1. Introduction

Farmers need access to a wide range of solutions to protect their crops from pests, weeds or diseases. Pesticides are, in many cases, the only option to effectively reduce a given pest or disease. The term “pesticides” encompasses a range of substances, including biocides and phytosanitary products, that are intended to reduce, eradicate or prevent the spread of certain organisms that are considered harmful [

1]. However, the excessive use of synthetic pesticides in agriculture represents a problem for the environment and their permanence poses a threat to the health of human beings and other living creatures.

The World Health Organization (WHO) established a classification for pesticides based on their hazard or degree of acute toxicity, defined as the ability of a pesticide to produce acute damage to health through single or multiple exposures in a relatively short period of time. Toxicity is measured by the median lethal dose (LD50) or the median lethal concentration (LC50) [

2]. Both parameters vary according to multiple factors such as product presentation (solid, gel, liquid, gas, dust, etc.), route of entry (oral, dermal, respiratory), temperature, diet, age, sex, among others. Since they are based on the monitoring of the animal species on which they act, it is important to note that these indicators do not provide information on the chronic effects, nor on the cytotoxicity of any of their compounds [

2].

In order to minimize their impact on organisms and on the environment, the current trend consists in the use of insecticides from natural sources. In this sense, natural pyrethrin extracts have a rapid action on the nervous system of insects, and are low in toxicity for humans or other warm-blooded animals. They have a low persistence and are easily degraded under the action of environmental agents (temperature and light) [

3].

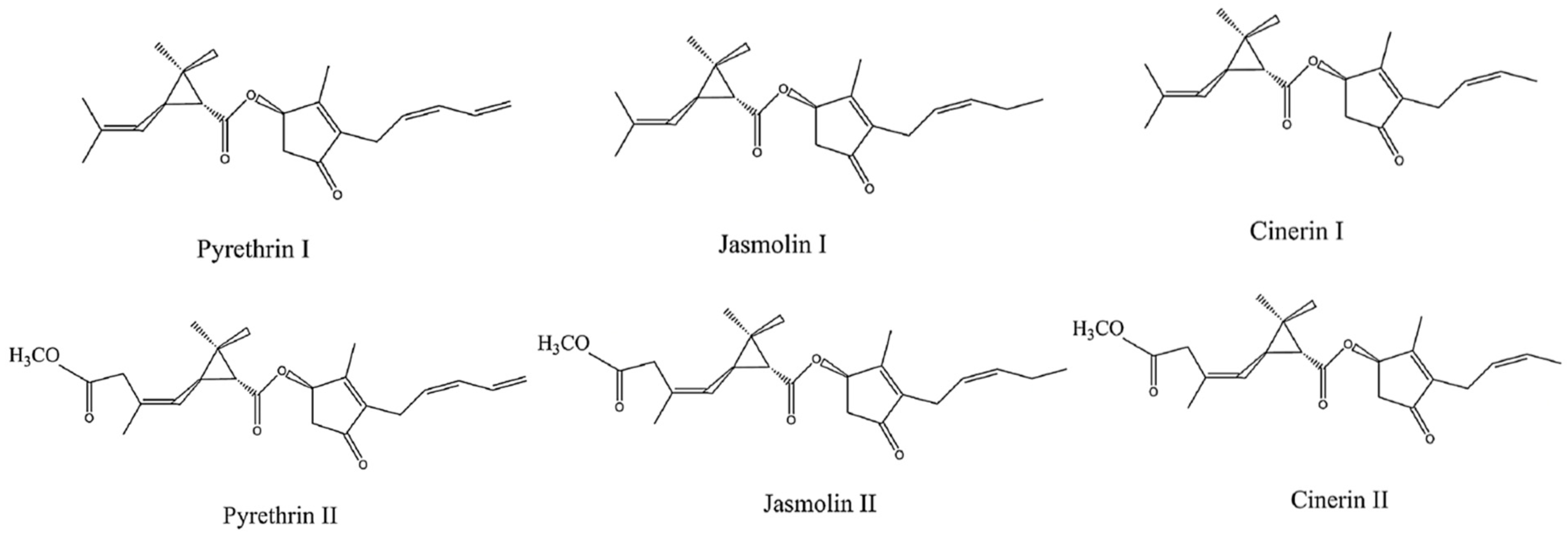

The extraction of pyrethrins (

Figure 1) has been extensively studied [

4,

5,

6,

7]. The selection of the appropriate extraction method requires taking into account factors such as extraction time, power consumption, cost-effectiveness, solvent toxicity and amount of waste—all of which may vary depending on the intended use (laboratory study, industrial production, etc.) [

8]. Among the non-conventional extraction techniques reported in the literature, supercritical fluid extraction (SFE) stands out as an efficient method that has been successfully used to obtain pyrethrins. The range of the CO

2 pressure levels that have been evaluated is very wide, from values as low as 8–10 MPa [

5,

6,

7,

9] to values as high as 40 MPa [

10]. However, all the authors seem to agree that temperatures below 40 °C are satisfactory.

New methods for the administration of pesticides are currently being studied, since certain applications, such as spraying, have been banned in certain areas [

7]. In this sense, the functionalization of polymers with insecticidal substances, which may not only act as physical barriers but also release their active substances in a controlled manner, has been the subject of study in the last decade. Some examples of the application of this way of adding an insecticide to a polymer are the preparation of trilayer films containing approximately 6 wt% malathion on a film blowing line [

11]; a long-lasting repellent-treated net designed by binding the skin repellents N,N-diethylm-toluamide [

12]; or insecticide-treated clothing and military uniforms for protection against bites from arthropods [

13].

Plastic polymers are widely used in agriculture. Such uses range from their application in irrigation networks in the form of filters, pipes or drippers, as shading, windbreak barriers or mosquito nets, threads, containers or packaging materials, as well as for fodder silage. Plastics are also used for crop protection (greenhouses, tunnels or mulching) [

14,

15]. The possibility of conferring special properties to the plastics used both as greenhouse covers or as mulching through the addition of active compounds that are slowly released would lessen the use of pesticides until the harvest of the crops, which would have a direct and positive impact on the environment and on human health.

One of the most novel techniques for the functionalization of polymers to be used as pesticide control is their supercritical impregnation. Impregnation with scCO

2 has a wide range of applications, mainly applications that are used to incorporate various active ingredients, such as pharmaceuticals, functional finishing agents, colorants and other agents into a polymer matrix. Impregnation of functional dyes, silicon and fluoropolymer-based functional agents, natural functional compounds, and organometallic-based functional agents are described in the bibliography [

16]. Goñi et al. [

17], investigated the supercritical CO

2-assisted impregnation of LDPE/sepiolite films with two insecticidal terpene ketones (thymoquinone and R-(+)-pulegone), with successful results. On the other hand, Pajnik et al. [

18], studied the supercritical fluid impregnation of a commercial pyrethrum extract into cotton fabric to be used as tick repellent. The impregnation experiments were carried out at 40 °C and under two different pressure levels of 8 and 10 MPa, for different impregnation times ranging from 1 to 24 h. In a later study, the same authors [

19], conducted the supercritical CO

2 impregnation of the same pyrethrum extract but into polypropylene and polyamide fabrics, as well as into cellulose acetate in the form of beads and films, with the aim of producing functionalized materials with repellent properties. The experiments were carried out at a temperature of 40 °C, pressures of 10 and 20 MPa and for a time ranging from 0.5 to 18 h. Finally, in previous work, the supercritical impregnation of commercial pyrethrin extract into PP films was studied by comparing batch (BM) and semi-continuous (SM) impregnation methods. The results indicated that BM provides the best results with respect to SM [

20]. In general, all of these works intended to determine the viability of these impregnation processes when using commercial extracts. However, no studies have been found in the literature that investigate the supercritical extraction process from flowers jointly with the impregnation process.

In view of the above, the present work proposes to analyze the extraction process of different varieties of chrysanthemum flowers, with the aim of obtaining an extract that can be successfully impregnated into PP films. The novelties in the present work are related to the extraction of different varieties of flowers and to impregnate the extract obtained by supercritical fluid extraction. The effect of pressure on the efficiency of the impregnation process has been determined and the results have been compared against previous works where commercial extracts had been used.

2. Materials and Methods

2.1. Chemical Reactants and Raw Materials

The raw material used for the extraction process were Chrysanthemum spp. flowers commercialized by the company Florabel (Cadiz, Spain). Four varieties have been studied: Atlantis (white variety), Atlantis Yellow (yellow variety), Feeling Green, Dark (green variety) and Wizard (red variety). The flowers were dried at room temperature, softly crushed using a Thermomix crusher provided by Vorwerk (Wuppertal, Germany) to maintain a constant apparent density in all experiments, and stored at ambient temperature until further use.

The polymer to be impregnated was polypropylene (PP), a polymer type that is particularly often used in greenhouses (G-800–200 µm, supplied by S21 Obinsur, Cadiz, Spain).

The carbon dioxide (99.99%) was purchased from Abello-Linde S.A. (Barcelona, Spain). The reagents 2,2-diphenyl-1-picrylhydrazyl (DPPH), ethyl acetate, acetonitrile and pyrethrum extract PESTANAL® analytical standard, were purchased from Sigma-Aldrich (Steinheim, Germany).

2.2. Supercritical Fluid Extraction (SFE)

The extraction experiments were carried out by means of Thar Technology equipment (Pittsburgh, PA, USA, model SF500), fitted with an extractor (500 mL capacity) and a high-pressure pump for the CO

2 (P200 model). The pressure was controlled by means of a back pressure regulator (BPR) and a thermostated jacket controlled the extraction temperature. The cyclonic separator allowed the continuous recovery of the extracted material over the process. The extractor was loaded with 20–30 g of previously dried and ground

Chrysanthemum cinereaii folium flowers, the CO

2 flow rate was kept constant at 10 g min

−1 over the 5 h extraction time. These conditions have been selected in order to guarantee that these variables are not process limiting factors.

Figure 2 is a diagram of the equipment used for this research. A detailed description of the operating methodology can be seen in a previous publication [

20].

Based on our literature review on the extraction of pyrethrin using supercritical CO

2 [

6,

10,

21,

22], the extractions were carried out under two different pressure levels: 10 and 40 MPa, at a constant temperature of 35 °C, since previous studies had reported that low temperatures result in more successful extractions. In order to collect the product obtained from the extraction, ethyl acetate was added to the cyclone separator. Subsequently, the organic solvent was eliminated using a rotoevaporator at 35 °C.

Extraction efficiency was calculated using the gravimetric method and the extract samples were stored at 4 °C in the absence of light until their subsequent use for the impregnation of the polypropylene film. Each extraction was carried out in duplicate and the resulting data were represented as the mean with 95% confidence intervals.

In order to determine the influence from pressure and the flower variety used on the extraction process, the results were analyzed using the computer application Statgraphics centurion XIX (Corp., Princeton, NJ, USA). The significance level of the different factors was established as p = 0.05, the mathematical sign next to each factor indicates the positive or negative effect attributable to each variable.

2.3. Supercritical Impregnation (SSI)

The impregnation experiments were carried out using Waters equipment (model SF104), fitted with a high-pressure pump with 50 g min

−1 maximum flow and a BPR to control the system pressure (

Figure 3). A detailed description of the equipment operation method can be found in [

20].

A batch mode impregnation process was developed in accordance with previous results [

20]. Approximately 93 mg of

Chrysanthemum cinereaii folium flower extract, previously obtained by supercritical CO

2, was dissolved in 1 mL of ethyl acetate and added to the impregnation vessel. A stir bar was fitted at the bottom of the vessel to ensure the homogenization through constant stirring (40 rpm). Then, a 17 × 2 cm PP film sample was placed inside the vessel. The CO

2 was pumped at a low flow rate in order to minimize the damage to the sample (10 g min

−1) until the pressure value set for each experiment was reached. Once the impregnation time was over, the equipment was depressurized. A number of samples were collected and stored at 4 °C in the absence of light until analysis. The impregnation time was set at 5 h, the natural extract placed inside the reactor was 0.09 ± 0.01 g/mL and the pressure analyzed was 10 and 40 MPa at 55 °C. The depressurization rate was 5 MPa min

−1.

2.4. HPLC Analysis

A “Hewlett Packard”, model 1100, HPLC with quaternary pump and UV-VIS detector was used for the identification of the pyrethrins in the extract. A Nova-Pack C18 (RP, 3.9 × 150 mm) was used as a stationary phase. The solvents that constituted the mobile phase were A (acetonitrile) and B (water). The elution conditions applied were: 0–23 min, 40% B isocratic; 23–40 min, linear gradient 40–20% B; 40–43 min, 20% B isocratic; 43–45 min, linear gradient 20–60% B, and finally, the washing and reconditioning steps of the column were included (45–50 min, linear gradient 60–40% B. The flow-rate was 1 mL/min and the injection volumes were 20 μL. The system was operated at room temperature. Pyrethrin compounds were detected at 230 nm by their retention times and quantified using a calibration curve of the corresponding standard compounds. A typical chromatogram of the compounds detected in the extract was shown in

Figure 4.

2.5. Determining the Polymer Films Impregnation Loads

The amount of extract impregnated into the PP films was determined by an indirect spectrophotometric method. This method is based on the ability of some extracts, e.g., pyrethrum, to reduce a 2,2-diphenyl-1-picrylhydrazyl (DPPH) reagent with the consequent color change from violet to yellow. The absorbance of the DPPH reagent was measured at 515 nm and the inhibition percentage at steady state was calculated according to Equation (1):

where

%I is the DPPH inhibition,

A0 is the initial absorbance and

At is the absorbance in steady state. Then, a calibration curve relating the DPPH inhibition (

I) vs. the amount of pyrethrum extract (mg) added to the DPPH solution was plotted.

To determine the amount of pyrethrin impregnated into the PP films, a known amount (1 × 6 cm) of impregnated PP film was submerged into 4 mL of 6 × 10−5 M DPPH solution during 174 min. The reduction in the absorbance was monitored at 515 nm. %I was calculated according to Equation (1), and the amount of pyrethrum extract impregnated into the PP films was determined by comparing their calibration curves.

Data are expressed as pyrethrum mg/cm2. Each measurement was performed in duplicate and the data have been represented as the means with 95% confidence intervals.

2.6. SEM Analysis

In order to check for any structural changes in the polymer film after the impregnation process, the impregnated samples were examined using a Quanta 200 scanning electron microscope (FEI, Hillsboro, OR, USA). The SEM images of the PP films were taken after the impregnation process with the natural pyrethrin extract obtained by supercritical extraction. The samples were previously washed using bi-distilled water to remove any particles that might have deposited on the surface of the polymer. For the examination, the samples were placed on a gold-coated carbon ribbon and the SEM images were processed using the computer application Scion for image analysis (Scion Corp., Torrance, CA, USA).

4. Discussion

The solvent capacity of a supercritical fluid depends on its density, which, unlike liquid solvents, is controlled by changes in pressure and/or temperature. This allows the selective extraction of certain compounds at a highly precise level. At a certain fixed temperature, an increment of the operating pressure causes an increase in the density of supercritical CO

2 and, therefore, an increase in its solvent capacity. However, this pressure increment may also cause a reduction in the interaction between the fluid and the matrix, as the diffusion coefficient also decreases with the increasing density. In the present case, this latter factor prevails over the former one and therefore a poorer performance can be observed when operating at 40 MPa. This behavior of pressure is discussed in the bibliography [

24]. The higher the pressure, the smaller the solvent volume needed for a particular extraction, but an excessive increase in pressure can reduce the extract’s antioxidant activity and decrease the diffusivity of the SCF, which reduces solute dissolution. For this reason, the selection of a high pressure in the extraction process is not suggested for all substances because it can result in a compacted raw material, which can adversely affect the extraction yield. An example of this behavior is observed in the extraction of essential oil from Jasmine flowers [

25]. The yields obtained at pressures of 10 MPa are similar or even higher than those obtained at 30 Mpa. The decrease in extraction yield at high pressures is attributed, in this case, to the fact that an increase in pressure can decrease diffusivity and cause liquid particles to diffuse into the strong pores by breaking up the solute. In addition, an increase in pressure can initiate a decrease in the strong grid free space and influence the extraction yield.

The extraction of pyrethrins using supercritical CO

2 has been previously studied by other authors. Kiriamiti et al. [

5], evaluated the effects of 7, 10 and 25 MPa pressure levels and temperatures of 20 or 40 °C on the extraction yield. They found that, at 40 °C, the amount of pyrethrin obtained remained invariable regardless of the pressure level, as long as it was above 10 MPa. They concluded that this was due to the poor solubility of pyrethrin in the dense supercritical CO

2 that resulted from high pressure levels [

5]. On the other hand, Baldino et al. [

7], reported that, at 40 °C, the best extraction yields of Pyrethrin I and Pyrethrin II were observed at 8 MPa (140 ± 18 mg and 55 ± 9 mg per 100 g of sample) and they reported in their publication that this could be attributed to the low density and high diffusivity of the supercritical carbon dioxide at low pressure levels. As the extraction pressure was increased from 8 to 14 MPa, the density of the supercritical carbon dioxide increased from 0.337 to 0.768 g mL

−1 and, as a result, the yields from the supercritical extraction of pyrethrins were significantly reduced. However, such a reduction in the extraction yields was less significant when the pressure was increased from 14 to 25 MPa, since, in that case, the density of supercritical carbon dioxide increased only to a lesser extent (0.768–0.885 g mL

−1) [

7].

Regarding the supercritical impregnation of the natural extract of pyrethrins, the chromatographic analysis is indicative of the high concentration of pyrethrins in the extract. Regarding the effect of the operating conditions, the results allow us to conclude that, at 10 MPa, the equilibrium of the impregnation process is favored towards the polymer and not towards the supercritical phase. The result is the increase in the load of pyrethrin into the polymer. It is important to note that, in the case of the natural extract obtained by supercritical extraction, the lower yield when increasing the pressure up to 40 MPa is much more pronounced than the result obtained in a previous work with a commercial extract [

20]. Moreover, the results obtained under the same pressure, but using different extracts reveals a lower efficiency of the impregnation process when using the extract obtained by supercritical extraction in comparison with the results obtained a commercial extract. This different behavior could be attributed to the fact that the commercial extract, obtained by conventional techniques [

20], and the natural extract, obtained by supercritical extraction, have different compositions. It should be noted that the supercritical extraction process is a more selective process and that, therefore, the purity level of the product obtained will be greater than that of the commercial extract. These results show a different behavior during the impregnation process that achieves poorer impregnation loadings when operating under 40 MPa. Under this pressure level, the natural extract will exhibit a different solubility in supercritical carbon dioxide than the commercial extract, that shifts towards the solvent phase and favors the decrease in the amount of the extract in the polymer. The fact that the natural extract had been obtained at 10 MPa, means that, when performing the impregnation procedure under 40 MPa, the solubility of the substances increases significantly, to the detriment of the impregnation efficiency. It seems obvious from the above that if the impregnation loadings obtained under 40 MPa were to be increased, the extract that had been obtained under the same pressure (40 MPa) should be used, so that the extracted substances would have adequate solubility in carbon dioxide under the operating pressure of the impregnation process.

Pajnick et al. [

18,

19], analyzed the impregnation of a commercial extract of pyrethrin in cotton, polypropylene, polyamide and cellulose acetate fabric. These authors performed the study on fibers working at a maximum pressure of 20 MPa. The conclusions of these authors indicate that a better performance of the impregnation process is obtained at the highest pressure studied.

5. Conclusions

Supercritical carbon dioxide has been proven to be an effective technique for the extraction of pyrethrins from chrysanthemum flowers. When comparing the extraction yields obtained from the different chrysanthemum flowers, similar results were registered under the two sets of conditions analyzed, even if at lower pressure all of the varieties of chrysanthemum provided their best results. On the other hand, although no significant differences were observed between extraction yields obtained from the different varieties in this study, greater yields were obtained from white chrysanthemums (Atlantis). Regarding the range of pressures and temperatures analyzed, the most effective extraction conditions were registered under 10 MPa pressure and at a temperature of 35 °C.

When comparing the impregnation efficiency of PP with the commercial pyrethrin extract against its impregnation with the extract obtained by supercritical extraction, similar behaviors were observed. Thus, in both cases, larger impregnation loadings were obtained when operating at 10 MPa instead of 40 MPa. Nevertheless, the impregnation loadings registered for the extract obtained by supercritical technology, in relation to the impregnation of the commercial extract, were significantly lower. This behavior could be attributed to the differences in the composition of the two extracts and to their different solubilities in supercritical carbon dioxide. These results show the feasibility of supercritical technology in the extraction and subsequent impregnation of pyrethrin extracts in the generation of bioactive plastics for application in protected agriculture.