Fuel Properties of Torrefied Pellets from Maize Residues and Cocopeat Byproducts

Abstract

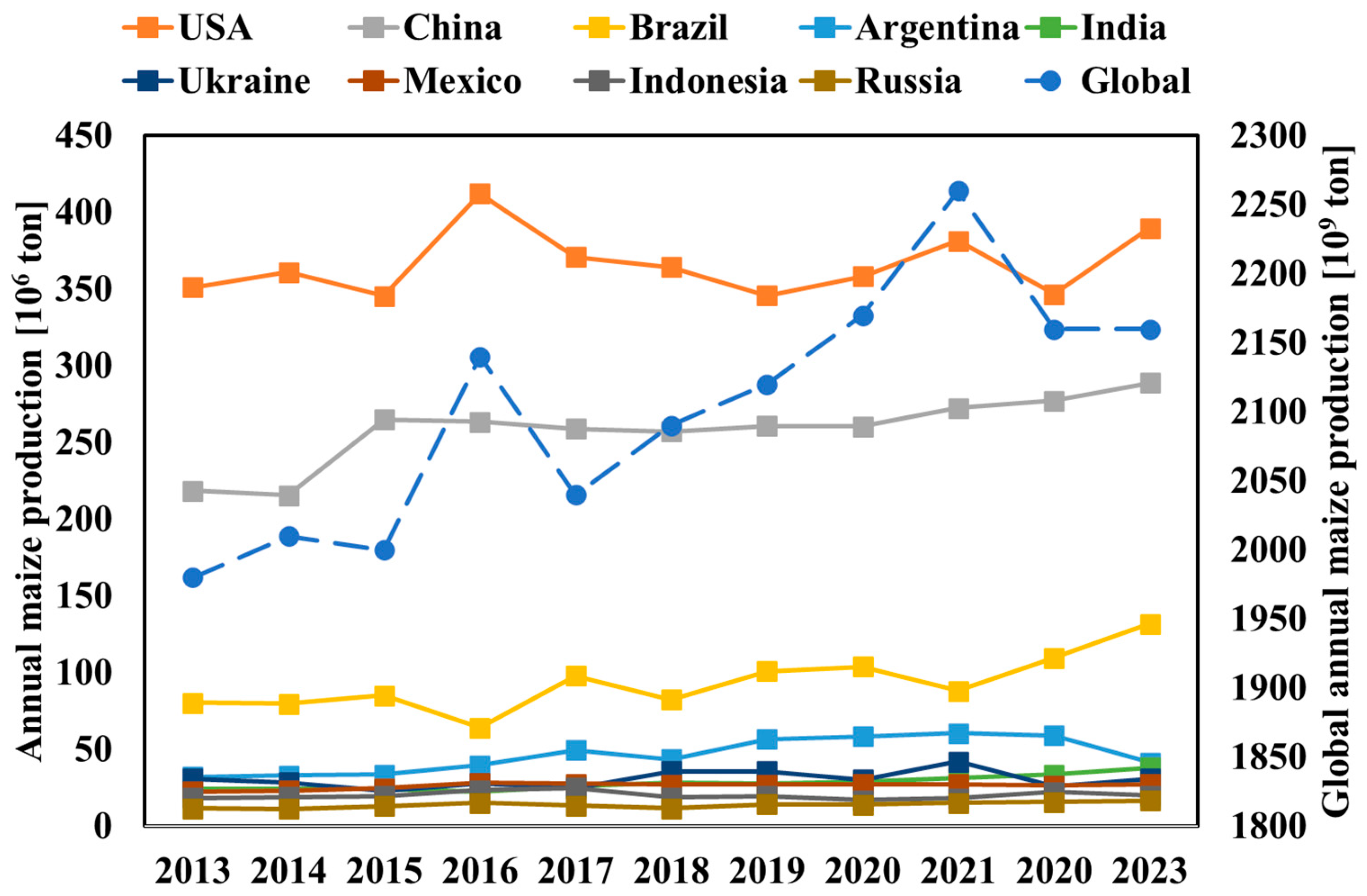

1. Introduction

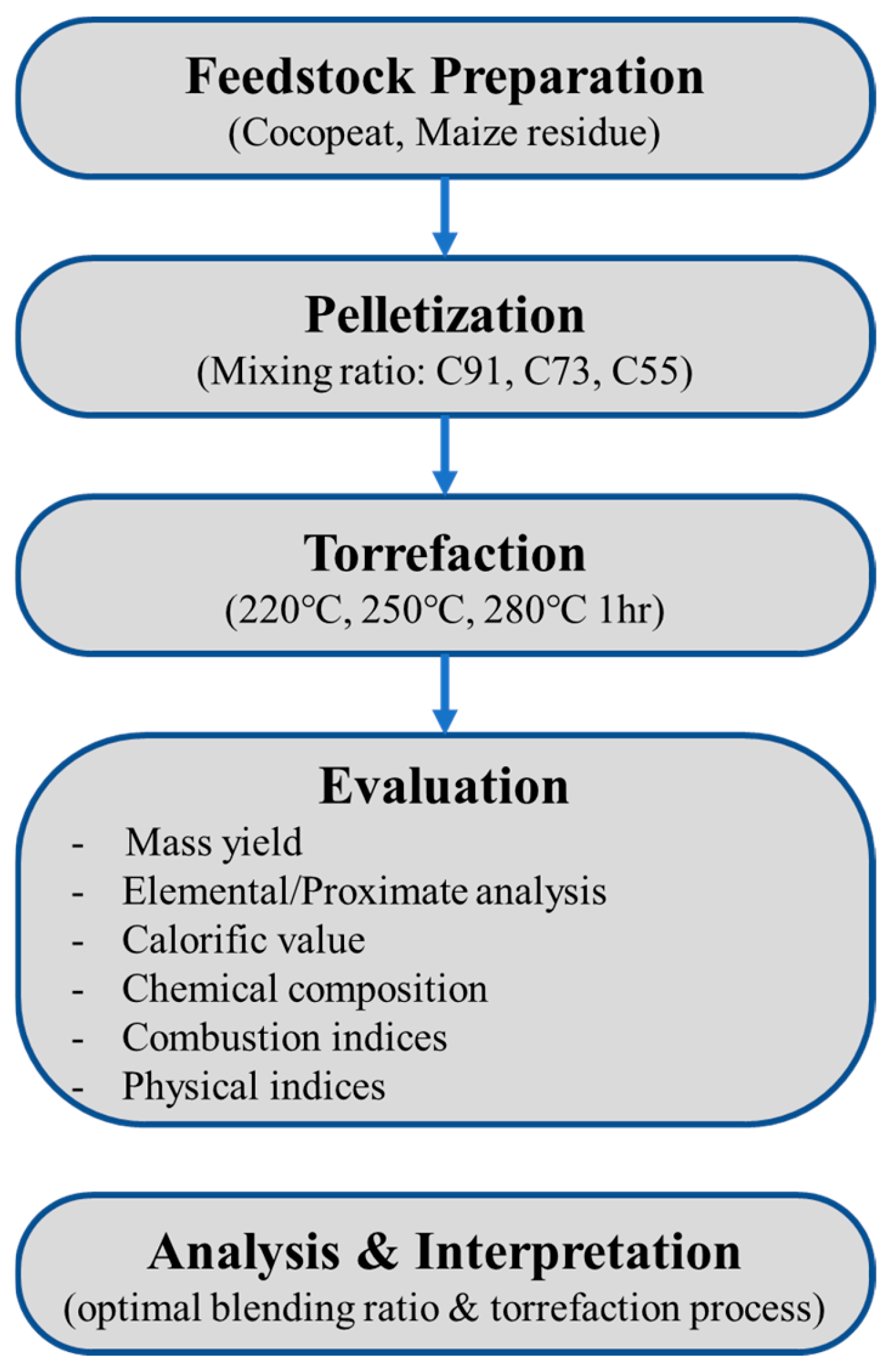

2. Materials and Methods

2.1. Pelletisation Process

2.2. Torrefaction Process

2.3. Fuel Characteristics Evaluation

2.3.1. Elemental Composition Changes

2.3.2. Proximate Analysis Changes

2.3.3. Chemical Composition Changes

2.3.4. Calorific Value and Energy Yield Changes

2.3.5. Combustion Indices

2.3.6. Physical Indices

3. Results and Discussion

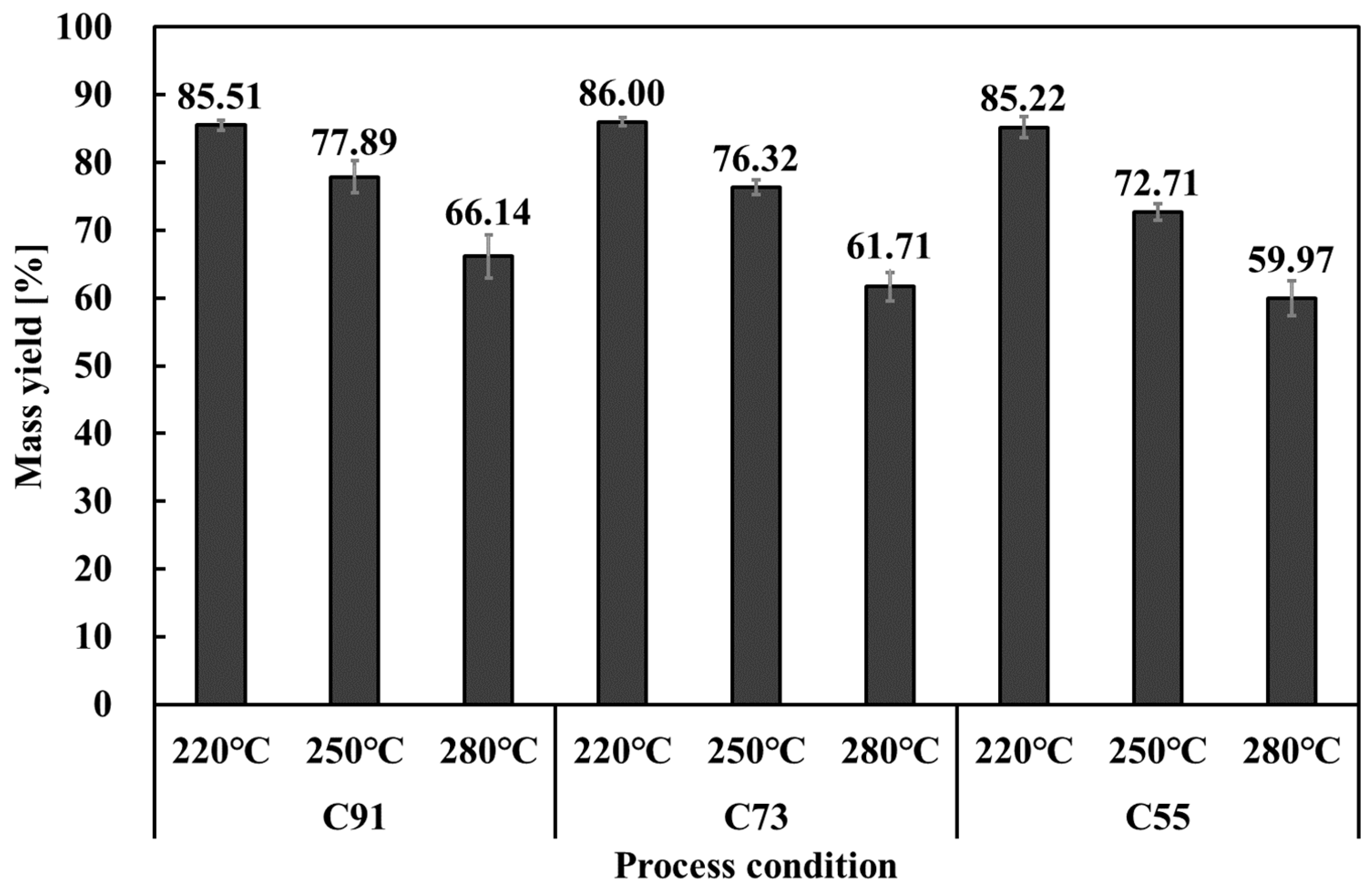

3.1. Effect of Torrefaction Temperature on Mass Yield

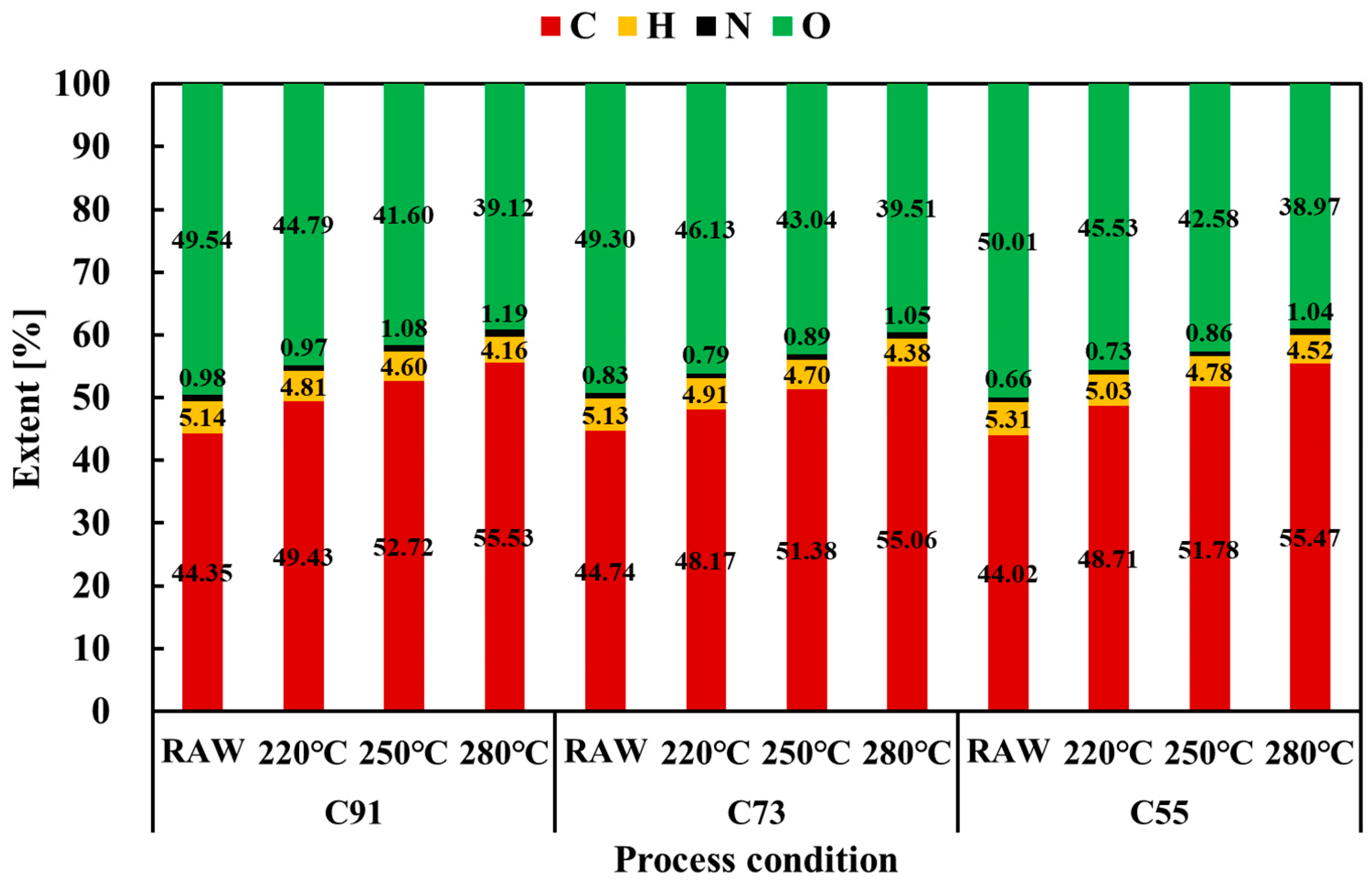

3.2. Dependence of Elemental Composition on Biomass Blend Ratio

3.3. Effect of Blending Ratio and Torrefaction Severity on Fuel Ratio

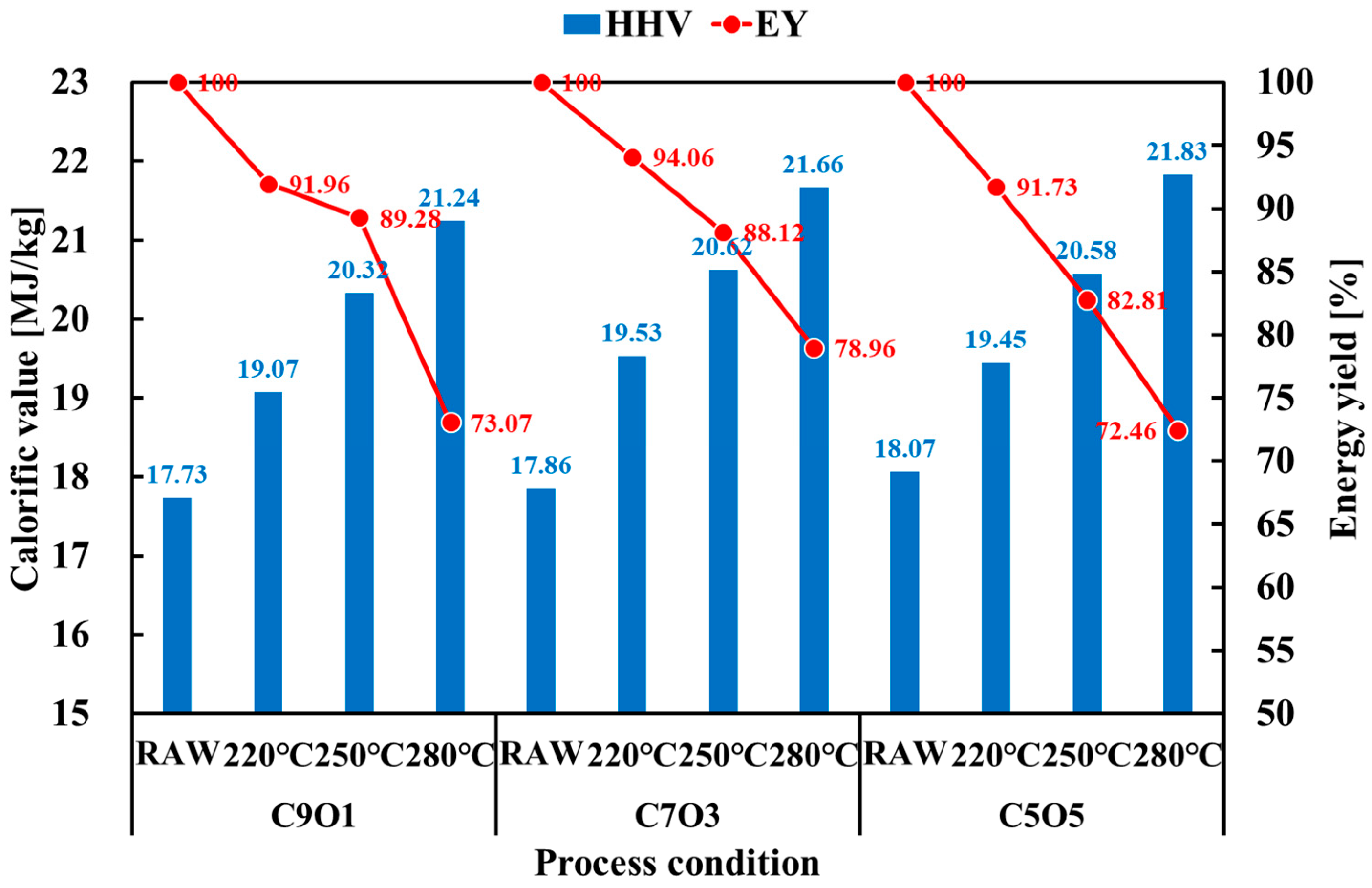

3.4. Effect of Torrefaction Conditions on Energy Yield

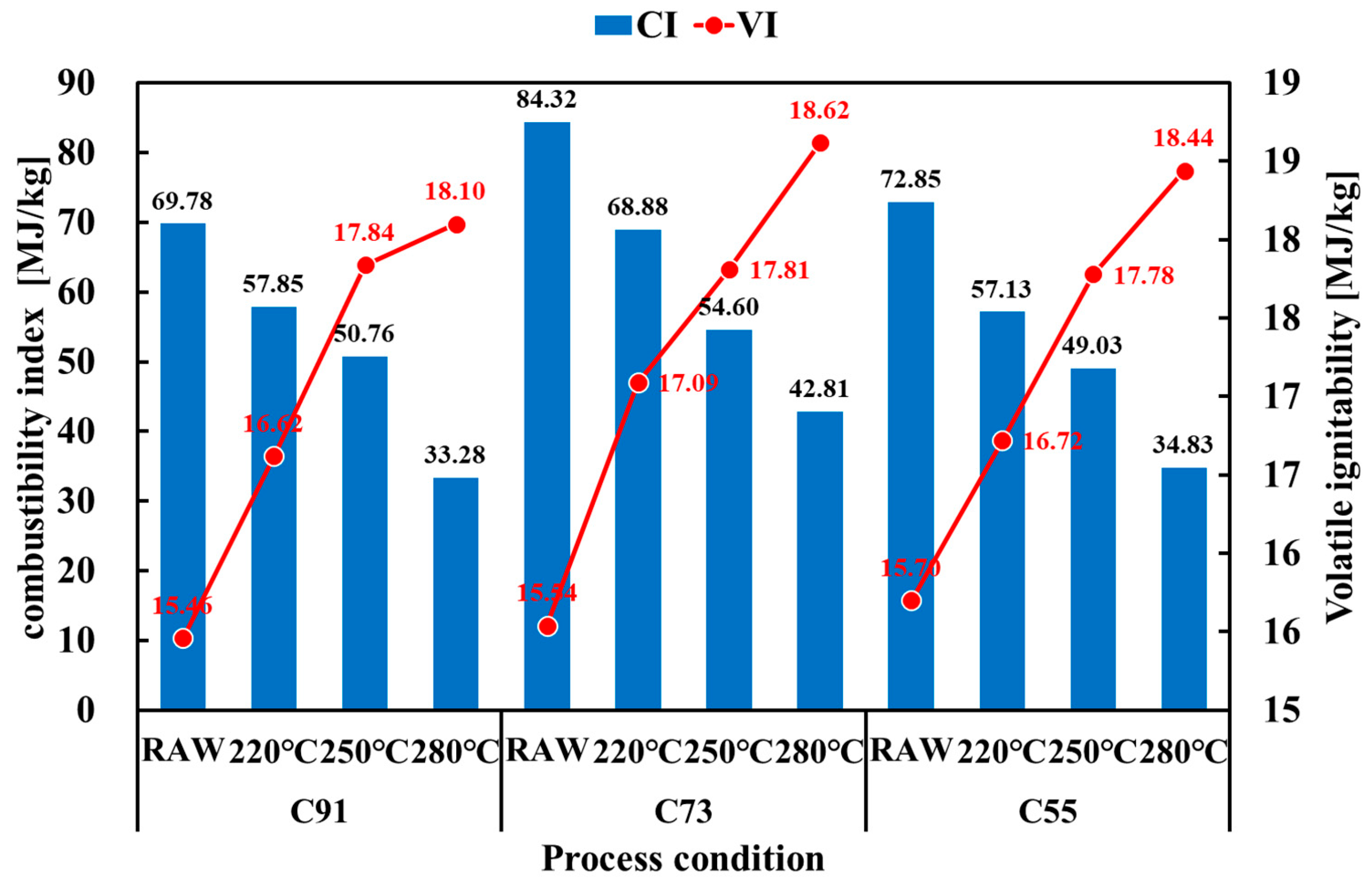

3.5. Influence of Torrefaction Temperature on Combustion Properties

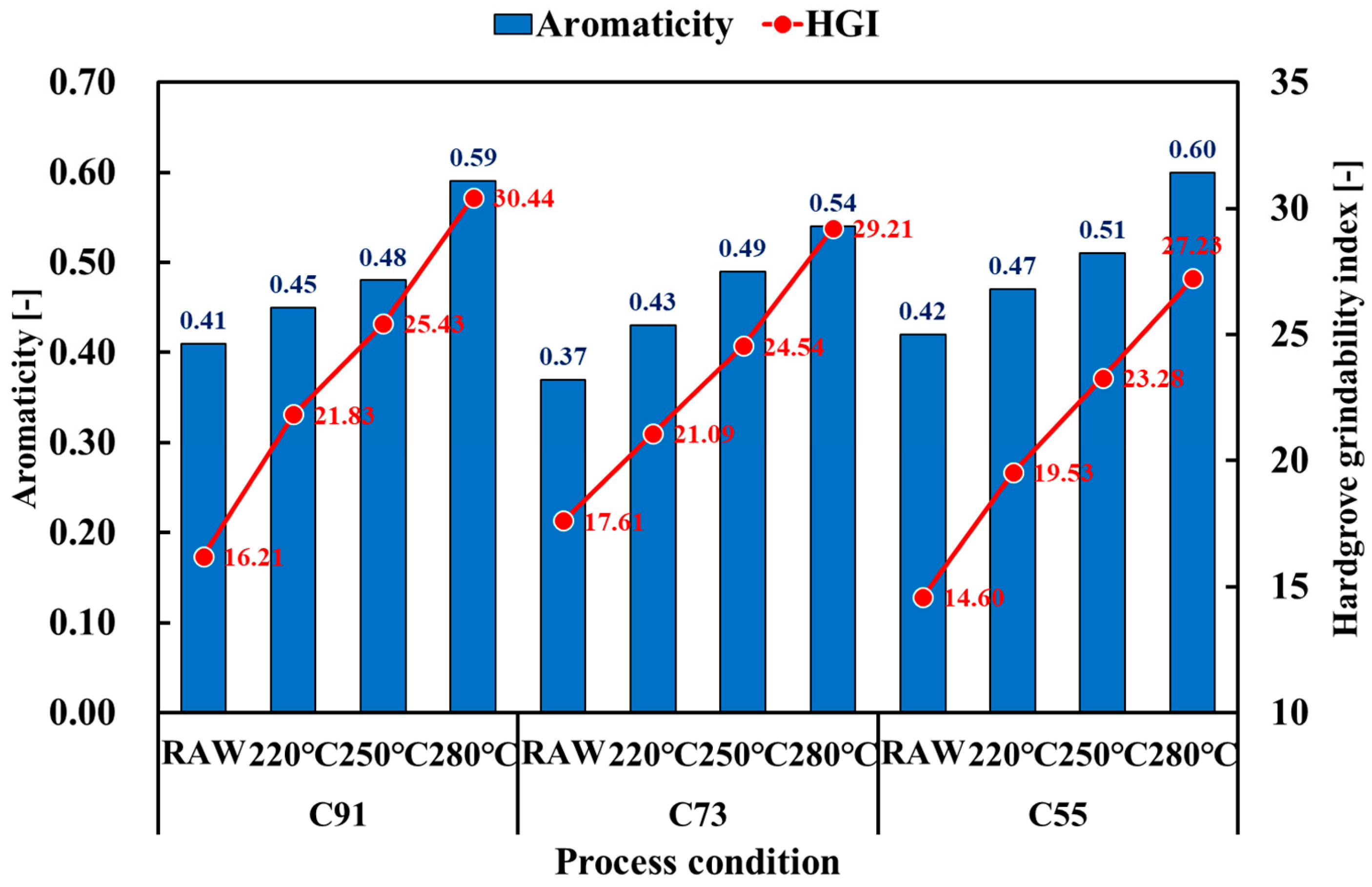

3.6. Influence of Torrefaction Temperature on Physical Indices

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MY | Mass yield |

| EY | Energy yield |

| DC | Decarbonisation |

| DH | Dehydrogenation |

| DO | Deoxygenation |

| FR | Fuel ratio |

| VM | Volatile matter |

| FC | Fixed carbon |

| HGI | Hardgrove Grindability Index |

References

- Victoria, B. The U.N. Warns ‘an Era of Global Boiling’ Has Started. What Does That Mean? The Washington Post, 29 July 2023. Available online: https://www.washingtonpost.com/climate-environment/2023/07/29/un-what-is-global-boiling/ (accessed on 4 August 2024).

- Akhtar, J.; Imran, M.; Ali, A.M.; Nawaz, Z.; Muhammad, A.; Butt, R.K.; Jillani, M.S.; Naeem, H.A. Torrefaction and Thermochemical Properties of Agriculture Residues. Energies 2021, 14, 4218. [Google Scholar] [CrossRef]

- Cardoen, D.; Joshi, P.; Diels, L.; Sarma, P.M.; Pant, D. Agriculture Biomass in India: Part 1. Estimation and Characterization. Resour. Conserv. Recycl. 2015, 102, 39–48. [Google Scholar] [CrossRef]

- Raj, T.; Kapoor, M.; Gaur, R.; Christopher, J.; Lamba, B.; Tuli, D.K.; Kumar, R. Physical and Chemical Characterization of Various Indian Agriculture Residues for Biofuels Production. Energy Fuels 2015, 29, 3111–3118. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.J.; Oh, K.C.; Paudel, P.P.; Kim, S.Y.; Kim, H.E.; Shin, J.Y.; Kim, D.H. Confirmation of the Feasibility of Using Agrobyproduct Biochar in Thermal Power Plants through Oxygen Pyrolysis and Conventional Pyrolysis. J. Anal. Appl. Pyrolysis 2024, 183, 106791. [Google Scholar] [CrossRef]

- Hu, J.; Song, Y.; Liu, J.; Evrendilek, F.; Buyukada, M.; Yan, Y.; Li, L. Combustions of Torrefaction-Pretreated Bamboo Forest Residues: Physicochemical Properties, Evolved Gases, and Kinetic Mechanisms. Bioresour. Technol. 2020, 304, 122960. [Google Scholar] [CrossRef]

- Chen, D.; Chen, F.; Cen, K.; Cao, X.; Zhang, J.; Zhou, J. Upgrading Rice Husk via Oxidative Torrefaction: Characterization of Solid, Liquid, Gaseous Products and a Comparison with Non-Oxidative Torrefaction. Fuel 2020, 275, 117936. [Google Scholar] [CrossRef]

- Grand View Research Hydroponics Market Size, Share & Trends Analysis Report by Type, by Crop Type (Tomatoes, Lettuce, Peppers, Cucumbers, Herbs, and Others), by Crop Area, by Region, and Segment Forecasts, 2024–2030. Available online: https://www.grandviewresearch.com/industry-analysis/hydroponics-market# (accessed on 19 March 2025).

- Business Research Insight Coco Peat Market Size, Share, Growth, and Industry Analysis, by Type (Brown Fibre, White Fibre, Others) Market Segment by Application (Packaging, Bedding and Flooring), and Regional Insight and Forecast to 2032. Available online: https://www.businessresearchinsights.com/market-reports/coco-peat-market-118120 (accessed on 19 March 2025).

- Ranum, P.; Peña-Rosas, J.P.; Garcia-Casal, M.N. Global Maize Production, Utilization, and Consumption. Ann. N. Y. Acad. Sci. 2014, 1312, 105–112. [Google Scholar] [CrossRef]

- Tridge. Maize Production and Major Producing Countries. Available online: https://www.tridge.com/ko/intelligences/corn (accessed on 23 September 2025).

- Erenstein, O.; Jaleta, M.; Sonder, K.; Mottaleb, K.; Prasanna, B.M. Global Maize Production, Consumption and Trade: Trends and R&D Implications. Food Secur. 2022, 14, 1295–1319. [Google Scholar] [CrossRef]

- Urban Cordeiro, E.; Samaddar, A.; Munshi, S.; Ajay, A.; Rossiter, D.G.; Sohane, R.K.; Malik, R.; Craufurd, P.; Pingali, P.; McDonald, A.J. Transitions to Crop Residue Burning Have Multiple Antecedents in Eastern India. Agron. Sustain. Dev. 2024, 44, 59. [Google Scholar] [CrossRef]

- Korczyk-Szabó, J.; Macák, M.; Jarecki, W.; Sterczyńska, M.; Jug, D.; Pużyńska, K.; Hromadová, Ľ.; Habán, M. Influence of Crop Residue Management on Maize Production Potential. Agronomy 2024, 14, 2610. [Google Scholar] [CrossRef]

- Ingwersen, J.; Poyda, A.; Kremer, P.; Streck, T. Harvest Residues: A Relevant Term in the Carbon Balance of Croplands? Agric. For. Meteorol. 2024, 349, 109935. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.J.; Oh, K.C.; Cho, L.; Kim, M.J.; Jeong, I.S.; Lee, C.G.; Kim, D.H. Investigation of Agro-Byproduct Pellet Properties and Improvement in Pellet Quality through Mixing. Energy 2020, 190, 116380. [Google Scholar] [CrossRef]

- Kaewtrakulchai, N.; Wongrerkdee, S.; Chalermsinsuwan, B.; Samsalee, N.; Huang, C.-W.; Manatura, K. Hydrophobicity and Performance Analysis of Beverage and Agricultural Waste Torrefaction for High-Grade Bio-Circular Solid Fuel. Carbon Resour. Convers. 2025, 8, 100243. [Google Scholar] [CrossRef]

- Kumar, P.; Subbarao, P.M.V.; Kala, L.; Vijay, V.K. Influence of Physical, Mechanical, and Thermal Properties of Biomass Pellets from Agriculture Residue: Pearl Millet Cob and Mix. Bioresour. Technol. Rep. 2022, 20, 101278. [Google Scholar] [CrossRef]

- Stulpinaite, U.; Tilvikiene, V.; Zvicevicius, E. Co-Pelletization of Hemp Residues and Agricultural Biomass: Effect on Pellet Quality and Stability. Energies 2023, 16, 5900. [Google Scholar] [CrossRef]

- Niedziółka, I.; Szpryngiel, M.; Kachel-Jakubowska, M.; Kraszkiewicz, A.; Zawiślak, K.; Sobczak, P.; Nadulski, R. Assessment of the Energetic and Mechanical Properties of Pellets Produced from Agricultural Biomass. Renew. Energy 2015, 76, 312–317. [Google Scholar] [CrossRef]

- Wan Ahmad, W.F.H.; Nagappan, Y. Moisture Retaining Test of Biochar, Coco Coir Peat, Palm Kernel Oil Cake and Charcoal Dust Mixtures for Grounding System Purposes. In Proceedings of the 2024 IEEE Sustainable Power and Energy Conference (iSPEC), Putrajaya, Malaysia, 24 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 445–450. [Google Scholar]

- Borres, E.C.; Virginia Mora, L.B. Evaluation and Analysis of Coffee Husk and Coco Peat Briquettes as Biomass Fuel. Eur. Online J. Nat. Soc. Sci. 2022, 11, 604. [Google Scholar]

- Dinesha, P.; Kumar, S.; Rosen, M.A. Biomass Briquettes as an Alternative Fuel: A Comprehensive Review. Energy Technol. 2019, 7, 1801011. [Google Scholar] [CrossRef]

- Kaliyan, N.; Vance Morey, R. Factors Affecting Strength and Durability of Densified Biomass Products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Agar, D.A.; Rudolfsson, M.; Kalén, G.; Campargue, M.; Da Silva Perez, D.; Larsson, S.H. A Systematic Study of Ring-Die Pellet Production from Forest and Agricultural Biomass. Fuel Process. Technol. 2018, 180, 47–55. [Google Scholar] [CrossRef]

- Duca, D.; Maceratesi, V.; Fabrizi, S.; Toscano, G. Valorising Agricultural Residues through Pelletisation. Processes 2022, 10, 232. [Google Scholar] [CrossRef]

- Shuma, R.; Madyira, D.M. Production of loose biomass briquettes from agricultural and forestry residues. In Proceedings of the Procedia Manufacturing, Nairobi, Kenya, 3–5 August 2017; Elsevier B.V.: Amsterdam, The Netherlands, 2017; Volume 7, pp. 98–105. [Google Scholar]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory, 2nd ed.; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Li, H.; Chen, J.; Zhang, W.; Zhan, H.; He, C.; Yang, Z.; Peng, H.; Leng, L. Machine-Learning-Aided Thermochemical Treatment of Biomass: A Review. Biofuel Res. J. 2023, 10, 1786–1809. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. Torrefaction of Wood. Part 2. Analysis of Products. J. Anal. Appl. Pyrolysis 2006, 77, 35–40. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. Torrefaction of Wood. Part 1. Weight Loss Kinetics. J. Anal. Appl. Pyrolysis 2006, 77, 28–34. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Jones, J.M.; Shield, I.; Williams, P.T. Torrefaction of Reed Canary Grass, Wheat Straw and Willow to Enhance Solid Fuel Qualities and Combustion Properties. Fuel 2008, 87, 844–856. [Google Scholar] [CrossRef]

- Basu, P.; Kulshreshtha, A.; Acharya, B. An Index for Quantifying the Degree of Torrefaction. Bioresources 2017, 12, 1749. [Google Scholar] [CrossRef]

- Bach, Q.V.; Skreiberg, O. Upgrading Biomass Fuels via Wet Torrefaction: A Review and Comparison with Dry Torrefaction. Renew. Sustain. Energy Rev. 2016, 54, 665–677. [Google Scholar] [CrossRef]

- Joshi, Y.; Di Marcello, M.; De Jong, W. Torrefaction: Mechanistic Study of Constituent Transformations in Herbaceous Biomass. J. Anal. Appl. Pyrolysis 2015, 115, 353–361. [Google Scholar] [CrossRef]

- Zhang, Z.; Duan, H.; Zhang, Y.; Guo, X.; Yu, X.; Zhang, X.; Rahman, M.M.; Cai, J. Investigation of Kinetic Compensation Effect in Lignocellulosic Biomass Torrefaction: Kinetic and Thermodynamic Analyses. Energy 2020, 207, 118290. [Google Scholar] [CrossRef]

- Kim, S.J.; Park, S.; Cho, L.; Oh, K.; Jeon, Y.G.; Lee, C.; Kim, D. Evaluation of Fuel Characteristics of Kenaf for Energy Source Utilization and Fuel Quality Improvement through Torrefaction. J. Agric. Life Sci. 2022, 56, 119–127. [Google Scholar] [CrossRef]

- Sui, H.; Chen, J.; Cheng, W.; Zhu, Y.; Zhang, W.; Hu, J.; Jiang, H.; Shao, J.; Chen, H. Effect of Oxidative Torrefaction on Fuel and Pelletizing Properties of Agricultural Biomass in Comparison with Non-Oxidative Torrefaction. Renew. Energy 2024, 226, 120423. [Google Scholar] [CrossRef]

- Kostyniuk, A.; Likozar, B. Dry Torrefaction of Biomass Waste into High-Energy Biochar and Selective Formation of Levoglucosenone and 1,4:3,6-Dianhydro-α-D-Glucopyranose. Renew. Energy 2025, 252, 123547. [Google Scholar] [CrossRef]

- Chen, W.H.; Lin, B.J.; Lin, Y.Y.; Chu, Y.S.; Ubando, A.T.; Show, P.L.; Ong, H.C.; Chang, J.S.; Ho, S.H.; Culaba, A.B.; et al. Progress in Biomass Torrefaction: Principles, Applications and Challenges. Prog. Energy Combust. Sci. 2021, 82, 100887. [Google Scholar] [CrossRef]

- Chen, D.; Cen, K.; Cao, X.; Li, Y.; Zhang, Y.; Ma, H. Restudy on Torrefaction of Corn Stalk from the Point of View of Deoxygenation and Decarbonization. J. Anal. Appl. Pyrolysis 2018, 135, 85–93. [Google Scholar] [CrossRef]

- ASTM D1762-84; Standard Test Method for Chemical Analysis of Wood Charcoal. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- Singh, S.; Chakraborty, J.P.; Mondal, M.K. Torrefaction of Woody Biomass (Acacia Nilotica): Investigation of Fuel and Flow Properties to Study Its Suitability as a Good Quality Solid Fuel. Renew. Energy 2020, 153, 711–724. [Google Scholar] [CrossRef]

- Park, S.-W.; Jang, C.-H. Carbonization of Mechanically Pre-Treated Waste: Investigation of Fuel Characteristics of The Products. J. Korea Soc. Waste Manag. 2013, 30, 383–389. [Google Scholar] [CrossRef]

- Park, S.-W.; Yang, J.-K.; Baek, K.-R. Fuel Ratio and Combustion Characteristics of Torrefied Biomass. J. Korea Soc. Waste Manag. 2013, 30, 376–382. [Google Scholar] [CrossRef]

- Park, S.Y.; Oh, K.C.; Kim, S.J.; Cho, L.H.; Jeon, Y.K.; Kim, D.H. Development of a Biomass Component Prediction Model Based on Elemental and Proximate Analyses. Energies 2023, 16, 5341. [Google Scholar] [CrossRef]

- Singh, K.P.; Kakati, M.C. Comprehensive Models for Predicting Aromaticity of Coals. Chem. Eng. Commun. 2003, 190, 1335–1347. [Google Scholar] [CrossRef]

- Wang, T.; Camps-Arbestain, M.; Hedley, M. Predicting C Aromaticity of Biochars Based on Their Elemental Composition. Org. Geochem. 2013, 62, 1–6. [Google Scholar] [CrossRef]

- Venkoba Rao, B.; Gopalakrishna, S.J. Hardgrove Grindability Index Prediction Using Support Vector Regression. Int. J. Miner. Process. 2009, 91, 55–59. [Google Scholar] [CrossRef]

- Khalsa, J.H.A.; Leistner, D.; Weller, N.; Darvell, L.I.; Dooley, B. Torrefied Biomass Pellets—Comparing Grindability in Different Laboratory Mills. Energies 2016, 9, 794. [Google Scholar] [CrossRef]

- Głód, K.; Lasek, J.A.; Supernok, K.; Pawłowski, P.; Fryza, R.; Zuwała, J. Torrefaction as a Way to Increase the Waste Energy Potential. Energy 2023, 285, 128606. [Google Scholar] [CrossRef]

- Williams, O.; Eastwick, C.; Kingman, S.; Giddings, D.; Lormor, S.; Lester, E. Investigation into the Applicability of Bond Work Index (BWI) and Hardgrove Grindability Index (HGI) Tests for Several Biomasses Compared to Colombian La Loma Coal. Fuel 2015, 158, 379–387. [Google Scholar] [CrossRef]

- Chelgani, S.C.; Hower, J.C.; Jorjani, E.; Mesroghli, S.; Bagherieh, A.H. Prediction of Coal Grindability Based on Petrography, Proximate and Ultimate Analysis Using Multiple Regression and Artificial Neural Network Models. Fuel Process. Technol. 2008, 89, 13–20. [Google Scholar] [CrossRef]

- Adeleke, A.A.; Odusote, J.K.; Ikubanni, P.P.; Lasode, O.A.; Malathi, M.; Paswan, D. The Ignitability, Fuel Ratio and Ash Fusion Temperatures of Torrefied Woody Biomass. Heliyon 2020, 6, e03582. [Google Scholar] [CrossRef]

- Ivanovski, M.; Petrovič, A.; Goričanec, D.; Urbancl, D.; Simonič, M. Exploring the Properties of the Torrefaction Process and Its Prospective in Treating Lignocellulosic Material. Energies 2023, 16, 6521. [Google Scholar] [CrossRef]

- Conag, A.T.; Villahermosa, J.E.R.; Cabatingan, L.K.; Go, A.W. Energy Densification of Sugarcane Bagasse through Torrefaction under Minimized Oxidative Atmosphere. J. Environ. Chem. Eng. 2017, 5, 5411–5419. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Jones, J.M.; Williams, A.; Waldron, D.J. An Investigation of the Grindability of Two Torrefied Energy Crops. Fuel 2010, 89, 3911–3918. [Google Scholar] [CrossRef]

- Tymoszuk, M.; Wnorowska, J.; Kalisz, S. Grindability Features of Torrefied Biomass. Energies 2025, 18, 1824. [Google Scholar] [CrossRef]

| Mixing Ratio (wt%) | Elemental Analysis (wt%, daf) | Proximate Analysis (wt%, d) | Chemical Composition Ratio (wt%, d) * | Calorific Value [MJ/kg] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cocopeat | Maize | C | H | N | S | O | VM | FC | Ash | Cell | Hemi | Lig | ||

| Cocopeat | 100 | 0 | 41.63 | 5.18 | 1.14 | 0.00 | 52.05 | 72.88 | 19.21 | 7.90 | 43.70 | 26.73 | 31.63 | 18.35 |

| C91 | 90 | 10 | 44.35 | 5.14 | 0.98 | 0.00 | 49.54 | 73.20 | 18.99 | 7.81 | 33.89 | 27.54 | 34.53 | 17.73 |

| C73 | 70 | 30 | 44.74 | 5.13 | 0.83 | 0.00 | 49.30 | 77.57 | 17.17 | 5.25 | 33.44 | 27.33 | 34.75 | 17.86 |

| C55 | 50 | 50 | 44.02 | 5.31 | 0.66 | 0.00 | 50.01 | 74.23 | 18.97 | 6.80 | 30.94 | 28.15 | 32.79 | 18.07 |

| Maize | 0 | 100 | 44.06 | 5.40 | 1.21 | 0.00 | 49.33 | 76.14 | 20.06 | 3.80 | 25.39 | 26.01 | 31.95 | 18.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.; Kim, S.Y.; Oh, K.C.; Kim, S.J.; Paudel, P.P.; Park, D.S.; Kang, K.S.; Ryu, S.H.; Kim, D.H. Fuel Properties of Torrefied Pellets from Maize Residues and Cocopeat Byproducts. Biomass 2025, 5, 59. https://doi.org/10.3390/biomass5040059

Park S, Kim SY, Oh KC, Kim SJ, Paudel PP, Park DS, Kang KS, Ryu SH, Kim DH. Fuel Properties of Torrefied Pellets from Maize Residues and Cocopeat Byproducts. Biomass. 2025; 5(4):59. https://doi.org/10.3390/biomass5040059

Chicago/Turabian StylePark, Sunyong, Seon Yeop Kim, Kwang Cheol Oh, Seok Jun Kim, Padam Prasad Paudel, Do Su Park, Kyeong Sik Kang, Sun Hwa Ryu, and Dae Hyun Kim. 2025. "Fuel Properties of Torrefied Pellets from Maize Residues and Cocopeat Byproducts" Biomass 5, no. 4: 59. https://doi.org/10.3390/biomass5040059

APA StylePark, S., Kim, S. Y., Oh, K. C., Kim, S. J., Paudel, P. P., Park, D. S., Kang, K. S., Ryu, S. H., & Kim, D. H. (2025). Fuel Properties of Torrefied Pellets from Maize Residues and Cocopeat Byproducts. Biomass, 5(4), 59. https://doi.org/10.3390/biomass5040059