Graphene Nanocomposite Materials for Supercapacitor Electrodes

Definition

1. Introduction

- Defined porosity, which translates into accessibility of the EASA, enabling its use in particular at high current densities (the defining property of a supercapacitor) and thus improved capacitance retention [21];

- High electronic conductivity supporting large current densities without excessive Ohmic losses and associated Joule heat generation (with heating of a supercapacitor known to contribute to ageing [22]);

- Sufficient chemical, electrochemical, mechanical, and thermal stability affordability.

2. Graphene and Related Materials

2.1. Graphene

2.2. Graphene Oxide

2.3. Reduced Graphene Oxide

2.4. Three-Dimensional Graphene Materials

3. Graphene in Supercapacitors

3.1. Graphenes as Active Materials

3.2. Graphenes as Conducting Additive

3.3. Graphenes in Nanocomposites

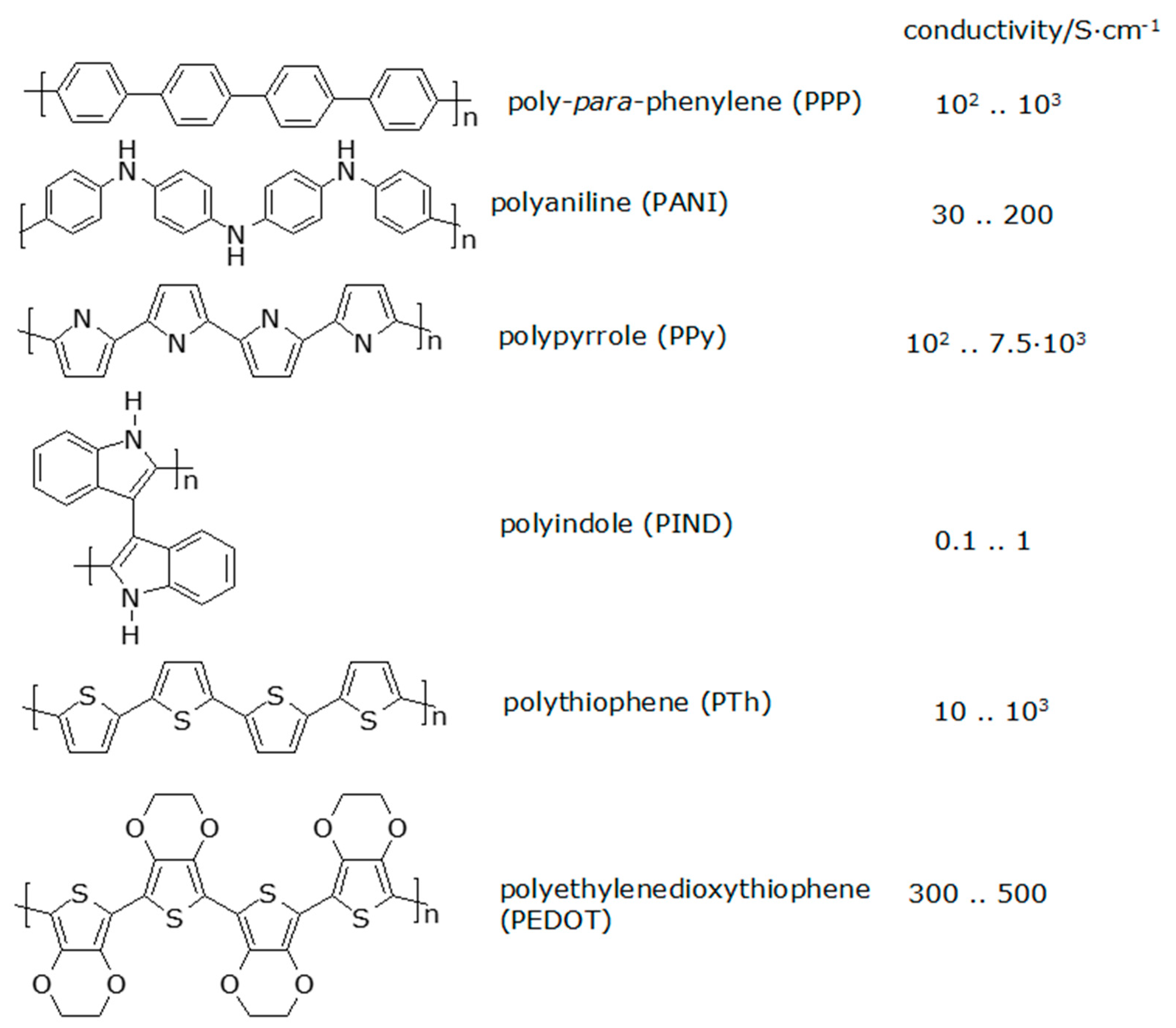

- Volume change (swelling/shrinking) during oxidation/reduction caused by ingress/egress of charge-balancing counterions with their solvation shells.

- Electronic conductivity insufficient for high current densities typical of supercapacitors; in addition conductivity may change substantially as a function of state of oxidation.

3.4. Graphenes as a Coating

3.5. Graphenes as an Auxiliary Material

4. Trends and Developments

4.1. Graphenes as Active Material

4.2. Graphenes as Conducting Additive

4.3. Graphenes in Composites

4.4. Graphenes as a Coating

4.5. Graphenes as an Auxiliary Material

5. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- El Rouby, W.M. A Crumpled graphene: Preparation and applications. RSC Adv. 2015, 5, 66767–66796. [Google Scholar] [CrossRef]

- Deng, S.; Berry, V. Wrinkled, rippled and crumpled graphene: An overview of formation mechanism, electronic properties, and applications. Mater. Today 2016, 19, 197–212. [Google Scholar] [CrossRef]

- Jiang, L.; Fan, Z. Design of advanced porous graphene materials: From graphene nanomesh to 3D architectures. Nanoscale 2014, 6, 1922–1945. [Google Scholar] [CrossRef] [PubMed]

- Mathew, E.E.; Balachandran, M. Crumpled and porous graphene for supercapacitor applications: A short review. Carb. Lett. 2021, 31, 537–555. [Google Scholar] [CrossRef]

- Liu, W.R. Graphene-Based Energy Devices. In Graphene-Based Energy Devices; Mohd Yusoff, A.R.b., Ed.; Wiley-VCH: Weinheim, Germany, 2015; pp. 85–122. [Google Scholar]

- Liu, J.; Xue, Y.; Zhang, M.; Dai, L. Graphene-based materials for energy applications. MRS Bull. 2012, 37, 1265–1272. [Google Scholar] [CrossRef]

- Liang, M.; Luo, B.; Zhi, L. Application of graphene and graphene-based materials in clean energy-related devices. Int. J. Energy Res. 2009, 33, 1161–1170. [Google Scholar] [CrossRef]

- Huang, Y.; Liang, J.; Chen, Y. An overview of the applications of graphene-based materials in supercapacitors. Small 2012, 8, 1805–1834. [Google Scholar] [CrossRef]

- Ghosh, A.; Lee, Y.H. Carbon-based electrochemical capacitors. ChemSusChem 2012, 5, 480–499. [Google Scholar] [CrossRef]

- Choi, H.J.; Jung, S.M.; Seo, J.M.; Chang, D.W.; Dai, L.; Baek, J.B. Graphene for energy conversion and storage in fuel cells and supercapacitors. Nano Energy 2012, 1, 534–551. [Google Scholar] [CrossRef]

- Minisha, S.; Vedhi, C.; Rajakani, P. Review-Methods of Graphene Synthesis and Graphene-Based Electrode Material for Supercapacitor Applications. ECS J. Solid State Sci. Technol. 2022, 11, 111002. [Google Scholar] [CrossRef]

- Aleksandrzak, M.; Mijowska, E. Graphene and Its Derivatives for Energy Storage. In Graphene Materials: Fundamentals and Emerging Applications; Tiwari, A., Syväjärvi, M., Eds.; Scrivener Publishing: Salem, MA, USA; WILEY: Hoboken, NJ, USA, 2015; pp. 191–224. [Google Scholar]

- Tan, Y.B.; Lee, J.M. Graphene for supercapacitor applications. J. Mater. Chem. A 2013, 1, 14814–14843. [Google Scholar] [CrossRef]

- Ramesha, G.K.; Sampath, S. Graphene and graphene-oxide-based materials for electrochemical energy systems. In Graphene; Rao, C.N.R., Sood, A.K., Eds.; Wiley-VCH: Weinheim, Germany, 2013; pp. 269–301. [Google Scholar]

- Hou, J.; Shao, Y.; Ellis, M.W.; Moore, R.B.; Yi, B. Graphene-based electrochemical energy conversion and storage: Fuel cells, supercapacitors and lithium ion batteries. Phys. Chem. Chem. Phys. 2011, 13, 15384–15402. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Wu, Q.; Shi, G. Graphene based new energy materials. Energy Environ. Sci. 2011, 4, 1113–1132. [Google Scholar] [CrossRef]

- Tiwari, A.; Uzun, L. (Eds.) Advanced Functional Materials; Scrivener Publishing: Beverly, MA, USA, 2015. [Google Scholar]

- Bich, H.N.; Van, H.N. Promising applications of graphene and graphene-based nanostructures. Adv. Nat. Sci. Nanosci. Nanotechnol. 2016, 7, 023002. [Google Scholar]

- Xie, X.; Holze, R. Electrode Kinetic Data: Geometric vs. Real Surface Area. Batteries 2022, 8, 146. [Google Scholar] [CrossRef]

- Xie, X.; Holze, R. Meaning and Determination of Electrode Surface Area. Available online: https://encyclopedia.pub/entry/41569 (accessed on 11 September 2023).

- Ge, Y.; Liu, Z.; Wu, Y.; Holze, R. On the utilization of supercapacitor electrode materials. Electrochim. Acta 2021, 366, 137390. [Google Scholar] [CrossRef]

- Chen, X.; Wu, Y.; Holze, R. Ag(e)ing and Degradation of Supercapacitors: Causes, Mechanisms, Models and Countermeasures. Molecules 2023, 28, 5028. [Google Scholar] [CrossRef]

- Velasco, A.; Ryu, Y.K.; Boscá, A.; Ladrón-De-Guevara, A.; Hunt, E.; Zuo, J.; Pedrós, J.; Calle, F.; Martinez, J. Recent trends in graphene supercapacitors: From large area to microsupercapacitors. Sustain. Energy Fuels 2021, 5, 1235–1254. [Google Scholar] [CrossRef]

- Liu, M.; Wei, F.; Yang, X.; Dong, S.; Li, Y.; He, X. Synthesis of porous graphene-like carbon materials for high-performance supercapacitors from petroleum pitch using nano-CaCO3 as a template. New Carbon Mater. 2018, 33, 316–323. [Google Scholar] [CrossRef]

- Meng, Y.; Wang, K.; Zhang, Y.; Wei, Z. Hierarchical Porous Graphene/Polyaniline Composite Film with Superior Rate Performance for Flexible Supercapacitors. Adv. Mater. 2013, 25, 6985–6990. [Google Scholar] [CrossRef]

- Chen, X.; Paul, R.; Dai, L. Carbon-based supercapacitors for efficient energy storage. Nat. Sci. Rev. 2017, 4, 453–489. [Google Scholar] [CrossRef]

- Jiang, H.; Lee, P.S.; Li, C. 3D carbon based nanostructures for advanced supercapacitors. Energy Environ. Sci. 2013, 6, 41–53. [Google Scholar] [CrossRef]

- Dai, L.; Chang, D.W.; Baek, J.B.; Lu, W. Carbon nanomaterials for advanced energy conversion and storage. Small 2012, 8, 1130–1166. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Liu, J. Carbon nanomaterials for flexible energy storage. Mater. Res. Lett. 2013, 1, 175–192. [Google Scholar] [CrossRef]

- Liu, F.; Xue, D. Advanced graphene nanomaterials for electrochemical energy storage. Mater. Res. Innov. 2015, 19, 7–19. [Google Scholar] [CrossRef]

- Arico, A.S.; Bruce, P.; Scrosati, B.; Tarascon, J.M.; van Schalkwijk, W. Nanostructured materials for advanced energy conversion and storage devices. Nat. Mater. 2005, 4, 366–377. [Google Scholar] [CrossRef]

- Stoller, M.D.; Park, S.; Zhu, Y.; An, J.; Ruoff, R.S. Graphene-Based Ultracapacitors. Nano Lett. 2008, 8, 3498–3502. [Google Scholar] [CrossRef]

- Li, J.; Östling, M. Prevention of graphene restacking for performance boost of supercapacitors-a review. Crystals 2013, 3, 163–190. [Google Scholar] [CrossRef]

- Xu, P.; Yang, J.; Wang, K.; Zhou, Z.; Shen, P. Porous graphene: Properties, preparation, and potential applications. Chin. Sci. Bull. 2012, 57, 2948–2955. [Google Scholar] [CrossRef]

- Lokhande, A.C.; Qattan, I.A.; Lokhande, C.D.; Patole, S.P. Holey graphene: An emerging versatile material. J. Mater. Chem. A 2020, 8, 918–977. [Google Scholar] [CrossRef]

- Chen, Z.; An, X.; Dai, L.; Xu, Y. Holey graphene-based nanocomposites for efficient electrochemical energy storage. Nano Energy 2020, 73, 104762. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Zhao, T.; Eisa, M.H.; Aldaghri, O.; Gupta, M.; Bocchetta, P. Green-Synthesized Graphene for Supercapacitors-Modern Perspectives. J. Compos. Sci. 2023, 7, 108. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef] [PubMed]

- Iro, Z.S.; Subramani, C.; Dash, S.S. A brief review on electrode materials for supercapacitor. Int. J. Electrochem. Sci. 2016, 11, 10628–10643. [Google Scholar] [CrossRef]

- Wang, M.; Cai, S.; Pan, C.; Wang, C.; Lian, X.; Zhuo, Y.; Xu, K.; Cao, T.; Pan, X.; Liang, S.J.; et al. Robust memristors based on layered two-dimensional materials. Nat. Electron. 2018, 1, 130–136. [Google Scholar] [CrossRef]

- Nikam, R.D.; Lee, J.; Choi, W.; Banerjee, W.; Kwak, M.; Yadav, M.; Hwang, H. Ionic Sieving Through One-Atom-Thick 2D Material Enables Analog Nonvolatile Memory for Neuromorphic Computing. Small 2021, 17, 2103543. [Google Scholar] [CrossRef]

- Nikam, R.D.; Lee, J.; Choi, W.; Kim, D.; Hwang, H. On-Chip Integrated Atomically Thin 2D Material Heater as a Training Accelerator for an Electrochemical Random-Access Memory Synapse for Neuromorphic Computing Application. ACS Nano 2022, 16, 12214–12225. [Google Scholar] [CrossRef]

- Brownson, D.A.C.; Kampouris, D.K.; Banks, C.E. An overview of graphene in energy production and storage applications. J. Power Sources 2011, 196, 4873–4885. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228–240. [Google Scholar] [CrossRef]

- Xu, B.; Yue, S.; Sui, Z.; Zhang, X.; Hou, S.; Cao, G.; Yang, Y. What is the choice for supercapacitors: Graphene or graphene oxide? Energy Environ. Sci. 2011, 4, 2826–2830. [Google Scholar] [CrossRef]

- Zhi, M.; Xiang, C.; Li, J.; Li, M.; Wu, N. Nanostructured carbon-metal oxide composite electrodes for supercapacitors: A review. Nanoscale 2013, 5, 72–88. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Lu, X.; Lei, S.; Song, Y. Graphene-based polyaniline nanocomposites: Preparation, properties and applications. J. Mater. Chem. A 2014, 2, 4491–4509. [Google Scholar] [CrossRef]

- Xiao, J.; Xu, Y.; Yang, S. High-Performance Supercapacitors Based on Novel Graphene Composites. In Graphene-Based Energy Devices; bin Mohd Yusoff, A.R., Ed.; WILEY-VCH: Weinheim, Germany, 2015; pp. 145–170. [Google Scholar]

- Wang, G.; Zhang, L.; Zhang, J. A review of electrode materials for electrochemical supercapacitors. Chem. Soc. Rev. 2012, 41, 797–828. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Ni, M.; Ren, X.; Tian, Y.; Li, N.; Su, Y.; Zhang, X. Graphene in Supercapacitor Applications. Curr. Opin. Colloid Interf. Sci. 2015, 20, 416–428. [Google Scholar] [CrossRef]

- Agrawal, R.; Chen, C.; Hao, Y.; Song, Y.; Wang, C. Graphene for Supercapacitors. In Graphene-Based Energy Devices; Wiley-VCH: Weinheim, Germany, 2015; pp. 171–214. [Google Scholar]

- Yan, J.; Wei, T.; Shao, B.; Ma, F.; Fan, Z.; Zhang, M.; Zheng, C.; Shang, Y.; Qian, W. Electrochemical properties of graphene nanosheet/carbon black composites as electrodes for supercapacitors. Carbon 2010, 48, 1731–1737. [Google Scholar] [CrossRef]

- Dong, L.; Chen, Z.; Yang, D.; Lu, H. Hierarchically structured graphene-based supercapacitor electrodes. RSC Adv. 2013, 3, 21183–21191. [Google Scholar] [CrossRef]

- Gu, Y.; Wu, H.; Xiong, Z.; Al Abdulla, W.; Zhao, X.S. The electrocapacitive properties of hierarchical porous reduced graphene oxide templated by hydrophobic CaCO3 spheres. J. Mater. Chem. A 2014, 2, 451–459. [Google Scholar] [CrossRef]

- Kumar, N.A.; Baek, J.B. Doped graphene supercapacitors. Nanotechnology 2015, 26, 492001. [Google Scholar] [CrossRef]

- Jeong, H.M.; Lee, J.W.; Shin, W.H.; Choi, Y.J.; Shin, H.J.; Kang, J.K.; Choi, J.W. Nitrogen-doped graphene for high-performance ultracapacitors and the importance of nitrogen-doped sites at basal planes. Nano Lett. 2011, 11, 2472–2477. [Google Scholar] [CrossRef]

- Rakhi, R.B.; Chen, W.; Cha, D.; Alshareef, H.N. High performance supercapacitors using metal oxide anchored graphene nanosheet electrodes. J. Mater. Chem. 2011, 21, 16197–16204. [Google Scholar] [CrossRef]

- Pacheco, I.; Buzea, C. Nanomaterials and Nanocomposites: Classification and Toxicity. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Application; Kharissova, O.V., Torres-Martínez, L.M., Kharisov, B.I., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Shalan, A.E.; Makhlouf, A.S.H.; Lanceros-Méndez, S. (Eds.) Advances in Nanocomposite Materials for Environmental and Energy Harvesting Applications; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Ul Hoque, M.I.; Holze, R. Intrinsically Conducting Polymer Composites as Active Masses in Supercapacitors. Polymers 2023, 15, 730. [Google Scholar] [CrossRef] [PubMed]

- Saha, S.; Jana, M.; Kuilal, T. High Performing Hybrid Nanomaterials for Supercapacitor Applications. In Hybrid Nanomaterials: Advances in Energy, Environment and Polymer Nanocomposites; Srivastava, S.K., Mittal, V., Eds.; Scrivener: Beverly, MA, USA, 2017; pp. 79–145. [Google Scholar]

- Holze, R. Composites of intrinsically conducting polymers with carbonaceous materials for supercapacitors—An update. Univ. J. Electrochem. 2023, 1, 16–50. [Google Scholar] [CrossRef]

- Dubal, D.P.; Wu, Y.P.; Holze, R. Supercapacitors: From the Leyden jar to electric busses. Chemtexts 2016, 2, 13. [Google Scholar] [CrossRef]

- Khorate, A.; Kadam, A.V. An overview of patents and recent development in flexible supercapacitors. J. Energy Storage 2022, 52, 104887. [Google Scholar] [CrossRef]

- Vilatela, J.J.; Eder, D. Nanocarbon composites and hybrids in sustainability: A review. ChemSusChem 2012, 5, 456–478. [Google Scholar] [CrossRef] [PubMed]

- Soren, S.; Chakroborty, S.; Pal, K. Enhanced in tunning of photochemical and electrochemical responses of inorganic metal oxide nanoparticles via rGO frameworks (MO/rGO): A comprehensive review. Mater. Sci. Eng. B 2022, 278, 115632. [Google Scholar] [CrossRef]

- Anwar, A.W.; Majeed, A.; Iqbal, N.; Ullah, W.; Shuaib, A.; Ilyas, U.; Bibi, F.; Rafique, H.M. Specific Capacitance and Cyclic Stability of Graphene Based Metal/Metal Oxide Nanocomposites: A Review. J. Mater. Sci. Technol. 2015, 31, 699–707. [Google Scholar] [CrossRef]

- Kim, J.W.; Choi, B.G. Preparation of three-dimensional graphene/metal oxide nanocomposites for application of supercapacitors. Appl. Chem. Eng. 2015, 26, 521–525. [Google Scholar] [CrossRef][Green Version]

- Khedekar, V.V.; Zaeem, S.M.; Das, S. Graphene-metal oxide nanocomposites for supercapacitors: A perspective review. Adv. Mater. Lett. 2018, 9, 2–19. [Google Scholar] [CrossRef]

- Kumar, H.; Sharma, R.; Yadav, A.; Kumari, R. Recent advancement made in the field of reduced graphene oxide-based nanocomposites used in the energy storage devices: A review. J. Energy Storage 2021, 33, 102032. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Thakur, A.K.; De Adhikari, A.; Zhu, Y.; Wang, N. Current research of graphene-based nanocomposites and their application for supercapacitors. Nanomaterials 2020, 10, 2046. [Google Scholar] [CrossRef] [PubMed]

- Yadav, S.; Devi, A. Recent advancements of metal oxides/Nitrogen-doped graphene nanocomposites for supercapacitor electrode materials. J. Energy Storage 2020, 30, 101486. [Google Scholar] [CrossRef]

- Nandi, D.; Mohan, V.B.; Bhowmick, A.K.; Bhattacharyya, D. Metal/metal oxide decorated graphene synthesis and application as supercapacitor: A review. J. Mater. Sci. 2020, 55, 6375–6400. [Google Scholar] [CrossRef]

- Majumdar, D.; Ghosh, S. Recent advancements of copper oxide based nanomaterials for supercapacitor applications. J. Energy Storage 2021, 34, 101995. [Google Scholar] [CrossRef]

- Majumdar, D. Recent progress in copper sulfide based nanomaterials for high energy supercapacitor applications. J. Electroanal. Chem. 2021, 880, 114825. [Google Scholar] [CrossRef]

- Miller, E.E.; Hua, Y.; Tezel, F.H. Materials for energy storage: Review of electrode materials and methods of increasing capacitance for supercapacitors. J. Energy Storage 2018, 20, 30–40. [Google Scholar] [CrossRef]

- Hong, S.H.; Ryu, H.J. Fabrication and applications of multi-functional nanocomposites filled with carbon based nanomaterials. In Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Ke, Q.; Wang, J. Graphene-based materials for supercapacitor electrodes—A review. J. Mater. 2016, 2, 37–54. [Google Scholar] [CrossRef]

- Ji, L.; Meduri, P.; Agubra, V.; Xiao, X.; Alcoutlabi, M. Graphene-Based Nanocomposites for Energy Storage. Adv. Energy Mater. 2016, 6, 1502159. [Google Scholar] [CrossRef]

- Ates, M. Graphene and its nanocomposites used as an active materials for supercapacitors. J. Solid State Electr. 2016, 20, 1509–1526. [Google Scholar] [CrossRef]

- Sharma, P.; Hussain, N.; Das, M.R.; Deshmukh, A.B.; Shelke, M.V.; Szunerits, S.; Boukherroub, R. Metal oxide-graphene nanocomposites: Synthesis to applications. In Handbook of Research on Nanoscience, Nanotechnology, and Advanced Materials Nanosciene; Bououdina, M., Davim, J.P., Eds.; Engineering Science Reference (IGI Global): Hershey, PA, USA, 2014; pp. 196–225. [Google Scholar]

- Aliofkhazraei, M.; Makhlouf, A.S.H. (Eds.) Handbook of Nanoelectrochemistry; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Mahmood, N.; Zhang, C.; Yin, H.; Hou, Y. Graphene-based nanocomposites for energy storage and conversion in lithium batteries, supercapacitors and fuel cells. J. Mater. Chem. A 2014, 2, 15–32. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, M.; He, Q.; Shao, L.; Wei, S.; Guo, Z. An overview of the engineered graphene nanostructures and nanocomposites. RSC Adv. 2013, 3, 22790–22824. [Google Scholar] [CrossRef]

- Chang, H.; Wu, H. Graphene-based nanocomposites: Preparation, functionalization, and energy and environmental applications. Energy Environm. Sci. 2013, 6, 3483–3507. [Google Scholar] [CrossRef]

- Huang, X.; Qi, X.; Boey, F.; Zhang, H. Graphene-based composites. Chem. Soc. Rev. 2012, 41, 666–686. [Google Scholar] [CrossRef]

- Holze, R. From current peaks to waves and capacitive currents-on the origins of capacitor-like electrode behavior. J. Solid State Electr. 2017, 21, 2601–2607. [Google Scholar] [CrossRef]

- Lota, K.; Sierczynska, A.; Lota, G. Supercapacitors Based on Nickel Oxide/Carbon Materials Composites. Int. J. Electrochem. 2011, 2011, 321473. [Google Scholar] [CrossRef]

- Wang, N.; Zhao, P.; Zhang, Q.; Yao, M.; Hu, W. Monodisperse nickel/cobalt oxide composite hollow spheres with mesoporous shell for hybrid supercapacitor: A facile fabrication and excellent electrochemical performance. Compos. Part B 2017, 113, 144–151. [Google Scholar] [CrossRef]

- Basirun, W.J.; Saeed, J.M.; Rahman, M.S.; Mazari, S.A. Nickel oxides/hydroxides-graphene as hybrid supercapattery nanocomposites for advanced charge storage materials-a review. Crit. Rev. Solid State Mater. Sci. 2021, 46, 553–586. [Google Scholar] [CrossRef]

- Kim, Y.; Park, T.; Na, J.; Yi, J.W.; Kim, J.; Kim, M.; Bando, Y.; Yamauchi, Y.; Lin, J. Layered transition metal dichalcogenide/carbon nanocomposites for electrochemical energy storage and conversion applications. Nanoscale 2020, 12, 8608–8625. [Google Scholar] [CrossRef]

- Tu, C.C.; Lin, L.-Y.; Xiao, B.C.; Chen, Y.S. Highly efficient supercapacitor electrode with two-dimensional tungsten disulfide and reduced graphene oxide hybrid nanosheets. J. Power Sources 2016, 320, 78–85. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, J.; Shao, Y.; Li, W.; Wu, Y.; Zhang, L.; Hao, X. Three-Dimensional MoS2@CNT/RGO Network Composites for High-Performance Flexible Supercapacitors. Chem. Eur. J. 2017, 23, 3438–3446. [Google Scholar] [CrossRef]

- Sun, T.; Li, Z.; Liu, X.; Ma, L.; Wang, J.; Yang, S. Facile construction of 3D graphene/MoS2 composites as advanced electrode materials for supercapacitors. J. Power Sources 2016, 331, 180–188. [Google Scholar] [CrossRef]

- Sarfraz, M.; Shakir, I. Recent advances in layered double hydroxides as electrode materials for high-performance electrochemical energy storage devices. J. Energy Storage 2017, 13, 103–122. [Google Scholar] [CrossRef]

- Li, X.; Du, D.; Zhang, Y.; Xing, W.; Xue, Q.; Yan, Z. Layered double hydroxides toward high-performance supercapacitors. J. Mater. Chem. A 2017, 5, 15460–15485. [Google Scholar] [CrossRef]

- Gao, Z.; Yang, W.; Wang, J.; Yan, H.; Yao, Y.; Ma, J.; Wang, B.; Zhang, M.; Liu, L. Electrochemical synthesis of layer-by-layer reduced graphene oxide sheets/polyaniline nanofibers composite and its electrochemical performance. Electrochim. Acta 2013, 91, 185–194. [Google Scholar] [CrossRef]

- Daud, M.; Kamal, M.S.; Shehzad, F.; Al-Harthi, M.A. Graphene/layered double hydroxides nanocomposites: A review of recent progress in synthesis and applications. Carbon 2016, 104, 241–252. [Google Scholar] [CrossRef]

- Gu, Y.; Yang, Z.; Zhou, J.; Chen, Z. Application of graphene/LDH in energy storage and conversion. Sustain. Mater. Technol. 2023, 37, e00695. [Google Scholar] [CrossRef]

- Chaudhuri, H.; Yun, Y.S. A critical review on the properties and energy storage applications of graphene oxide/layered double hydroxides and graphene oxide/MXenes. J. Power Sources 2023, 564, 232870. [Google Scholar] [CrossRef]

- Varadwaj, G.B.B.; Nyamori, V.O. Layered double hydroxide- and graphene-based hierarchical nanocomposites: Synthetic strategies and promising applications in energy conversion and conservation. Nano Res. 2016, 9, 3598–3621. [Google Scholar] [CrossRef]

- Chae, J.H.; Ng, K.C.; Chen, G.Z. Nanostructured materials for the construction of asymmetrical supercapacitors. Proc. Inst. Mech. Eng. A 2010, 224, 479–503. [Google Scholar] [CrossRef]

- Zhang, Y.; Ju, P.; Zhao, C.; Qian, X. In-situ Grown of MoS2/RGO/MoS2@Mo Nanocomposite and Its supercapacitor Performance. Electrochim. Acta 2016, 219, 693–700. [Google Scholar] [CrossRef]

- Wang, C.; Liu, F.; Chen, J.; Yuan, Z.; Liu, C.; Zhang, X.; Xu, M.; Wei, L.; Chen, Y. A graphene-covalent organic framework hybrid for high-performance supercapacitors. Energy Storage Mater. 2020, 32, 448–457. [Google Scholar] [CrossRef]

- Li, S.; Wu, D.; Cheng, C.; Wang, J.; Zhang, F.; Su, Y.; Feng, X. Polyaniline-coupled multifunctional 2D metal oxide/hydroxide graphene nanohybrids. Angew. Chem. Int. Ed. 2013, 52, 12105–12109. [Google Scholar] [CrossRef] [PubMed]

- Selvakumar, D.; Nagaraju, P.; Arivanandhan, M.; Jayavel, R. Metal oxide-grafted graphene nanocomposites for energy storage applications. Emerg. Mater. 2021, 4, 1143–1165. [Google Scholar] [CrossRef]

- Chrisma, R.B.; Jafri, R.I.; Anila, E.I. A review on the electrochemical behavior of graphene-transition metal oxide nanocomposites for energy storage applications. J. Mater. Sci. 2023, 58, 6124–6150. [Google Scholar] [CrossRef]

- Low, W.H.; Khiew, P.S.; Lim, S.S.; Siong, C.W.; Ezeigwe, E.R. Recent development of mixed transition metal oxide and graphene/mixed transition metal oxide based hybrid nanostructures for advanced supercapacitors. J. Alloys Compd. 2019, 775, 1324–1356. [Google Scholar] [CrossRef]

- Yuan, H.; Kong, L.; Li, T.; Zhang, Q. A review of transition metal chalcogenide/graphene nanocomposites for energy storage and conversion. Chin. Chem. Lett. 2017, 28, 2180–2194. [Google Scholar] [CrossRef]

- Lawal, A.T. Graphene-based nano composites and their applications. A review. Biosens. Bioelectron. 2019, 141, 111384. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhao, C.; Gui, R.; Jin, H.; Xia, J.; Zhang, F.; Xia, Y. Synthetic methods and potential applications of transition metal dichalcogenide/graphene nanocomposites. Coord. Chem. Rev. 2016, 326, 86–110. [Google Scholar] [CrossRef]

- Shearer, C.J.; Cherevan, A.; Eder, D. Application of Functional Hybrids Incorporating Carbon Nanotubes or Graphene. In Carbon Nanotubes and Graphene, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 387–433. [Google Scholar]

- Zhang, X.; Hu, T.; Xie, M. Graphene-Based Nanocomposites for Supercapacitors. In Graphene-Based Energy Devices; bin Mohd Yusoff, A.R., Ed.; WILEY-VCH: Weinheim, Germany, 2015; pp. 123–144. [Google Scholar]

- Tale, B.; Nemade, K.R.; Tekade, P.V. Graphene based nano-composites for efficient energy conversion and storage in Solar cells and Supercapacitors: A Review. Polym. Plast. Technol. Mater. 2021, 60, 784–797. [Google Scholar] [CrossRef]

- Majeed, A.; Ullah, W.; Anwar, A.W.; Nasreen, F.; Sharif, A.; Mustafa, G.; Khan, A. Graphene-metal oxides/hydroxide nanocomposite materials: Fabrication advancements and supercapacitive performance. J. Alloys Compd. 2016, 671, 1–10. [Google Scholar] [CrossRef]

- Skotheim, T.A. (Ed.) Handbook of Conducting Polymers, 2nd ed.; Marcel Dekker Inc.: New York, NY, USA, 1998. [Google Scholar]

- Kumar, V.; Kalia, S.; Swart, H.C. (Eds.) Conducting Polymer Hybrids; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Alcácer, L. (Ed.) Conducting Polymers, Special Applications; D. Reidel Publishing Company: Dordrecht, The Netherlands, 1987. [Google Scholar]

- Wan, M. Conducting Polymers with Micro and Nanostructures; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Inzelt, G. Conducting Polymers—A New Era in Electrochemistry; Scholz, F., Ed.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Choudhary, R.B.; Ansari, S.; Majumder, M. Recent advances on redox active composites of metal-organic framework and conducting polymers as pseudocapacitor electrode material. Renew. Sustain. Energy Rev. 2021, 145, 110854. [Google Scholar] [CrossRef]

- Waltman, R.J.; Diaz, A.F.; Bargon, J. Substituent Effects in the Electropolymerization of Aromatic Heterocyclic Compounds. J. Phys. Chem. 1984, 88, 4343–4346. [Google Scholar] [CrossRef]

- Arjomandi, J.; Nematollahi, D.; Amani, A. Enhanced electrical conductivity of polyindole prepared by electrochemical polymerization of indole in ionic liquids. J. Appl. Polym. Sci. 2014, 131, 40094. [Google Scholar] [CrossRef]

- Mudila, H.; Prasher, P.; Kumar, M.; Kumar, A.; Zaidi, M.G.H.; Kumar, A. Critical analysis of polyindole and its composites in supercapacitor application. Mater. Renew. Sustain. Energy 2019, 8, 9. [Google Scholar] [CrossRef]

- Dai, L. Conjugated and fullerene-containing polymers for electronic and photonic applications: Advanced syntheses and microlithographic fabrications. J. Macromol. Sci. Polym. Rev. 1999, 39, 273–387. [Google Scholar] [CrossRef]

- Pettersson, L.A.; Carlsson, F.; Inganäs, O.; Arwin, H. Spectroscpic ellipsometry Study of the optical properties of doped poly(3,4-ethylenedioxythiophene): An anisotropic metal. Thin Solid Films 1998, 313–314, 356–361. [Google Scholar] [CrossRef]

- Czardybon, A.; Lapkowski, M. Synthesis and electropolymerisation of 3,4-ethylenedoxythiophene functionalized with alkoxy groups. Synth. Met. 2001, 119, 161–162. [Google Scholar] [CrossRef]

- Guimard, N.K.; Gomez, N.; Schmidt, C.E. Conducting polymers in biomedical engineering. Prog. Polym. Sci. 2007, 32, 876–921. [Google Scholar] [CrossRef]

- Kaur, G.; Adhikari, R.; Cass, P.; Bown, M.; Gunatillake, P. Electrically conductive polymers and composites for biomedical applications. RSC Adv. 2015, 5, 37553–37567. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, S.; Yadav, B.C. Conducting Polymers: Synthesis, Properties and Applications. Int. Adv. Res. J. Sci. Eng. Technol. 2015, 2, 110–124. [Google Scholar]

- Dai, L. Intelligent Macromolecules for Smart Devices; Springer: London, UK, 2004. [Google Scholar]

- Choudhary, R.B.; Ansari, S.; Purty, B. Robust electrochemical performance of polypyrrole (PPy) and polyindole (PIn) based hybrid electrode materials for supercapacitor application: A review. J. Energy Storage 2020, 29, 101302. [Google Scholar] [CrossRef]

- MacDiarmid, A.G. “Synthetic metals”: A novel role for organic polymers (Nobel lecture). Angew. Chem. Int. Ed. 2001, 40, 2581–2590. [Google Scholar] [CrossRef]

- Holze, R.; Wu, Y.P. Intrinsically conducting polymers in electrochemical energy technology: Trends and progress. Electrochim. Acta 2014, 122, 93–107. [Google Scholar] [CrossRef]

- Bryan, A.M.; Santino, L.M.; Lu, Y.; Acharya, S.; D’Arcy, J.M. Conducting Polymers for Pseudocapacitive Energy Storage. Chem. Mater. 2016, 28, 5989–5998. [Google Scholar] [CrossRef]

- Sumdani, M.G.; Islam, M.R.; Yahaya, A.N.A.; Safie, S.I. Recent advancements in synthesis, properties, and applications of conductive polymers for electrochemical energy storage devices: A review. Polym. Eng. Sci. 2022, 62, 269–303. [Google Scholar] [CrossRef]

- Holze, R. Composites and Copolymers Containing Redox-Active Molecules and Intrinsically Conducting Polymers as Active Masses for Supercapacitor Electrodes-An Introduction. Polymers 2020, 12, 1835. [Google Scholar] [CrossRef]

- Kondratiev, V.V.; Holze, R. Intrinsically conducting polymers and their combinations with redox-active molecules for rechargeable battery electrodes: An update. Chem. Pap. 2021, 75, 4981–5007. [Google Scholar] [CrossRef]

- Holze, R. Conjugated Molecules and Polymers in Secondary Batteries: A Perspective. Molecules 2022, 27, 546. [Google Scholar] [CrossRef]

- Li, Z.; Gong, L. Research progress on applications of polyaniline (PANI) for electrochemical energy storage and conversion. Materials 2020, 13, 548. [Google Scholar] [CrossRef]

- Wang, H.; Lin, J.; Shen, Z.X. Polyaniline (PANi) based electrode materials for energy storage and conversion. J. Sci. Adv. Mater. Dev. 2016, 1, 225–255. [Google Scholar] [CrossRef]

- Huang, Y.; Li, H.; Wang, Z.; Zhu, M.; Pei, Z.; Xue, Q.; Huang, Y.; Zhi, C. Nanostructured Polypyrrole as a flexible electrode material of supercapacitor. Nano Energy 2016, 22, 422–438. [Google Scholar] [CrossRef]

- Candelaria, S.L.; Shao, Y.; Zhou, W.; Li, X.; Xiao, J.; Zhang, J.G.; Wang, Y.; Liu, J.; Li, J. Nanostructured carbon for energy storage and conversion. Nano Energy 2012, 1, 195–220. [Google Scholar] [CrossRef]

- Huang, Z.; Li, L.; Wang, Y.; Zhang, C.; Liu, T. Polyaniline/graphene nanocomposites towards high-performance supercapacitors: A review. Comp. Commun. 2018, 8, 83–91. [Google Scholar] [CrossRef]

- Bao, C.; Han, J.; Cheng, J.; Zhang, R. Electrode Materials Blended with Graphene/Polyaniline for Supercapacitor. Prog. Chem. 2018, 30, 1349–1363. [Google Scholar]

- Kausar, A. Polyaniline/graphene nanoplatelet nanocomposite towards high-end features and applications. Mater. Res. Innov. 2021, 26, 249–261. [Google Scholar] [CrossRef]

- Liu, P.; Yan, J.; Guang, Z.; Huang, Y.; Li, X.; Huang, W. Recent advancements of polyaniline-based nanocomposites for supercapacitors. J. Power Sources 2019, 424, 108–130. [Google Scholar] [CrossRef]

- Chauhan, N.P.S.; Mozafari, M.; Chundawat, N.S.; Meghwal, K.; Ameta, R.; Ameta, S.C. High-performance supercapacitors based on polyaniline-graphene nanocomposites: Some approaches, challenges and opportunities. J. Ind. Eng. Chem. 2016, 36, 13–29. [Google Scholar] [CrossRef]

- Yang, M.; Hou, Y.; Kotov, N.A. Graphene-based multilayers: Critical evaluation of materials assembly techniques. Nano Today 2012, 7, 430–447. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Q.; Zhou, A.; Huang, Z.; Bai, H.; Li, L. Phase-Separated Polyaniline/Graphene Composite Electrodes for High-Rate Electrochemical Supercapacitors. Adv. Mater. 2016, 28, 10211–10216. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Y.; Zhu, J.; Ren, P. Electrochemical in situ polymerization of reduced graphene oxide/polypyrrole composite with high power density. J. Power Sources 2012, 208, 138–143. [Google Scholar] [CrossRef]

- Sardar, A.; Gupta, P.S. Polypyrrole based nanocomposites for supercapacitor applications: A review. AIP Conf. Proc. 2018, 1953, 030020. [Google Scholar]

- Chu, C.Y.; Tsai, J.T.; Sun, C.L. Synthesis of PEDOT-modified graphene composite materials as flexible electrodes for energy storage and conversion applications. Int. J. Hydrogen Energy 2012, 37, 13880–13886. [Google Scholar] [CrossRef]

- Shen, F.; Pankratov, D.; Chi, Q. Graphene-conducting polymer nanocomposites for enhancing electrochemical capacitive energy storage. Curr. Opin. Electrochem. 2017, 4, 133–144. [Google Scholar] [CrossRef]

- Zhang, X.; Samor, P. Graphene/Polymer Nanocomposites for Supercapacitors. ChemNanoMat 2017, 3, 362–372. [Google Scholar] [CrossRef]

- Diez-Pascual, A.M. Development of Graphene-Based Polymeric Nanocomposites: A Brief Overview. Polymers 2021, 13, 2978. [Google Scholar] [CrossRef] [PubMed]

- Naarmann, H. Polymers, Electrically Comducting. In Ullmann’s Encyclopedia of Industrial Electrochemistry; Wiley: Hoboken, NJ, USA, 2000. [Google Scholar]

- Gopal, J.; Muthu, M.; Sivanesan, I. A Comprehensive Compilation of Graphene/Fullerene Polymer Nanocomposites for Electrochemical Energy Storage. Polymers 2023, 15, 701. [Google Scholar] [CrossRef]

- Sun, Y.; Shi, G. Graphene/polymer composites for energy applications. J. Polym. Sci. B 2013, 51, 231–253. [Google Scholar] [CrossRef]

- Li, C.; Shi, G. Synthesis and electrochemical applications of the composites of conducting polymers and chemically converted graphene. Electrochim. Acta 2011, 56, 10737–10743. [Google Scholar] [CrossRef]

- Pieta, P.; Obraztsov, I.; D’Souza, F.; Kutner, W. Composites of conducting polymers and various carbon nanostructures for electrochemical supercapacitors. ECS J. Solid State Sci. Technol. 2013, 2, M3120–M3134. [Google Scholar] [CrossRef]

- Fu, L.; Qu, Q.; Holze, R.; Kondratiev, V.V.; Wu, Y. Composites of metal oxides and intrinsically conducting polymers as supercapacitor electrode materials: The best of both worlds? J. Mater. Chem. A 2019, 7, 14937–14970. [Google Scholar] [CrossRef]

- Ehsani, A.; Heidari, A.A.; Shiri, H.M. Electrochemical Pseudocapacitors Based on Ternary Nanocomposite of Conductive Polymer/Graphene/Metal Oxide: An Introduction and Review to it in Recent Studies. Chem. Rec. 2019, 19, 908–926. [Google Scholar] [CrossRef] [PubMed]

- Golkhatmi, S.Z.; Sedghi, A.; Miankushki, H.N.; Khalaj, M. Structural properties and supercapacitive performance evaluation of the nickel oxide/graphene/polypyrrole hybrid ternary nanocomposite in aqueous and organic electrolytes. Energy 2021, 214, 118950. [Google Scholar] [CrossRef]

- Shinde, S.K.; Kim, D.Y.; Kumar, M.; Murugadoss, G.; Ramesh, S.; Tamboli, A.M.; Yadav, H.M. MOFs-Graphene Composites Synthesis and Application for Electrochemical Supercapacitor: A Review. Polymers 2022, 14, 511. [Google Scholar] [CrossRef] [PubMed]

- Idisi, D.O.; Oke, J.A.; Bello, I.T. Graphene oxide/Au nanoparticles: Synthesis, properties, and application: A mini-review. Int. J. Energy Res. 2021, 45, 19772–19788. [Google Scholar] [CrossRef]

- Kong, H.X. Hybrids of carbon nanotubes and graphene/graphene oxide. Curr. Opin. Solid State Mater. Sci. 2013, 17, 31–37. [Google Scholar] [CrossRef]

- Fan, Z.; Yan, J.; Zhi, L.; Zhang, Q.; Wei, T.; Feng, J.; Zhang, M.; Qian, W.; Wei, F. A three-dimensional carbon nanotube/graphene sandwich and its application as electrode in supercapacitors. Adv. Mater. 2010, 22, 3723–3728. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.D.; Zhang, B.; Oh, S.W.; Zheng, Q.B.; Lin, X.Y.; Yousefi, N.; Kim, J.K. Self-assembled reduced graphene oxide/carbon nanotube thin films as electrodes for supercapacitors. J. Mater. Chem. 2012, 22, 3591–3599. [Google Scholar] [CrossRef]

- Yu, D.; Dai, L. Self-assembled graphene/carbon nanotube hybrid films for supercapacitors. J. Phys. Chem. Lett. 2010, 1, 467–470. [Google Scholar] [CrossRef]

- Kim, Y.S.; Kumar, K.; Fisher, F.T.; Yang, E.H. Out-of-plane growth of CNTs on graphene for supercapacitor applications. Nanotechnology 2012, 23, 015301. [Google Scholar] [CrossRef]

- Baimova, J.A.; Shcherbinin, S.A. Metal/Graphene Composites: A Review on the Simulation of Fabrication and Study of Mechanical Properties. Materials 2023, 16, 202. [Google Scholar] [CrossRef]

- Safina, L.R.; Baimova, J.A.; Krylova, K.A.; Murzaev, R.T.; Mulyukov, R.R. Simulation of metal-graphene composites by molecular dynamics: A review. Lett. Mater. 2020, 10, 351–360. [Google Scholar] [CrossRef]

- Yang, S.; Feng, X.; Ivanovici, S.; Müllen, K. Fabrication of graphene-encapsulated oxide nanoparticles: Towards high-performance anode materials for lithium storage. Angew. Chem. Int. Ed. 2010, 49, 8408–8411. [Google Scholar] [CrossRef] [PubMed]

- Ye, G.; Gong, Y.; Keyshar, K.; Husain, E.A.M.; Brunetto, G.; Yang, S.; Vajtai, R.; Ajayan, P.M. 3D Reduced Graphene Oxide Coated V2O5 Nanoribbon Scaffolds for High-Capacity Supercapacitor Electrodes. Part. Part. Syst. Charact. 2015, 32, 817–821. [Google Scholar] [CrossRef]

- Majumdar, D.; Mandal, M.; Bhattacharya, S.K. V2O5 and its carbon-based nanocomposites for supercapacitor applications. ChemElectroChem 2019, 6, 1623–1648. [Google Scholar] [CrossRef]

- Raja, A.; Son, N.; Kang, M. Reduced graphene oxide decorated transition metal manganese vanadium oxide nanorods for electrochemical supercapacitors and photocatalytic degradation of pollutants in water. J. Taiwan Inst. Chem. Eng. 2023, 144, 104762. [Google Scholar] [CrossRef]

- Zardkhoshoui, A.M.; Ameri, B.; Davarani, S.S.H. A hybrid supercapacitor assembled by reduced graphene oxide encapsulated lollipop-like FeNi2S4@Co9S8 nanoarrays. Chem. Eng. J. 2023, 470, 144132. [Google Scholar] [CrossRef]

- Ma, L.; Shen, X.; Ji, Z.; Wang, S.; Zhou, H.; Zhu, G. Carbon coated nickel sulfide/reduced graphene oxide nanocomposites: Facile synthesis and excellent supercapacitor performance. Electrochim. Acta 2014, 146, 525–532. [Google Scholar] [CrossRef]

- Pedrós, J.; Boscá, A.; Martínez, J.; Ruiz-Gómez, S.; Pérez, L.; Barranco, V.; Calle, F. Polyaniline nanofiber sponge filled graphene foam as high gravimetric and volumetric capacitance electrode. J. Power Sources 2016, 317, 35–42. [Google Scholar] [CrossRef]

- Sun, S.; Wang, S.; Li, S.; Li, Y.; Zhang, Y.; Chen, J.; Zhang, Z.; Fang, S.; Wang, P. Asymmetric supercapacitors based on a NiCo2O4/three dimensional graphene composite and three dimensional graphene with high energy density. J. Mater. Chem. A 2016, 4, 18646–18653. [Google Scholar] [CrossRef]

- Böhm, S. Graphene against corrosion. Nat. Nanotechnol. 2014, 9, 741–742. [Google Scholar] [CrossRef]

- Yu, G.; Hu, L.; Liu, N.; Wang, H.; Vosgueritchian, M.; Yang, Y.; Cui, Y.; Bao, Z. Enhancing the supercapacitor performance of graphene/MnO2 nanostructured electrodes by conductive wrapping. Nano Lett. 2011, 11, 4438–4442. [Google Scholar] [CrossRef] [PubMed]

- Obreja, V.V.N. Supercapacitors specialities—Materials review. AIP Conf. Proc. 2014, 1597, 98–120. [Google Scholar]

- Bakker, M.G.; Frazier, R.M.; Bara, J.E.; Chopra, N.; Spear, S.; Pan, S.; Xu, C. Perspectives on supercapacitors, pseudocapacitors and batteries. Nanomater. Energy 2012, 1, 136–158. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ul Hoque, M.I.; Donne, S.W.; Holze, R. Graphene Nanocomposite Materials for Supercapacitor Electrodes. Encyclopedia 2024, 4, 101-116. https://doi.org/10.3390/encyclopedia4010009

Ul Hoque MI, Donne SW, Holze R. Graphene Nanocomposite Materials for Supercapacitor Electrodes. Encyclopedia. 2024; 4(1):101-116. https://doi.org/10.3390/encyclopedia4010009

Chicago/Turabian StyleUl Hoque, Md. Ikram, Scott W. Donne, and Rudolf Holze. 2024. "Graphene Nanocomposite Materials for Supercapacitor Electrodes" Encyclopedia 4, no. 1: 101-116. https://doi.org/10.3390/encyclopedia4010009

APA StyleUl Hoque, M. I., Donne, S. W., & Holze, R. (2024). Graphene Nanocomposite Materials for Supercapacitor Electrodes. Encyclopedia, 4(1), 101-116. https://doi.org/10.3390/encyclopedia4010009