1. Introduction

Research and development in materials science is continuously advancing, leading to the emergence of advanced materials such as nanomaterials, composites, biomaterials, and high-performance metals. These materials possess unique properties, offering potential innovative applications across various industries. For their successful implementation in industry and market integration, reliable quality assessments of these materials are essential, with standardization playing a pivotal role. The scientific community has shown growing interest in the standardization of emerging advanced materials, fostering productive discussions between researchers and standardization experts [

1,

2]. The importance of material standardization is closely linked to metrology, which affects the reliability of material assessments.

As interest in this area grows, the relationship between metrological protocols and industrial innovations has been widely explored in various studies [

3]. International standardization activities in ISO and IEC began in the mid-2000s on nanotechnology, with a focus on developing standards for material specification and testing standards [

4].

Standardization can ensure the consistency and reliability of material assessments for application industries and markets. In the case of established materials like steel, material specification standards function effectively by explicitly defining allowable ranges for key characteristics and relying on standardized measurement methods and procedures. However, such a rigid approach cannot be directly applied to emerging advanced materials due to their measurement uncertainties, technological advancements, and evolving market demands. Given these challenges, this paper offers a flexible and robust approach to developing testing standards for the quality assessment of emerging advanced materials. It is important that this standardization can create opportunities for efficiently connecting outcomes of basic research and their industrial applications.

In response to the challenges posed by emerging advanced materials, this paper presents a structured methodology for developing flexible and robust quality testing standards to assess their performance and suitability for industrial applications. It begins by exploring the overall structure of standardization frameworks, comparing both established and emerging materials, and examining differences between material specification and quality testing standards. Based on these considerations, a scenario-based methodology is offered, which systematically identifies key tasks, integrating them into a standardized framework for quality testing standards development. The methodology incorporates metrology as a central element for developing quality testing standards, particularly by evaluating various stages of measurement techniques.

An essential aspect of this methodology is metrology, which plays a critical role in ensuring the flexibility and reliability of quality testing standards. The most critical aspect is evaluating the stages of validity, maturity, and applicability of measurement methods and procedures. Based on these stages, normative statuses are identified for each measurement method and procedure. These statuses can be categorized as requirements, recommendations, or information provisions depending on the stages, which helps ensure appropriate specification in quality testing standards. Furthermore, as metrological techniques advance and market demands become more specific, quality testing standards are updated and may ultimately transition into material specification standards for established materials.

It should be noted that, in this study, measurement methods, which establish measurement principles, and measurement procedures, which specify detailed measurement processes, are distinguished as separate concepts.

Hereafter, throughout this paper, “quality testing standard” is referred to as “testing standard” for simplicity.

2. Frameworks of Materials Standardization

This chapter analyzes fundamental frameworks of material standardization. Material production and market transactions are described in terms of standardization. Two types of materials, established and emerging, are explored in terms of their attributes. Additionally, two types of standards are comparatively examined: material specification standards and testing standards.

2.1. Material Production and Market Transactions

Figure 1 illustrates typical production and transaction chains for materials. A material manufacturer procures source materials, produces materials, and supplies them to intermediate product manufacturers, such as those producing composites, coatings, bulk materials, and suspensions. These production and transaction chains extend to the final consumers.

At every interface between adjacent manufacturing layers in

Figure 1, commercial contracts require reliable quality assessments of traded goods. Standards facilitate market transactions of materials by ensuring transparency, fairness, and reliability. Between material manufacturers and users (indicated as intermediate manufacturers) in

Figure 1, standards define the types of materials to be assessed, their key characteristics influencing intended applications, allowable ranges of characteristics where applicable, measurement methods and procedures, and reporting requirements for material manufacturers.

Figure 2 specifically illustrates market transactions between material manufacturers and users. Materials can be traded in two ways: through public catalog listings or private procurement specifications. In either case, material manufacturers provide users with the purchased materials along with testing reports or certificates. Standards support them by offering guidelines to facilitate these transactions.

2.2. Types of Materials

This section examines two types of materials: established materials and emerging advanced materials.

Table 1 compares their attributes.

Established materials are widely used in mature markets. Since their applications are clearly defined, the key characteristics influencing these applications are well specified. Material specification standards are effectively applied to these materials, relying on standardized measurement methods and procedures, with allowable ranges of characteristic values. Development methodologies for standards are commonly shared across technical fields.

Emerging advanced materials are still in the early stages of market adoption. While they have broad potential applications, specific application products are often not yet clearly defined due to market dynamics. Measurement methods and procedures may still be under development or in the process of standardization. Rigid material specification standards are not feasible for emerging advanced materials due to their evolving nature. Instead, flexible testing standards are effectively applied, without specified characteristic values. Development methodologies for such standards tend to be independent within each technical field.

2.3. Types of Standards

Table 2 compares the attributes of material specification standards and testing standards.

Material specification standards are defined by common methodologies across technical fields. These methodologies include defining target materials and their applications, specifying allowable ranges for characteristic values, and adopting standardized measurement methods and procedures. This type of standard mandates the exclusive use of a specified measurement method and procedure, thereby ensuring baseline material quality and facilitating broader industrial implementation. For example, approximately 100 material specification standards and 200 measurement procedure standards have been established for steel at both international and national levels.

In contrast, testing standards are applied to emerging advanced materials to assess material quality. While they define target materials, intended applications, and measurement methods and procedures, they do not specify fixed characteristic values. Testing standards offer recommendations and informational guidelines to accommodate the inherent uncertainties of emerging advanced materials. Consequently, multiple measurement methods and procedures may be recommended, allowing manufacturers and users to select the most appropriate ones for their specific needs. However, the chosen measurement method and procedure must be documented and disclosed to users.

The following testing standards play a crucial role in enabling market adoption of emerging advanced materials by:

Promoting consistency and transparency through objective quality assessment frameworks;

Enhancing confidence by providing credible, reproducible data;

Facilitating market entry by aligning materials with industry benchmarks and regulatory requirements.

2.4. Standardization Processes

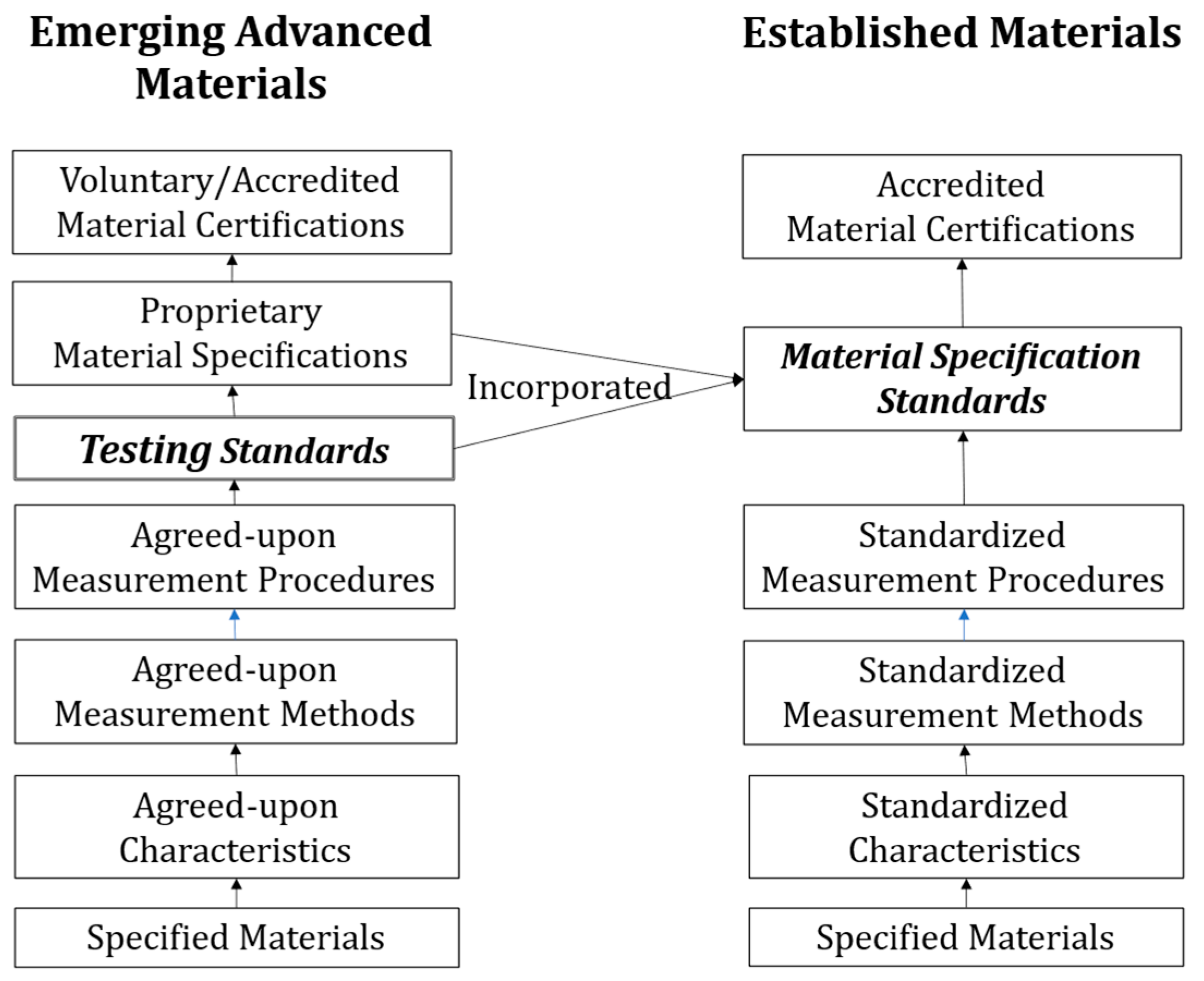

Figure 3 illustrates typical standardization processes for established and emerging advanced materials. In both cases, the process begins by defining target materials and determining their characteristics using specified measurement protocols, which include methods and procedures.

For established materials, applications are well defined, and the characteristics to be measured are clearly identified. Validated measurement methods and procedures are then applied directly, enabling the straightforward development of material specification standards. These standards can be employed for material certifications by accredited certification bodies, ensuring material quality.

For emerging advanced materials, the characteristics to be measured are sometimes unclear due to varying intended applications in the evolving market, and the measurement methods and procedures are often not yet standardized due to the material’s novelty. Specifications must therefore be established individually by manufacturers and users. Under such uncertain conditions, testing standards can provide them with guidance on selecting appropriate characteristics and measurement approaches. Manufacturers may provide their proprietary specifications, bypassing standardized ones, and voluntary bodies may conduct material certification.

As technologies mature and markets stabilize, proprietary material specifications can transition into formal standards. Ultimately, both proprietary specifications and testing standards are integrated into comprehensive material specification standards.

3. Scenario-Based Methodologies for Quality Testing Standards

This chapter presents comprehensive methodologies for systematically developing testing standards for assessing the quality of emerging advanced materials. These methodologies are organized into a structured process, referred to as ‘scenario-based methodologies.’ Elements of these methodologies have been partially incorporated into the development of ISO testing standards for nanomaterials. For a deeper understanding, see [

5] (pp. 2–9), which discusses the fundamental concept behind these methodologies.

3.1. Scenario-Based Methodologies

A typical scenario is illustrated in

Figure 4. It outlines a staged process for integrating key tasks into a testing standard. This scenario encompasses essential approaches for developing an effective testing standard that is well-structured, clearly defined, and beneficial to relevant industrial communities.

Throughout the process, emphasis is placed on ensuring flexibility and robustness in testing standards, considering the uncertainties inherent in emerging advanced materials. Particular emphasis is placed on adaptability and the reliability of measurements.

The scenario consists of the following sequential stages:

- (a)

Market and literature surveys;

- (b)

Identification of key standardization issues;

- (c)

Definition of scope;

- (d)

Specification of standardized items;

- (e)

Finalization of the overall process;

- (f)

Achievement of the goal.

Note that the process may not follow a strictly linear path from Stage (a) to Stage (f); iterative refinements may be necessary to ensure overall harmonization and consistency.

It is recommended that a scenario be prepared before drafting the standards, with careful execution of standardization tasks.

3.2. Market and Literature Surveys

In Stage (a) of the scenario, market and literature surveys are conducted on emerging advanced materials that are industrially manufactured. The survey involves manufacturers (sellers) and users (buyers) of these materials within the production chain. It is important to survey testing laboratories specialized in measuring relevant characteristics. If there are health or safety concerns regarding these materials, consumers and regulatory authorities should also be included.

A review of the literature on relevant emerging advanced materials is essential. It covers existing standards, scientific papers, and technical reports that discuss these materials, their characteristics, and measurements.

3.3. Identification of Key Issues

During Stage (b), the focus shifts to identifying key standardization issues related to emerging advanced materials, laying the foundation for scope definition in the next stage. Among these, the key priority is to identify potential emerging advanced materials for standardization, with priority given to those of global interest and commercial use.

It is crucial to identify the intended application fields and specific products that utilize emerging advanced materials and define their desired performance. The characteristics to be measured are determined based on the intended applications, as these characteristics represent the quality of the materials.

Relevant references, such as existing standards, scientific papers, and technical reports, are also identified. The literature serves as technical evidence supporting the development of testing standards.

3.4. Scope Definition

In Stage (c), the scope of testing standards for emerging advanced materials is defined. The scope serves as the core of the standard, indicating what is standardized. All other clauses must align with the defined scope. Typical items defined in the scope include the following:

- (a)

Target Materials: Essential attributes are clearly stated to identify the target materials for standardization. These attributes should be scientifically precise and rigorously outlined to avoid ambiguity. Common attributes include material types, chemical composition, crystallinity, and form (bulk, powder, suspension, composite, porous materials, etc.). Commercial brand names and manufacturing methods should be excluded, as well as the desired material quality;

- (b)

Material Applications: Intended applications of the target materials are defined, specifying general application fields or specific products. Desired performance for the intended applications may also be stated;

- (c)

Material Characteristics: Types of material characteristics to be measured are defined, including physical, chemical, engineering, biological, and toxicological properties;

- (d)

Measurement Methods: It is stated whether applicable measurement methods for determining material characteristics are specified;

- (e)

Measurement Procedures: It is stated whether measurement procedures for the specified methods are defined;

- (f)

Exceptions: Any exceptional matters not addressed in the testing standard can be explicitly stated;

- (g)

Purpose: When necessary, the intent and purpose of the testing standard are clarified.

4. Metrological Specifications and Normative Status

In Stage (d) of the scenario, standardized items are specified in detail according to the defined scope. This stage includes specifying the characteristics to be measured for the target materials, selecting applicable measurement methods, identifying adopted measurement procedures, and determining the reported items. This chapter defines the normative status of specifications and discusses their application to characteristics, measurement methods, and procedures. The normative statuses and their criteria are summarized in

Table 3, each of which is then explained in detail.

4.1. Normative Status of Specifications

Each specification in a standard falls into one of the following normative statuses: required, recommended, or informatively provided. As ISO Directives Part 2 defines [

6], requirements indicate that only the specified item(s) are permitted, while others are not allowed, and recommendation suggests that the specified item(s) should preferably be taken, but others are also allowed. The assigned status depends on how well a specification meets the corresponding criteria. For the purposes of this paper, the symbols N and I indicate whether a specification is normatively required (N) or either recommended or informatively provided (I), respectively. The primary focus of this paper’s metrological approach is the normative status of measurement methods and procedures specified in standards.

4.2. Characteristics

Characteristics subject to measurement are the physical, chemical, or biological parameters of emerging advanced materials that influence the performance of application products. Various characteristics are identified and evaluated to assess comprehensive material quality. These characteristics may be either intrinsic properties or those defined by specific measurement methods. To ensure clarity for standard users, precise definitions should be established based on scientific principles or international standards.

The selection of characteristics for measurement depends on their relevance to the intended application, with priority given to the unique features of emerging advanced materials. These characteristics may include dimensional, structural, chemical, biological, mechanical, optical, and thermal properties.

In addition to technically significant properties, commercially important characteristics are also prioritized for measurement. Examples include moisture content for powders, dry matter content for suspensions or dispersions, and loss on ignition for solids. These characteristics also influence further processing, storage stability, and end-use performance.

The normative status of characteristics is classified based on their significance to the intended application as follows:

Core characteristics, which are essential for general applications and must be measured;

Optional characteristics, which are relevant to specific applications and recommended for measurement;

Informative characteristics, which may become necessary under certain conditions and are provided as supplementary information.

These classification methodologies have been incorporated into the ISO testing standards for clay nanoplates [

7] (pp. 2–5), cellulose nanofibrils [

8] (pp. 2–9), and nanostructured magnetic beads for nucleic acid extraction [

9] (pp. 4–10).

4.3. Measurement Methods

The normative status of measurement methods is evaluated based on their validity, maturity, and applicability to the target materials.

4.3.1. Validity of Measurement Methods

The validity of a measurement method depends on the clarity of its definition and the quality of measurement results. Measurement method definitions are typically established by academic societies or standardizing organizations. The levels of definition are categorized in descending order of rigor as follows:

- (a)

Defined by recognized academic societies;

- (b)

Defined by international or national standardizing organizations;

- (c)

Defined by consortia or industrial associations.

For example, ISO documents [

10,

11] specify the definitions and applicability of various measurement methods for nanomaterials.

The consistency of measurement results is assessed based on accuracy, repeatability, and reproducibility. These aspects are typically evaluated in scientific papers and technical reports. If appropriate reference materials are available, accuracy can also be evaluated using certified reference materials.

4.3.2. Maturity of Measurement Methods

The criteria for maturity include industrial accessibility, global availability, cost-effectiveness, and ease of equipment operation. The maturity levels of measurement methods are categorized in descending order of rigor according to their level of endorsement:

- (a)

Endorsed by international standards;

- (b)

Endorsed by national standards;

- (c)

Endorsed by consortia or industrial standards.

4.3.3. Applicability of Measurement Methods

When assessing the applicability of a measurement method to the target materials, it is categorized based on the material type into three levels in descending order of rigor as follows:

- (a)

Demonstrated specifically with the target materials;

- (b)

Demonstrated with materials of a similar type to the target materials;

- (c)

Demonstrated with materials of a different type from the target materials.

4.3.4. Determination of Measurement Methods’ Normative Status

The normative status of a measurement method is determined based on a comprehensive evaluation of its validity, maturity, and applicability. These indicators are assessed in terms of their acceptance in industry and market. A lower level in any of these indicators may result in a lower normative status, whereas a higher level may enhance it.

These methodologies for determining the normative status of measurement methods have been incorporated into the ISO testing standards for clay nanoplates [

7] (pp. 2–5), cellulose nanofibrils [

8] (pp. 2–9), and nanostructured magnetic beads for nucleic acid extraction [

9] (pp. 4–10).

4.4. Measurement Procedures

Measurement procedures for a specific measurement method are specified based on their validity, maturity, and applicability, taking into account related characteristics and target materials.

4.4.1. Validity of Measurement Procedures

The validity of a measurement procedure refers to the reliability of the measurement results when obtained according to the procedure for specific characteristics. Reliability is assessed in terms of accuracy, repeatability, reproducibility, and consistency.

Accuracy in measurement results can be assessed by comparing them with the reference values of certified reference materials available for the same type as the target materials. Repeatability and reproducibility, as defined in 3.12 and 3.13, are assessed based on variations in data obtained by an organization or an individual according to the specified measurement procedure. Consistency is evaluated by comparing measurement data from different organizations and individuals under identical conditions, typically through interlaboratory comparisons.

These aspects are typically assessed and referenced in scientific papers, technical reports, or industrial practices.

4.4.2. Maturity of Measurement Procedures

Measurement procedures for specific measurement methods should be documented and standardized. Their maturity levels are classified based on the developing entities, as listed below in descending order of rigor:

- (a)

Standardized by international or national standards organizations;

- (b)

Standardized by consortia or industrial associations;

- (c)

Documented in peer-reviewed scientific papers or technical reports;

- (d)

Documented by individual companies.

Refer to the Standards Maturity Levels (SML) described in IEC TS 62565–1 [

12] (pp. 17–20) for evaluating the maturity of measurement procedure standards.

4.4.3. Applicability of Measurement Procedures

The applicability of measurement procedures is classified into three levels in descending order of rigor:

- (a)

Demonstrated exactly with the target materials;

- (b)

Demonstrated with materials of a similar type to the target materials;

- (c)

Demonstrated with materials of a different type from the target materials.

4.4.4. Determination of Measurement Procedures’ Normative Status

The normative status of a measurement procedure is evaluated based on a comprehensive review of its validity, maturity, and applicability. It is determined by assessing these indicators based on their acceptance in industrial and commercial applications. A lower level in any of these indicators may lead to a lower normative status, while a higher level in any of these indicators may enhance the normative status.

These methodologies for determining the normative status of measurement procedures have been incorporated into the ISO testing standards for clay nanoplates [

7] (pp. 7–11), cellulose nanofibrils [

8] (pp. 10–26), and nanostructured magnetic beads for nucleic acid extraction [

9] (pp. 4–10).

4.5. Reporting of Measurements

The reporting of test results for emerging advanced materials is essential for effective communication between manufacturers and users. Testing standards specify both general information on the target materials, such as their basic attributes, and specific metrological information, which typically requires the following:

Measurement methods used for individual characteristics;

Measurement procedures used for individual measurement methods, such as sample preparation, experimental conditions significantly influencing results, and data analysis;

Measurement results—the average of measurement data obtained;

Uncertainties in the measurement results, including at least repeatability and reproducibility of data.

These methodologies for reporting test results have been applied to the ISO testing standards for clay nanoplates [

7] (pp. 5–6), cellulose nanofibrils [

8] (p. 9), and nanostructured magnetic beads for nucleic acid extraction [

9] (p. 10).

5. Standards’ Flexibility and Metrological Reliability

This chapter describes the methodologies for introducing flexibility into testing standards and assessing the reliability of measurement results.

5.1. Introducing Flexibility into Testing Standards

Flexibility within testing standards refers to the capacity to modify the normative status of specifications through mutual agreement between the manufacturer and the user. As characteristics and their measurement protocols depend on emerging advanced materials and their applications, situations may arise where the normative status should be adjusted to meet standard users’ needs. Consequently, testing standards incorporate a certain degree of flexibility in implementing their specifications.

There are two primary approaches to incorporating flexibility into testing standards: predefined flexibility in standards and justified deviations.

The first approach embeds flexibility within the testing standard by incorporating varying normative statuses for specifications. For example, instead of requiring a single measurement method, a testing standard may recommend multiple methods, allowing standard users to select the most appropriate one for their materials and conditions. This flexibility enables users to adapt to specific situations concerning their emerging advanced materials and assessment conditions.

The second approach permits deviations from the standard if properly justified and documented. For instance, a measurement method or procedure may differ from the standard if an alternative approach is justified for a specific application and agreed upon by buyers and sellers. In such cases, these deviations and their justifications must be formally recorded and reported.

These two approaches broaden the applicability of testing standards, particularly for users dealing with emerging advanced materials. ISO has issued testing standards that incorporate these flexibility approaches.

5.2. Reliability Assessment of Measurement Results

Reliability represents the uncertainty in measurement results, including consistency and accuracy. Uncertainty can exist even when data are obtained in strict accordance with the specified measurement methods and procedures. Typically, such uncertainty can be evaluated at the industrial level through interlaboratory comparisons of measurement data. The variation in measurement results is assessed to determine the consistency of the data.

Introducing flexibility, such as allowing different measurement methods, into testing standards may increase variability in measurements across different organizations and individuals. Therefore, testing standards should require testing laboratories and/or material manufacturers to assess and report measurement uncertainty. At a minimum, this assessment should address measurement repeatability and reproducibility. Furthermore, testing laboratories’ measurement capability, as evaluated by certification bodies, should be reported, along with proficiency testing results and interlaboratory comparison results, where applicable.

6. Evolution of Standardization for Emerging Advanced Materials

Testing standards for emerging advanced materials define and standardize the following specifications:

Target materials and their intended applications;

Key characteristics that influence application performance;

Measurement methods for these characteristics;

Measurement procedures for these methods.

The normative status of each specification is determined individually in accordance with the current state of technology and market conditions. Testing standards still evolve even after their first publication, gaining greater normative significance as metrological techniques advance and market conditions develop.

6.1. Progression of Normative Status in Testing Standards

The Provision Normative Level (PNL) indicates the degree of requirement for a provision regarding characteristics and measurements. The levels are determined based on the validity, maturity, and applicability of each standardized specification. These criteria apply to characteristics, measurement methods, and measurement procedures specified in the standards.

Table 4 lists PNLs in ascending order of normative status from Level 1 to 10. The symbol ‘N’ indicates mandatory adoption, while ‘I’ indicates that the specifications are recommended or provided for informational purposes. A dash ‘–’ means the specifications are not included in the provision and are subject to market agreements between buyers and sellers.

The PNL is determined based on whether the criteria align with industry standards or benchmarks. As measurement technologies advance and markets evolve, the PNL increases, reflecting higher sophistication and broader industrial acceptance.

In the progression of PNL levels, once the 10th level is reached, the standards transition from testing standards to material specification standards.

6.2. Standardization Pathway: From Quality Testing to Material Specification

After the publication of the first edition of a testing standard for emerging advanced materials, the standard may evolve as measurement technologies advance and market demands become more specific.

Figure 5 illustrates this progression, showing the stages of evolution in material characteristics, measurement methods, and procedures as market demands become more specific. Vertical arrows represent the chronological development of each specification, while dashed horizontal arrows indicate logical relationships between them.

As market demands for emerging advanced materials become more specific, applications progress from general to specialized uses, eventually leading to actual products. Correspondingly, the normative status of material characteristics shifts from informative to normative. This transition generally follows a structured process: initially providing descriptive information, then offering recommendations, and ultimately establishing mandatory requirements.

As measurement technologies advance, measurement methods and procedures evolve. This progression enhances measurement data consistency, reducing variability, as shown schematically in

Figure 5. The availability of reference materials further enables quantitative validation of measurement procedures. Following this trend, descriptions of measurement methods and procedures evolve from documentation to standardization, and from informative to normative specifications.

To stay relevant with technological advancements and evolving market demands, regular updates to testing standards are essential. As normative requirements become increasingly stringent, testing standards eventually transition into material specification standards, as is the case for established materials.

7. Conclusions

Emerging advanced materials are expected to drive innovation across various industries. However, a standardized framework for assessing their properties and performance remains underdeveloped. This paper offers a new approach: flexible and robust testing standards tailored to these materials, providing an alternative to the rigid material specification standards traditionally applied to established materials.

To assess material quality amid the uncertainties inherent in emerging materials, this paper presents methodologies for developing adaptable testing standards. These standards serve as a technical foundation to ensure consistency and transparency in industrial applications and market transactions, thereby enhancing user confidence in the materials they purchase. Specifically, the scenario-based methodologies enable standards developers and stakeholders to identify key standardization tasks and integrate them effectively into robust testing standards.

Achieving flexibility and reliability in quality assessments is vital for emerging advanced materials. Metrology plays a central role in defining measurement methods and procedures for determining material characteristics. Appropriately selecting the normative status—such as requirement, recommendation, or informational provision—relies on evaluating the validity, maturity, and applicability of the specifications. This paper emphasizes the importance of evaluating measurement uncertainty to ensure reliability and recommends prioritizing flexible specifications to enhance adaptability.

Furthermore, continuous revision of these standards is essential to align with advances in measurement technology and evolving market demands.