Mechanochemical-Activated Organomontmorillonite for Uranium Pollution Protection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Synthesis

2.3. Characterization Methods

2.4. Adsorption Experiments

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MMT | Montmorillonite |

| CEC | Cationic exchange capacity |

| HDTMA | Hexadecyltrimethylammonium bromide |

| MMT-HDTMA | Organomodified montmorillonite |

| MMT-MCA | Mechanochemically activated montmorillonite |

| MMT-HDTMA-MCA | Mechanochemically activated organomontmorillonite |

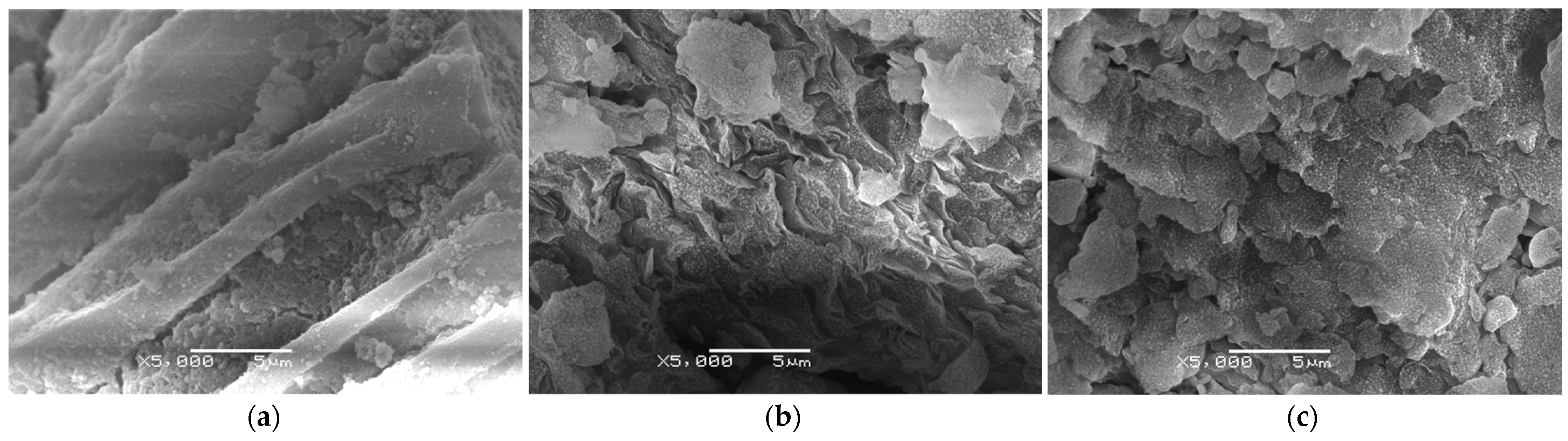

| SEM | Scanning electron microscopy |

| TEM | Transmission electron microscopy |

| XRD | X-ray powder diffraction |

| EDS | Energy-dispersive X-ray |

| TG | Thermogravimetric analysis |

| DTG | Derivative thermogravimetric analysis |

| DTA | Differential thermal analysis |

References

- Nunez-Delgado, A. (Ed.) Sorbents Materials for Controlling Environmental Pollution. Current State and Trends; Elsevier: Amsterdam, The Netherlands, 2021; 749p. [Google Scholar]

- Strelko, V.V. (Ed.) Selective Sorption and Catalysis on Active Carbons and Inorganic Ion Exchangers; Naukova Dumka: Kyiv, Ukraine, 2008; 304p. (In Russian) [Google Scholar]

- Uddin, M.K. A Review on the Adsorption of Heavy Metals by Clay Minerals, with Special Focus on the past Decade. Chem. Eng. J. 2017, 308, 438–462. [Google Scholar] [CrossRef]

- Gu, S.; Kang, X.; Wang, L.; Lichtfouse, E.; Wang, C. Clay Mineral Adsorbents for Heavy Metal Removal from Wastewater: A Review. Environ. Chem. Lett. 2019, 17, 629–654. [Google Scholar] [CrossRef]

- Churchman, G.J.; Gates, W.P.; Theng, B.K.G.; Yuan, G. Clays and clay minerals for pollution control. In Handbook of Clay Science; Bergaya, F., Theng, B.K.G., Lagaly, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2006; Volume 1, pp. 625–675. [Google Scholar]

- Neto, S.L.D.; Maged, A.; Gabriel, R.; Lins, P.V.S.; Haneklaus, N.H.; Hlawitschka, M.W.; Meili, L. Nanoclays in water treatment: Core concepts, modifications, and application insights. J. Water Proc. Eng. 2024, 67, 106180. [Google Scholar] [CrossRef]

- Kornilovych, B.; Kovalchuk, I. Selective Sorption of Heavy Metals and Radionuclides by Natural and Modified Layered Silicates; Naukova Dumka: Kyiv, Ukraine, 2024; 208p. (In Ukrainian) [Google Scholar]

- Bergaya, F.; Theng, B.K.G.; Lagaly, G. (Eds.) Modified Clays and Clay Minerals. In Handbook of Clay Science; Elsevier: Amsterdam, The Netherlands, 2006; Volume 1, pp. 261–263. [Google Scholar]

- Lee, S.M.; Tiwari, D. Organo and Inorgano-Organo-Modified Clays in the Remediation of Aqueous Solutions: An Overview. Appl. Clay Sci. 2012, 59–60, 84–102. [Google Scholar] [CrossRef]

- Majdan, M.; Pikus, S.; Gajowiak, A.; Gładysz-Płaska, A.; Krzyzanowska, H.; Zuk, J.; Bujacka, M. Characterization of uranium (VI) sorption by organobentonite. Appl. Surf. Sci. 2010, 256, 5416–5421. [Google Scholar] [CrossRef]

- Golembiovskyi, A.O.; Kovalchuk, I.A.; Kornilovych, B.Y.; Zhdanyuk, N.V. Remediation of the U(VI) Ions from Waters Using Organic Clays. Naukovi Visti NTUU-KPI 2011, 2011, 154–158. (In Ukrainian) [Google Scholar]

- Kovalchuk, I.A.; Laguta, A.N.; Kornilovych, B.Y.; Tobilko, V.Y. Organophilic layered silicates for sorption removal of uranium (VI) from mine water. Chem. Phys. Surf. Technol. 2020, 11, 215–227. [Google Scholar]

- Kyriakopoulos, G.; Doulia, D. Morphology of polymeric resins in adsorb of organic pesticides. Fres. Environ. Bull. 2007, 16, 731–734. [Google Scholar]

- Mucsi, G. A review on mechanical activation and mechanical alloying in stirred media mill. Chem. Eng. Res. Des. 2019, 148, 460–474. [Google Scholar] [CrossRef]

- Al Bazedi, G.A.; Al-Rawajfeh, A.E.; Abdel-Fatah, M.A.; Alrbaihat, M.R.; AlShamaileh, E. Synthesis of nanomaterials by mechanochemistry. In Handbook of Greener Synthesis of Nanomaterials and Compounds; Kharisov, B., Kharissova, O., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 1, pp. 405–418. [Google Scholar]

- Tole, I.; Habermehl-Cwirzen, K.; Cwirzen, A. Mechanochemical activation of natural clay minerals: An alternative to produce sustainable cementitious binders—Review. Mineral. Petrol. 2019, 113, 449–462. [Google Scholar] [CrossRef]

- Baki, V.A.; Ke, X.; Heath, A.; Calabria-Holley, J.; Terzi, C.; Sirin, M. The impact of mechanochemical activation on the physicochemical properties and pozzolanic reactivity of kaolinite, muscovite and montmorillonite. Cement Concr. Res. 2022, 162, 106962. [Google Scholar] [CrossRef]

- Kovalchuk, I.; Zakutevskyy, O.; Sydorchuk, V.; Diyuk, O.; Lakhnik, A. The Effect of High-Energy Ball Milling of Montmorillonite for Adsorptive Removal of Cesium, Strontium, and Uranium Ions from Aqueous Solution. Eng 2023, 4, 2812–2825. [Google Scholar] [CrossRef]

- Yariv, S.; Lapides, I. The Effect of Mechanochemical Treatments on Clay Minerals and the Mechanochemical Adsorption of Organic Materials onto Clay Minerals. J. Mater. Synth. Proc. 2000, 8, 223–233. [Google Scholar] [CrossRef]

- Napola, A.; Pizzigallo, M.D.R.; Di Leo, P.; Spagnuolo, M.; Ruggiero, P. Mechanochemical approach to remove phenanthrene from a contaminated soil. Chemosphere 2006, 65, 15831590. [Google Scholar] [CrossRef]

- Ovadyahu, D.; Yariv, S.; Lapides, I.; Deutsch, Y. Mechanochemical Adsorption of Phenol by Tot Swelling Clay Minerals. J. Therm. Anal. Calorim. 1998, 51, 431–447. [Google Scholar] [CrossRef]

- Obijole, O.A.; Gitari, M.W.; Ndungu, P.G.; Samie, A. Mechanochemically Activated Aluminosilicate Clay Soils and their Application for Defluoridation and Pathogen Removal from Groundwater. Int. J. Environ. Res. Public Health 2019, 16, 654. [Google Scholar] [CrossRef] [PubMed]

- Kornilovych, B.Y. Structure and Surface Properties of Mechanochemically Activated Silicates and Carbonates; Naukova Dumka: Kyiv, Ukraine, 1994; 127p. (In Russian) [Google Scholar]

- Sun, W.; Li, J.; Li, H.; Jin, B.; Li, Z.; Zhang, T.; Zhu, X. Mechanistic insights into ball milling enhanced montmorillonite modification with tetramethylammonium for adsorption of gaseous toluene. Chemosphere 2022, 296, 133962. [Google Scholar] [CrossRef]

- Kostjukovs, J.; Actinš, A.; Karasa, J. Mechanochemical Method for Obtaining Organoclays from Smectites. US Patent EP2690067A1, 29 January 2014. [Google Scholar]

- Sun, W.; Zhang, T.; Li, J.; Zhu, X. Enhanced gaseous acetone adsorption on montmorillonite by ball milling generated Si–OH and interlayer under synergistic modification with H2O2 and tetramethylammonium bromide. Chemosphere 2023, 321, 138114. [Google Scholar] [CrossRef]

- Hrachová, J.; Billik, P.; Fajnor, V.Š. Influence of organic surfactants on structural stability of mechanochemically treated bentonite. J. Therm. Anal. Calorim. 2009, 101, 161–168. [Google Scholar] [CrossRef]

- Ramadan, A.R.; Esawi, A.M.K.; Gawad, A.A. Effect of Ball Milling on the Structure of Na+-Montmorillonite and Organo-Montmorillonite. Appl. Clay Sci. 2010, 47, 196–202. [Google Scholar] [CrossRef]

- Cheng, H.; Liu, Q.; Zhang, J.; Yang, J.; Frost, R.L. Delamination of kaolinite–potassium acetate intercalates by ball-milling. J. Coll. Interface Sci. 2010, 348, 355–359. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://world-nuclear.org/ (accessed on 10 January 2025).

- Atwood, D.A. Radionuclides in the Environment; Wiley: New York, NY, USA, 2010; 522p. [Google Scholar]

- Tarasevich, Y.I.; Ovcharenko, F.D. Adsorption on Clay Minerals; Naukova Dumka: Kyiv, Ukraine, 1975; 351p. (In Russian) [Google Scholar]

- Brindley, G.W.; Brown, G. Crystal Structures of Clay Minerals and Their X-Ray Identification; Mineral. Soc.: London, UK, 1980; 496p. [Google Scholar]

- Patterson, A.L. The Scherrer Formula for X-Ray Particle Size Determination. Phys. Rev. 1939, 56, 978–982. [Google Scholar] [CrossRef]

- Rouquerol, F.; Rouquerol, J.; Sing, K.S.W.; Llewellyn, P.; Maurin, G. Adsorption by Powders and Porous Solids; Elsevier: Amsterdam, The Netherlands, 2014; 467p. [Google Scholar]

- Ehiomogue, P.; Ahuchaogu, I.I.; Ahaneku, I.E. Review of adsorption isotherms models. Acta Tech. Corviniensis Bull. Eng. 2021, 14, 87–96. [Google Scholar]

- Limousin, G.; Gaudet, J.-P.; Charlet, L.; Szenknect, S.; Barthès, V.; Krimissa, M. Sorption isotherms: A review on physical bases, modeling and measurement. Appl. Geochem. 2007, 22, 249–275. [Google Scholar] [CrossRef]

- Hu, B.; Luo, H. Adsorption of hexavalent chromium onto montmorillonite modified with hydroxyaluminum and cetyltrimethylammonium bromide. Appl. Surf. Sci. 2010, 257, 769–775. [Google Scholar] [CrossRef]

- Perkins, S.T.; Cullen, D.E.; Chen, M.H.; Hubbell, J.H.; Rathkopf, J.; Scofield, J. Tables and Graphs of Atomic Subshell and Relaxation Data Derived from the LLNL Evaluated Atomic Data Library (EADL), Z = 1–100; Technical Report UCRL-50400; Lawrence Livermore National Laboratory: Livermore, CA, USA, 1991; Volume 30. [Google Scholar]

- He, H.; Frost, R.L.; Bostrom, T.; Yuan, P.; Duong, L.; Yang, D.; Kloprogge, J.T. Changes in the morphology of organoclays with HDTMA+ surfactant loading. Appl. Clay Sci. 2006, 31, 262–271. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewska, T. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Langmuir, D. Aqueous Environmental Geochemistry; Prentice Hall: Upper Saddle River, NJ, USA, 1997; 600p. [Google Scholar]

- Majdan, M.; Maryuk, O.; Pikus, S.; Olszewska, E.; Kwiatkowski, R.; Skrzypek, H. Equilibrium, FTIR, scanning electron microscopy and small wide angle X-ray scattering studies of chromates adsorption on modified bentonite. J. Mol. Struct. 2005, 740, 203–211. [Google Scholar] [CrossRef]

- Majdan, M.; Pikus, S.; Gajowiak, A.; Sternik, D.; Zieba, E. Uranium sorption on bentonite modified by octadecyltrimethylammonium bromide. J. Hazard. Mater. 2010, 184, 662–670. [Google Scholar] [CrossRef]

- Sprynskyy, M.; Kovalchuk, I.; Buszewski, B. The separation of uranium ions by natural and modified diatomite from aqueous solution. J. Hazard. Mater. 2010, 181, 700–707. [Google Scholar] [CrossRef]

- Cagnetta, G.; Vakili, M. Nonthermal Mechanochemical Destruction of POPs. In Persistent Organic Pollutants (POPs)—Monitoring, Impact and Treatment; Rashed, M.N., Ed.; IntechOpen: London, UK, 2022. [Google Scholar]

| Sample | Moisture Loss, % | Residual Mass at 739 °C, g | Temperature at the DTG Peaks, °C |

|---|---|---|---|

| MMT | 12.9 | 174.2 | 133.6 |

| MMT-HDTMA | 28.5 | 143.0 | 282.5 |

| 10 min MMT-HDTMA-MCA | 24.2 | 151.7 | 172.8; 298.9 |

| Sample | SSSA(BET), m2/g | SSSA(BJH), m2/g | Vtot, cm3/g | Vmeso (BJH), cm3/g | Meso-Pores, % | raver., nm |

|---|---|---|---|---|---|---|

| MMT | 89.1 | 39.5 | 0.08 | 0.05 | 62.5 | 1.8 |

| MMT-HDTMA | 0.9 | 1.9 | 0.005 | 0.005 | 100 | 10.1 |

| 10 min MMT-HDTMA-MCA | 3.1 | 4.6 | 0.012 | 0.013 | 100 | 7.8 |

| Adsorbent | Langmuir | Freundlich | Temkin | ||||||

|---|---|---|---|---|---|---|---|---|---|

| qmax, μmol/g | KL, L/μmol | R2 | 1/n | KF, L/μmol | R2 | KT L/μmol | bT | R2 | |

| MMT | 87.0 | 6.1 | 0.994 | 0.97 | 12.9 | 0.995 | 9.5 | 182.1 | 0.957 |

| MMT-HDTMA | 111.1 | 45.0 | 0.999 | 0.26 | 8.7 | 0.846 | 1.0 | 134.5 | 0.916 |

| 2 min MMT-HDTMA-MCA | 476.2 | 21 | 0.953 | 1.55 | 96.9 | 0.994 | 2.2 | 80.8 | 0.993 |

| 5 min MMT-HDTMA-MCA | 526.3 | 19 | 0.926 | 1.31 | 64.1 | 0.999 | 11.2 | 12.8 | 0.968 |

| 10 min MMT-HDTMA-MCA | 769.2 | 6.5 | 0.979 | 0.83 | 27.8 | 0.995 | 8.3 | 19.0 | 0.950 |

| 25 min MMT-HDTMA-MCA | 434.8 | 23 | 0.942 | 0.99 | 37.3 | 0.970 | 2.2 | 18.4 | 0.964 |

| MMT-MCA | 123.5 | 81.0 | 0.996 | 0.32 | 10.5 | 0.914 | 6.2 | 25.1 | 0.905 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kovalchuk, I.; Farbun, I.; Sydorchuk, V.; Lakhnik, A.; Diyuk, O. Mechanochemical-Activated Organomontmorillonite for Uranium Pollution Protection. AppliedChem 2025, 5, 5. https://doi.org/10.3390/appliedchem5010005

Kovalchuk I, Farbun I, Sydorchuk V, Lakhnik A, Diyuk O. Mechanochemical-Activated Organomontmorillonite for Uranium Pollution Protection. AppliedChem. 2025; 5(1):5. https://doi.org/10.3390/appliedchem5010005

Chicago/Turabian StyleKovalchuk, Iryna, Iryna Farbun, Volodymyr Sydorchuk, Andrey Lakhnik, and Olena Diyuk. 2025. "Mechanochemical-Activated Organomontmorillonite for Uranium Pollution Protection" AppliedChem 5, no. 1: 5. https://doi.org/10.3390/appliedchem5010005

APA StyleKovalchuk, I., Farbun, I., Sydorchuk, V., Lakhnik, A., & Diyuk, O. (2025). Mechanochemical-Activated Organomontmorillonite for Uranium Pollution Protection. AppliedChem, 5(1), 5. https://doi.org/10.3390/appliedchem5010005