents or nanocarriers to overcome microbial resistance, improve biofilm penetration, and enhance bioavailability. Applications span feed supplementation to boost immunity, water disinfection to control environmental pathogens, topical therapies for external infections, and antimicrobial coatings for aquaculture infrastructure. Collectively, these interventions support fish health, reduce mortality, and minimize antibiotic overuse, promoting sustainability, biosecurity, and economic viability. However, despite encouraging in vitro and limited in vivo results, widespread adoption of CurNPs requires further validation through well-designed field trials, safety assessments, and scalable manufacturing strategies.

A critical research priority is expanded antimicrobial testing across aquaculture matrices. Most current evaluations are confined to in vitro assays with isolated bacterial cultures under controlled conditions, providing limited insight into real-world performance. The antibacterial efficacy of CurNPs when applied to aqua feed, aquaculture water, and biofilm-prone surfaces (e.g., tank walls, nets, pipes) remains largely unexplored, despite these being primary sites of pathogen persistence. These environments introduce physicochemical challenges, such as variable salinity, organic matter content, and biofilm extracellular polymeric substances, that can alter NP stability, release rates, and bioavailability. Standardized testing protocols that mimic farm conditions, incorporating factors like temperature shifts, fluctuating pH, and organic load, are essential for generating predictive and transferable results.

Another key gap is the limited composition–activity correlation for aquatic systems. Few studies systematically investigate how formulation parameters, particle size, zeta potential, carrier composition, encapsulation efficiency, and drug loading influence antibacterial potency. These attributes govern NP interactions with bacterial cell walls, biofilms, and aquatic media, yet optimization is rare. Addressing this requires controlled formulation-variable studies in which one parameter is altered at a time, enabling the identification of causative links between NP design and antimicrobial performance. Establishing such predictive formulation rules will accelerate the development of CurNPs tailored for aquaculture applications.

By addressing these experimental gaps alongside advances in smart delivery, biofilm-targeting strategies, environmental safety assessments, and green scalable synthesis, CurNPs could emerge as a safe, effective, and sustainable alternative to antibiotics in modern aquaculture.

Author Contributions

E.D.: literature search and manuscript writing; G.E.O.: Drafted the manuscript outline, critically reviewed the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The author declares no conflicts of interest.

References

- FAO. In Brief to The State of World Fisheries and Aquaculture 2024; Blue Transformation Action; FAO: Rome, Italy, 2024. [Google Scholar] [CrossRef]

- Bouwmeester, M.M.; Goedknegt, M.A.; Poulin, R.; Thieltges, D.W. Collateral Diseases: Aquaculture Impacts on Wildlife Infections. J. Appl. Ecol. 2021, 58, 453–464. [Google Scholar] [CrossRef]

- Hegde, A.; Kabra, S.; Basawa, R.M.; Khile, D.A. Bacterial Diseases in Marine Fish Species: Current Trends and Future Prospects in Disease Management. World J. Microbiol. Biotechnol. 2023, 39, 317. [Google Scholar] [CrossRef]

- Yusoff, F.M.; Umi, W.A.D.; Ramli, N.M.; Harun, R. Water Quality Management in Aquaculture. Camb. Prism. Water 2024, 2, e8. [Google Scholar] [CrossRef]

- Mohammed, E.A.H.; Kovács, B.; Kuunya, R.; Mustafa, E.O.A.; Abbo, A.S.H.; Pál, K. Antibiotic Resistance in Aquaculture: Challenges, Trends Analysis, and Alternative Approaches. Antibiotics 2025, 14, 598. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.K.; Hussein, S.; Qurbani, K.; Ibrahim, R.H.; Fareeq, A.; Mahmood, K.A.; Mohamed, M.G. Antimicrobial Resistance: Impacts, Challenges, and Future Prospects. J. Med. Surg. Public Health 2024, 2, 100081. [Google Scholar] [CrossRef]

- Ripanda, A.; Rwiza, M.J.; Nyanza, E.C.; Hossein, M.; Alfred, M.S.; El Din Mahmoud, A.; Murthy, H.C.A.; Bakari, R.; Hamad Vuai, S.A.; Machunda, R.L. Ecological Consequences of Antibiotics Pollution in Sub-Saharan Africa: Understanding Sources, Pathways, and Potential Implications. Emerg. Contam. 2025, 11, 100475. [Google Scholar] [CrossRef]

- Chinemerem Nwobodo, D.; Ugwu, M.C.; Oliseloke Anie, C.; Al-Ouqaili, M.T.S.; Chinedu Ikem, J.; Victor Chigozie, U.; Saki, M. Antibiotic Resistance: The Challenges and Some Emerging Strategies for Tackling a Global Menace. J. Clin. Lab. Anal. 2022, 36, e24655. [Google Scholar] [CrossRef]

- Ajanaku, C.O.; Ademosun, O.T.; Atohengbe, P.O.; Ajayi, S.O.; Obafemi, Y.D.; Owolabi, O.A.; Akinduti, P.A.; Ajanaku, K.O. Functional Bioactive Compounds in Ginger, Turmeric, and Garlic. Front. Nutr. 2022, 9, 1012023. [Google Scholar] [CrossRef]

- Cozmin, M.; Lungu, I.I.; Gutu, C.; Stefanache, A.; Duceac, L.D.; Șoltuzu, B.D.; Damir, D.; Calin, G.; Bogdan Goroftei, E.R.; Grierosu, C.; et al. Turmeric: From Spice to Cure. A Review of the Anti-Cancer, Radioprotective and Anti-Inflammatory Effects of Turmeric Sourced Compounds. Front. Nutr. 2024, 11, 1399888. [Google Scholar] [CrossRef] [PubMed]

- Hussain, Y.; Alam, W.; Ullah, H.; Dacrema, M.; Daglia, M.; Khan, H.; Arciola, C.R. Antimicrobial Potential of Curcumin: Therapeutic Potential and Challenges to Clinical Applications. Antibiotics 2022, 11, 322. [Google Scholar] [CrossRef]

- Wahnou, H.; El Kebbaj, R.; Liagre, B.; Sol, V.; Limami, Y.; Duval, R.E. Curcumin-Based Nanoparticles: Advancements and Challenges in Tumor Therapy. Pharmaceutics 2025, 17, 114. [Google Scholar] [CrossRef]

- Karthikeyan, A.; Senthil, N.; Min, T. Nanocurcumin: A Promising Candidate for Therapeutic Applications. Front. Pharmacol. 2020, 11, 487. [Google Scholar] [CrossRef]

- Gera, M.; Sharma, N.; Ghosh, M.; Huynh, D.L.; Lee, S.J.; Min, T.; Kwon, T.; Jeong, D.K. Nanoformulations of Curcumin: An Emerging Paradigm for Improved Remedial Application. Oncotarget 2017, 8, 66680–66698. [Google Scholar] [CrossRef] [PubMed]

- Tagde, P.; Tagde, P.; Islam, F.; Tagde, S.; Shah, M.; Hussain, Z.D.; Rahman, M.H.; Najda, A.; Alanazi, I.S.; Germoush, M.O.; et al. The Multifaceted Role of Curcumin in Advanced Nanocurcumin Form in the Treatment and Management of Chronic Disorders. Molecules 2021, 26, 7109. [Google Scholar] [CrossRef]

- Moon, D.O. Curcumin in Cancer and Inflammation: An In-Depth Exploration of Molecular Interactions, Therapeutic Potentials, and the Role in Disease Management. Int. J. Mol. Sci. 2024, 25, 2911. [Google Scholar] [CrossRef] [PubMed]

- Sathyabhama, M.; Priya Dharshini, L.C.; Karthikeyan, A.; Kalaiselvi, S.; Min, T. The Credible Role of Curcumin in Oxidative Stress-Mediated Mitochondrial Dysfunction in Mammals. Biomolecules 2022, 12, 1405. [Google Scholar] [CrossRef] [PubMed]

- Cox, F.F.; Misiou, A.; Vierkant, A.; Ale-Agha, N.; Grandoch, M.; Haendeler, J.; Altschmied, J. Protective Effects of Curcumin in Cardiovascular Diseases—Impact on Oxidative Stress and Mitochondria. Cells 2022, 11, 342. [Google Scholar] [CrossRef]

- He, Y.; Liu, Y.; Zhang, M. The Beneficial Effects of Curcumin on Aging and Age-Related Diseases: From Oxidative Stress to Antioxidant Mechanisms, Brain Health and Apoptosis. Front. Aging Neurosci. 2025, 17, 1533963. [Google Scholar] [CrossRef]

- Memarzia, A.; Khazdair, M.R.; Behrouz, S.; Gholamnezhad, Z.; Jafarnezhad, M.; Saadat, S.; Boskabady, M.H. Experimental and Clinical Reports on Anti-Inflammatory, Antioxidant, and Immunomodulatory Effects of Curcuma longa and Curcumin, an Updated and Comprehensive Review. BioFactors 2021, 47, 311–350. [Google Scholar] [CrossRef]

- Gabe, H.B.; Queiroga, F.R.; Taruhn, K.A.; Trevisan, R. Mitigating Oxidative Stress in Oyster Larvae: Curcumin Promotes Enhanced Redox Balance, Antioxidant Capacity, Development, and Resistance to Antifouling Compounds. Aquat. Toxicol. 2025, 279, 107231. [Google Scholar] [CrossRef]

- Wang, P.R.-X.; Zhou, M.; Ma, H.-L.; Qiao, P.Y.-B.; Li, P.Q.-S. The Role of Chronic Inflammation in Various Diseases and Anti-Inflammatory Therapies Containing Natural Products. ChemBioChem 2021, 16, 1576–1592. [Google Scholar] [CrossRef]

- Hasibuan, P.A.Z.; Simanjuntak, Y.; Hey-Hawkins, E.; Lubis, M.F.; Rohani, A.S.; Park, M.N.; Kim, B.; Syahputra, R.A. Unlocking the Potential of Flavonoids: Natural Solutions in the Fight against Colon Cancer. Biomed. Pharmacother. 2024, 176, 116827. [Google Scholar] [CrossRef]

- Hussain, Y.; Khan, H.; Alotaibi, G.; Khan, F.; Alam, W.; Aschner, M.; Jeandet, P.; Saso, L. How Curcumin Targets Inflammatory Mediators in Diabetes: Therapeutic Insights and Possible Solutions. Molecules 2022, 27, 4058. [Google Scholar] [CrossRef] [PubMed]

- Lan, Z.; Yang, R.; Wang, H.; Xue, X.; Sun, Y.; Wang, S.; Zhang, Y.; Meng, J. Rapid Identifying of COX-2 Inhibitors from Turmeric (Curcuma longa) by Bioaffinity Ultrafiltration Coupled with UPLC-Q Exactive-Orbitrap-MS and Zebrafish-Based in Vivo Validation. Bioorg. Chem. 2024, 147, 107357. [Google Scholar] [CrossRef] [PubMed]

- Dai, C.; Lin, J.; Li, H.; Shen, J.; Shen, Z.; Wang, Y.; Velkov, T. The Natural Product Curcumin as an Antibacterial Agent: Current Achievements and Problems. Antioxidants 2022, 11, 459. [Google Scholar] [CrossRef] [PubMed]

- Adamczak, A.; Ożarowski, M.; Karpiński, T.M. Curcumin, a Natural Antimicrobial Agent with Strain-Specific Activity. Pharmaceuticals 2020, 13, 153. [Google Scholar] [CrossRef]

- Dube, E.; Okuthe, G.E. Silver Nanoparticle-Based Antimicrobial Coatings: Sustainable Strategies for Microbial Contamination Control. Microbiol. Res. 2025, 16, 110. [Google Scholar] [CrossRef]

- Wang, W.; Li, M.; Wang, L.; Chen, L.; Goh, B.C. Curcumin in Cancer Therapy: Exploring Molecular Mechanisms and Overcoming Clinical Challenges. Cancer Lett. 2023, 570, 216332. [Google Scholar] [CrossRef]

- Sudhesh Dev, S.; Zainal Abidin, S.A.; Farghadani, R.; Othman, I.; Naidu, R. Receptor Tyrosine Kinases and Their Signaling Pathways as Therapeutic Targets of Curcumin in Cancer. Front. Pharmacol. 2021, 12, 772510. [Google Scholar] [CrossRef]

- Cao, Z.; He, S.; Peng, Y.; Liao, X.; Lu, H. Nanocurcumin Inhibits Angiogenesis via Down-Regulating Hif1a/VEGF-A Signaling in Zebrafish. Curr. Neurovasc. Res. 2020, 17, 147–154. [Google Scholar] [CrossRef]

- Baghcheghi, Y.; Razazpour, F.; Seyedi, F.; Arefinia, N.; Hedayati-Moghadam, M. Exploring the Molecular Mechanisms of PPARγ Agonists in Modulating Memory Impairment in Neurodegenerative Disorders. Mol. Biol. Rep. 2024, 52, 945. [Google Scholar] [CrossRef]

- Satpathy, L.; Parida, S.P. Neuroprotective Role of Curcumin Against Benzo[a]Pyrene-Induced Neurodegeneration in Zebrafish. Biointerface Res. Appl. Chem. 2022, 12, 7311–7320. [Google Scholar] [CrossRef]

- Cheng, M.; Ding, F.; Li, L.; Dai, C.; Sun, X.; Xu, J.; Chen, F.; Li, M.; Li, X. Exploring the Role of Curcumin in Mitigating Oxidative Stress to Alleviate Lipid Metabolism Disorders. Front. Pharmacol. 2025, 16, 1517174. [Google Scholar] [CrossRef] [PubMed]

- Racz, L.Z.; Racz, C.P.; Pop, L.; Tomoaia, G.; Mocanu, A.; Barbu, I.; Melinda, S.; Roman, I.; Avram, A.; Tomoaia-cotisel, M.; et al. Strategies for Improving Bioavailability, Bioactivity, and Physical-Chemical Behavior of Curcumin. Molecules 2022, 27, 6854. [Google Scholar] [CrossRef] [PubMed]

- Tabanelli, R.; Brogi, S.; Calderone, V. Improving Curcumin Bioavailability: Current Strategies and Future Perspectives. Pharmaceutics 2021, 13, 1715. [Google Scholar] [CrossRef]

- Rai, M.; Feitosa, C.M.; Ingle, A.P.; Golinska, P. Harnessing Bioactive Nanocurcumin and Curcumin Nanocomposites to Combat Microbial Pathogens: A Comprehensive Review. Crit. Rev. Biotechnol. 2025, 1–23. [Google Scholar] [CrossRef]

- No, D.S.; Algburi, A.; Huynh, P.; Moret, A.; Ringard, M.; Comito, N.; Drider, D.; Takhistov, P.; Chikindas, M.L. Antimicrobial Efficacy of Curcumin Nanoparticles against Listeria Monocytogenes Is Mediated by Surface Charge. J. Food Saf. 2017, 37, e12353. [Google Scholar] [CrossRef]

- Hettiarachchi, S.S.; Perera, Y.; Dunuweera, S.P.; Dunuweera, A.N.; Rajapakse, S.; Rajapakse, R.M.G. Comparison of Antibacterial Activity of Nanocurcumin with Bulk Curcumin. ACS Omega 2022, 7, 46494–46500. [Google Scholar] [CrossRef]

- Kumar, R.; Thakur, A.K.; Chaudhari, P.; Kumar, R.; Naresh, K.; Thapliyal, D.; Bedar, A.; Krishna, R.S. Nanoparticle Preparation of Pharmaceutical Compounds via Wet Milling: Current Status and Future Prospects. Powder Technol. 2024, 435, 119430. [Google Scholar] [CrossRef]

- Manikandan, S.; El Mabrouk, K.; Ballamurugan, A.M. Synthesis of Nanocurcumin and Evaluation of Its Properties for Biomedical Applications. Trends Biomater. Artif. Organs 2022, 36, 67–69. [Google Scholar]

- Lapcikova, B.; Valenta, T.; Lapcık, L.; Li, P. Curcuma Particle Size Evolution by Application of Bead Milling Process and Curcuminoids Content Determination. Int. J. Food Sci. Technol. 2023, 58, 5738–5744. [Google Scholar] [CrossRef]

- Malamatari, M.; Taylor, K.M.G.; Malamataris, S.; Douroumis, D.; Kachrimanis, K. Pharmaceutical Nanocrystals: Production by Wet Milling and Applications. Drug Discov. Today 2018, 23, 534–547. [Google Scholar] [CrossRef] [PubMed]

- Kuddushi, M.; Xu, B. Bin Recent Advances in Nanoprecipitation: From Mechanistic Insights to Applications in Nanomaterial Synthesis. Soft Matter 2025, 21, 2759–2781. [Google Scholar] [CrossRef] [PubMed]

- Kakran, M.; Sahoo, N.G.; Tan, I.-L.; Li, L. Preparation of Nanoparticles of Poorly Water-Soluble Antioxidant Curcumin by Antisolvent Precipitation Methods. J. Nanopart. Res. 2012, 14, 757. [Google Scholar] [CrossRef]

- Hettiarachchi, S.S.; Dunuweera, S.P.; Dunuweera, A.N.; Rajapakse, R.M.G. Synthesis of Curcumin Nanoparticles from Raw Turmeric Rhizome. ACS Omega 2021, 6, 8246–8252. [Google Scholar] [CrossRef]

- Yadav, D.; Kumar, N. Nanonization of Curcumin by Antisolvent Precipitation: Process Development, Characterization, Freeze Drying and Stability Performance. Int. J. Pharm. 2014, 477, 564–577. [Google Scholar] [CrossRef]

- Kumar, V.; Kumar, R.; Jain, V.K.; Nagpal, S. Preparation and Characterization of Nanocurcumin Based Hybrid Virosomes as a Drug Delivery Vehicle with Enhanced Anticancerous Activity and Reduced Toxicity. Sci. Rep. 2021, 11, 368. [Google Scholar] [CrossRef]

- Zamanidehyaghoubi, G.; Shahidi, F.; Edalatian Dovom, M.R.; Mohebbi, M.; Roshanak, S. Enhancing Curcumin Nanoparticle Synthesis through Wet-Milling: Comparative Analysis of Physico-Chemical and Antimicrobial Properties of Nano-Curcumin with Micro-Curcumin. LWT—Food Sci. Technol. 2024, 205, 116553. [Google Scholar] [CrossRef]

- Bhawana; Basniwal, R.K.; Buttar, H.S.; Jain, V.K.; Jain, N. Curcumin Nanoparticles: Preparation, Characterization, and Antimicrobial Study. J. Agric. Food Chem. 2011, 59, 2056–2061. [Google Scholar] [CrossRef] [PubMed]

- Sahibzada, M.U.K.; Sadiq, A.; Khan, S.; Faidah, H.S.; Naseemullah; Khurram, M.; Amin, M.U.; Haseeb, A. Fabrication, Characterization and in Vitro Evaluation of Silibinin Nanoparticles: An Attempt to Enhance Its Oral Bioavailability. Drug Des. Dev. Ther. 2017, 11, 1453–1464. [Google Scholar] [CrossRef]

- Kanwal, Q.; Ahmed, M.; Hamza, M.; Ahmad, M.; Atiq-ur-Rehman; Yousaf, N.; Javaid, A.; Anwar, A.; Khanf, I.H.; Muddassar, M. Curcumin Nanoparticles: Physicochemical Fabrication, Characterization, Antioxidant, Enzyme Inhibition, Molecular Docking and Simulation Studies. RSC Adv. 2023, 13, 22268–22280. [Google Scholar] [CrossRef]

- Aditya, N.P.; Hamilton, I.E.; Noon, J.; Norton, I.T. Microwave Assisted Nanonization of Poorly Water-Soluble Curcumin. ACS Sustain. Chem. Eng. 2019, 7, 9771–9781. [Google Scholar] [CrossRef]

- Shibatani, A.; Kan, H.; Matsumura, S.; Asakuma, Y.; Saptoro, A. Synergistic Effect of High Irradiation Power and Antisolvent Addition for Enhanced Microwave Assisted Nanoparticle Synthesis Process. J. Chem. Eng. Jpn. 2020, 53, 397–401. [Google Scholar] [CrossRef]

- Al Fatease, A.; Alqahtani, A.; Khan, B.A.; Mohamed, J.M.M.; Farhana, S.A. Preparation and Characterization of a Curcumin Nanoemulsion Gel for the Effective Treatment of Mycoses. Sci. Rep. 2023, 13, 22730. [Google Scholar] [CrossRef] [PubMed]

- Inal, A.; Yenipazar, H.; Şahin-Yeşilçubuk, N. Preparation and Characterization of Nanoemulsions of Curcumin and Echium Oil. Heliyon 2022, 8, e08974. [Google Scholar] [CrossRef]

- Moghaddasi, F.; Housaindokht, M.R.; Darroudi, M.; Bozorgmehr, M.R.; Sadeghi, A. Synthesis of Nano Curcumin Using Black Pepper Oil by O/W Nanoemulsion Technique and Investigation of Their Biological Activities. LWT—Food Sci. Technol. 2018, 92, 92–100. [Google Scholar] [CrossRef]

- Mogahed, N.; Gaafar, M.; Shalaby, T.; Sheta, E.; Arafa, F. Potential Efficacy of Curcumin and Curcumin Nanoemulsion against Experimental Cyclosporiasis. Parasitol. United J. 2023, 16, 197–207. [Google Scholar] [CrossRef]

- Aguilera, L.F.; Araujo, L.O.; Facchinatto, W.M.; Lima, R.G.; da Silva Pontes, M.; Pulcherio, J.H.V.; Caires, C.S.A.; de Oliveira, K.T.; de Oliveira, S.L.; Caires, A.R.L. Blue-Light Photoactivated Curcumin-Loaded Chitosan Nanoparticles Prepared by Nanoprecipitation and Ionic Gelation: A Promising Approach for Antimicrobial Photodynamic Inactivation. ACS Appl. Bio Mater. 2025, 8, 4055–4064. [Google Scholar] [CrossRef] [PubMed]

- Jha, R.; Mayanovic, R.A. A Review of the Preparation, Characterization, and Applications of Chitosan Nanoparticles in Nanomedicine. Nanomaterials 2023, 13, 1302. [Google Scholar] [CrossRef]

- Wathoni, N.; Herdiana, Y.; Suhandi, C.; Mohammed, A.F.A.; El-Rayyes, A.; Narsa, A.C. Chitosan/Alginate-Based Nanoparticles for Antibacterial Agents Delivery. Int. J. Nanomed. 2024, 19, 5021–5044. [Google Scholar] [CrossRef] [PubMed]

- Shende, P.; Gupta, H. Formulation and Comparative Characterization of Nanoparticles of Curcumin Using Natural, Synthetic and Semi-Synthetic Polymers for Wound Healing. Life Sci. 2020, 253, 117588. [Google Scholar] [CrossRef] [PubMed]

- Bhoopathy, S.; Inbakandan, D.; Rajendran, T.; Chandrasekaran, K.; Prabha S, B.; Reddy, B.A.; Kasilingam, R.; RameshKumar, V.; Dharani, G. Dietary Supplementation of Curcumin-Loaded Chitosan Nanoparticles Stimulates Immune Response in the White Leg Shrimp Litopenaeus vannamei Challenged with Vibrio harveyi. Fish Shellfish Immunol. 2021, 117, 188–191. [Google Scholar] [CrossRef]

- Malamatari, M.; Charisi, A.; Malamataris, S.; Kachrimanis, K.; Nikolakakis, I. Spray Drying for the Preparation of Nanoparticle-Based Drug Formulations as Dry Powders for Inhalation. Processes 2020, 8, 788. [Google Scholar] [CrossRef]

- Attri, N.; Kaur, S.; Aggarwal, P. Spray Drying: A Promising Technique in Food Processing—Concept, Applications, and Latest Advancements. In Novel Drying Technologies in Food Science; Chandrapala, J., Ed.; IntechOpen: London, UK, 2025. [Google Scholar]

- Dube, E. Antibacterial Activity of Engineered Nanoparticles against Fish Pathogens. Aquac. Rep. 2024, 37, 102240. [Google Scholar] [CrossRef]

- Jastaniah, S.D.; Mansour, A.A.; Al-Tarawni, A.H.; El-Haroun, E.; Munir, M.B.; Saghir, S.A.M.; Abdul Kari, Z.; Téllez-Isaías, G.; Bottje, W.G.; AL-Farga, A.; et al. The Effects of Nano-Curcumin on Growth Performance, Feed Utilization, Blood Biochemistry, Disease Resistance, and Gene Expression in European Seabass (Dicentrarchus labrax) Fingerlings. Aquac. Rep. 2024, 36, 102034. [Google Scholar] [CrossRef]

- Gandapu, U.; Chaitanya, R.K.; Kishore, G.; Reddy, R.C.; Kondapi, A.K. Curcumin-Loaded Apotransferrin Nanoparticles Provide Efficient Cellular Uptake and Effectively Inhibit HIV-1 Replication In Vitro. PLoS ONE 2011, 6, e23388. [Google Scholar] [CrossRef]

- Unnikrishnan, G.; Joy, A.; Megha, M.; Kolanthai, E.; Senthilkumar, M. Exploration of Inorganic Nanoparticles for Revolutionary Drug Delivery Applications: A Critical Review; Springer: New York, NY, USA, 2023; Volume 18, ISBN 0123456789. [Google Scholar]

- Zhao, Y.; Wang, Y.; Ran, F.; Cui, Y.; Liu, C.; Zhao, Q.; Gao, Y.; Wang, D.; Wang, S. A Comparison between Sphere and Rod Nanoparticles Regarding Their in Vivo Biological Behavior and Pharmacokinetics. Sci. Rep. 2017, 7, 4131. [Google Scholar] [CrossRef]

- Xuan, Y.; Zhang, W.; Zhu, X.; Zhang, S. An Updated Overview of Some Factors That Influence the Biological Effects of Nanoparticles. Front. Bioeng. Biotechnol. 2023, 11, 1254861. [Google Scholar] [CrossRef]

- Pochapski, D.J.; Carvalho Dos Santos, C.; Leite, G.W.; Pulcinelli, S.H.; Santilli, C.V. Zeta Potential and Colloidal Stability Predictions for Inorganic Nanoparticle Dispersions: Effects of Experimental Conditions and Electrokinetic Models on the Interpretation of Results. Langmuir 2021, 37, 13379–13389. [Google Scholar] [CrossRef] [PubMed]

- Ly, P.D.; Ly, K.N.; Phan, H.L.; Nguyen, H.H.T.; Duong, V.A.; Nguyen, H.V. Recent Advances in Surface Decoration of Nanoparticles in Drug Delivery. Front. Nanotechnol. 2024, 6, 1456939. [Google Scholar] [CrossRef]

- Abbas, Q.; Yousaf, B.; Amina; Ali, M.U.; Munir, M.A.M.; El-Naggar, A.; Rinklebe, J.; Naushad, M. Transformation Pathways and Fate of Engineered Nanoparticles (ENPs) in Distinct Interactive Environmental Compartments: A Review. Environ. Int. 2020, 138, 105646. [Google Scholar] [CrossRef]

- Gad, H.A.; Alshubaily, F.A.; Alsieni, M.A.; Tayel, A.A.; Diab, A.M. Biosynthesis of Nano-Curcumin/Nano-Selenium Composite and Their Potentialities as Bactericides against Fish-Borne Pathogens. Green Process. Synth. 2022, 11, 1098–1107. [Google Scholar] [CrossRef]

- Sayyar, Z.; Jafarizadeh-Malmiri, H. Enhancing the Efficacy of Nano-Curcumin on Cancer Cells through Mixture Design Optimization of Three Emulsifiers. BMC Chem. 2024, 18, 62. [Google Scholar] [CrossRef]

- Singh, A.K.; Prakash, P.; Singh, R.; Nandy, N.; Firdaus, Z.; Bansal, M.; Singh, R.K.; Srivastava, A.; Roy, J.K.; Mishra, B.; et al. Curcumin Quantum Dots Mediated Degradation of Bacterial Biofilms. Front. Microbiol. 2017, 8, 1517. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Chen, L.; Zhang, W. Influence of Ionic Surfactants on the Properties of Nanoemulsions Emulsified by Nonionic Surfactants Span 80/Tween 80. J. Dispers. Sci. Technol. 2016, 37, 1511–1517. [Google Scholar] [CrossRef]

- Kumavat, S.D.; Chaudhari, Y.S.; Borole, P.; Mishra, P.; Shenghani, K.; Duvvuri, P. Degradation Studies of Curcurmin. Int. J. Pharm. Rev. Res. 2015, 3, 50–55. [Google Scholar]

- Sedghi, R.; Ashrafzadeh, S.; Heidari, B. PH-Sensitive Molecularly Imprinted Polymer Based on Graphene Oxide for Stimuli Actuated Controlled Release of Curcumin. J. Alloys Compd. 2021, 857, 157603. [Google Scholar] [CrossRef]

- Chen, M.; Li, L.; Xia, L.; Jiang, S.; Kong, Y.; Chen, X.; Wang, H. The Kinetics and Release Behaviour of Curcumin Loaded PH-Responsive PLGA/Chitosan Fibers with Antitumor Activity against HT-29 Cells. Carbohydr. Polym. 2021, 265, 118077. [Google Scholar] [CrossRef]

- Zhu, J.; Sanidad, K.Z.; Sukamtoha, E.; Zhang, G. Potential Roles of Chemical Degradation in the Biological Activities of Curcumin. Food Funct. 2017, 8, 907–914. [Google Scholar] [CrossRef]

- Morsy, M.K.; Al-Dalain, S.Y.; Haddad, M.A.; Diab, M.; Abd-Elaaty, E.M.; Abdeen, A.; Ibrahim, S.F.; Shukry, M.; Banatean-Dunea, I.; Fericean, L.; et al. Curcumin Nanoparticles as a Natural Antioxidant and Antimicrobial Preservative against Foodborne Pathogens in Processed Chicken Fingers. Front. Sustain. Food Syst. 2023, 7, 1267075. [Google Scholar] [CrossRef]

- Ring, L.C.; Yenn, T.W.; Wen-Nee, T.; Tumin, N.D.; Yusof, F.A.M.; Yacob, L.S.; Bin Rosli, M.I.H.; Taher, M.A. Synthesis of Curcumin Quantum Dots and Their Antimicrobial Activity on Necrotizing Fasciitis Causing Bacteria. Mater. Today Proc. 2020, 31, 31–35. [Google Scholar] [CrossRef]

- Hosseini, A.; Nejadsattari, T.; Zargar, M. In Vitro Anti-Biofilm Activity of Curcumin Nanoparticles in Acinetobacter Baumannii: A Culture-Based and Molecular Approach. Arch. Clin. Infect. Dis. 2019, 14, e83263. [Google Scholar] [CrossRef]

- Mansour, S.; Bakry, K.A.; Alwaleed, E.A.; Ahmed, H.; Al-Amgad, Z.; Mohammed, H.H.; Emeish, W.F.A. Dietary Nanocurcumin Impacts Blood Biochemical Parameters and Works Synergistically with Florfenicol in African Catfish Challenged with Aeromonas Veronii. Fishes 2023, 8, 298. [Google Scholar] [CrossRef]

- Panwar, D.; Sidhu, K.; Bhushan, J.; Kakkar, V.; Mehta, M.; Sharma, J. Evaluation of Antimicrobial Efficacy of Nanocurcumin-coated Gutta-percha against Enterococcus faecalis: An in Vitro Study. J. Conserv. Dent. 2023, 26, 160–164. [Google Scholar] [CrossRef]

- Khan, M.A.; Moghul, N.B.; Butt, M.A.; Kiyani, M.M.; Zafar, I.; Bukhari, A.I. Assessment of Antibacterial and Antifungal Potential of Curcuma longa and Synthesized Nanoparticles: A Comparative Study. J. Basic Microbiol. 2021, 61, 603–611. [Google Scholar] [CrossRef]

- Negahdari, R.; Sharifi, S.; Ghavimi, M.A.; Memar, M.Y. Curcumin Nanocrystals: Production, Physicochemical Assessment, and In Vitro Evaluation of the Antimicrobial Effects against Bacterial Loading of the Implant Fixture. Appl. Sci. 2020, 10, 8356. [Google Scholar] [CrossRef]

- Adahoun, M.A.; Al-Akhras, M.A.H.; Jaafar, M.S.; Bououdina, M. Enhanced Anti-Cancer and Antimicrobial Activities of Curcumin Nanoparticles. Artif. Cells Nanomed. Biotechnol. 2017, 45, 98–107. [Google Scholar] [CrossRef]

- Shariati, A.; Asadian, E.; Fallah, F.; Azimi, T.; Hashemi, A.; Sharahi, J.Y.; Moghadam, M.T. Evaluation of Nano-Curcumin Effects on Expression Levels of Virulence Genes and Biofilm Production of Multidrug-Resistant Pseudomonas aeruginosa Isolated from Burn Wound Infection in Tehran, Iran. Infect. Drug Resist. 2019, 12, 2223–2235. [Google Scholar] [CrossRef]