3.1. Identification of Factors Causing Road Construction Delay

The identified factors causing delays in road construction projects were systematically grouped into categories based on thematic similarity, ensuring a coherent analysis of their shared characteristics. This categorization process was essential to organize the diverse factors into meaningful groups for better understanding and addressing the delays effectively. Supporting references for each factor with corresponding codes that fall under every criterion are shown in

Table 3.

Factors related to clients were grouped, including delays in payments for completed work and economic difficulties faced by contractors. These financial challenges directly impact the cash flow and resource availability, critical for project continuity. Studies such as those by Abdul-rahman et al. (2011) [

7] and Dolage and Pathmarajah (2015) [

6] emphasized the significance of financial stability in preventing project delays.

- 2.

Contractor

Contractor-related factors were grouped based on subcontractor performance, site management, inadequate construction methods, and improper planning. This category underscores the critical role of contractors in ensuring efficient project execution. R. F. Aziz and Abdel-Hakam (2016) [

8] discussed how contractor performance directly affects project timelines and quality.

- 3.

Consultants

Consultant-related factors included aspects like contract management, preparation of drawings, and quality assurance. The efficiency and competence of consultants in managing and overseeing construction projects were identified as vital for preventing delays. Vaidya and Kumar (2006) [

10] highlighted the impact of consultant performance on project success.

- 4.

Material

Material factors were categorized, focusing on delays in material delivery and quality issues. Effective material management is crucial for maintaining a steady workflow on construction sites. Orji et al. (2016) [

5] discussed how material management is essential for timely project completion.

- 5.

Labor and Equipment

Labor and equipment factors were categorized, focusing on labor productivity, supply, and availability. These logistical issues are crucial for maintaining a steady workflow on construction sites. Orji et al. (2016) [

5] discussed how labor and equipment management are essential for timely project completion.

- 6.

Contractual Relationships

Contractual relationship factors included major disputes and negotiations, inappropriate overall organizational structure, and lack of communication between parties. These issues can significantly disrupt the project timeline and quality. Effective communication and clear contractual agreements are essential to prevent delays.

- 7.

External Factors

Finally, external factors such as weather conditions, regulatory changes, and unforeseen ground conditions were grouped based on their nature outside the project stakeholders’ direct control. These external influences can unpredictably impact project schedules. Sweis (2008) [

2] identified these factors as significant contributors to delays in construction projects.

The identification of delay factors was grounded in an extensive literature review covering both international and Philippine-specific studies on construction delays. Several sources emphasized recurring causes such as inadequate financial management, delayed payments, poor subcontractor performance, scheduling inefficiencies, and regulatory bottlenecks as primary contributors to delays in road infrastructure projects [

4,

5,

7,

8,

40]. These causes are not isolated; rather, they interact across project stages and stakeholder responsibilities, particularly in public-sector construction managed by agencies like DPWH. The review also highlighted the lack of an integrative, stakeholder-aligned framework that considers localized factors such as right-of-way clearance, procurement hurdles, and climatic vulnerability, which are distinct challenges in the Philippine setting [

25,

52]. Based on thematic analysis of the reviewed literature and further validated by expert consultation, delay factors were categorized into seven domains—Client, Contractor, Consultant, Materials, Labor and Equipment, Contractual Relationships, and External Factors. These are summarized in

Table 3 and further analyzed in

Section 3.3 to reflect their relevance in real-world construction management. This literature-backed approach ensures that the framework is both evidence-informed and contextually grounded.

The identified factors were validated through a focus group discussion with the district engineer. This expert validation confirmed that all listed factors apply to road construction projects in the district, ensuring the factors’ relevance and accuracy. The focus group emphasized prioritizing each factor to determine its relative significance. This prioritization is critical for the AHP analysis, which requires a structured approach to ranking these factors based on their impact on project delays. Additionally, the respondents suggested ranking the main criteria categories; by prioritizing these factors and ranking the main criteria, the analysis can provide a comprehensive view of the most critical areas requiring attention.

3.2. AHP Analysis and Evaluation

Factors causing delays in road construction were identified and assessed using the AHP. Experts participated in the assessment, including consultants, project engineers, project inspectors, contractors’ project managers, and specialists from academic institutions. These experts, drawn from government agencies (DPWH), private consultants, and contractors, evaluated the factors through online and printed pairwise comparison questionnaires. The objective was to determine the weights of each factor to prioritize the most significant causes of delays. The AHP hierarchy was constructed, breaking the decision into three levels: goal, criteria, and indicators. The primary goal, placed at the top of the hierarchy, was to analyze the main factors affecting road construction delays. The second level comprised the main criteria: clients, contractors, consultants, material, labor and equipment, contractual relationships, and external factors. These criteria were detailed to guide decision-making. The lowest level included the specific factors or indicators for decision-makers.

Figure 2 illustrates the hierarchical tree representing the goal, criteria, and factors. A pairwise comparison questionnaire was prepared and distributed online and face-to-face to fifteen (15) experts from road construction and academia, each with 5–20 years of experience in road construction.

Table A1 lists these experts and their qualifications, ensuring their eligibility to provide informed responses for the AHP analysis.

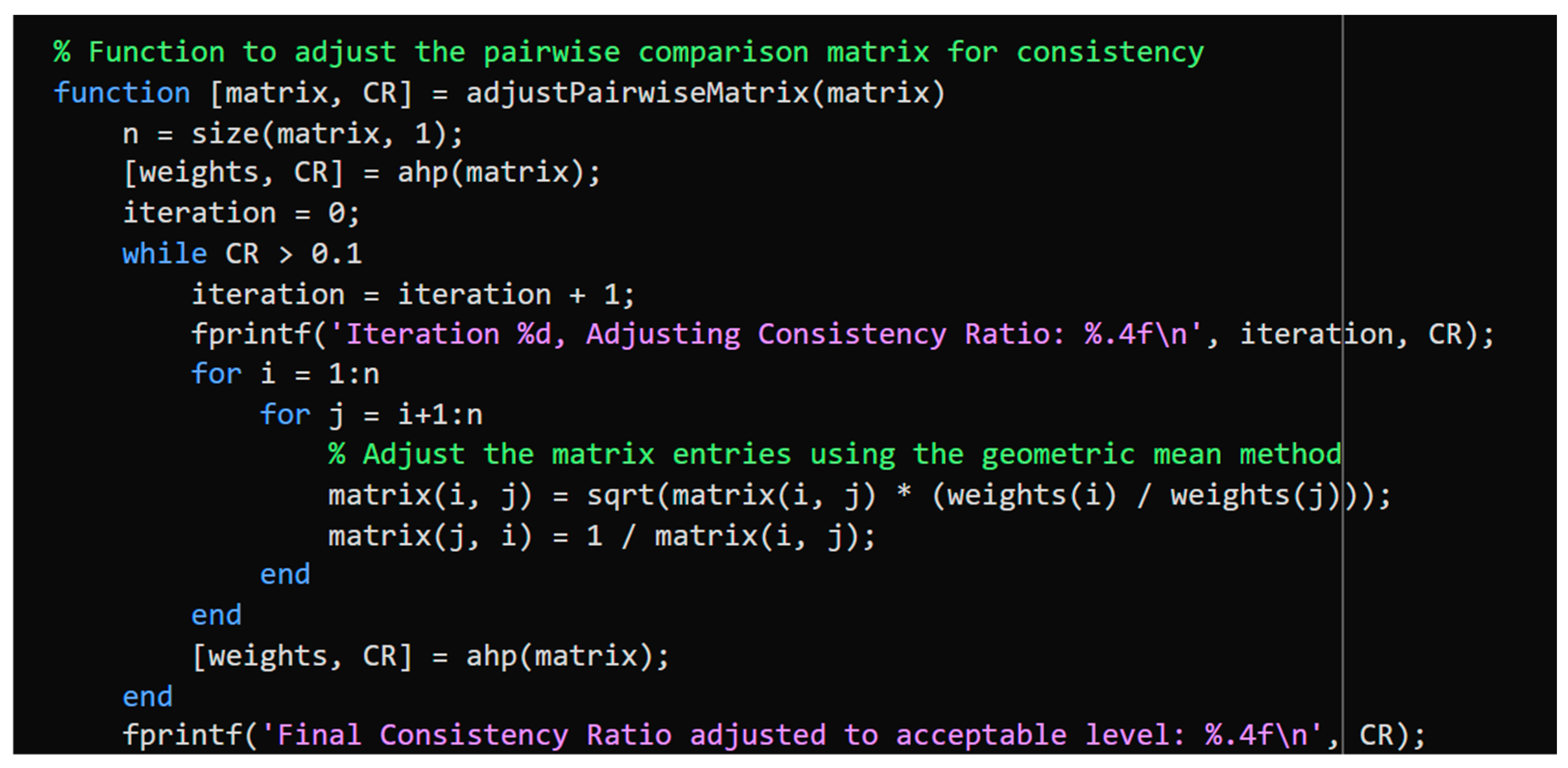

A customized MATLAB 2024B script was developed to automate the pairwise comparison matrix processing, eigenvector calculation, consistency ratio (CR) validation, and final priority weight derivation in the AHP model. Using the formula of the AHP process, pairwise comparison results were encoded to sheets and transposed into MATLAB codes to ease solving the method.

Table 4 summarizes all the factors with their initial and adjusted weights based on the AHP analysis coded in MATLAB. Only the ‘client’ and ‘contractor’ criteria have an adjustment using the geometric method (see example of adjustment code in

Figure 3), and the rest of the factors have no adjustment, noting that all of their CR is below 0.10 or 10%, which satisfies the AHP analysis consistently. The code allowed systematic handling of the expert responses and ensured accuracy in calculating weights across multiple stakeholders and criteria. This computational tool enhanced the transparency and reproducibility of the analysis, minimizing manual calculation errors and enabling the scalable application to other similar datasets.

To promote transparency and reproducibility, the complete MATLAB 2024b code used in this study is provided as a

Supplementary File (

Supplementary File S1). It includes annotated functions for matrix construction, normalization, consistency checking, and weight aggregation, and may be adapted by other researchers or practitioners conducting similar AHP analyses.

The result of AHP has shown and ranked essential factors in every criterion considered in this study.

Figure 4 shows the radar chart of each criterion to emphasize the relative importance and weight value based on the AHP of various factors.

To ensure the reliability and internal consistency of expert judgments in rating the severity of road construction delay factors, Cronbach’s Alpha was calculated for each category. Cronbach’s Alpha is a widely used statistical measure that determines how well a set of survey items measures the same underlying concept. A value of 0.7 or higher indicates acceptable reliability, while values below 0.7 may suggest inconsistencies in expert ratings. In this study, Cronbach’s Alpha was computed for each delay criterion, allowing us to assess the consistency of responses across financial, managerial, material-related, and other critical delay factors. The results are presented in

Table 5, which provides the computed Cronbach’s Alpha values per category.

The CI from the AHP ensures the logical consistency of expert judgments; however, it does not validate whether responses are statistically reliable. To address this limitation, Cronbach’s Alpha is incorporated to provide a more robust validation framework. CI ensures that experts’ pairwise comparisons are logically structured and do not contradict one another, while Cronbach’s Alpha confirms whether responses within a specific delay category are statistically consistent. By integrating both CI and Cronbach’s Alpha, this study enhances the reliability of expert assessments, ensuring that the severity rankings of delay factors are both logically and statistically valid. This dual validation approach strengthens the credibility of the results and supports informed decision-making in mitigating construction delays. These statistical measures comprehensively validate expert evaluations, ensuring the identified factors are significant and reliably assessed.

The regression analysis was conducted to validate the relationship between the AHP weight rankings and expert-rated delay severity (refer to

Table 6). Based on responses from 45 engineers and experts from DPWH, LGU, academe, and the private sector, this statistical evaluation aimed to assess whether the AHP-derived rankings align with the perceived severity of delay factors. The correlation coefficient (R) and the coefficient of determination (R

2) were analyzed, along with significance levels (

p-values), to determine the statistical relevance of each factor.

The analysis identified Material-Related Factors (R = 0.788, R2 = 0.789, p = 0.112) and Labor and Equipment Factors (R = 0.956, R2 = 0.913, p = 0.045) as the most influential contributors to road construction delays. Labor and Equipment Factors exhibited a strong correlation (R > 0.95) with statistical significance (p < 0.05), confirming their critical role in predicting project delays. While Material-Related Factors also had a high correlation, its p-value slightly exceeded 0.05, suggesting moderate significance.

Contractual Relationships (R = 0.799, R2 = 0.397, p = 0.370) and External Factors (R = 0.683, R2 = 0.342, p = 0.098) demonstrated moderate correlations with delay severity. However, their p-values were above the 0.05 threshold, indicating that while these factors contribute substantially to project delays, they were not statistically significant at the conventional level.

In contrast, Contractor-Related Factors (R = 0.191, R2 = 0.038, p = 0.522), Consultant-Related Factors (R = 0.300, R2 = 0.321, p = 0.088), and Client-Related Factors (R = 0.161, R2 = 0.069, p = 0.567) exhibited weaker correlations and higher p-values, suggesting that these factors were not strong predictors of delay severity in the regression model. The weak statistical significance of these categories may be attributed to the subjective nature of expert evaluations, external influences not captured in the model, or underlying factors affecting delays that were not fully accounted for in the AHP framework.

The high correlation and R2 values for Material-Related and Labor and Equipment Factors confirm that AHP weight rankings effectively predict project delays, reinforcing the framework’s robustness. The validation survey involving 31 respondents provided a strong empirical basis for statistical testing, strengthening confidence in the model’s predictive capacity. However, for categories with weaker statistical significance, additional refinements—such as incorporating more diverse expert perspectives or adjusting weighting criteria—may be necessary to enhance model accuracy.

While regression analysis is not traditionally used to validate AHP weights in the MCDM literature, it was employed in this study as a complementary validation tool to assess the consistency and explanatory power of the AHP-derived prioritization. By correlating the final weighted scores of delay factors with observed expert judgment rankings (e.g., Likert-scale severity scores), the regression analysis helped verify whether the AHP results align with stakeholder perceptions in practice. This approach has been used in related decision-making contexts to evaluate internal validity and to explore the strength of association between computed priorities and empirical feedback [

25,

27]. Although not a substitute for CR analysis or eigenvalue checks, the regression model served as an additional robustness check to strengthen the reliability of the AHP outcome in a real-world setting.

3.4. Strategic Framework Development

The framework for mitigating delays in road construction, developed using the AHP, identifies several key factors that significantly impact project timelines and outcomes. The final framework is effectively visualized using an Ishikawa (Fishbone) Diagram, as shown in

Figure 5, which categorizes these factors based on their significance and weight. This diagram was chosen for its ability to organize causes under thematic categories, reflecting the structured output of the AHP while making complex interrelationships among delay factors easier to interpret. Each “bone” of the diagram represents a stakeholder domain (e.g., contractor, consultant, client), enabling users to trace specific issues back to responsible parties. To provide a more detailed and actionable guide, an expanded version with proposed mitigation strategies is included in the

Supplementary Material (Supplementary Figure S1), offering an implementation-oriented roadmap aligned with the framework’s prioritized delay factors.

In this diagram, the central spine represents the overall goal of mitigating delays in road construction. The primary bones of the diagram are arranged from top to bottom, reflecting the weight of each factor and rank as determined by the AHP analysis. Factors with the highest weight values significantly impacting construction delays are placed at the top of the diagram. The factors have progressively lower weight values as you move downward, indicating their lesser impact. The diagram is divided into two main sections: ‘High Weight Factors’ and ‘Low/Mid-Weight Factors’. The high-weight factors in the upper section are the priority factors that require immediate attention due to their significant influence on construction delays. The low/mid-weight factors, found in the lower section, still contribute to delays but are of less priority than the high-weight factors.

Each criterion in the diagram is further broken down into sub-categories, representing specific factors contributing to road construction delays. These sub-categories are visually represented as secondary bones branching out from the primary bones. Additionally, mitigation strategies are linked to these specific factors, depicted as tertiary bones. These strategies are designed to address the root causes of the delays, preventing them from affecting subsequent stages of the project.

The fishbone diagram for mitigating delays in road construction provides a structured and prioritized approach to mitigating delays in road construction, ensuring that the most critical issues are identified and addressed first. The precise categorization and visualization of factors and their corresponding weights allow stakeholders to quickly understand which areas require the most attention, facilitating more effective decision-making and project management. While drafting the framework, it was found that some strategies share common solutions across multiple factors. These solutions emerged from the framework analysis and are designed to streamline processes, enhance planning, and improve overall project efficiency.

First, streamlining processes involves implementing strict timelines for approvals and standardizing payment procedures to ensure prompt decision-making and smooth operations, thereby reducing potential delays. Early planning and assessment are crucial, as they involve thorough site and document reviews during the planning phase to anticipate and address potential challenges, such as change orders or unforeseen site conditions, before they impact the project timeline.

Technology and digital tools, such as automated payment systems and digital platforms, are recommended to facilitate faster reviews, approvals, and decision-making processes, all essential for maintaining project schedules. Clear roles and communication within the project team are also emphasized, with clear responsibilities to prevent confusion and reduce unnecessary stakeholder involvement. Efficient communication channels, including regular meetings and dedicated liaisons, ensure that issues are addressed promptly and that all team members are aligned with the project’s goals.

Oversight and accountability are maintained through strict internal controls, regular audits, and the establishment of dedicated committees. These measures ensure transparency, prevent fraudulent practices, and uphold the project’s integrity. By focusing on these common solutions, the framework addresses key factors contributing to delays, leading to more efficient project management and timely completion of road construction projects.

While

Figure 5 presents the core structure of the strategic AHP-based framework, a more detailed implementation roadmap is provided in

Supplementary Figure S1. This supplementary diagram visualizes the full prioritization of delay factors based on AHP weights, categorized under key stakeholder domains (e.g., Client, Contractor, Consultant, External). High-weight and low-weight factors are grouped accordingly, enabling practitioners to identify not only root causes but also the sequence and urgency of recommended mitigation actions. This roadmap can serve as a decision-support tool for agencies like DPWH, allowing them to operationalize the framework in project planning, monitoring, and policy development. This fishbone diagram visually integrates the delay factors across stakeholder domains and illustrates how certain factors (e.g., material shortages, poor planning, or consultant delays) are not isolated, but can influence multiple project aspects.

For instance, material shortages (MA2) are closely linked to contractor-level issues such as inadequate planning (CO6), procurement delays (MA4), and subcontractor mismanagement (CO7). These implicit interconnections are reflected structurally in the supplementary figure, which organizes the framework not only by AHP ranking but also by domain-level cause-effect chains. This provides a more realistic and systemic view of delay mechanisms in Philippine road construction projects. By offering both a high-level overview and a detailed implementation roadmap (

Supplementary Figure S1), we aim to meet the needs of both conceptual understanding and practical application.

The validation process involved ten (10) professionals specializing in road construction, including representatives from the academe, consultancy sector, inspection teams, and primarily from the DPWH (see

Table 7). On average, participants had 17.25 years of industry experience, ensuring that the feedback reflected deep, field-based knowledge. While the group included only one representative each from the consultancy and academic sectors, the emphasis on DPWH officials was intentional and aligned with the study’s objectives. Given that DPWH is the primary implementing agency for public road projects in the Philippines and is directly accountable for addressing delays, focusing on their perspectives was deemed both relevant and essential. These officials regularly encounter systemic and operational challenges tied to delays, such as procurement bottlenecks, contractor non-performance, and right-of-way issues. Their front-line experience offers critical insights into delay mitigation strategies, making their input highly appropriate for validating a framework centered on national road infrastructure delivery. Although broader representation can enhance generalizability, the targeted engagement of DPWH experts ensures the framework is context-specific, practical, and policy-relevant. All experts were selected based on their direct involvement in road construction projects and familiarity with delay-related challenges. Participation was voluntary, and all responses were anonymized to reduce bias.

The mean scores and standard deviations from the expert evaluations are presented in

Table 8. The results indicate a generally positive perception of the framework, with most ratings exceeding 4.0, signifying strong agreement among experts. The highest-rated aspects were “The framework presents the major factors affecting delays” and “The structure of the framework is easy to understand”, both receiving a mean score of 4.6. Meanwhile, the lowest-rated aspect was “The framework effectively mitigates delays”, with a mean of 4.0, suggesting potential areas for improvement.

The validation process provided valuable qualitative insights from experienced professionals in road construction. Experts highlighted several strengths of the framework, suggested areas for improvement, and recommended additional factors that could enhance its effectiveness. The summary of feedback is listed below (

Table 9).

The experts generally found the framework to be clear, structured, and applicable to real-world road construction projects. Many respondents appreciated its detailed categorization of delay factors, which they believed helped in prioritizing the most critical contributors to project delays. One expert noted, “It is simple and can be applied in real situations”, while another emphasized, “The framework prioritizes the factors that actually delay road construction”. The respondents also highlighted that the framework effectively identifies and organizes high-weight and low-mid-weight factors, making it a practical tool for decision-makers.

- 2.

Suggested Improvements

While the framework was well-received, some experts suggested minor refinements to improve its readability and usability. A few respondents recommended simplifying the wording and enhancing presentation clarity to ensure better comprehension. One expert suggested “Minimize wordings and enhance presentation”, while another stated, “It is indeed effective but could be streamlined for better memorability”. These responses indicate that making the framework more concise and visually engaging could improve its accessibility.

- 3.

Additional Factors to Consider

Several respondents recommended incorporating safety-related considerations into the framework. Since road construction is a high-risk industry, experts suggested including safety site precautions and contingency plans for pandemics or unforeseen disruptions. One expert commented, “Safety site precautions as construction is one of the high-risk industries”. At the same time, another recommended: “Safety provisions and contingencies in case of another pandemic or any other causes”. These suggestions highlight the importance of integrating risk management measures into the framework.

- 4.

Final Comments and Recommendations

Some experts emphasized the need for stronger safety measures to protect workers and the general public. One respondent stated, “More focus on safety both for the general public, the contractor’s personnel, and end users”. These comments reinforce the need to expand the framework’s scope beyond time-related delays to include broader project risks.

To further contextualize the findings, a representative road project implemented by DPWH was briefly examined. The project experienced a six-month delay primarily due to issues identified in this study: right-of-way acquisition, limited contractor capacity, and delays in fund disbursement. By mapping these real-world issues against the top-ranked delay factors derived from AHP analysis, we found strong alignment. Moreover, the proposed mitigation strategies, such as early community engagement for right-of-way clearance, prequalification enhancement for contractors, and phased fund releases, were partly adopted in the latter phase of the project, which helped improve schedule adherence. This case highlights the practical relevance and effectiveness of the developed AHP-based framework when applied to actual road construction settings in the Philippines.