Optimizing Graphene Oxide Content in Cellulose Matrices: A Comprehensive Review on Enhancing the Structural and Functional Performance of Composites

Abstract

1. Introduction

2. Rheological Impact of Graphene on Polymeric Matrices

3. Theoretical Framework

3.1. Theoretical Modeling and Simulation of Graphene–Cellulose Composites

3.2. Molecular Dynamics Simulations

3.3. Finite Element Analysis

3.4. Multiscale Modeling

3.5. Density Functional Theory (DFT)

3.6. Machine Learning Models

4. Optimization of Graphene Content

4.1. Response Surface Methodology (RSM)

4.1.1. Optimization of Thermal Conductivity and Viscosity

4.1.2. Optimization of Dye Removal

4.2. Artificial Neural Networks (ANN)

5. Quantitative Analysis of Structural and Functional Performance

5.1. Mechanical Properties

5.2. Thermal Stability

5.3. Electrical Conductivity

5.4. Barrier Properties

5.5. Biocompatibility and Tissue Engineering Applications

5.6. Energy Storage and Environmental Remediation Applications

6. Challenges and Future Perspectives

7. Conclusions

Funding

Conflicts of Interest

Abbreviations

| ANN | artificial neural network |

| CNC | cellulose nanocrystal |

| CNF | cellulose nanofiber |

| CPF | chlorpyrifos |

| CVD | chemical vapor deposition |

| DIC | Digital Image Correlation |

| DSC | differential scanning calorimetry |

| ECC | engineered cementitious composites |

| FTIR | Fourier Transform Infrared spectroscopy |

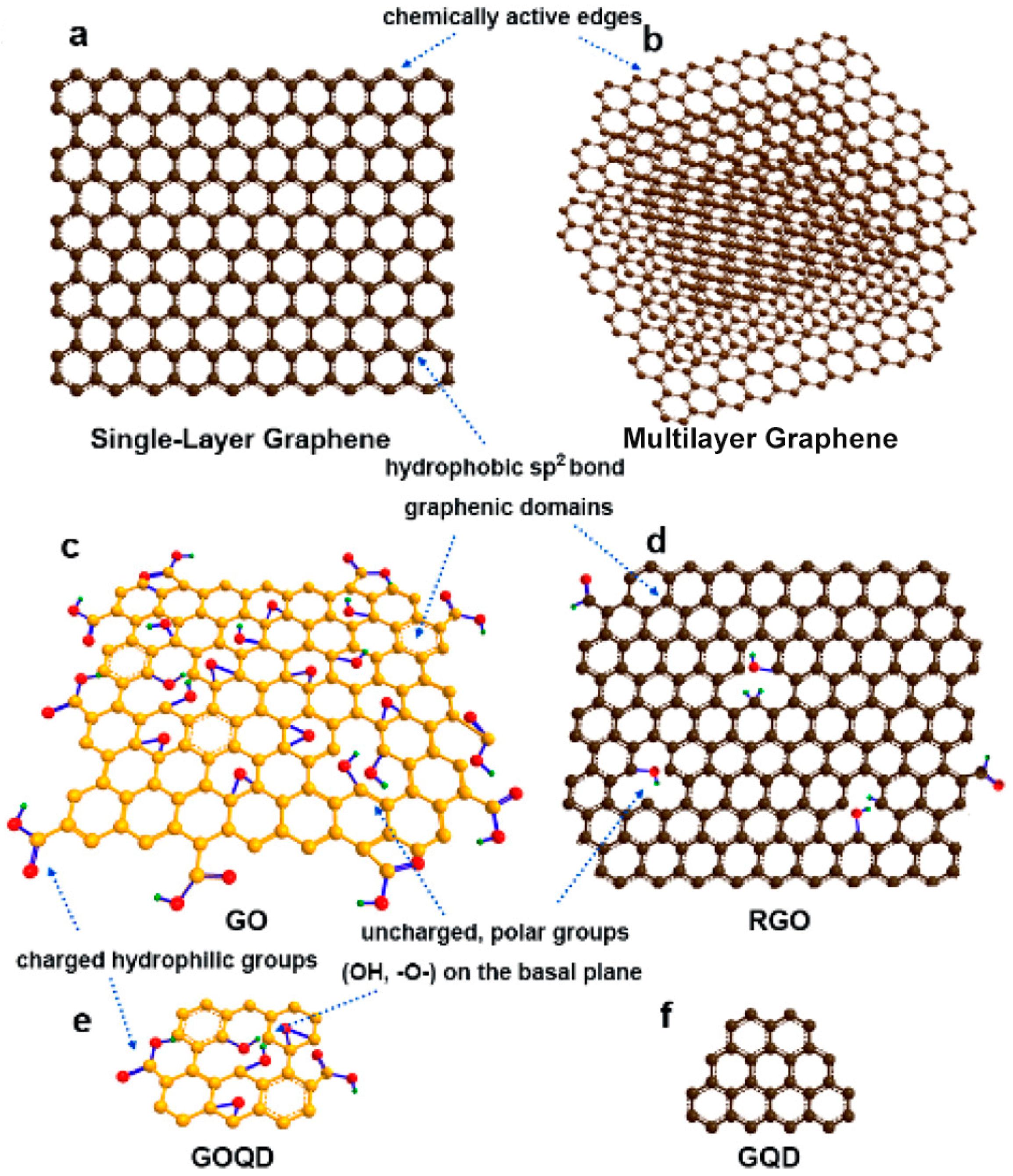

| GO | graphene oxide |

| GOQD | graphene oxide quantum dots |

| GNP | graphene nanoplatelets |

| GQD | graphene quantum dots |

| MFC | microfibrillated cellulose |

| NFC | nanofibrillated cellulose |

| PHBV | Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) |

| PSO | particle swarm optimization |

| PVA | polyvinyl alcohol |

| RSM | response surface methodology |

| TGA | thermogravimetric analysis |

| UTS | ultimate tensile strength |

References

- Malnarič, I.; Krajnc, M.; Šebenik, U. Rheological study of hybrid aqueous suspension of TEMPO-oxidized cellulose nanofibrils and graphene oxide. Cellulose 2024, 31, 6105–6122. [Google Scholar] [CrossRef]

- Ramezani, H.; Haji Ali Koohpayeh, M.; Tajedini, A.; Ramezani, G.; Mohseni, A. Nonlocal stability of curved carbon nanotubes conveying fluid based on Eringen’s nonlocal elasticity theory in a thermomagnetic environment. Acta Mech. 2024, 235, 4273–4287. [Google Scholar] [CrossRef]

- Luo, H.; Dong, J.; Yao, F.; Yang, Z.; Li, W.; Wang, J.; Xu, X.; Hu, J.; Wan, Y. Layer-by-Layer Assembled Bacterial Cellulose/Graphene Oxide Hydrogels with Extremely Enhanced Mechanical Properties. Nano-Micro Lett. 2018, 10, 42. [Google Scholar] [CrossRef] [PubMed]

- Song, N.; Jiao, D.; Cui, S.; Hou, X.; Ding, P.; Shi, L. Highly Anisotropic Thermal Conductivity of Layer-by-Layer Assembled Nanofibrillated Cellulose/Graphene Nanosheets Hybrid Films for Thermal Management. ACS Appl. Mater. Interfaces 2017, 9, 2924–2932. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Yu, H.-Y.; Wang, Y.-Y.; Zhou, Y.; Zhang, H.; Yao, J.-M.; Abdalkarim, S.Y.H.; Tam, K.C. Natural Biodegradable Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Nanocomposites with Multifunctional Cellulose Nanocrystals/Graphene Oxide Hybrids for High-Performance Food Packaging. J. Agric. Food Chem. 2019, 67, 10954–10967. [Google Scholar] [CrossRef] [PubMed]

- Basha, I.K.; Abd El-Monaem, E.M.; Khalifa, R.E.; Omer, A.M.; Eltaweil, A.S. Sulfonated graphene oxide impregnated cellulose acetate floated beads for adsorption of methylene blue dye: Optimization using response surface methodology. Sci. Rep. 2022, 12, 9339. [Google Scholar] [CrossRef]

- Khiam, G.K.; Karri, R.R.; Mubarak, N.M.; Khalid, M.; Walvekar, R.; Abdullah, E.C.; Rahman, M.E. Modelling and optimization for methylene blue adsorption using graphene oxide/chitosan composites via artificial neural network-particle swarm optimization. Mater. Today Chem. 2022, 24, 100946. [Google Scholar] [CrossRef]

- Balasubramani, K.; Sivarajasekar, N.; Muthusaravanan, S.; Ram, K.; Naushad, M.; Ahamad, T.; Sharma, G. Efficient removal of antidepressant Flupentixol using graphene oxide/cellulose nanogel composite: Particle swarm algorithm based artificial neural network modelling and optimization. J. Mol. Liq. 2020, 319, 114371. [Google Scholar] [CrossRef]

- Chen, Y.; Li, G.; Li, L.; Zhang, W.; Dong, K. Molecular dynamics simulation and experimental study on mechanical properties and microstructure of cement-based composites enhanced by graphene oxide and graphene. Mol. Simul. 2023, 49, 251–262. [Google Scholar] [CrossRef]

- Tao, Y.; Du, J.; Cheng, Y.; Lu, J.; Min, D.; Wang, H. Advances in Application of Cellulose—MOF Composites in Aquatic Environmental Treatment: Remediation and Regeneration. Int. J. Mol. Sci. 2023, 24, 7744. [Google Scholar] [CrossRef]

- Castellanos, H.G.; Aryanfar, Y.; Mohtaram, S.; Keçebaş, A.; Karaca-Dolgun, G.; Ahmad, S.; Asiri, A.N.M.; Islam, S. The efficacy of nano-cellulose-based composites in heavy metal removal from wastewater: A comprehensive review. J. Chem. Technol. Biotechnol. 2024, jctb.7775. [Google Scholar] [CrossRef]

- Mohamed, E.N.; Abd-Elhamid, A.I.; El-Bardan, A.A.; Soliman, H.M.A.; Mohy-Eldin, M.S. Development of carboxymethyl cellulose-graphene oxide biobased composite for the removal of methylene blue cationic dye model contaminate from wastewater. Sci. Rep. 2023, 13, 14265. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Liu, Z.; Zhang, J.; Jiao, C.; Ding, L.; Yang, S. Synthesis and Adsorption Properties of Novel Bacterial Cellulose/Graphene Oxide/Attapulgite Materials for Cu and Pb Ions in Aqueous Solutions. Materials 2020, 13, 3703. [Google Scholar] [CrossRef] [PubMed]

- D’Amora, U.; Dacrory, S.; Hasanin, M.S.; Longo, A.; Soriente, A.; Kamel, S.; Raucci, M.G.; Ambrosio, L.; Scialla, S. Advances in the Physico-Chemical, Antimicrobial and Angiogenic Properties of Graphene-Oxide/Cellulose Nanocomposites for Wound Healing. Pharmaceutics 2023, 15, 338. [Google Scholar] [CrossRef] [PubMed]

- Qian, C.; Li, L.; Gao, M.; Yang, H.; Cai, Z.; Chen, B.; Xiang, Z.; Zhang, Z.; Song, Y. All-printed 3D hierarchically structured cellulose aerogel based triboelectric nanogenerator for multi-functional sensors. Nano Energy 2019, 63, 103885. [Google Scholar] [CrossRef]

- Zhu, P.; Yu, Z.; Sun, H.; Zheng, D.; Zheng, Y.; Qian, Y.; Wei, Y.; Lee, J.; Srebnik, S.; Chen, W.; et al. 3D Printed Cellulose Nanofiber Aerogel Scaffold with Hierarchical Porous Structures for Fast Solar-Driven Atmospheric Water Harvesting. Adv. Mater. 2024, 36, 2306653. [Google Scholar] [CrossRef]

- Santamaria, A.D.; Chandrasekaran, S.; Philbrick, O.; Worsley, M.A. 3D Printed Carbon Aerogels for Polymer-Electrolyte Fuel Cells. ECS Trans. 2022, 108, 153–163. [Google Scholar] [CrossRef]

- Hashemi, S.A.; Ghaffarkhah, A.; Hosseini, H.; Arjmand, M. 3D-Printed Interfacially Jammed Emulsion Aerogels. ACS Appl. Mater. Interfaces 2024, 16, 46923–46936. [Google Scholar] [CrossRef]

- Biswas, P.K.; Omole, O.; Peterson, G.; Cumbo, E.; Agarwal, M.; Dalir, H. Carbon and cellulose based nanofillers reinforcement to strengthen carbon fiber-epoxy composites: Processing, characterizations, and applications. Front. Mater. 2023, 9, 1089996. [Google Scholar] [CrossRef]

- Sengupta, J.; Hussain, C.M. Advanced Graphene-Based Technologies for Antibiotic Removal from Wastewater: A Review (2016–2024). C 2024, 10, 92. [Google Scholar] [CrossRef]

- Kasprzak, D.; Mayorga-Martinez, C.C.; Alduhaish, O.; Pumera, M. Wearable and Flexible All-Solid-State Supercapacitor Based on MXene and Chitin. Energy Technol. 2023, 11, 2201103. [Google Scholar] [CrossRef]

- Cheng, C.; Li, S.; Thomas, A.; Kotov, N.A.; Haag, R. Functional Graphene Nanomaterials Based Architectures: Biointeractions, Fabrications, and Emerging Biological Applications. Chem. Rev. 2017, 117, 1826–1914. [Google Scholar] [CrossRef] [PubMed]

- Tavares, L.; Sousa, L.R.; Silva, S.M.d.; Lima, P.S.; Oliveira, J.M. Effect of Incorporation of Graphene Nanoplatelets on Physicochemical, Thermal, Rheological, and Mechanical Properties of Biobased and Biodegradable Blends. Polymers 2023, 15, 3622. [Google Scholar] [CrossRef] [PubMed]

- Hassanifard, S.; Behdinan, K. Impact of Rheology-Based Optimum Parameters on Enhancing the Mechanical Properties and Fatigue of Additively Manufactured Acrylonitrile-Butadiene-Styrene/Graphene Nanoplatelet Composites. Polymers 2024, 16, 1273. [Google Scholar] [CrossRef] [PubMed]

- Narimani, A.; Kordnejad, F.; Kaur, P.; Bazgir, S.; Hemmati, M.; Duong, A. Rheological and thermal stability of interpenetrating polymer network hydrogel based on polyacrylamide/hydroxypropyl guar reinforced with graphene oxide for application in oil recovery. J. Polym. Eng. 2021, 41, 788–798. [Google Scholar] [CrossRef]

- Kang, D.; Kim, S.H.; Shin, D.; Oh, J.T.; Kim, M.-G.; Lee, P.-C. Hygroscopic Behavior of Polypropylene Nanocomposites Filled with Graphene Functionalized by Alkylated Chains. Nanomaterials 2022, 12, 4130. [Google Scholar] [CrossRef]

- Katti, P.; Verma, K.K.; Kumar, S.; Bose, S. Tuning the interface in epoxy-based composites and laminates through epoxy grafted graphene oxide enhances mechanical properties. Nanoscale Adv. 2021, 3, 6739–6749. [Google Scholar] [CrossRef]

- Joshi, S.R.; Kumar, S.; Kim, S. Ecofriendly Polymer–Graphene-Based Conductive Ink for Multifunctional Printed Electronics. Adv. Mater. Technol. 2023, 8, 2201917. [Google Scholar] [CrossRef]

- Islam, A.A. New wonder materials—Exciting technological horizon. J. Bangladesh Acad. Sci. 2024, 48, 1–25. [Google Scholar] [CrossRef]

- He, F.; Yang, X.R.; Liu, Q.H.; Gong, X.Z. Preparation and Performance Evaluation of Graphene Heating Film. Mater. Sci. Forum 2022, 1060, 161–166. [Google Scholar] [CrossRef]

- Jayatilaka, G.; Mohammadi, M.M.; Tehrani, M. Investigating Stress Transfer and Failure Mechanisms in Graphene Oxide-Cellulose Nanocrystals Films. In Proceedings of the American Society for Composites 2021, Online, 14–18 September 2021; Destech Publications, Inc.: Lancaster, PA, USA, 2021. [Google Scholar]

- Naufal, M.I.; Wong, K.J.; Israr, H.A.; Nejad, A.F.; Rahimian Koloor, S.S.; Gan, K.W.; Faizi, M.K.; Siebert, G. Digital image correlation technique for failure and crack propagation of fibre-reinforced polymer composites—A review. Compos. Adv. Mater. 2024, 33, 26349833241253620. [Google Scholar] [CrossRef]

- Vu, H.; Woodcock, J.W.; Krishnamurthy, A.; Obrzut, J.; Gilman, J.W.; Coughlin, E.B. Visualization of Polymer Dynamics in Cellulose Nanocrystal Matrices Using Fluorescence Lifetime Measurements. ACS Appl. Mater. Interfaces 2022, 14, 10793–10804. [Google Scholar] [CrossRef] [PubMed]

- Ilyaei, S.; Sourki, R.; Akbari, Y.H.A. Capsule-based healing systems in composite materials: A review. Crit. Rev. Solid State Mater. Sci. 2021, 46, 491–531. [Google Scholar] [CrossRef]

- Zhu, Z.; Tian, Z.; Liu, Y.; Yue, S.; Li, Y.; Wang, Z.L.; Yu, Z.; Yang, D. Human Nervous System Inspired Modified Graphene Nanoplatelets/Cellulose Nanofibers-Based Wearable Sensors with Superior Thermal Management and Electromagnetic Interference Shielding. Adv. Funct. Mater. 2024, 34, 2315851. [Google Scholar] [CrossRef]

- Wang, N.; Li, Z.; Zhu, G.; Yu, Z.; Qin, R.; Zhou, J.; Lin, N. Chemical Modifications on Cellulose Nanocrystals for Composites: Surface Chemistry to Tailored Compatibility and Mechanical Enhancement. Macromolecules 2023, 56, 7505–7519. [Google Scholar] [CrossRef]

- Cruz-Benítez, M.M.; Gónzalez-Morones, P.; Hernández-Hernández, E.; Villagómez-Ibarra, J.R.; Castro-Rosas, J.; Rangel-Vargas, E.; Fonseca-Florido, H.A.; Gómez-Aldapa, C.A. Covalent Functionalization of Graphene Oxide with Fructose, Starch, and Micro-Cellulose by Sonochemistry. Polymers 2021, 13, 490. [Google Scholar] [CrossRef]

- Han, F.; Huang, H.; Liu, L. Dual bio-inspired strong and humidity-responsive composite cellulose nanofibril papers. J. Mater. Sci. 2022, 57, 8727–8738. [Google Scholar] [CrossRef]

- Nekooei, A.; Miroliaei, M.R.; Shahabi-Nejad, M.; Sheibani, G.; Sheibani, H. Cellulose-wrapped graphene oxide as efficient adsorbents for pharmaceutical contaminants. Inorg. Chem. Commun. 2023, 154, 110997. [Google Scholar] [CrossRef]

- Mohamed, A.; Ardyani, T.; Bakar, S.A.; Sagisaka, M.; Umetsu, Y.; Hussin, M.R.M.; Ahmad, M.K.; Mamat, M.H.; King, S.; Czajka, A.; et al. Preparation of conductive cellulose paper through electrochemical exfoliation of graphite: The role of anionic surfactant ionic liquids as exfoliating and stabilizing agents. Carbohydr. Polym. 2018, 201, 48–59. [Google Scholar] [CrossRef]

- Dahiya, M.; Khanna, V.; Gupta, N. Review—Computational Studies of Graphene Reinforced Nanocomposites: Techniques, Parameters, and Future Perspectives. ECS J. Solid State Sci. Technol. 2024, 13, 061005. [Google Scholar] [CrossRef]

- Ramezani, G.; Stiharu, I.; Van De Ven, T.G.M.; Nerguizian, V. Advancements in Hybrid Cellulose-Based Films: Innovations and Applications in 2D Nano-Delivery Systems. J. Funct. Biomater. 2024, 15, 93. [Google Scholar] [CrossRef]

- Naddeo, F.; Baldino, L.; Cardea, S.; Naddeo, A.; Reverchon, E. Finite element multiscale modelling of elastic behavior of cellulose acetate—Graphene oxide nanocomposites, produced using a SC-CO2 assisted technique. J. Supercrit. Fluids 2018, 140, 248–257. [Google Scholar] [CrossRef]

- Petry, R.; Silvestre, G.H.; Focassio, B.; Crasto de Lima, F.; Miwa, R.H.; Fazzio, A. Machine Learning of Microscopic Ingredients for Graphene Oxide/Cellulose Interaction. Langmuir 2022, 38, 1124–1130. [Google Scholar] [CrossRef]

- Rahman, R.; Foster, J.T.; Haque, A. Molecular dynamics simulation and characterization of graphene-cellulose nanocomposites. J. Phys. Chem. A 2013, 117, 5344–5353. [Google Scholar] [CrossRef]

- Alqus, R.; Eichhorn, S.J.; Bryce, R.A. Molecular Dynamics of Cellulose Amphiphilicity at the Graphene–Water Interface. Biomacromolecules 2015, 16, 1771–1783. [Google Scholar] [CrossRef]

- Wang, S.; Wang, S.; Chen, S.; Li, A.; Ma, H.; Zhao, S.; Chen, Y.; Zhu, M.; Xie, M. Properties of Ag-GNP silver-graphene composites and finite element analysis of electrical contact coupling field. J. Phys. Conf. Ser. 2023, 2587, 012106. [Google Scholar] [CrossRef]

- Wei, X.; Xia, Z.; Zhou, W.; Huang, P.; Fu, P. Simplified finite element method for resistance response of graphene composites considering size distribution and agglomeration. J. Mater. Sci. 2023, 58, 15696–15713. [Google Scholar] [CrossRef]

- Nukala, S.G.; Kong, I.; Kakarla, A.B.; Patel, V.I.; Abuel-Naga, H. Simulation of Wood Polymer Composites with Finite Element Analysis. Polymers 2023, 15, 1977. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.-P.; Tan, T.-F.; Hsu, H.-T. A Size-Dependent Finite Element Method for the 3D Free Vibration Analysis of Functionally Graded Graphene Platelets-Reinforced Composite Cylindrical Microshells Based on the Consistent Couple Stress Theory. Materials 2023, 16, 2363. [Google Scholar] [CrossRef]

- Tayebi, M.S.; Jedari Salami, S.; Tavakolian, M. Free vibration analysis of functionally graded composite rectangular plates reinforced with graphene nanoplatelets (GPLs) using full layerwise finite element method. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 5865–5883. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Chandrasekar, M.; Jawaid, M.; Rajini, N.; Alothman, O.Y.; Siengchin, S. Evaluation of mechanical and free vibration properties of the pineapple leaf fibre reinforced polyester composites. Constr. Build. Mater. 2019, 195, 423–431. [Google Scholar] [CrossRef]

- Rafiee, R.; Eskandariyun, A. Predicting Young’s modulus of agglomerated graphene/polymer using multi-scale modeling. Compos. Struct. 2020, 245, 112324. [Google Scholar] [CrossRef]

- Zhu, C.; Monti, S.; Mathew, A.P. Cellulose Nanofiber-Graphene Oxide Biohybrids: Disclosing the Self-Assembly and Copper-Ion Adsorption Using Advanced Microscopy and ReaxFF Simulations. ACS Nano 2018, 12, 7028–7038. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, H.; Zirakjou, A.; McClements, D.J.; Goodarzi, V.; Chen, W.-H. Removal of methylene blue from wastewater using ternary nanocomposite aerogel systems: Carboxymethyl cellulose grafted by polyacrylic acid and decorated with graphene oxide. J. Hazard. Mater. 2022, 421, 126752. [Google Scholar] [CrossRef]

- Méndez Martínez, K.M.; Nava Maldonado, F.M. DFT formalism studies on the structural and electronic properties of hexagonal graphene quantum dot with B, N and Si substitutional impurities. Rev. Mex. Física 2024, 70, 041601. [Google Scholar] [CrossRef]

- Zhang, H.; Ding, L.; Zhang, Y.; Wu, T.; Li, Q. Adsorption of graphene oxide with cellulose acetate: Insights from DFT. Mol. Phys. 2022, 120, e2044083. [Google Scholar] [CrossRef]

- Tachikawa, H. Hydrogen Storages Based on Graphene Nano-Flakes: Density Functional Theory Approach. C 2022, 8, 36. [Google Scholar] [CrossRef]

- Dacrory, S. Antimicrobial Activity, DFT Calculations, and Molecular Docking of Dialdehyde Cellulose/Graphene Oxide Film Against COVID-19. J. Polym. Environ. 2021, 29, 2248–2260. [Google Scholar] [CrossRef]

- Balasubramani, K.; Sivarajasekar, N.; Sarojini, G.; Naushad, M. Removal of Antidiabetic Pharmaceutical (Metformin) Using Graphene Oxide Microcrystalline Cellulose (GOMCC): Insights to Process Optimization, Equilibrium, Kinetics, and Machine Learning. Ind. Eng. Chem. Res. 2023, 62, 4713–4728. [Google Scholar] [CrossRef]

- Champa-Bujaico, E.; Díez-Pascual, A.M.; Garcia-Diaz, P. Poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) Bionanocomposites with Crystalline Nanocellulose and Graphene Oxide: Experimental Results and Support Vector Machine Modeling. Polymers 2023, 15, 3746. [Google Scholar] [CrossRef]

- Soltani, H.; Karimi, A.; Falahatpisheh, S. The optimization of biodiesel production from transesterification of sesame oil via applying ultrasound-assisted techniques: Comparison of RSM and ANN–PSO hybrid model. Chem. Prod. Process Model. 2022, 17, 55–67. [Google Scholar] [CrossRef]

- Ratnam, M.V.; Murugesan, M.P.; Komarabathina, S.; Samraj, S.; Abdulkadir, M.; Kalifa, M.A. Methylene Blue Adsorption BY UV-Treated Graphene Oxide Nanoparticles (UV/n-GO): Modeling and Optimization Using Response Surface Methodology and Artificial Neural Networks. Int. J. Chem. Eng. 2022, 2022, 1–13. [Google Scholar] [CrossRef]

- Wang, W.; Wu, X.; Long, S. Optimizing the Methylene Blue Removalfrom Aqueous Solution Using Pomelo Peel BasedBiochar Assisted by RSM and ANN-PSO. Pol. J. Environ. Stud. 2021, 31, 329–346. [Google Scholar] [CrossRef]

- Dolatabadi, M.; Naidu, H.; Ahmadzadeh, S. Adsorption characteristics in the removal of chlorpyrifos from groundwater using magnetic graphene oxide and carboxy methyl cellulose composite. Sep. Purif. Technol. 2022, 300, 121919. [Google Scholar] [CrossRef]

- Bheel, N.; Mohammed, B.S.; Liew, M.S.; Zawawi, N.A.W.A. Effect of Graphene Oxide as a Nanomaterial on the Durability Behaviors of Engineered Cementitious Composites by Applying RSM Modelling and Optimization. Buildings 2023, 13, 2026. [Google Scholar] [CrossRef]

- Yaw, C.T.; Koh, S.P.; Sandhya, M.; Ramasamy, D.; Kadirgama, K.; Benedict, F.; Ali, K.; Tiong, S.K.; Abdalla, A.N.; Chong, K.H. An Approach for the Optimization of Thermal Conductivity and Viscosity of Hybrid (Graphene Nanoplatelets, GNPs: Cellulose Nanocrystal, CNC) Nanofluids Using Response Surface Methodology (RSM). Nanomaterials 2023, 13, 1596. [Google Scholar] [CrossRef]

- Huang, X.; Mo, Y.; Wu, W.; Ye, M.; Hu, C. Preparation and Properties of Waterborne Polyurethane/Carbon Nanotube/Graphene/Cellulose Nanofiber Composites. Processes 2024, 12, 1913. [Google Scholar] [CrossRef]

- Perec, A.; Radomska-Zalas, A.; Fajdek-Bieda, A.; Pude, F. Process Optimization by Applying the Response Surface Methodology (Rsm) to the Abrasive Suspension Water Jet Cutting of Phenolic Composites. Facta Univ. Ser. Mech. Eng. 2023, 21, 575. [Google Scholar] [CrossRef]

- Tan, H.; Xiao, D.; Navik, R.; Zhao, Y. Facile Fabrication of Polyaniline/Pristine Graphene–Bacterial Cellulose Composites as High-Performance Electrodes for Constructing Flexible All-Solid-State Supercapacitors. ACS Omega 2021, 6, 11427–11435. [Google Scholar] [CrossRef]

- Kato, T.; Matsumoto, T.; Hongo, C.; Nishino, T. Mechanical and thermal properties of cellulose nanofiber composites with nanodiamond as nanocarbon filler. Nanocomposites 2018, 4, 127–136. [Google Scholar] [CrossRef]

- Wang, S.; Ma, X.; Zheng, P. Sulfo-functional 3D porous cellulose/graphene oxide composites for highly efficient removal of methylene blue and tetracycline from water. Int. J. Biol. Macromol. 2019, 140, 119–128. [Google Scholar] [CrossRef]

- Rahaman, H.; Islam, R.; Islam, R.; Alam, S.N.; Rahman, S.; Rahman, A.; Begum, B.A. Preparation, characterization, and adsorption kinetics of graphene oxide/chitosan/carboxymethyl cellulose composites for the removal of environmentally relevant toxic metals. Int. J. Biol. Macromol. 2024, 257, 128357. [Google Scholar] [CrossRef]

- Cao, R.; Fan, M.; Hu, J.; Ruan, W.; Wu, X.; Wei, X. Artificial Intelligence Based Optimization for the Se(IV) Removal from Aqueous Solution by Reduced Graphene Oxide-Supported Nanoscale Zero-Valent Iron Composites. Materials 2018, 11, 428. [Google Scholar] [CrossRef]

- Xiang, G.; Long, S.; Dang, A. Fabrication of the Ordered Mesoporous nZVI/Zr-Ce-SBA-15 Composites Used for Crystal Violet Removal and Their Optimization Using RSM and ANN–PSO. Sustainability 2022, 14, 6566. [Google Scholar] [CrossRef]

- Cai, Z.; Remadevi, R.; Al Faruque, M.A.; Setty, M.; Fan, L.; Haque, A.N.M.A.; Naebe, M. Fabrication of a cost-effective lemongrass (Cymbopogon citratus) membrane with antibacterial activity for dye removal. RSC Adv. 2019, 9, 34076–34085. [Google Scholar] [CrossRef]

- Bheel, N.; Mohammed, B.S.; Abdulkadir, I.; Liew, M.S.; Zawawi, N.A.W.A. Effects of Graphene Oxide on the Properties of Engineered Cementitious Composites: Multi-Objective Optimization Technique Using RSM. Buildings 2023, 13, 2018. [Google Scholar] [CrossRef]

- Peng, Y.; Khaled, U.; Al-Rashed, A.A.A.A.; Meer, R.; Goodarzi, M.; Sarafraz, M.M. Potential application of Response Surface Methodology (RSM) for the prediction and optimization of thermal conductivity of aqueous CuO (II) nanofluid: A statistical approach and experimental validation. Phys. A Stat. Mech. Its Appl. 2020, 554, 124353. [Google Scholar] [CrossRef]

- Solanki, D.; Sugandhi, S. A PSO-ANN Hybrid Model for Temporal Traffic Speed Forecasts in Urban Environments. Int. J. Sci. Res. Eng. Manag. 2024, 8, 1–6. [Google Scholar] [CrossRef]

- Kim, H.C.; Panicker, P.S.; Kim, D.; Adil, S.; Kim, J. High-strength cellulose nanofiber/graphene oxide hybrid filament made by continuous processing and its humidity monitoring. Sci. Rep. 2021, 11, 13611. [Google Scholar] [CrossRef]

- Sofyana; Muslim, A.; Supardan, M.D.; Ambarita, A.C.; Arahman, N. Combination of cellulose nanocrystal and graphene oxide as modifying agent for improving the performance of PVDF membranes. Case Stud. Chem. Environ. Eng. 2024, 10, 100873. [Google Scholar] [CrossRef]

- Cicek Ozkan, B. Cellulose and chitosan biopolymer composites reinforced with graphene and their adsorption properties for basic blue 41. Cellulose 2022, 29, 9637–9655. [Google Scholar] [CrossRef]

- Habibi, B.; Pashazadeh, S.; Pashazadeh, A.; Saghatforoush, L.A. An amplified electrochemical sensor employing one-step synthesized nickel–copper–zinc ferrite/carboxymethyl cellulose/graphene oxide nanosheets composite for sensitive analysis of omeprazole. RSC Adv. 2023, 13, 29931–29943. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Li, Y.; Huang, P.; Zou, R.; Li, Y.; Fu, S. Graphene nanoplatelet/cellulose acetate film with enhanced antistatic, thermal dissipative and mechanical properties for packaging. Cellulose 2023, 30, 4499–4509. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Huang, Y.; Xia, W.; Xu, L.; Wang, X. Dispersion characteristics and mechanical properties of epoxy nanocomposites reinforced with carboxymethyl cellulose functionalized nanodiamond, carbon nanotube, and graphene. Polym. Compos. 2024, 45, 398–412. [Google Scholar] [CrossRef]

- Tabernero, A.; Baldino, L.; Cardea, S.; Martín Del Valle, E.; Reverchon, E. A Phenomenological Approach to Study Mechanical Properties of Polymeric Porous Structures Processed Using Supercritical CO2. Polymers 2019, 11, 485. [Google Scholar] [CrossRef]

- Zhang, H.; Zhai, D.; He, Y. Graphene oxide/polyacrylamide/carboxymethyl cellulose sodium nanocomposite hydrogel with enhanced mechanical strength: Preparation, characterization and the swelling behavior. RSC Adv. 2014, 4, 44600–44609. [Google Scholar] [CrossRef]

- Phiri, J.; Johansson, L.-S.; Gane, P.; Maloney, T.C. Co-exfoliation and fabrication of graphene based microfibrillated cellulose composites—Mechanical and thermal stability and functional conductive properties. Nanoscale 2018, 10, 9569–9582. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, X.; Su, J.; Lin, L.; Jiang, Z.; Qiu, L.; Wang, S.; Wu, B.; Pu, C.; Cai, X.; et al. Significantly Enhancing Mechanical and Thermal Properties of Cellulose-Based Composites by Adding Small Amounts of Lysozyme-Modified Graphene Nanoplatelets via Forming Strong Double-Cross-Linked Interface Interactions. ACS Appl. Mater. Interfaces 2023, 15, 43159–43168. [Google Scholar] [CrossRef]

- Mustapha, N.I.; Mohamed, M.; Bakar, M.B.A.; Sobri, S.A. Thermal Properties of Unsaturated Polyester Reinforced Kenaf Core Fiber with Hybrid Nanofillers of Cellulose Nanocrystal and Graphene Nanoplatelet. Borneo J. Sci. Technol. 2023, 5, 75–83. [Google Scholar] [CrossRef]

- Meng, X.; Wang, S.; Gao, W.; Han, W.; Lucia, L.A. Thermal pyrolysis characteristics and kinetic analysis of nanofibrillated cellulose/graphene oxide composites. BioResources 2020, 15, 4851–4865. [Google Scholar] [CrossRef]

- Hekimoğlu, G.; Çakır, E.; Sarı, A.; Gencel, O.; Tyagi, V.V.; Sharma, R.K. Shape stabilized microcrystalline cellulose/methyl stearate/graphene nanoplatelet composite with enriched thermal conductivity and thermal energy storage/release performance. Cellulose 2023, 30, 10199–10214. [Google Scholar] [CrossRef]

- Kashi, S.; Gupta, R.K.; Kao, N.; Hadigheh, S.A.; Bhattacharya, S.N. Influence of graphene nanoplatelet incorporation and dispersion state on thermal, mechanical and electrical properties of biodegradable matrices. J. Mater. Sci. Technol. 2018, 34, 1026–1034. [Google Scholar] [CrossRef]

- Pottathara, Y. Graphene Based Composites with Cellulose Nanofibrils for Energy Storage Applications. 2017. Available online: https://www.semanticscholar.org/paper/Graphene-based-Composites-with-Cellulose-for-Energy-Pottathara/cd70dcdf88ae3abdc342aa4e85e726553377f6cf (accessed on 10 September 2024).

- Piotr, K.; Jeszka, J.K.; Artur, M.; Leszek, S. Regenerated Cellulose/Graphene Composite Fibers with Electroconductive Properties. Autex Res. J. 2022, 22, 177–183. [Google Scholar] [CrossRef]

- Santillo, C.; Wang, Y.; Buonocore, G.G.; Gentile, G.; Verdolotti, L.; Kaciulis, S.; Xia, H.; Lavorgna, M. Hybrid Graphenene Oxide/Cellulose Nanofillers to Enhance Mechanical and Barrier Properties of Chitosan-Based Composites. Front. Chem. 2022, 10, 926364. [Google Scholar] [CrossRef]

- Qing, Y.; Sabo, R.; Cai, Z.; Wu, Y. Flexible Cellulose Nanofibril Composite Films with Reduced Hygroscopic Capacity. 2013. Available online: https://www.semanticscholar.org/paper/Flexible-cellulose-nanofibril-composite-films-with-Qing-Sabo/ab799ddf27e61a8f6f722b54a214362657c264c0 (accessed on 10 September 2024).

- Oprea, M.; Voicu, S.I. Cellulose Composites with Graphene for Tissue Engineering Applications. Materials 2020, 13, 5347. [Google Scholar] [CrossRef]

- Luo, Y.; Shen, H.; Fang, Y.; Cao, Y.; Huang, J.; Zhang, M.; Dai, J.; Shi, X.; Zhang, Z. Enhanced proliferation and osteogenic differentiation of mesenchymal stem cells on graphene oxide-incorporated electrospun poly(lactic-co-glycolic acid) nanofibrous mats. ACS Appl. Mater. Interfaces 2015, 7, 6331–6339. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, T.; He, Z.; Liu, M.; Zhang, C.; Sun, G.; Wang, Q. Effect of Graphene Oxide in an Injectable Hydrogel on the Osteogenic Differentiation of Mesenchymal Stem Cells. 2024. Available online: https://pubmed.ncbi.nlm.nih.gov/39225005/ (accessed on 12 September 2024).

- Sheikh, T.; Behdinan, K. Fused Deposition Modelling of Thermoplastic Polymer Nanocomposites: A Critical Review. C 2024, 10, 29. [Google Scholar] [CrossRef]

- Cheng, Y. Advancements and challenges in nanomaterial-based medical implants. Appl. Comput. Eng. 2024, 58, 60–67. [Google Scholar] [CrossRef]

- Karunanidhi, M.; Kanniyappan, H.; Zhan, E.; Mathew, R.; Sun, Y.; Wu, J.; Yan, Y.; Munirathinum, G.; Mathew, M.T. Abstract 7289: PancreaAlert: Intelligent nanoengineered biosensor for pancreatic cancer. Cancer Res. 2024, 84, 7289. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, J.; Tang, J.; Tang, W. Three-Dimensional, Chemically Bonded Polypyrrole/Bacterial Cellulose/Graphene Composites for High-Performance Supercapacitors. Chem. Mater. 2015, 27, 7034–7041. [Google Scholar] [CrossRef]

- Shen, Y.-D.; Xiao, Z.-C.; Miao, L.-X.; Kong, D.-B.; Zheng, X.-Y.; Chang, Y.-H.; Zhi, L.-J. Pyrolyzed bacterial cellulose/graphene oxide sandwich interlayer for lithium–sulfur batteries. Rare Met. 2017, 36, 418–424. [Google Scholar] [CrossRef]

- Wang, Y.; He, Z.; Wang, Y.; Fan, C.; Liu, C.; Peng, Q.; Chen, J.; Feng, Z. Preparation and characterization of flexible lithium iron phosphate/graphene/cellulose electrode for lithium ion batteries. J. Colloid Interface Sci. 2018, 512, 398–403. [Google Scholar] [CrossRef]

- Bacakova, L.; Pajorova, J.; Tomkova, M.; Matejka, R.; Broz, A.; Stepanovska, J.; Prazak, S.; Skogberg, A.; Siljander, S.; Kallio, P. Applications of Nanocellulose/Nanocarbon Composites: Focus on Biotechnology and Medicine. Nanomaterials 2020, 10, 196. [Google Scholar] [CrossRef]

- Qian, Y.; Han, N.; Zhang, Z.; Cao, R.; Tan, L.; Li, W.; Zhang, X. Enhanced Thermal-to-Flexible Phase Change Materials Based on Cellulose/Modified Graphene Composites for Thermal Management of Solar Energy. ACS Appl. Mater. Interfaces 2019, 11, 45832–45843. [Google Scholar] [CrossRef]

- Atif, R.; Inam, F. Reasons and remedies for the agglomeration of multilayered graphene and carbon nanotubes in polymers. Beilstein J. Nanotechnol. 2016, 7, 1174–1196. [Google Scholar] [CrossRef]

- Gao, Y.-X.; Zou, J.-W.; Wang, X.-F.; Yang, J.; Li, Z.; Zhu, Y.-Y.; Wang, H.-M. An Approach to the Uniform Dispersion of Graphene Nanosheets in Powder Metallurgy Nickel-Based Superalloy. Materials 2019, 12, 974. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wang, Q.; Huang, X.; Qian, X. Surface Functionalization of Graphene Oxide with Hyperbranched Polyamide-Amine and Microcrystalline Cellulose for Efficient Adsorption of Heavy Metal Ions. ACS Omega 2022, 7, 10944–10954. [Google Scholar] [CrossRef]

- Rabchinskii, M.K.; Sysoev, V.V.; Ryzhkov, S.A.; Eliseyev, I.A.; Stolyarova, D.Y.; Antonov, G.A.; Struchkov, N.S.; Brzhezinskaya, M.; Kirilenko, D.A.; Pavlov, S.I.; et al. A Blueprint for the Synthesis and Characterization of Thiolated Graphene. Nanomaterials 2021, 12, 45. [Google Scholar] [CrossRef]

- Rabchinskii, M.K.; Besedina, N.A.; Brzhezinskaya, M.; Stolyarova, D.Y.; Ryzhkov, S.A.; Saveliev, S.D.; Antonov, G.A.; Baidakova, M.V.; Pavlov, S.I.; Kirilenko, D.A.; et al. Graphene Amination towards Its Grafting by Antibodies for Biosensing Applications. Nanomaterials 2023, 13, 1730. [Google Scholar] [CrossRef]

- Li, M.; Xiao, M.; Wang, Q.; Zhang, J.; Xue, X.; Zhao, J.; Zhang, W.; Lu, C. Mechanically Strong and Electrically Conductive Polyethylene Oxide/Few-Layer Graphene/Cellulose Nanofibrils Nanocomposite Films. Nanomaterials 2022, 12, 4152. [Google Scholar] [CrossRef]

- Sekwele, K.G.; Tichapondwa, S.M.; Mhike, W. Cellulose, graphene and graphene-cellulose composite aerogels and their application in water treatment: A review. Discov. Mater. 2024, 4, 23. [Google Scholar] [CrossRef]

- Kuanyshbekov, T.; Guseinov, N.; Tolepov, Z.; Kurbanova, B.; Tulegenova, M.; Akatan, K.; Kantay, N.; Zhasasynov, E. Thermally Reduced Graphene Oxide Membranes From Local Kazakhstan Graphite “Ognevsky”. ChemistrySelect 2023, 8, e202301746. [Google Scholar] [CrossRef]

- Xie, Z.-T.; Asoh, T.-A.; Uetake, Y.; Sakurai, H.; Uyama, H. Dual roles of cellulose monolith in the continuous-flow generation and support of gold nanoparticles for green catalyst. Carbohydr. Polym. 2020, 247, 116723. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.; Zhang, F.; Li, C.; Xiong, G.; Zhu, Y.; Luo, H. Facile and scalable production of three-dimensional spherical carbonized bacterial cellulose/graphene nanocomposites with a honeycomb-like surface pattern as potential superior absorbents. J. Mater. Chem. A 2015, 3, 24389–24396. [Google Scholar] [CrossRef]

- Méndez-Lozano, N.; Pérez-Reynoso, F.; González-Gutiérrez, C. Eco-Friendly Approach for Graphene Oxide Synthesis by Modified Hummers Method. Materials 2022, 15, 7228. [Google Scholar] [CrossRef] [PubMed]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Studies on durability of sustainable biobased composites: A review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef]

- Madhu, B.M.; Rashmi, T.V. Water Aging Effects on Graphene Nanoplatelets and Multi-walled Carbon Nanotube Reinforced Epoxy Glass Fiber Nanocomposites. Indian J. Adv. Chem. Sci. 2020, 8, 14–17. [Google Scholar]

- Asghar, M.S.A.; Amir, M.; Hussain, U.; Sabri, M.M. Zinc and graphene oxide composites as new protective coatings for oil and gas pipes. Polimery 2023, 68, 378–385. [Google Scholar] [CrossRef]

- Xu, W.; Lv, Y.; Kong, M.; Huang, Y.; Yang, Q.; Li, G. In-situ polymerization of eco-friendly waterborne polyurethane/polydopamine-coated graphene oxide composites towards enhanced mechanical properties and UV resistance. J. Clean. Prod. 2022, 373, 133942. [Google Scholar] [CrossRef]

- Lyu, S.; Chen, Y.; Han, S.; Guo, L.; Chen, Z.; Lu, Y.; Chen, Y.; Yang, N.; Wang, S. Layer-by-layer assembled polyaniline/carbon nanomaterial-coated cellulosic aerogel electrodes for high-capacitance supercapacitor applications. RSC Adv. 2018, 8, 13191–13199. [Google Scholar] [CrossRef]

- Mohan, D.; Sajab, M.S.; Kaco, H.; Bakarudin, S.B.; Mohamed Noor, A. 3D Printing of UV-Curable Polyurethane Incorporated with Surface-Grafted Nanocellulose. Nanomaterials 2019, 9, 1726. [Google Scholar] [CrossRef] [PubMed]

- Ul-Islam, M.; Yasir, S.; Mombasawala, L.; Manan, S.; Wajid Ullah, M. Bacterial Cellulose: A Versatile Material for Fabrication of Conducting Nanomaterials. Curr. Nanosci. 2021, 17, 393–405. [Google Scholar] [CrossRef]

- Rashid, A.B.; Haque, M.; Islam, S.M.M.; Uddin Labib, K.M.R. Nanotechnology-enhanced fiber-reinforced polymer composites: Recent advancements on processing techniques and applications. Heliyon 2024, 10, e24692. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhou, R.; Yuan, M.; He, H. Nano Ag/PPy Biocomposites Based on Graphene Oxide Modified Bacterial Cellulose from the Juice of Xinhui Citrus and Its Antibacterial Activity. Micromachines 2023, 14, 1809. [Google Scholar] [CrossRef]

- Khan, M.U.A.; Stojanović, G.M.; Hassan, R.; Anand, T.J.S.; Al-Ejji, M.; Hasan, A. Role of Graphene Oxide in Bacterial Cellulose−Gelatin Hydrogels for Wound Dressing Applications. ACS Omega 2023, 8, 15909–15919. [Google Scholar] [CrossRef]

- Yang, Y.; Wan, C.; Huang, Q.; Hua, J. Pore-Rich Cellulose-Derived Carbon Fiber@Graphene Core-Shell Composites for Electromagnetic Interference Shielding. Nanomaterials 2022, 13, 174. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramezani, G.; Stiharu, I.; van de Ven, T.G.M.; Nerguizian, V. Optimizing Graphene Oxide Content in Cellulose Matrices: A Comprehensive Review on Enhancing the Structural and Functional Performance of Composites. Encyclopedia 2024, 4, 1827-1856. https://doi.org/10.3390/encyclopedia4040120

Ramezani G, Stiharu I, van de Ven TGM, Nerguizian V. Optimizing Graphene Oxide Content in Cellulose Matrices: A Comprehensive Review on Enhancing the Structural and Functional Performance of Composites. Encyclopedia. 2024; 4(4):1827-1856. https://doi.org/10.3390/encyclopedia4040120

Chicago/Turabian StyleRamezani, Ghazaleh, Ion Stiharu, Theo G. M. van de Ven, and Vahe Nerguizian. 2024. "Optimizing Graphene Oxide Content in Cellulose Matrices: A Comprehensive Review on Enhancing the Structural and Functional Performance of Composites" Encyclopedia 4, no. 4: 1827-1856. https://doi.org/10.3390/encyclopedia4040120

APA StyleRamezani, G., Stiharu, I., van de Ven, T. G. M., & Nerguizian, V. (2024). Optimizing Graphene Oxide Content in Cellulose Matrices: A Comprehensive Review on Enhancing the Structural and Functional Performance of Composites. Encyclopedia, 4(4), 1827-1856. https://doi.org/10.3390/encyclopedia4040120