Abstract

Inductive Power Transfer (IPT) is evolving fast in many domains, but its efficiency, its extensive resource requirements, and its cost remain crucial problems for its development. Although the inverter is mainly responsible for its cost and material consumption, a considerable quantity of conductors is required for the coupling realization. Therefore, A drastic cost reduction is possible when comparing the traditional most efficient copper Litz wire with aluminum conductors for a similar volume and a lighter embedded system. However, alternative ribbon wire solutions are also characterized and seem promising as substitutes for such applications. First, standard electrical efficiency is evaluated for all cases, before the price and weight. To complement the results and as the alternative couplers imply different materials and production processes, a Life Cycle Assessment is performed. A comparison is carried out on copper and aluminum litz wires and copper and aluminum ribbons. Results demonstrate the promising interest in industrial application of such study, furthermore for systems requiring many couplers as Dynamic IPT (DIPT).

1. Introduction

The future of mobility leans towards electric cars, focusing on developing batteries for autonomy, generating cost expansion, and electrical structure for charging. Dynamic Inductive Power Transfer (DIPT) has emerged as a solution for vehicle autonomy, offering better electricity consumption, lighter vehicle weight, and lower costs because of battery reduction in the vehicle [1]. However, despite its potential, concerns about implementation costs, system reliability, and ecological impact still need to be addressed for its development. One of the most critical components of the DIPT system is the coupler, commonly made of copper Litz wires because of its efficiency, considering its high-frequency application of 85 kHz [2].

This type of conductor offers lower losses based on proximity and skin effect reduction than a full or emailed conductor. The coupler resistance increases at high frequencies and significantly contributes to DIPT system losses [3], which can be reduced with copper Litz wire. There is almost no alternative conductor for this application. However, their manufacturing is expensive, and their extraction process has a significant ecological impact, limiting the DIPT expansion over roads. Other potentially interesting conductors for industrial development at this frequency are foiled wire or ribbon.

Due to its availability and low cost [4], aluminum has become a key solution for replacing copper in various industrial applications, including the automotive industry [5]. In the cable industry, using aluminum instead of copper increases internal resistance as experimented for IPT [6]. It affectsg slightly the electrical properties but can significantly reduce linear weight and carbon print concerning its cable design and its recyclability. It is, therefore, a promising alternative for applications for a large development of contactless energy transfer.

Other conductors such as foiled aluminum or copper have never been used for IPT systems.

After a brief presentation of the DIPT system, this work compares several conductor technologies in terms of electrical characteristics, efficiency, cost, volume and weight, and Life Cycle Assessment (LCA). The efficiency impact is finally mitigated by considering the energy cost for such an application.

2. System Design for DIPT

2.1. Topology of the Studied IPT System Used for Comparison

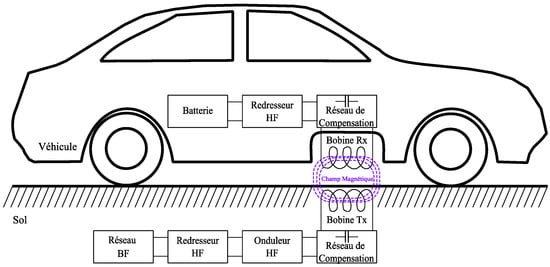

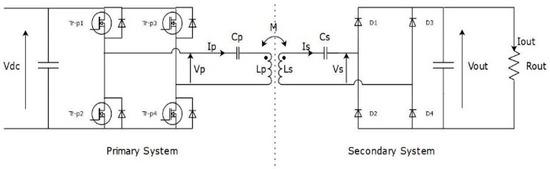

Before optimizing the coupler, other parts of the vehicle battery load converter chain will be described. Firstly, the grid voltage is rectified by an AC–DC converter supplying the systems and allowing the integration of PV energy directly along the road. The voltage applied on the primary of the coupler is obtained with an individual full bridge converter operating at around 85 kHz. The frequency can vary in a range going from 90 kHz to 81.38 kHz and is selected in function of the car position for a best efficiency allowing a permanent transfer of power [7]. Several inverter topologies can be used in DIPT for high efficiency [8] with, for example, a maximum to four outputs with one inverter, reducing by a factor 4 the needs for inverters [9], but this work is not focused on this aspect. Capacities in series are inserted before the coupler because it permits an efficient constant current and a constant voltage load configuration of a battery. A 15 cm air gap is then considered in the coupler, before a compensation network, a rectifier bridge and battery on the secondary, as shown in Figure 1. The electromagnetic field generated in the coupler by the alternating voltage through the coil Lp will induce an AC voltage in Ls, as represented in Figure 2. After the rectifier stage, this voltage will imply a DC current charging the vehicle battery, modeled presently as a resistance as depicted in [10].

Figure 1.

Dynamic Inductive Power Transfer System.

Figure 2.

Power converter schematic for DIPT.

2.2. Magnetic Coupler Architecture

The adopted geometry is considered for a 30 kW coupler, made of the primary coil (Lp) on the ground and of the secondary coil (Ls) embedded is a 48 cm × 48 cm square with six spires for obtaining an inductance value of 65 µH [11] at 85 kHz. The conductor classically used for this frequency range is the copper Litz wire due to its low resistance because of the skin effect and the reduction in the proximity effect. These specifications are described in Table 1 We notify that the strand size of the Cooper Litz wire should be inferior to the double of the skin effect size delta determined as follows at f = 85 kHz in Equation (1).

Table 1.

Technical information on the copper and aluminum Litz wires selected for the coupler design.

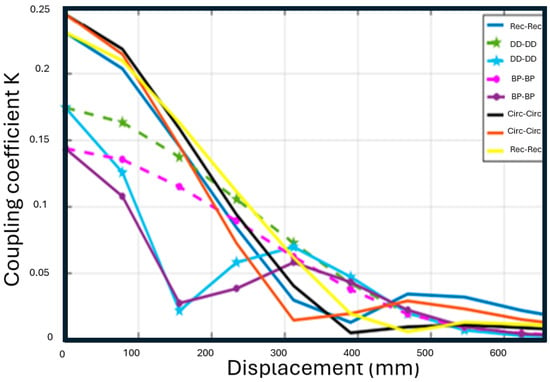

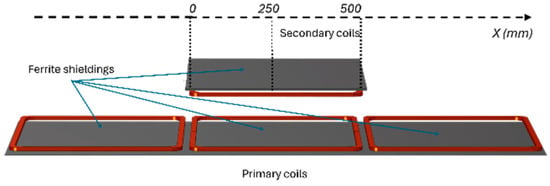

The magnetic coupler is the main one responsible for the system efficiency of the WPT design. Although different topologies of coils (circular, rectangular, double D, bipolar…) exist, we select for the dynamic transfer the one offering the best coupling coefficient despite the impact of the misalignment (Figure 3). The rectangular shape is, therefore, chosen to enhance the continuity of magnetic coupling in the dynamic aspect [12]. In addition, ferrite plates were added over the conductor to improve the magnetic field canalization, thus, enhancing the coupling coefficient between a primary and a secondary (Figure 4).

Figure 3.

Coupling coefficient in function of displacement [1].

Figure 4.

Model of the implemented coils with ferrite plates for shielding.

As described previously, the coils are made of copper Litz wire to limit both the skin effect and the proximity effect, which increases the conductor’s resistance when operating at high frequencies. It is also possible to use other materials, such as aluminum, or another format of conductors, such as ribbon, to conduct efficiently at high frequencies but resistance will be increased. This study aims to select conductors for magnetic couplers, the one presenting the lowest resistance, the lowest price, and the best environmental impact. The following Equations (2) and (3) show that the electrical system efficiency depends on the coupling coefficient Q, which is related to its internal resistance for a similar value of inductance [13].

3. Presentation of the Reference System

3.1. Proposed Solutions

We decided to use aluminum Litz wire to try to reduce the global cost and the system’s weight. Moreover, due to the skin effect, it becomes possible with aluminum to use larger strands because of the difference in the intrinsic resistivity, as viewed in the following equation:

The filling factor of the aluminum Litz wire is better with a lower number of strands, while the equivalent resistance should be a bit superior for the same volume than with copper as shown in the following equation:

Accordingly, we evaluate the performance in terms of resistance of ribbon by using a width inferior to the double of the respective skin effect. The total current determines the larger of the foil and should be superior to 4 mm for the aluminum and 9 mm for the copper. By adding a large security factor in both cases, a 50 mm large ribbon was selected. Their respective resistance are determined as below:

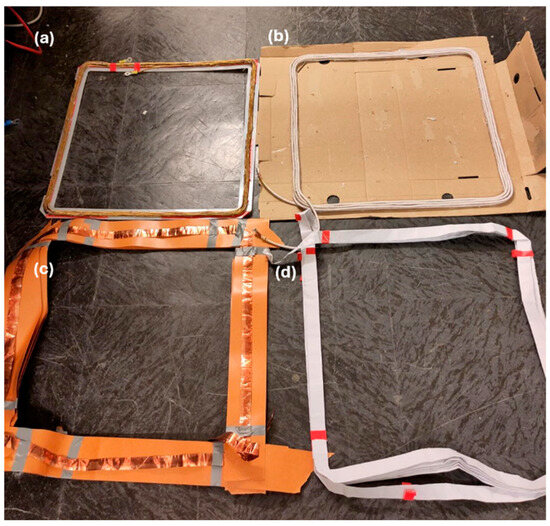

The resistance values of ribbon can be lower in comparison with Litz wire but due to the proximity effect at the center of the coil, the resistance will increase. The values will be measured in the next part with experimental demonstrators. The four alternatives are prototyped, as depicted in Figure 5.

Figure 5.

Prototypes of the four coupler architectures: (a) copper Litz wires, (b) aluminum Litz wires, (c) copper ribbon, and (d) aluminum ribbon.

The physical specificity of each conductor is sorted in Table 1 for the Litz wire and Table 2 for the ribbon. We observe that the price of one coil and its weight is divided by almost four times. The weight is also reduced by four between aluminum and copper Litz wire and by 2 for the ribbon. The aluminum ribbon is the lighter conductor and the cheapest.

Table 2.

Technical information on the copper and aluminum ribbon selected for the coupler design.

Considering the weight reduction in function of the coupler, it could be interesting to mix several solutions but coupling coefficient is, therefore, reduced. The best case corresponds to an identical coil in the primary and secondary of the coupler.

3.2. Experimental Results

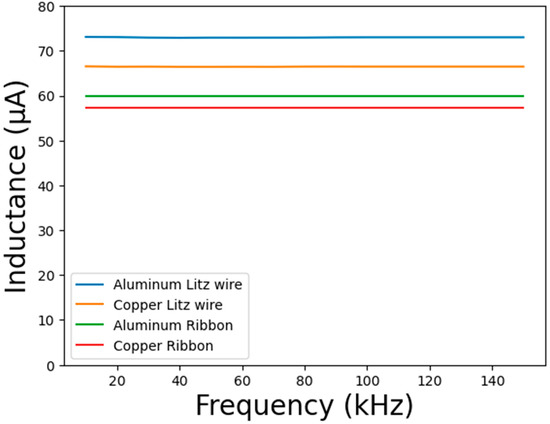

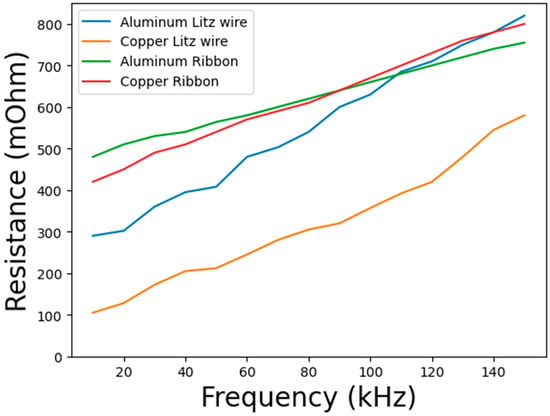

Using an impedance analyzer, the 4192A, the resistance and inductance of each conductor are measured in function of the frequency from 10 kHz to 100 kHz, as observed in Figure 6 and Figure 7, respectively, with determination of the resistance at 80 kHz in case of the Litz copper wire.

Figure 6.

Various inductance values with several conductors of the coupler.

Figure 7.

Various resistance values with several conductors of the coupler.

While the goal is to compare the resistance with an identical inductance, we note that the inductance value varies slightly from 58 µH to 70 µH. This difference can be explained by the realization process, which is not perfectly reproducible, and an aluminum permeability a bit higher with 1.000022 instead of 0.999994 for copper [14].

The resistance value measurement is notable, with a similar variation for the Litz wire and a shift of 200 mΩ, higher than estimated. This higher resistance can be explained by the fact that, in practice, contacts are difficult to make with aluminum wire as they do not adhere to the tin during soldering. The ribbon resistance is, however, higher with 350 mΩ for aluminum and 450 mΩ for copper in addition to the reference. We note, however, that in the function of frequency, the internal resistance of the ribbon is increasing slower, favoring its adoption for higher frequencies. A curve crossing is observed with aluminum Litz wire at 130 kHz and with copper Litz wire estimated at around 200 kHz, meaning that optimal design can probably be proposed for reducing this resistance again. This resistance increase induces a thermal issue, but this is not prejudicial because the ribbon is more performant in dissipation than the Litz wire, and the design is adapted in each case by adjusting the current density.

In addition, as expected, the internal resistance of the ribbon is higher than estimated by calculation, because it is related to the magnetic field emitted at the center of the coil. For example, the ribbon’s resistance is reduced without the ferrite plate. We then tried to use folded ribbons in two to limit the width of the ribbon. We increase the inductance from 51 µH to 60 µH as if there were more turns. Still, as the section is lower, the resistance increases from 460 to 590 mΩ. A tradeoff can be found for an optimized solution in terms of resistance and inductance.

These several resistance values can be expressed in terms of power efficiency thanks to Equation (2) and assuming a coupling coefficient k of 0.2. We can, therefore, compare the electrical efficiency of the coupler, as shown in Table 3, for a range of operating frequencies from 80 kHz to 90 kHz with a similar coupling coefficient.

Table 3.

Comparison of the coupler efficiency for the operating frequency range.

As expected theoretically, the copper Litz wire presents the highest efficiency at the operating frequency (85 kHz), while the aluminum Litz wire is slightly lower, with a 3% difference. Then, although price and weight are the lowest, the copper and aluminum ribbons have the lowest efficiency at around 88%, representing 6% of difference with the reference.

4. Comparative LCA of Conductor Types

This section delves into the life cycle assessment (LCA) [15,16] of wire windings in couplers, specifically for copper and aluminum Litz wires or ribbons. These two materials were chosen due to their properties, cost, societal relevance, and environmental significance. These two geometries do not present the same production process, inducing a strong difference to consider. Indeed, traditional efficiency should consider the LCA impact and the energy considered all along the converter’s lifespan, for giving service, for being representative of the best tradeoff for society, and for becoming a sustainable efficiency [17].

4.1. Goal and Scope Definition

This study aims to assess and compare the environmental impacts of four solutions for the coupler (copper/aluminum Litz wire, copper/aluminum ribbon) through a cradle-to-gate perspective.

The present study considers four solutions for a coupler embedded in a dynamic charging system composed of transmitter and receiver modules, as depicted in Figure 1. The four proposed solutions are evaluated thanks to the LCA from a cradle-to-gate perspective. The system boundaries include the extraction and transportation of raw materials to the production site and the production process. The installation of the couplers both in the car and in the road infrastructure is excluded from the study. The end-of-life treatment of the competing solutions is also excluded from the study because of the lack of information regarding such innovative systems but aluminum solution seems to have an advantage in this field [18].

The Functional Unit (FU) encompasses the different subcomponents aforementioned in the system description. The FU is defined as follows:

To manufacture a coupler that satisfies the technical requirements of continuous 30 kW electric charging. The couplers investigated are there aforementioned. The study compares copper and aluminum Litz wires to copper and aluminum ribbon solutions.

LCAs are performed using the OpenLCA software v2.0.3 (https://openlca.org (accessed on 11 December 2024)). Most Life Cycle Inventories (LCI) are compiled using the Ecoinvent database V3.8 [19], the scientific literature, and additional information from suppliers’ websites. Data are representative of Western European activities and processes except for the supply of copper and aluminum, for which worldwide representative data are selected. The CML v4.8 2016 impact characterization method is applied to perform the Life Cycle Impact Assessment (LCIA) [20]. Eleven impact categories are evaluated at first stance. Second, the study focuses on the five following: climate change, marine ecotoxicity, energy resources, material resources (metal and minerals), and human toxicity.

4.2. Life Cycle Inventory and Assumptions

4.2.1. Litz Wire Production Process

Litz wires modeling encompasses the raw materials extraction, i.e., copper and aluminum, and their transportation to the production site. The wires are drawn, twisted, and stranded thanks to the bunch machine [21]. Masses of material, wire sections, and coil length are reported in Table 1. Before being twisted and stranded, the wires undergo enamel surface treatment. The energy consumed during the bunching manufacturing process considers the installed power of the bunch machine, the linear speed, and the total length of individual wires twisted. According to suppliers’ websites, several insulation resins are available. In the present study, insulation is assumed to be made with PA66 (Nylon) as it satisfies the technical requirements.

4.2.2. Ribbon Production Process

The processes for producing copper and aluminum ribbons are the same; both are typically made through rolling processes, where a thick billet or ingot is passed through rolling mills to reduce its thickness to the desired level. However, the specific parameters of the rolling process, such as temperature and pressure, may vary depending on the material being processed. Milling, rolling, and cutting steps were modeled thanks to LCI databases.

4.3. Results and Interpretations

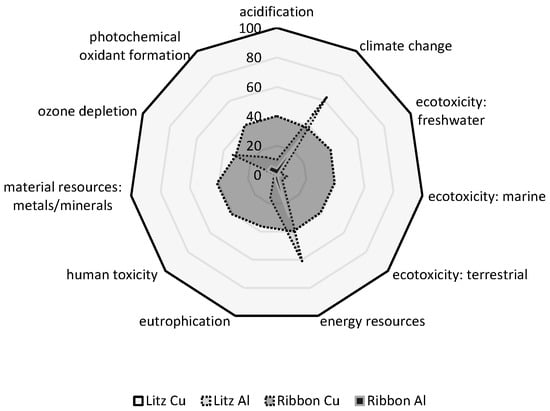

Simulation results highlight that the copper Litz wire solution for the coupler is responsible for the highest environmental impact among the four solutions, regardless of the impact category supervised.

Conversely, the aluminum ribbon coupler is responsible for the lowest environmental impacts.

The comparison between the aluminum Litz wire and the copper ribbon is more contrasted. Indeed, the copper ribbon provides better results than the aluminum Litz wire for three impact categories (climate change, energy resources, and ozone depletion). For the other categories, the aluminum Litz wire dominates the copper ribbon (Table 4).

Table 4.

Life Cycle Impacts Assessment results.

Results of Figure 8 underline the influence of the material selected on the overall environmental profile. Indeed, fewer minerals are consumed to produce aluminum architectures than copper ones. As aforementioned, Litz wires require 683.62 g of copper and 187.62 g of aluminum, while ribbons require 281.25 g of copper and 130.12 g of aluminum, respectively (Table 1 and Table 2). This implied lower environmental impacts, as stressed by the resource depletion impact category, i.e., material resources: metal/minerals.

Figure 8.

Life Cycle Inventory Assessment of the Litz wires and ribbons.

Moreover, the production of Litz wires, whatever the material considered, is more energy intensive than the production of ribbons. Marginal energy consumption is explained by the additional operations required to twist and strand the wires. A difference between the production of copper Litz wires and aluminum Litz wires is also observed due to the number of individual wires to be processed. The thinner the section of individual wire, the higher the number of twisting and bunching operations and, consequently, the higher the energy consumed. As a result, the environmental profile of producing aluminum Litz wire is better than that of copper Litz wire.

In addition, one should notice that solely Litz wire are enameled. This surface treatment also sometimes accounts for the environmental impact. As an example, enameling is responsible for 34.4% of climate change impact in the case of copper Litz wire (54.9% for aluminum Litz wire), 34.39% in the case of acidification (29.6% for aluminum Litz wire), and 33.6% considering the energy resources (55.05% for aluminum Litz wire).

Finally, the four proposed solutions are insulated using PA66. Its contribution is higher in the case of ribbons, i.e., according to the impact category than for the Litz wires, i.e., 1% to 17% according to the impact category. The contribution occurs especially for acidification, between 10 and 17% for Litz wires against 40 and 48.4% for the ribbons, and for climate change this is between 10 and 15% for Litz wires against 36% for the ribbons.

5. Comparison of the Results

The results obtained in this study allow the comparison of the different architectures. Results are summarized in Table 5.

Table 5.

Comparison of the different conductors.

We can observe that aluminum foil presents the best tradeoff, with significant resistance but a reduced price, weight, and ecological impact. The gain is around 10 euros for 1 coil, and if we consider 1 km, 2000 couplers are required, inducing a gain of 20,000 euros. In addition, weight reduction can be traduced in terms of efficiency and is presently not negligeable. To conclude, this solution can be the best in terms of efficiency if the energy used for fabrication and the use phase of the coupler are considered. This coil is also more reliable and easier to replace in case of failure. Nevertheless, depending on the cost of electrical energy and the number of couplers requirements, electrical efficiency can be more critical. For example, for a similar road in Poland and in France, the environmental impact will not be the same if the electrical efficiency is reduced by 6% because electrical energy represents a huge impact. A specific study must be conducted to determine the best solution in the function of the localization and the number of coils. Indeed, as efficiency is slightly worn, a more powerful system is required, or cars have to stay longer over the inductive road to be fully charged.

6. Conclusions

This paper focuses on inductive wireless power transfer and specifically on dynamic applications. Integration of a high quantity of copper into the road is a limit for development of such solution in terms of price and environmental print. Advantages such as weight reduction can, in addition, contribute to a more efficient system, and reliability and handling facility can be provided in addition to the aforementioned parameters by an aluminum ribbon. Electrical efficiency in the counterpart will be reduced by 6% in comparison to the reference system made of copper Litz wire. This current solution can be used for specific operations requiring the best electrical efficiency but is not adapted for large projects. The tradeoff has to be evaluated and investigated for each application considering the origin of the project and its societal aspects. This paper shows how electrical efficiency is no longer the only parameter to consider for commercial development. Presently, although a less efficient configuration, the aluminum ribbon looks really promising for this technology.

Further developments will be proposed to validate the computability between the several conductors.

Author Contributions

R.B. and H.R. have done the measurements and all around was conceptualized, analyzed and written by T.P.; The ACV analysis was carried on and written by Y.L.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data can be obtained by sending an e-mail to tanguy.phulpin@centralesupelec.fr. Concerning the Litz wire details, we thanks Vicente Torns for providing the wires.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fyhr, P.; Domingues, G.; Andersson, M.; Marquez-Fernandez, F.J.; Bangtsson, H.; Alakula, M. Electric roads: Reducing the societal cost of automotive electrification. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo (ITEC), Chicago, IL, USA, 22–24 June 2017; IEEE: New York, NY, USA, 2017; pp. 773–778. [Google Scholar] [CrossRef]

- Kabbara, W.; Phulpin, T.; Bensetti, M. A Review of Standard in Inductive Power Transfer. J. Electr. Electron. Eng. 2024, 3, 1–7. [Google Scholar]

- Stankiewicz, J.M. Estimation of the Influence of the Coil Resistance on the Power and Efficiency of the WPT System. Energies 2023, 16, 6210. [Google Scholar] [CrossRef]

- Yanniello, R.; Pollak, P.; Rooks, J. Technical and Economic Considerations of Aluminum Conductors. In Proceedings of the Conference Record of 2007 Annual Pulp and Paper Industry Technical Conference, Williamsburg, VA, USA, 24–28 June 2007; IEEE: New York, NY, USA, 2007; pp. 63–67. [Google Scholar] [CrossRef]

- Sullivan, C.R. Aluminum Windings and Other Strategies for High-Frequency Magnetics Design in an Era of High Copper and Energy Costs. IEEE Trans. Power Electron. 2008, 23, 2044–2051. [Google Scholar] [CrossRef]

- Maezawa, T.; Zhou, H.; Sato, M.; Bu, Y.; Mizuno, T. Low Loss on a Litz Aluminum Wire Coil Using Magnetic Tape for Automotive Wireless Power Transmission. IEEE Trans. Magn. 2021, 57, 8700307. [Google Scholar] [CrossRef]

- Kabbara, W.; Bensetti, M.; Phulpin, T.; Caillierez, A.; Sadarnac, S.L.E.D. A Control Strategy to Avoid Drop and Inrush Currents during Transient Phases in a Multi-Transmitters DIPT System. Energies 2022, 15, 2911. [Google Scholar] [CrossRef]

- Busacca, A.; Tommaso, A.O.D.; Campagna, N.; Miceli, R.; Valtchev, V.C.S. Design and Validation of a Dynamic Inductive Power Transfer System for EV Battery Charging. In Proceedings of the 2022 Second International Conference on Sustainable Mobility Applications, Renewables and Technology (SMART), Cassino, Italy, 23–25 November 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Ge, X.; Wang, Y.; Ren, D.; Tang, M.; Wang, L. A Single-Input Multi-Output Inverter with Voltage Boosting for Multi-Load Wireless Power Transfer Systems. Appl. Sci. 2024, 14, 10453. [Google Scholar] [CrossRef]

- Kabbara, W.; Bensetti, M.; Phulpin, T.; Sadarnac, D.; Caillierez, A.; Loudot, S. First Harmonic Approximation of a Full Bridge Rectifier with a Weak Capacitive Filter. In Proceedings of the Journées Scientifiques URSI-France 2023, L’ÉNERGIE AU CŒUR DES ONDES RESSOURCES ET ENVIRONNEMENT: GESTION “INTELLIGENTE” ⟨hal-04042964⟩, Gif-Sur-Yvettes, France, 21–22 March 2023; Available online: https://hal.science/hal-04042964/ (accessed on 11 December 2024).

- Kadem, K.; Bensetti, M.; Le Bihan, Y.; Labouré, E.; Debbou, M. Optimal Coupler Topology for Dynamic Wireless Power Transfer for Electric Vehicle. Energies 2021, 14, 3983. [Google Scholar] [CrossRef]

- Edwards, T.C.; Steer, M.B. Foundations for Microstrip Circuit Design, 1st ed.; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Carretero, C. Coupling power losses in inductive power transfer systems with Litz-wire coils. IEEE Trans. Ind. Electron. 2017, 64, 4474–4482. [Google Scholar] [CrossRef]

- Huber, J.; Imperiali, L.; Menzi, D.; Musil, F.; Kolar, J.W. Energy Efficiency is Not Enough! IEEE Power Electron. Mag. 2024, 11, 18–31. [Google Scholar] [CrossRef]

- ISO 14040:2006(E); ISO 14040: Environmental Management—Life Cycle Assessment—Principles and Framework. International Standards Organization: Geneva, Switzerland, 2006.

- ISO 14044:2006(E); ISO 14044: Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Standards Organization: Geneva, Switzerland, 2006.

- Born, H.C.; Blanc, F.S.-L.; Platte, V.; Kampker, A.; Heimes, H.; Dorn, B.; Brans, F.; Drexler, D.; Oehler, F.; zu Munster, A.; et al. Development of a Production Process for Formed Litz Wire Stator Windings. In Proceedings of the 2022 12th International Electric Drives Production Conference (EDPC), Regensburg, Germany, 29–30 November 2022; IEEE: New York, NY, USA, 2022; pp. 1–9. [Google Scholar] [CrossRef]

- Wędrychowicz, M.; Kurowiak, J.; Skrzekut, T.; Noga, P. Recycling of Electrical Cables—Current Challenges and Future Prospects. Materials 2023, 16, 6632. [Google Scholar] [CrossRef] [PubMed]

- Steubing, B.; Wernet, G.; Reinhard, J.; Bauer, C.; Moreno-Ruiz, E. The ecoinvent database version 3 (part II): Analyzing LCA results and comparison to version 2. Int. J. Life Cycle Assess. 2016, 21, 1269–1281. [Google Scholar] [CrossRef]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; Koning, A.D.; Oers, L.V.; Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; et al. Handbook on Life Cycle Assessment. Operational Guide to the ISO Standards. I: LCA in Perspective. IIa: Guide. IIb: Operational Annex. III: Scientific Background; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002; 692p, ISBN 1-4020-0228-9. [Google Scholar]

- Born, H.C.; Oehler, F.; Platte, V.; Kampker, A.; Heimes, H.; Dorn, B.; Brans, F.; Drexler, D.; Blanc, F.S.-L.; Reising, S. Manufacturing Process and Design Requirements of Litz Wire with Focus on Efficiency Improvement of Traction Motors. In Proceedings of the 2022 12th International Electric Drives Production Conference (EDPC), Regensburg, Germany, 29–30 November 2022; IEEE: New York, NY, USA, 2022; pp. 1–7. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).