An Updated Review of Recent Applications and Perspectives of Hydrogen Production from Biomass by Fermentation: A Comprehensive Analysis

Abstract

1. Introduction

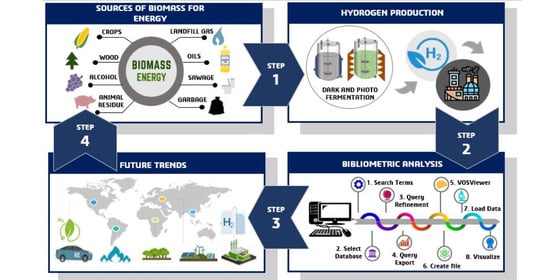

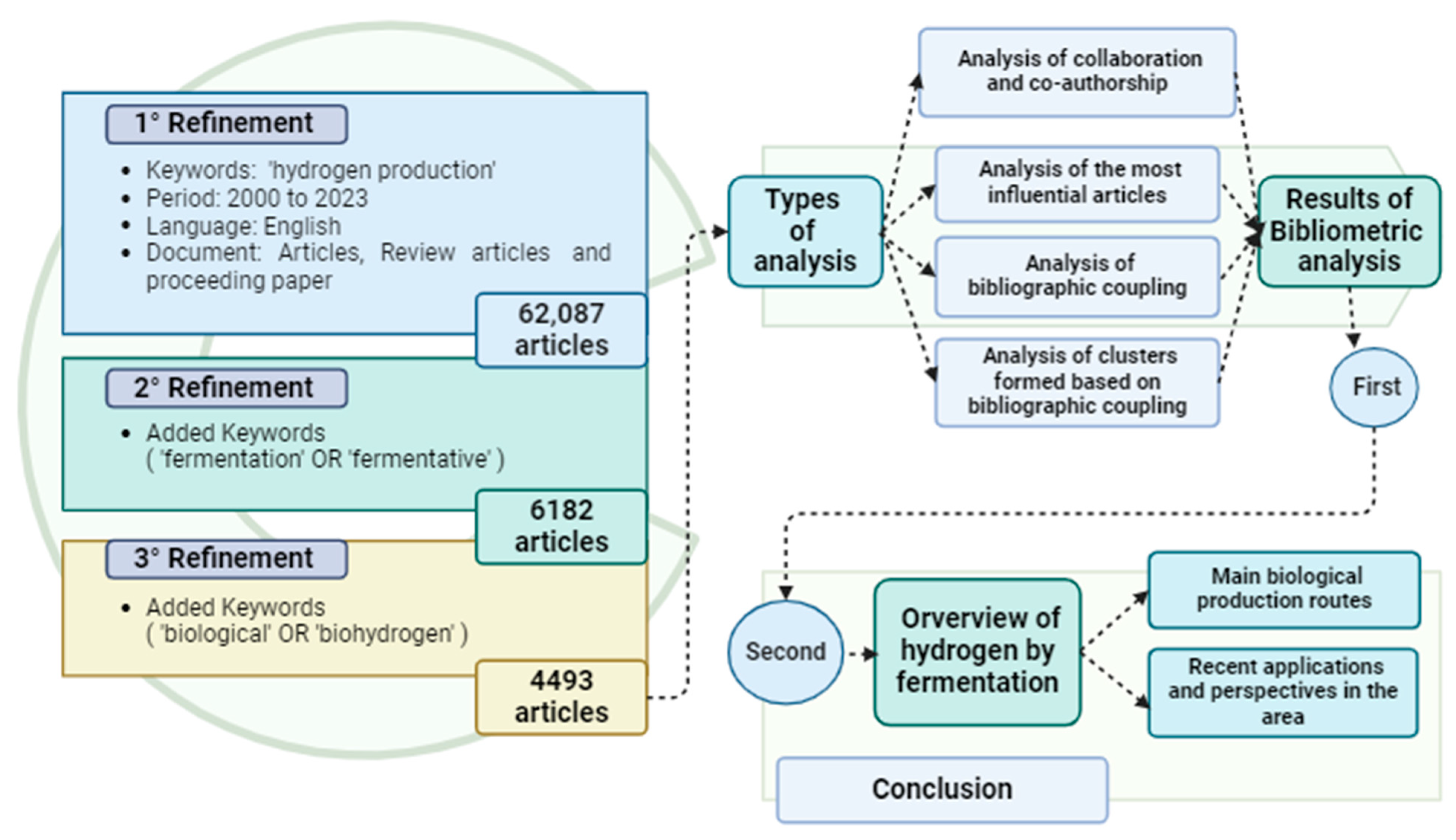

2. Materials and Methods

- RQ1—What is the pattern of collaboration between journals, countries, institutions, and authors?

- RQ2—Which manuscripts are the most influential in the field?

- RQ3—Which topics are highlighted in the literature?

- RQ4—What should be the agenda for future research in this area?

3. Results and Discussion

3.1. Performance Indicators

3.1.1. Results Related to Publications

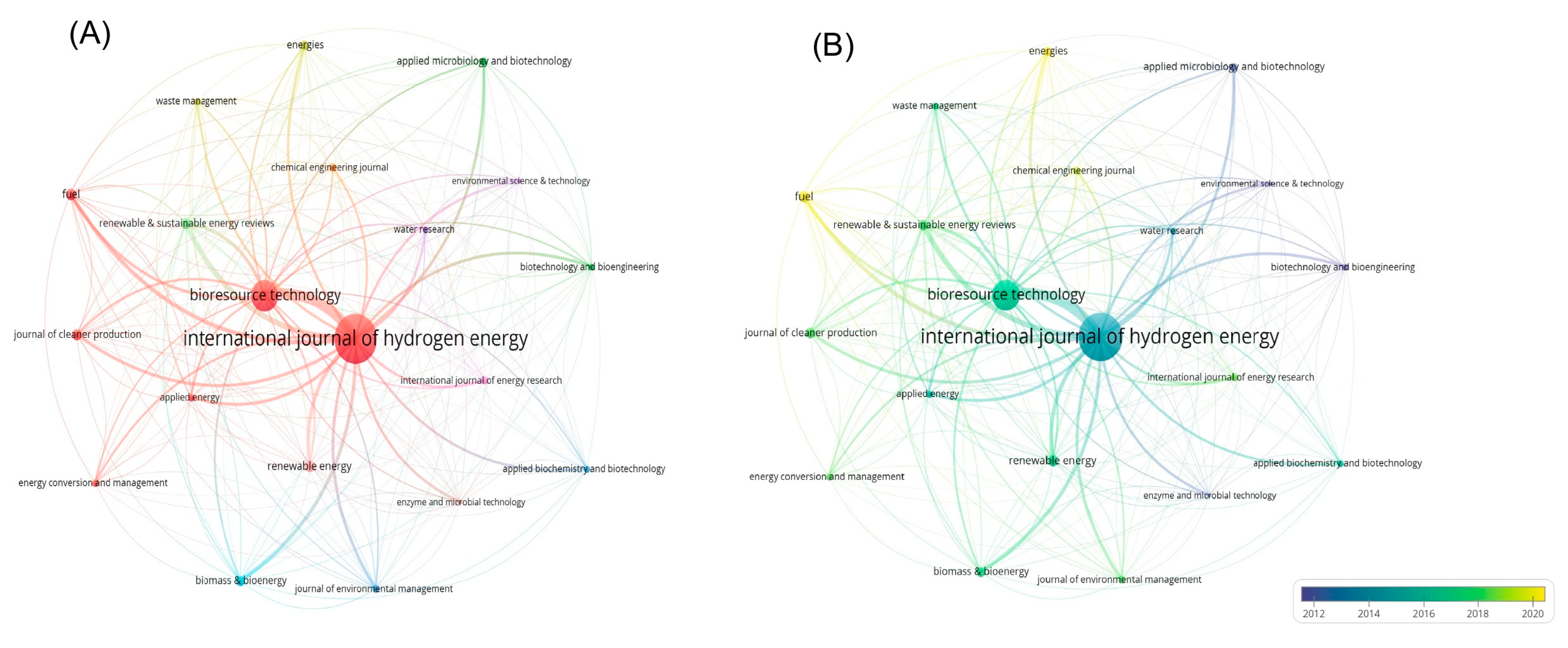

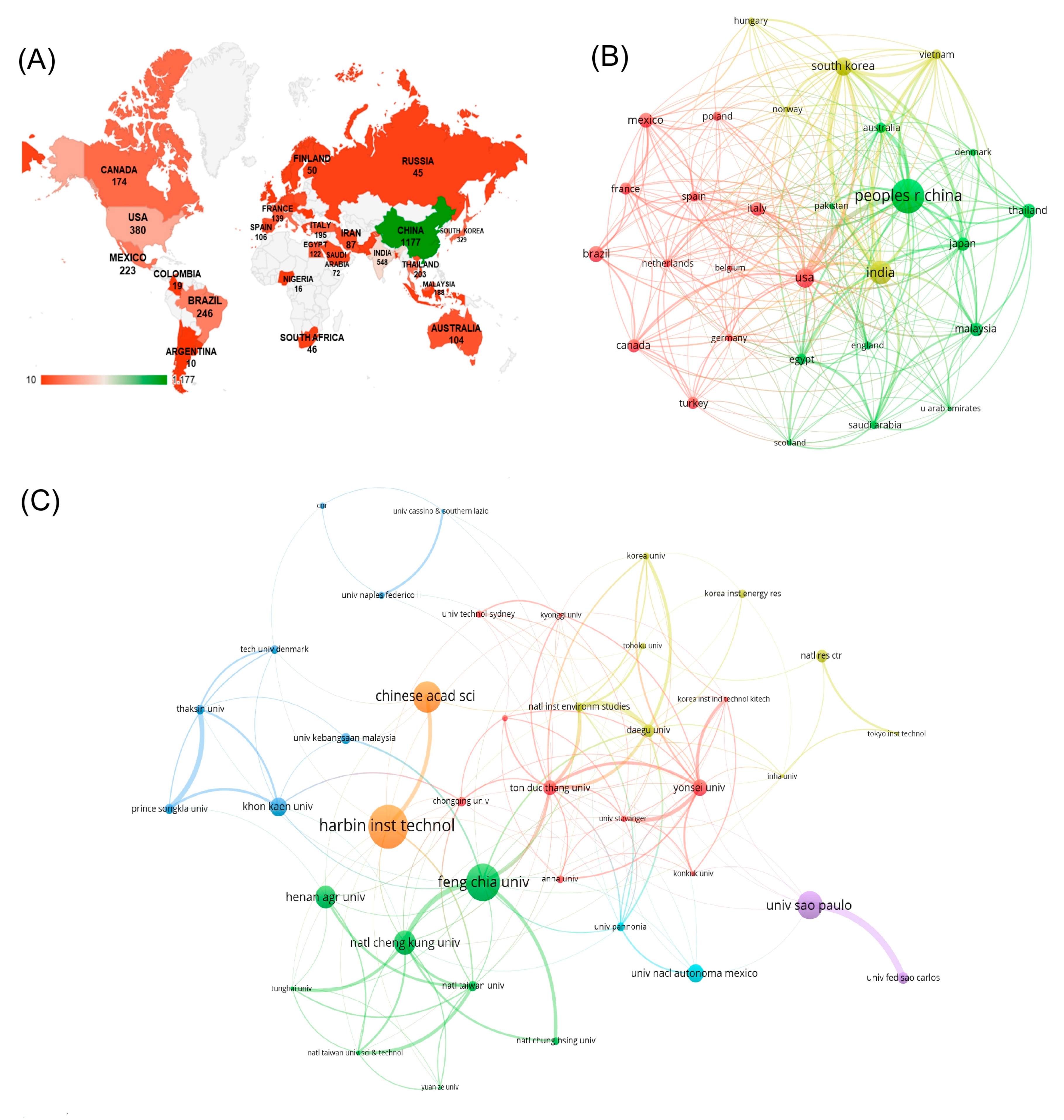

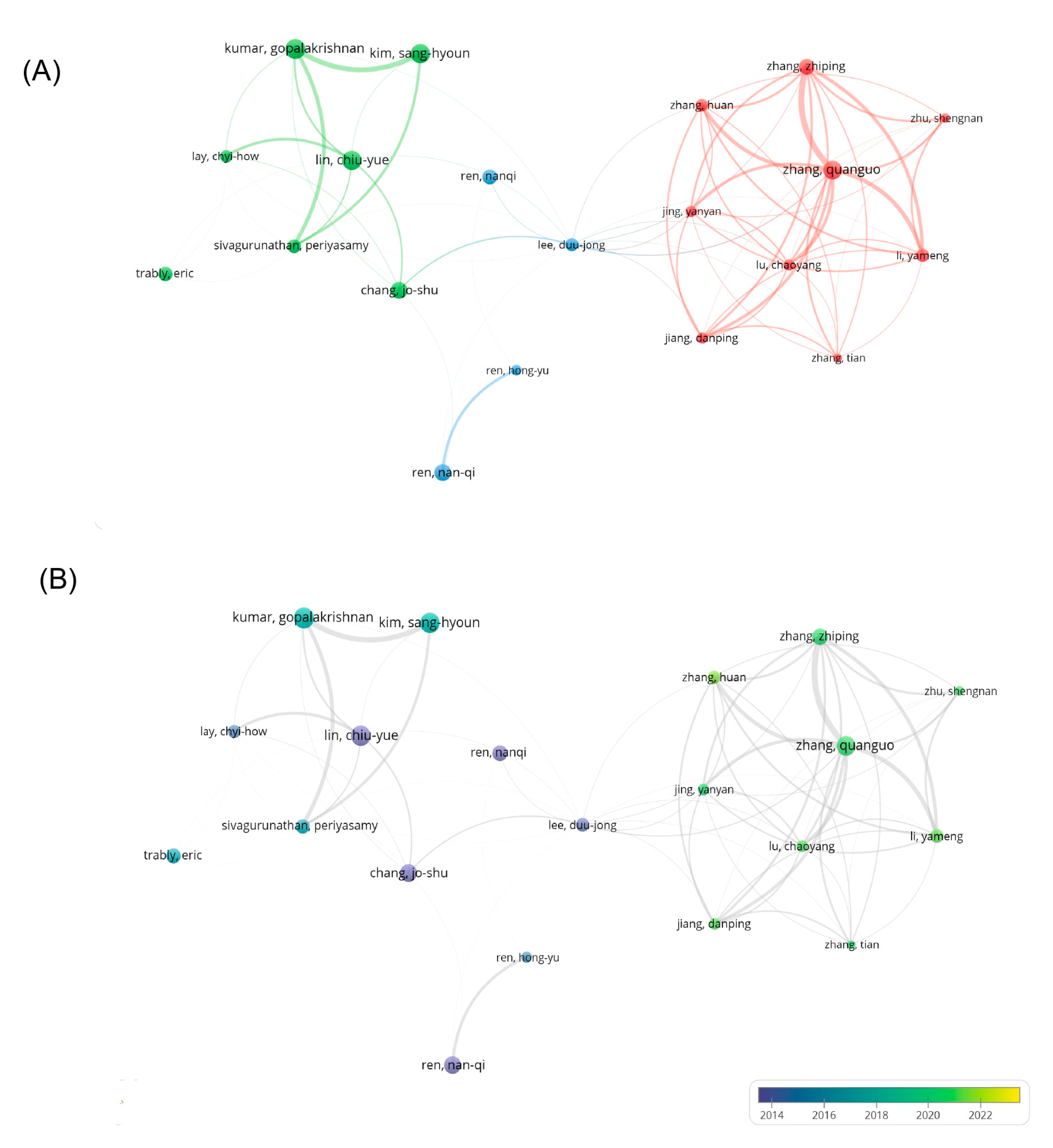

3.1.2. Distribution of Scientific Journals, Countries, Institutions, and Authors

3.2. Research Points

The Most Cited Articles

3.3. Background Research Topics

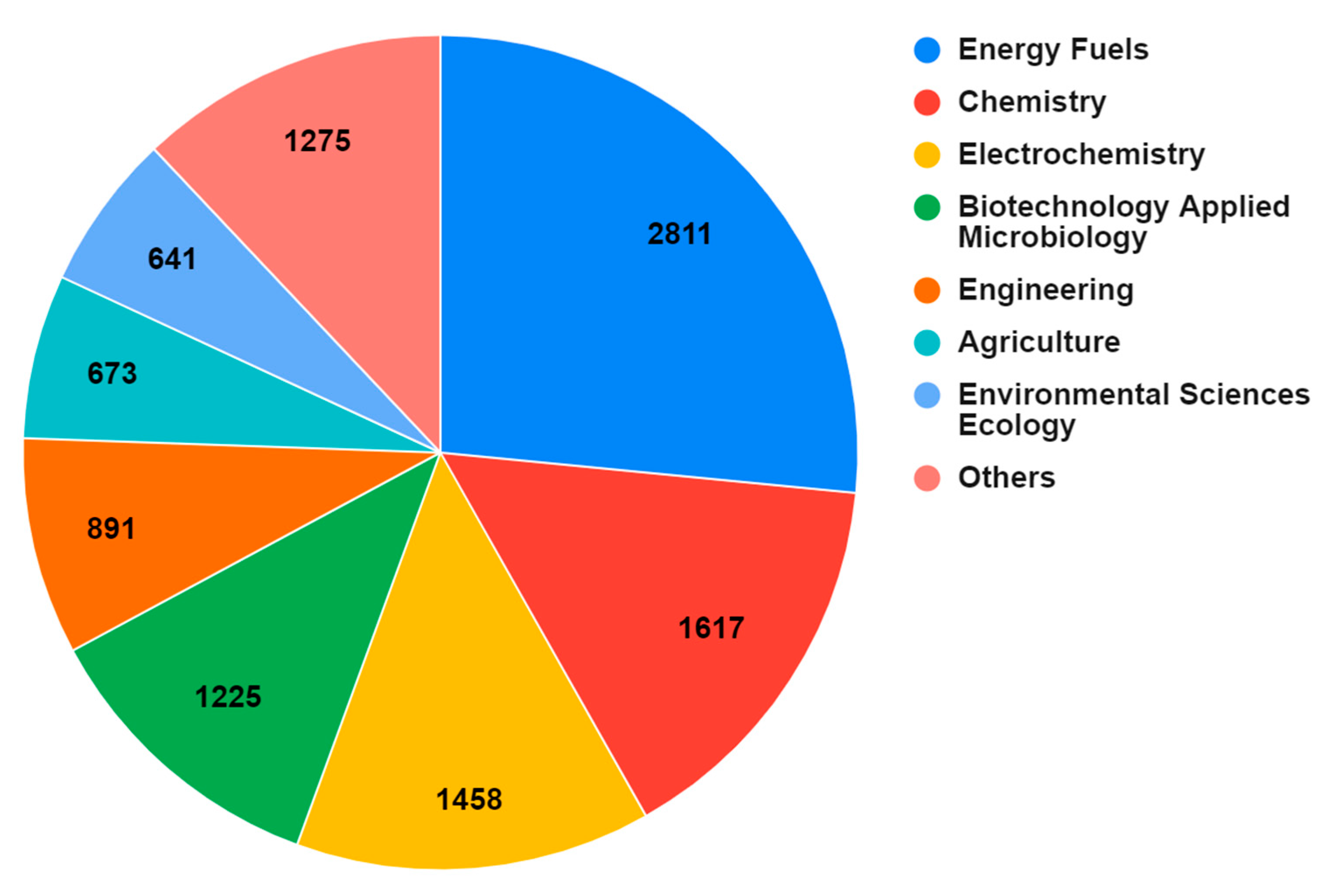

Research Areas

3.4. Emerging Areas of Research

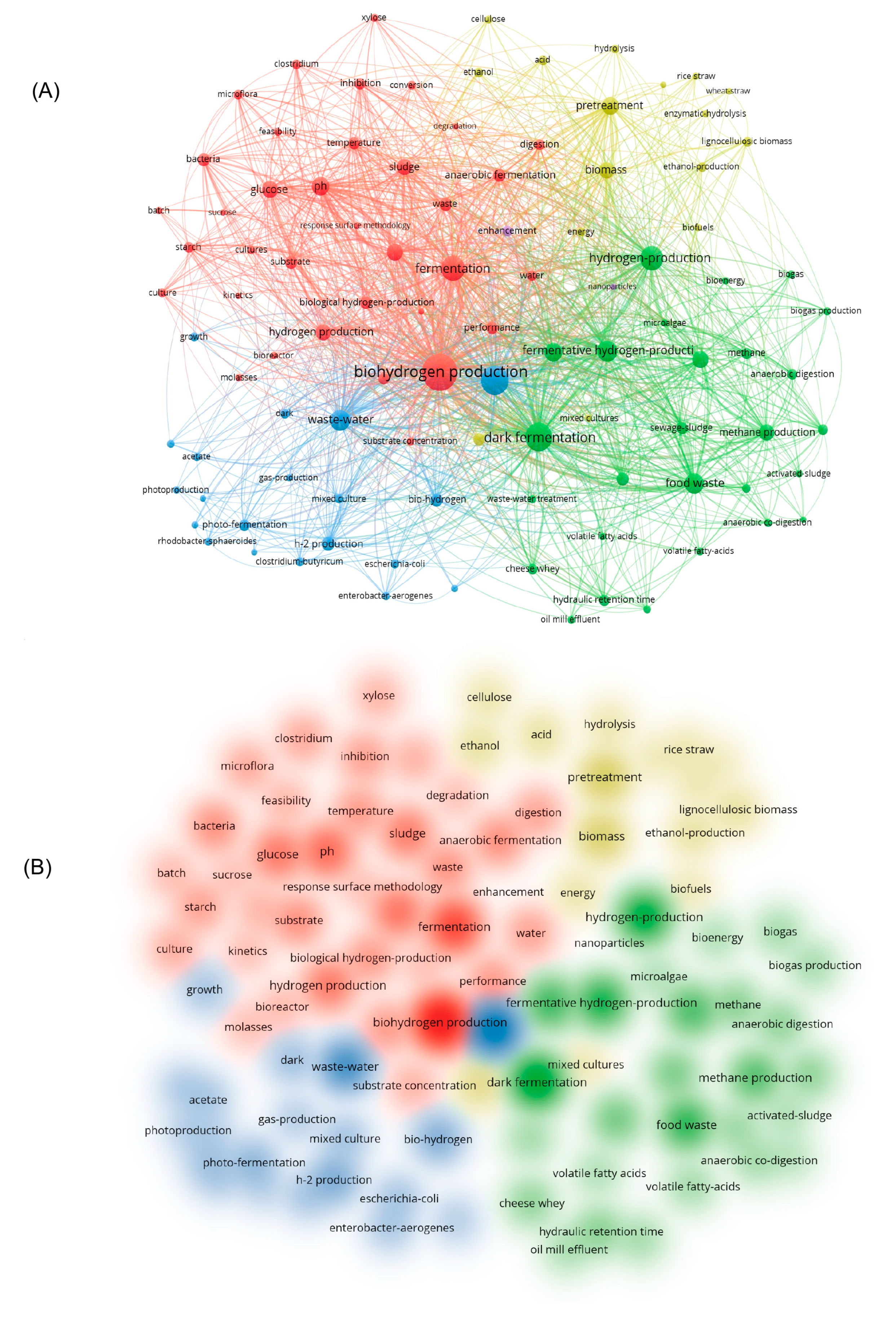

Quantitative Analysis of Frequent Keywords

4. Overview of Hydrogen Produced by Fermentation

4.1. Main Biomasses Used

- I.

- Agricultural waste

- II.

- Forest residues

- III.

- Food Waste

- IV.

- Agro-industrial effluents

- V.

- Herbaceous Biomass and Microalgae

- VI.

- Urban Organic Waste

4.2. Fermentative Processes

4.3. Influential Factors in the Production Process

4.4. Applications of Fermentative Biohydrogen

4.4.1. Industrial Applications

4.4.2. Transport Applications

4.4.3. Energy Sector

4.5. Recent Technological Advances in Hydrogen Production from Biomass

4.6. Challenges to Overcome and Gaps

5. Future Perspectives

6. Overview

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Genovese, M.; Schlüter, A.; Scionti, E.; Piraino, F.; Corigliano, O.; Fragiacomo, P. Power-to-Hydrogen and Hydrogen-to-X Energy Systems for the Industry of the Future in Europe. Int. J. Hydrogen Energy 2023, 48, 16545–16568. [Google Scholar] [CrossRef]

- Guban, D.; Muritala, I.K.; Roeb, M.; Sattler, C. Assessment of Sustainable High Temperature Hydrogen Production Technologies. Int. J. Hydrogen Energy 2020, 45, 26156–26165. [Google Scholar] [CrossRef]

- Liu, M.; Yao, Z.; Gu, J.; Li, C.; Huang, X.; Zhang, L.; Huang, Z.; Fan, M. Issues and Opportunities Facing Hydrolytic Hydrogen Production Materials. Chem. Eng. J. 2023, 461, 141918. [Google Scholar] [CrossRef]

- Tezel, E.; Figen, H.E.; Baykara, S.Z. Hydrogen Production by Methane Decomposition Using Bimetallic Ni–Fe Catalysts. Int. J. Hydrogen Energy 2019, 44, 9930–9940. [Google Scholar] [CrossRef]

- Borges, P.T.; Sales, M.B.; César Guimarães, C.E.; de França Serpa, J.; de Lima, R.K.C.; Sanders Lopes, A.A.; de Sousa Rios, M.A.; Desai, A.S.; da Silva Lima, A.M.; Lora, E.E.S.; et al. Photosynthetic Green Hydrogen: Advances, Challenges, Opportunities, and Prospects. Int. J. Hydrogen Energy 2024, 49, 433–458. [Google Scholar] [CrossRef]

- Li, T.; Yue, X.G.; Qin, M.; Norena-Chavez, D. Towards Paris Climate Agreement Goals: The Essential Role of Green Finance and Green Technology. Energy Econ. 2024, 129, 107273. [Google Scholar] [CrossRef]

- Saccardo, R.R.; Domingues, A.M.; Battistelle, R.A.G.; Bezerra, B.S.; Siqueira, R.M.; Neto, J.B.S. dos S. Investment in Photovoltaic Energy: An Attempt to Frame Brazil within the 2030 Passage Target of the Paris Agreement. Clean. Energy Syst. 2023, 5, 100070. [Google Scholar] [CrossRef]

- Nnabuife, S.G.; Ugbeh-Johnson, J.; Okeke, N.E.; Ogbonnaya, C. Present and Projected Developments in Hydrogen Production: A Technological Review. Carbon Capture Sci. Technol. 2022, 3, 100042. [Google Scholar] [CrossRef]

- AbouSeada, N.; Hatem, T.M. Climate Action: Prospects of Green Hydrogen in Africa. Energy Rep. 2022, 8, 3873–3890. [Google Scholar] [CrossRef]

- Mallett, A.; Pal, P. Green Transformation in the Iron and Steel Industry in India: Rethinking Patterns of Innovation. Energy Strategy Rev. 2022, 44, 100968. [Google Scholar] [CrossRef]

- Al-tabatabaie, K.F.; Hossain, M.B.; Islam, M.K.; Awual, M.R.; TowfiqulIslam, A.R.M.; Hossain, M.A.; Esraz-Ul-Zannat, M.; Islam, A. Taking Strides towards Decarbonization: The Viewpoint of Bangladesh. Energy Strategy Rev. 2022, 44, 100948. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, X.D.; Zhong, J.T.; Guo, L.F.; Guo, S.Y.; Wang, D.Y.; Miao, C.H.; Zhang, X.L.; Zhang, X.Y. A Representative CO2 Emissions Pathway for China toward Carbon Neutrality under the Paris Agreement’s 2 °C Target. Adv. Clim. Change Res. 2023, 14, 941–951. [Google Scholar] [CrossRef]

- Liang, Y.; Li, C.; Liu, Z.; Wang, X.; Zeng, F.; Yuan, X.; Pan, Y. Decarbonization Potentials of the Embodied Energy Use and Operational Process in Buildings: A Review from the Life-Cycle Perspective. Heliyon 2023, 9, e20190. [Google Scholar] [CrossRef] [PubMed]

- Shiva Kumar, S.; Lim, H. An Overview of Water Electrolysis Technologies for Green Hydrogen Production. Energy Rep. 2022, 8, 13793–13813. [Google Scholar] [CrossRef]

- Hong, S.; Kim, E.; Jeong, S. Evaluating the Sustainability of the Hydrogen Economy Using Multi-Criteria Decision-Making Analysis in Korea. Renew. Energy 2023, 204, 485–492. [Google Scholar] [CrossRef]

- Aquilas, N.A.; Atemnkeng, J.T. Climate-Related Development Finance and Renewable Energy Consumption in Greenhouse Gas Emissions Reduction in the Congo Basin. Energy Strategy Rev. 2022, 44, 100971. [Google Scholar] [CrossRef]

- Zhou, R.; Yang, X.; Han, Y. Cleaner Production and Total Factor Productivity of Polluting Enterprises. J. Clean Prod. 2023, 423, 138827. [Google Scholar] [CrossRef]

- Balsalobre-Lorente, D.; Contente dos Santos Parente, C.; Leitão, N.C.; Cantos-Cantos, J.M. The Influence of Economic Complexity Processes and Renewable Energy on CO2 Emissions of BRICS. What about Industry 4.0? Resour. Policy 2023, 82, 103547. [Google Scholar] [CrossRef]

- Ourya, I.; Abderafi, S. Clean Technology Selection of Hydrogen Production on an Industrial Scale in Morocco. Results Eng. 2023, 17, 100815. [Google Scholar] [CrossRef]

- Riera, J.A.; Lima, R.M.; Knio, O.M. A Review of Hydrogen Production and Supply Chain Modeling and Optimization. Int. J. Hydrogen Energy 2023, 48, 13731–13755. [Google Scholar] [CrossRef]

- Otto, M.; Chagoya, K.L.; Blair, R.G.; Hick, S.M.; Kapat, J.S. Optimal Hydrogen Carrier: Holistic Evaluation of Hydrogen Storage and Transportation Concepts for Power Generation, Aviation, and Transportation. J. Energy Storage 2022, 55, 105714. [Google Scholar] [CrossRef]

- Miao, Z.; Wu, G.; Wang, Q.; Yang, J.; Wang, Z.; Yan, P.; Sun, P.; Lei, Y.; Mo, Z.; Xu, H. Recent Advances in Graphitic Carbon Nitride-Based Photocatalysts for Solar-Driven Hydrogen Production. Mater. Rep. Energy 2023, 3, 100235. [Google Scholar] [CrossRef]

- Aravindan, M.; Praveen Kumar, G. Hydrogen towards Sustainable Transition: A Review of Production, Economic, Environmental Impact and Scaling Factors. Results Eng. 2023, 20, 101456. [Google Scholar] [CrossRef]

- Srirangan, K.; Pyne, M.E.; Perry Chou, C. Biochemical and Genetic Engineering Strategies to Enhance Hydrogen Production in Photosynthetic Algae and Cyanobacteria. Bioresour. Technol. 2011, 102, 8589–8604. [Google Scholar] [CrossRef] [PubMed]

- Nagar, R.; Srivastava, S.; Hudson, S.L.; Amaya, S.L.; Tanna, A.; Sharma, M.; Achayalingam, R.; Sonkaria, S.; Khare, V.; Srinivasan, S.S. Recent Developments in State-of-the-Art Hydrogen Energy Technologies—Review of Hydrogen Storage Materials. Sol. Compass 2023, 5, 100033. [Google Scholar] [CrossRef]

- Andriani, D.; Bicer, Y. A Review of Hydrogen Production from Onboard Ammonia Decomposition: Maritime Applications of Concentrated Solar Energy and Boil-Off Gas Recovery. Fuel 2023, 352, 128900. [Google Scholar] [CrossRef]

- Rahim Malik, F.; Yuan, H.B.; Moran, J.C.; Tippayawong, N. Overview of Hydrogen Production Technologies for Fuel Cell Utilization. Eng. Sci. Technol. Int. J. 2023, 43, 101452. [Google Scholar] [CrossRef]

- Catumba, B.D.; Sales, M.B.; Borges, P.T.; Ribeiro Filho, M.N.; Lopes, A.A.S.; de Sousa Rios, M.A.; Desai, A.S.; Bilal, M.; dos Santos, J.C.S. Sustainability and Challenges in Hydrogen Production: An Advanced Bibliometric Analysis. Int. J. Hydrogen Energy 2023, 48, 7975–7992. [Google Scholar] [CrossRef]

- De Sá, L.R.V.; Cammarota, M.C.; Ferreira-Leitão, V.S. Produção de Hidrogênio via Fermentação Anaeróbia—Aspectos Gerais e Possibilidade de Utilização de Resíduos Agroindustriais Brasileiros. Quim. Nova 2014, 37, 857–867. [Google Scholar]

- Massarweh, O.; Al-khuzaei, M.; Al-Shafi, M.; Bicer, Y.; Abushaikha, A.S. Blue Hydrogen Production from Natural Gas Reservoirs: A Review of Application and Feasibility. J. CO2 Util. 2023, 70, 102438. [Google Scholar] [CrossRef]

- Rinaldi, A.; Syla, A.; Patel, M.K.; Parra, D. Optimal Pathways for the Decarbonisation of the Transport Sector: Trade-Offs between Battery and Hydrogen Technologies Using a Whole Energy System Perspective. Clean. Prod. Lett. 2023, 5, 100044. [Google Scholar] [CrossRef]

- Böhm, M.; Fernández Del Rey, A.; Pagenkopf, J.; Varela, M.; Herwartz-Polster, S.; Nieto Calderón, B. Review and Comparison of Worldwide Hydrogen Activities in the Rail Sector with Special Focus on On-Board Storage and Refueling Technologies. Int. J. Hydrogen Energy 2022, 47, 38003–38017. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, S.X.; Yao, R.; Wu, Y.H.; Qiu, J.S. Progress and Prospects of Hydrogen Production: Opportunities and Challenges. J. Electron. Sci. Technol. 2021, 19, 100080. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Brooks, G.; Rhamdhani, M.A. Decarbonisation and Hydrogen Integration of Steel Industries: Recent Development, Challenges and Technoeconomic Analysis. J. Clean. Prod. 2023, 395, 136391. [Google Scholar] [CrossRef]

- Hilali, İ.; Işıker, Y.; Ulker, N. The Hydrogen Perspective for Türkiye, Which Is on the Asia-Europe Energy Transition Route. Can Türkiye Become Hydrogen Hub? Int. J. Hydrogen Energy 2024, in press. [Google Scholar] [CrossRef]

- Guo, Q.; Geng, J.; Pan, J.; Zou, L.; Tian, Y.; Chi, B.; Pu, J. Brief Review of Hydrocarbon-Reforming Catalysts Map for Hydrogen Production. Energy Rev. 2023, 2, 100037. [Google Scholar] [CrossRef]

- Wilkinson, J.; Mays, T.; McManus, M. Review and Meta-Analysis of Recent Life Cycle Assessments of Hydrogen Production. Clean. Environ. Syst. 2023, 9, 100116. [Google Scholar] [CrossRef]

- Al-Fatesh, A.S.; AL-Garadi, N.Y.A.; Osman, A.I.; Al-Mubaddel, F.S.; Ibrahim, A.A.; Khan, W.U.; Alanazi, Y.M.; Alrashed, M.M.; Alothman, O.Y. From Plastic Waste Pyrolysis to Fuel: Impact of Process Parameters and Material Selection on Hydrogen Production. Fuel 2023, 344, 128107. [Google Scholar] [CrossRef]

- Ji, M.; Wang, J. Review and Comparison of Various Hydrogen Production Methods Based on Costs and Life Cycle Impact Assessment Indicators. Int. J. Hydrogen Energy 2021, 46, 38612–38635. [Google Scholar] [CrossRef]

- Javed, M.A.; Zafar, A.M.; Aly Hassan, A.; Zaidi, A.A.; Farooq, M.; El Badawy, A.; Lundquist, T.; Mohamed, M.M.A.; Al-Zuhair, S. The Role of Oxygen Regulation and Algal Growth Parameters in Hydrogen Production via Biophotolysis. J Environ. Chem. Eng. 2022, 10, 107003. [Google Scholar] [CrossRef]

- Redding, K.E.; Appel, J.; Boehm, M.; Schuhmann, W.; Nowaczyk, M.M.; Yacoby, I.; Gutekunst, K. Advances and Challenges in Photosynthetic Hydrogen Production. Trends Biotechnol. 2022, 40, 1313–1325. [Google Scholar] [CrossRef]

- Sillero, L.; Sganzerla, W.G.; Forster-Carneiro, T.; Solera, R.; Perez, M. A Bibliometric Analysis of the Hydrogen Production from Dark Fermentation. Int. J. Hydrogen Energy 2022, 47, 27397–27420. [Google Scholar] [CrossRef]

- Ramprakash, B.; Lindblad, P.; Eaton-Rye, J.J.; Incharoensakdi, A. Current Strategies and Future Perspectives in Biological Hydrogen Production: A Review. Renew. Sustain. Energy Rev. 2022, 168, 112773. [Google Scholar] [CrossRef]

- Zhang, T.; Jiang, D.; Zhang, H.; Jing, Y.; Tahir, N.; Zhang, Y.; Zhang, Q. Comparative Study on Bio-Hydrogen Production from Corn Stover: Photo-Fermentation, Dark-Fermentation and Dark-Photo Co-Fermentation. Int. J. Hydrogen Energy 2020, 45, 3807–3814. [Google Scholar] [CrossRef]

- Villanueva-Galindo, E.; Vital-Jácome, M.; Moreno-Andrade, I. Dark Fermentation for H2 Production from Food Waste and Novel Strategies for Its Enhancement. Int. J. Hydrogen Energy 2023, 48, 9957–9970. [Google Scholar] [CrossRef]

- Aydin, M.I.; Karaca, A.E.; Qureshy, A.M.M.I.; Dincer, I. A Comparative Review on Clean Hydrogen Production from Wastewaters. J. Environ. Manag. 2021, 279, 111793. [Google Scholar] [CrossRef] [PubMed]

- Saravanan, A.; Kumar, P.S.; Mat Aron, N.S.; Jeevanantham, S.; Karishma, S.; Yaashikaa, P.R.; Chew, K.W.; Show, P.L. A Review on Bioconversion Processes for Hydrogen Production from Agro-Industrial Residues. Int. J. Hydrogen Energy 2022, 47, 37302–37320. [Google Scholar] [CrossRef]

- Konur, O. The Scientometric Evaluation of the Research on the Production of Bioenergy from Biomass. Biomass Bioenergy 2012, 47, 504–515. [Google Scholar] [CrossRef]

- Chen, Y.; Lin, M.; Zhuang, D. Wastewater Treatment and Emerging Contaminants: Bibliometric Analysis. Chemosphere 2022, 297, 133932. [Google Scholar] [CrossRef] [PubMed]

- Guimarães, C.E.C.; Neto, F.S.; de Castro Bizerra, V.; do Nascimento, J.G.A.; Valério, R.B.R.; de Sousa Junior, P.G.; de Sousa Braz, A.K.; Melo, R.L.F.; de França Serpa, J.; de Lima, R.K.C.; et al. Sustainable Bioethanol Production from First- and Second-Generation Sugar-Based Feedstocks: Advanced Bibliometric Analysis. Bioresour. Technol. Rep. 2023, 23, 101543. [Google Scholar] [CrossRef]

- Ferreira, V.C.; Ampese, L.C.; Sganzerla, W.G.; Colpini, L.M.S.; Forster-Carneiro, T. An Updated Review of Recent Applications and Future Perspectives on the Sustainable Valorization of Pitaya (Hylocereus spp.) by-Products. Sustain. Chem. Pharm. 2023, 33, 101070. [Google Scholar] [CrossRef]

- Sales, M.B.; Borges, P.T.; Ribeiro Filho, M.N.; Miranda da Silva, L.R.; Castro, A.P.; Sanders Lopes, A.A.; Chaves de Lima, R.K.; de Sousa Rios, M.A.; dos Santos, J.C.S. Sustainable Feedstocks and Challenges in Biodiesel Production: An Advanced Bibliometric Analysis. Bioengineering 2022, 9, 539. [Google Scholar] [CrossRef]

- Nogueira, R.C.; Neto, F.S.; Junior, P.G.d.S.; Valério, R.B.R.; Serpa, J.d.F.; Lima, A.M.d.S.; de Souza, M.C.M.; de Lima, R.K.C.; Lopes, A.A.S.; Guimarães, A.P.; et al. Research Trends and Perspectives on Hydrothermal Gasification in Producing Biofuels. Energy Nexus 2023, 10, 100199. [Google Scholar] [CrossRef]

- Neto, F.S.; Fernandes de Melo Neta, M.M.; Sales, M.B.; Silva de Oliveira, F.A.; de Castro Bizerra, V.; Sanders Lopes, A.A.; de Sousa Rios, M.A.; dos Santos, J.C.S. Research Progress and Trends on Utilization of Lignocellulosic Residues as Supports for Enzyme Immobilization via Advanced Bibliometric Analysis. Polymers 2023, 15, 2057. [Google Scholar] [CrossRef] [PubMed]

- Sales, M.B.; Neto, J.G.L.; De Sousa Braz, A.K.; De Sousa Junior, P.G.; Melo, R.L.F.; Valério, R.B.R.; de Serpa, J.F.; Da Silva Lima, A.M.; De Lima, R.K.C.; Guimarães, A.P.; et al. Trends and Opportunities in Enzyme Biosensors Coupled to Metal-Organic Frameworks (MOFs): An Advanced Bibliometric Analysis. Electrochem 2023, 4, 181–211. [Google Scholar] [CrossRef]

- Rodrigues, A.F.S.; da Silva, A.F.; da Silva, F.L.B.; dos Santos, K.M.; de Oliveira, M.P.; Nobre, M.M.R.; Catumba, B.D.; Sales, M.B.; Silva, A.R.M.; Braz, A.K.S.; et al. A Scientometric Analysis of Research Progress and Trends in the Design of Laccase Biocatalysts for the Decolorization of Synthetic Dyes. Process Biochem. 2023, 126, 272–291. [Google Scholar] [CrossRef]

- Melo, R.L.F.; Sales, M.B.; de Castro Bizerra, V.; de Sousa Junior, P.G.; Cavalcante, A.L.G.; Freire, T.M.; Neto, F.S.; Bilal, M.; Jesionowski, T.; Soares, J.M.; et al. Recent Applications and Future Prospects of Magnetic Biocatalysts. Int. J. Biol. Macromol. 2023, 253, 126709. [Google Scholar] [CrossRef] [PubMed]

- Cavalcante, I.O.; Simão Neto, F.; Sousa, P.d.S.; Aires, F.I.d.S.; Dari, D.N.D.; Chaves de Lima, R.K.; dos Santos, J.C.S. Evolving Sustainable Energy Technologies and Assessments through Global Research Networks: Advancing the Role of Blue Hydrogen for a Cleaner Future. RSC Sustain. 2024, 2, 348–368. [Google Scholar] [CrossRef]

- de Castro Bizerra, V.; Sales, M.B.; Fernandes Melo, R.L.; Andrade do Nascimento, J.G.; Junior, J.B.; França Silva, M.P.; Moreira dos Santos, K.; da Silva Sousa, P.; Marques da Fonseca, A.; de Souza, M.C.M.; et al. Opportunities for Cleaner Leather Processing Based on Protease Enzyme: Current Evidence from an Advanced Bibliometric Analysis. Renew. Sustain. Energy Rev. 2024, 191, 17. [Google Scholar] [CrossRef]

- Villalobos, D.; Povedano-Montero, J.; Fernández, S.; López-Muñoz, F.; Pacios, J.; del Río, D. Scientific Research on Verbal Fluency Tests: A Bibliometric Analysis. J. Neurolinguist. 2022, 63, 101082. [Google Scholar] [CrossRef]

- Quispe, C.A.G.; Coronado, C.J.R.; Carvalho, J.A. Glycerol: Production, Consumption, Prices, Characterization and New Trends in Combustion. Renew. Sustain. Energy Rev. 2013, 27, 475–493. [Google Scholar] [CrossRef]

- Essaaidi, M.; Zaz, Y. Biohydrogen production by dark and photo-fermentation processes. Proceedings of 2013 International Renewable and Sustainable Energy Conference (IRSEC), Ouarzazate, Morocco, 7–9 March 2013. [Google Scholar] [CrossRef]

- Woon, J.M.; Khoo, K.S.; AL-Zahrani, A.A.; Alanazi, M.M.; Lim, J.W.; Cheng, C.K.; Sahrin, N.T.; Ardo, F.M.; Yi-Ming, S.; Lin, K.S.; et al. Epitomizing Biohydrogen Production from Microbes: Critical Challenges vs. Opportunities. Environ. Res. 2023, 227, 115780. [Google Scholar] [CrossRef]

- Yadav, S.; Singh, V.; Mahata, C.; Das, D. Optimization for Simultaneous Enhancement of Biobutanol and Biohydrogen Production. Int. J. Hydrogen Energy 2021, 46, 3726–3741. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, H.; Liu, W.; Guo, J.; Xian, M. Debottlenecking the Biological Hydrogen Production Pathway of Dark Fermentation: Insight into the Impact of Strain Improvement. Microb. Cell Factories 2022, 21, 166. [Google Scholar] [CrossRef] [PubMed]

- Aslam, A.; Bahadar, A.; Liaquat, R.; Muddasar, M. Recent Advances in Biological Hydrogen Production from Algal Biomass: A Comprehensive Review. Fuel 2023, 350, 128816. [Google Scholar] [CrossRef]

- Singh, T.; Alhazmi, A.; Mohammad, A.; Srivastava, N.; Haque, S.; Sharma, S.; Singh, R.; Yoon, T.; Gupta, V.K. Integrated Biohydrogen Production via Lignocellulosic Waste: Opportunity, Challenges & Future Prospects. Bioresour. Technol. 2021, 338, 125511. [Google Scholar] [CrossRef]

- Aravind Kumar, J.; Sathish, S.; Krithiga, T.; Praveenkumar, T.R.; Lokesh, S.; Prabu, D.; Annam Renita, A.; Prakash, P.; Rajasimman, M. A Comprehensive Review on Bio-Hydrogen Production from Brewery Industrial Wastewater and Its Treatment Methodologies. Fuel 2022, 319, 123594. [Google Scholar] [CrossRef]

- Pandey, A.K.; Park, J.; Ko, J.; Joo, H.H.; Raj, T.; Singh, L.K.; Singh, N.; Kim, S.H. Machine Learning in Fermentative Biohydrogen Production: Advantages, Challenges, and Applications. Bioresour. Technol. 2023, 370, 128502. [Google Scholar] [CrossRef] [PubMed]

- Šabić Runjavec, M.; Vuković Domanovac, M.; Jukić, A. Application of Industrial Wastewater and Sewage Sludge for Biohydrogen Production. Energies 2023, 16, 2383. [Google Scholar] [CrossRef]

- Das, D.; Veziroǧlu, T.N. Hydrogen Production by Biological Processes: A Survey of Literature. Int. J. Hydrogen Energy 2001, 26, 13–28. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Hydrogen Production from Renewable and Sustainable Energy Resources: Promising Green Energy Carrier for Clean Development. Renew. Sustain. Energy Rev. 2016, 57, 850–866. [Google Scholar] [CrossRef]

- Kapdan, I.K.; Kargi, F. Bio-Hydrogen Production from Waste Materials. Enzym. Microb. Technol. 2006, 38, 569–582. [Google Scholar] [CrossRef]

- Levin, D.B.; Pitt, L.; Love, M. Biohydrogen Production: Prospects and Limitations to Practical Application. Int. J. Hydrogen Energy 2004, 29, 173–185. [Google Scholar] [CrossRef]

- Ni, M.; Leung, D.Y.C.; Leung, M.K.H.; Sumathy, K. An Overview of Hydrogen Production from Biomass. Fuel Process. Technol. 2006, 87, 461–472. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, S.; Logan, B.E. Production of Electricity from Acetate or Butyrate Using a Single-Chamber Microbial Fuel Cell. Environ. Sci. Technol. 2005, 39, 658–662. [Google Scholar] [CrossRef] [PubMed]

- Hallenbeck, P.C.; Benemann, J.R. Biological Hydrogen Production; Fundamentals and Limiting Processes. Int. J. Hydrogen Energy 2002, 27, 1185–1193. [Google Scholar] [CrossRef]

- Hawkes, F.R.; Dinsdale, R.; Hawkes, D.L.; Hussy, I. Sustainable Fermentative Hydrogen Production: Challenges for Process Optimisation. Int. J. Hydrog. Energy 2002, 27, 1339–1347. [Google Scholar] [CrossRef]

- Angenent, L.T.; Karim, K.; Al-Dahhan, M.H.; Wrenn, B.A.; Domíguez-Espinosa, R. Production of Bioenergy and Biochemicals from Industrial and Agricultural Wastewater. Trends Biotechnol. 2004, 22, 477–485. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wan, W. Factors Influencing Fermentative Hydrogen Production: A Review. Int. J. Hydrogen Energy 2009, 34, 799–811. [Google Scholar] [CrossRef]

- Chung Han Chua, E.; Wee, S.K.; Kansedo, J.; Lau, S.Y.; Lim, K.H.; Dol, S.S.; Lipton, A.N. Biological Hydrogen Energy Production by Novel Strains Bacillus paramycoides and Cereibacter azotoformans through Dark and Photo Fermentation. Energies 2023, 16, 3807. [Google Scholar] [CrossRef]

- Husaini, C.U.N.; Roslan, R.; Ramzi, A.B.; Luthfi, A.A.I.; Tan, J.P.; Lim, S.S.; Ding, G.T.; Jahim, J.M.; Abdul, P.M. The CRISPR Technology: A Promising Strategy for Improving Dark Fermentative Biohydrogen Production Using Clostridium spp. Int. J. Hydrogen Energy 2023, 48, 23498–23515. [Google Scholar] [CrossRef]

- Braga, A.F.M.; Lens, P.N.L. Natural Fermentation as an Inoculation Strategy for Dark Fermentation of Ulva spp. Hydrolysate. Biomass Bioenergy 2023, 176, 106902. [Google Scholar] [CrossRef]

- Musa Ardo, F.; Shiong Khoo, K.; Min Woon, J.; Tasnim Sahrin, N.; Fong Yeong, Y.; Ng, H.S.; Sean Goh, P.; Dina Setiabudi, H.; Kiatkittipong, W.; Wei Lim, J.; et al. Green Hydrogen Derived from Municipal Wastewater via Bioconversion by Attached Microalgae onto Various Sizes of Polyurethane Foam Cubes. Fuel 2023, 350, 128894. [Google Scholar] [CrossRef]

- Parakh, S.K.; Tian, Z.; Wong, J.Z.E.; Tong, Y.W. From Microalgae to Bioenergy: Recent Advances in Biochemical Conversion Processes. Fermentation 2023, 9, 529. [Google Scholar] [CrossRef]

- Ramanaiah, S.V.; Chandrasekhar, K.; Cordas, C.M.; Potoroko, I. Bioelectrochemical Systems (BESs) for Agro-Food Waste and Wastewater Treatment, and Sustainable Bioenergy—A Review. Environ. Pollut. 2023, 325, 121432. [Google Scholar] [CrossRef] [PubMed]

- Rocha, D.H.D.; Freitas, F.R.S.; Sakamoto, I.K.; Silva, E.L.; Varesche, M.B.A. Co-Digestion of Solid-Liquid Waste from Citrus Agroindustrial: Effect of Hydraulic Retention Time and Organic Loading Rate on H2 Production in a Long-Term Continuous Operation Leach Bed Reactor. Int. J. Hydrogen Energy 2024, 49, 554–571. [Google Scholar] [CrossRef]

- Tang, H.; Tang, C.; Luo, H.; Wu, J.; Wu, J.; Wang, J.; Jin, L.; Sun, D. Study on the Effect of Two-Phase Anaerobic Co-Digestion of Rice Straw and Rural Sludge on Hydrogen and Methane Production. Sustainability 2023, 15, 16112. [Google Scholar] [CrossRef]

- Sitthikitpanya, N.; Khamtib, S.; Sittijunda, S.; Imai, T.; Reungsang, A. Valorization of Sugarcane Leaves and Co-Digestion with Microalgal Biomass to Produce Biofuels and Value-Added Products under the Circular Economy and Zero-Waste Concepts. Energy Convers. Manag. 2024, 299, 117854. [Google Scholar] [CrossRef]

- Liu, H.; Wang, G. Fermentative Hydrogen Production from Macro-Algae Laminaria japonica Using Anaerobic Mixed Bacteria. Int. J. Hydrogen Energy 2014, 39, 9012–9017. [Google Scholar] [CrossRef]

- Xia, A.; Cheng, J.; Ding, L.; Lin, R.; Song, W.; Su, H.; Zhou, J.; Cen, K. Substrate Consumption and Hydrogen Production via Co-Fermentation of Monomers Derived from Carbohydrates and Proteins in Biomass Wastes. Appl. Energy 2015, 139, 9–16. [Google Scholar] [CrossRef]

- Latifi, A.; Avilan, L.; Brugna, M. Clostridial Whole Cell and Enzyme Systems for Hydrogen Production: Current State and Perspectives. Appl. Microbiol. Biotechnol. 2019, 103, 567–575. [Google Scholar] [CrossRef]

- Esercizio, N.; Lanzilli, M.; Landi, S.; Caso, L.; Xu, Z.; Nuzzo, G.; Gallo, C.; Manzo, E.; Esposito, S.; Fontana, A.; et al. Occurrence of Capnophilic Lactic Fermentation in the Hyperthermophilic Anaerobic Bacterium Thermotoga sp. Strain RQ7. Int. J. Mol. Sci. 2022, 23, 12049. [Google Scholar] [CrossRef]

- Schorer, L.; Schmitz, S.; Weber, A. Membrane Based Purification of Hydrogen System (MEMPHYS). Int. J. Hydrogen Energy 2019, 44, 12708–12714. [Google Scholar] [CrossRef]

- Rhandi, M.; Trégaro, M.; Druart, F.; Deseure, J.; Chatenet, M. Electrochemical Hydrogen Compression and Purification versus Competing Technologies: Part I. Pros and Cons. Chin. J. Catal. 2020, 41, 756–769. [Google Scholar] [CrossRef]

- Lebrouhi, B.E.; Djoupo, J.J.; Lamrani, B.; Benabdelaziz, K.; Kousksou, T. Global Hydrogen Development—A Technological and Geopolitical Overview. Int. J. Hydrogen Energy 2022, 47, 7016–7048. [Google Scholar] [CrossRef]

- Akroum-Amrouche, D.; Akroum, H.; Lounici, H. Simultaneous Optimization of the Hydrogen Production Rate and Substrate Conversion Efficiency Using a Response Surface Methodology. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 10633–10645. [Google Scholar] [CrossRef]

- Maintinguer, S.I.; Fernandes, B.S.; Duarte, I.C.; Saavedra, N.K.; Adorno, M.A.T.; Varesche, M.B. Fermentative Hydrogen Production by Microbial Consortium. Int. J. Hydrogen Energy 2008, 33, 4309–4317. [Google Scholar] [CrossRef]

- Hassan, A.H.S.; Mietzel, T.; Brunstermann, R.; Schmuck, S.; Schoth, J.; Küppers, M.; Widmann, R. Fermentative Hydrogen Production from Low-Value Substrates. World J. Microbiol. Biotechnol. 2018, 34, 176. [Google Scholar] [CrossRef]

- Tran, V.G.; Chu, C.Y.; Unpaprom, Y.; Ramaraj, R.; Chen, T.H. Effects of Substrate Concentration and Hydraulic Retention Time on Hydrogen Production from Common Reed by Enriched Mixed Culture in Continuous Anaerobic Bioreactor. Int. J. Hydrogen Energy 2021, 46, 14036–14044. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A.; Jamil, M.M.; Azli, A.A.M.; Misbah, M.F. A Review on Biomass-Based Hydrogen Production for Renewable Energy Supply. Int. J. Energ. Res. 2015, 39, 1597–1615. [Google Scholar] [CrossRef]

- Lepage, T.; Kammoun, M.; Schmetz, Q.; Richel, A. Biomass-to-Hydrogen: A Review of Main Routes Production, Processes Evaluation and Techno-Economical Assessment. Biomass Bioenergy 2021, 144, 105920. [Google Scholar] [CrossRef]

- Khan, A.; Niazi, M.B.K.; Ansar, R.; Jahan, Z.; Javaid, F.; Ahmad, R.; Anjum, H.; Ibrahim, M.; Bokhari, A. Thermochemical Conversion of Agricultural Waste to Hydrogen, Methane, and Biofuels: A Review. Fuel 2023, 351, 128947. [Google Scholar] [CrossRef]

- Nadaleti, W.C.; Cardozo, E.; Bittencourt Machado, J.; Maximilla Pereira, P.; Costa dos Santos, M.; Gomes de Souza, E.; Haertel, P.; Kunde Correa, E.; Vieira, B.M.; Rodrigues da Silva Junior, F.M. Hydrogen and Electricity Potential Generation from Rice Husks and Persiculture Biomass in Rio Grande Do Sul, Brazil. Renew. Energy 2023, 216, 118940. [Google Scholar] [CrossRef]

- Mukherjee, T.; Trably, E.; Kaparaju, P. Critical Assessment of Hydrogen and Methane Production from 1G and 2G Sugarcane Processing Wastes Using One-Stage and Two-Stage Anaerobic Digestion. Energies 2023, 16, 4919. [Google Scholar] [CrossRef]

- Zhu, Q.; Dong, H.; Yan, D.; Gao, D.; Xu, K.; Cheng, X.; Xin, J.; Lu, X. High Concentration Bioethanol Production from Corn Stalk via Enhanced Pretreatment with Ionic Liquids. Chem. Eng. Sci. 2024, 283, 119375. [Google Scholar] [CrossRef]

- Cao, W.; Guo, L.; Yan, X.; Zhang, D.; Yao, X. Assessment of Sugarcane Bagasse Gasification in Supercritical Water for Hydrogen Production. Int. J. Hydrogen Energy 2018, 43, 13711–13719. [Google Scholar] [CrossRef]

- Sheth, P.N.; Babu, B.V. Production of Hydrogen Energy through Biomass (Waste Wood) Gasification. Int. J. Hydrogen Energy 2010, 35, 10803–10810. [Google Scholar] [CrossRef]

- Song, Z.; Yang, G.; Guo, Y.; Zhang, T. Comparison of Two Chemical Pretreatments of Rice Straw for Biogas Production by Anaerobic Digestion. Bioresources 2012, 7, 3223–3236. [Google Scholar] [CrossRef]

- Wijeyekoon, S.L.J.; Vaidya, A.A. Woody Biomass as a Potential Feedstock for Fermentative Gaseous Biofuel Production. World J. Microbiol. Biotechnol. 2021, 37, 134. [Google Scholar] [CrossRef] [PubMed]

- Gupta, J.; Kumari, M.; Mishra, A.; Swati; Akram, M.; Thakur, I.S. Agro-Forestry Waste Management—A Review. Chemosphere 2022, 287, 132321. [Google Scholar] [CrossRef] [PubMed]

- Nurek, T.; Gendek, A.; Roman, K. Forest Residues as a Renewable Source of Energy: Elemental Composition and Physical Properties. Bioresources 2019, 14, 6–20. [Google Scholar] [CrossRef]

- Silva, V.; Rouboa, A. Optimizing the Gasification Operating Conditions of Forest Residues by Coupling a Two-Stage Equilibrium Model with a Response Surface Methodology. Fuel Process. Technol. 2014, 122, 163–169. [Google Scholar] [CrossRef]

- Michalopoulos, I.; Lytras, G.M.; Mathioudakis, D.; Lytras, C.; Goumenos, A.; Zacharopoulos, I.; Papadopoulou, K.; Lyberatos, G. Hydrogen and Methane Production from Food Residue Biomass Product (FORBI). Waste Biomass Valorization 2020, 11, 1647–1655. [Google Scholar] [CrossRef]

- Schanes, K.; Dobernig, K.; Gözet, B. Food Waste Matters—A Systematic Review of Household Food Waste Practices and Their Policy Implications. J. Clean. Prod. 2018, 182, 978–991. [Google Scholar] [CrossRef]

- Braguglia, C.M.; Gallipoli, A.; Gianico, A.; Pagliaccia, P. Anaerobic Bioconversion of Food Waste into Energy: A Critical Review. Bioresour. Technol. 2018, 248, 37–56. [Google Scholar] [CrossRef]

- Capson-Tojo, G.; Rouez, M.; Crest, M.; Steyer, J.P.; Delgenès, J.P.; Escudié, R. Food Waste Valorization via Anaerobic Processes: A Review. Rev. Environ. Sci. Biotechnol. 2016, 15, 499–547. [Google Scholar] [CrossRef]

- Li, M.; Zhao, Y.; Guo, Q.; Qian, X.; Niu, D. Bio-Hydrogen Production from Food Waste and Sewage Sludge in the Presence of Aged Refuse Excavated from Refuse Landfill. Renew. Energy 2008, 33, 2573–2579. [Google Scholar] [CrossRef]

- Cardoso, V.; Romão, B.B.; Silva, F.T.M.; Santos, J.G.; Batista, F.R.X.; Ferreira, J.S. Hydrogen Production by Dark Fermentation. Chem. Eng. Trans. 2014, 38, 481–486. [Google Scholar] [CrossRef]

- Dareioti, M.A.; Vavouraki, A.I.; Kornaros, M. Effect of PH on the Anaerobic Acidogenesis of Agroindustrial Wastewaters for Maximization of Bio-Hydrogen Production: A Lab-Scale Evaluation Using Batch Tests. Bioresour. Technol. 2014, 162, 218–227. [Google Scholar] [CrossRef]

- Azman, N.F.; Abdeshahian, P.; Al-Shorgani, N.K.N.; Hamid, A.A.; Kalil, M.S. Production of Hydrogen Energy from Dilute Acid-Hydrolyzed Palm Oil Mill Effluent in Dark Fermentation Using an Empirical Model. Int. J. Hydrogen Energy 2016, 41, 16373–16384. [Google Scholar] [CrossRef]

- Martinez-Burgos, W.J.; Bittencourt Sydney, E.; Bianchi Pedroni Medeiros, A.; Magalhães, A.I.; de Carvalho, J.C.; Karp, S.G.; Porto de Souza Vandenberghe, L.; Junior Letti, L.A.; Thomaz Soccol, V.; de Melo Pereira, G.V.; et al. Agro-Industrial Wastewater in a Circular Economy: Characteristics, Impacts and Applications for Bioenergy and Biochemicals. Bioresour. Technol. 2021, 341, 125795. [Google Scholar] [CrossRef]

- Ekwenna, E.B.; Tabraiz, S.; Wang, Y.; Roskilly, A. Exploring the Feasibility of Biological Hydrogen Production Using Seed Sludge Pretreated with Agro-Industrial Wastes. Renew. Energy 2023, 215, 118934. [Google Scholar] [CrossRef]

- Gomes, A.; Borges, A.; Peres, J.A.; Lucas, M.S. Bioenergy Production from Agro-Industrial Wastewater Using Advanced Oxidation Processes as Pre-Treatment. Catalysts 2023, 13, 1186. [Google Scholar] [CrossRef]

- Ozdemir, S.; Yetilmezsoy, K. A Mini Literature Review on Sustainable Management of Poultry Abattoir Wastes. J. Mater. Cycles Waste Manag. 2020, 22, 11–21. [Google Scholar] [CrossRef]

- Anwar, M.; Lou, S.; Chen, L.; Li, H.; Hu, Z. Recent Advancement and Strategy on Bio-Hydrogen Production from Photosynthetic Microalgae. Bioresour. Technol. 2019, 292, 121972. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Li, F.; Zhu, X.; Liao, Q.; Chang, J.S.; Ho, S.H. Biohydrogen Production from Microalgae for Environmental Sustainability. Chemosphere 2022, 291, 132717. [Google Scholar] [CrossRef]

- Cai, Z.; Zhang, W.; Zhang, J.; Zhang, J.; Ji, D.; Gao, W. Effect of Ammoniated Fiber Explosion Combined with H2O2 Pretreatment on the Hydrogen Production Capacity of Herbaceous and Woody Waste. ACS Omega 2022, 7, 21433–21443. [Google Scholar] [CrossRef]

- Irmak, S.; Öztürk, L. Hydrogen Rich Gas Production by Thermocatalytic Decomposition of Kenaf Biomass. Int. J. Hydrogen Energy 2010, 35, 5312–5317. [Google Scholar] [CrossRef]

- Wang, J.; Yin, Y. Fermentative Hydrogen Production Using Various Biomass-Based Materials as Feedstock. Renew. Sustain. Energy Rev. 2018, 92, 284–306. [Google Scholar] [CrossRef]

- Roles, J.; Yarnold, J.; Hussey, K.; Hankamer, B. Techno-Economic Evaluation of Microalgae High-Density Liquid Fuel Production at 12 International Locations. Biotechnol. Biofuels 2021, 14, 133. [Google Scholar] [CrossRef]

- Golberg, A.; Polikovsky, M.; Epstein, M.; Slegers, P.M.; Drabik, D.; Kribus, A. Hybrid Solar-Seaweed Biorefinery for Co-Production of Biochemicals, Biofuels, Electricity, and Water: Thermodynamics, Life Cycle Assessment, and Cost-Benefit Analysis. Energy Convers. Manag. 2021, 246, 114679. [Google Scholar] [CrossRef]

- De Gioannis, G.; Muntoni, A.; Polettini, A.; Pomi, R. A Review of Dark Fermentative Hydrogen Production from Biodegradable Municipal Waste Fractions. Waste Manag. 2013, 33, 1345–1361. [Google Scholar] [CrossRef]

- Vyas, S.; Prajapati, P.; Shah, A.V.; Varjani, S. Municipal Solid Waste Management: Dynamics, Risk Assessment, Ecological Influence, Advancements, Constraints and Perspectives. Sci. Total Environ. 2022, 814, 152802. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Yu, L.; Zhang, C.; Wu, Y.; Li, T. Environmental Impact Assessment of Multi-Source Solid Waste Based on a Life Cycle Assessment, Principal Component Analysis, and Random Forest Algorithm. J Environ. Manag. 2023, 339, 117942. [Google Scholar] [CrossRef] [PubMed]

- Nie, E.; He, P.; Zou, J.; Zhang, H.; Lü, F. Neglected Effect of Transportation on the Property of Municipal Biowaste and the Subsequent Biomethane Potential. J. Clean. Prod. 2022, 352, 131603. [Google Scholar] [CrossRef]

- Tian, H.; Li, J.; Yan, M.; Tong, Y.W.; Wang, C.H.; Wang, X. Organic Waste to Biohydrogen: A Critical Review from Technological Development and Environmental Impact Analysis Perspective. Appl. Energy 2019, 256, 113961. [Google Scholar] [CrossRef]

- Hsu, C.-W.; Lin, C.-Y. Commercialization Model of Hydrogen Production Technology in Taiwan: Dark Fermentation Technology Applications. Int. J. Hydrogen Energy 2016, 41, 4489–4497. [Google Scholar] [CrossRef]

- Chong, M.-L.; Sabaratnam, V.; Shirai, Y.; Hassan, M.A. Biohydrogen Production from Biomass and Industrial Wastes by Dark Fermentation. Int. J. Hydrogen Energy 2009, 34, 3277–3287. [Google Scholar] [CrossRef]

- Mathews, J.; Wang, G. Metabolic Pathway Engineering for Enhanced Biohydrogen Production. Int. J. Hydrogen Energy 2009, 34, 7404–7416. [Google Scholar] [CrossRef]

- de Sá, L.R.V.; Cammarota, M.C.; Ferreira-Leitão, V.S. Hydrogen Production by Anaerobic Fermentation—General Aspects and Possibility of Using Brazilian Agro-Industrial Wastes. Quim. Nova 2014, 37, 857–867. [Google Scholar] [CrossRef]

- Basak, N.; Jana, A.K.; Das, D.; Saikia, D. Photofermentative Molecular Biohydrogen Production by Purple-Non-Sulfur (PNS) Bacteria in Various Modes: The Present Progress and Future Perspective. Int. J. Hydrogen Energy 2014, 39, 6853–6871. [Google Scholar] [CrossRef]

- dos Santos, K.G.; De Rossi, E.; Kugelmeier, C.L.; Tietz, C.M.; Alvez, H.J. Fermentação Anaeróbia: Uma Alternativa Para a Produção de Hidrogênio. Rev. Bras. Energ. Renov. 2013, 1–12. [Google Scholar] [CrossRef]

- Khusnutdinova, A.N.; Ovchenkova, E.P.; Khristova, A.P.; Laurinavichene, T.V.; Shastik, E.S.; Liu, J.; Tsygankov, A.A. New Tolerant Strains of Purple Nonsulfur Bacteria for Hydrogen Production in a Two-Stage Integrated System. Int. J. Hydrogen Energy 2012, 37, 8820–8827. [Google Scholar] [CrossRef]

- Rai, P.K.; Singh, S.P. Integrated Dark- and Photo-Fermentation: Recent Advances and Provisions for Improvement. Int. J. Hydrogen Energy 2016, 41, 19957–19971. [Google Scholar] [CrossRef]

- Abdel-Fattah, Y.R.; Olama, Z.A. L-Asparaginase Production by Pseudomonas aeruginosa in Solid-State Culture: Evaluation and Optimization of Culture Conditions Using Factorial Designs. Process Biochem. 2002, 38, 115–122. [Google Scholar] [CrossRef]

- Zappi, A.; Hernandez, R.; Holmes, W.E. A Review of Hydrogen Production from Anaerobic Digestion. Int. J. Environ. Sci. Technol. 2021, 18, 4075–4090. [Google Scholar] [CrossRef]

- Wang, J.; Wan, W. Effect of Temperature on Fermentative Hydrogen Production by Mixed Cultures. Int. J. Hydrogen Energy 2008, 33, 5392–5397. [Google Scholar] [CrossRef]

- Valdez-Vazquez, I.; Poggi-Varaldo, H.M. Hydrogen Production by Fermentative Consortia. Renew. Sustain. Energy Rev. 2009, 13, 1000–1013. [Google Scholar] [CrossRef]

- Li, C.; Fang, H.H.P. Fermentative Hydrogen Production From Wastewater and Solid Wastes by Mixed Cultures. Crit. Rev. Environ. Sci. Technol. 2007, 37, 1–39. [Google Scholar] [CrossRef]

- Van Ginkel, S.; Sung, S.; Lay, J.-J. Biohydrogen Production as a Function of PH and Substrate Concentration. Environ. Sci. Technol. 2001, 35, 4726–4730. [Google Scholar] [CrossRef] [PubMed]

- Khanal, S. Biological Hydrogen Production: Effects of PH and Intermediate Products. Int. J. Hydrogen Energy 2003, 28, 1123–1131. [Google Scholar] [CrossRef]

- Ntaikou, I.; Antonopoulou, G.; Lyberatos, G. Biohydrogen Production from Biomass and Wastes via Dark Fermentation: A Review. Waste Biomass Valorization 2010, 1, 21–39. [Google Scholar] [CrossRef]

- Morimoto, M. Biological Production of Hydrogen from Glucose by Natural Anaerobic Microflora. Int. J. Hydrogen Energy 2004, 29, 709–713. [Google Scholar] [CrossRef]

- Antonopoulou, G.; Stamatelatou, K.; Venetsaneas, N.; Kornaros, M.; Lyberatos, G. Biohydrogen and Methane Production from Cheese Whey in a Two-Stage Anaerobic Process. Ind. Eng. Chem. Res. 2008, 47, 5227–5233. [Google Scholar] [CrossRef]

- El Bari, H.; Lahboubi, N.; Habchi, S.; Rachidi, S.; Bayssi, O.; Nabil, N.; Mortezaei, Y.; Villa, R. Biohydrogen Production from Fermentation of Organic Waste, Storage and Applications. Clean. Waste Syst. 2022, 3, 100043. [Google Scholar] [CrossRef]

- El-Qelish, M.; El-Shafai, S.A.; Azouz, R.A.M.; Rashad, E.; Elgarahy, A.M. From Seashells to Sustainable Energy: Trailblazing the Utilization of Anadara uropigimelana Shells for Sustainable Biohydrogen Production from Leftover Cooking Oil. J. Environ. Chem. Eng. 2024, 12, 111914. [Google Scholar] [CrossRef]

- Murugaiyan, J.; Narayanan, A.; Naina Mohamed, S. An Overview of Microbial Electrolysis Cell Configuration: Challenges and Prospects on Biohydrogen Production. Int. J. Energy Res. 2022, 46, 20811–20827. [Google Scholar] [CrossRef]

- Goria, K.; Kothari, R.; Singh, A.; Singh, H.M.; Tyagi, V.V. Biohydrogen: Potential Applications, Approaches, and Hurdles to Overcome. In Handbook of Biofuels; Academic Press: Cambridge, MA, USA, 2022; pp. 399–418. [Google Scholar] [CrossRef]

- Shao, W.; Wang, Q.; Rupani, P.F.; Krishnan, S.; Ahmad, F.; Rezania, S.; Rashid, M.A.; Sha, C.; Md Din, M.F. Biohydrogen Production via Thermophilic Fermentation: A Prospective Application of Thermotoga Species. Energy 2020, 197, 117199. [Google Scholar] [CrossRef]

- Samrot, A.V.; Rajalakshmi, D.; Sathiyasree, M.; Saigeetha, S.; Kasipandian, K.; Valli, N.; Jayshree, N.; Prakash, P.; Shobana, N. A Review on Biohydrogen Sources, Production Routes, and Its Application as a Fuel Cell. Sustainability 2023, 15, 12641. [Google Scholar] [CrossRef]

- Squadrito, G.; Maggio, G.; Nicita, A. The Green Hydrogen Revolution. Renew. Energy 2023, 216, 119041. [Google Scholar] [CrossRef]

- Muhsen, H.; Al-Mahmodi, M.; Tarawneh, R.; Alkhraibat, A.; Al-Halhouli, A. The Potential of Green Hydrogen and Power-to-X Utilization in Jordanian Industries: Opportunities and Future Prospects. Energies 2023, 17, 213. [Google Scholar] [CrossRef]

- Kumar, S.; Baalisampang, T.; Arzaghi, E.; Garaniya, V.; Abbassi, R.; Salehi, F. Synergy of Green Hydrogen Sector with Offshore Industries: Opportunities and Challenges for a Safe and Sustainable Hydrogen Economy. J. Clean. Prod. 2023, 384, 135545. [Google Scholar] [CrossRef]

- Candelaresi, D.; Valente, A.; Iribarren, D.; Dufour, J.; Spazzafumo, G. Comparative Life Cycle Assessment of Hydrogen-Fuelled Passenger Cars. Int. J. Hydrogen Energy 2021, 46, 35961–35973. [Google Scholar] [CrossRef]

- Handwerker, M.; Wellnitz, J.; Marzbani, H. Comparison of Hydrogen Powertrains with the Battery Powered Electric Vehicle and Investigation of Small-Scale Local Hydrogen Production Using Renewable Energy. Hydrogen 2021, 2, 76–100. [Google Scholar] [CrossRef]

- Dash, S.K.; Chakraborty, S.; Roccotelli, M.; Sahu, U.K. Hydrogen Fuel for Future Mobility: Challenges and Future Aspects. Sustainability 2022, 14, 8285. [Google Scholar] [CrossRef]

- Le, T.T.; Sharma, P.; Bora, B.J.; Tran, V.D.; Truong, T.H.; Le, H.C.; Nguyen, P.Q.P. Fueling the Future: A Comprehensive Review of Hydrogen Energy Systems and Their Challenges. Int. J. Hydrogen Energy 2024, 54, 791–816. [Google Scholar] [CrossRef]

- Hartanto, F.C.; Atikah, N.N.; Indrawan, M.S.; Tambunan, A.H. Potential for Utilizing POME to Produce Biohydrogen Gas Using Microbial Electrolysis Cell. Int. J. Oil Palm 2022, 5, 58–65. [Google Scholar] [CrossRef]

- Bello, K.A.; Awogbemi, O.; Kanakana-Katumba, M.G. Assessment of Alternative Fuels for Sustainable Road Transportation. In Proceedings of the 2023 IEEE 11th International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 13 August 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 7–15. [Google Scholar]

- Feng, S.; Hao Ngo, H.; Guo, W.; Woong Chang, S.; Duc Nguyen, D.; Thanh Bui, X.; Zhang, X.; Ma, X.Y.; Ngoc Hoang, B. Biohydrogen Production, Storage, and Delivery: A Comprehensive Overview of Current Strategies and Limitations. Chem. Eng. J. 2023, 471, 144669. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Shetti, N.P.; Reddy, K.R.; Aminabhavi, T.M. Biofuels, Biodiesel and Biohydrogen Production Using Bioprocesses—A Review. Environ. Chem. Lett. 2020, 18, 1049–1072. [Google Scholar] [CrossRef]

- Puricelli, S.; Cardellini, G.; Casadei, S.; Faedo, D.; van den Oever, A.E.M.; Grosso, M. A Review on Biofuels for Light-Duty Vehicles in Europe. Renew. Sustain. Energy Rev. 2021, 137, 110398. [Google Scholar] [CrossRef]

- Full, J.; Hohmann, S.; Ziehn, S.; Gamero, E.; Schließ, T.; Schmid, H.-P.; Miehe, R.; Sauer, A. Perspectives of Biogas Plants as BECCS Facilities: A Comparative Analysis of Biomethane vs. Biohydrogen Production with Carbon Capture and Storage or Use (CCS/CCU). Energies 2023, 16, 5066. [Google Scholar] [CrossRef]

- Oliveira, A.M.; Beswick, R.R.; Yan, Y. A Green Hydrogen Economy for a Renewable Energy Society. Curr. Opin. Chem. Eng. 2021, 33, 100701. [Google Scholar] [CrossRef]

- Hassan, Q.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M.; Al-Jiboory, A.K. Hydrogen Energy Future: Advancements in Storage Technologies and Implications for Sustainability. J. Energy Storage 2023, 72, 108404. [Google Scholar] [CrossRef]

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen Production for Energy: An Overview. Int. J. Hydrogen Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- Soares, J.F.; Confortin, T.C.; Todero, I.; Mayer, F.D.; Mazutti, M.A. Dark Fermentative Biohydrogen Production from Lignocellulosic Biomass: Technological Challenges and Future Prospects. Renew. Sustain. Energy Rev. 2020, 117, 109484. [Google Scholar] [CrossRef]

- Pal, D.B.; Singh, A.; Bhatnagar, A. A Review on Biomass Based Hydrogen Production Technologies. Int. J. Hydrogen Energy 2022, 47, 1461–1480. [Google Scholar] [CrossRef]

- Goria, K.; Singh, H.M.; Singh, A.; Kothari, R.; Tyagi, V.V. Insights into Biohydrogen Production from Algal Biomass: Challenges, Recent Advancements and Future Directions. Int. J. Hydrogen Energy 2024, 52, 127–151. [Google Scholar] [CrossRef]

- Kim, S.-H.; Kumar, G.; Chen, W.-H.; Khanal, S.K. Renewable Hydrogen Production from Biomass and Wastes (ReBioH2-2020). Bioresour. Technol. 2021, 331, 125024. [Google Scholar] [CrossRef] [PubMed]

- Baeyens, J.; Zhang, H.; Nie, J.; Appels, L.; Dewil, R.; Ansart, R.; Deng, Y. Reviewing the Potential of Bio-Hydrogen Production by Fermentation. Renew. Sustain. Energy Rev. 2020, 131, 110023. [Google Scholar] [CrossRef]

- Singh, H.; Tomar, S.; Qureshi, K.A.; Jaremko, M.; Rai, P.K. Recent Advances in Biomass Pretreatment Technologies for Biohydrogen Production. Energies 2022, 15, 999. [Google Scholar] [CrossRef]

- Aziz, M.; Darmawan, A.; Juangsa, F.B. Hydrogen Production from Biomasses and Wastes: A Technological Review. Int. J. Hydrogen Energy 2021, 46, 33756–33781. [Google Scholar] [CrossRef]

- Dahiya, S.; Chatterjee, S.; Sarkar, O.; Mohan, S.V. Renewable Hydrogen Production by Dark-Fermentation: Current Status, Challenges and Perspectives. Bioresour. Technol. 2021, 321, 124354. [Google Scholar] [CrossRef] [PubMed]

- Kumar, G.; Shobana, S.; Nagarajan, D.; Lee, D.-J.; Lee, K.-S.; Lin, C.-Y.; Chen, C.-Y.; Chang, J.-S. Biomass Based Hydrogen Production by Dark Fermentation—Recent Trends and Opportunities for Greener Processes. Curr. Opin. Biotechnol. 2018, 50, 136–145. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, P.K.T.; Das, G.; Kim, J.; Yoon, H.H. Hydrogen Production from Macroalgae by Simultaneous Dark Fermentation and Microbial Electrolysis Cell. Bioresour. Technol. 2020, 315, 123795. [Google Scholar] [CrossRef]

- Kırtay, E. Recent Advances in Production of Hydrogen from Biomass. Energy Convers. Manag. 2011, 52, 1778–1789. [Google Scholar] [CrossRef]

- Hitam, C.N.C.; Jalil, A.A. A Review on Biohydrogen Production through Photo-Fermentation of Lignocellulosic Biomass. Biomass Convers. Biorefinery 2023, 13, 8465–8483. [Google Scholar] [CrossRef]

- Łukajtis, R.; Hołowacz, I.; Kucharska, K.; Glinka, M.; Rybarczyk, P.; Przyjazny, A.; Kamiński, M. Hydrogen Production from Biomass Using Dark Fermentation. Renew. Sustain. Energy Rev. 2018, 91, 665–694. [Google Scholar] [CrossRef]

- Zhao, Z.-T.; Ding, J.; Wang, B.-Y.; Bao, M.-Y.; Liu, B.-F.; Pang, J.-W.; Ren, N.-Q.; Yang, S.-S. Advances in the Biomass Valorization in Dark Fermentation Systems: A Sustainable Approach for Biohydrogen Production. Chem. Eng. J. 2024, 481, 148444. [Google Scholar] [CrossRef]

- Pachaiappan, R.; Cornejo-Ponce, L.; Sagade, A.A.; Mani, M.; Aroulmoji, V.; Femilaa Rajan, V.; Manavalan, K. A Concise Review of Recent Biohydrogen Production Technologies. Sustain. Energy Technol. Assess. 2024, 62, 103606. [Google Scholar] [CrossRef]

- Arun, J.; Sasipraba, T.; Gopinath, K.P.; Priyadharsini, P.; Nachiappan, S.; Nirmala, N.; Dawn, S.S.; Thuy Lan Chi, N.; Pugazhendhi, A. Influence of Biomass and Nanoadditives in Dark Fermentation for Enriched Bio-Hydrogen Production: A Detailed Mechanistic Review on Pathway and Commercialization Challenges. Fuel 2022, 327, 125112. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, G.; Wang, S.; Su, H. Application of Nanomaterials in Dark or Light-Assisted Fermentation for Enhanced Biohydrogen Production: A Mini-Review. Bioresour. Technol. Rep 2023, 21, 101295. [Google Scholar] [CrossRef]

- Sindhu, M.; Sharma, R.; Saini, A.; Khanna, V.; Singh, G. Nanomaterials Mediated Valorization of Agriculture Waste Residue for Biohydrogen Production. Int. J. Hydrogen Energy 2024, 52, 1241–1253. [Google Scholar] [CrossRef]

- Krishnan, S.; Kamyab, H.; Nasrullah, M.; Wahid, Z.A.; Yadav, K.K.; Reungsang, A.; Chaiprapat, S. Recent Advances in Process Improvement of Dark Fermentative Hydrogen Production through Metabolic Engineering Strategies. Fuel 2023, 343, 127980. [Google Scholar] [CrossRef]

- Akaniro, I.R.; Oladipo, A.A.; Onwujekwe, E.C. Metabolic Engineering Approaches for Scale-up of Fermentative Biohydrogen Production—A Review. Int. J. Hydrogen Energy 2024, 52, 240–264. [Google Scholar] [CrossRef]

- Peña-Castro, J.M.; Muñoz-Páez, K.M.; Robledo-Narvaez, P.N.; Vázquez-Núñez, E. Engineering the Metabolic Landscape of Microorganisms for Lignocellulosic Conversion. Microorganisms 2023, 11, 2197. [Google Scholar] [CrossRef] [PubMed]

- D’Silva, T.C.; Khan, S.A.; Kumar, S.; Kumar, D.; Isha, A.; Deb, S.; Yadav, S.; Illathukandy, B.; Chandra, R.; Vijay, V.K.; et al. Biohydrogen Production through Dark Fermentation from Waste Biomass: Current Status and Future Perspectives on Biorefinery Development. Fuel 2023, 350, 128842. [Google Scholar] [CrossRef]

- Yang, X.; Yang, J.; Liu, X.; Wang, Q.; Liu, D.; Wang, D. Carbamazepine Improves Hydrogen Production from Anaerobic Fermentation of Waste Activated Sludge. Chem. Eng. J. 2023, 460, 141831. [Google Scholar] [CrossRef]

- Liu, L.; Cao, X.; Zhang, M.; Dong, W.; Feng, Z.; Hu, X.; Zang, L. Unraveling the Role of Polymeric Ferric Sulfate in Promoting Propionic Acid in Anaerobic Sludge Hydrogen Production Fermentation. J. Environ. Chem. Eng. 2023, 11, 110752. [Google Scholar] [CrossRef]

- Cui, P.; Wang, S.; Su, H. Enhanced Biohydrogen Production of Anaerobic Fermentation by the Fe3O4 Modified Mycelial Pellets-Based Anaerobic Granular Sludge. Bioresour. Technol. 2022, 366, 128144. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Zhu, W.; Zhao, Y.; Wang, N.; Gao, M.; Wang, Q. Anaerobic Fermentation of Organic Solid Waste: Recent Updates in Substrates, Products, and the Process with Multiple Products Co-Production. Environ. Res 2023, 233, 116444. [Google Scholar] [CrossRef]

- Ayodele, D.T.; Ogunbiyi, O.D.; Akamo, D.O.; Otun, K.O.; Akinpelu, D.A.; Adegoke, J.A.; Fapojuwo, D.P.; Oladoye, P.O. Factors Affecting Biohydrogen Production: Overview and Perspectives. Int. J. Hydrogen Energy 2023, 48, 27513–27539. [Google Scholar] [CrossRef]

- Aceves-Lara, C.A.; Latrille, E.; Steyer, J.P. Optimal Control of Hydrogen Production in a Continuous Anaerobic Fermentation Bioreactor. Int. J. Hydrogen Energy 2010, 35, 10710–10718. [Google Scholar] [CrossRef]

- Wang, B.N.; Yang, C.F.; Lee, C.M. The Factors Influencing Direct Photohydrogen Production and Anaerobic Fermentation Hydrogen Production Combination Bioreactors. Int. J. Hydrogen Energy 2011, 36, 14069–14077. [Google Scholar] [CrossRef]

- Kyrpel, T.; Saska, V.; de Poulpiquet, A.; Luglia, M.; Soric, A.; Roger, M.; Tananaiko, O.; Giudici-Orticoni, M.T.; Lojou, E.; Mazurenko, I. Hydrogenase-Based Electrode for Hydrogen Sensing in a Fermentation Bioreactor. Biosens. Bioelectron. 2023, 225, 115106. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Kosaki, Y.; Kawamura, K.; Watanabe, N. Operational Load Enhancement for an Anaerobic Membrane Bioreactor through Ethanol Fermentation Pretreatment of Food Waste. Energy Convers. Manag. 2021, 249, 114840. [Google Scholar] [CrossRef]

- Kumar, D.; Abraham, J.E.; Varghese, M.; George, J.; Balachandran, M.; Cherusseri, J. Nanocarbon Assisted Green Hydrogen Production: Development and Recent Trends. Int. J. Hydrogen Energy 2024, 50, 118–141. [Google Scholar] [CrossRef]

- Sillero, L.; Solera, R.; Perez, M. Anaerobic Co-Digestion of Sewage Sludge, Wine Vinasse and Poultry Manure for Bio-Hydrogen Production. Int. J. Hydrogen Energy 2022, 47, 3667–3678. [Google Scholar] [CrossRef]

- Badawi, E.Y.; Elkharsa, R.A.; Abdelfattah, E.A. Value Proposition of Bio-Hydrogen Production from Different Biomass Sources. Energy Nexus 2023, 10, 100194. [Google Scholar] [CrossRef]

- Eloffy, M.G.; Elgarahy, A.M.; Saber, A.N.; Hammad, A.; El-Sherif, D.M.; Shehata, M.; Mohsen, A.; Elwakeel, K.Z. Biomass-to-Sustainable Biohydrogen: Insights into the Production Routes, and Technical Challenges. Chem. Eng. J. Adv. 2022, 12, 100410. [Google Scholar] [CrossRef]

- Trinh, V.L.; Chung, C.K. Renewable Energy for SDG-7 and Sustainable Electrical Production, Integration, Industrial Application, and Globalization: Review. Clean. Eng. Technol. 2023, 15, 100657. [Google Scholar] [CrossRef]

- Oduro, R.A.; Taylor, P.G. Future Pathways for Energy Networks: A Review of International Experiences in High Income Countries. Renew. Sustain. Energy Rev. 2023, 171, 113002. [Google Scholar] [CrossRef]

- Elshahed, M.S. Microbiological Aspects of Biofuel Production: Current Status and Future Directions. J. Adv. Res. 2010, 1, 103–111. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, W.; Ling, W. Policy Optimization of Hydrogen Energy Industry Considering Government Policy Preference in China. Sustain. Prod. Consum. 2022, 33, 890–902. [Google Scholar] [CrossRef]

- Johnson, S.; Sabharwall, P.; Ballout, Y. Global Energy Policy Analysis to Achieve Near-Term Climate Goals in the United States. Next Energy 2023, 1, 100070. [Google Scholar] [CrossRef]

- Gale, F.; Goodwin, D.; Lovell, H.; Murphy-Gregory, H.; Beasy, K.; Schoen, M. Renewable Hydrogen Standards, Certifications, and Labels: A State-of-the-Art Review from a Sustainability Systems Governance Perspective. Int. J. Hydrogen Energy 2024, 59, 654–667. [Google Scholar] [CrossRef]

- De-León Almaraz, S.; Kocsis, T.; Azzaro-Pantel, C.; Szántó, Z.O. Identifying Social Aspects Related to the Hydrogen Economy: Review, Synthesis, and Research Perspectives. Int. J. Hydrogen Energy 2024, 49, 601–618. [Google Scholar] [CrossRef]

- Babayomi, O.O.; Dahoro, D.A.; Zhang, Z. Affordable Clean Energy Transition in Developing Countries: Pathways and Technologies. iScience 2022, 25, 104178. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Xue, B.; Cai, G.; Thomas, H.; Stückrad, S. Comparing the Energy Transitions in Germany and China: Synergies and Recommendations. Energy Rep. 2019, 5, 1249–1260. [Google Scholar] [CrossRef]

- Li, L.; Lin, J.; Wu, N.; Xie, S.; Meng, C.; Zheng, Y.; Wang, X.; Zhao, Y. Review and Outlook on the International Renewable Energy Development. Energy Built Environ. 2022, 3, 139–157. [Google Scholar] [CrossRef]

- Lui, J.; Chen, W.H.; Tsang, D.C.W.; You, S. A Critical Review on the Principles, Applications, and Challenges of Waste-to-Hydrogen Technologies. Renew. Sustain. Energy Rev. 2020, 134, 110365. [Google Scholar] [CrossRef]

- Piadeh, F.; Offie, I.; Behzadian, K.; Rizzuto, J.P.; Bywater, A.; Córdoba-Pachón, J.R.; Walker, M. A Critical Review for the Impact of Anaerobic Digestion on the Sustainable Development Goals. J. Environ. Manag. 2024, 349, 119458. [Google Scholar] [CrossRef] [PubMed]

- Qu, X.; Zeng, H.; Gao, Y.; Mo, T.; Li, Y. Bio-Hydrogen Production by Dark Anaerobic Fermentation of Organic Wastewater. Front. Chem. 2022, 10, 978907. [Google Scholar] [CrossRef] [PubMed]

- Almeida, E.L.; Olivo, J.E.; Andrade, C.M.G. Production of Biofuels from Glycerol from the Biodiesel Production Process—A Brief Review. Fermentation 2023, 9, 869. [Google Scholar] [CrossRef]

- Chandran, E.M.; Mohan, E. Sustainable Biohydrogen Production from Lignocellulosic Biomass Sources—Metabolic Pathways, Production Enhancement, and Challenges. Environ. Sci. Pollut. Res. 2023, 30, 102129–102157. [Google Scholar] [CrossRef] [PubMed]

- Taipabu, M.I.; Viswanathan, K.; Wu, W.; Hattu, N.; Atabani, A.E. A Critical Review of the Hydrogen Production from Biomass-Based Feedstocks: Challenge, Solution, and Future Prospect. Process. Saf. Environ. Prot. 2022, 164, 384–407. [Google Scholar] [CrossRef]

- Lin, C.Y.; Lay, C.H.; Sen, B.; Chu, C.Y.; Kumar, G.; Chen, C.C.; Chang, J.S. Fermentative Hydrogen Production from Wastewaters: A Review and Prognosis. Int. J. Hydrogen Energy 2012, 37, 15632–15642. [Google Scholar] [CrossRef]

- Wang, J.; Yin, Y. Fermentative Hydrogen Production Using Pretreated Microalgal Biomass as Feedstock. Microb. Cell Factories 2018, 17, 22. [Google Scholar] [CrossRef]

- Jain, R.; Panwar, N.L.; Jain, S.K.; Gupta, T.; Agarwal, C.; Meena, S.S. Bio-Hydrogen Production through Dark Fermentation: An Overview. Biomass Convers. Biorefinery 2022. [Google Scholar] [CrossRef]

- Kanwal, F.; Torriero, A.A.J. Biohydrogen—A Green Fuel for Sustainable Energy Solutions. Energies 2022, 15, 7783. [Google Scholar] [CrossRef]

- Jayachandran, V.; Basak, N.; De Philippis, R.; Adessi, A. Novel Strategies towards Efficient Molecular Biohydrogen Production by Dark Fermentative Mechanism: Present Progress and Future Perspective. Bioprocess Biosyst. Eng. 2022, 45, 1595–1624. [Google Scholar] [CrossRef]

- Li, M.; Ning, P.; Sun, Y.; Luo, J.; Yang, J. Characteristics and Application of Rhodopseudomonas palustris as a Microbial Cell Factory. Front. Bioeng. Biotechnol. 2022, 10, 897003. [Google Scholar] [CrossRef] [PubMed]

- Dzulkarnain, E.L.N.; Audu, J.O.; Wan Dagang, W.R.Z.; Abdul-Wahab, M.F. Microbiomes of Biohydrogen Production from Dark Fermentation of Industrial Wastes: Current Trends, Advanced Tools and Future Outlook. Bioresour Bioprocess 2022, 9, 16. [Google Scholar] [CrossRef]

- Gupta, S.; Fernandes, A.; Lopes, A.; Grasa, L.; Salafranca, J. Photo-Fermentative Bacteria Used for Hydrogen Production. Appl. Sci. 2024, 14, 1191. [Google Scholar] [CrossRef]

- Zhou, M.; Yan, B.; Wong, J.W.C.; Zhang, Y. Enhanced Volatile Fatty Acids Production from Anaerobic Fermentation of Food Waste: A Mini-Review Focusing on Acidogenic Metabolic Pathways. Bioresour. Technol. 2018, 248, 68–78. [Google Scholar] [CrossRef]

- Blasi, A.; Verardi, A.; Lopresto, C.G.; Siciliano, S.; Sangiorgio, P. Lignocellulosic Agricultural Waste Valorization to Obtain Valuable Products: An Overview. Recycling 2023, 8, 61. [Google Scholar] [CrossRef]

- Stenina, I.; Yaroslavtsev, A. Modern Technologies of Hydrogen Production. Processes 2022, 11, 56. [Google Scholar] [CrossRef]

- Panchenko, V.A.; Daus, Y.V.; Kovalev, A.A.; Yudaev, I.V.; Litti, Y.V. Prospects for the Production of Green Hydrogen: Review of Countries with High Potential. Int. J. Hydrogen Energy 2023, 48, 4551–4571. [Google Scholar] [CrossRef]

- Sarkar, O.; Modestra, J.A.; Rova, U.; Christakopoulos, P.; Matsakas, L. Waste-Derived Renewable Hydrogen and Methane: Towards a Potential Energy Transition Solution. Fermentation 2023, 9, 368. [Google Scholar] [CrossRef]

- Kindra, V.; Maksimov, I.; Oparin, M.; Zlyvko, O.; Rogalev, A. Hydrogen Technologies: A Critical Review and Feasibility Study. Energies 2023, 16, 5482. [Google Scholar] [CrossRef]

- Sahota, S.; Kumar, S.; Lombardi, L. Biohythane, Biogas, and Biohydrogen Production from Food Waste: Recent Advancements, Technical Bottlenecks, and Prospects. Energies 2024, 17, 666. [Google Scholar] [CrossRef]

| Ranking | NP | NC | AC | |

|---|---|---|---|---|

| Journals | ||||

| 1 | INTERNATIONAL JOURNAL OF HYDROGEN ENERGY | 1440 | 71,296 | 49.51 |

| 2 | BIORESOURCE TECHNOLOGY | 579 | 27,624 | 47.71 |

| 3 | RENEWABLE ENERGY | 87 | 2378 | 27.33 |

| 4 | FUEL | 81 | 2269 | 28.01 |

| 5 | RENEWABLE SUSTAINABLE ENERGY REVIEWS | 74 | 8680 | 117.3 |

| 6 | JOURNAL OF CLEANER PRODUCTION | 70 | 2048 | 29.23 |

| 7 | BIOMASS BIOENERGY | 61 | 2117 | 34.70 |

| 8 | ENERGIES | 56 | 650 | 11.60 |

| 9 | BIOTECHNOLOGY FOR BIOFUELS | 46 | 1641 | 35.67 |

| 10 | APPLIED MICROBIOLOGY AND BIOTECHNOLOGY | 43 | 2870 | 66.74 |

| Countries | ||||

| 1 | China | 1117 | 42,795 | 38.31 |

| 2 | India | 548 | 23,257 | 42.43 |

| 3 | The USA | 380 | 23,805 | 62.64 |

| 4 | South Korea | 329 | 13,720 | 41.70 |

| 5 | Brazil | 246 | 6775 | 27.54 |

| 6 | Mexico | 223 | 6453 | 28.93 |

| 7 | Thailand | 203 | 5600 | 27.58 |

| 8 | Italy | 195 | 7675 | 39.35 |

| 9 | Malaysia | 188 | 8634 | 45.92 |

| 10 | Canada | 174 | 10,708 | 61.54 |

| Institutions | ||||

| 1 | HARBIN INSTITUTE OF TECHNOLOGY | 189 | 7812 | 41.33 |

| 2 | FENG CHIA UNIVERSITY | 162 | 8477 | 52.32 |

| 3 | CHINESE ACADEMY OF SCIENCES | 136 | 5639 | 41.46 |

| 4 | UNIVERSITY OF SÃO PAULO | 123 | 3849 | 31.29 |

| 5 | TSINGHUA UNIVERSITY | 108 | 6050 | 56.01 |

| 6 | NATIONAL CHENG KUNG UNIVERSITY | 104 | 6866 | 66.01 |

| 7 | HENAN AGRICULTURAL UNIVERSITY | 97 | 1883 | 19.41 |

| 8 | KHON KAEN UNIVERSITY | 81 | 2357 | 29.09 |

| 9 | NATIONAL AUTONOMOUS UNIVERSITY OF MEXICO | 77 | 1782 | 23.14 |

| 10 | YONSEI UNIVERSITY | 72 | 1989 | 27.62 |

| Authors | ||||

| 1 | Kumar, Gopalakrishnan | 105 | 4412 | 42.01 |

| 2 | Kim, Sang-Hyoun | 98 | 3723 | 37.98 |

| 3 | Lin, Chiu-Yue | 96 | 4113 | 42.84 |

| 4 | Zhang, Quanguo | 92 | 1782 | 19.36 |

| 5 | Mohan, S. Venkata | 79 | 3962 | 50.15 |

| 6 | Reungsang, Alissara | 76 | 2229 | 29.32 |

| 7 | Ren, Nan Qi | 75 | 2925 | 39.00 |

| 8 | Chang, Jo-Shu | 74 | 4680 | 63.24 |

| 9 | Wang, Jianlong | 66 | 4265 | 64.62 |

| 10 | Zhang, Zhiping | 64 | 1292 | 20.18 |

| Rank | Title | Authors | Journal | Year Published | Citations Total | Average Annual Citations | Reference |

|---|---|---|---|---|---|---|---|

| 1 | Hydrogen production by biological processes: a survey of literature | Das, D.; Veziroglu, T.N. | International Journal of Hydrogen Energy | 2001 | 1539 | 66.91 | [71] |

| 2 | Hydrogen production from renewable and sustainable energy resources: Promising green energy carrier for clean development | Hosseini, S. E.; Wahid, M. A. | Renewable and Sustainable Energy Reviews | 2016 | 1260 | 157.5 | [72] |

| 3 | Bio-hydrogen production from waste materials | Kapdan, I.K.; Kargi, F. | Enzyme and Microbial Technology | 2006 | 1204 | 66.89 | [73] |

| 4 | Biohydrogen production: prospects and limitations to practical application | Levin, D.B.; Pitt, L.; Love, M. | International Journal of Hydrogen Energy | 2004 | 1106 | 55.3 | [74] |

| 5 | An overview of hydrogen production from biomass | Ni, M.; Leung, D.Y.C.; Leung, M.K.H.; Sumathy, K. | Fuel Processing Technology | 2006 | 857 | 47.61 | [75] |

| 6 | Production of electricity from acetate or butyrate using a single-chamber microbial fuel cell | Liu, H.; Cheng, S.A.; Logan, B.E. | Environmental Science & Technology | 2005 | 765 | 40.26 | [76] |

| 7 | Biological hydrogen production: fundamentals and limiting processes | Hallenbeck, P.C.; Benemann, J.R. | International Journal of Hydrogen Energy | 2002 | 732 | 33.27 | [77] |

| 8 | Sustainable fermentative hydrogen production: challenges for process optimisation | Hawkes, F.R.; Dinsdale, R.; Hawkes, D.L.; Hussy, I. | International Journal of Hydrogen Energy | 2002 | 721 | 32.77 | [78] |

| 9 | Production of bioenergy and biochemicals from industrial and agricultural wastewater | Angenent, L.T.; Karim, K.; Al-Dahhan, M.H.; Domíguez-Espinosa, R. | Trends In Biotechnology | 2004 | 718 | 35.9 | [79] |

| 10 | Factors influencing fermentative hydrogen production: A review | Wang, J.; Wan, W. | International Journal of Hydrogen Energy | 2009 | 667 | 44.47 | [80] |

| Rank | Keywords | TOs | TLS | Rank | Keywords | TOs | TLS |

|---|---|---|---|---|---|---|---|

| 1 | Biohydrogen production | 2194 | 5905 | 11 | Pretreatment | 555 | 1893 |

| 2 | Biohydrogen | 1414 | 3937 | 12 | Optimization | 518 | 1736 |

| 3 | Dark fermentation | 1306 | 4062 | 13 | Anaerobic digestion | 504 | 1763 |

| 4 | Fermentation | 1075 | 3150 | 14 | Glucose | 493 | 1606 |

| 5 | Hydrogen production | 984 | 2553 | 15 | Hydrogen production | 477 | 1332 |

| 6 | Fermentative hydrogen production | 780 | 2126 | 16 | Biomass | 474 | 1513 |

| 7 | Wastewater | 733 | 2424 | 17 | Methane production | 464 | 1705 |

| 8 | Food waste | 676 | 2459 | 18 | Sludge | 456 | 1623 |

| 9 | pH | 623 | 2093 | 19 | H2 production | 329 | 995 |

| 10 | Hydrogen | 586 | 1723 | 20 | Microbial communities | 311 | 1158 |

| Cluster | Items | Keywords in the VOSviewer Network |

|---|---|---|

| #1 | 35 | Anaerobic fermentation, bacteria, batch, biohydrogen production, biological hydrogen production, bioreactor, clostridium, conversion, culture, cultures, degradation, digestion, feasibility, fermentation, generation, glucose, hydrogen production, inhibition, kinetics, microflora, molasses, optimization, performance, pH, reactor, response surface methodology, sludge, starch, substrate, substrate concentration, sucrose, temperature, waste, water, and xylose |

| #2 | 27 | Activated sludge, anaerobic co-digestion, anaerobic digestion, anaerobic digestion, bioenergy, biogas, biogas production, cheese whey, co-digestion, dark fermentation, fermentative hydrogen-production, food waste, hydraulic retention time, hydrogen, hydrogen production, methane, methane production, microalgae, microbial community, municipal solid waste, oil mill effluent, organic fraction, organic loading rate, sewage sludge, volatile fatty acids, volatile fatty acids, and wastewater treatment |

| #3 | 20 | Acetate, biohydrogen, clostridium butyricum, crude glycerol, dark, dark fermentation, enterobacter aerogenes, escherichia coli, gas production, growth, h-2 production, metabolism, mixed culture, photofermentation, photoproduction, photosynthetic bacteria, rhodobacter sphaeroides, and wastewater |

| #4 | 16 | Acid, biohydrogen production, biofuels, biomass, cellulose, corn stover, energy, enzymatic hydrolysis, ethanol, ethanol production, hydrolysis, lignocellulosic biomass, mixed cultures, pretreatment, rice straw, and wheat straw |

| #5 | 2 | Enhancement and nanoparticles |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dari, D.N.; Freitas, I.S.; Aires, F.I.d.S.; Melo, R.L.F.; dos Santos, K.M.; da Silva Sousa, P.; Gonçalves de Sousa Junior, P.; Luthierre Gama Cavalcante, A.; Neto, F.S.; da Silva, J.L.; et al. An Updated Review of Recent Applications and Perspectives of Hydrogen Production from Biomass by Fermentation: A Comprehensive Analysis. Biomass 2024, 4, 132-163. https://doi.org/10.3390/biomass4010007

Dari DN, Freitas IS, Aires FIdS, Melo RLF, dos Santos KM, da Silva Sousa P, Gonçalves de Sousa Junior P, Luthierre Gama Cavalcante A, Neto FS, da Silva JL, et al. An Updated Review of Recent Applications and Perspectives of Hydrogen Production from Biomass by Fermentation: A Comprehensive Analysis. Biomass. 2024; 4(1):132-163. https://doi.org/10.3390/biomass4010007

Chicago/Turabian StyleDari, Dayana Nascimento, Isabelly Silveira Freitas, Francisco Izaias da Silva Aires, Rafael Leandro Fernandes Melo, Kaiany Moreira dos Santos, Patrick da Silva Sousa, Paulo Gonçalves de Sousa Junior, Antônio Luthierre Gama Cavalcante, Francisco Simão Neto, Jessica Lopes da Silva, and et al. 2024. "An Updated Review of Recent Applications and Perspectives of Hydrogen Production from Biomass by Fermentation: A Comprehensive Analysis" Biomass 4, no. 1: 132-163. https://doi.org/10.3390/biomass4010007

APA StyleDari, D. N., Freitas, I. S., Aires, F. I. d. S., Melo, R. L. F., dos Santos, K. M., da Silva Sousa, P., Gonçalves de Sousa Junior, P., Luthierre Gama Cavalcante, A., Neto, F. S., da Silva, J. L., Carlos de Castro, É., Santos Alexandre, V., da S. Lima, A. M., Serpa, J. d. F., Souza, M. C. M. d., & Santos, J. C. S. d. (2024). An Updated Review of Recent Applications and Perspectives of Hydrogen Production from Biomass by Fermentation: A Comprehensive Analysis. Biomass, 4(1), 132-163. https://doi.org/10.3390/biomass4010007