Techno-Economic Analysis of Hemp Production, Logistics and Processing in the U.S

Abstract

1. Introduction

2. Materials and Methods

2.1. System Definition

2.2. Discrete Production Processes

2.2.1. Field Production

- Seeding: Seeding was considered to be completed using a 4.5 m drill planter for both grain and fiber hemp. The inter-row spacing for grain hemp was considered to be 0.4 m [25], and for fiber hemp it was considered to be 0.3 m [12], based on agronomic practices. Due to the larger inter-row spacing for grain hemp, the planting density was lower per acre than that for fiber hemp (Table 1). The seeding rate was estimated using the optimal planting density, germination rate, and 1000 kernel weight of hemp seeds (Table 1). The field productivity of the seeding equipment was estimated using the seeding width, speed, and field efficiency (Table 2). The field efficiency used was based on literature values and is similar to the ASABE standard [30], which is widely used for making machinery management decisions for farm operations in the U.S. Since field conditions vary greatly due to variations in topography, it is important to use a more generic field efficiency that can be applicable to a wider geographic region as the same equipment will function differently on different fields. This was considered for all operations and is not specific to the seeding operation.

- Fertilization: Dry fertilizers were considered for both grain and fiber hemp production at the recommended rates (Table 1). Urea was used as the source for nitrogen, di-ammonium phosphate (DAP) for phosphorus, and potassium chloride for potassium. Fertilization was considered to be applied using a dry fertilizer spreader with a 0.45 Mg capacity and spreading width of 1.2 m. The productivity of the fertilizer spreader was estimated based on field speed, field efficiency, spreading width, and fertilizer holding capacity (Table 2).

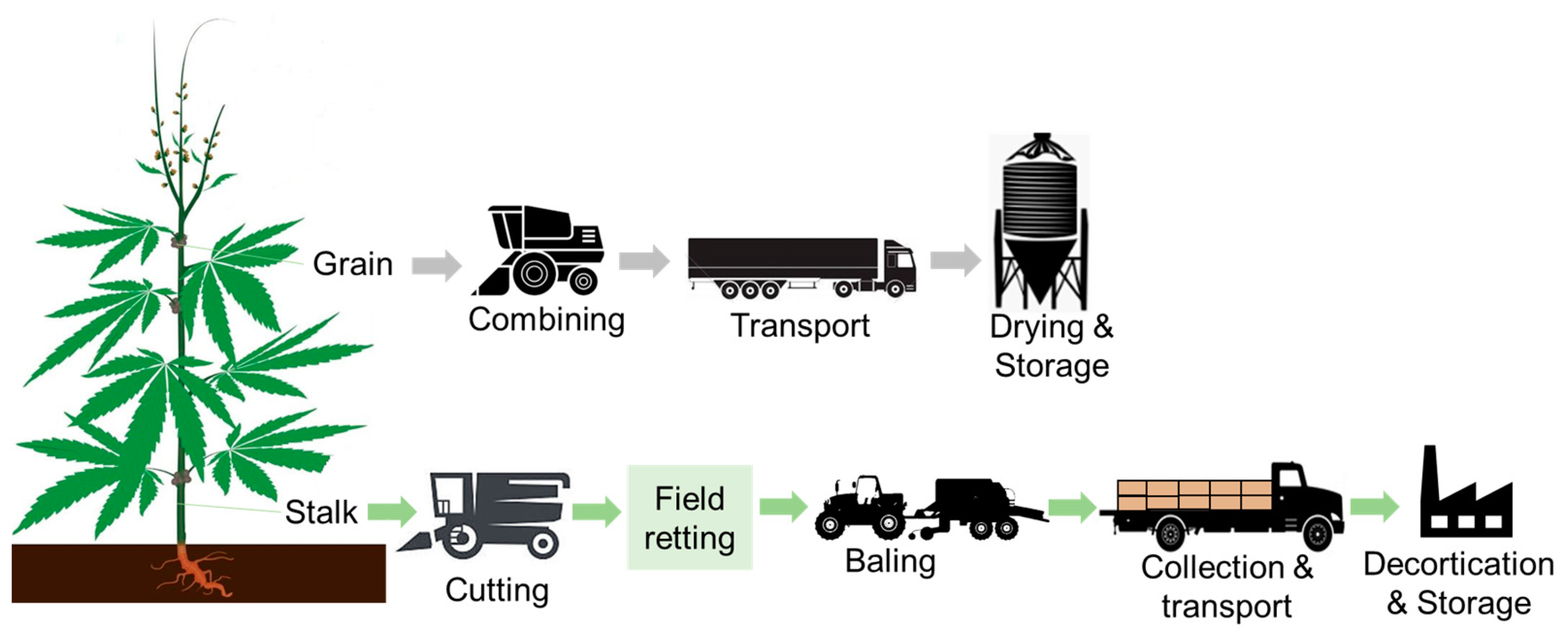

2.2.2. Harvest and Post-Harvest Logistics

- Grain harvest and transport: Combining was considered for harvesting hemp grain, as it is the most common grain harvesting method in the U.S. Due to the small size of the farm, a 2-row plot combine (1.7 m), with a storage capacity of 1.4 m3 and an unloading rate of 58 kg s−1, was considered for harvesting the hemp grain. The productivity of the combine was calculated based on the field speed, working width, and field efficiency. A small grain cart, with a 26.4 m3 storage capacity, was considered for collecting and transporting the hemp grain from the field to the field edge for drying and storage. The speed of the grain cart was considered to be 6.4 km h−1 for collection and transportation. For the transportation distance, the farm was considered to be circular, with the radius used as the transport distance.

- Fiber harvest: Hemp stalk harvesting for fiber was considered to be achieved using a multi-pass system consisting of mowing, windrowing, baling, and collecting and stacking bales at the field edge. Mowing was considered to be performed at a hemp moisture content of 30% for field retting [44], in which hemp is left in the field until the stalk dries to a moisture content of 15% [45]. It was assumed that the hemp fiber yield was 20–30% of the hemp stalk [46]. Thus, the amount of material to be mowed, windrowed, and baled was estimated based on the total hemp stalk yield. Windrowing was considered to be performed after the hemp had field retted for two weeks [45].

2.2.3. Storage and Processing

- Grain: Grain was considered to be stored in a silo at the farm. Since grain was to be harvested at 15% average moisture content (12–20% range) [45] and safe grain storage was at 8% [45], grain drying prior to storage was necessary. The energy required for grain drying was estimated to be 34–56 MJ Mg−1 of grain and was based on the amount of water that needed to be removed to reach 8% moisture. It was assumed that hemp grain drying and storage would be performed using existing systems used for other grains such as corn and soybean.

- Fiber: Hemp stalks require decortication to separate the outer bast fiber from the inner hurd. Decortication and baling of the hemp fibers was considered for the processing of hemp stalks. Processing of hemp fibers was considered to be performed on farm; thus, a small scale decortication system was considered for the analysis [47]. This system also included conveying, cleaning, and sorting of the bast fiber and hurd post-decortication. The decorticating capacity of the system was 454 kg h−1 and its power requirement was 7.5 kW based on a similarly sized decorticating unit [48]. To facilitate the post-process handling and transportation of hemp fiber bales, a stationary compacting unit with a productivity of 4–6 bales h−1 was considered [49]. The bales were considered to be 80–120 kg by weight and their dimensions were 0.8 m × 0.4 m × 0.8 m [49]. The power requirement of the unit was 4 kW [49]. The operating hour requirements of the processing plant were estimated based on the productivity of the processing equipment, which were also used to estimate the total power and labor hour requirements.

2.3. Economic Considerations

- Consumables and labor: The major cost inputs required for this study, excluding the capital cost of equipment, were the land rental cost; the price of consumables including seeds, fertilizers, and fuel; and farm labor wages (Table 3). License fees for growers and processors were not included because this fee would be negligible over time for the farm size and the service life considered in the analysis [50]. For grain, on-farm drying and storage costs were also considered [51] and were assumed to be the same as current commercial grain drying and storage costs (Table 3). The labor requirement for the field operations were estimated to be 1.2 times the actual machinery hours in the field [52]. Fuel use for the different operations was estimated using the rated power required for the operation (Table 2) and a specific fuel consumption coefficient of 0.015 l kW-h−1 (0.044 gal hp-h−1) [53], as well as the total hours used every year.

- Equipment: The costs of the different pieces of equipment were obtained from the manufacturers’ websites (Table 4). The actual purchase price of the equipment was assumed to be 85% of the list price [52]. The annualized cost, salvage value, and annual repair and maintenance cost of the equipment were estimated using equations from ASABE standards [59,60] and factors listed in Table 4 [60]. In addition, other relevant costs, including taxes, housing, insurance rates, and lubrication, were based on the annualized equipment cost and are summarized in Table 4.

- Processing: Processing costs for hemp fiber stalks were estimated based on the purchase price of the equipment and the factors for building the processing facility based on the equipment price, as provided in Table 5. The annual facility-dependent cost was estimated based on the service life of the plant and the interest rate.

2.4. Uncertainty and Sensitivity Analyses

3. Results and Discussion

3.1. Feedstock Production and Fertilizer Requirement

3.2. Machinery, Fuel and Labor Requirements for Field Operations

3.3. Hemp Fiber Stalk Processing Resource Requirements

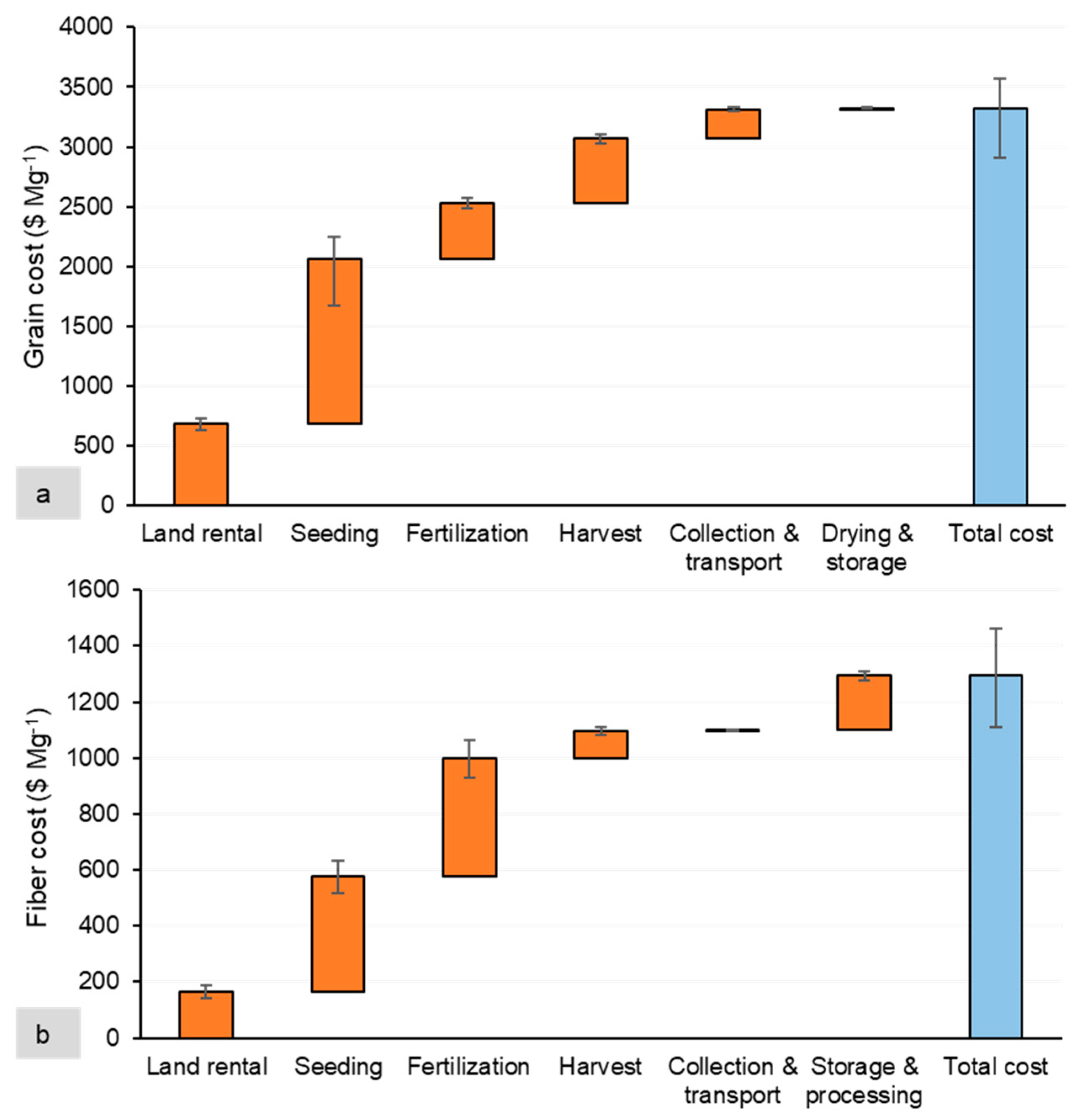

3.4. Hemp Grain and Fiber Production Cost

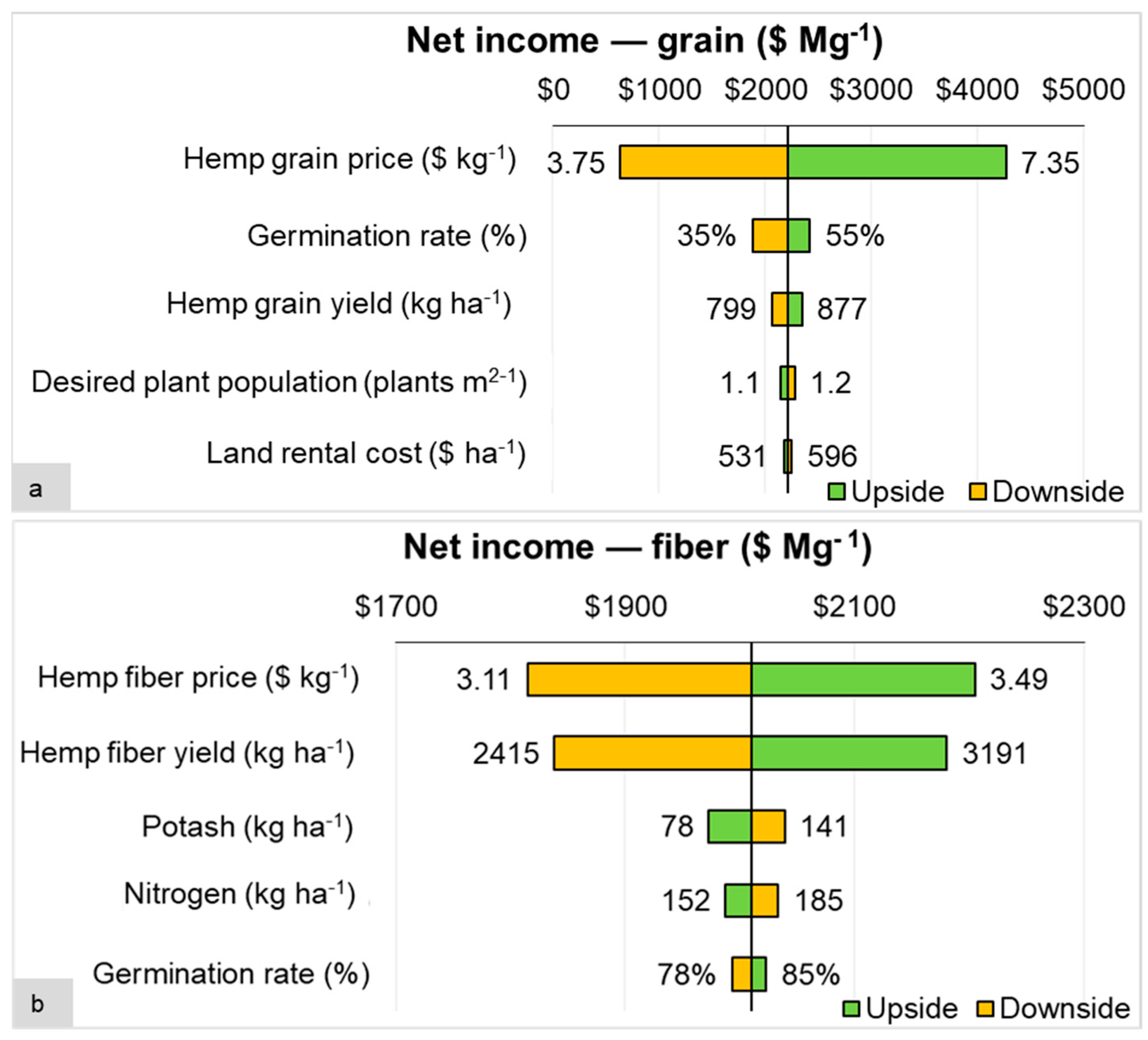

3.5. Income from Hemp Grain and Fiber

3.6. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mark, T.; Shepherd, J.; Olson, D.; Snell, W.; Proper, S.; Thornsbury, S. Economic Viability of Industrial Hemp in the United States: A Review of State Pilot Programs; United States Department of Agriculture: Washington, DC, USA, 2020. Available online: https://www.ers.usda.gov/webdocs/publications/95930/eib-217.pdf (accessed on 19 July 2023).

- Kaur, G.; Kander, R. The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability. Sustainability 2023, 15, 6457. [Google Scholar] [CrossRef]

- Grand View Research. Industrial Hemp Market Size, Share & Trends Analysis Report by Product (Seeds, Fiber, Shivs), by Application (Animal Care, Textiles, Food & Beverages, Construction Materials, Personal Care), by Region, and Segment Forecasts, 2023–2030. 2023. Available online: https://www.grandviewresearch.com/industry-analysis/industrial-hemp-market (accessed on 19 July 2023).

- USDA NASS. National Hemp Report. 2023. Available online: https://downloads.usda.library.cornell.edu/usda-esmis/files/gf06h2430/76538f824/w9506f61g/hempan23.pdf (accessed on 20 July 2023).

- Honig, L. National Hemp Report. 2022. Available online: https://www.nass.usda.gov/Newsroom/Executive_Briefings/2022/02-17-2022.pdf (accessed on 20 July 2023).

- Ruscitto, A. Hemp Numbers Plummet Across the Board in 2022 USDA Acreage and Production Survey; Cannabis Business Times: Valley View, OH, USA, 2023; Available online: https://www.cannabisbusinesstimes.com/news/usda-releases-hemp-acreage-production-survey-results-2022/ (accessed on 25 July 2023).

- Cerino, P.; Buonerba, C.; Cannazza, G.; D’Auria, J.; Ottoni, E.; Fulgione, A.; Di Stasio, A.; Pierri, B.; Gallo, A. A Review of Hemp as Food and Nutritional Supplement. Cannabis Cannabinoid Res. 2021, 6, 19–27. [Google Scholar] [CrossRef] [PubMed]

- Musio, S.; Mussig, J.; Amaducci, S. Optimizing Hemp Fiber Production for High Performance Composite Applications. Front. Plant Sci. 2018, 9, 1702. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, M.; Bhoopathi, R. Hemp fibers, their composites and applications. In Plant Fibers, Their Composites and Applications; Woodhead Publishing: Cambridge, UK, 2022. [Google Scholar]

- Derrick, L. 2023 Farm Bill Could Bolster Production of Newly Legalized Hemp. 2023. Available online: https://www.eesi.org/articles/view/2023-farm-bill-could-bolster-production-of-newly-legalized-hemp (accessed on 31 August 2023).

- Alberta Agriculture and Rural Development. Industrial Hemp Harvest and Storage. 2020. Available online: https://www1.agric.gov.ab.ca/$department/deptdocs.nsf/all/crop15539/$file/HempHarvestStorage.pdf?OpenElement (accessed on 1 December 2020).

- Wortmann, C.; Dweikat, I. Hemp Production for Fiber or Grain; University of Nebraska–Lincoln: Lincoln, NE, USA, 2020; Available online: https://cropwatch.unl.edu/2019/hemp-production-fiber-or-grain (accessed on 30 July 2023).

- Buetow, R.; Lubenow, L. Hemp for Grain Production in North Dakota; North Dakota State University Extension: Fargo, ND, USA, 2020; Available online: https://www.ndsu.edu/agriculture/ag-hub/ag-topics/crop-production/crops/hemp-seed/hemp-grain-production-north-dakota (accessed on 30 July 2023).

- Darby, H.; Malone, R.; Bruce, J.; Luke, I.; Ziegler, S. 2019 Industrial Grain Hemp Variety Trial; University of Vermont Extension: Burlington, VT, USA, 2019; Available online: https://www.uvm.edu/sites/default/files/media/2019_Grain_hemp_VT.pdf (accessed on 30 July 2023).

- Schluttenhofer, C. Growing Hemp for Fiber or Grain; Central State University Extension: Wilberforce, OH, USA, 2020; Available online: https://agnr.osu.edu/sites/agnr/files/imce/pdfs/events/Growing%20Hemp%20for%20Fiber%20or%20Seed.pdf (accessed on 30 July 2023).

- Bennett, C. Growing Hemp for CBD, Seed or Fiber; AgWeb: Philadelphia, PA, USA, 2019; Available online: https://www.agweb.com/news/crops/crop-production/growing-hemp-cbd-seed-or-fiber-0 (accessed on 31 July 2023).

- Harper, J.K.; Collins, A.; Kime, L.; Roth, G.W.; Manzo, H.E. Industrial Hemp Production; PennState Extension: University Park, PA, USA, 2018; Available online: https://extension.psu.edu/industrial-hemp-production (accessed on 31 July 2023).

- Roseberg, R.J.; Jeliazkov, V.D.; Angima, S.D. Soil, Seedbed Preparation and Seeding for Hemp; Oregon State University Extension: Oregon City, OR, USA, 2019; Available online: https://catalog.extension.oregonstate.edu/em9239/html (accessed on 31 July 2023).

- TBarnes; Parajuli, R.; Leggett, Z.; Suchoff, D. Assessing the financial viability of growing industrial hemp with loblolly pine plantations in the southeastern United States. Front. For. Glob. Chang. 2023, 6, 1148221. [Google Scholar] [CrossRef]

- Vávrová, K.; Solcova, O.; Knápek, J.; Weger, J.; Soukup, K.; Humešová, T.; Králík, T.; Bím, J. Economic evaluation of Hemp’s (Cannabis sativa) residual biomass for production of direct energy or biochar. Fuel 2022, 329, 125435. [Google Scholar] [CrossRef]

- Ceyhan, V.; Türkten, H.; Yıldırım, Ç.; Canan, S. Economic viability of industrial hemp production in Turkey. Ind. Crops Prod. 2022, 176, 114354. [Google Scholar] [CrossRef]

- Visković, J.; Zheljazkov, V.D.; Sikora, V.; Noller, J.; Latković, D.; Ocamb, C.M.; Koren, A. Industrial Hemp (Cannabis sativa L.) Agronomy and Utilization: A Review. Agronomy 2023, 13, 931. [Google Scholar] [CrossRef]

- USDA NASS. Farms and Land in Farms 2021 Summary. 2022. Available online: https://www.nass.usda.gov/Publications/Todays_Reports/reports/fnlo0222.pdf (accessed on 25 July 2023).

- HempIndustry Daily. Median Acreage of US Hemp Operations Decreases, but Average Acreage Rises. 2019. Available online: https://hempindustrydaily.com/median-size-of-u-s-hemp-operations-decreases-while-average-size-increases/#:~:text=The%20Hemp%20%26%20CBD%20Industry%20Factbook,of%2020%20acres%20in%202018 (accessed on 31 July 2023).

- Purdue University. Grain Hemp. 2023. Available online: https://ag.purdue.edu/hemp-project/production/grain-hemp.html (accessed on 10 August 2023).

- Suchoff, D.; Inoa, S.H. Not All Hemp Seed Are Created Equal; NC State Extension: Raleigh, NC, USA, 2022; Available online: https://content.ces.ncsu.edu/size-matters-accounting-for-hemp-seed-size-when-calibrating-your-grain-drill (accessed on 10 August 2023).

- Anderson, R.D. Effects of Nitrogen Fertilizer Rate, Timing, and Herbicide Use on Industrial Hemp (Cannabis sativa); Western Kentucky University: Bowling Green, KY, USA, 2018; Available online: https://digitalcommons.wku.edu/cgi/viewcontent.cgi?article=3105&context=theses (accessed on 10 August 2023).

- Minnesota Department of Agriculture. 2020 Hemp Program Annual Report. 2021. Available online: https://www.mda.state.mn.us/sites/default/files/docs/2021-03/MDA%202020%20Hemp%20Program%20Annual%20Report.pdf (accessed on 10 August 2023).

- Minnesota Department of Agriculture. Hemp Pilot Program. 2021. Available online: https://www.mda.state.mn.us/sites/default/files/2020-02/hempprogramannualreport2019.pdf (accessed on 10 August 2023).

- ASAE. ASAE D497.4: Agricultural Machinery Managment Data; ASAE: St. Joseph, MI, USA, 2000. [Google Scholar] [CrossRef]

- John Deere. New N530C No-Till Air Drill. 2023. Available online: https://www.agprocompanies.com/new-equipment/agriculture/planting-seeding/seeders/n530c-air-drill-central-commodity-system-ccs-/ (accessed on 2 August 2023).

- Hanna, M. Estimating the Field Capacity of Farm Machines; Ag Decision Maker-Iowa State University Extension and Outreach: Ames, IA, USA, 2016; Available online: https://www.extension.iastate.edu/agdm/crops/pdf/a3-24.pdf (accessed on 5 August 2023).

- John Deere. 2023 John Deere 1590. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/224806955/2023-john-deere-1590-grain-drills-planting-equipment (accessed on 5 August 2023).

- John Deere. Frontier Spreaders. 2009. Available online: https://www.deere.com/assets/pdfs/common/products/frontier/10_20_spreaders.pdf (accessed on 7 August 2023).

- Almaco. Specialized Plot Combine—SPC40. 2023. Available online: https://www.almaco.com/store/c10/combines/p298/specialized-plot-combine--spc40/ (accessed on 5 August 2023).

- John Deere. Single Auger Grain Carts. 2023. Available online: https://www.brentequip.com/grain-carts/v-series/ (accessed on 10 August 2023).

- John Deere. SB31 3-PT Sickle Bar Mower. 2023. Available online: https://configure.deere.com/cbyo/#/en_us/products/agriculture (accessed on 10 August 2023).

- Pottinger. Pottinger Novacat 3007 T RCB Collector Trailed Mower. 2023. Available online: https://www.farmcompare.com/products/pottinger-novacat-3007-t-rcb-collector-trailed-mower (accessed on 10 August 2023).

- Kubota. DMC8028R. 2023. Available online: https://www.parishtractor.com/new/brand-catalogs/kubota/farm-implements/disc-mower-conditioners/dmc8028r (accessed on 10 August 2023).

- CLAAS. 2020 Claas Quadrant 5300RC. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/204374853/2020-claas-quadrant-5300rc-large-square-balers-hay-and-forage-equipment (accessed on 10 August 2023).

- HayTalk. Baling Speed Square Baler. 2013. Available online: https://www.haytalk.com/threads/baling-speed-square-baler.20218/ (accessed on 10 August 2023).

- Anderson. Stackpro5400. 2023. Available online: https://grpanderson.com/en/trailers/square-bales/stackpro5400/ (accessed on 15 August 2023).

- Highline. FaStack 1800 Large Square Stacker Quick Specs. 2023. Available online: https://www.highlinemfg.com/en-us/products/large-square-bale-stackers/fastack-1800-large-square-stacker (accessed on 15 August 2023).

- Nelson, R.A. Hemp Husbandry. 2000. Available online: https://www.hempbasics.com/hhusb/hh3fiber.htm#:~:text=Hemp%20that%20is%20to%20be,requires%20about%2030%25%20moisture%20content (accessed on 17 August 2023).

- Brook, H.; Slaski, J.; James, B. Industrial Hemp Harvest and Storage, (n.d.). Available online: https://www1.agric.gov.ab.ca/$department/deptdocs.nsf/all/crop15539/$file/HempHarvestStorage.pdf (accessed on 30 July 2023).

- Texas Hemp Growers Association. Growing Hemp for Fiber, (n.d.). Available online: https://txhempgrowersassociation.com/education/growing-fiber/#:~:text=Depending%20on%20variety%20(or%20usage,-30%20%25%20of%20the%20stalk (accessed on 18 August 2023).

- Hubbard, C. Appropriate Scale for Fiber Processing. 2020. Available online: https://thejacobsen.com/2020/07/28/appropriate-scale-for-fiber-processing/ (accessed on 15 September 2023).

- Made in China. Manual Diesel Engine Mobile Sisal Fiber Extracting Decorticator. 2023. Available online: https://shuliymachinery.en.made-in-china.com/product/jnSRUOJEOtWh/China-Manual-Diesel-Engine-Mobile-Sisal-Fiber-Extracting-Decorticator.html (accessed on 15 September 2023).

- Made in China. Vertical Hydraulic Coconut Fiber Baler Machine. 2023. Available online: https://cnshjiajing.en.made-in-china.com/product/qwdasQbDfAYX/China-Vertical-Hydraulic-Coconut-Fiber-Baler-Machine-Scrap-Metal-Compressing-Machine-Clothes-Pressing-Machine.html (accessed on 15 September 2023).

- Cannabis Business Times. Hemp Application and Licensing Fees by State. 2021. Available online: https://www.cannabisbusinesstimes.com/news/state-by-state-guide-hemp-cultivation-processing-license-fees/ (accessed on 21 August 2023).

- Ward, B.; Barker, F.J.; Richer, E. Ohio Farm Custom Rates 2022. 2022. Available online: https://farmoffice.osu.edu/sites/aglaw/files/site-library/farmmgtpdf/Ohio%20Farm%20Custom%20Rates%202022%20July17.pdf (accessed on 21 August 2023).

- American Agricultural Economics Association. Commodity Costs and Returns Estimation Handbook; American Agricultural Economics Association: Ames, IA, USA, 2000. [Google Scholar]

- Grisso, R. Predicting Tractor Diesel Fuel Consumption; Virginia Cooperative Extension: Blacksburg, VA, USA, 2020; Available online: https://vtechworks.lib.vt.edu/bitstream/handle/10919/98875/BSE-328.pdf?sequence=1 (accessed on 23 August 2023).

- Ward, B. Western Ohio Cropland Values and Cash Rents 2021–2022. 2022. Available online: https://farmoffice.osu.edu/sites/aglaw/files/site-library/farmBusiness/Western%20Ohio%20Cropland%20Values%20and%20Cash%20Rents%202021-22%20Aug10.pdf (accessed on 18 August 2023).

- Quinn, R. DTN Retail Fertilizer Trends. 2023. Available online: https://www.dtnpf.com/agriculture/web/ag/crops/article/2023/05/10/fertilizer-prices-mixed-five-eight (accessed on 25 August 2023).

- US EIA. Weekly Retail Gasoline and Diesel Prices. 2023. Available online: https://www.eia.gov/dnav/pet/pet_pri_gnd_dcus_nus_m.htm (accessed on 25 August 2023).

- USDA NASS. Farm Labor. 2022. Available online: https://downloads.usda.library.cornell.edu/usda-esmis/files/x920fw89s/mp48tj815/0c484p887/fmla0522.pdf (accessed on 25 August 2023).

- U.S. Bureau of Labor Statistics. Occupational Employment and Wage Statistics. 2022. Available online: https://www.bls.gov/oes/current/oes519199.htm (accessed on 15 September 2023).

- ASABE. ASAE D497.7 MAR2011 Agricultural Machinery Management Data; ASABE: St. Joseph, MO, USA, 2011. [Google Scholar]

- ASABE. ASAE EP496.3 FEB2006 Agricultural Machinery Management; ASABE: St. Joseph, MO, USA, 2006. [Google Scholar]

- USDA Farm Service Agency. Current FSA Loan Interest Rates. 2023. Available online: https://www.fsa.usda.gov/programs-and-services/farm-loan-programs/index (accessed on 10 September 2023).

- Coinnews Media Group. Current US Inflation Rates: 2000–2023. 2023. Available online: https://www.usinflationcalculator.com/inflation/current-inflation-rates/ (accessed on 15 September 2023).

- John Deere. 2023 John Deere 6R 175. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/225737555/2023-john-deere-6r-175-175-hp-to-299-hp-tractors (accessed on 5 August 2023).

- John Deere. 2023 John Deere 6175M. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/225468219/2023-john-deere-6175m-175-hp-to-299-hp-tractors (accessed on 5 August 2023).

- Case IH. 2023 Case IH PUMA 175 CVX, (n.d.). Available online: https://www.tractorhouse.com/listing/for-sale/226229415/2023-case-ih-puma-175-cvx-175-hp-to-299-hp-tractors (accessed on 5 August 2023).

- Great Plains. 2023 Great Plains 1206NT. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/210841157/2023-great-plains-1206nt-grain-drills-planting-equipment (accessed on 15 August 2023).

- Great Plains. 2023 Great Plains 1006NT. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/224045545/2023-great-plains-1006nt-grain-drills-planting-equipment (accessed on 15 August 2023).

- Zimmerman. 2023 ESCH 5612. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/193479583/2023-esch-5612-grain-drills-planting-equipment (accessed on 15 August 2023).

- Rankin. 2023 Rankin PTB560. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/224892067/2023-rankin-ptb560-pull-type-dry-fertilizer-applicators-chemical-applicators (accessed on 16 August 2023).

- Brent. 2023 Brent V700. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/224855467/2023-brent-v700-grain-carts-harvest-equipment (accessed on 15 August 2023).

- Kubota. 2023 Kubota DMC8028R. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/223949211/2023-kubota-dmc8028r-pull-type-mower-conditioners-slash-windrowers-hay-and-forage-equipment (accessed on 15 August 2023).

- Pottinger. 2023 Pottinger Novacat 3007TRCB. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/217370273/2023-pottinger-novacat-3007trcb-pull-type-mower-conditioners-slash-windrowers-hay-and-forage-equipment (accessed on 15 August 2023).

- New Holland. 2023 New Holland Big Baler 330 Plus P. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/225949477/2023-new-holland-big-baler-330-plus-p-large-square-balers-hay-and-forage-equipment (accessed on 15 August 2023).

- Massey Ferguson. 2023 Massey Ferguson LB2234XD. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/226192083/2023-massey-ferguson-lb2234xd-large-square-balers-hay-and-forage-equipment (accessed on 15 August 2023).

- KRONE. 2021 KRONE BP1290HDP XC. 2021. Available online: https://www.tractorhouse.com/listing/for-sale/224779271/2021-krone-bp1290hdp-xc-large-square-balers-hay-and-forage-equipment (accessed on 15 August 2023).

- Case IH. 2023 Case IH LB436HD. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/219944881/2023-case-ih-lb436hd-large-square-balers-hay-and-forage-equipment (accessed on 15 August 2023).

- Anderson. 2023 Anderson STACKPRO5400. 2023. Available online: https://www.tractorhouse.com/listing/for-sale/223789781/2023-anderson-stackpro5400-bale-accumulators-slash-movers-hay-and-forage-equipment (accessed on 17 August 2023).

- Intelligen Inc. SuperPro Designer. 1991. Available online: https://www.intelligen.com/products/superpro-overview/ (accessed on 25 September 2023).

- Mosaic. Nutrient Needs of Continous Corn. 2023. Available online: https://www.cropnutrition.com/resource-library/nutrient-needs-of-continuous-corn/#:~:text=A%20200-bushel%20corn%20crop,pounds%20of%20sulfur%20(S) (accessed on 25 September 2023).

- Jardine, D.J. Soybean Fertility; Soybean Research Information Network. 2020. Available online: https://soybeanresearchinfo.com/agronomics/soybean-fertility/#:~:text=Soybeans%20require%2014%20mineral%20nutrients,(Ni)%20to%20grow%20successfully (accessed on 25 September 2023).

- Wakelyn, P.J.; Thompson, D.W.; Norman, B.M.; Nevius, C.B.; Findley, D.S. Why cotton ginning is considered agriculture? Cotton Gin Oil Mill Press 2005, 106, 5–9. Available online: https://www.cotton.org/tech/safety/ginagclass.cfm (accessed on 3 January 2024).

- Schnitkey, G.; Paulson, N.; Swanson, K.; Baltz, J. Fertilizer Prices, Rates and Costs for 2023; Farmdoc Daily: Urbana IL, USA, 2022; Available online: https://farmdocdaily.illinois.edu/2022/09/fertilizer-prices-rates-and-costs-for-2023.html (accessed on 2 September 2023).

- Schnitkey, G.; Swanson, K.; Paulson, N.; Baltz, J.; Zulauf, C. April Update to 2022 Crop Budgets: Projected Profits Even with Record Costs; Farmdoc Daily: Urbana IL, USA, 2022; Available online: https://farmdocdaily.illinois.edu/2022/04/april-update-to-2022-crop-budgets-projected-profits-even-with-record-costs.html (accessed on 25 September 2023).

- USDA. Cotton Price Statistics 2022–2023. 2023. Available online: https://www.ams.usda.gov/mnreports/cnaacps.pdf (accessed on 29 September 2023).

- Moreno, I. CBD Prices Are Falling as Companies Seek New Consumers. Is That a Good Thing? Hemp Industry Daily: Lakewood, CO, USA, 2020. Available online: https://hempindustrydaily.com/consumer-cbd-prices-are-falling-as-companies-seek-new-consumers-is-that-a-good-thing/ (accessed on 30 September 2023).

| Parameters | Unit | Grain | Fiber |

|---|---|---|---|

| Seeding | |||

| Optimal planting density | plants ha−1 | 1,347,385 (1,075,932–1,613,898) [25] | 3,496,779 (3,227,796–3,765,762) [18] |

| Germination rate | % | 45% (10–80%) [13] | 83% (70–91%) [26] |

| Hemp seeds weight | g 1000 kernels−1 | 20 (18–22) [12] | 20 (18–22) [12] |

| Fertilizer | |||

| Nitrogen | kg ha−1 | 157 (64–168) [14,17,27] | 168 (112–225) [14,17] |

| Phosphorus | kg ha−1 | 38 (15–64) [14,17,27] | 45 (22–90) [14,17] |

| Potassium | kg ha−1 | 43 (19–64) [14,17,27] | 84 (22–225) [14,17] |

| Yield | kg ha−1 | 339 (285–393) [5] | 2620 (2140–4773) [5,28,29] |

| Equipment Parameters | Unit | Values * | Assumption # |

|---|---|---|---|

| Seeding | |||

| Speed | km h−1 | 9.6 (6.4–12.8) [31] | Rated speed |

| Field efficiency | % | 70% | Based on literature [32] |

| Power | kW | 75 [33] | Rated power |

| Fertilization | |||

| Speed | km h−1 | 9.6 | Based on literature [32] |

| Field efficiency | % | 70% | Based on literature [32] |

| Power | kW | 30 [34] | Rated power |

| Harvest and post-harvest | |||

| Grain harvest | |||

| Combine speed | km h−1 | 6.4 (4.8–8.0) [35] | Rated speed |

| Combine field efficiency | % | 77% (75–78%) | Based on literature [32] |

| Combine power | kW | 68.25 [35] | Rated power |

| Grain cart storage capacity | m3 | 26.4 [36] | Rated capacity |

| Grain cart tractor power | kW | 112.5 [36] | Rated power |

| Grain cart unload speed | m3 s−1 | 0.29 [36] | Rated capacity |

| Fiber harvest | |||

| Mower width | m | 2.1 [37] | Rated width |

| Mowing speed | km h−1 | 11.2 | Based on literature [32] |

| Mower field efficiency | % | 80% (78–83%) | Based on literature [32] |

| Windrower width | m | 2.7 [38,39] | Rated width |

| Windrowing speed | km h−1 | 6.4 (4.8–8.0) | Based on literature d [32] |

| Windrowing field efficiency | % | 79% (78–80%) | Based on literature [32] |

| Baling width | m | 2.7 [40] | Rated width |

| Baling speed | km h−1 | 4.8 (3.2–6.4) | Based on usual practice [41] |

| Baling field efficiency | % | 80% (70–90%) | Based on literature [32] |

| Bale handling capacity | no. load−1 | 12 [42,43] | Rated load capacity |

| Bale handler transport speed | km h−1 | 9.6 (8.0–11.2) [43] | Rated speed |

| Parameters | Units | Values * |

|---|---|---|

| Land rental cost | USD ha−1 | 563 (452–674) [54] |

| Urea ammonium nitrate (UAN) ** | USD Mg−1 | 658 (599–732) [55] |

| Diammonium phosphate (DAP) ** | USD Mg−1 | 835 (818–868) [55] |

| Potash ** | USD Mg−1 | 672 (623–742) [55] |

| Diesel price *** | USD l−1 | 1.07 (1.00–1.16) [56] |

| Hourly wage for field workers **** | USD h−1 | 17.77 (17.64–17.89) [57] |

| Grain drying costs | USD Mg−1 | 0.15 (0.10–0.21) [51] |

| Grain storage costs | USD Mg−1 | 10.91 (5.91–15.91) [51] |

| Hourly wage for production workers | USD h−1 | 17.06 (13.23–27.01) [58] |

| Hemp grain selling price | USD kg−1 | 3.32 (1.45–12.25) [5] |

| Hemp fiber selling price | USD kg−1 | 3.30 (2.64–3.96) [5] |

| Parameters | Units | Values * |

|---|---|---|

| Factors applicable to all equipment | ||

| Interest rate ** | % | 9.5 (9.0–10.0) [61,62] |

| Taxes, housing and insurance rate | % | 2% [60] |

| Lubrication cost as percent of fuel cost | % | 15% [60] |

| Tractor | ||

| Tractor list price (131.25 kW) | USD | 219,654 (183,800–269,161) [63,64,65] |

| C1, C2, C3 *** | 0.976, 0.119, 0.0019 | |

| Service life | hours | 16,000 |

| RF1, RF2 *** | 0.003, 2 | |

| Grain drill | ||

| Grain drill list price (75 kW) | USD | 51,100 (37,500–69,900) [66,67,68] |

| C1, C2 | 0.943, 0.111 | |

| Service life | hours | 5000 |

| RF1, RF2 | 0.41, 1.3 | |

| Fertilizer spreader | ||

| Fertilizer spreader list price (30 kW) | USD | 3599 (2879–4319) [69] |

| C1, C2 | 0.943, 0.111 | |

| Service life | hours | 1000 |

| RF1, RF2 | 0.41, 1.3 | |

| Combine | ||

| Combine list price (68.25 kW) | USD | 550,000 (440,000–660,000) |

| C1, C2, C3 | 1.132, 0.165, 0.0079 | |

| Service life | hours | 5000 |

| RF1, RF2 | 0.12, 2.3 | |

| Grain cart | ||

| Grain cart list price (112.5 kW) | USD | 61,900 (49,520–74,280) [70] |

| C1, C2 | 0.943, 0.111 | |

| Service life | hours | 5000 |

| RF1, RF2 | 0.41, 1.3 | |

| Mower | ||

| Mower list price (28.12 kW) | USD | 7178 (5742–8613) [37] |

| C1, C2 | 0.756, 0.067 | |

| Service life | hours | 5000 |

| RF1, RF2 | 0.44, 2 | |

| Windrower | ||

| Windrower list price (54.37 kW) | USD | 35,875 (34,850–36,900) [71,72] |

| C1, C2 | 0.791, 0.091 | |

| Service life | hours | 5000 |

| RF1, RF2 | 0.03, 2 | |

| Baler | ||

| Baler list price (131.25 kW) | USD | 192,998 (169,900–253,900) [73,74,75,76] |

| C1, C2 | 0.852, 0.101 | |

| Service life | hours | 3000 |

| RF1, RF2 | 0.1, 1.8 | |

| Bale loader | ||

| Baler loader list price (112.5 kW) | USD | 173,500 (138,800–208,200) [77] |

| C1, C2, C3 | 0.943, 0.111 | |

| Service life | hours | 5000 |

| RF1, RF2 | 0.41, 1.3 |

| Parameters | Units | Values * |

|---|---|---|

| Equipment purchase price | ||

| Decorticator assembly | USD | 229,000 [47] |

| Stationary fiber compactor | USD | 10,000 [49] |

| Factors for estimating facility cost * | ||

| Interest rate ** | % | 9.5 (9.0–10.0) [61,62] |

| Direct cost (DC) | ||

| Total Equipment purchase cost (TP) | 239,000 | |

| Instrumentation as % of TP | % | 15 |

| Electrical as % of TP | % | 5 |

| Buildings as % of TP | % | 10 |

| Yard improvement as % of TP | % | 5 |

| Indirect cost (IDC) | ||

| Engineering as % of DC | % | 10 |

| Construction as % of DC | % | 10 |

| Miscellaneous cost (MC) | ||

| Contractor’s fee as % of DC + IDC | % | 5 |

| Contingency as % of DC + IDC | % | 5 |

| Direct Fixed Capital (DFC) | DC + IDC + MC | |

| Repair and maintenance as % of DFC | % | 3 |

| Taxes and insurance as % of DFC | % | 1 |

| Salvage value as % of DFC | % | 11 |

| Service life of the plant | years | 30 |

| Machinery Hours (h year−1) | Grain | Fiber |

| Tractor—seeding | 68 (60–74) | 68 (61–74) |

| Tractor—fertilization | 117 (115–120) | 129 (126–132) |

| Combine—grain harvest | 198 (183–212) | |

| Tractor—stalk harvest | 241 (227–253) | |

| Tractor—collection and transport | 207 (192–221) | 63 (52–71) |

| Total machinery hours | 590 (559–618) | 500 (482–517) |

| Fuel (Diesel) (l year−1) | Grain | Fiber |

| Seeding | 1128 (1007–1227) | 1131 (1010–1231) |

| Fertilization | 783 (768–798) | 859 (838–881) |

| Harvest | 3009 (2772–3214) | 4490 (4115–4807) |

| Collection and transport | 5184 (4791–5526) | 1591 (1328–1809) |

| Labor Hours (h year−1) | Grain | Fiber |

| Seeding | 81 (72–88) | 81 (73–89) |

| Fertilization | 141 (138–144) | 155 (151–158) |

| Harvest | 238 (219–254) | 289 (273–304) |

| Collection and transport | 249 (230–265) | 75 (63–86) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khanal, A.; Shah, A. Techno-Economic Analysis of Hemp Production, Logistics and Processing in the U.S. Biomass 2024, 4, 164-179. https://doi.org/10.3390/biomass4010008

Khanal A, Shah A. Techno-Economic Analysis of Hemp Production, Logistics and Processing in the U.S. Biomass. 2024; 4(1):164-179. https://doi.org/10.3390/biomass4010008

Chicago/Turabian StyleKhanal, Asmita, and Ajay Shah. 2024. "Techno-Economic Analysis of Hemp Production, Logistics and Processing in the U.S" Biomass 4, no. 1: 164-179. https://doi.org/10.3390/biomass4010008

APA StyleKhanal, A., & Shah, A. (2024). Techno-Economic Analysis of Hemp Production, Logistics and Processing in the U.S. Biomass, 4(1), 164-179. https://doi.org/10.3390/biomass4010008