Beyond Hertz: Accurate Analytical Force–Indentation Equations for AFM Nanoindentation with Spherical Tips

Abstract

1. Introduction

2. Materials and Methods

2.1. An Analytical Approach to Obtain a Force–Indentation Relationship

2.2. Extended Solution for Larger Indentation Depths

2.3. Simulated and Experimental Results

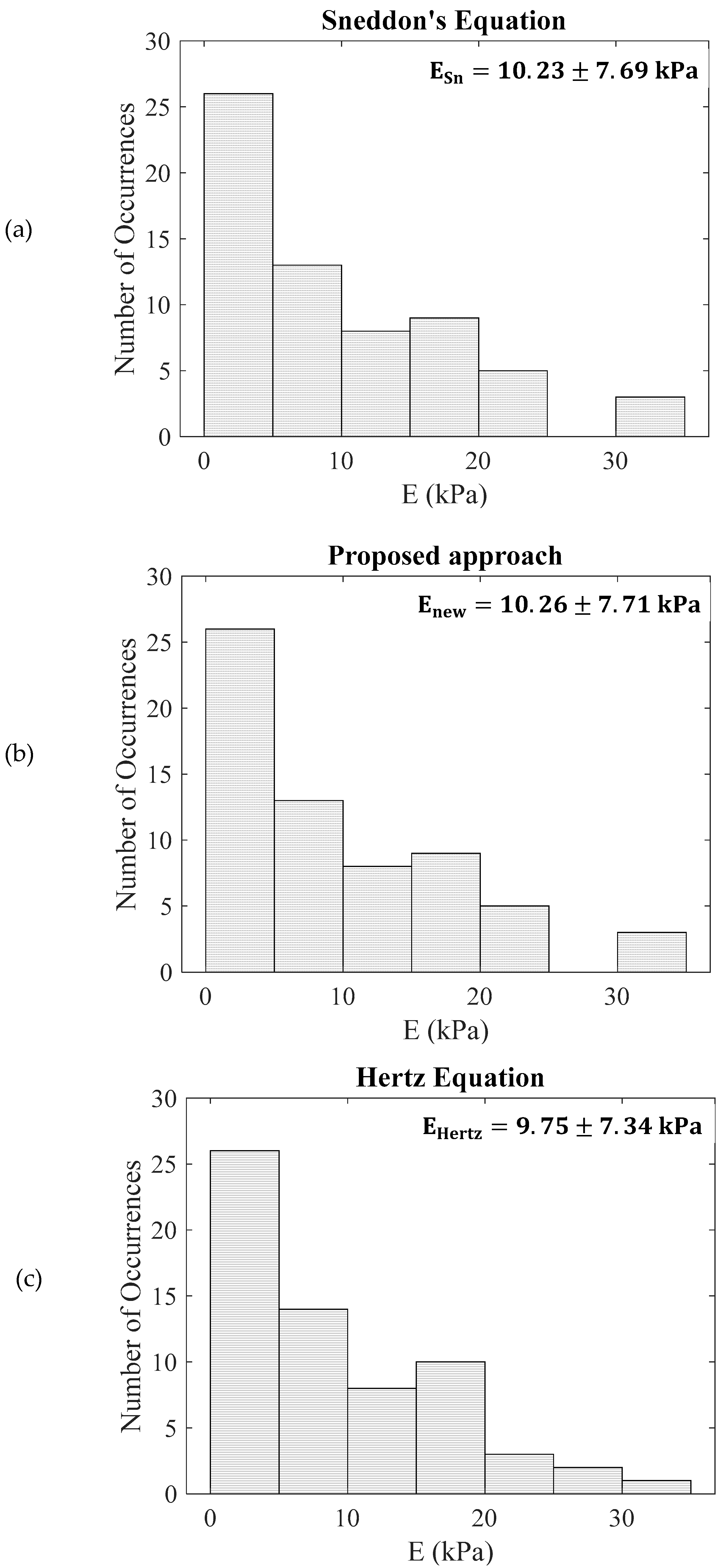

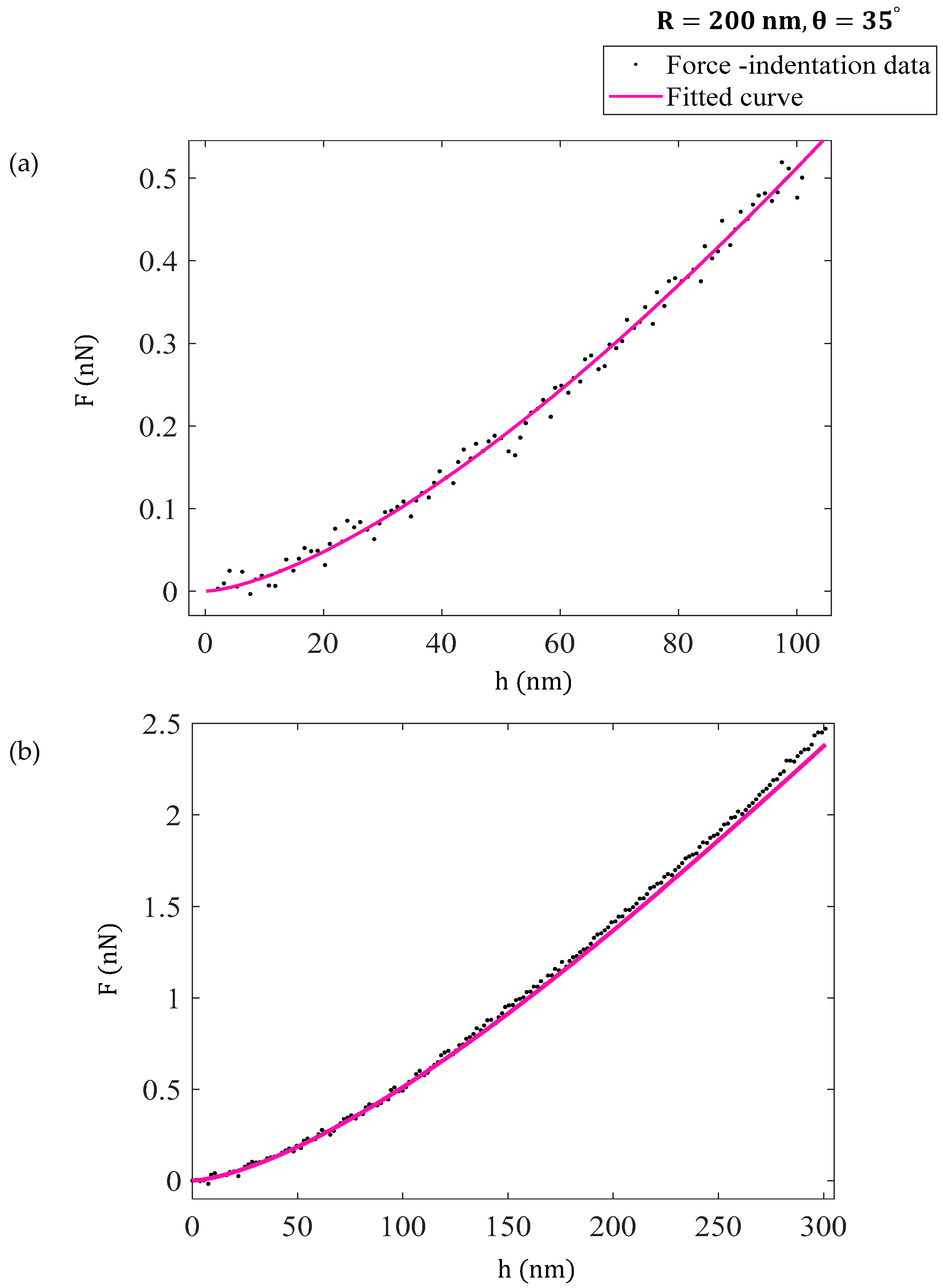

3. Results

4. Discussion

- The proposed four-term equation is valid across all indentation depths, from shallow to very deep, eliminating the need to switch between models.

- The method presented in this paper provides a direct, closed-form force–indentation relationship without numerical iteration or empirical fitting.

- The proposed equations (two-term and four-term) are free from arbitrary coefficients, ensuring consistent results across different applications.

- They simplify data processing, accelerate analysis, and improve accuracy in biomechanical studies and diagnostics.

- They offer a physically grounded model that supports further extensions to complex materials.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Krawczyk-Wołoszyn, K.; Roczkowski, D.; Reich, A.; Żychowska, M. Applying the Atomic Force Microscopy Technique in Medical Sciences—A Narrative Review. Biomedicines 2024, 12, 2012. [Google Scholar] [CrossRef] [PubMed]

- Argatov, I.; Jin, X.; Mishuris, G. Atomic force microscopy-based indentation of cells: Modelling the effect of a pericellular coat. J. R. Soc. Interface 2023, 20, 20220857. [Google Scholar] [CrossRef]

- Kiio, T.M.; Park, S. Nano-scientific Application of Atomic Force Microscopy in Pathology: From Molecules to Tissues. Int. J. Med. Sci. 2020, 17, 844–858. [Google Scholar] [CrossRef]

- Hinterdorfer, P.; Garcia-Parajo, M.F.; Dufrêne, Y.F. Single-Molecule Imaging of Cell Surfaces Using Near-Field Nanoscopy. Acc. Chem. Res. 2012, 45, 327–336. [Google Scholar] [CrossRef]

- Li, M.; Dang, D.; Liu, L.; Xi, N.; Wang, Y. Imaging and Force Recognition of Single Molecular Behaviors Using Atomic Force Microscopy. Sensors 2017, 17, 200. [Google Scholar] [CrossRef]

- Carvalho, F.A.; Connell, S.; Miltenberger-Miltenyi, G.; Pereira, S.V.; Tavares, A.; Ariëns, R.A.S.; Santos, N.C. Atomic Force Microscopy-Based Molecular Recognition of a Fibrinogen Receptor on Human Erythrocytes. ACS Nano 2010, 4, 4609–4620. [Google Scholar] [CrossRef] [PubMed]

- Rusu, M.; Dulebo, A.; Curaj, A.; Liehn, E.A. Ultra-rapid non-invasive clinical nano-diagnostic of inflammatory diseases. Discov. Rep. 2014, 1, e2. [Google Scholar] [CrossRef]

- Lekka, M.; Gil, D.; Pogoda, K.; Dulińska-Litewka, J.; Jach, R.; Gostek, J.; Klymenko, O.; Prauzner-Bechcicki, S.; Stachura, Z.; Wiltowska-Zuber, J.; et al. Cancer cell detection in tissue sections using AFM. Arch. Biochem. Biophys. 2012, 518, 151–156. [Google Scholar] [CrossRef]

- Goldmann, W.H.; Ezzell, R.M. Viscoelasticity in wild-type and vinculin-deficient (5.51) mouse F9 embryonic carcinoma cells examined by atomic force microscopy and rheology. Exp. Cell Res. 1996, 226, 234–237. [Google Scholar] [CrossRef]

- Goldmann, W.H.; Galneder, R.; Ludwig, M.; Xu, W.; Adamson, E.D.; Wang, N.; Ezzell, R.M. Differences in elasticity of vinculin-deficient F9 cells measured by magnetometry and atomic force microscopy. Exp. Cell Res. 1998, 239, 235–242. [Google Scholar] [CrossRef]

- Lekka, M.; Laidler, P.; Gil, D.; Lekki, J.; Stachura, Z.; Hrynkiewicz, A.Z. Elasticity of normal and cancerous human bladder cells studied by scanning force microscopy. Eur. Biophys. J. 1999, 28, 312–316. [Google Scholar] [CrossRef] [PubMed]

- Lekka, M.; Lekki, J.; Marszałek, M.; Golonka, P.; Stachura, Z.; Cleff, B.; Hrynkiewicz, A.Z. Local elastic properties of cells studied by SFM. Appl. Surf. Sci. 1999, 141, 345–349. [Google Scholar] [CrossRef]

- Li, Q.S.; Lee, G.Y.H.; Ong, C.N.; Lim, C.T. AFM indentation study of breast cancer cells. Biochem. Biophys. Res. Commun. 2008, 374, 609–613. [Google Scholar] [CrossRef] [PubMed]

- Faria, E.C.; Ma, N.; Gazi, E.; Gardner, P.; Brown, M.; Clarke, N.W.; Snook, R.D. Measurement of elastic properties of prostate cancer cells using AFM. Analyst 2008, 133, 1498–1500. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Ngan, A.H.W.; Tang, B.; Wang, A.X. Reliable measurement of elastic modulus of cells by nanoindentation in an atomic force microscope. J. Mech. Behav. Biomed. Mater. 2012, 8, 134–142. [Google Scholar] [CrossRef] [PubMed]

- Cross, S.E.; Jin, Y.-S.; Rao, J.; Gimzewski, J.K. Nanomechanical analysis of cells from cancer patients. Nat. Nanotechnol. 2007, 2, 780–783. [Google Scholar] [CrossRef]

- Stylianou, A.; Gkretsi, V.; Stylianopoulos, T. Transforming Growth Factor-β modulates Pancreatic Cancer Associated Fibroblasts cell shape, stiffness and invasion. Biochim. Biophys. Acta 2018, 1862, 1537–1546. [Google Scholar] [CrossRef]

- Plodinec, M.; Loparic, M.; Monnier, C.A.; Obermann, E.C.; Zanetti-Dallenbach, R.; Oertle, P.; Hyotyla, J.T.; Aebi, U.; Bentires-Alj, M.; Lim, R.Y.H.; et al. The nanomechanical signature of breast cancer. Nat. Nanotechnol. 2012, 7, 757–765. [Google Scholar] [CrossRef]

- Ansardamavandi, A.; Tafazzoli-Shadpour, M.; Omidvar, R.; Jahanzad, I. Quantification of effects of cancer on elastic properties of breast tissue by Atomic Force Microscopy. J. Mech. Behav. Biomed. Mater. 2016, 60, 234–242. [Google Scholar] [CrossRef]

- Tian, M.; Li, Y.; Liu, W.; Jin, L.; Jiang, X.; Wang, X.; Ding, Z.; Peng, Y.; Zhou, J.; Fan, J.; et al. The nanomechanical signature of liver cancer tissues and its molecular origin. Nanoscale 2015, 7, 12998–13010. [Google Scholar] [CrossRef]

- Ciasca, G.; Sassun, T.E.; Minelli, E.; Antonelli, M.; Papi, M.; Santoro, A.; Giangaspero, F.; Delfini, R.; De Spirito, M. Nanomechanical signature of brain tumors. Nanoscale 2016, 8, 19629–19643. [Google Scholar] [CrossRef]

- Cui, Y.; Zhang, X.; You, K.; Guo, Y.; Liu, C.; Fang, X.; Geng, L. Nanomechanical Characteristics of Cervical Cancer and Cervical Intraepithelial Neoplasia Revealed by Atomic Force Microscopy. Med. Sci. Monit. 2017, 23, 4205–4213. [Google Scholar] [CrossRef]

- Minelli, E.; Ciasca, G.; Sassun, T.E.; Antonelli, M.; Palmieri, V.; Papi, M.; Maulucci, G.; Santoro, A.; Giangaspero, F.; Delfini, R.; et al. A fully-automated neural network analysis of AFM force-distance curves for cancer tissue diagnosis. Appl. Phys. Lett. 2017, 111, 143701. [Google Scholar] [CrossRef]

- Stolz, M.; Gottardi, R.; Raiteri, R.; Miot, S.; Martin, I.; Imer, R.; Staufer, U.; Raducanu, A.; Düggelin, M.; Baschong, W.; et al. Early detection of aging cartilage and osteoarthritis in mice and patient samples using atomic force microscopy. Nat. Nanotechnol. 2009, 4, 186–192. [Google Scholar] [CrossRef] [PubMed]

- Loparic, M.; Wirz, D.; Daniels, A.U.; Raiteri, R.; Vanlandingham, M.R.; Guex, G.; Martin, I.; Aebi, U.; Stolz, M. Micro- and nanomechanical analysis of articular cartilage by indentation-type atomic force microscopy: Validation with a gel-microfiber composite. Biophys. J. 2010, 98, 2731–2740. [Google Scholar] [CrossRef] [PubMed]

- Connelly, L.; Jang, H.; Teran Arce, F.; Capone, R.; Kotler, S.A.; Ramachandran, S.; Kagan, B.L.; Nussinov, R.; Lal, R. Atomic force microscopy and MD simulations reveal pore-like structures of all-d-enantiomer of Alzheimer’s β-amyloid peptide: Relevance to the ion channel mechanism of AD pathology. J. Phys. Chem. B 2012, 116, 1728–1735. [Google Scholar] [CrossRef]

- Hane, F.; Drolle, E.; Choi, Y.; Attwood, S.; Gaikwad, R.; Leonenko, Z. Atomic force microscopy and Kelvin probe force microscopy to study Alzheimer’s disease. In Proceedings of the Materials Science & Technology Conference and Exhibition 2013, Montreal, QC, Canada, 27–31 October 2013; pp. 2817–2824. [Google Scholar]

- Song, S.; Ma, X.; Zhou, Y.; Xu, M.; Shuang, S.; Dong, C. Studies on the interaction between vanillin and β-amyloid protein via fluorescence spectroscopy and atomic force microscopy. Chem. Res. Chin. Univ. 2016, 32, 172–177. [Google Scholar] [CrossRef]

- Han, S.W.; Shin, H.K.; Adachi, T. Nanolithography of amyloid precursor protein cleavage with β-secretase by atomic force microscopy. J. Biomed. Nanotechnol. 2016, 12, 546–553. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, W.; Wang, S.; Wang, C.; Xie, J.; Chen, X.; Xu, Y.; Mao, P. Detection of human erythrocytes influenced by iron deficiency anemia and thalassemia using atomic force microscopy. Micron 2012, 43, 1287–1292. [Google Scholar] [CrossRef]

- Mendová, K.; Otáhal, M.; Drab, M.; Daniel, M. Size Matters: Rethinking Hertz Model Interpretation for Cell Mechanics Using AFM. Int. J. Mol. Sci. 2024, 25, 7186. [Google Scholar] [CrossRef]

- Krieg, M.; Fläschner, G.; Alsteens, D.; Gaub, B.M.; Roos, W.H.; Wuite, G.J.L.; Gaub, H.E.; Gerber, C.; Dufrêne, Y.F.; Müller, D.J. Atomic force microscopy-based mechanobiology. Nat. Rev. Phys. 2019, 1, 41–57. [Google Scholar] [CrossRef]

- Abuhattum, S.; Mokbel, D.; Müller, P.; Soteriou, D.; Guck, J.; Aland, S. An explicit model to extract viscoelastic properties of cells from AFM force-indentation curves. iScience 2022, 25, 104016. [Google Scholar] [CrossRef]

- Han, R.; Chen, J. A modified Sneddon model for the contact between conical indenters and spherical samples. J. Mater. Res. 2021, 36, 1762–1771. [Google Scholar] [CrossRef]

- Sun, W.; Ma, J.; Wang, C.; Li, H.; Wu, C.; Zhang, W. Precise determination of elastic modulus of cell using conical AFM probe. J. Biomech. 2021, 118, 110277. [Google Scholar] [CrossRef]

- Chen, S.W.; Teulon, J.M.; Kaur, H.; Godon, C.; Pellequer, J.-L. Nano-structural stiffness measure for soft biomaterials of heterogeneous elasticity. Nanoscale Horiz. 2023, 8, 75–82. [Google Scholar] [CrossRef]

- Gavara, N. A beginner’s guide to atomic force microscopy probing for cell mechanics. Microsc. Res. Tech. 2017, 80, 75–84. [Google Scholar] [CrossRef]

- Yuan, W.; Ding, Y.; Wang, G. Universal contact stiffness of elastic solids covered with tensed membranes and its application in indentation tests of biological materials. Acta Biomater. 2023, 171, 202–208. [Google Scholar] [CrossRef] [PubMed]

- Koruk, H.; Pouliopoulos, A.N. Elasticity and Viscoelasticity Imaging Based on Small Particles Exposed to External Forces. Processes 2023, 11, 3402. [Google Scholar] [CrossRef]

- Kontomaris, S.V.; Malamou, A. A novel approximate method to calculate the force applied on an elastic half space by a rigid sphere. Eur. J. Phys. 2021, 42, 025010. [Google Scholar] [CrossRef]

- Sneddon, I.N. The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 1965, 3, 47–57. [Google Scholar] [CrossRef]

- Müller, P.; Abuhattum, S.; Möllmert, S.; Ulbricht, E.; Taubenberger, A.V.; Guck, J. nanite: Using machine learning to assess the quality of atomic force microscopy-enabled nano-indentation data. BMC Bioinform. 2019, 20, 465. [Google Scholar] [CrossRef]

- Pharr, G.M.; Oliver, W.C.; Brotzen, F.R. On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation. J. Mater. Res. 1992, 7, 613–617. [Google Scholar] [CrossRef]

- Kontomaris, S.V.; Malamou, A. Revisiting the theory behind AFM indentation procedures: Exploring the physical significance of fundamental equations. Eur. J. Phys. 2022, 43, 015010. [Google Scholar] [CrossRef]

- Hermanowicz, P.; Sarna, M.; Burda, K.; Gabryś, H. AtomicJ: An open source software for analysis of force curves. Rev. Sci. Instrum. 2014, 85, 063703. [Google Scholar] [CrossRef]

- Kontomaris, S.V.; Malamou, A.; Ismail, G.M.; Psychogios, I.; Stylianou, A. Global linear modeling of AFM indentation curves for soft samples with various indenter geometries. Next Mater. 2025, 9, 101299. [Google Scholar] [CrossRef]

- Kontomaris, S.V.; Psychogios, I.; Stergiopoulos, M.; Malamou, A.; Stylianou, A. Quantitative criteria for the validity of the elastic half-space assumption in AFM nanoindentation. Next Mater. 2025, 9, 101180. [Google Scholar] [CrossRef]

- Butt, H.J.; Jaschke, M. Calculation of thermal noise in atomic force microscopy. Nanotechnology 1995, 6, 1. [Google Scholar] [CrossRef]

- Louca, M.; Stylianou, A.; Minia, A.; Pliaka, V.; Alexopoulos, L.G.; Gkretsi, V.; Stylianopoulos, T. Ras suppressor-1 (RSU-1) promotes cell invasion in aggressive glioma cells and inhibits it in non-aggressive cells through STAT6 phospho-regulation. Sci. Rep. 2019, 9, 7782. [Google Scholar] [CrossRef]

- Polezzi, M. On the Weighted Mean Value Theorem for Integrals. Int. J. Math. Educ. Sci. Technol. 2006, 37, 868–870. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Sebastian, K.S.; Adams, M.J. The effect of indenter geometry on the elastic response to indentation. J. Phys. D Appl. Phys. 1994, 27, 1156–1162. [Google Scholar] [CrossRef]

- Kontomaris, S.V.; Malamou, A.; Stylianou, A. Development of an accurate simplified approach for data processing in AFM indentation experiments. Micron 2025, 190, 103782. [Google Scholar] [CrossRef]

- Wang, B.; Lançon, P.; Bienvenu, C.; Vierling, P.; Di Giorgio, C.; Bossis, G. A general approach for the microrheology of cancer cells by atomic force microscopy. Micron 2013, 44, 287–297. [Google Scholar] [CrossRef] [PubMed]

- Pathak, S.; Kalidindi, S.R. Spherical nanoindentation stress-strain curves. Mater. Sci. Eng. R Rep. 2015, 91, 1–36. [Google Scholar] [CrossRef]

- Popov, V.L. Contact Mechanics and Friction: Physical Principles and Applications, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Hinterdorfer, P.; Dufrêne, Y.F. Detection and localization of single molecular recognition events using atomic force microscopy. Nat. Methods 2006, 3, 347–355. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Li, B.; Liao, Z.; Li, J.; Li, X.; Yin, J.; Guo, W. Principles and applications of liquid-environment atomic force microscopy. Adv. Mater. Interfaces 2022, 9, 2201864. [Google Scholar] [CrossRef]

- Wei, Z.; Zhao, Y.-P. Growth of liquid bridge in AFM. J. Phys. D Appl. Phys. 2007, 40, 4368–4375. [Google Scholar] [CrossRef]

- Dokukin, M.B.; Guz, N.V.; Sokolov, I. Quantitative study of the elastic modulus of loosely attached cells in AFM indentation experiments. Biophys. J. 2013, 104, 2123–2131. [Google Scholar] [CrossRef] [PubMed]

- Efremov, Y.M.; Okajima, T.; Raman, A. Measuring viscoelasticity of soft biological samples using atomic force microscopy. Soft Matter 2020, 16, 64–81. [Google Scholar] [CrossRef]

- Brückner, B.R.; Nöding, H.; Janshoff, A. Viscoelastic properties of confluent MDCK II cells obtained from force cycle experiments. Biophys. J. 2017, 112, 724–735. [Google Scholar] [CrossRef]

- Garcia, P.D.; Garcia, R. Determination of the elastic moduli of a single cell cultured on a rigid support by force microscopy. Biophys. J. 2018, 114, 2923–2932. [Google Scholar] [CrossRef]

| Model | Equation |

|---|---|

| Sneddon 1965 [41] | |

Note: This is an exact mathematical solution. However, it has the disadvantage of not directly relating the applied force to the indentation depth, which complicates the fitting process. | |

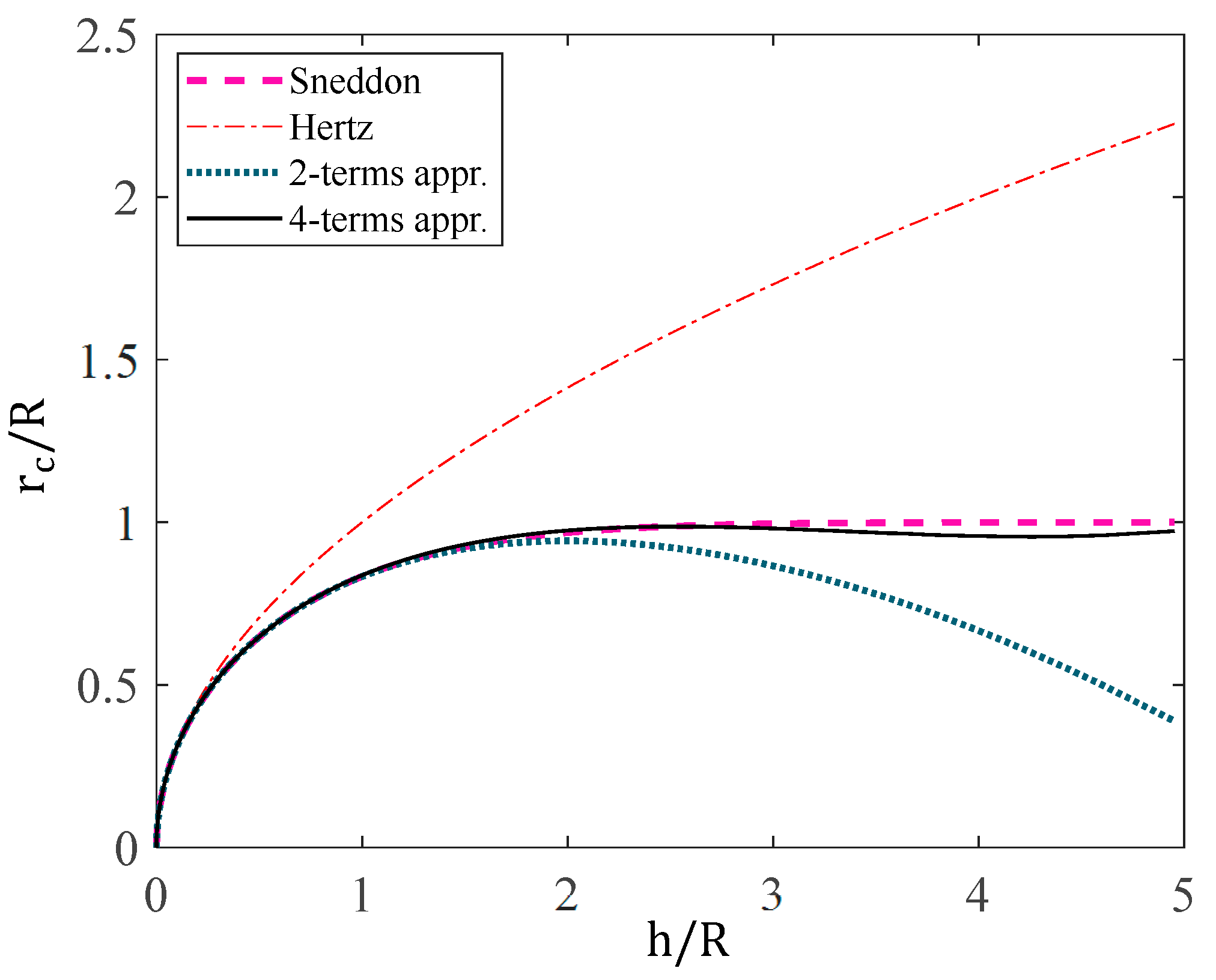

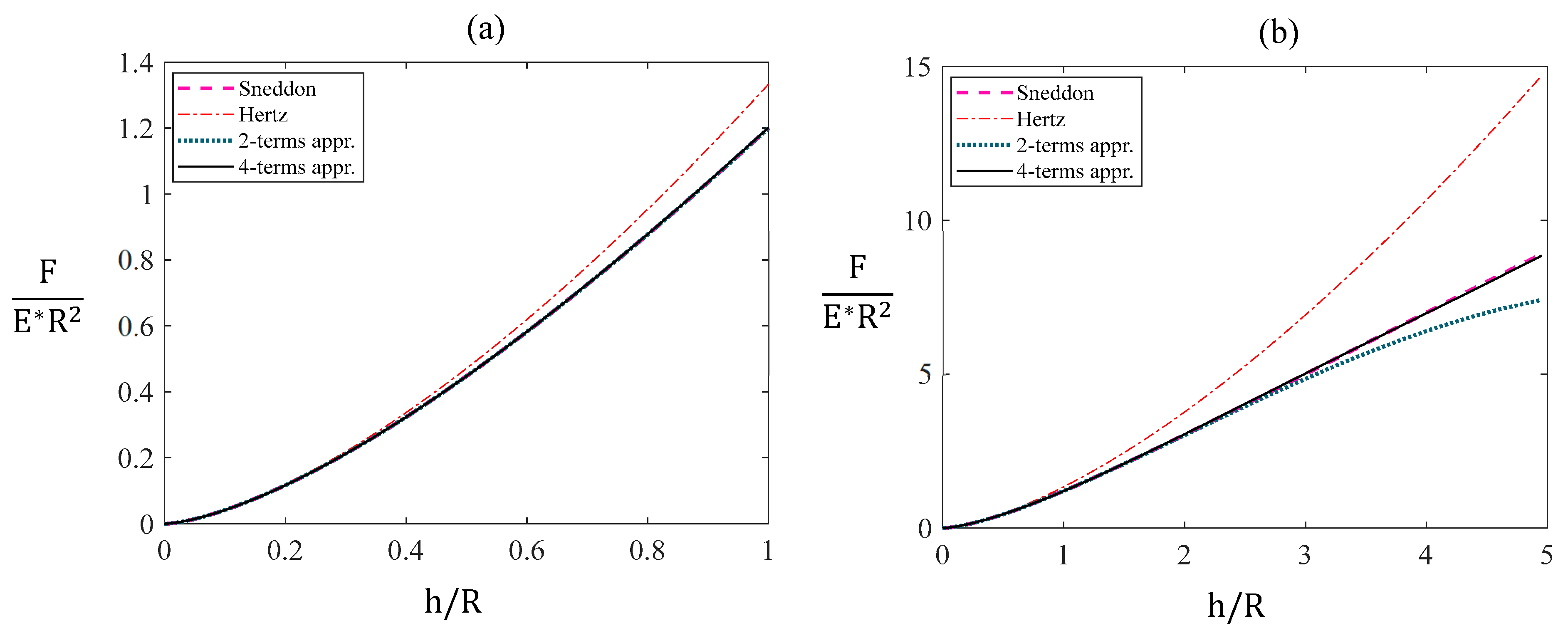

| Müller et al., 2019 [42] | Note: It fails to capture the system’s behavior for large indentations. |

| Kontomaris & Malamou 2021 [40] | where . Note: It leads to errors for shallow indentations (Hertzian limit) since it was designed for deep indentations. |

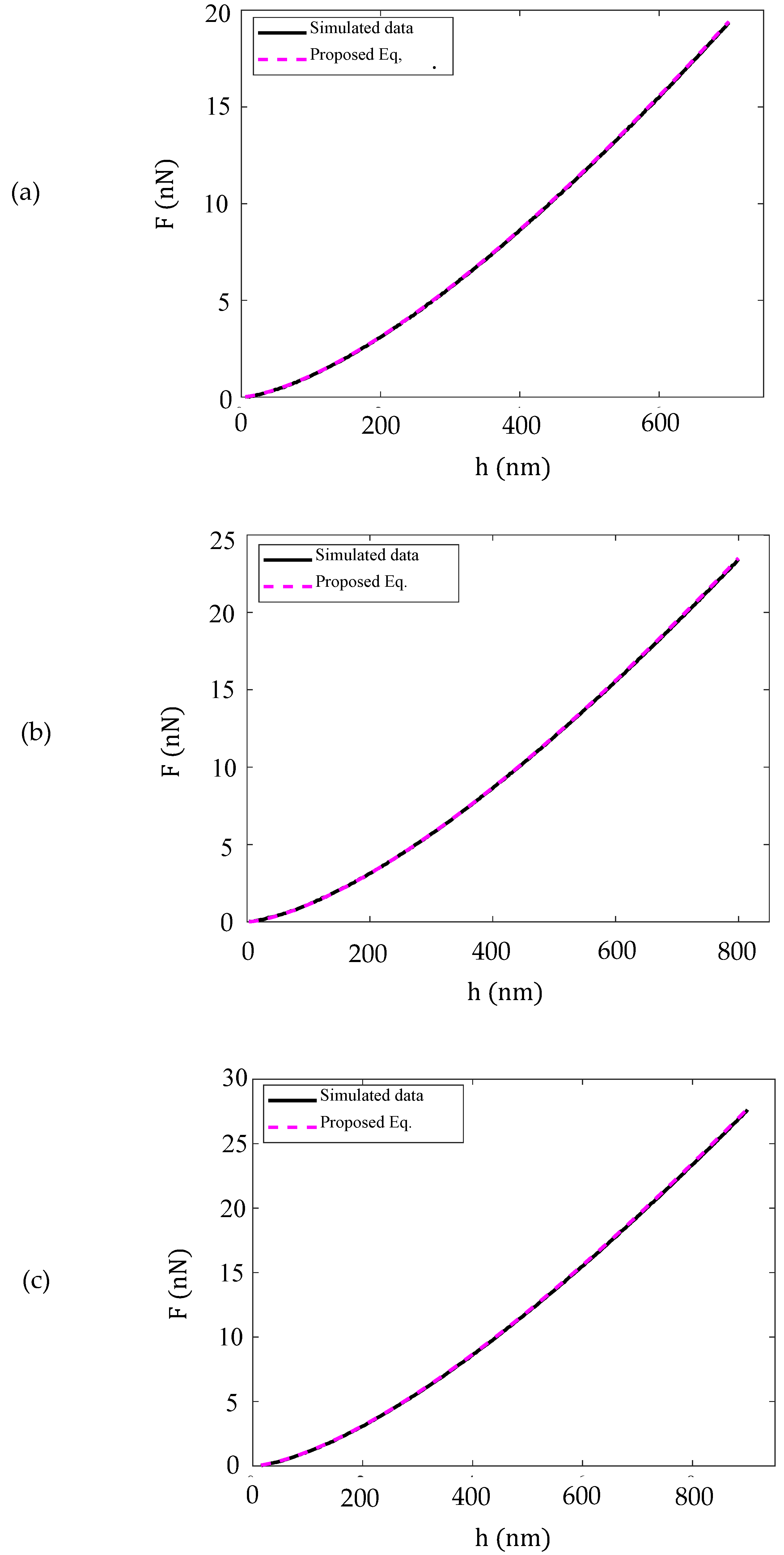

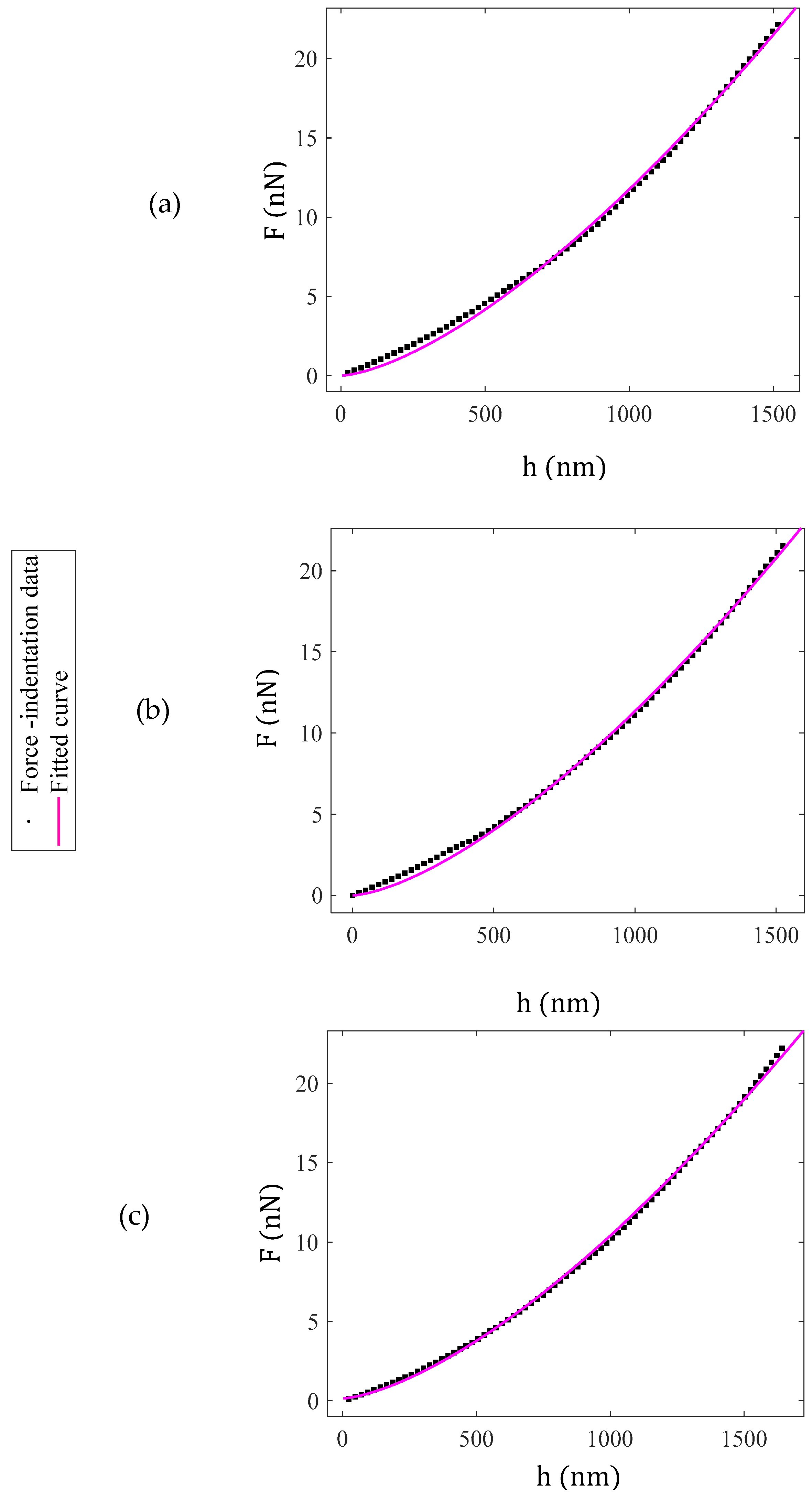

| Two-term solution | . |

| Four-term solution | Note: Perfectly accurate for any indentation depth. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kontomaris, S.-V.; Malamou, A.; Ismail, G.M.; Katsiki, A.; Stylianou, A. Beyond Hertz: Accurate Analytical Force–Indentation Equations for AFM Nanoindentation with Spherical Tips. Metrology 2025, 5, 63. https://doi.org/10.3390/metrology5040063

Kontomaris S-V, Malamou A, Ismail GM, Katsiki A, Stylianou A. Beyond Hertz: Accurate Analytical Force–Indentation Equations for AFM Nanoindentation with Spherical Tips. Metrology. 2025; 5(4):63. https://doi.org/10.3390/metrology5040063

Chicago/Turabian StyleKontomaris, Stylianos-Vasileios, Anna Malamou, Gamal M. Ismail, Anna Katsiki, and Andreas Stylianou. 2025. "Beyond Hertz: Accurate Analytical Force–Indentation Equations for AFM Nanoindentation with Spherical Tips" Metrology 5, no. 4: 63. https://doi.org/10.3390/metrology5040063

APA StyleKontomaris, S.-V., Malamou, A., Ismail, G. M., Katsiki, A., & Stylianou, A. (2025). Beyond Hertz: Accurate Analytical Force–Indentation Equations for AFM Nanoindentation with Spherical Tips. Metrology, 5(4), 63. https://doi.org/10.3390/metrology5040063