Unlocking Blockchain’s Potential in Supply Chain Management: A Review of Challenges, Applications, and Emerging Solutions

Abstract

1. Introduction

1.1. Motivations

1.2. Contributions

- Comprehensive Functional Mapping: Identification of key SCM functions—such as product traceability, inventory management, compliance verification, and stakeholder coordination—that can benefit most from blockchain adoption. This paper highlights how blockchain can enhance transparency, data integrity, and trust across complex supply networks.

- Critical Analysis of Adoption Challenges: This paper provides a rigorous examination of the primary barriers to blockchain implementation in SCM, including technical, organizational, and regulatory obstacles. Special attention is given to privacy protection and data security, providing a holistic understanding of adoption challenges.

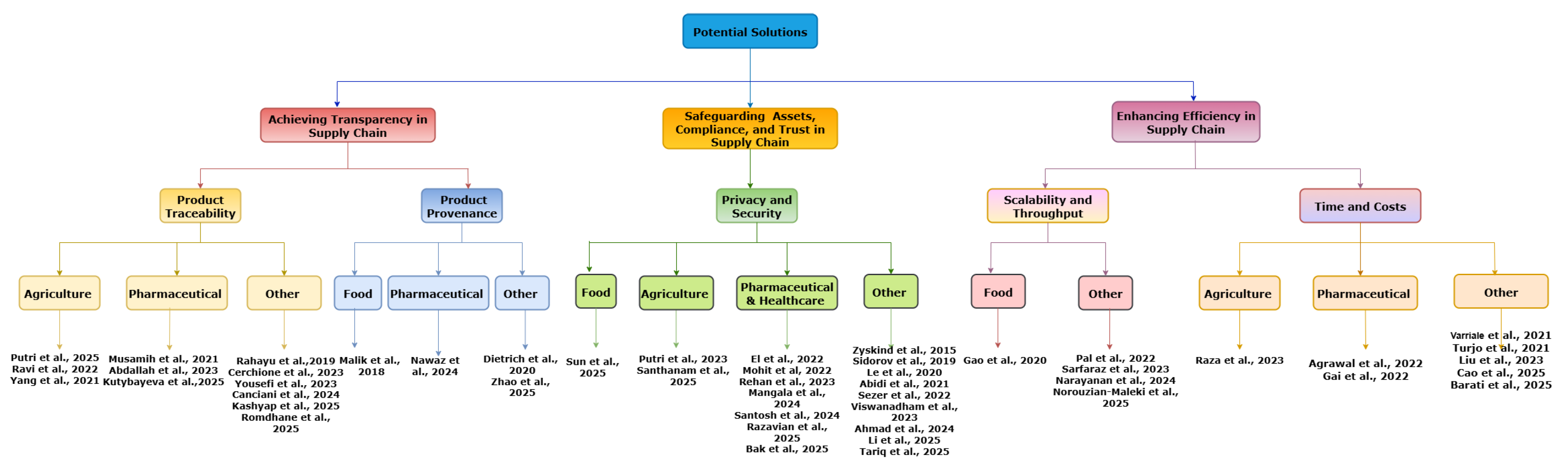

- Structured Classification of Solutions: Introduction of a novel three-dimensional classification of blockchain solutions tailored to the most pressing challenges in SCM. Solutions are grouped into (1) achieving transparency, (2) safeguarding assets, compliance, and trust, and (3) enhancing efficiency. For each group, unresolved technical and operational issues are discussed in “Critical Issues to Consider” sections.

- Forward-Looking Integration Strategy: Exploration of how emerging technologies—such as Internet of Things (IoT), Artificial Intelligence (AI), and big data—can be combined with blockchain to build intelligent, adaptive, and secure supply chains.

- Research and Practice Guidance: Actionable insights for researchers and industry stakeholders, highlighting research gaps and offering guidance on selecting scalable and cost-effective blockchain frameworks tailored to operational needs.

1.3. Structure of This Paper

2. Comparison of Related Surveys

2.1. Security-Centric Surveys

2.2. Transparency, Traceability, and Trust

2.3. Sustainability and Supply Chain Visibility

2.4. Emerging Technologies and Integration

2.5. Sector-Specific and Cross-Industry Analyses

3. Background

3.1. Supply Chain Management Concepts

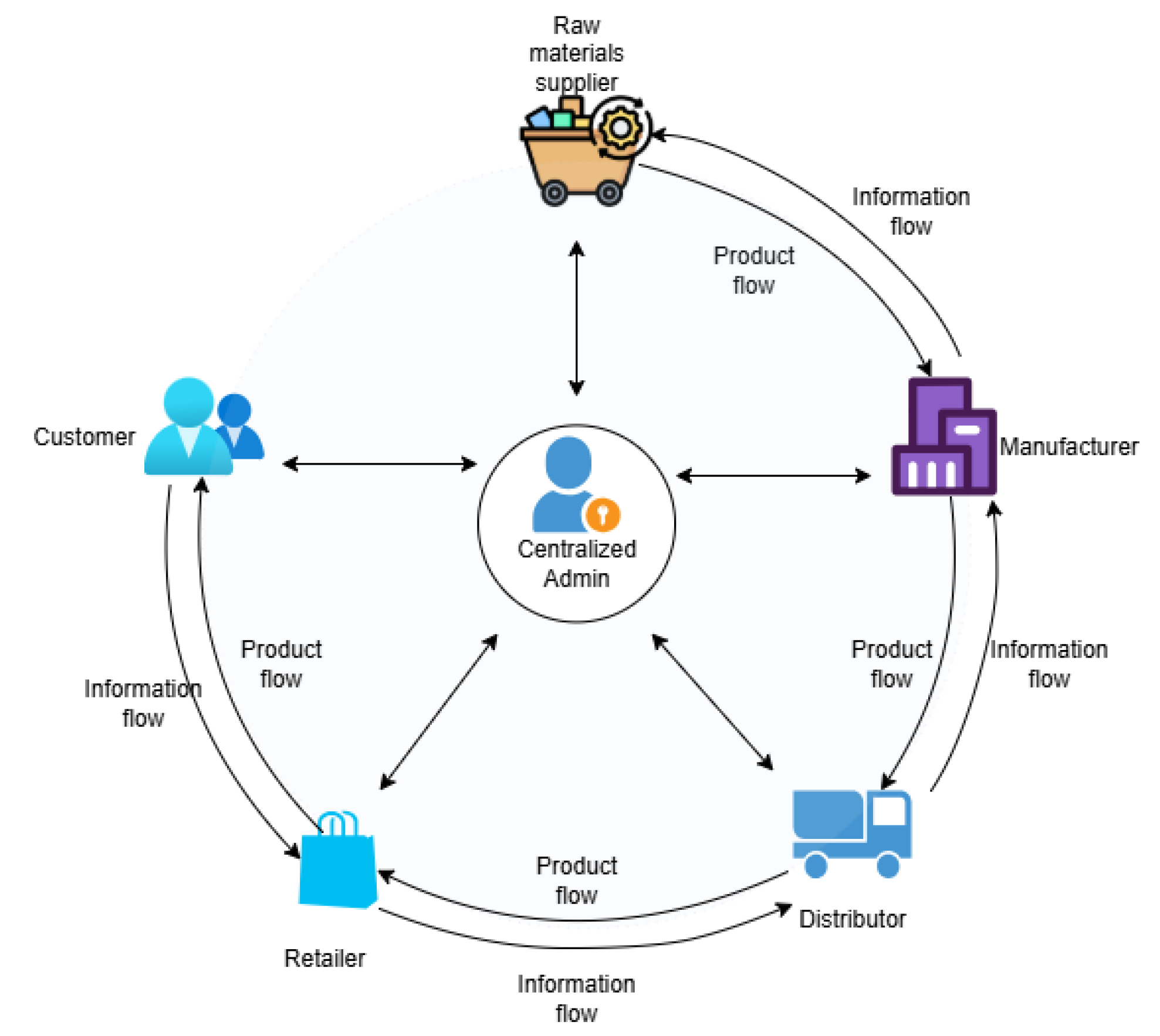

3.1.1. Traditional Supply Chain Management

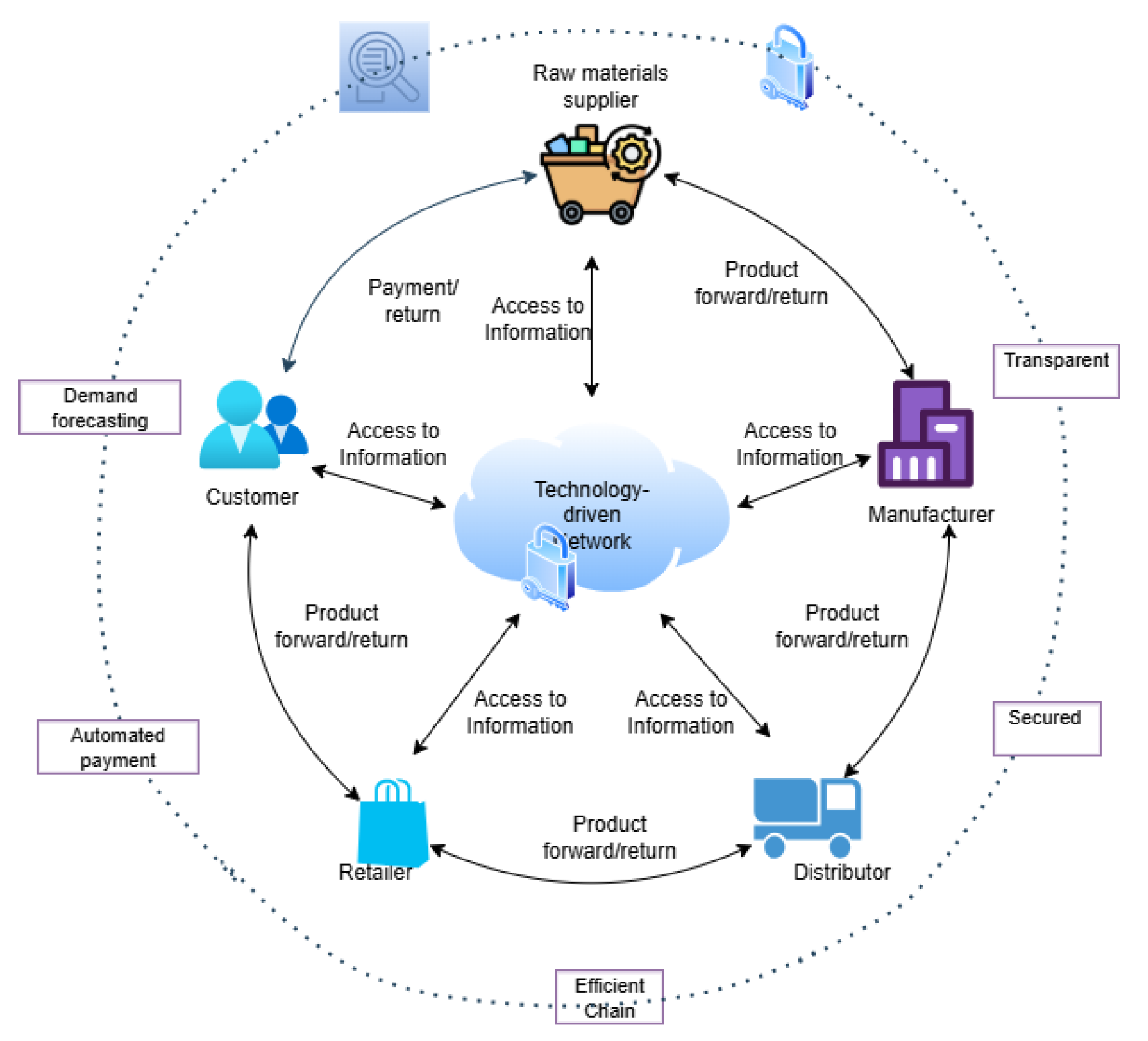

3.1.2. Modern Supply Chain Management

3.2. Blockchain Technology Concepts

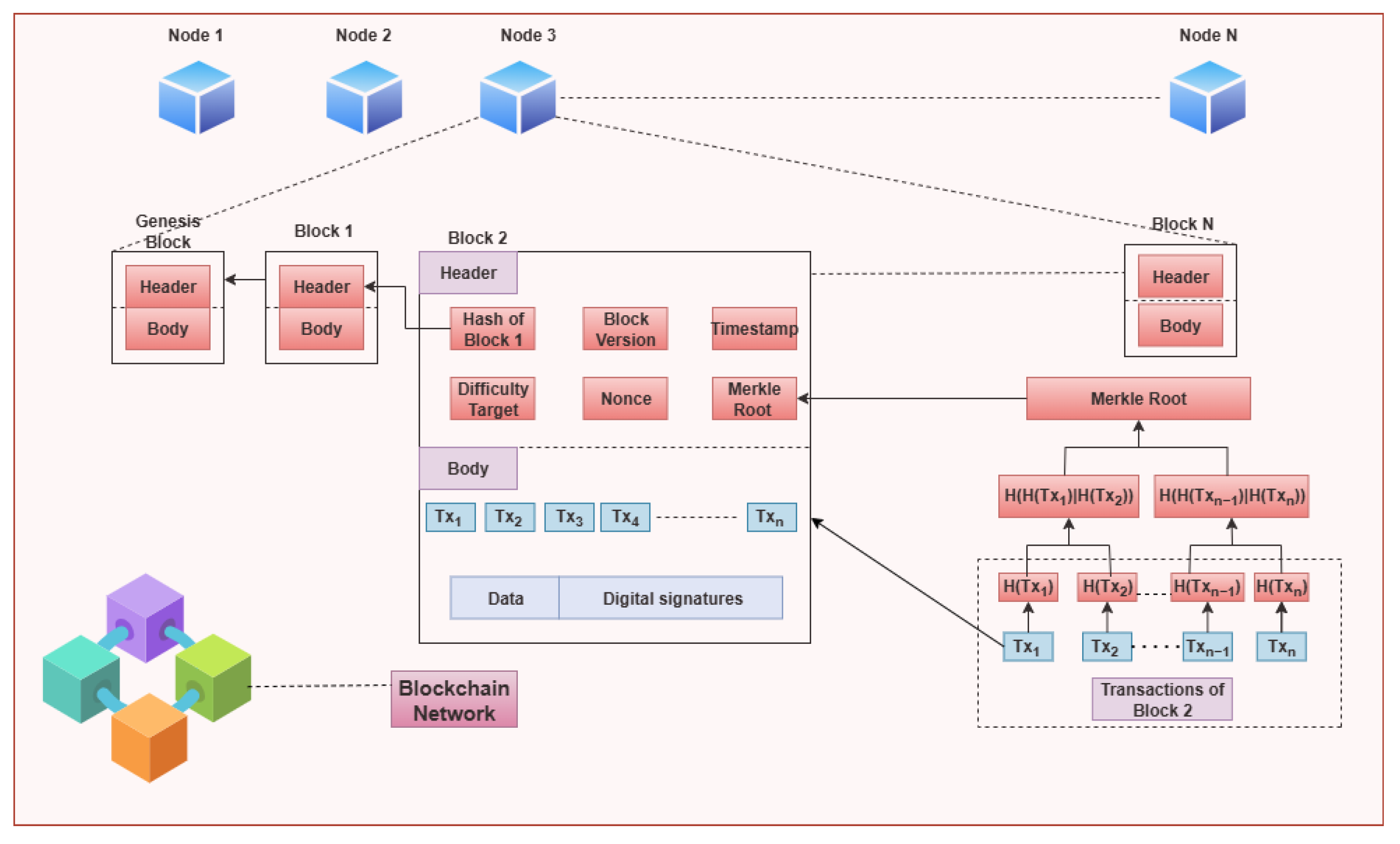

Blockchain Basics

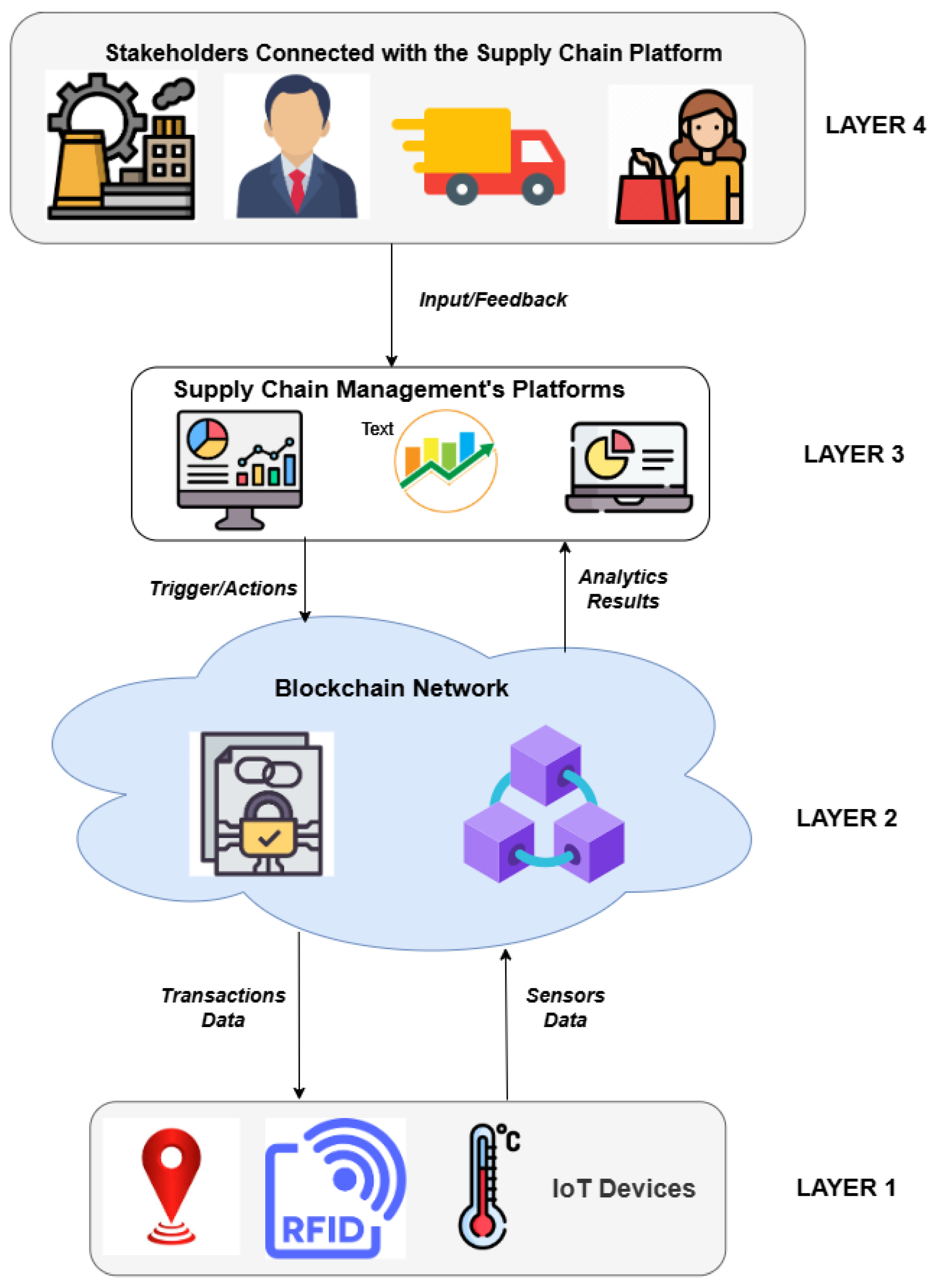

3.3. Layered Architecture of Blockchain-Enabled Supply Chain with IoT Integration

4. Blockchain Integration with Supply Chain: Advantages

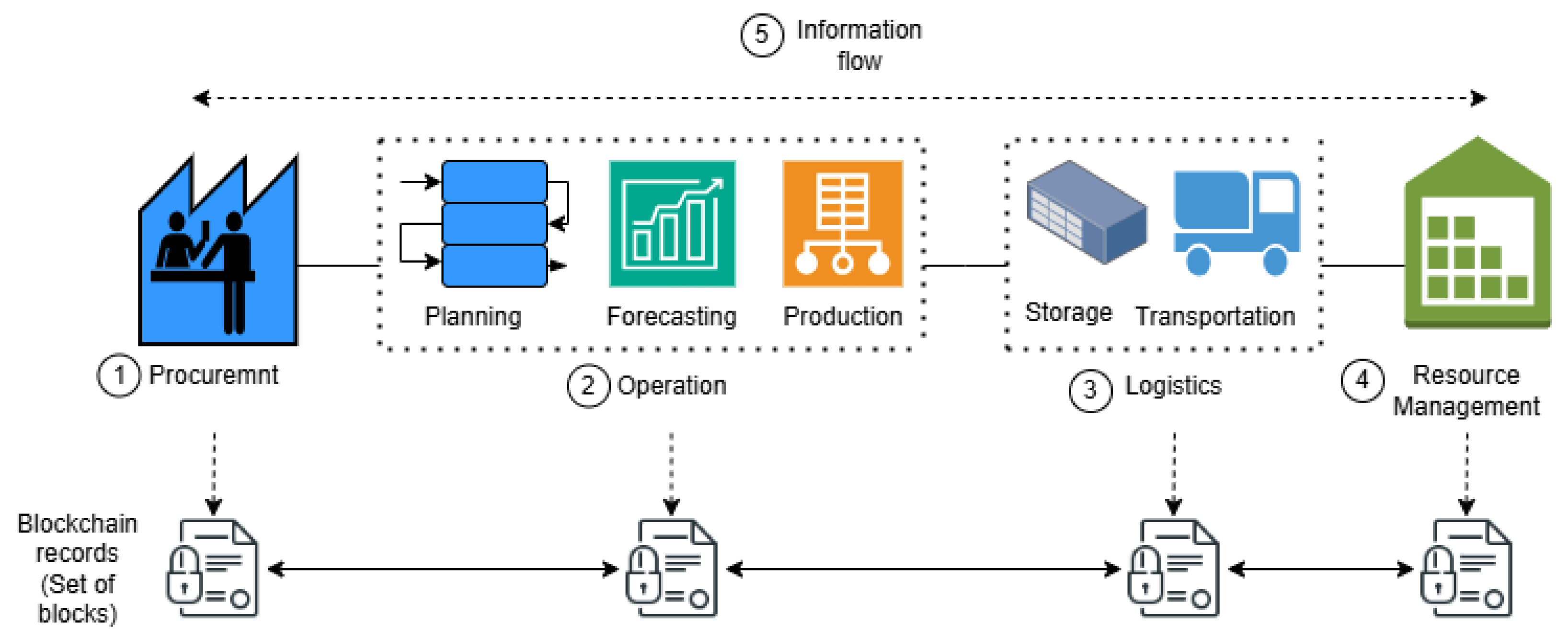

4.1. Blockchain Integration Across Core SCM Functions

4.1.1. Procurement

4.1.2. Operation

4.1.3. Logistics

4.1.4. Resource Management

4.1.5. Information Flow

4.2. Advantages of Using Blockchain: How Blockchain Is Reshaping Modern SCM Processes

4.2.1. Decentralized and Distributed Ledger Technology: Trusted, Transparent, and Traceable Supply Chains

4.2.2. Cryptography with Immutable Records: Secure and Reliable Supply Chains

4.2.3. Smart Contracts: Automated Efficient Supply Chain Processes

4.2.4. Blockchain-Powered Auditing: Reducing Time and Labor Costs

4.2.5. Integration with Emerging Technologies: Future-Proofing Supply Chains

5. Blockchain Adoption in Supply Chains: Challenges, Opportunities, and Policy Outlook

5.1. Challenges of Blockchain Adoption in Supply Chain Management

- Energy Consumption: One of the most significant challenges is the high energy requirement. Certain blockchain consensus algorithms, particularly Proof-of-Work, need significant computational resources, which use a lot of electricity. For example, Bitcoin’s annual energy consumption is expected to be larger than that of several small countries, leading to environmental concerns and increased operational costs [20]. In supply chain contexts, this can make blockchain solutions unsustainable in terms of both the environment and finances, particularly for large-scale real-time applications.

- The reliability of private blockchains: It is difficult to ensure reliable and resilient performance in decentralized, permissioned environments, especially when nodes are geographically distributed and maintained by different stakeholders.

- Transaction fees: High and fluctuating transaction costs are difficult to manage in public chains, which can have an impact on the economic feasibility of frequent or micro-transactions in supply chain management.

- Security Expenses: Balancing the costs of securing blockchain infrastructure while limiting the risks of cyberattacks is a significant challenge, since advanced security methods frequently require increased hardware, software, and maintenance costs.

- Regulatory Concerns: It is challenging to handle changing legal frameworks and compliance requirements between nations, particularly in multinational supply chains where regulations may conflict.

- High Implementation Costs: The costs of establishing, maintaining, and operating blockchain networks are truly costly, including infrastructure investment, system integration, and continuing energy consumption.

- Challenges in Integration: Integrating blockchain into existing supply chain systems necessitates overcoming compatibility issues with legacy platforms, ensuring interoperability (the ability of various blockchain platforms and enterprise systems in a supply chain to seamlessly exchange, validate, and utilize data), and managing data migration without minimal service disruption.

- Shortage of Skills: The complexity of blockchain technology has resulted in a shortage of skilled experts capable of efficiently creating, deploying, and maintaining blockchain-based SCM solutions.

- Use of Intermediaries: Using intermediaries in blockchain-based supply chains can reduce transparency, increase prices, and decrease efficiency [14].

- Digital Integration Challenges: As SCM systems strive for end-to-end digital integration, from product sourcing to delivery and returns, blockchain adoption must address concerns such as system synchronization, varying data standards, and real-time processing capabilities.

- General Data Protection Regulation (GDPR): GDPR increases individuals’ control over personal data by establishing access permissions, usage, storage, and processing regulations. When data removal is sought under the “right to be forgotten” in supply chains, other parties on the blockchain network may choose to preserve the data for operational or legal purposes.

- Privacy Issues: Blockchain’s immutability can pose significant privacy concerns, as recorded transactions cannot be edited or deleted [16].

- Balancing Security and Performance: Strong security often necessitates limiting block size or transaction rate, which can reduce throughput. Achieving the best trade-off between security and performance remains a constant problem.

5.2. Practical Implications: Blockchain Adoption for SMEs

5.3. Practical Performance Insights

5.4. Policy Considerations and Regulatory Readiness

- European Union: The European Blockchain Services Infrastructure (EBSI) and the proposed Markets in Crypto-Assets (MiCA) regulations aim to align blockchain usage with General Data Protection Regulation (GDPR) compliance and cross-border data exchange [65].

- United States: The approach is still sector-specific, with regulatory guidance from organizations such as the FDA (for food traceability) and the Department of Transportation (for logistics and customs clearance).

- Asia-Pacific: Singapore has announced national blockchain programs emphasizing digitization and trade facilitation [66].

5.5. Blockchain in Sustainability Reporting

- Carbon Footprints Tracking: Carbon emission data is recorded at each level of the supply chain for transparent reporting.

- Circular Economy Facilitation: Documenting material reuse, recycling rates, and product lifecycle information to assist Extended Producer Responsibility (EPR).

- Renewable Energy Certification: Verifiable records of renewable energy generation and consumption can be stored utilizing integrated platforms with Energy Attribute Certificates (EACs).

6. Potential Solutions and Their Limitations

- Achieving transparency in the supply chain: through improving product traceability and product provenance.

- Safeguarding assets, compliance, and trust in the supply chain: through enhancing privacy and security.

- Enhancing efficiency in the supply chain: through improving scalability and throughput, reducing time and costs.

6.1. Achieving Transparency in the Supply Chain

- (1)

- Leveraging Product Traceability

- (a)

- Supply Chain Management in the Agricultural Sector:

- (b)

- Supply Chain Management in the Pharmaceutical Sector:

- (c)

- Supply Chain Management in Other Sectors:

- (2)

- Leveraging Product Provenance

- (a)

- Supply Chain Management in the Food Sector:

- (b)

- Supply Chain Management in the Pharmaceutical Sector:

- (c)

- Supply Chain Management in Other Sectors:

- Scalability Challenges: Public and hybrid blockchain systems often struggle to handle high transaction volumes, particularly in large-scale or global supply chains.

- High Implementation Costs: Adopting advanced technologies—such as smart contracts, IoT sensors, and satellite integrations—can be prohibitively expensive for small and medium-sized enterprises (SMEs), limiting their ability to implement blockchain solutions.

- Dependence on Infrastructure: Real-time tracking relies on robust digital infrastructure and reliable internet connectivity, which may not be available in remote or underdeveloped regions.

- Integration Barriers and Technical Complexity: Integrating blockchain with existing supply chain management systems and third-party logistics platforms often demands significant technical expertise and standardized protocols.

- Lack of Stakeholder Engagement: Many traditional stakeholders lack awareness or understanding of emerging technologies. Their resistance to adoption underscores the need for intuitive user interfaces and comprehensive training.

- Smart Contract Vulnerabilities: Poorly written or unverified smart contracts can introduce security risks, potentially undermining the integrity and transparency of the entire system.

| Related Survey | Year | Key Contributions | Evaluation Factor | Experimental Validation | Technologies Used | Limitations |

|---|---|---|---|---|---|---|

| [81] | 2018 | End-to-end traceability and monitoring, Improving scalability, Transaction vocabulary for data handling | Traceability and Scalability | Implementation | Blockchain (Permissioned), Sharding, Smart contracts, Cryptographic methods, IoT (Sensor data and HACCP) | Limited automation, Complexity in sharding management, Disconnected product ledger |

| [75] | 2019 | Developed a conceptual model for military blockchain, Enhanced authenticity, reliability, and security | Traceability and Security | Conceptual | A fully private blockchain, Smart contracts, Proof-of-Work (PoW) consensus mechanism | Implementation and scalability challenges, High costs |

| [69] | 2020 | A detailed framework for chili supply chain management, Enhanced data traceability and security, Improved product quality and consumer confidence, Reduced waste and fraud | Traceability, Cost, and Security | Conceptual | Blockchain (Hyperledger), RFID, IoT sensors, Google maps, Smart contracts | Scalability issues, High initial costs, Dependence on internet and power infrastructure |

| [82] | 2020 | Smart contract-based framework for transparency, Vertical and horizontal blockchain integration, Timestamp Function for Hash IDs | Transparency | Conceptual | Blockchain, Smart contract, Hash IDs | Scalability issues, Complex integration, Limited stakeholder access |

| [71] | 2021 | Implementation of a trusted traceability system for agricultural products, Improved traceability, Dual storage structure, Secure data management | Traceability | Implementation | Hyperledger fabric, Smart contracts, CBC | Complexity of dual storage, Privacy and security concerns |

| [72] | 2021 | Blockchain-based pharmaceutical supply chain solution, Enhanced confidentiality, traceability, immutability, and accessibility, Security and cost analysis | Traceability, Security, and Cost | Implementation | Blockchain (Ethereum), Smart contracts, InterPlanetary File System (IPFS), DApp, QR codes, IoT-enabled smart containers | Regulatory challenges, Limited focus on external threats, Adoption of new technologies is challenging |

| [70] | 2022 | Balanced transparency with privacy and secrecy, Enhanced efficiency and scalability, Performance evaluation | Data Integrity, Transparency, Privacy, and Scalability | Simulation (Hyperledger Fabric, Docker, Couch-DB, Caliper) | Blockchain (Hyperledger fabric), Smart contracts, Hyperledger Caliper | Complexity of implementation, Scalability issues |

| [73] | 2023 | Blockchain-Based pharmaceutical supply chain solution, Elimination of trusted third-party authenticators, Increased transparency, reliability and security | Transparency and Security | Implementation | Blockchain (Ethereum), Smart contracts, Cloud-hosted servers and MQTT (Messaging Queuing Telemetry Transport) protocols and IoT-enabled containers | High implementation costs, Complexity of technology integration, Scalability concerns |

| [76] | 2023 | Enhanced understanding and provided guidelines of integrating blockchain into SCM | Transparency, Traceability, and Privacy | Conceptual | Blockchain (Hyperledger), IoT, Smart contracts | The proof-of-concept (PoC) is not fully tested on a broad scale |

| [77] | 2023 | Enhanced socioenvironmental sustainability and traceability | Sustainability, Traceability | Implementation | Blockchain, Fuzzy Cognitive Mapping (FCM), Combined Compromise Solution (CoCoSo) Method | One disadvantage of this work is the absence of uncertainty in the FCM model, as well as the risk of bias from assigning weights to choice criteria via pairwise comparisons. |

| [17] | 2024 | Development of PHTrack for pharmaceuticals supply chain, Enhanced Traceability and security, Improved interoperability, Flexible data model | Traceability and Security | Implementation | Blockchain (Hyperledger Sawtooth), Quantum-secure off-chain communication, TLS-based secure connection, Dynamic QR codes, Smart contracts | Scalability issues, High implementation costs. |

| [78] | 2024 | Proposed a hybrid blockchain model for DPP, Enhanced transparency and privacy | Transparency and Privacy | Conceptual | Digital Product Passport (DPP), Hybrid blockchain, Smart contracts | Integration challenges of hybrid blockchain architecture |

| [83] | 2025 | Developed a blockchain-based smart factory supply chain traceability model (BCTMSSF) with a novel Verifiable Delegated Proof-of-Stake (VDPoS) consensus mechanism. | Traceability, Accuracy, and Data transparency | Simulation to evaluate the performance of the BCTMSSF model | Blockchain, the VDPoS consensus algorithm with dynamic probability and fuse mechanisms, and a custom smart factory simulation environment | Restricted data diversity and application exclusively to alliance chains limit its generalizability to public blockchain ecosystems. |

| [79] | 2025 | Identified blockchain-based enablers (e.g., TAT, SC, RC) for decreasing food loss and waste (FLW), with the circular economy and SDGs. | Traceability and Transparency | Implementation | Blockchain, Fuzzy DEMATEL, IoT, Smart contracts, Digital Identity Verification. | Subjectivity of expert opinions, restricted geographical breadth, and limitations in blockchain deployment and scalability. |

| [80] | 2025 | Proposed a blockchain and IoT-based traceability architecture with three validation models for live biological goods in SME supply chains. | Traceability, Security, and Operational costs. | Hybrid simulation using FlexSim® and Java based on real-world data from a Quebec lobster supply chain. | Blockchain (EOSIO), IoT middleware (Pareto Anywhere), Bloom Filters, Substreams, SCOR, ADACOR. | Relies on simulation rather than real-world deployment, with limited IoT hardware availability. |

| [74] | 2025 | Proposed EBETPSCM model consisting of hyperledger fabric and big data analytics to improve traceability, transparency, and efficiency in pharmaceutical supply chains. | Data immutability, Traceability, and Operational visibility across stakeholders. | Conceptual and Prototype Implementation | Hyperledger fabric, Big data analytics, and cryptographic methods | Scalability issues and real-world deployment challenges. |

6.2. Safeguarding Assets, Compliance, and Trust in the Supply Chain

- (1)

- Ensuring Privacy and Security

- (a)

- Supply Chain Management in the Food Sector:

- (b)

- Supply Chain Management in the Agricultural Sector:

- (c)

- Supply Chain Management in the Pharmaceutical and Healthcare Sector:

- (d)

- Supply Chain Management in Other Sectors:

- Balancing Transparency and Confidentiality: Many systems struggle to maintain a balance between protecting private information and ensuring public accountability. One proposed solution is the use of hybrid methods, which combine both private and public blockchain architectures or integrate on-chain and off-chain storage. However, this approach can increase system complexity without fully resolving the underlying tension.

- Key Management and Encryption Overhead: Generating, distributing, and storing keys is still challenging. Another issue is single points of failure, which may result from relying on centralized key management systems like CDS or MySQL.

- Regulatory Compliance and Legal Ambiguities: Many supply chain systems, particularly those aiming to deploy off-chain data storage and manage user consent, fail to meet the compliance requirements set by regulations such as GDPR, HIPAA, or other industry-specific standards.

- Trustworthiness of Off-Chain Storage: Spying, stealing, or deleting data from off-chain storage is relatively easy. Therefore, if sensitive data is stored off-chain using systems like IPFS or LevelDB, they may encounter challenges related to auditability, access control, and durability.

- Classifying Data to Sensitive and Non-sensitive: Many privacy-preserving methods in blockchain-based supply chains rely on classifying data as sensitive or non-sensitive. However, inaccurate classification can lead to serious privacy risks—exposing sensitive information if mislabeled as non-sensitive, or reducing efficiency if non-sensitive data is overprotected. This highlights the need for accurate, standardized classification mechanisms to ensure proper data handling without compromising privacy or transparency.

- Complexity of Access Control Mechanisms’: Sometimes, some access control mechanisms such as even/odd Hamming weights or attribute-based access control (ABAC) can be very successful, but their implementation and maintenance are difficult and also prone to mistakes.

- IoT System Security Vulnerabilities: Edge devices, sensors, and IoT systems are still vulnerable to attacks like firmware assaults, spoofing, and physical tampering. These vulnerabilities can jeopardize the integrity of the blockchain record.

- Overhead of Optimization Algorithms: Authors have proposed to use different optimization algorithms like WNU, ABC-ROA, and PCGSO to improve efficiency and security of BC-based SCN system, but due to their computing demands, it is difficult to use them in real-time settings.

| Related Survey | Year | Key Contributions | Evaluation Factor | Experimental Validation | Technologies Used | Limitations |

|---|---|---|---|---|---|---|

| [94] | 2015 | Data ownership and control, fine-grained access control, transparency and auditability, integration with mobile SDKs | Data privacy and transparency | Conceptual | Blockchain, DHT, Off-blockchain key-value storage | Only conceptual design; assumption of honest-but-curious services; scalability concerns |

| [95] | 2019 | Enhanced security, transparency, and efficiency using lightweight RFID protocol in permissioned blockchain, Hamming weight-based access control | Transparency and security | Simulation (GNY logic and AVISPA tool with OFMC and CL-AtSe) | Blockchain (permissioned), RFID, SHA-256, Hamming weight | Unsecured communication between reader and tag; Hamming weight might be vulnerable to specific attacks or errors |

| [96] | 2020 | Creation of trusted environment, enhanced security and scalability, flexible modular design | Trust, security | Implementation | Blockchain (Ethereum), Smart contracts, IPFS, Contract Name Service (CNS) | On-chain/off-chain data complexity; network scalability concerns; complex implementation |

| [14] | 2021 | New optimization technique (WNU), four-level supply chain network, performance evaluation, secure data transmission | Data privacy | Simulation (MATLAB, dataset from Kaggle) | Blockchain, Public-private key cryptography, Data sanitization and restoration, Crosspoint-based Optimization (WNU) | Limited transaction capacity; transparency issues; complex network |

| [97] | 2022 | Off-chain/on-chain integration, enhanced transparency, data privacy | Transparency, traceability, data privacy | Implementation | Permissioned blockchain, Smart contracts, ECDSA, Web3 | Scalability issues; complexity of integration |

| [87] | 2022 | Enhanced security and privacy, protect sensitive data during transmission, Information Hiding Techniques (IHTs), comprehensive security framework | Data privacy and security | Simulation (NS-3 with Go Ethereum) | Ethereum, Hyperledger, ECDSA, Steganography, Smart contracts, IHT, Edge/fog computing, NS-3 | Latency issues; scalability concerns; lack of encryption/decryption process details |

| [88] | 2022 | Enhanced traceability and privacy; security/privacy assessments | Data privacy and traceability | Implementation | Hyperledger Sawtooth, Centralized Data Store (CDS), Smart contracts, Base64 Encoding, SHA-256 | Limited transaction throughput; scalability issues; dependence on CDS; network bandwidth limitations |

| [6] | 2023 | Enhanced privacy and supply chain security, data sanitization/restoration techniques, ABC-ROA algorithm | Data privacy and security | Simulation (MATLAB) | Ethereum blockchain, Smart contracts, ABC-ROA, R software, Machine learning, Khatri-Rao product | Scalability concerns; high computational overhead; complex implementation |

| [15] | 2023 | Secure/trustworthy info sharing, optimization-based privacy preservation | Data privacy | Simulation (Dataco_Smart_Supply_Chain from Kaggle) | Blockchain, PCGSO algorithm | Limited implementation details; no real-world testing; scalability issues |

| [89] | 2023 | Blockchain-based smart bidding system, enhanced data security/transparency, optimized pricing | Transparency, security, profit boost | Implementation | Ethereum, Smart contracts, Unity 3D, Moralis | Model tailored to Indonesian agricultural supply chain |

| [85] | 2023 | Enhanced SCM for sensitive products, privacy/security, modular architecture | Transparency, traceability, security, data integrity | Implementation | Hyperledger Fabric, Industrial IoT, IPFS, AMOP, Smart contracts, Kubernetes | Scalability/compatibility issues; slow transactions; cybersecurity risks; high cost |

| [98] | 2024 | Blockchain + IoT + Edge computing, RF-PO optimization, improved transparency/security, reduced delays | Security and transparency | Implementation | Hyperledger, IoT, Edge computing, RF-PO, heuristic algorithm | Scalability/interoperability issues |

| [91] | 2024 | Novel CMBC consensus mechanism, enhanced security | Security | Conceptual | Ethereum blockchain, Smart contracts | Implementation and scalability concerns |

| [90] | 2024 | Blockchain + IoT + Mist–Edge–Fog–Cloud computing, compare three blockchain platforms | Security and scalability | Implementation | Bitcoin, Ethereum, Filecoin, IoT, Mist–Edge–Fog–Cloud, IPFS | High cost; complex system; data privacy issues |

| [84] | 2025 | Hybrid blockchain (public/private) + AC mechanism for privacy/security; ML-based recommender for inventory prediction | Transparency, security, inventory efficiency, consumer satisfaction | Implemented in Python’s scrappy-redis framework with simulations | Hybrid blockchain, Access control, Collaborative filtering, Web scraping, ML (scikit-learn) | Scalability beyond 20 nodes not validated; encryption overhead; recommender overfitting |

| [99] | 2025 | Fine-grained access via smart contracts, dynamic searchable encryption, operator credibility consensus | Security, efficiency, scalability | Implementation | Hyperledger Fabric, Smart contracts, Cloud storage, Searchable encryption | Abstract model; lacks full development |

| [93] | 2025 | Eight challenges in blockchain adoption; conceptual assessment framework for HCSCs | Data access/verification, resilience, interoperability, adoption barriers, staff adaptation | Implementation | Blockchain, EHR, Computer-on-wheels, Web/mobile integration, IoT devices | Lack of interoperability with external systems; analog process alignment challenges |

| [86] | 2025 | BC-CYD algorithm for agricultural SCM; blockchain storage, authentication, data quality/reliability | Precision, accuracy, AUC-ROC, processing time, training time | Simulation with implementation | Blockchain, Authentication mechanisms, Smart contracts, Cryptographic ledger storage | Current limitations not explicit; future work to integrate IoT for real-time data |

| [92] | 2025 | Two-stage decision-making (HFBWM + IZSHFG) for HSCM method selection | Prioritizing blockchain adoption barriers | Conceptual | HFBWM, IZSHFG, Weighted Sum Operator, Blockchain | Limited to developing countries; small expert panel |

| [100] | 2025 | Secure/authentication for RFID-enabled SCMS with blockchain + PUFs | Lower computational/communication cost with higher security | Simulation and protocol analysis | Blockchain, RFID, PUFs, Authentication protocols | Budget constraints for large-scale deployment; PUF hardware heterogeneity |

6.3. Enhancing Efficiency in the Supply Chain

- (1)

- Scalability and Throughput for Efficient Operations

- (a)

- Supply Chain Management in the Food Sector:

- (b)

- Supply Chain Management in Other Sectors:

- (2)

- Reducing Time and Costs for Competitive Advantage

- (a)

- Supply Chain Management in the Agricultural Sector:

- (b)

- Supply Chain Management in the Pharmaceutical Sector:

- (c)

- Supply Chain Management in Other Sectors:

- Cross-Platform Communication: In many systems, the interoperability between cross-chain platforms lacks behind which makes it difficult for different blockchain networks to work together with existing enterprise systems.

- Energy Consumption and Consensus Overhead: Some consensus techniques like PBFT (Practical Byzantine Fault Tolerance) and POW (Proof-of-Work) require high energy consumption, which may be offset the efficiency of SCM. As a result, it is critical to implement more energy-efficient algorithms more widely.

- Inadequate Focus on Real-time implementation: Real-world stress circumstances may not be well simulated, and there is still a lack of performance validation in situations with high transaction volumes and frequencies.

- Security of Oracle and Smart Contracts: Strengthening smart contracts and external data sources (oracles) against manipulation or errors is essential, since these flaws can compromise trust, speed, and cost effectiveness.

- Handling Data Migration and Legacy Systems: While real-world supply chains usually rely on outdated data and legacy systems, many frameworks suggested by the scholars assume clean data and modern technology, which is impractical.

- Difficulties in Assuring Edge Device Connectivity and Reliability: There is no doubt that IoT sensors along with RFID tags are very essential parts of many systems, but they need a constant power source and network access, which may lead to inefficient supply chain management.

| Related Survey | Year | Key Contributions | Evaluation Factor | Experimental Validation | Technologies Used | Limitations |

|---|---|---|---|---|---|---|

| [102] | 2020 | Introduced a hybrid information system architecture, Enhanced end-to-end traceability of data | Traceability | Conceptual | Permissioned BC, IoT | Lack of practical implementation, High costs, Security and privacy concerns |

| [101] | 2020 | Implementation of a Food Supply Chain Traceability System (FSCTS), Improved traceability | Traceability | Implementation | Hyperledger fabric, Smart contracts | Dependence on single organizations, Integration challenges between blockchain and ERP |

| [108] | 2021 | Simulation Comparison, Improved data visibility, product tracking, and efficiency, Reduction of Order management time and waste, Secure transaction and real-time monitoring | Sustainability and Time | Simulation (Anylogic 7.0.2 Professional) | Blockchain, IoT, RFID, and Smart contract | Single simulation, Exclusion of cost analysis, Limited scope, Short time frame |

| [109] | 2021 | Elimination of a third party, Web-based network, Enhanced data security, and streamline transactions, detailed evaluation and validation of the system | Security | Implementation | Ethereum, Smart contract, Web development technologies and framework | High transaction volumes could lead to higher transaction costs and lower scalability, Off-chain data is vulnerable to security attacks |

| [106] | 2022 | Blockchain integration for pharmaceutical product recalls, Cost and time reduction, Mathematical models and equations for cost optimization | Transparency, Security, Cost and Time | Implementation | Blockchain, Hyperledger composer, SHA256 hashing, Dynamic QR codes | Distribution is based on a single country, Data privacy and scalability issues, Shift to blockchain-based ERP would be challenging and time-consuming |

| [107] | 2022 | Blockchain-based digital twin solution, Improved throughput, Reduced time and energy consumption | Time and Energy | Simulation | Blockchain (Hyperledger fabric), Digital twin technology | Scalability would be a great concern in certain peak scenarios like pandemics. |

| [111] | 2023 | Emphasizes the benefits of blockchain integration for enterprise operations, OSBFT Algorithm, Reduced cost | Cost | Simulation (MATLAB) | Blockchain (Ether-based), OSBFT and Genetic Algorithm | Limitations in variable design and sample selection |

| [13] | 2023 | Introduction of AccessChain, Advanced access-control, Improved throughput, latency, and scalability, Secure transactions | Data Privacy, Scalability and Throughput | Implementation | Blockchain, ABAC protocol, Sharding | Unweighed mining costs of PoW, Limited scope of evaluation |

| [105] | 2023 | Automate and digitalize agricultural supply chain procedures, Increased efficiency and reduced cost | Automation, Transparency, Traceability, and Cost analysis | Conceptual | Blockchain (Ethereum), Smart contract, IoT | Interoperability and scalability issues |

| [110] | 2023 | Implemented a novel architecture using Directed Acyclic Graph (DAG), Introduced a new parallel search algorithm, Reduced time overhead | Traceability and Time | Implementation | Blockchain (Hyperledger fabric), DAG, Graph search algorithm | Enhanced storage overhead, Scalability issues. |

| [103] | 2024 | Blockchain-based product circulation system, Enhanced traceability, scalability, and efficiency, reduced cost and delays | Product authenticity, Traceability, and Accountability | Implementation | Blockchain (Ethereum), ERC-721 smart contract, RFID Tags, Holographic Labels, and MetaMask | Complex and costly implementation, High energy consumption, Limited real-world testing |

| [112] | 2025 | Proposed a blockchain-based SCM architecture, Enhanced Raft consensus with preparatory candidates and election index rules, Developed a multi-business collaboration model, Parallelized genetic algorithm (GA) crossover for faster computation, Used TOPSIS for optimal decision-making | Computation time savings, Throughput (TPS), CPU, Memory, and Disk usage | Simulation | Hyperledger Fabric, Solidity, Truffle framework, Parallel GA and TOPSIS | Not tested on dynamic tasking scenarios and real-world deployment adaptability is not fully verified |

| [113] | 2025 | Applies system dynamics modeling to capture long-term effects on cost and performance. Offers strategic insights for phased blockchain adoption. | Forecasting accuracy, Cost optimization, and Supply chain efficiency | Simulation through system dynamics models | Blockchain (Ethereum), ERC-721 smart contract, RFID Tags, Holographic Labels, and MetaMask | High initial expenses. Furthermore, industry-wide adoption and data integration across all supply chain nodes are necessary for maximum benefits. |

| [104] | 2025 | Proposed a unique simulation-optimization framework that combines system dynamics, DEA, and bi-objective model to enable a blockchain-enabled blood supply chain. | Donor participation, Fair platelet distribution, and Efficiency | Simulation | Blockchain, System Dynamics Modeling, Data Envelopment Analysis (DEA), Bi-objective Optimization. | Limited to platelet supply chain modeling; Real-time data integration or broader clinical validation are not included. |

7. Main Findings and Research Pathways

7.1. Emerging Solutions for Mitigating Challenges

- IoT-Enabled Blockchain Integration:Incorporating IoT with blockchain enhances data integrity and real-time monitoring, directly addresses data reliability and trust issues. However, it often involves substantial setup and operational costs, linking back to the high implementation cost challenge making widespread adoption difficult without scalable, cost-effective infrastructure [48,51].

- Off-Chain Data Storage: Technologies such as the InterPlanetary File System (IPFS) are used to store large datasets off-chain, addressing blockchain scalability and reducing transaction load, while still maintaining the verifiability of important data [52]. However, a key challenge lies in determining which data should remain off-chain that affects system design and trust.

- Blockchain Sharding: Sharding enhances transaction throughput and reduces latency by dividing the network into smaller partitions (shards) that can process transactions in parallel that mitigates the performance limitations noted earlier. However, it introduces complexity in cross-shard communication and interoperability.

- Data Protection with Optimization Algorithms: Algorithms like PCGSO, ABC-ROA, and WNU improve data privacy and security by enabling secure key generation and data sanitization [114]. However, these methods cause high computational complexity, parameter sensitivity, and scalability issues, especially in large-scale SCM environments.

- Smart Contracts and Security Risks: Smart contracts automate transactions, reducing reliance on intermediaries and addressing trust challenges [48]. However, they face vulnerabilities such as Denial of Service (DoS), integer overflow/underflow, and front-running attacks [53]. These risks require secure coding practices, continuous auditing, and integration with reliable oracles.

7.2. Current Gaps and Research Opportunities

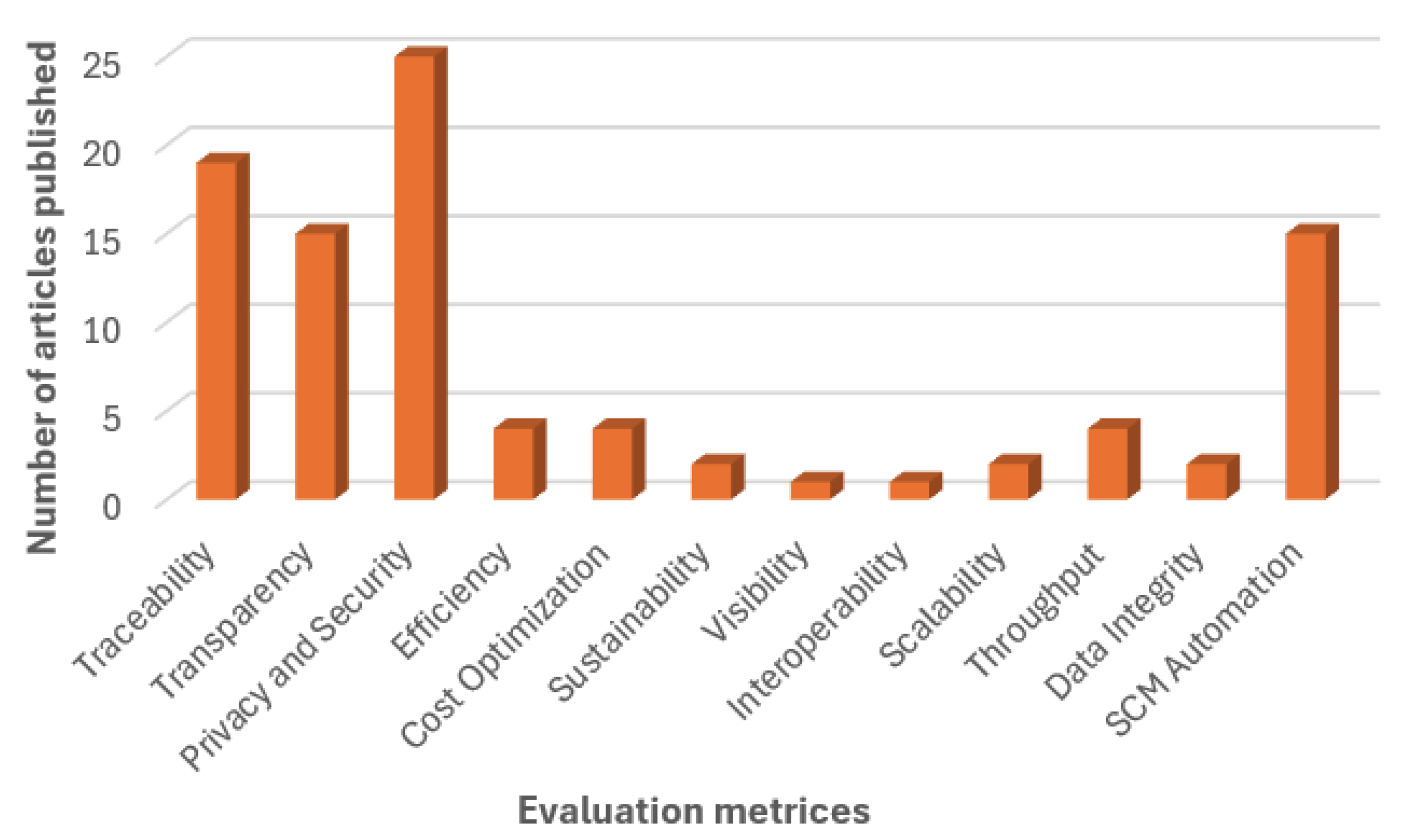

- Limited Focus Beyond Traceability: Most existing studies emphasize traceability, transparency, data privacy, and automation. However, areas like sustainability, transaction throughput, interoperability, and long-term scalability are comparatively underexplored.

- Interoperability Challenges: Seamless data exchange across different blockchain platforms remains a major hurdle. Current research on blockchain interoperability is still nascent, with few practical solutions. Particular challenges include the integration of private and public blockchains and the implementation of cross-sharding techniques, both of which are technically complex and costly.

- Need for Universal Communication Protocols: Future research should aim to develop standardized protocols that facilitate secure, reliable data exchange across hybrid blockchain architectures, enabling broader collaboration among supply chain stakeholders.

- Energy Consumption in Consensus Mechanisms: Many blockchain platforms rely on consensus mechanisms like Proof-of-Work (PoW), which are energy-intensive and environmentally unsustainable. There is a pressing need to explore and deploy more energy-efficient consensus algorithms that retain security while lowering power usage.

- Integration with Emerging Technologies: Greater efforts should be made to integrate blockchain with complementary technologies such as Artificial Intelligence (AI), big data, Internet of Things (IoT), and machine learning. These integrations can support predictive analytics, anomaly detection, and intelligent automation in SCM systems.

- Cybersecurity as a Priority: As cyber threats evolve, securing blockchain platforms must remain a top research priority. This includes developing frameworks for threat detection, intrusion prevention, smart contract verification, and secure multi-party computation.

7.3. Underexplored Domains for Blockchain in SCM

- Aerospace: This sector involves highly sensitive, mission-critical components, where part traceability is essential to ensure safety, compliance, and performance, requiring immutable provenance tracking for safety-critical parts [53].Possible approach: Create blockchain-based digital twins for each component, preserving manufacturing details, test results, and maintenance records in an immutable ledger. Smart contracts can verify compliance with regulatory criteria before parts are permitted for use [53].

- Luxury Goods: The luxury market suffers from widespread counterfeiting, damage reputation of brand value and consumer trust.Possible approach: Use blockchain-based certificates of authenticity embedded in NFC or QR-enabled tags. This enables consumers, retailers, and customs officials to instantaneously verify product provenance and ownership history, lowering counterfeit penetration and increasing resale value [50].

- Automotive: Automotive supply chains are vast and complex, tracking parts from manufacture to installation supports efficient recalls and warranty claims [51].Possible approach: Use blockchain to maintain a tamper-proof record of part origin, quality inspections, and installation dates. Smart contracts can automate recall notifications by cross-referencing affected part IDs, and transparently track sustainability metrics (e.g., carbon footprint of production).

- Energy and Utilities: Energy source verification lacks transparency, and peer-to-peer energy trade is inefficient.Possible approach: Use blockchain-based energy certificates to verify renewable energy generation at the source. Integrate with IoT-enabled smart meters for real-time energy usage data. Use smart contracts to settle peer-to-peer trades with transparent pricing [48].

- Fashion and Apparel: Unethical sourcing and counterfeit goods jeopardize labor conditions, environmental impact, sustainability and brand credibility.Possible approach: Implement blockchain-based supply chain mapping, from raw materials to final delivery, including supplier audits and sustainability certificates. QR codes on product tags enable buyers to access sourcing and labor condition details, encouraging ethical behaviors [49].

- Consumer Electronics: Supply chains for electronics often involve the movement of high-value components and sensitive intellectual property that are prone to fraud and supply chain penetration.Possible approach: Use blockchain to record every transaction, from component manufacture to product assembly, including firmware versions and IP ownership information. Smart contracts can restrict access to critical design files, and immutable records can simplify warranty claims and regulatory audits [52].

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moosavi, J.; Naeni, L.; Fathollahi-Fard, A.; Fiore, U. Blockchain in supply chain management: A review, bibliometric, and network analysis. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef]

- Hassija, V.; Chamola, V.; Gupta, V.; Jain, S.; Guizani, N. A Survey on Supply Chain Security: Application Areas, Security Threats, and Solution Architectures. IEEE Internet Things J. 2021, 8, 6222–6246. [Google Scholar] [CrossRef]

- Chang, S.; Chen, Y. When blockchain meets supply chain: A systematic literature review on current development and potential applications. IEEE Access 2020, 8, 62478–62494. [Google Scholar] [CrossRef]

- Dutta, P.; Choi, T.; Somani, S.; Butala, R. Blockchain technology in supply chain operations: Applications, challenges and research opportunities. Transp. Res. Part E Logist. Transp. Rev. 2020, 142, 102067. [Google Scholar] [CrossRef]

- Wu, H.; Cao, J.; Yang, Y.; Tung, C.; Jiang, S.; Tang, B.; Liu, Y.; Wang, X.; Deng, Y. Data management in supply chain using blockchain: Challenges and a case study. In Proceedings of the 2019 28th International Conference on Computer Communication and Networks (ICCCN), Valencia, Spain, 29 July–1 August 2019; pp. 1–8. [Google Scholar]

- Viswanadham, Y.; Jayavel, K. A framework for data privacy preserving in supply chain management using hybrid meta-heuristic algorithm with ethereum blockchain technology. Electronics 2023, 12, 1404. [Google Scholar] [CrossRef]

- Hussein, Z.; Salama, M.A.; El-Rahman, S.A. Evolution of Blockchain Consensus Algorithms: A Review on the Latest Milestones. Cybersecurity 2023, 6, 30. [Google Scholar] [CrossRef]

- Bada, A.O.; Damianou, A.; Angelopoulos, C.M.; Katos, V. Towards a Green Blockchain: A Review of Consensus Mechanisms and Their Energy Consumption. Technical Report. Bournemouth University. 2022. Available online: https://eprints.bournemouth.ac.uk/36968/1/GREEN_BLOCKCHAIN.pdf (accessed on 3 July 2025).

- GS1. EPCIS & CBV—Standards for Sharing Supply Chain Event Data. GS1 Standard. 2024. Available online: https://www.gs1.org/standards/epcis (accessed on 3 July 2025).

- Eren, H.; Karaduman, Ö.; Gençoğlu, M.T. Security Challenges and Performance Trade-Offs in On-Chain and Off-Chain Blockchain Storage: A Comprehensive Review. Appl. Sci. 2025, 15, 3225. [Google Scholar] [CrossRef]

- Zhu, H.; Yang, L.; Wang, L.; Sheng, V.S. A Survey on Security Analysis Methods of Smart Contracts. IEEE Trans. Serv. Comput. 2024, 17, 4522–4539. [Google Scholar] [CrossRef]

- Hejazi, N.; Lashkari, A.H. A Comprehensive Survey of Smart Contracts Vulnerability Analysis Tools. J. Netw. Comput. Appl. 2025, 237, 104142. [Google Scholar] [CrossRef]

- Sarfaraz, A.; Chakrabortty, R.; Essam, D. AccessChain: An access control framework to protect data access in blockchain enabled supply chain. Future Gener. Comput. Syst. 2023, 148, 380–394. [Google Scholar] [CrossRef]

- Abidi, M.; Alkhalefah, H.; Umer, U.; Mohammed, M. Blockchain-based secure information sharing for supply chain management: Optimization assisted data sanitization process. Int. J. Intell. Syst. 2021, 36, 260–290. [Google Scholar] [CrossRef]

- Aljabhan, B.; Obaidat, M. Privacy-preserving blockchain framework for supply chain management: Perceptive Craving Game Search Optimization (PCGSO). Sustainability 2023, 15, 6905. [Google Scholar] [CrossRef]

- Bernabe, J.; Canovas, J.; Hernandez-Ramos, J.; Moreno, R.; Skarmeta, A. Privacy-preserving solutions for blockchain: Review and challenges. IEEE Access 2019, 7, 164908–164940. [Google Scholar] [CrossRef]

- Nawaz, A.; Wang, L.; Irfan, M.; Westerlund, T. Hyperledger sawtooth based supply chain traceability system for counterfeit drugs. Comput. Ind. Eng. 2024, 190, 110021. [Google Scholar] [CrossRef]

- Sunmola, F.; Lawrence, G.L. Key Success Factors for Integration of Blockchain and ERP Systems: A Systematic Literature Review. Procedia Comput. Sci. 2024, 230, 187–195. [Google Scholar] [CrossRef]

- Dalal, A.; Abdul, S. Integrating Blockchain with ERP Systems: Benefits and Challenges. SSRN Working Paper. 2024. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5171901 (accessed on 5 July 2025).

- Asante, D.; Amoako-Gyampah, K.; Agyei-Owusu, B. The effect of supply chain integration on operational performance. J. SCM 2021, 57, 123–140. [Google Scholar]

- Al-Farsi, S.; Rathore, M.; Bakiras, S. Security of blockchain-based supply chain management systems: Challenges and opportunities. Appl. Sci. 2021, 11, 5585. [Google Scholar] [CrossRef]

- Cheung, K.; Bell, M.; Bhattacharjya, J. Cybersecurity in logistics and supply chain management: An overview and future research directions. Transp. Res. Part E Logist. Transp. Rev. 2021, 146, 102217. [Google Scholar] [CrossRef]

- Agarwal, U.; Rishiwal, V.; Tanwar, S.; Chaudhary, R.; Sharma, G.; Bokoro, P.; Sharma, R. Blockchain technology for secure supply chain management: A comprehensive review. IEEE Access 2022, 10, 85493–85517. [Google Scholar] [CrossRef]

- Dietrich, F.; Ge, Y.; Turgut, A.; Louw, L.; Palm, D. Review and analysis of blockchain projects in supply chain management. Procedia Comput. Sci. 2021, 180, 724–733. [Google Scholar] [CrossRef]

- Hellani, H.; Sliman, L.; Samhat, A.; Exposito, E. On blockchain integration with supply chain: Overview on data transparency. Logistics 2021, 5, 46. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 9000:2005—Quality Management Systems—Fundamentals and Vocabulary, 3rd ed.; ISO: Geneva, Switzerland, 2005; Withdrawn, new version available: ISO 9000:2015.; Available online: https://www.iso.org/standard/42180.html (accessed on 20 August 2025).

- Batwa, A.; Norrman, A. Blockchain technology and trust in supply chain management: A literature review and research agenda. Oper. Supply Chain Manag. Int. J. 2021, 14, 203–220. [Google Scholar] [CrossRef]

- Berneis, M.; Bartsch, D.; Winkler, H. Applications of blockchain technology in logistics and supply chain management—Insights from a systematic literature review. Logistics 2021, 5, 43. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Simske, S.; Treiblmaier, H. Blockchain technologies in logistics and supply chain management: A bibliometric review. Logistics 2021, 5, 72. [Google Scholar] [CrossRef]

- Thanasi-Boçe, M. Blockchain for Sustainable Development: A Systematic Literature Review. Sustainability 2025, 17, 4848. [Google Scholar] [CrossRef]

- Sahoo, S.; Kumar, S.; Sivarajah, U.; Lim, W.; Westland, J.; Kumar, A. Blockchain for sustainable supply chain management: Trends and ways forward. Electron. Commer. Res. 2024, 24, 1563–1618. [Google Scholar] [CrossRef]

- Sahoo, S.; Kumar, A.; Mishra, R.; Tripathi, P. Strengthening supply chain visibility with blockchain: A Prisma-based review. IEEE Trans. Eng. Manag. 2022, 71, 1787–1803. [Google Scholar] [CrossRef]

- Mohammed, A.; Potdar, V.; Quaddus, M.; Hui, W. Blockchain adoption in food supply chains: A systematic literature review on enablers, benefits, and barriers. IEEE Access 2023, 11, 14236–14255. [Google Scholar] [CrossRef]

- Singh, G.; Dadhich, M. Supply Chain Management Growth with the Adoption of Blockchain Technology (BoT) and Internet of Things (IoT). In Proceedings of the 2023 3rd International Conference on Advance Computing and Innovative Technologies in Engineering (ICACITE), Greater Noida, India, 12–13 May 2023; pp. 321–325. [Google Scholar]

- Singh, I.; Singh, B. Integration of Decentralized BlockChain with Cloud & IoT Based SCM. In Proceedings of the 2023 International Conference on Advancement in Computation & Computer Technologies (InCACCT), Gharuan, India, 5–6 May 2023; pp. 887–892. [Google Scholar]

- Kumar, N.; Kumar, K.; Aeron, A.; Verre, F. Blockchain technology in supply chain management: Innovations, applications, and challenges. Telemat. Inform. Rep. 2025, 18, 100204. [Google Scholar] [CrossRef]

- Samantray, B.; Reddy, K. Blockchain-enabled secured supply chain for smart cities: A systematic review on architecture, technology, and service management. Peer-to-Peer Netw. Appl. 2025, 18, 174. [Google Scholar] [CrossRef]

- Owusu-Berko, L. Advanced supply chain analytics: Leveraging digital twins, IoT and blockchain for resilient, data-driven business operations. World J. Adv. Res. Rev. 2025, 25, 1777–1799. [Google Scholar] [CrossRef]

- Chang, A.; El-Rayes, N.; Shi, J. Blockchain technology for supply chain management: A comprehensive review. FinTech 2022, 1, 191–205. [Google Scholar] [CrossRef]

- Dudczyk, P.; Dunston, J.; Crosby, G. Blockchain Technology for Global Supply Chain Management: A Survey of Applications, Challenges, Opportunities & Implications. IEEE Access 2024, 12, 70065–70088. [Google Scholar]

- Jadon, S.; Rao, A.; Jagadish, N.; Nadakatti, S.; R., T.; Honnavalli, P. Blockchain in the Electronics Industry for Supply Chain Management: A Survey. IEEE Access 2024, 12, 7089–7120. [Google Scholar] [CrossRef]

- Vern, P.; Panghal, A.; Mor, R.; Kamble, S. Blockchain technology in the agri-food supply chain: A systematic literature review of opportunities and challenges. Manag. Rev. Q. 2025, 75, 643–675. [Google Scholar] [CrossRef]

- Ellahi, R.M. Blockchain-Driven Food Supply Chains: A Systematic Literature Review. Appl. Sci. 2024, 14, 8944. [Google Scholar] [CrossRef]

- Wangthong, S.; Juicharoen, N. Challenges of Using Blockchain Technology in Supply Chain Management within the Manufacturing Industry. Asian J. Manag. Entrep. Soc. Sci. 2025, 5, 62–77. [Google Scholar]

- Deshmukh, A.; Vasudevan, H. Emerging Supplier Selection Criteria in The Context of Traditional VS Green Supply Chain Management. Int. J. Manag. Value Supply Chain. 2014, 5, 19–33. [Google Scholar] [CrossRef]

- PlanetTogether. The Five Functions of Supply Chain Management. 2021. Available online: https://www.planettogether.com/aps-trends/the-five-functions-of-supply-chain-management (accessed on 6 July 2025).

- Yazıcılar Sola, F.G.; Güzel, D. The Role of Supply Chain Transparency and Supplier Trust in Blockchain Adoption. Sustainability 2025, 17, 5171. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain Technology and Its Relationships to Sustainable Supply Chain Management. Int. J. Prod. Res. 2018, 57, 2117–2135. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. A Supply Chain Transparency and Blockchain Technology Evaluation System. Int. J. Prod. Res. 2022, 60, 6198–6215. [Google Scholar] [CrossRef]

- Francisco, K.; Swanson, D. The Supply Chain Has No Clothes: Technology Adoption of Blockchain for Supply Chain Transparency. Logistics 2021, 5, 4. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Keogh, J.G.; Treiblmaier, H. Blockchain Technology in the Smart Supply Chain: A Review of the Literature and Implications for the Future. Technol. Forecast. Soc. Change 2022, 176, 121429. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Simske, S.J.; Keogh, J.G.; Treiblmaier, H. How Blockchain Smart Contracts Are Transforming Supply Chain Management. Technol. Forecast. Soc. Change 2022, 175, 121336. [Google Scholar] [CrossRef]

- Kshetri, N. Blockchain and Supply Chain Management; Elsevier: Amsterdam, The Netherlands, 2025. [Google Scholar]

- Morell, M.; Kirshner, J.; Schoenberger, T. An Analysis of Bitcoin’s Use in Illicit Finance; Crypto Council for Innovation: Washington, DC, USA, 2021. [Google Scholar]

- Frizzo-Barker, J.; Chow-White, P.A.; Adams, P.R.; Mentanko, J.; Ha, D.; Green, S. Blockchain as a disruptive technology for business: A systematic review. Int. J. Inf. Manag. 2020, 51, 102029. [Google Scholar] [CrossRef]

- Mahjoub, Y.I.; Hassoun, M.; Trentesaux, D. Blockchain adoption for SMEs: Opportunities and challenges. IFAC-PapersOnLine 2022, 55, 1834–1839. [Google Scholar] [CrossRef]

- Deng, N.; Shi, Y.; Wang, J.; Gaur, J. Testing the adoption of blockchain technology in supply chain management among MSMEs in China. Ann. Oper. Res. 2025, 350, 629–648. [Google Scholar] [CrossRef]

- Espahbod, S.; Tashakkori, A.; Mohsenibeigzadeh, M.; Zarei, M.; Arani, G.G.; Dzikuć, M. Blockchain-Driven Supply Chain Analytics and Sustainable Performance: Analysis Using PLS-SEM and ANFIS. Sustainability 2024, 16, 6469. [Google Scholar] [CrossRef]

- Muduli, K.; Raut, R.; Narkhede, B.E.; Shee, H. Blockchain Technology for Enhancing Supply Chain Performance and Reducing the Threats Arising from the COVID-19 Pandemic. Sustainability 2022, 14, 3290. [Google Scholar] [CrossRef]

- Kamath, R. Food Traceability on Blockchain: Walmart’s Pork and Mango Pilots with IBM. J. Br. Blockchain Assoc. 2018, 1. [Google Scholar] [CrossRef]

- Walmart and Sam’s Club to Require Real-Time, End-to-End Food Traceability with Blockchain. 24 September 2018. Available online: https://corporate.walmart.com/content/dam/corporate/documents/press-center/in-wake-of-romaine-e-coli-scare-walmart-deploys-blockchain-to-track-leafy-greens/press-release-leafy-greens-on-blockchain.pdf (accessed on 10 August 2025).

- TradeLens. TradeLens Overview and Benefits. Maersk and IBM White Paper. 2020. Available online: https://www.maersk.com/~/media_sc9/maersk/local-information/files/west-central-asia/india/tradelens-solution-brief.pdf (accessed on 10 August 2025).

- Dawson, E.N.; Taylor, A.; Chen, Y. ISO/TC 307 Blockchain and Distributed Ledger Technologies. 2016. Available online: https://www.iso.org/committee/6266604.html (accessed on 10 August 2025).

- Delimatsis, P. When Disruptive Meets Streamline: International Standardization in Blockchain. In Blockchains, Smart Contracts, Decentralised Autonomous Organisations and the Law; Edward Elgar Publishing: Cheltenham, UK, 2019; pp. 83–100. [Google Scholar]

- Santos, R.; Almeida, J.; Martins, C.; Gomes, H.; Guimarães, C.; Costa, F.; Pina, R.; Saraiva, A. Sustainable Supply Chain Strategies: A Review of EU Policies and Blockchain Implementations (2019–2024). In Marketing and Smart Technologies; Springer Nature: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Cheah, S.; Pattalachinti, S.; Ho, Y.P. Blockchain Industries, Regulations and Policies in Singapore. Asian Research Policy 2018, 9, 83–98. [Google Scholar]

- Del Negro, G. Bridging Methodologies for Sustainability: A Review of Environmental Assessment Frameworks. Master’s Thesis, Utrecht University, Utrecht, The Netherlands, 2025. [Google Scholar]

- Zhang, L.; Fröhling, M. Integration of Blockchain and Life Cycle Assessment: A Systematic Literature Review. Int. J. Life Cycle Assess. 2025, 30, 1–19. [Google Scholar] [CrossRef]

- Putri, A.; Hariadi, M.; Wibawa, A. Smart agriculture using supply chain management based on hyperledger blockchain. IOP Conf. Ser. Earth Environ. Sci. 2020, 466, 012007. [Google Scholar] [CrossRef]

- Ravi, D.; Ramachandran, S.; Vignesh, R.; Falmari, V.; Brindha, M. Privacy preserving transparent supply chain management through Hyperledger Fabric. Blockchain Res. Appl. 2022, 3, 100072. [Google Scholar] [CrossRef]

- Yang, X.; Li, M.; Yu, H.; Wang, M.; Xu, D.; Sun, C. A Trusted Blockchain-Based Traceability System for Fruit and Vegetable Agricultural Products. IEEE Access 2021, 9, 36282–36293. [Google Scholar] [CrossRef]

- Musamih, A.; Salah, K.; Jayaraman, R.; Arshad, J.; Debe, M.; Al-Hammadi, Y.; Ellahham, S. A blockchain-based approach for drug traceability in healthcare supply chain. IEEE Access 2021, 9, 9728–9743. [Google Scholar] [CrossRef]

- Abdallah, S.; Nizamuddin, N. Blockchain-based solution for pharma supply chain industry. Comput. Ind. Eng. 2023, 177, 108997. [Google Scholar] [CrossRef]

- Kutybayeva, K.; Razaque, A.; Rai, H. Enhancing Pharmaceutical Supply Chain Transparency and Security with Blockchain and Big Data Integration. Procedia Comput. Sci. 2025, 259, 1511–1522. [Google Scholar] [CrossRef]

- Rahayu, S.; Kamarudin, N.; Azahari, A. Military blockchain for supply chain management. J. Educ. Soc. Sci. 2019, 13, 353–361. [Google Scholar]

- Cerchione, R.; Centobelli, P.; Angelino, A. Blockchain-based IoT model and experimental platform design in the defence supply chain. IEEE Internet Things J. 2023, 10, 22033–22039. [Google Scholar] [CrossRef]

- Yousefi, S.; Tosarkani, B. Exploring the role of blockchain technology in improving sustainable supply chain performance: A system-analysis-based approach. IEEE Trans. Eng. Manag. 2023, 71, 4389–4405. [Google Scholar] [CrossRef]

- Canciani, A.; Felicioli, C.; Severino, F.; Tortola, D. Enhancing Supply Chain Transparency through Blockchain Product Passports. In Proceedings of the 2024 IEEE International Conference on Pervasive Computing and Communications Workshops and other Affiliated Events (PerCom Workshops), Biarritz, France, 11–15 March 2024; pp. 751–756. [Google Scholar]

- Kashyap, A.; Shukla, O.; Soni, G.; Ramtiyal, B. Blockchain-Driven Circular Economy Practices in Perishable Supply Chain for Mitigating Food Loss and Waste. J. Syst. Sci. Syst. Eng. 2025. [Google Scholar] [CrossRef]

- Romdhane, S.; Zhang, K.; De, L. Towards efficient and fine-grained traceability for a live lobster supply chain using blockchain technology. Procedia Comput. Sci. 2025, 253, 612–625. [Google Scholar] [CrossRef]

- Malik, S.; Kanhere, S.; Jurdak, R. Productchain: Scalable blockchain framework to support provenance in supply chains. In Proceedings of the 2018 IEEE 17th International Symposium on Network Computing and Applications (NCA), Cambridge, MA, USA, 1–3 November 2018; pp. 1–10. [Google Scholar]

- Dietrich, F.; Palm, D.; Louw, L. Smart contract based framework to increase transparency of manufacturing networks. Procedia CIRP 2020, 91, 278–283. [Google Scholar] [CrossRef]

- Zhao, H.; Hu, K.; Yuan, Z.; Yao, S.; Feng, L. BCTMSSF: A blockchain consensus-based traceability method for supply chain in smart factory. J. Intell. Manuf. 2025, 36, 1861–1877. [Google Scholar] [CrossRef]

- Sun, F.; Wang, P.; Zhang, Y.; Kar, P. βFSCM: An enhanced food supply chain management system using hybrid blockchain and recommender systems. Blockchain Res. Appl. 2025, 6, 100245. [Google Scholar] [CrossRef]

- Putri, A.; Hariadi, M.; Rachmad, R. Supply chain management serious game using blockchain smart contract. IEEE Access 2023. [Google Scholar] [CrossRef]

- Santhanam, E.; Kamatchi, K. Advanced agricultural supply chain management: Integrating blockchain and young’s double-slit experiment for enhanced security. Int. J. Inf. Technol. 2025, 17, 1329–1337. [Google Scholar] [CrossRef]

- El Azzaoui, A.; Chen, H.; Kim, S.; Pan, Y.; Park, J. Blockchain-based distributed information hiding framework for data privacy preserving in medical supply chain systems. Sensors 2022, 22, 1371. [Google Scholar] [CrossRef]

- Mohit, M.; Kaur, S.; Singh, M. Design and implementation of transaction privacy by virtue of ownership and traceability in blockchain based supply chain. Clust. Comput. 2022, 25, 2223–2240. [Google Scholar] [CrossRef]

- Rehan, M.; Javed, A.; Kryvinska, N.; Gadekallu, T.; Srivastava, G.; Jalil, Z. Supply chain management using an industrial internet of things hyperledger fabric network. Hum.-Centric Comput. Inf. Sci. 2023, 13, 4. [Google Scholar] [CrossRef]

- Mangala, N.; Naveen, D.R.; Reddy, B.E.; Buyya, R.; Venugopal, K.R.; Iyengar, S.S.; Patnaik, L.M. Secure pharmaceutical supply chain using blockchain in IoT cloud systems. Internet Things 2024, 26, 101215. [Google Scholar] [CrossRef]

- Santosh, K.; Dash, C.; Aarif, M.; Kumar, Y.; Verma, M.; KiranBala, B. Blockchain-Based Smart Contracts for Supply Chain Management: A Strategic Analysis. In Proceedings of the 2024 Third International Conference on Intelligent Techniques in Control, Optimization and Signal Processing (INCOS), Krishnankoil, India, 14–16 March 2024; pp. 1–6. [Google Scholar]

- Razavian, S.; Tirkolaee, E.; Simic, V.; Ali, S.; Görün, Ö.F. Blockchain-enabled healthcare supply chain management: Identification and analysis of barriers and solutions based on improved zero-sum hesitant fuzzy game theory. Eng. Appl. Artif. Intell. 2025, 154, 110991. [Google Scholar] [CrossRef]

- Bak, O.; Braganza, A.; Chen, W. Exploring blockchain implementation challenges in the context of healthcare supply chain (HCSC). Int. J. Prod. Res. 2025, 63, 687–702. [Google Scholar] [CrossRef]

- Zyskind, G.; Nathan, O.; Pentland, A. Decentralizing privacy: Using blockchain to protect personal data. In Proceedings of the 2015 IEEE Security and Privacy Workshops, San Jose, CA, USA, 21–22 May 2015; pp. 180–184. [Google Scholar]

- Sidorov, M.; Ong, M.; Sridharan, R.; Nakamura, J.; Ohmura, R.; Khor, J. Ultralightweight mutual authentication RFID protocol for blockchain enabled supply chains. IEEE Access 2019, 7, 7273–7285. [Google Scholar] [CrossRef]

- Le, G.; Gu, Q.; Jiang, Q.; Lin, W. TrustedChain: A blockchain-based data sharing scheme for supply chain. In Proceedings of the 2020 International Conference on Data Mining Workshops (ICDMW), Sorrento, Italy, 17–20 November 2020; pp. 895–901. [Google Scholar]

- Sezer, B.; Topal, S.; Nuriyev, U. TPPSUPPLY: A traceable and privacy-preserving blockchain system architecture for the supply chain. J. Inf. Secur. Appl. 2022, 66, 103116. [Google Scholar] [CrossRef]

- Ahmad, A.; Verma, N.; Sarhan, N.; Awwad, E.; Arora, A.; Nyangaresi, V. An IoT and Blockchain-Based Secure and Transparent Supply Chain Management Framework in Smart Cities Using Optimal Queue Model. IEEE Access 2024, 12, 51752–51771. [Google Scholar] [CrossRef]

- Li, J.; Han, D.; Weng, T.; Wu, H.; Li, K.; Castiglione, A. A secure data storage and sharing scheme for port supply chain based on blockchain and dynamic searchable encryption. Comput. Stand. Interfaces 2025, 91, 103887. [Google Scholar] [CrossRef]

- Tariq, T.; Obaidat, M.; Kuo, W.; Mahmood, K.; Ayub, M.; Alenazi, M. A Blockchain-Assisted Authentication Protocol for RFID-Enabled Supply Chain Management System. IEEE Trans. Netw. Sci. Eng. 2025, 12, 3108–3117. [Google Scholar] [CrossRef]

- Gao, K.; Liu, Y.; Xu, H.; Han, T. Design and implementation of food supply chain traceability system based on Hyperledger Fabric. Int. J. Comput. Sci. Eng. 2020, 23, 185–193. [Google Scholar] [CrossRef]

- Pal, K.; Yasar, A.U.H. Internet of things and blockchain technology in apparel manufacturing supply chain data management. Procedia Comput. Sci. 2020, 170, 450–457. [Google Scholar] [CrossRef]

- Narayanan, G.; Cvitić, I.; Peraković, D.; Raja, S. Role of blockchain technology in supplychain management. IEEE Access 2023, 11. [Google Scholar] [CrossRef]

- Norouzian-Maleki, P.; Hosseini-Motlagh, S.; Yaghoubi, S. Impact of Blockchain Technology on Social Aspects of Blood Supply Chain: A Simulation–Optimization Approach. IEEE Trans. Eng. Manag. 2025, 72, 591–603. [Google Scholar] [CrossRef]

- Raza, Z.; Haq, I.; Muneeb, M. Agri-4-all: A framework for blockchain based agricultural food supply chains in the era of fourth industrial revolution. IEEE Access 2023, 11, 29851–29867. [Google Scholar] [CrossRef]

- Agrawal, D.; Minocha, S.; Namasudra, S.; Gandomi, A. A robust drug recall supply chain management system using hyperledger blockchain ecosystem. Comput. Biol. Med. 2022, 140, 105100. [Google Scholar] [CrossRef]

- Gai, K.; Zhang, Y.; Qiu, M.; Thuraisingham, B. Blockchain-enabled service optimizations in supply chain digital twin. IEEE Trans. Serv. Comput. 2022, 16, 1673–1685. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. Sustainable supply chains with blockchain, IoT and RFID: A simulation on order management. Sustainability 2021, 13, 6372. [Google Scholar] [CrossRef]

- Turjo, M.; Khan, M.; Kaur, M.; Zaguia, A. Smart supply chain management using the blockchain and smart contract. Sci. Program. 2021, 2021, 6092792. [Google Scholar] [CrossRef]

- Wu, H.; Jiang, S.; Cao, J. High-Efficiency Blockchain-Based Supply Chain Traceability. IEEE Trans. Intell. Transp. Syst. 2023, 24, 3748–3758. [Google Scholar] [CrossRef]

- Liu, T.; Yuan, Y.; Yu, Z. An Intelligent Optimization Control Method for Enterprise Cost Under Blockchain Environment. IEEE Access 2023, 11, 3597–3606. [Google Scholar] [CrossRef]

- Cao, Z. Blockchain technology application and optimisation algorithm in enterprise supply chain management. Int. J. Inf. Commun. Technol. 2025, 26, 104–120. [Google Scholar] [CrossRef]

- Barati, S. A system dynamics approach for leveraging blockchain technology to enhance demand forecasting in supply chain management. Supply Chain Anal. 2025, 10, 100115. [Google Scholar] [CrossRef]

- Awan, U.; Sroufe, R.; Kraslawski, A. Creativity Enables Sustainable Development: Supplier Engagement as a Boundary Condition for the Positive Effect on Green Innovation. J. Clean. Prod. 2019, 226, 172–185. [Google Scholar] [CrossRef]

- Gariya, N.; Asrani, A.; Mandal, A.; Shaikh, A.; Cha, D. A Comprehensive Analysis of Integrating Blockchain Technology into the Energy Supply Chain for the Enhancement of Transparency and Sustainability. Energies 2025, 18, 2951. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khatun, M.; Darwish, T. Unlocking Blockchain’s Potential in Supply Chain Management: A Review of Challenges, Applications, and Emerging Solutions. Network 2025, 5, 34. https://doi.org/10.3390/network5030034

Khatun M, Darwish T. Unlocking Blockchain’s Potential in Supply Chain Management: A Review of Challenges, Applications, and Emerging Solutions. Network. 2025; 5(3):34. https://doi.org/10.3390/network5030034

Chicago/Turabian StyleKhatun, Mahafuja, and Tasneem Darwish. 2025. "Unlocking Blockchain’s Potential in Supply Chain Management: A Review of Challenges, Applications, and Emerging Solutions" Network 5, no. 3: 34. https://doi.org/10.3390/network5030034

APA StyleKhatun, M., & Darwish, T. (2025). Unlocking Blockchain’s Potential in Supply Chain Management: A Review of Challenges, Applications, and Emerging Solutions. Network, 5(3), 34. https://doi.org/10.3390/network5030034