Thermal Hydraulics Simulation of a Water Spray System for a Cooling Fluid Catalytic Cracking (FCC) Regenerator

Abstract

:1. Introduction

- (1)

- Air/Oxygen introduction: Air or oxygen is introduced into the regenerator to support the combustion process. This helps to burn off the coke and generate heat. The flow rate of air or oxygen can be adjusted to control the temperature and ensure efficient coke combustion.

- (2)

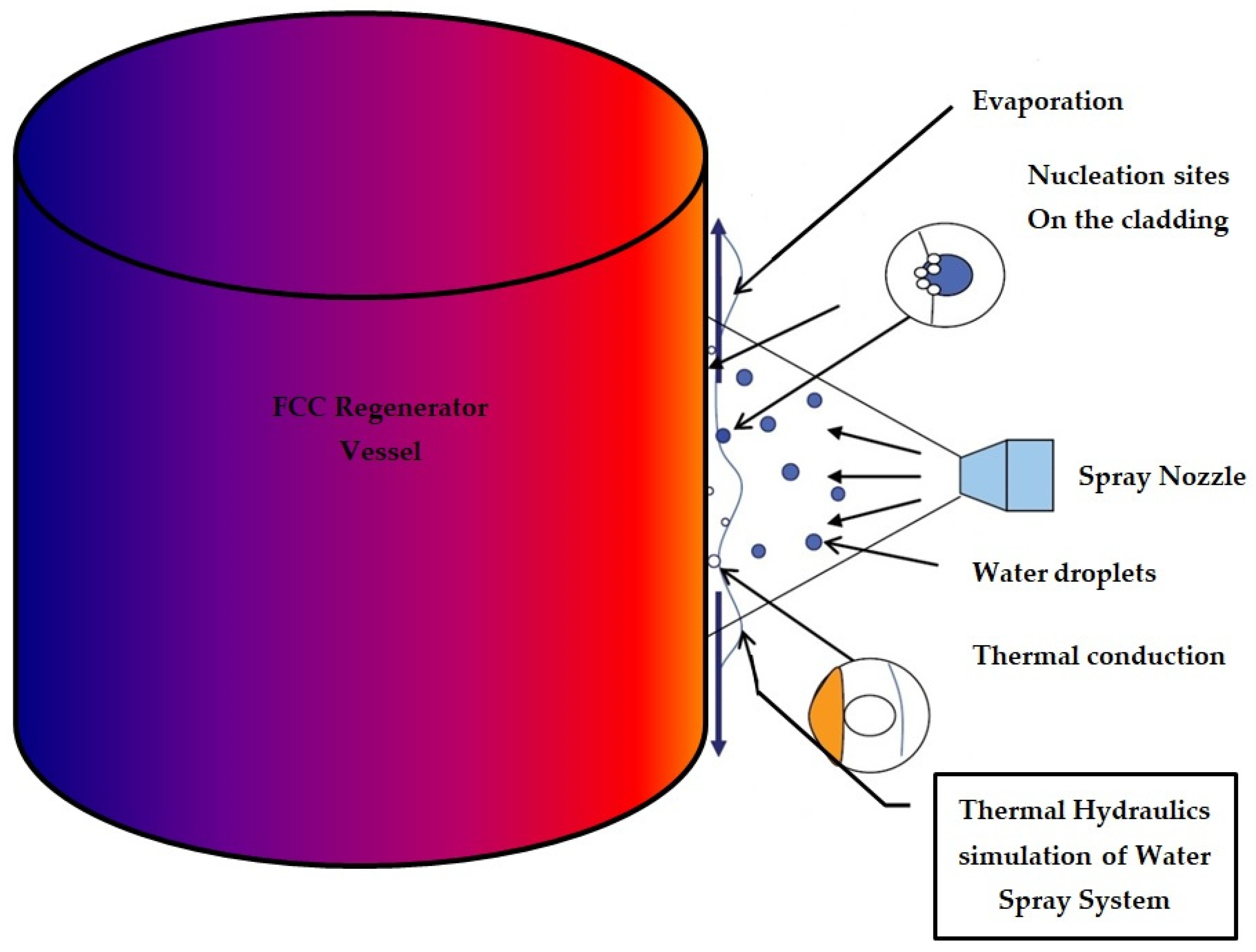

- Steam or water injection: Steam or water can be injected into the regenerator as a method of cooling. This is achieved by evaporating the injected water or steam, which absorbs heat from the regenerator and reduces the temperature. The injected steam or water can also help to dilute the flue gas and control the oxygen concentration, aiding in the combustion process.

- (3)

- Internal refractory lining: The regenerator vessel is often lined with refractory materials, which have high heat resistance. These refractory linings help to minimize heat transfer to the vessel shell, reducing the overall temperature. They also protect the vessel from excessive heat and prolong its lifespan.

- (4)

- Catalyst cooler: The FCC catalyst cooler helps to regulate the regenerator temperature and ensures the continuous and efficient operation of the fluid catalytic cracking process in petroleum refineries [4]. The catalyst cooler is basically a vertical shell-and-tube heat exchanger attached to the regenerator [5]. The cooler extracts high quality heat from the catalyst in the regenerator to produce high pressure steam. The hot catalyst enters the cooler at a high temperature, and as it passes through the heat exchangers, it comes into contact with a cooling medium, such as air or water, which absorbs the excess heat and lowers the catalyst’s temperature. The cooled catalyst is then directed back into the FCC reactor to continue the cracking process [6].

- (5)

- Catalyst Withdrawal: Some FCC units utilize a catalyst (such as zeolite) withdrawal system that removes a portion of the catalyst from the regenerator before it reaches excessively high temperatures. This helps to control increases in temperature and it prevents damage to the catalyst [7].

1.1. Spray Cooling Heat Transfer Mechansims

1.2. Literature Survey Concerning Numerical Simulations of Spray Cooling

1.3. Scope and Novelty of This Paper

2. Materials and Methods

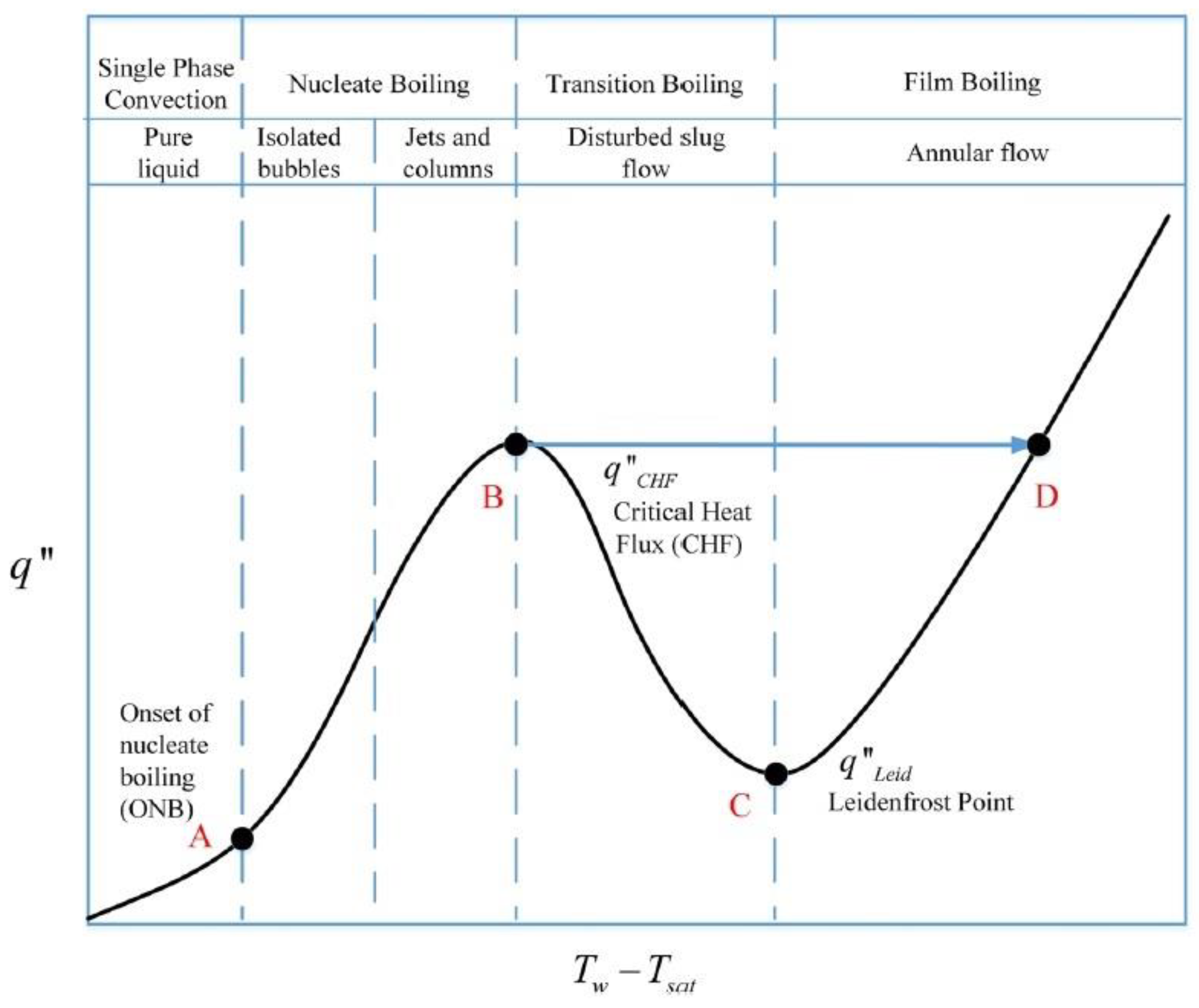

2.1. Critical Heat Flux (CHF) of Spray Cooling

- (a)

- Natural convection (region OA), where heat is removed via natural convection from the cladding surface to the bulk. The liquid water starts to evaporate.

- (b)

- The onset of nucleate boiling (ONB), where the cladding is superheated so that it is able to cause vapor nucleation at the heating surface.

- (c)

- The nucleate boiling region (AB), where vapor nucleation occurs on the cladding surface. It starts with a few bubbles at low heat fluxes, then, the vapor structure becomes more intense as the heat flux is increased. The bubbles begin to coalesce, and finally, at high heat fluxes, vapor patches are formed close to the cladding surface (Annular flow).

- (d)

- The critical heat flux (CHF or point B) marks the maximal value of nucleate boiling heat flux (see Figure 2). At this point, there is a restriction on the liquid supply to the heating surface.

- (e)

- The transition boiling region (DE) is characterized by the existence of an unstable vapor blanket over the heating surface. Large amounts of vapor may be released.

- (f)

- The film boiling region (CD), where a stable vapor film forms and covers the entire heating surface. The heat is transferred via convection and conduction through the vapor film. Thermal radiation heat transfer increases with the cladding surface temperature.

2.2. Thermophysical Properties of the Steel

2.3. Fire Dynamic Simulation Modeling of Water Spray Cooling

- (a)

- Computational Fluid Dynamics: FDS is based on the principles of fluid dynamics, heat transfer, combustion, and spray cooling. It uses computational algorithms to model and simulate the movement of air, heat, and combustion products during a fire event.

- (b)

- Geometry and Meshing: Users can create complex 3D geometries of buildings or structures using various software tools, and they can import them into FDS. The geometry is typically represented using a computational grid (mesh) that allows the simulation of fire dynamics within the defined space.

- (c)

- Heating and Evaporation of Droplets: Droplets are represented either as discrete particles propelled by the carrying gas, or as rectangular blocks that collectively form a thin liquid film on solid objects. They are individually tracked as Lagrangian particles. The mass and heat transfer coefficients are different.

- (d)

- Combustion and Heat Transfer: The software models the combustion process, taking into account the chemical reactions and heat transfer between fire and surrounding objects.

- (e)

- Absorption and Scattering of Thermal Radiation by Water Droplets: The thermal radiation attenuation of liquid droplets should be considered, especially for water mist systems. Liquid droplets attenuate thermal radiation via a combination of absorption and scattering. The radiative Transfer Equation (RTE), which includes these interactions, should be solved for both the accurate prediction of the radiation field and for the droplet energy balance.

- (f)

- Validation and Verification: FDS has been extensively validated against experimental data to ensure its accuracy and reliability in predicting fire behavior in various scenarios.

- (g)

- Fire Safety Engineering: FDS is used to evaluate the effectiveness of fire protection measures, such as sprinkler systems, smoke control systems, and fire-resistant materials in buildings.

2.4. FDS Modelling of the Spray Cooling System

2.5. Calculation of the Convective Heat Transfer Coefficient of the Cladding Surface

3. Results

3.1. Computational Model Validation

3.2. Grid Sensitivity Study Results

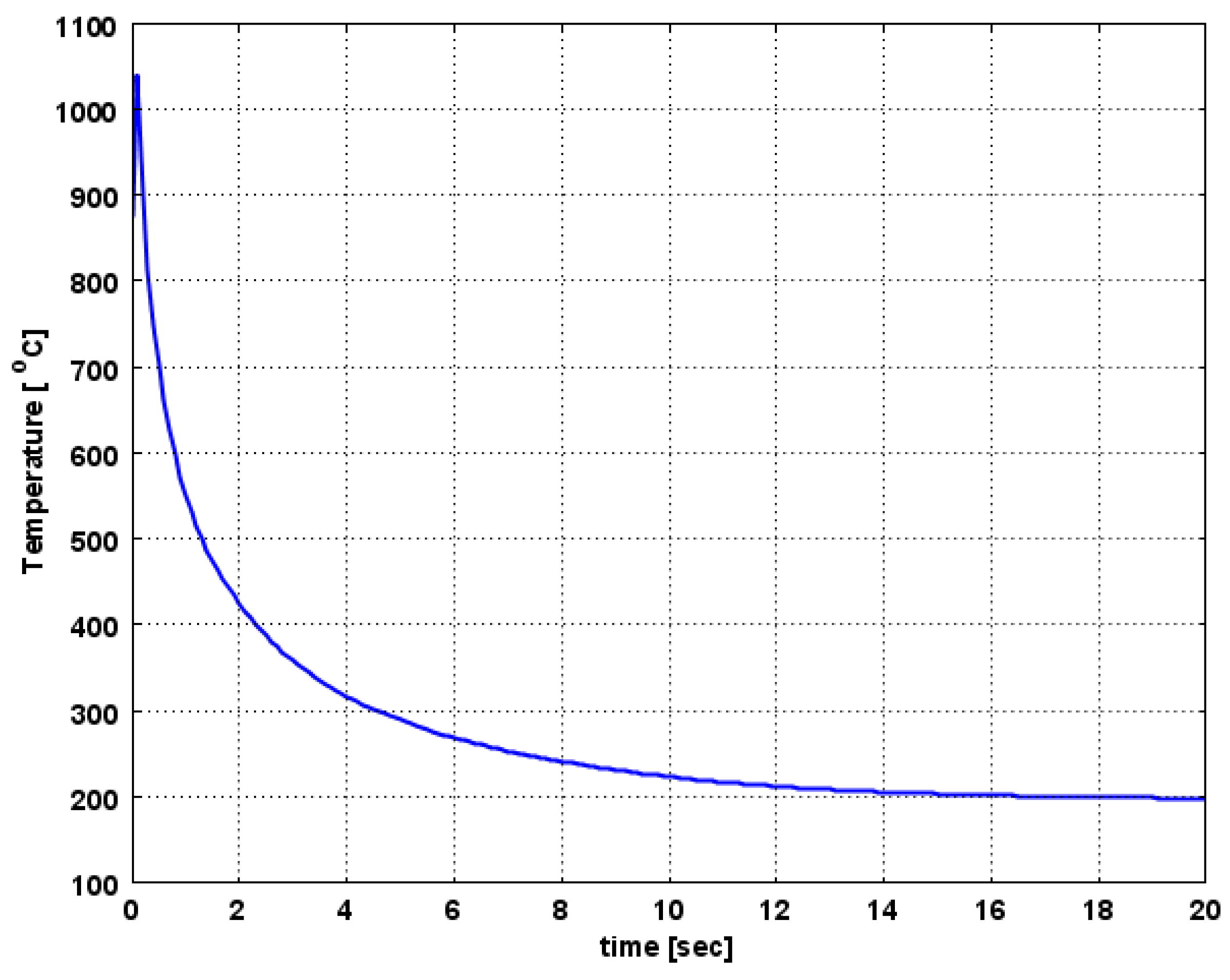

3.3. Numerical Model Results

3.3.1. Results Obtained for the First Case

3.3.2. Results Obtained for the Second Case

4. Discussion

- (1)

- Efficient Heat Transfer: Evaporative cooling using water spray can effectively transfer large amounts of heat due to the high latent heat of water vapor.

- (2)

- Cost-Effective: Water is readily available and relatively inexpensive compared with other cooling methods.

- (3)

- Environmental Benefits: Water spray cooling is considered environmentally friendly as it does not require the use of refrigerants or other chemicals that may be harmful to the environment.

- (4)

- Flexibility: Water spray cooling can be easily applied to various surfaces and systems, making it a versatile cooling technique.

- (5)

- However, there are also some considerations when using water spray cooling, as follows:

- (6)

- Water Consumption: It is essential to manage water usage and avoid excessive waste when employing water spray cooling systems.

- (7)

- Corrosion and Scaling: Depending on the quality of the water and the materials involved, there may be a risk of corrosion or scaling on the cooled surfaces or equipment.

- (8)

- Maintenance: Water spray systems require regular maintenance to ensure proper functioning, including cleaning nozzles, checking for blockages, and monitoring water quality.

Funding

Conflicts of Interest

Nomenclature

| cp | Specific heat in J/(kg·K) |

| h | Convective coefficient in w/(m2·K) |

| k | Thermal conductivity in w/(m·K) |

| L | Distance between the injector nozzle and the regenerator cladding surface m |

| p | Pressure in Pa |

| Pr | Prandtl number |

| Re | Reynolds number |

| Nu | Nusselt number |

| T | Temperature in K |

| u | Velocity in m/s |

| Water volumetric flow rate in m3/s |

Greek Letters

| ρwater | Water density in kg/m3 |

| ϕ | Spatial angle in rad |

Abbreviations

| CHF | Critical Heat Flux |

| CFD | Computational Fluid Dynamics |

| FCC | Fluid Catalytic Cracking |

| FDS | Fire Dynamic Simulation |

| HTC | Heat Transfer Coefficient |

References

- Gholami, Z.; Gholami, F.; Tišler, Z.; Tomas, M.; Vakili, M.A. Review on Production of Light Olefins via Fluid Catalytic Cracking. Energies 2021, 14, 1089. [Google Scholar] [CrossRef]

- Fewel, K. Analyzing FCC Hot Spots. April 2017. Available online: https://www.digitalrefining.com/article/1001349/analysing-fcc-hot-spots#.YY_kQlVBzX4 (accessed on 28 June 2023).

- González, J.L.; Gómez, S.; Rivas, D. Integrity assessment and rehabilitation recommendation of the stripper section of a FCC reactor in the creep regime. Procedia Struct. Integr. 2017, 3, 48–56. [Google Scholar] [CrossRef]

- Oloruntoba, A.; Zhang, Y.; Hsu, C.S. State-of-the-Art Review of Fluid Catalytic Cracking (FCC) Catalyst Regeneration Intensification Technologies. Energies 2022, 15, 2061. [Google Scholar] [CrossRef]

- Pillai, R.; Niccum, P. FCC Catalyst Coolers in Maximum Propylene Mode. March 2012. Available online: https://www.digitalrefining.com/article/1000350/fcc-catalyst-coolers-in-maximum-propylene-mode (accessed on 28 June 2023).

- Yao, X.; Sun, F.; Zhang, Y.; Lu, C. Experimental validation of a new heat transfer intensification method for FCC external catalyst coolers. Chem. Eng. Process. Process Intensif. 2014, 75, 19–30. [Google Scholar] [CrossRef]

- Hovey, K.; Fisher, R. Automating Catalyst Withdrawal for Improved Safety. April 2018. Available online: https://www.digitalrefining.com/article/1001492/automating-catalyst-withdrawal-for-improved-safety (accessed on 28 June 2023).

- Gao, X.; Li, R. Spray Impingement Cooling: The State of the Art; Intech-Open: Rijeka, Croatia, 2019. [Google Scholar] [CrossRef]

- Yang, W.J.; Clark, D.W. Spray Cooling of Air Cooled Compact Heat Exchanger. In International Journal of Heat and Mass Transfer; Pergamon Press: Oxford, UK, 1975; Volume 18, pp. 311–317. [Google Scholar]

- Goldstein, M.E.; Yang, W.J.; Clark, J.A. Boundary-layer analysis of two-phase flow over an oscillating flat plate. AIAA J. 1967, 5, 43–50. [Google Scholar] [CrossRef]

- Scherberg, M.G.; Wright, H.E.; Elrod, W.C. Heat transfer potential of liquid-gas spray flows. In International Symposium on Two-Phase Systems; Technion: Haifa, Israel, 1971. [Google Scholar]

- Yin, J.; Wang, S.; Sang, X.; Zhou, Z.; Chen, B.; Thrassos, P.; Romeos, A.; Giannadakis, A. Spray Cooling as a High-Efficient Thermal Management Solution: A Review. Energies 2022, 15, 8547. [Google Scholar] [CrossRef]

- Anisiuba, V.; Ma, H.; Silaen, A.; Zhou, C. Computational Studies of Air-Mist Spray Cooling in Continuous Casting. Energies 2021, 14, 7339. [Google Scholar] [CrossRef]

- Jafari, M. Analysis of Heat Transfer in Spray Cooling Systems Using Numerical Simulations. Master’s Thesis, Faculty of Graduate Studies through Mechanical, Automotive and Materials Engineering, University of Windsor, Windsor, UK, 2014; 5028p. Available online: https://scholar.uwindsor.ca/etd/5028/ (accessed on 23 October 2023).

- Salman, A.S. Enhanced Heat Transfer in Spray Cooling Through Surface Modifications: An Experimental and Computational Study. Ph.D. Thesis, Mechanical Engineering College of Engineering and Computing, University of South Carolina, Columbia, SC, USA, 2019. [Google Scholar]

- da Silva Kranzfeld, L.; Mitre, J.F.; Nichele, J. Investigation of the Particle Size Influence over the Behavior of Aerosol Free Jets Based on CFD-Eulerian Simulations. Braz. J. Dev. 2020, 6, 51444–51461. [Google Scholar] [CrossRef]

- Davidy, A. Thermal Hydraulics and Thermochemical Design of Fatty Acid Methyl Ester (Biodiesel) Esterification Reactor byHeating with High Boiling Point Phenyl-Naphthalene Liquid. Fluids 2022, 7, 93. [Google Scholar] [CrossRef]

- Yan, Z.; Rui, Z.; Fei, D.; Teck, N.; Kok, C.; Kok, F.; Poh, K.; Yong, S. Spray Cooling in Two Phase Flow, Phase Change and Numerical Modeling; Intech-Open: Rijeka, Croatia, 2011. [Google Scholar] [CrossRef]

- Collier, J.G. Convective Boiling and Condensation; McGraw-Hill Book Company: London, UK, 1972. [Google Scholar]

- AZO. Materials Network Site, Stainless Steel—Properties and Applications of Grade 4340 Stainless Steel. Available online: https://www.azom.com/article.aspx?ArticleID=6772 (accessed on 11 September 2023).

- McGrattan, K. Fire Dynamics Simulator (Version 5)—Technical Reference Guide Volume 1: Mathematical Model; NIST Special Publication 1018; National Institute of Standards and Technology U.S. Department of Commerce: Gaithersburg, MD, USA, 2010.

- McGrattan, K.; Forney, G.P. Fire Dynamics Simulator (Version 5)—User’s Guide; NIST Special Publication 1019; National Institute of Standards and Technology U.S. Department of Commerce: Gaithersburg, MD, USA, 2010.

- Davidy, A. Thermodynamic Design of Organic Rankine Cycle (ORC) Based on Petroleum Coke Combustion. ChemEngineering 2021, 5, 37. [Google Scholar] [CrossRef]

- Zhang, T.; Mo, Z.; Xu, X.; Liu, X.; Chen, H.; Han, Z.; Yan, Y.; Jin, Y. Advanced Study of Spray Cooling: From Theories to Applications. Energies 2022, 15, 9219. [Google Scholar] [CrossRef]

- Karwa, N.; Kale, S.R.; Subbarao, P.M.V. Experimental study of non-boiling heat transfer from a horizontal surface by water sprays. Exp. Therm. Fluid Sci. 2008, 32, 571–579. [Google Scholar] [CrossRef]

- Cebo-Rudnicka, A.; Buczek, A. The Influence of Selected Parameters of Water Spray Cooling on the Heat Transfer Coefficient. Comput. Methods Mater. Sci. 2009, 9, 200–206. Available online: https://www.researchgate.net/publication/262352847 (accessed on 23 October 2023).

| Material Property | Value |

|---|---|

| ρ | 7850 (kg/m3) |

| Cp | 475 (J/(kg·°C)) |

| k | 44.5 (w/(m·°C)) |

| Sensor | Position (m) |

|---|---|

| TC1, H2O-1 | x = 0, y = 1, z = 0.1 |

| TC2, H2O-2 | x = 0, y = 1, z = 0.4 |

| TC3, H2O-3 | x = 0, y = 1, z = 0.6 |

| TC4, H2O-4 | x = 0, y = 1, z = 0.8 |

| TC5, H2O-5 | x = 0, y = 1, z = 1.0 |

| Thermocouple | Difference (%) |

|---|---|

| TC1 | 0.8 |

| TC2 | 3.5 |

| TC3 | 6.3 |

| TC4 | 7.4 |

| TC5 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Davidy, A. Thermal Hydraulics Simulation of a Water Spray System for a Cooling Fluid Catalytic Cracking (FCC) Regenerator. Dynamics 2023, 3, 737-749. https://doi.org/10.3390/dynamics3040039

Davidy A. Thermal Hydraulics Simulation of a Water Spray System for a Cooling Fluid Catalytic Cracking (FCC) Regenerator. Dynamics. 2023; 3(4):737-749. https://doi.org/10.3390/dynamics3040039

Chicago/Turabian StyleDavidy, Alon. 2023. "Thermal Hydraulics Simulation of a Water Spray System for a Cooling Fluid Catalytic Cracking (FCC) Regenerator" Dynamics 3, no. 4: 737-749. https://doi.org/10.3390/dynamics3040039

APA StyleDavidy, A. (2023). Thermal Hydraulics Simulation of a Water Spray System for a Cooling Fluid Catalytic Cracking (FCC) Regenerator. Dynamics, 3(4), 737-749. https://doi.org/10.3390/dynamics3040039