Analysis and Design of a Brushless WRSM with Harmonic Excitation Based on Electromagnetic Induction Power Transfer Optimization

Abstract

1. Introduction

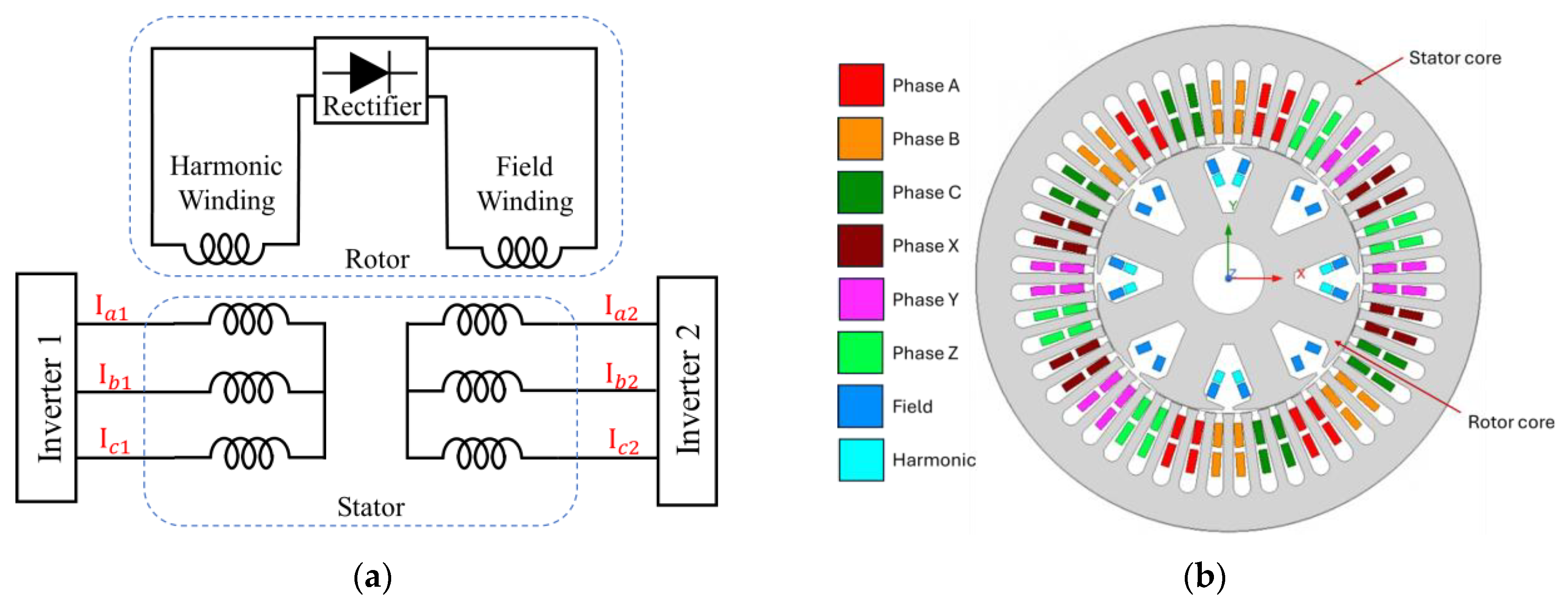

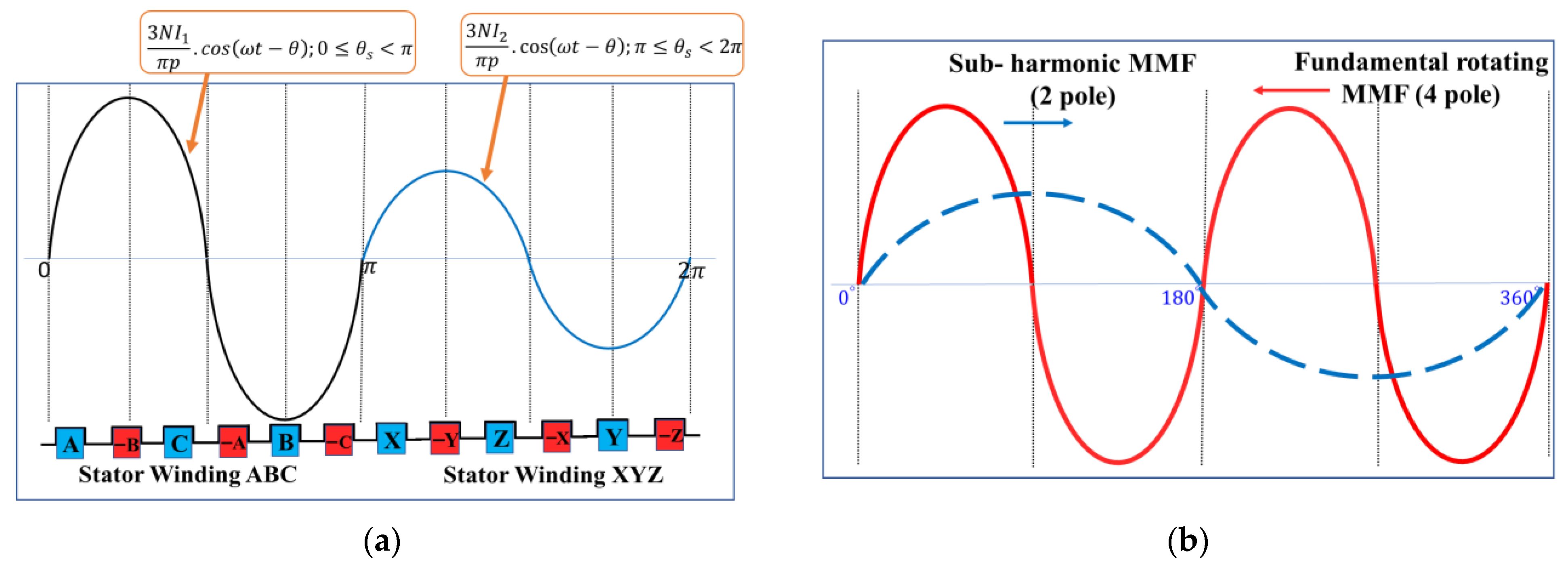

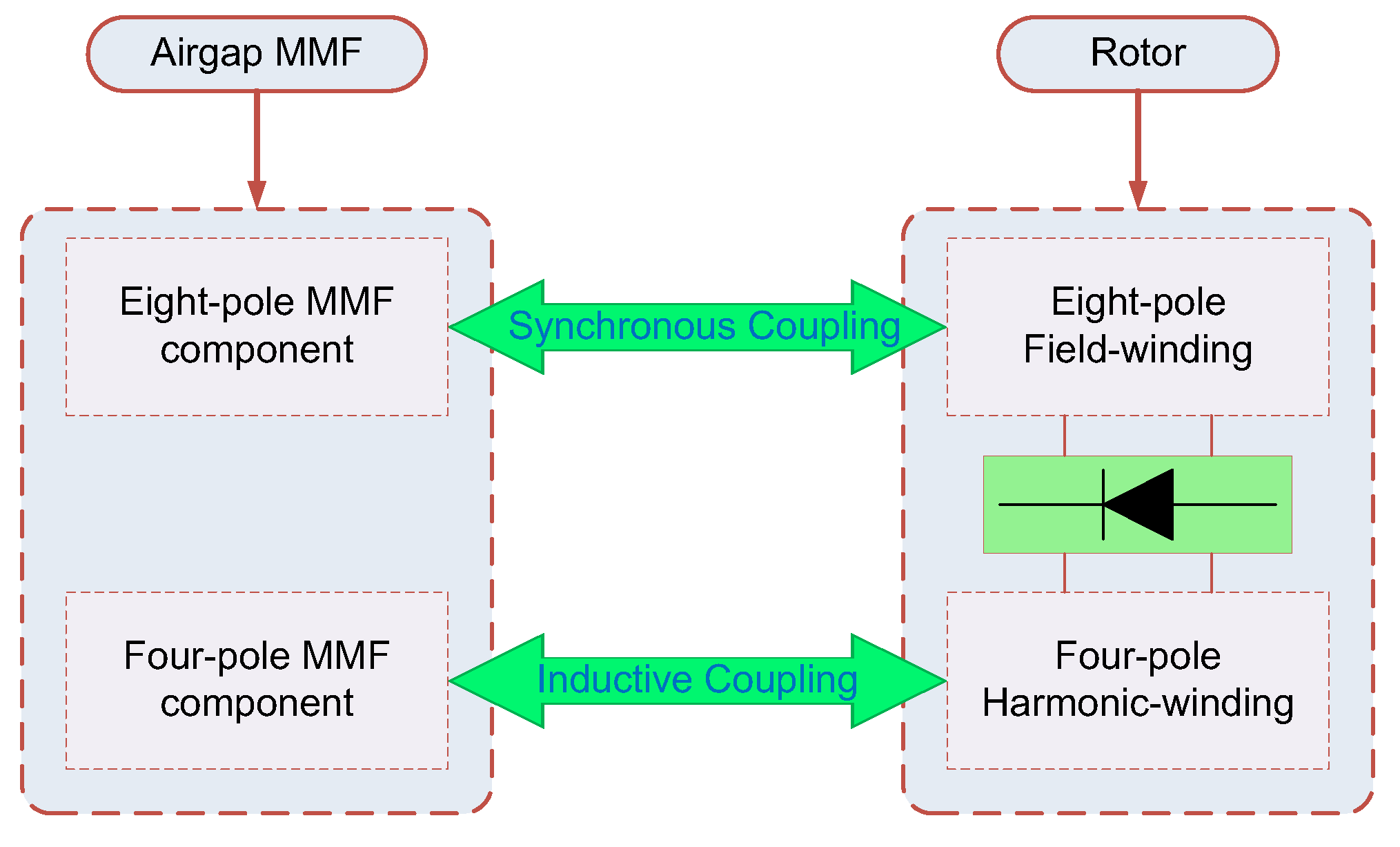

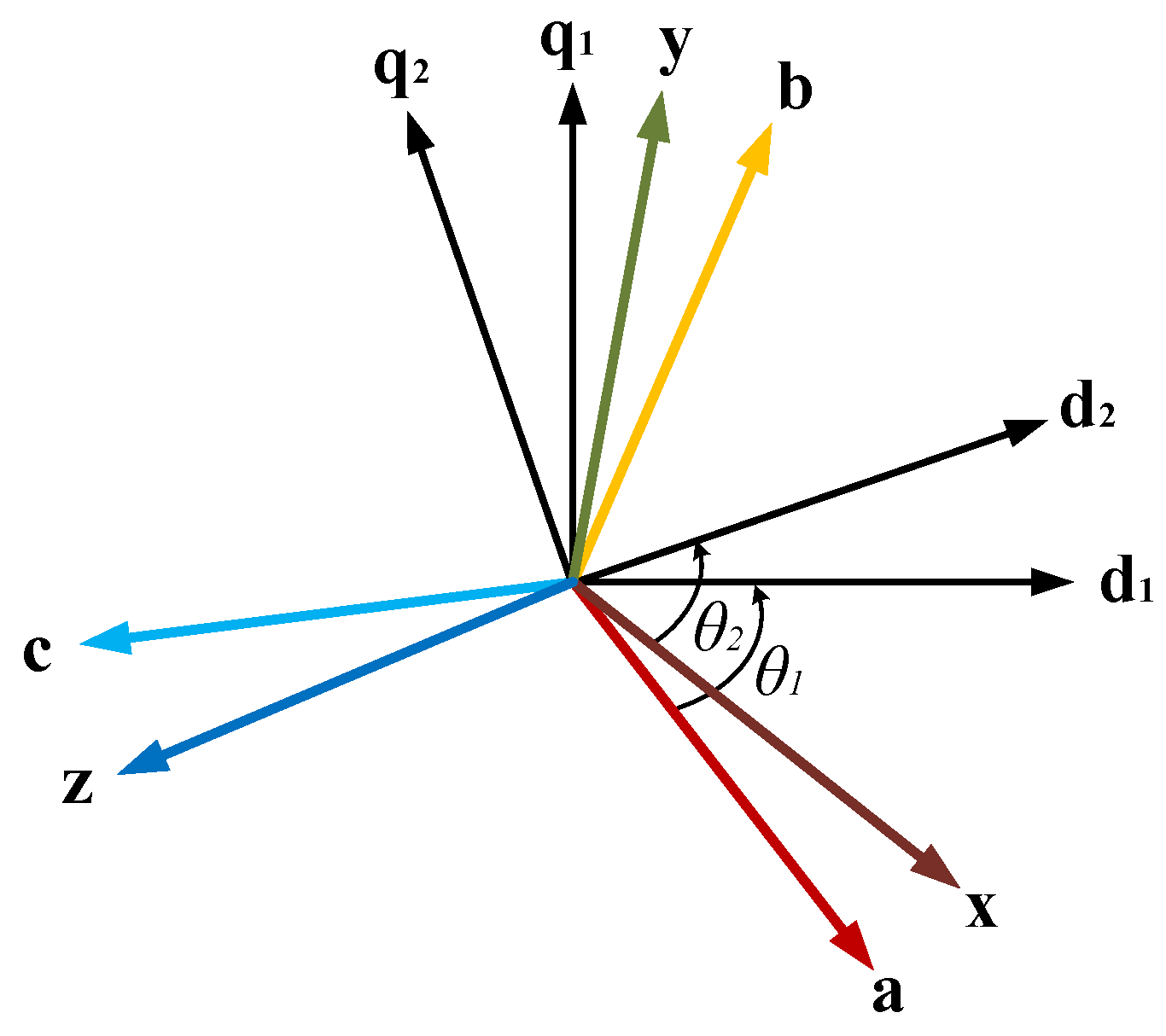

2. Topology and Working Principles

- Layered winding arrangement: By placing the harmonic winding and the field winding in separate radial layers within the slot, mutual interference can be reduced. This configuration also helps manage insulation stress and thermal dissipation.

- Magnetic barriers or slot wedges: Introducing magnetic barriers (such as low-permeability slot liners or flux diverters) can reduce the coupling of higher-order harmonics while preserving available copper space for the windings.

- Optimized slot geometry: Adjusting slot opening and tooth width allows for a trade-off between winding accommodation and harmonic suppression without significantly increasing rotor size.

| Parameter | Value | Unit |

|---|---|---|

| Stator outer diameter | 120 | mm |

| Stator inner diameter | 72 | mm |

| Air gap length | 1 | mm |

| Stack length | 120 | mm |

| Number of slots | 48 | - |

| Number of poles | 8 | - |

| Base speed | 900 | - |

| Core material | M-19 | - |

3. Effect of Harmonic Winding Turns with Fixed Field Winding Turns

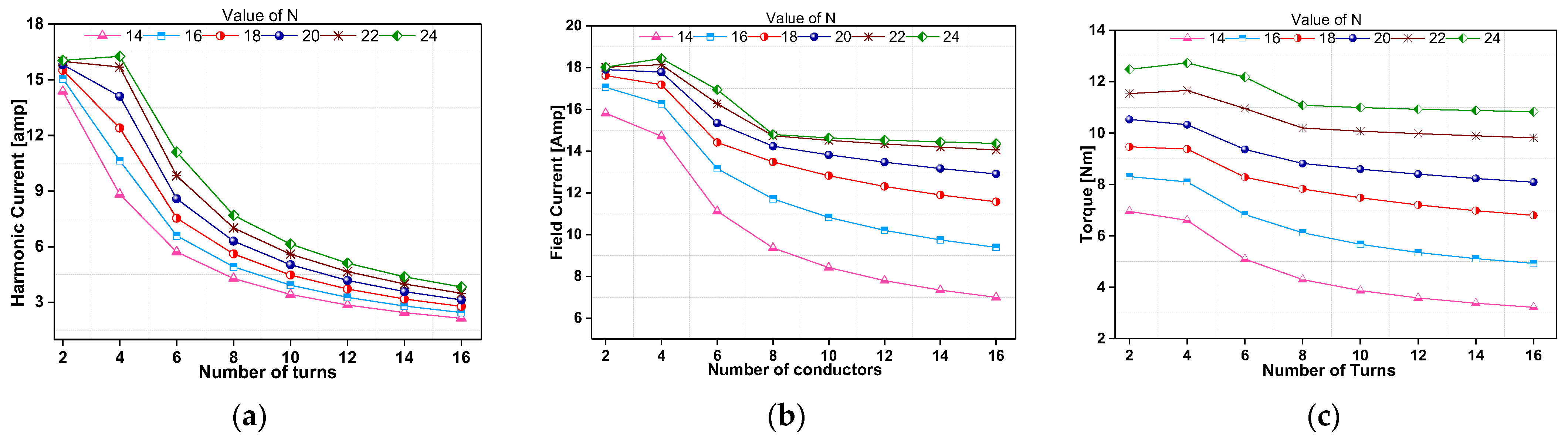

3.1. Turn Variations in Harmonic Winding with a Different Number of Armature Windings

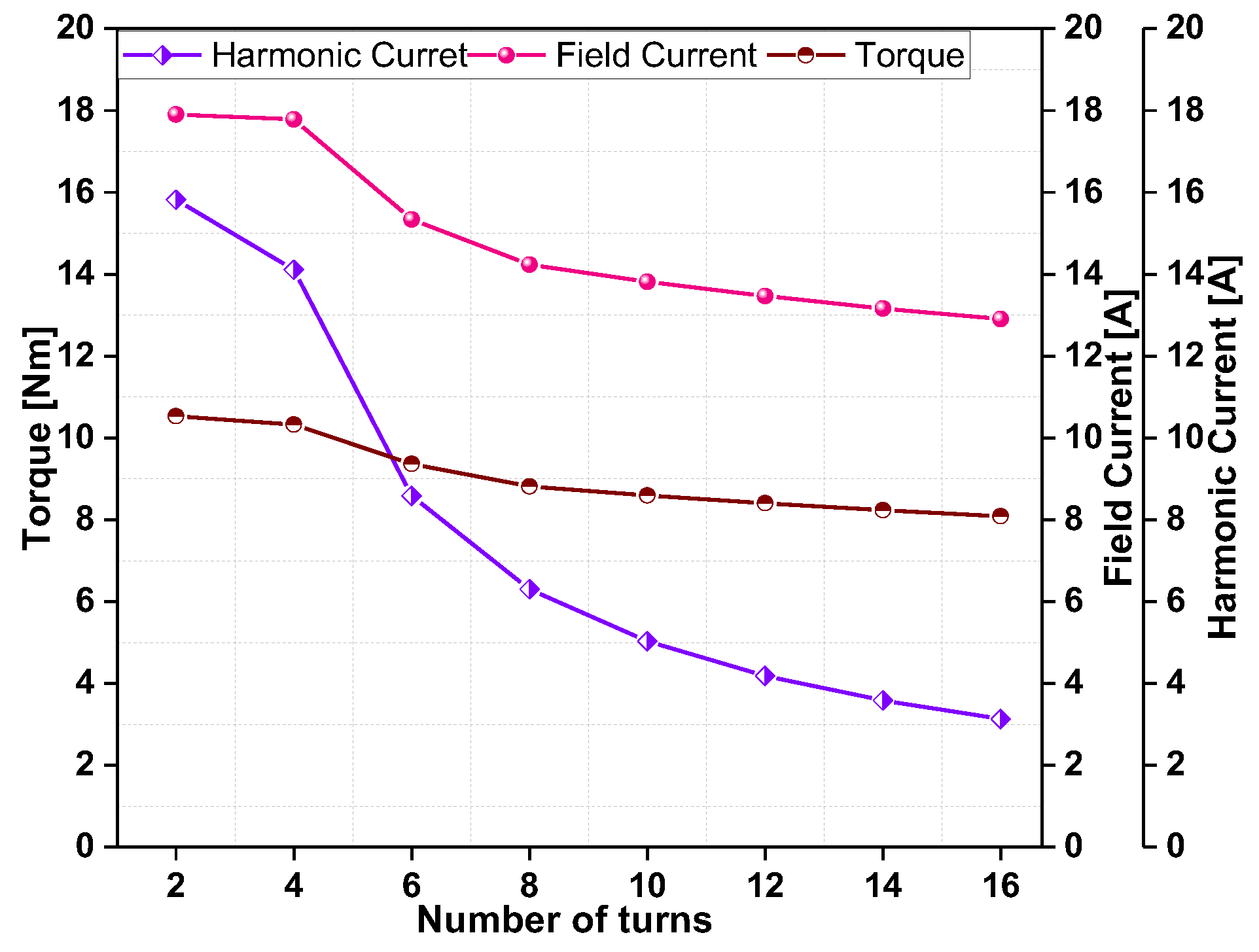

3.2. Turn Variations in Harmonic Winding with the Same Number of Armature Winding Turns

4. Effect of Harmonic Winding Turns Considering Variation in Field Winding Turns

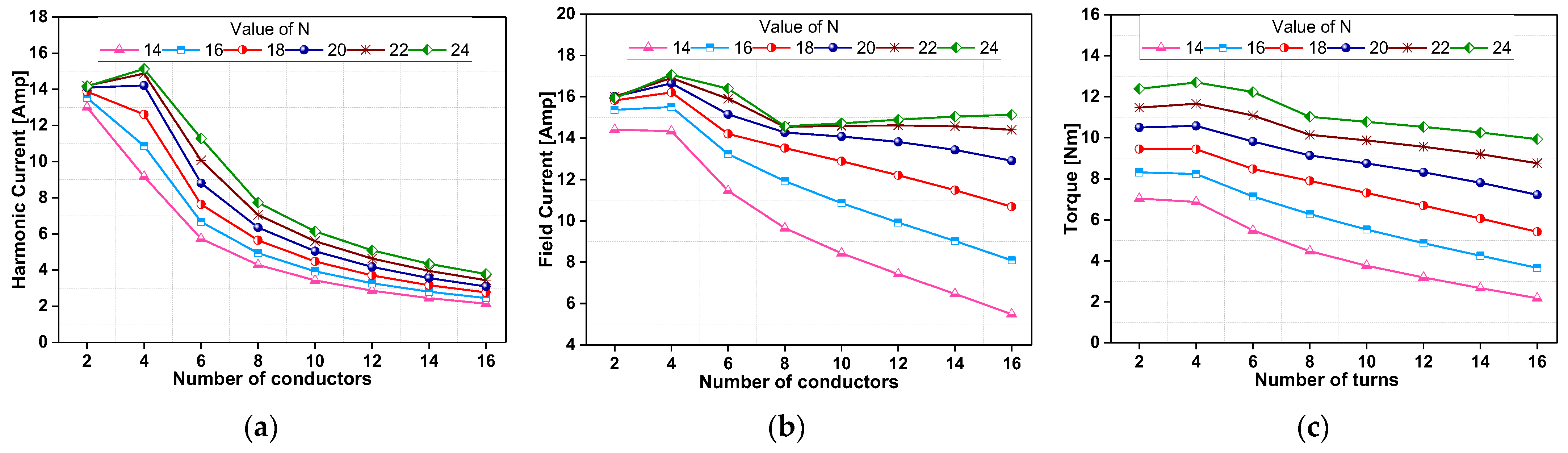

4.1. Turn Variations in Harmonic Winding with a Different Number of Armature Windings

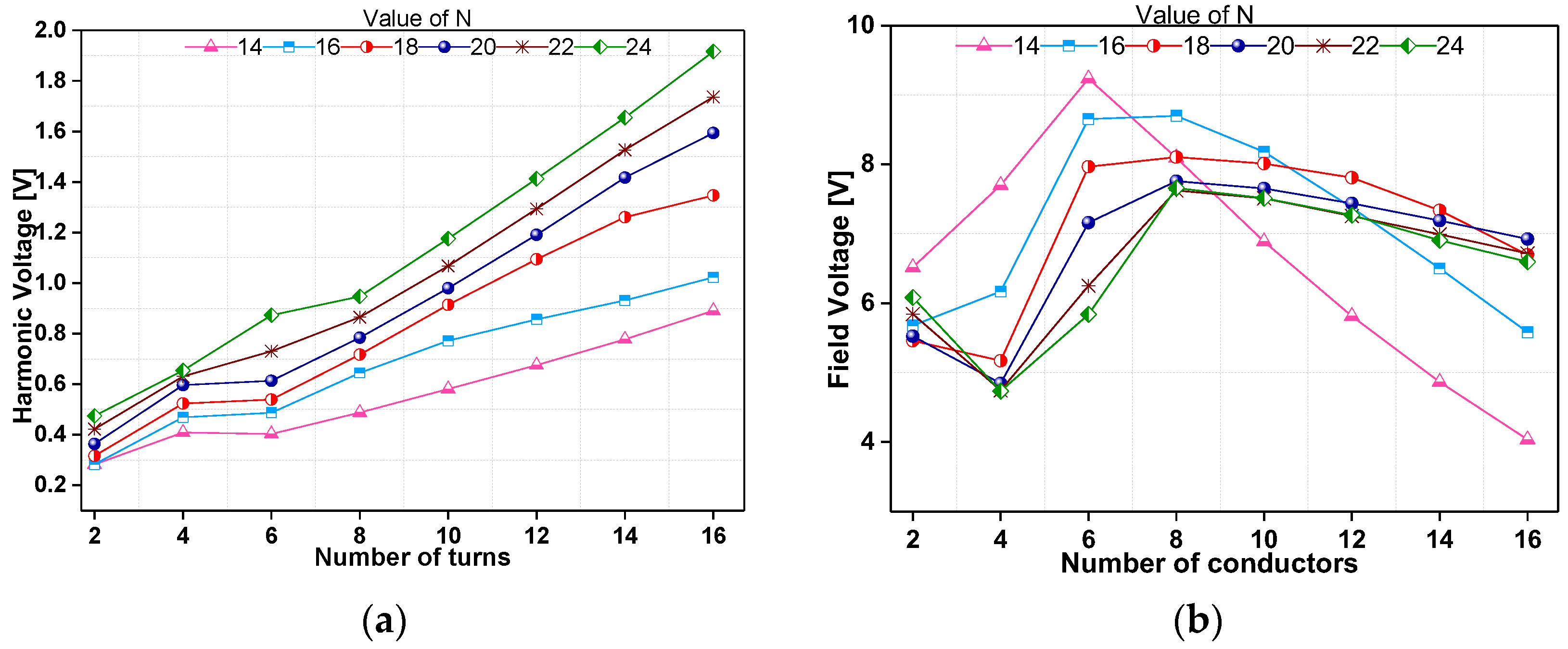

4.2. Turn Variations in Harmonic Winding with the Same Number of Armature Winding Turns

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PM | Permanent magnet |

| IPMSM | Interior permanent magnet synchronous machine |

| WRSM | Wound rotor synchronous machine |

| MMF | Magnetomotive force |

| Back-EMF | Back electromotive force |

| DQ | Direct and quadrature |

| RMS | Root-mean-squared |

| FEA | Finite-element analysis |

| PWM | Pulse width modulation |

| SHE | Selective Harmonic Elimination |

| MPC | Model Predictive Control |

References

- Scaglione, G.; Nevoloso, C.; Schettino, G.; Tommaso, A.O.D.; Miceli, R. A Novel Multiobjective Finite Control Set Model Predictive Control for IPMSM Drive Fed by A Five-Level Cascaded H-Bridge Inverter. IEEE J. Emerg. Sel. Top. Power Electron. 2024, 12, 1959–1973. [Google Scholar] [CrossRef]

- Rahman, M.M.; Uddin, M.N. Third harmonic injection based nonlinear control of IPMSM drive for wide speed range operation. In Proceedings of the 2017 IEEE Industry Applications Society Annual Meeting, Cincinnati, OH, USA, 1–5 October 2017; pp. 1–8. [Google Scholar] [CrossRef]

- Zhao, X.; Niu, S. A New Slot-PM Vernier Reluctance Machine with Enhanced Zero-Sequence Current Excitation for Electric Vehicle Propulsion. IEEE Trans. Ind. Electron. 2020, 67, 3528–3539. [Google Scholar] [CrossRef]

- Arif, A.; Baloch, N.; Kwon, B.-I. Winding Switching and Turn Switching in Permanent Magnet Vernier Machines for Wide Speed Range Operation and High Efficiency. IEEE Access 2019, 7, 55344–55357. [Google Scholar] [CrossRef]

- Chai, W.; Cai, Z.; Kwon, B.-I.; Kwon, J.-W. Design of A Novel Low-Cost Consequent-Pole Permanent Magnet Synchronous Machine. IEEE Access 2020, 8, 194251–194259. [Google Scholar] [CrossRef]

- Sirewal, G.J.; Bukhari, S.S.H. Cost-Effective Scheme for A Brushless Wound Rotor Synchronous Machine. World Electr. Veh. J. 2021, 12, 194. [Google Scholar] [CrossRef]

- Edmondson, J. Will Rare-Earths Be Eliminated in Electric Vehicle Motors? Available online: https://www.idtechex.com/en/research-article/will-rare-earths-be-eliminated-in-electric-vehicle-motors/21972 (accessed on 1 October 2025).

- Kaya, E.E.; Kaya, O.; Stopic, S.; Gürmen, S.; Friedrich, B. NdFeB Magnets Recycling Process: An Alternative Method to Produce Mixed Rare Earth Oxide from Scrap NdFeB Magnets. Metals 2021, 11, 716. [Google Scholar] [CrossRef]

- Rare Earths Trade Dispute. Wikipedia. Available online: https://en.wikipedia.org/wiki/Rare_earths_trade_dispute (accessed on 1 October 2025).

- Seyedi, S.M.; Talebi, D.; Toliyat, H.A. A PM-Free Brushless Synchronous Machine with A Novel Compensated Wound-Field Excited by Modulated Rotating Magnetic Flux. IEEE Trans. Energy Convers. 2024, 39, 2068–2080. [Google Scholar] [CrossRef]

- Lipo, T.A.; Du, Z.S. Synchronous motor drives—A forgotten option. In Proceedings of the 2015 Intl Aegean Conference on Electrical Machines & Power Electronics (ACEMP), 2015 Intl Conference on Optimization of Electrical & Electronic Equipment (OPTIM) & 2015 Intl Symposium on Advanced Electromechanical Motion Systems (ELECTROMOTION), Side, Türkiye, 2–4 September 2015; pp. 1–5. [Google Scholar] [CrossRef]

- Dmitrievskii, V.; Prakht, V.; Valeev, E.; Paramonov, A.; Kazakbaev, V.; Anuchin, A. Comparative Study of Induction and Wound Rotor Synchronous Motors for the Traction Drive of a Mining Dump Truck Operating in Wide Constant Power Speed Range. IEEE Access 2023, 11, 68395–68409. [Google Scholar] [CrossRef]

- Chen, H.; Tang, J.; Liu, Y.; Jiang, B.; Boscaglia, L. Electromagnetic Performance Investigation of a Brushless Electrically Excited Synchronous Machine for Long-Distance Heavy-Duty Electric Vehicles. IEEE Trans. Transp. Electrif. 2025, 11, 225–235. [Google Scholar] [CrossRef]

- Bian, W.; Zhang, Z.; Li, L.; Jin, C.; Li, J.; Guo, F. An Approximate Three-Phase AC Excitation Method with Parallel Capacitors for Aircraft Wound Rotor Synchronous Starter/Generator. IEEE Trans. Transp. Electrif. 2025, 11, 5497–5508. [Google Scholar] [CrossRef]

- Graffeo, F.; Vaschetto, S.; Tenconi, A.; Cavagnino, A. Fast Sizing Procedure for Salient-Pole Wound Field Synchronous Motors for Transportation Electrification. In Proceedings of the 2023 IEEE International Electric Machines & Drives Conference (IEMDC), San Francisco, CA, USA, 15–18 May 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Akuru, U.B.; Ullah, W.; Okojie, D.E.; Masisi, L.; Idoko, H.C.; Khan, F. Comparative Performance Evaluation, Prototyping and Experimentation of the Double-Stator Wound-Field Flux Switching Machine. IEEE Trans. Ind. Appl. 2024, 60, 6706–6714. [Google Scholar] [CrossRef]

- Nguyen, M.-D.; Hoang, D.-T.; Kim, S.-M.; Jung, W.-S.; Shin, K.-H.; Kim, Y.-J. Nonlinear Modeling and Analysis Considering Coupling Stator Flux of Wound-Rotor Synchronous Motors. In Proceedings of the 2024 International Conference on Electrical Machines (ICEM), Torino, Italy, 1–4 September 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.; Zhang, Z.; Li, J. Investigation and Development of the Brushless and Magnetless Wound Field Synchronous Motor Drive System for Electric Vehicle Application. World Electr. Veh. J. 2023, 14, 81. [Google Scholar] [CrossRef]

- Dorrell, D.G. Are wound-rotor synchronous motors suitable for use in high efficiency torque-dense automotive drives? In Proceedings of the IECON 2012—38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; pp. 4880–4885. [Google Scholar] [CrossRef]

- Laldin, O.; Sudhoff, S.D.; Pekarek, S. An Analytical Design Model for Wound Rotor Synchronous Machines. IEEE Trans. Energy Convers. 2015, 30, 1299–1309. [Google Scholar] [CrossRef]

- Liu, W.; Lipo, T.A. Saliency enhancement of salient pole wound field synchronous machines for variable speed applications. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017. [Google Scholar] [CrossRef]

- Sirewal, G.J.; Choi, G. Analysis and Design of a Self-Excitation Scheme for An Open-End Armature Winding Wound-Rotor Synchronous Machine. In Proceedings of the 2024 IEEE Energy Conversion Congress and Exposition (ECCE), Phoenix, AZ, USA, 20–24 October 2024; pp. 5846–5851. [Google Scholar] [CrossRef]

- Sirewal, G.J.; Kim, E.; Choi, G. Dual Inverter Controlled Third Harmonic Current Injection Scheme for an Open-End Winding Brushless Wound Rotor Synchronous Machine. In Proceedings of the 2024 27th International Conference on Electrical Machines and Systems (ICEMS), Fukuoka, Japan, 26–29 November 2024; pp. 3374–3380. [Google Scholar] [CrossRef]

- Wang, X.; Xiong, Z.; Jiang, H.; Li, Y.; Lin, X.; Xie, W. Field Oriented Control Strategy for Five-Phase Self-Excited Synchronous Motor Based on Injecting High-Frequency Current. In Proceedings of the IECON 2023—49th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 16–19 October 2023. [Google Scholar] [CrossRef]

- Cui, S.; Zhang, Y.; Song, B.; Gao, X.; Zhao, T.; Dong, S. Resonant Coupled Excitation Brushless Synchronous Motor. In Proceedings of the 2023 26th International Conference on Electrical Machines and Systems (ICEMS), Zhuhai, China, 5–8 November 2023. [Google Scholar] [CrossRef]

- Mao, S.; Wang, L.; Ma, C.; Zhang, S.; Liu, W. Enhanced I/F Starting Control Method of Brushless Synchronous Starter/Generator with High-Frequency Signal Injection. In Proceedings of the IECON 2023—49th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 16–19 October 2023. [Google Scholar] [CrossRef]

- Zhu, S.; Liu, C.; Wang, K.; Zhou, Z.; Yu, J. Structure and Operating Performance of a Double Electrical Excitation Synchronous Generator with Embedded Brushless Synchronous Exciter Utilizing DC-Field Excitation. IEEE Trans. Energy Convers. 2022, 37, 50–64. [Google Scholar] [CrossRef]

- Jiao, N.; Liu, W.; Meng, T.; Peng, J.; Mao, S. Design and Control of a Two-Phase Brushless Exciter for Aircraft Wound-Rotor Synchronous Starter/Generator in the Starting Mode. IEEE Trans. Power Electron. 2016, 31, 4452–4461. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, W.; Zhao, D.; Mao, S.; Meng, T.; Jiao, N. Steady-state performance evaluations of three-phase brushless asynchronous excitation system for aircraft starter/generator. IET Electr. Power Appl. 2016, 10, 788–798. [Google Scholar] [CrossRef]

- Wang, L.; Cheung, R.W.; Ma, Z.; Ruan, J.; Peng, Y. Finite-Element Analysis of Unbalanced Magnetic Pull in A Large Hydro-Generator Under Practical Operations. IEEE Trans. Magn. 2008, 44, 1558–1561. [Google Scholar] [CrossRef]

- Kutt, F.; Michna, M.; Kostro, G. Non-Salient Brushless Synchronous Generator Main Exciter Design for More Electric Aircraft. Energies 2020, 13, 2696. [Google Scholar] [CrossRef]

- Yao, F.; Sun, L.; Sun, D.; Lipo, T.A. Design and Excitation Control of a Dual Three-Phase Zero-Sequence Current Starting Scheme for Integrated Starter/Generator. IEEE Trans. Ind. Appl. 2021, 57, 3776–3786. [Google Scholar] [CrossRef]

- Li, J.; Wang, K.; Liu, C. Improvement of Integrated-Induction-Based Hybrid Excitation Brushless DC Generator by Employing Novel Consequent-Pole Rotor. IEEE Trans. Ind. Electron. 2022, 69, 12042–12054. [Google Scholar] [CrossRef]

- Yao, F.; An, Q.; Gao, X.; Sun, L.; Lipo, T.A. Principle of Operation and Performance of a Synchronous Machine Employing a New Harmonic Excitation Scheme. IEEE Trans. Ind. Appl. 2015, 51, 3890–3898. [Google Scholar] [CrossRef]

- Jawad, G.; Ali, Q.; Lipo, T.A.; Kwon, B.-I. Novel Brushless Wound Rotor Synchronous Machine with Zero-Sequence Third-Harmonic Field Excitation. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Yao, F.; Sun, D.; Sun, L.; Lipo, T.A. Dual Third-Harmonic-Current Excitation Principle of a Brushless Synchronous Machine Based on Double Three-Phase Armature Windings. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019. [Google Scholar] [CrossRef]

- Chung, J.; Hofmann, H. Brushless Self-Excited Synchronous Field-Winding Machine with Five- and Higher-Phase Design Using Independently Controlled Spatial Harmonics. IEEE Trans. Energy Convers. 2024, 39, 533–543. [Google Scholar] [CrossRef]

- Ayub, M.; Sirewal, G.J.; Bukhari, S.S.H.; Kwon, B. Brushless wound rotor synchronous machine with third-harmonic field excitation. Electr. Eng. 2020, 102, 259–265. [Google Scholar] [CrossRef]

- Ayub, M.; Bukhari, S.S.H.; Jawad, G.; Kwon, B. Brushless wound field synchronous machine with third-harmonic field excitation using a single inverter. Electr. Eng. 2019, 101, 165–173. [Google Scholar] [CrossRef]

- Ayub, M.; Hussain, A.; Jawad, G.; Kwon, B.-I. Brushless operation of a wound-field synchronous machine using a novel winding scheme. IEEE Trans. Magn. 2019, 55, 1–4. [Google Scholar] [CrossRef]

- Bukhari, S.S.H.; Sirewal, G.J.; Ayub, M.; Ro, J.-S. A New Small-Scale Self-Excited Wound Rotor Synchronous Motor Topology. IEEE Trans. Magn. 2021, 57, 1–5. [Google Scholar] [CrossRef]

- Ayub, M.; Atiq, S.; Sirewal, G.J.; Kwon, B.-I. Fault-Tolerant Operation of Wound Field Synchronous Machine Using Coil Switching. IEEE Access 2019, 7, 67130–67138. [Google Scholar] [CrossRef]

- Hussain, A.; Baig, Z.; Toor, W.T.; Ali, U.; Idrees, M.; Shloul, T.A.; Ghadi, Y.Y.; Alkahtani, H.K. Wound Rotor Synchronous Motor as Promising Solution for Traction Applications. Electronics 2022, 11, 4116. [Google Scholar] [CrossRef]

- Ali, Q.; Lipo, T.A.; Kwon, B.-I. Design and Analysis of a Novel Brushless Wound Rotor Synchronous Machine. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Li, T.; Sun, X.; Su, Z.; Zha, X.; Dianov, A.; Prakht, V. Model-Free Predictive Control for Harmonic Suppression of PMSMs Based on Adaptive Resonant Controller. IEEE Trans. Energy Convers. 2025, 1–10. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Y.; Liang, X.; Guo, H.; Zhuang, X. Robust Model Predictive Current Control of PMSM Based on Nonlinear Extended State Observer. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 862–873. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arif, A.; Arif, F.; Abbas, Z.; Sirewal, G.J.; Saleem, M.; Ali, Q.; Ullah, M. Analysis and Design of a Brushless WRSM with Harmonic Excitation Based on Electromagnetic Induction Power Transfer Optimization. Magnetism 2025, 5, 26. https://doi.org/10.3390/magnetism5040026

Arif A, Arif F, Abbas Z, Sirewal GJ, Saleem M, Ali Q, Ullah M. Analysis and Design of a Brushless WRSM with Harmonic Excitation Based on Electromagnetic Induction Power Transfer Optimization. Magnetism. 2025; 5(4):26. https://doi.org/10.3390/magnetism5040026

Chicago/Turabian StyleArif, Arsalan, Farhan Arif, Zuhair Abbas, Ghulam Jawad Sirewal, Muhammad Saleem, Qasim Ali, and Mukhtar Ullah. 2025. "Analysis and Design of a Brushless WRSM with Harmonic Excitation Based on Electromagnetic Induction Power Transfer Optimization" Magnetism 5, no. 4: 26. https://doi.org/10.3390/magnetism5040026

APA StyleArif, A., Arif, F., Abbas, Z., Sirewal, G. J., Saleem, M., Ali, Q., & Ullah, M. (2025). Analysis and Design of a Brushless WRSM with Harmonic Excitation Based on Electromagnetic Induction Power Transfer Optimization. Magnetism, 5(4), 26. https://doi.org/10.3390/magnetism5040026