Abstract

This paper explores how modular construction can enhance airport sustainability, highlighting example applications at US airports. Whereas traditional construction builds sequentially on-site, modular construction (also known as prefabricated, off-site and industrialized construction) utilizes prefabricated modules that are built off-site, transported, and integrated into the final structure on-site. Modular construction shifts activities to the fabrication site, accelerating the construction schedule on-site and reducing disruptions to airport operations. Modular construction also supports airport sustainability, which encompasses operations, economic, environment and community impacts. Modular construction is increasingly utilized at airports due to its significant advantages: (1) minimizing disruption to airport operations, supporting operations; (2) accelerating on-site construction schedules by shifting activities to the fabrication site, supporting economic and operations components; (3) reducing issues with airport security, construction noise and disruption by moving module construction to the fabrication site, supporting all components of sustainability; and (4) increasing safety for construction workers, passengers, and airport workers, supporting the community component of sustainability. Although modular construction is increasingly common at airports, there is little documentation of its use in the scholarly literature, and even less discussion of the benefits of modular construction for airport sustainability. This paper addresses that gap by documenting modular construction activities at US airports and identifying how these projects contribute to airport sustainability.

1. Introduction and Background: Modular Construction at Airports

Modular construction has early roots, with the Romans building prefabricated components for aqueducts and other structures [1]. In the Victorian Era, the construction of the Crystal Palace featured modular cast-iron components and interchangeable parts; this structure was designed for the Great Exhibition in 1851 [2]. In the mid-1900s, modular construction was used during World War II for temporary military facilities and housing [3,4].

Today, modular construction supports a variety of sectors. In the industrial sector, modular components are used for offshore platforms in the oil and gas industry, where quick and efficient assembly with minimal on-site labor is important. Prefabricated modules are used for data centers and power generation, including windmills and solar installations. Healthcare facilities use pre-assembled units for ICU, x-ray, and emergency centers. Modular construction benefits traditional facilities and facilities built in response to emergencies, such as national disasters and healthcare crises [5].

The assembly of components in a factory environment can provide increased quality and efficiency, and reduced on-site impacts, including operational impacts. Gibb and Pendlebury [6] categorized modular components into four main areas: (1) component subassemblies (small scale items); (2) non-volumetric preassembly (e.g., wall assembly units); (3) volumetric preassembly units (e.g., bathroom pods); and (4) complete buildings or systems. This paper discusses how modular construction supports airport sustainability, addressing the gap in the literature by documenting applications of airport modular construction and discussing how modular construction contributes to airport sustainability.

Traditional construction involves building the foundation, structure and finishes on-site in a sequential process. In contrast, modular construction uses prefabricated modules or components that are built off-site, transported, and integrated into the final structure on-site. Construction off-site allows modular construction activities to occur in parallel to on-site construction activities, accelerating the construction schedule and reducing disruptions to airport operations. While the on-site component of the construction schedule is typically accelerated, the complexity of airport modular construction usually requires additional time for planning and design due to the complex logistics. For example, in traditional design–build projects construction is often started prior to the completion of final design; however, due to the complex logistics, constrained environment, and transport considerations, the planning and design of modular construction projects often takes longer and must be completed prior to starting construction [7]. As airport modular construction becomes more common, and as modeling tools advance, the planning and design phases for airport modular construction may become shorter, especially as standards evolve for modular components.

Airport sustainability encompasses operations, economic, environment and community issues and modular construction addresses all these aspects. Modular construction is increasingly being utilized at airports since it provides significant advantages in terms of minimizing disruption to airport operations since it accelerates the on-site construction schedule since activities are shifted to the off-site location (also known as fabrication site) where the modules are constructed; this supports the operations and economic components of sustainability. Modular construction also reduces issues with airport security, construction noise and other construction disruption by moving activities to the fabrication site; this supports all components of sustainability. Modular airport construction also provides opportunities for increased worker safety, which supports the community element of sustainability. Although modular construction is increasingly common at airports, there is little documentation of its use in the scholarly literature, and even less discussion of the benefits of modular construction to support airport sustainability. This paper addresses that gap by documenting some of the modular construction activities at US airports and identifying how these projects contribute to airport sustainability.

Modular construction can provide significant benefits over traditional construction methods and contribute to airport sustainability. After a brief review of modular construction, the following sections discuss accelerated bridge construction (ABC). ABC is a construction technique in the US that has been leveraged for modular construction at airports and now is being utilized to support airport sustainability. This background provides a foundation for the research questions addressed by this paper.

1.1. Modular Construction

Modular construction has been used for a variety of commercial, industrial and residential applications and is well suited to projects with on-site constraints such as (1) limited space due to surroundings, (2) on-site labor issues, (3) a construction in a difficult to access and/or in a remote location, and (4) weather issues on-site [8]. An airport project meets the first three of these criteria since airport projects pose unique challenges due to on-going airport activities, airport security requirements, and the need to provide security screening for construction workers.

Modular construction has been successfully used for airport construction. For example, Heathrow Terminal 5 (T5) used modular construction for both the terminal and the air traffic control tower (ATCT). The main terminal utilized an 18,500 tonne (40.8 M lb or 20,400 US ton) steel roof and steel box rafters that provide a clear span of 156 m [9] and an expansive interior with a maximum roof height of 120 feet (37 m) [10]. The bridge was built off-site and then jacked into place with strand jacks, as shown in Figure 1. The 1100 tonne (2.43 M lb or 1213 US tons) steel ATCT was similarly constructed and lifted into place with strand jacks. Seventy percent of the mechanical and electrical components were also manufactured off site [11]. The construction began in 2002 and T5 opened in March 2008 on time and within budget (USD 8.5 B) using an innovative approach with modular construction as well as an innovative approach to project management with a cost-plus contract paying for supplier actual cost plus an agreed upon fixed fee for the architects and engineers, general and specialized contractors and manufacturers [11]. In addition to the innovative contract and delivery, the remarkable success of the project was supported by a 15-year planning and design lead time, a robust research and design (R&D) framework that tested all new technologies at smaller airports prior to installation, and an integrated project team approach [11]. Before assembly at Heathrow, some parts of the roof and terminal façade were constructed off-site to ensure that the tolerances were met and all sequencing issues could be addressed prior to on-site installation [10]. Modular construction at Heathrow may partly be attributed to an organized initiative in the United Kingdom in support of modular construction to increase construction productivity [6,12]. It is interesting to note that other Heathrow projects during this era utilized modular construction, including the widening of the M25 roadway serving Heathrow Airport which utilized modular walls to reduce the disruption to road users [13], and the Heathrow Terminal 5 energy center which utilized off-site manufacturing and testing of mechanical, electrical and structural systems and rapid on-site assembly using strand-jacking [14]. Interest in modular construction was not limited to the UK at this time. Recognizing the possible benefits of modular construction, Schiphol Airport conducted a study between June 2002 and September 2002 to evaluate the possibility of using modular construction for the J-pier; this study was inspired by the successful construction of the Bollard, an 11-story cylindrical office building successfully built and transported to serve as the new main office in the Netherlands for heavy lift and transport company Mammoet [15].

Figure 1.

Modular construction at London Heathrow Airport (Images: DLT Engineering [9]).

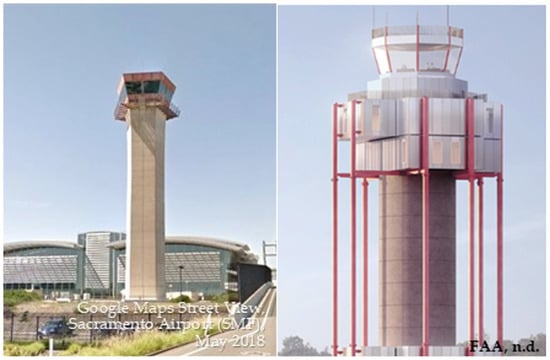

Both Terminal 5 and the ATCT were built off-site and then raised with strand jacks at London Heathrow. This was an interesting and very successful project, however there is no documentation of this project in the scholarly literature. Similarly, ATCT have a history of modular construction, with a design by IM Pei that utilized a standard cab and 13 design variations and was installed at numerous airports across the US in the 1960s and early 1970s [16]. The FAA program was recently renewed with criteria that included standardized elements to reduce construction and operational costs and the New York firm Practice for Architecture and Urbanism (PAU) was selected with the design shown in Figure 2 [17]. Modular construction at airports has been successfully implemented and is becoming increasingly common; however, there is little information regarding airport modular construction in the academic literature.

Figure 2.

ATCT based on FAA modular design by IM Pei and PAU (images: Google maps; FAA [17]).

A Scopus search on 3 June 2025 for English language journal articles using airport AND modular AND construction within the article title, abstract and keywords with the keywords “modular construction” or “airports” and no date restrictions found nine articles, as shown in Table 1. A second Scopus search for English language journal articles on 5 June 2025 for airport AND prefabrication within the article title, abstract and keywords using the keywords “prefabrication” or “airports” and no date restrictions found four articles, including two that were already identified and two additional articles, as shown in Table 1.

Only three of these articles were open access articles [18,19]. The first open access article focused on the analysis of airport chairs and did not address airport modular construction. The second open access article focused on theoretical decision making that reflects risk management and was more relevant to management theory; while it did address modular airport construction, it focused on a theoretical rather than practical considerations.

For the seven articles that were not open access, five were not very relevant to modular construction at airports. Ascaso Til and Wong focused on the hydraulic equipment required for temporary structures and modular construction [20]. Zimmels and Boas focused on the construction of an offshore airport [21] which is not very relevant to most airport projects. Grogan discussed the construction of a new terminal that uses modular metal wall panels, rather than issues related to modular construction [22]. Besjak et al. discussed the Integrated Terminal Building at Mumbai’s Chhatrapati Shivaji International Airport which used a repetitive, modular design; however, the focus was on structural engineering rather than the airport development [23]. Wolfman discussed modular construction and mentions the addition to Phoenix Sky Harbor Airport but did not provide any discussion about modular construction at Phoenix Sky Harbor or any other airport [24]. A search for information about modular construction at Phoenix Sky Harbor Airport did not yield any information.

Two of the papers did address modular construction at airports. Whitfield et al. [25] discussed the construction of a hotel expansion at Crowne Plaza Changi, where modular construction was selected due to the site constraints and support from the Singapore Government. Each hotel room was a single module, with a steel frame, concrete floors, acoustic and fire-resistant walls, a complete bathroom and standard connections for electricity, water, HVAC, and waste disposal. The modules were made in China, where modular construction manufacturing is more prevalent. The project included 243 standard modules plus nine modules for ancillary facilities. The modules were manufactured in six months and shipped to Singapore for storage and installation. Overall, the project was deemed a success, with a high-quality project completed in a short period of time without some of the challenges of a traditional construction project. While this illustrates the potential for the modular construction of hotels on the landside at airports, there was no discussion of the elements related to construction at an airport and no mention of constraints or benefits related to modular construction at US airports.

Charkas and Needham [26] discussed the history of modular construction and the use of modular construction at DFW airport, the first airport in the US to use modular construction for a concourse expansion at the High C Gates, where the modules were finished by the airline on site. The modular approach minimized construction disruption on an active airfield, shortened the schedule and saved USD 90 M (a 45% savings). DFW built on this success and is using modular construction for projects at Terminals A and C, where the modules will be finished prior to delivery to increase efficiency and will include restrooms and concessions. DFW is also using modular construction for restroom renovation and is experimenting with modular construction for concessions to facilitate transitions with less disruption. Key technical considerations noted include the selection of the laydown or fabrication space; transportation considerations; design challenges to accommodate transport, lift and placement of the modules; team qualifications and the recommended use of design–build; and the need for standards for prefabricated components if they will be used changed out to accommodate different concessions. The future for modular construction at US airports is promising, and it builds on the success of ABC practices, as discussed below.

Table 1.

Scopus search results for articles related to modular construction and prefabrication at airports.

Table 1.

Scopus search results for articles related to modular construction and prefabrication at airports.

| Article | Open Access | Year | Relevance to Applications for Modular Construction and Sustainability at US Airports |

|---|---|---|---|

| Liang & Chen (2024). [18] | Yes | 2024 | No, this article focuses on analysis of airport chairs and does not address airport modular construction. |

| Krystallis, et al. (2024). [19] | Yes | 2024 | Minimal; this article proposes a theoretical decision making model for design decisions for large infrastructure projects. Modular construction is a conceptual framework presented to support flexibility in an example at Heathrow Airport. While this research may be useful for management theory, it does not significantly contribute to an understanding of the benefits of modular construction at airports or how modular construction contributes to airport sustainability. |

| Charkas & Needham (2023) [26]. | No | 2023 | Yes, this article discusses the use of modular construction at Dallas Fort Worth International (DFW) for terminals and gates in a concourse expansion project at Terminal C. The paper documents the benefits of modular construction, including reduced disruptions and lower costs to airport operations, as well as some of the technical considerations of modular design, and how it may provide future benefits for design and concession leasing. |

| Ascaso Til & Wong (2023) [20]. | No | 2023 | No, this paper focuses on the use of hydraulic equipment to support temporary structures and modular construction for infrastructure including airport infrastructure; while the information may be useful to support modular airport construction, the technical focus is on the hydraulic equipment rather than airport modular construction. |

| Whitfield, Noordzy & Lin (2022) [25]. | No | 2022 | Yes, this paper presents a case study for the modular construction for the extension to the Crowne Plaza Changi Airport in Singapore. The application to US airports is limited because it focuses on modules fabricated in a manufacturing environment and it does not address any issues specific to the airport environment. |

| Besjak et al. (2013) [23]. | No | 2013 | No, the focus on this paper is on structural design considerations for the new Integrated Terminal Building at Mumbai’s Chhatrapati Shivaji International Airport. When the paper uses the term modular construction it refers to repeating components used in the design; the paper does not address issues related to airport development. It may be relevant for structural engineers who carry out airport work. |

| Zimmels & Boas (2003) [21]. | No | 2003 | No, this paper discusses the construction of an offshore airport and the bridges to access it. It does not contain significant information that would be relevant to US airports interested in modular construction. |

| Grogan (1990) [22]. | No | 1990 | No, the article describes the construction of a new terminal that uses modular metal wall panels that will provide a consistent look between sections of the building completed in different phasing and provide flexibility for future changes. |

| Wolfman (1988) [24]. | No | 1988 | No, the article discusses modular construction but not specifically its application to airports, although a major addition to the Phoenix Sky Harbor airport is mentioned but not discussed. |

| Guan, et al, (2022) [27]. | Yes | 2022 | No, this paper focuses on the analysis of a new kind of prefabricated bolted joint. |

| Santorelli. (1974). Ultimate Project for Using Reinforced and Prefabricated Concrete in the Construction of Hangars. Giornale Del Genio Civile, 112(7–8–9), pp. 287–297 [28]. | No | 1974 | A method is proposed for the realization of a hangar of considerable dimensions with industrial prefabricated sections. The aim is to illustrate how such a complex building can be conceived as the outcome of structural components constructed separately and then assembled on the spot, greatly reducing production and building time. This was not available electronically or via interlibrary loan. |

Additional Scopus searches conducted on 23 June 2025 for airport AND off-site AND construction, airport AND off-site AND construction, and airport AND industrialized AND construction did not identify any additional journal articles in English (no date restrictions) that were relevant to the topic.

1.2. Accelerated Bridge Construction (ABC)

In the US, modular construction often builds on concepts developed through ABC. ABC uses prefabricated elements as part of an accelerated schedule that supports faster delivery and less disruption to traffic operations, enhancing safety for construction workers and the traveling public. Supported by the Federal Highway Administration (FHWA), ABC utilizes innovative planning, design, material selection and construction methods, often focusing on prefabricated elements and systems to minimize the impacts of on-site construction activities [29]. Off-site construction techniques can also be used in conjunction with accelerated contracting methods to further reduce the time required for project delivery, and reduce the associated operational impacts. Additional benefits of off-site construction include improved safety and quality, which are realized since the prefabricated elements are built in a more controlled environment [29]. One fast track method is the completion of construction activities in parallel rather than in series; for example, laying a foundation while a prefabricated element is constructed off-site. In traditional construction, it is necessary to complete the foundation prior to beginning fabrication of the bridge elements on site. Although ABC was developed for large bridge projects, the same principles can be applied to other kinds of infrastructure projects. Modular construction is the use of prefabricated or modular components to streamline the construction process. FHWA has found that, in addition to a reduced impact on traffic operations, modular construction leads to reduced on-site construction time and reduced delays due to weather, ABC improves safety, quality, and durability, as well as social costs and environmental impacts [30].

1.3. Airport Sustainability

Sustainability may be defined as meeting today’s needs without limiting the ability to meet the needs of the future; thus, traditionally it encompasses the protection of the environment from pollution and using fewer natural resources. This definition was reflected in the culture of the late 1960s and early 70s when the US Environmental Protection Act (EPA) was created [31]. Over time, sustainability has expanded to include recognition of the importance of social and community impacts [32], as well as the fact that organizations must address economic considerations to ensure viability. This philosophy is illustrated by the Triple Bottom Line framework that was created by Elkington [33]. All of these concepts are important at airports. Airports must also address operations, since safe and efficient operations is an important priority. Airport operations in this context generally refers to the safe and efficient service of aircraft landing and taking off, as well as all the related activities, including passenger services in the terminal, landside activities such as parking, maintenance and inspection activities conducted by airport personnel, cargo activities, and the many business aviation activities that occur near the airport. These concepts form the basis for FAA’s framework for sustainable airport development, which is shown in Figure 3 [34]. The environment includes the air, water, and land, as well as noise, waste, and light and the protection of animals, wildlife, and biotic communities. The economy refers to the fact that that US airports should operate as a business enterprise, which is a government entity that operates as a business and should be self-sustaining financially, covering their expenses with generated revenue. Operations refers to aircraft landings and takeoffs, as well as supporting activities, both aeronautical and non-aeronautical, that occur at the airport. Community refers to both the airport community, which is employees and passengers, as well as the larger community that is a neighbor to the airport. Modular construction can support airport development and can contribute to airport sustainability.

Figure 3.

FAA’s framework for sustainable airport development (Image: FAA [34]).

2. Research Questions and Methodology

Despite the growing interest in modular construction as a solution for development projects, there is little documentation of the use of modular construction in scholarly journals and there is little information about the use, characteristics, and benefits of modular construction for US airports. This descriptive research aims to address this gap by investigating examples of modular construction at US airports, identifying key characteristics and lessons learned, and exploring how modular construction supports airport sustainability. By providing insights into these areas, the research seeks to inform future airport construction projects and identify when modular construction can be used to support airport sustainability.

This paper will investigate the following research questions.

- 1.

- What are some examples of modular construction at US airports?

- 2.

- What are the characteristics of modular construction at airports in the US?

- 3.

- How does modular construction support airport sustainability?

The objective of this research is to answer these questions and document the status and value of modular construction at airports and to provide a better understanding of how modular construction can support airport sustainability. The case studies reflect a range of airports in terms of geographic spread and airport size, ranging from less than 10 M enplanements to more than 50 M enplanements. The case studies also reflect a variety of project types from temporary corridors to permanent installations and both airside and landside locations.

To answer the research questions, this study leverages information published by airports, contractors, and vendors, including videos, articles in popular press, webinars, trade journal articles, webpage information, and press releases. Follow-up with airports, contractors, and vendors is conducted to obtain additional information as needed. There were a few discrepancies (e.g., whether the fabrication site was a mile or a mile and a half from the terminal, whether transit took 45 min or an hour); however, these were usually minor and were resolved through follow-up with the airport, constructor, or designer, when possible.

3. Results

This section provides examples of modular construction at US airports, the characteristics of these modular construction projects, and a discussion of how modular construction contributes to airport sustainability.

3.1. Examples of Modular Construction at US Airports

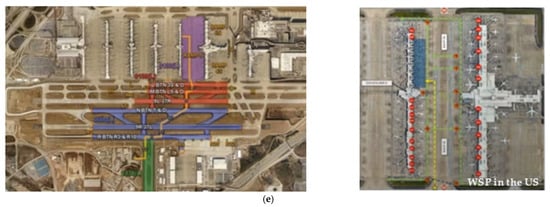

This section provides a description of modular construction projects at the following seven airports, as shown in Figure 4 below and as described in the following sections: Dallas Fort Worth International Airport (DFW), Atlanta International Airport (ATL), George Bush Intercontinental Airport in Houston (IAH), Seattle International Airport (SEA), Chicago O’Hare Airport (ORD), Portland International Airport (PDX), and San Francisco International Airport (SFO). DFW, ATL, IAH, ORD, SEA, and SFO are all large hub airports on the National Plan of Integrated Airport Systems (NPIAS) and each one serves over one percent of the passenger enplanements [35]. PDX is a medium hub airport, serving between 0.25 and 1 percent of all passenger enplanements in the US. The number of enplanements at each airport is shown in Table 2. ATL serves the most enplanements, with more than 50 million per year, followed by DFW and ORD. SEA, SFO and IAH all serve between 20 and 30 million enplanements per year, and PDX serves over 8 million enplanements per year. These airports also play an important role in cargo movement, which is important for the mobility of goods and to support economic activities. ORD has the greatest role in cargo movement, with over 7 M lbs of cargo landing in a year. This is followed by DFW and ATL (3.4 and 3.9 B lbs), then SEA and IAH (2.7 B and 2.3 B lbs), then PDX (almost 2 B lbs), and SFO (0.2 B lbs). In all cases, these airports serve a significant volume of passengers, aircraft and cargo, and disruptions due to construction can have dramatic operational and financial impacts for the airports and the communities they serve.

Figure 4.

Example modular construction projects at major US airports (image: Google Maps).

Table 2.

Passenger enplanements at airports with modular construction (sources: [35,36]).

3.1.1. Dallas Fort Worth International Airport (DFW)

The High C Gates at DFW’s Terminal C were originally built in 1988 as temporary gates [37]; however, they remained in service for over 30 years because they were critical for American Airline (AA) operations. DFW is AA’s largest hub and serves over 73,000,000 passengers each year [38]; a critical component of this service is the domestic connections that are provided at the five High C gates (gates 33, 35–37 and 39) which serve narrow-body aircraft and regional jets [39]. By 2019, these gates needed to be demolished and reconstructed because they no longer met required codes; however, since AA operations needed to continue, the reconstruction was like rebuilding the engine of a car while the car is still running. To address the critical need for a new facility and ensure minimal disruption, DFW and the design–build team led by Archer Western (a company in the Walsh Group) used a progressive design–build approach that utilized modular construction with prefabricated modular units that included a shell and core for the 80,000 square foot, USD 115 M project [37].

DFW was interested in prefab construction prior to Terminal C and Walsh Construction (one of the companies within the Walsh Group) had begun a study to develop an accelerated concourse delivery system that built on the success of the ABC technology [40]. The resulting airport modular construction project was delivered ahead of schedule (by 4 months) and below budget [39]. The modular approach was effective not only in minimizing operational disruptions, but also to address site restrictions, since the site was constrained on four sides (The Walsh Group [41]). The High C Gates project included six prefabricated modules that were built off-site on airport property near the T1 taxiway [42]. The modules were clad with metal panels and glass curtain walls, roofing and concrete slabs as well as some mechanical shafts and pipes [40,43]. The modules were constructed on foundations that were four feet above ground, lower than their final installed height (18 feet high), which enhanced safety for the construction crews fabricating the modules [40,41]. The construction of the modules is shown in Figure 5a. The structural design had to consider the loads during construction, transport, and final placement, including lateral loads, deflections, and moments due to transport acceleration and deceleration as well as wind [43].

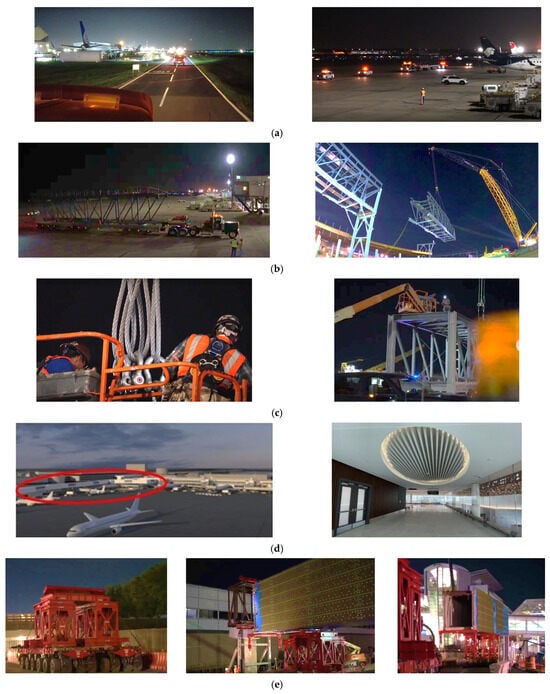

Figure 5.

DFW High C Terminal modular construction (images: Walsh, DFW Airport [40,44]). (a) Modular construction and transport; (b) module transport; (c) final placement; (d) On-site construction and the completed terminal.

Once constructed, the modules were transported on self-propelled modular transporters (SPMTs) by the Dutch firm Mommoet. The modules were transported at night, when there was less airport activity, and each module traveled about a mile, traversing a taxiway and runway and two 90 degree turns [40,42]. Upon arrival, they were jacked up eight feet into place, welded and then the final support columns were poured [40]. The transport and final placement of a module is shown in Figure 5a–c.

Since this was an inaugural project, there were no best practices to reference for the transport. The transportation requirements did present size restrictions and structural considerations that needed to be considered during the module design phase. One constraint was the height of the Skylink structure (a bridge for the airport train); during transport, there were just a few inches of clearance between the module and the Skylink structure. This is just one example of the very tight tolerances on the project which mandated strong quality control. Tolerances were relevant for transport and final placement, where everything had to line up, including the curtain walls and steel [40]. Each module was approximately 85 ft by 85 ft and weighed approximately 900,000 lbs [40,41]). For comparison, the maximum takeoff weight for an A380 is about 1.2 M lbs [45]; however, module transport speeds are closer to walking speeds than aircraft taxi, take-off and landing speeds.

The modular approach presented advantages in terms of reduced disruption as well as time savings and associated savings on project cost. The construction schedule was compressed by months since demolition and foundation work could be undertaken while the modular units were being built at a different location. The modular approach reduced the schedule by 22% (American Institute of Steel Construction) [43].

Three sections were built in place using conventional construction techniques (also known as “stick-built”) to connect the prefabricated module units to the existing terminal [40]. The phasing of construction activities was important since some columns at the terminal could not be put in place until after the nearby modules had been placed since the columns were in the transport path for the SPMT [43]. To address this, a composite design was used, and once the SPMT was removed, a concrete column was poured around the steel to support the finished building [43]. This composite design enabled the steel beam to support the module after the SPMT was removed and before the concrete column cured; this was necessary since the SMPTs needed to be removed and returned to the fabrication yard to support the next module.

The new High C gates are 30% larger than other DFW gates and the 16 ft tall windows in the High C terminal have dynamic self-tinting glass, which will improve efficiency and passenger comfort; there are also smart restrooms and video screens which provide airport information and support wayfinding [42]. AA was responsible for the interior finishes [46].

The modular construction of the High C gates was a success and served as a reference point for projects at other airports (e.g., NextATL) and at DFW. DFW is utilizing modular construction for projects at existing Terminals A and C, and for the construction of a new terminal, Terminal F [47]. Leveraging their previous success, the new modular projects include modules with mechanical, plumbing and fire protection systems. The new modules are also twice as large as the High C project modules, weighing about 2.4 M lbs (1200 tons) and being as large as 204 ft by 68 ft and [47].

3.1.2. Atlanta International Airport (ATL)

ATL has initiated a modular construction program for the expansion of Concourse D as part of the ATLNext Capital improvement program. The USD 1.4 B project will expand the concourse from 60 ft to 99 feet wide with a 288 ft long extension and is scheduled for completion in 2029; the concourse will remain open throughout the project with no more than eight gates closed at a time throughout each of the six construction phases [48]. The limit on gate closures is not surprising, since each gate makes more than USD 350,000 per day in revenue [49]. If the entire concourse had been closed for a more traditional construction approach, a 46-month closure would have cost the airport more than USD 400 M USD [49].

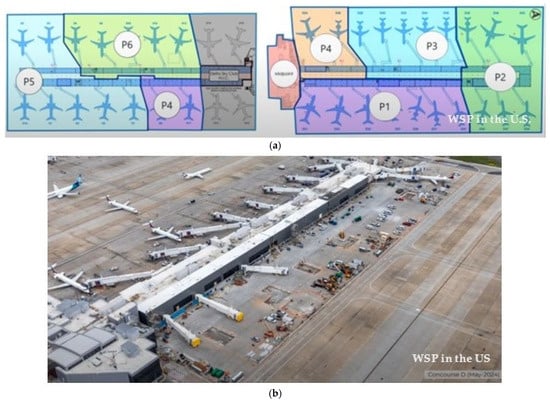

The construction phases moved around the north and south portions of Concourse D, as shown in Figure 6a. To illustrate the mix of modular and traditional construction methods, on the north pier there are 10 modular units and Phase 1 is 100% modular, Phase 2 is hybrid (modular and traditional), and Phases 3 and 4 are traditional stick built [50]. The north pier is similar with nine modular units and a mix of modular and traditional construction [50]. In Figure 6b, the foundation work can be seen at Concourse D site on the right side. The five modules on the north pier initially served as temporary circulation corridors for passengers and were designed to transition into holding rooms in the final concourse [51].

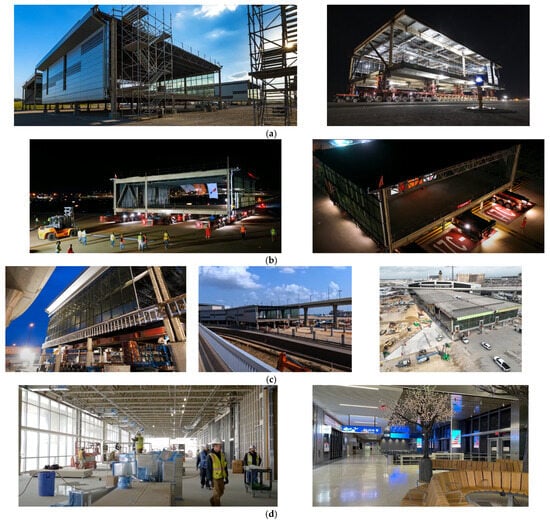

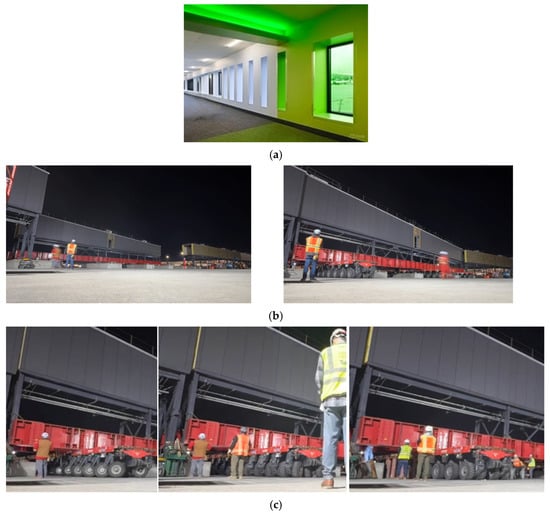

Figure 6.

Atlanta ATLNext program modular construction (images: WSP in the US [50]). (a) Phasing to ensure that no more than 8 gates are closed at a time for construction. (b) Phase 1 Activities (note aircraft activities at other gates at the concourse). (c) Activities at the six acre mod yard and concourse in Feb (left) and March 2024 (right). (d) Transport and placement of module; Mommoet Trailer software supported analysis (right). (e) Airfield closure plan and ramp closure plan.

The simultaneous construction of the foundations at Concourse D was underway while module construction was underway in December 2023 at the secured “Mod Yard” about a mile away [51], as shown in Figure 6b. The fabrication site was on the public side of the airport, so workers did not have to go through any airport security screening, which saved time and reduced inconvenience [49].

Stakeholders were involved throughout all phases of the design and construction. The team coordinated with the FAA to ensure compliance with height restrictions at the six-acre mod yard (to ensure compliance with Part 77 for the preservation of navigable airspace), as well as clear lines of sight for the ATCT [50]. The modules were designed and sized to reflect the travel path and deflections, dead loads, center of gravity, lift and set planning, the temporary bracing needed during transport, and the procession and event planning [50].

Modular construction reduced the project schedule and minimized disruption to the airport, including operational disruptions and noise. The first modules were delivered in the early morning between 1 am and 4 am when there are fewer airport activities [52]. The first modules had unfinished interiors with exterior skin and glass as well as rough-ins for mechanical electrical and plumbing (MEP) [51]. Later modules had additional finishes and then activities shifted to traditional construction as the height and width of the existing concourse was increased within the module envelope [53]. During the second phase, productivity was increased, and two modules were transported per week, with lift and transport via SPMTs provided by Mammoet [52].

Transport activities are shown in Figure 6d. The first module was lifted 18 inches off the temporary foundation [51] and transported at about 1 mph on 320 wheels traversing two runways, and making 90 degree turns [50]. The longest module was 192 feet long and 35 feet wide, and modules were placed sideways within 3.5 inches of the existing concourse [51]. The actual move took about an hour, and all activities were closely coordinated with air traffic control (ATC) and other stakeholders [50]. Close coordination was critical since runways and taxiways were shut down during the transport, as shown in Figure 6e. Given the wide variety of stakeholders and the impacts on airport operations, a robust communications plan was developed early, and communications were an important component of the project. This is consistent with other activities at an airport, such as those addressed by the Airport Emergency Plan (AEP) which has well-defined communication and activity protocols for both planned and unplanned airport emergencies (Advisory Circular (AC) 150/5200-31C) [54]. The plan included a detailed playbook that was more than 60 pages and considered a variety of possible challenges ranging from flat tires to computer malfunctions and weather issues [51]. The “go/no go” decision was made based on the weather, (min 200 ft visibility), winds (less than 25 mph), precipitation, lightning proximity and operational considerations (both the local ATCT and the FAA NAS) [50,51]. There were even plans in place for the module to be destroyed and removed en route if it got stuck on a runway [49].

The contract method was construction manager at risk with joint venture HMBS comprised of Holder Construction Group, C.D. Moody Construction Co., Bryson Constructors and Sovereign Construction and Development [49]. The project team visited the DFW High C gate project to leverage lessons learned from other airport modular construction activities and the project required ballot approval from the airlines due to the majority in interest clause (MII) [49]. The design and transport required close coordination, and designers modeled deflections due to lifting, transport and placement to ensure that it was within the design limits; additional temporary bracing was added to support the modules during lift and transfer and to provide additional stiffness [51]. The SPMT axles can move up and down to ensure the modules stay level; engineers modeled transport considering the pavement elevation on the route between the mod yard and final concourse, as well as the modules sizes and load requirements [51], The modules weighed from 400 tons to 700 tons, and the largest was carried using an SPMT with 92 axles and lifted and lowered with eighteen 300-tonne capacity climbing jacks at the installation site [55]. There were tight tolerances (as tight as 1/8 inch for placement in some cases, with placement usually within 1/16 inch) and exceptional quality control procedures are evidenced by testing procedures at the mod yard and again on site, and the use of three survey teams to measure elements multiple times and represent the Department of Aviation (DOA), the CMAR and the design team [50]. Other tools used to support precision throughout the design, transport and construction included 3D scanning and mapping, BIM modeling, 4D scheduling and animation [50]. The first modules were 29 ft wide empty structures; the last modules were 48 ft wide and had interior components, such as drywall, plumbing components for restrooms, and utility features such as an elevator shaft [49]. An ATL architect with Corgan suggests that in the future, modules could extend beyond 200 ft as builders gain knowledge and experience [49].

Sustainability certifications include LEED silver designation [48], and the project addressed operations with an ongoing commitment to an “airport first, construction second” philosophy [50] as well as a reduction in disruptions that was enabled by modular construction. Sustainability also supports the community pillar via the increased level of service (LOS) provided to passengers with the new terminal, and the reduced disruption enabled by modular construction; the economic pillar is supported by the increased concessions in the new terminal, which are expected to provide additional non-aeronautical revenue and the increased efficiency of the modular approach.

3.1.3. George Bush Intercontinental Airport in Houston, Texas (IAH)

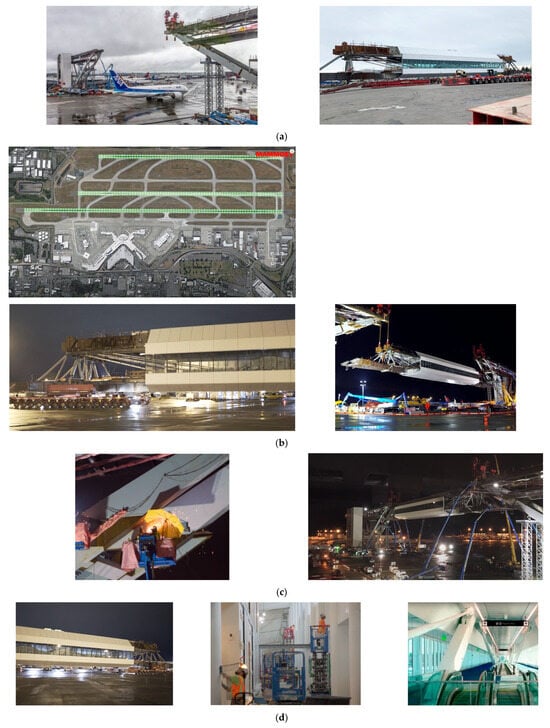

Modular construction techniques were used at George Bush Intercontinental Airport in Houston, Texas (IAH), as part of the Mickey Leland International Terminal Project (MLIT) for the construction of a new passenger corridor that connects the new international Terminal D West Pier to Terminal D which opened in October 2024 [56]. Eleven steel trusses were constructed and then transported for placement and final erection for the new sterile passenger corridor, as shown in Figure 7. The transport escort procession is shown in Figure 7a.

Figure 7.

IAH sterile corridor and baggage bridge (images: Houston Airports [56]). (a) Escort and procession includes lead and follow cars for steel for sterile corridor; (b) steel for sterile corridor transport and placement; (c) large cables are used in the rigging and must be adjusted for tension and length to ensure appropriate angles are maintained during the lift and placement of the trusses; (d) location of sterile corridor and completed sterile corridor; (e) transfer and lift of baggage bridge for international terminal by Fagioli.

Modular elements included trusses for the sterile passenger corridor and a baggage bridge for the international terminal. One truss was 127 feet long and weighed 127,000 lbs, and the transport was completed by Italian heavy transport and lift firm, Fagioli [56]. Lifting and taking the truss off the transporter and installation represents a complicated and high-risk maneuver with tight tolerances. Some of the trusses were installed at an elevated angle, which required them to be lifted and placed at the required angle, so when they were loaded into position everything lined up [56]. Taking it off the transporter requires alignment with the boom and cables, which must have the right tension and the right distances to ensure the angles are correct [56]. In this case, a semi was used for transport (Figure 7b). The crane used to lift and place the truss is shown in Figure 7b,c; note the heavy cables used for rigging. These cables must be adjusted for tension and length to ensure the appropriate angles are maintained during the lifting and placement of the trusses.

Teams worked in 10 h shifts beginning at 8 pm from Sunday night through Thursday morning, with the first move on 8 May 2022. Night crews completed steel detailing, welding, and decking for the trusses once they were placed at the terminal [53]. Nightshift work reduced disruptions to airport activities and increased safety for both airport and construction activities. Safety was heavily emphasized each work night and a spotter on the apron level coordinated traffic on the ground below the work area and fire watch was provided to ensure safety whenever there were welding activities [53]. Communications to support awareness and safety included prominent signage displayed at all levels on doors, in corridors and in offices throughout the duration of the project.

The project was led by Gilbane Building Company and joint venture Austin Commercial (also known as Austin Gilbane Joint Venture (AGJV)), with a CMAR contract provided for two phases. Phase 1 was for pre-construction services and early/enabling construction work, and Phase 2 was for full construction services once a guaranteed maximum price construction solution was achieved [57]. The early construction work included demolition of the Old Terminal C North pier as well as the relocation of fuel lines and hydrant pits to accommodate the new pier [57]. The project team leveraged expertise from both companies to successfully execute the complex project while coordinating the many operational, security, and safety protocols that are required when working at an active airport [58]. The airport prioritized passenger experience and was committed to mitigating construction impacts, especially during holidays and busy travel seasons [59].

3.1.4. Seattle International Airport (SEA)

The modular construction of the signature pedestrian walkway at Seattle International Airport (SEA) provides a connection from the South Satellite terminal to the new customs processing facility in the main terminal and spans an active taxiway that can accommodate wide-body aircraft [61]. There is only one other airport walkway over a taxiway that can accommodate a Boeing 747 [62]. Seattle’s 780 ft walkway is the longest in the world over a taxiway and opened to passengers in 2022 [61,63] and has an 80 ft rise served by five escalators [63].

The project was an important component of the USD 1 B IAF. The project was contracted as a progressive design–build with Clark Construction as the lead contractor, working with architect Kidmore, Owings and Merrill, and designer Arup for the aircraft gates which were designed to accommodate existing conditions such as the boarding bridge and fuel infrastructure [61,64]. The aerial walkway was designed as a cable-stayed bridge and utilized ABC methods for the design and construction [63]. These principles provided a significantly faster completion time with much less disruption to airport operations; the success of the project was the result of collaboration throughout the almost eight years of planning, design and construction [63].

The walkway provides views of Mount Rainier as well as the aircraft taxiing underneath [65]. The center span of the walkway is 320 feet long, weighs more than 3 million pounds and is 85 ft above the pavement (shown in Figure 8a). It was constructed about 3 miles away at a cargo area on the north end of the airfield [62,64]. Fabrication included installation of the glass and metal panel façade, as well as the structural stay cables, located in the center of the walkway to facilitate maintenance and provide a clear view out of the walkway windows (Figure 8d).

Prefabrication off-site improved safety and minimized impacts to airport operations; it also provided the opportunity to troubleshoot potential challenges [61]. Strand jacks were used to lift the center span. Before the lift, the side spans of the walkway were adjusted to account for the weight of the center section and the deflections that would be expected when the structure was fully loaded. Strand jacks provided a controlled lift of the walkway to its final position and met the required tolerances. Tolerances were less than an inch between the side spans and center walkway and accuracy was supported by virtual design and construction modeling that surveyed the components before placement and connection on site.

Upon completion, the 17 major prefabricated components were transported by Mommoet after midnight on 24 January 2020, with a four-hour window for transfer and lift [62]; within ten days, the taxiway below the pedestrian bridge was opened to aircraft [61,63,65].

The move was coordinated through months of planning by the construction and design team, airport operations, and the FAA. The modules traveled 3 miles in three and a half hours on 56 axle lines of SPMTs in a caravan with escorts from the cargo area to the terminal via the center runway (see Figure 8a,b) while airplanes continued to land and take off on other runways [62]. The SPMTs use hydraulic trailers, and the axles can rotate in all directions and can telescope independently of one another. These features help keep the loads level and support the even distribution of weight, even when the loads traverse uneven terrain. This reduces movement and stress on the structure during transport and placement. The wheels on the SPMTs all turn at precise angles and are linked together with controls from a single operator and one control box [62]. The bridge was vulnerable to stress and deflections during the transport and lift. Strain gages were used to monitor the stresses during transport, and there were no cracks during transport or jacking.

Once transported into position, crews used a system with strand jacks and steel frames from the Netherlands; the placement of the SEA pedestrian walkway was the inaugural time these 900-ton frames were used in the US [62]. The bridge span was raised into place 72 ft (22 m) above the taxiway, and welded in place (see Figure 8c). It took 36 h for the final welds to be completed, and the heavy lift team provided coverage while the welding was completed [62]. The welds were critical for structural integrity and were as long as 6 ft and as deep as 3.5, connecting steel components that weighed from 130 tons to 170 tons each [63]. Due to the size and thickness of the steel, the welds were large and difficult and had to meet stringent welding codes [63].

A trial run was executed to ensure everything was ready to go and to increase familiarity with the process since most of the team was not familiar with the heavy lifting industry. The team walked at the speed the bridge would be transferred, specified the intensity of runway lighting and identified exclusion zones for travel clearances. Computer animation was also used to sequence the transport and ensure there were no issues with clearances. With the bridge on the trailer, the crew practiced driving back and forth, and practiced a slight turn and adjusting the trailer height so the client could obtain baseline data.

The safety features included lighting on the runway and convoy lighting; a spill crew with sweepers to pick up debris (this ensures that no foreign object debris (FOD) is left on the airfield); a tool truck to provide trailer maintenance, if needed, en route; and continuous radio communication with all team members, who provide different perspectives on the activities since they provide different points of view (POV) [62].

Four-dimensional computer modeling with building information management (BIM) was used throughout the planning, design and construction [66]. Four-dimensional modeling refers to a three-dimensional modeling of the facilities integrated with the changes over time as represented by the activities in the construction schedule. The software provides visualization and supports analysis and detailed understanding that are useful for planning, design, fabrication, transport and construction activities. Laser surveys of the site, the remote assembly of the bridge span, the on-site pier supports, and the airfield along the travel path were surveyed and represented in the model to ensure accuracy and safe transport along the busy airport grounds [66]. The data also provided a basis for a digital twin that was provided as a deliverable to the client [66]. The contractor incorporated the digital tools and data from the beginning of the design process and the digital twin included 18 standard attributes per asset, which is useful for facility management and the ongoing operations of the airport [66]. The animation provided by the computer model supported the optimization of construction sequencing and allowed the team to test a variety of plans, which reduced the impacts on airport operations [66]. The animation also provided a useful communication tool for project stakeholders. The laser scan surveys used in the modeling were also used by structural engineers whose planning and preparation also included validation through a peer review [61].

Sustainability features include LEED silver certification [66] and the use of local and regional steel fabricators [63].

Figure 8.

SEA pedestrian bridge to IAF (Images: Mammoet [62,67]); (a) the terminal and center span; (b) transport and lift; (c) securing pedestrian bridge with welds; (d) panels required special care; finish work and finished interior; (e) completed structure.

3.1.5. Chicago O’Hare International Airport (ORD)

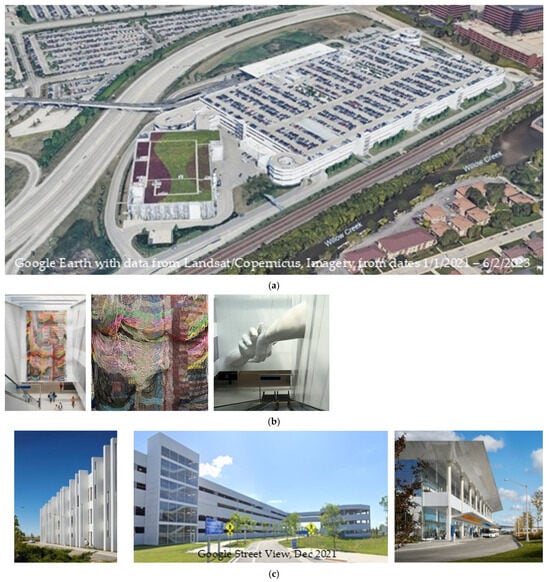

The multi-modal facility (MMF) at Chicago O’Hare International Airport (ORD) was completed in 2018 and although the original design used a cast-in-place facility, the design was shifted to precast concrete as a value engineering alternative [68]. The MMF is shown in Figure 9. This facility illustrates the benefits of a precast as a modular design, as well as the opportunities for modular construction on the airport landside. The benefits of modular construction may be realized landside at airports, as well as airside, where activities are more strictly governed by the FAA and where there are greater security and inspection requirements. Although not discussed in this paper, precast panels for the runway can also provide numerous advantages and have been well documented in the literature [69,70,71].

Within the MMF is the consolidated car rental facility (ConRac) which includes three floors for rental cars. There are also two floors for public parking, and a landside terminal for light rail, rail, bus, and shuttle services (JA Watts, Inc.) [72]. The ConRac has 72 vehicle fueling stations, 15 car washes, and serves 10 rental companies [73]. The associated equipment resulted in additional project complexity, since items such as the foam fire suppressing system must be considered in the pre-cast design prior to fabrication. The focus on sustainability required water reuse and rainwater collection be incorporated into the design.

This project was completed in 2018 for USD 414 M [72,74] and Austin Power Partners was the construction manager at risk (CMAR) for the project, which was a joint venture with Power Construction, Austin Commercial and UJAMAA [74]. TransSystems was the architect [74] and there were seven DBE subcontractors [68]. The five-story precast garage can be expended to nine stories in the future and includes 2.5 M square feet on a 33-acre site [74]. When designed with a long-term perspective, modular construction can support different uses over time, as was illustrated when two levels of a parking garage in Chicago were converted into a 30,000-square-foot Level 1 emergency trauma center [75,76].

The use of precast rather than cast-in-place concrete provided numerous advantages including a lower price, and greater long-term durability due to the lower water-to-cement ratio that can be used in a manufactured setting; the resulting structure is more impervious to chloride [68]. The structure has a 75-year life with appropriate maintenance.

The design has complex geometric features due to all the ramps (which use triangular floor planks), as well as the precast helix structure for cars to travel to and from the different levels of the parking garage [68]. There are numerous flat wall panels in the middle as structural walls, with columns on the perimeter. The garage also has a snow melt system [68].

The facility includes 5900 manufactured precast components, each of which arrived on a truck and was lifted into place with a 350-ton crane with a 220 ft boom [77]. The crane had a height restriction of 190 ft due to ensure the safety of aircraft at O’Hare and for compliance with FAA regulations for Part 157 and Part 77. The precast components include beams, columns, double tees, hollow-core slabs, stairs and walls, and about 20 to 25 components were placed per day, and the garage and rental car quick turnaround facility was completed in about a year [77]. Transport considerations were considered during the design phase, and the design was adjusted accordingly. For example, the size of the double tees was reduced from 15 ft to 14 ft to reduce the costs associated with the escort companies required to transport the components across state lines [68].

Although prefabrication sometimes uses standard components, it does not imply a “cookie cutter” design, and there were a variety of panel sizes and spans required [68]. A variety of finish textures were also used, including the concrete as cast, concrete with light sandblasting, and polished concrete; this variety added architectural interest. The facility used a white cement which incurred a slightly higher material cost but reduced the overall costs since it eliminated the need for painting, providing savings both in the initial cost as well as the long-term maintenance cost. The facility is designed without shear walls, which supports clear visibility, wayfinding, security, improved lighting and future flexibility [68]. The facility includes two courtyards which enhance the sense of place and support intuitive wayfinding. Pieces of precast were left out to let the trees through, which provides a landmark and visual continuity across the entire surface [68]. The terminal and lobby feature local art, as shown in Figure 9b.

Some of the advantages of using precast for this project include the aesthetic advantages, the factory control, and substantial cost savings with upfront costs often estimated to be 25% lower [68]. There are also time savings associated with the schedule compression with precast, which can be significant. Sustainability features included rainwater collection and water re-use, LEED silver certification and Parksmart certification, a sustainability certification for parking facilities.

Figure 9.

Chicago ORD MMF (images: Google Earth, Google Street View, Adventures on the Road [78]). (a) Aerial view of MMF; (b) facility includes local art (images: Adventures on the Road, 2023 [78]). (c) white cement was used and finished as cast, with light sandblasting, or polished concrete.

3.1.6. Portland International Airport (PDX)

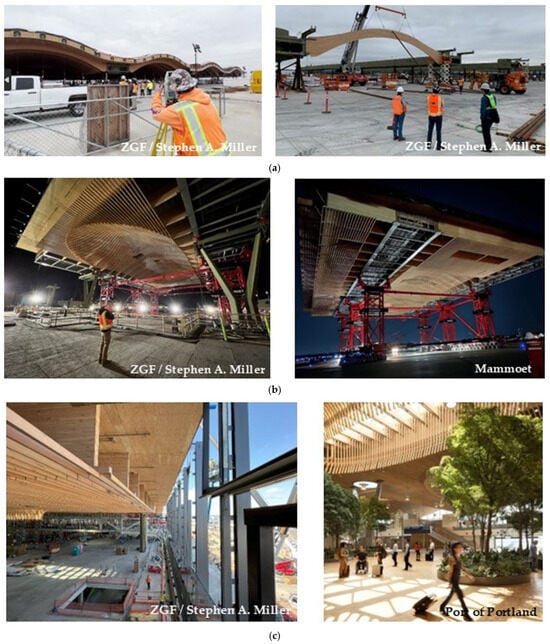

The iconic nine-acre mass timber roof at Portland International Airport, PDX, reflects innovative design as well as innovative modular construction. It weighs 18 million pounds, is designed to withstand a 9.0 magnitude earthquake with lateral deflection up to 2 ft in either direction, and was constructed as 14 prefabricated modules which were built from local Douglas fir from 13 local landowners [79,80]. The project was led by Skanska and Hoffman Construction and began in 2017. The modular roof was part of the larger project known as the Terminal Core Redevelopment.

The 400-by-1000-foot roof was built in three large sections over an 18-month period at the prefabrication yard about half a mile from the terminal. The roof panels included skylights, roofing, and finishes with building system components integrated into the module (see Figure 10). This integrated design increased complexity and required extensive coordination in the planning, design and preconstruction. The roof modules were built in three enormous sections for (1) the new ticket hall and market hall, (2) the north hall and (3) the south hall and then disassembled into smaller panels for transport to the terminal; this method reduced the construction schedule and increased efficiencies in terms of work sequencing [80]. The panels ranged from 44 tons to 695 tons and were as large as 236 ft × 164 ft × 20 ft [81].

Figure 10.

PDX modular roof (images: Courtesy of ZGF/Stephen A. Miller; ZGF/Ema Peter; Mammoet; Port of Portland [82,83]). (a) Large glulam beam and a surveyor measuring roof deflections under preloading; (b) roof lift and transport (Images: ZGF and Mammoet); (c) roof rests on 68 seismic isolators on 34 Y-columns in terminal in finished installation.

For transport, the panels were raised approximately 56 ft by four towers of computer-controlled hydraulic jacks and the SPMTs were driven underneath with supporting falsework to support the load during transport [81]. The runways were closed while the panels were transported approximately a mile to the terminal, at a speed of about a mile per hour [81]. Since panels were above the existing terminal in the north and south hall, installation was performed during night closures so there were no people in the construction area [81].

While the roof was being built, work at the terminal included demolition of the existing structure and the construction of new below-grade utilities and foundations for the 53-ft tall steel Y-columns to support the new roof and the terminal expansion to the west [80]. All work was conducted while operations were maintained at the airport. The roof modules and steel Y-columns were transported and placed at night to minimize disruption to flights, passengers, and airport activities. Nighttime placement was less disruptive and allowed the roof panels to be installed when there were no people in the terminal below, since the north hall and south hall were both existing terminals.

Surveys were critical for success during the planning, construction, transport and installation. Surveys ensured the actual shrinkage, deflection, creep and loads on the long spans of the steel and wood structure were within the design and construction requirements. Surveys were used when the roof was pre-loaded to simulate the weight of the curtainwall which is hung from the timber roof to meet seismic requirements [82]. Surveys were also conducted to measure deflections during jacking, transport and installation [81]. Mockups were used to test concepts and manufacturing capabilities and enabled the use of a single arched glulam beam (rather than two beams) which provided cost savings, eliminated the need for another connection and improved aesthetics [80]. The 80-foot arched glulam beam that was manufactured to demonstrate proof of concept was used in the project since it me the specifications [80]. Transport partner Mammoet also performed extensive testing before and during the move. Mammoet built a roof panel mockup at its yard in Texas to conduct friction tests and ensure that the roof would not be damaged during the lift, move and placement [81].

The modular approach supported the safety of building occupants and construction workers and supported quality since craftsmen could work in a more protected environment at a more convenient height. Modular construction also reduced operational disruption in the terminal since activities were shifted to the fabrication site. There were challenges in the project, such as the interruption of the procurement due to COVID-19 and record-breaking heat. Temperatures as high as 118 degrees presented challenges since the heat caused expansion in the steel, which required additional structural analysis regarding the differential movement of the steel and timber in the long spans. There were also durability issues with the temporary roofing which was designed to serve as a vapor barrier in the final structure due to the heat and rain; in retrospect, an additional material over the vapor barrier would have provided redundancy and reduced the risk of leakage [80].

Some of the essential lessons learned included explicit guiding principles and project goals that are shared with all team members to set expectations and maintain focus. Project success required a collaborative approach, open-minded engagement and commitment from all stakeholders, and recognition that the entire team would ultimately share in the success, or failure, of the project [80].

3.1.7. San Francisco International Airport (SFO)

San Francisco International Airport (SFO) recently used modular construction to provide a temporary corridor as shown in Figure 11 as part of the USD 2.6 B modernization of Terminal 3 [84]. The temporary corridor will alleviate the need for ongoing corridor reconfigurations during construction and will be removed when the upgraded terminal is open in fall 2027 [85].

Figure 11.

Modular temporary corridor at SFO (images: Turner Construction Company [84]). (a) Natural light helps the interim corridor feel less temporary for passengers. (b) Two modules are placed between existing modules; (c) wheels pivot on the transporter to move the module into place with precision.

The 1000 ft West Corridor and 400 ft East Corridor utilize 1130 ft tall modules that were constructed at an air cargo yard and transported about a mile over 11 nights by Fagioli [85]. The corridors opened in early November 2024 before holiday travel began [86]; provision of the passenger corridors allowed demolition activities to begin and reduced noise and operational disruptions. The corridor is elevated 17 feet above the apron and provides passenger access to boarding areas for United Airlines throughout the reconstruction, as well as natural light, colorful graphics and wayfinding consistent with the rest of the airport [86]. The temporary corridors have windows overlooking the airfield, audio recordings and artwork representing the Bay Area which could be stored and re-used for other applications after the temporary corridor is no longer in use [85].

The USD 40 M temporary corridor routes passengers around the existing building and the cost was offset by savings derived from a faster construction schedule, reduced phasing requirements, and the elimination of the need for building and rebuilding interior tunnels for passenger access for each construction phase [86]. The modular corridor provides a positive and safe passenger experience while minimizing disruption due to construction. To ensure smooth passenger flow, there is no seating or amenities in the corridor, and it is intended for movement only [86].

The project is led by Turner Construction Company using a progressive design–build contract with joint venture Gensler and TEF Design [86]. Project partners work together in a shared workspace that can accommodate 200 people from the design teams, contractors, and subcontractors. This shared space facilitated coordination, collaboration and communication [86]. The concept of a temporary modular corridor was initially dismissed due to cost concerns; however, during a three-year project delay due to COVID-19, the business case was refined and it became clear that the cost was offset by savings [86]. In this case, prefabrication enabled revenue-generating airport concessions to continue during construction, which provides significant benefits for the airport, as well as cost efficiencies and safety efficiencies [86]. The project is funded through general revenue bonds. The corridor was designed to withstand high winds and seismic forces and can serve small service vehicles and pallet jacks to transport goods, in addition to passengers [86].

Construction began in the prefabrication yard in February 2024 and took six months. The prefabrication yard was located on airport property away from the terminal. Prior to transport, the current conditions at the terminal (including the connection points) were validated with a laser survey of the exterior and interior; this supported accurate placement on the bolt foundations with ¾ inch tolerance [86]. Despite careful planning, the existing building presented challenges such as unexpected utility locations.

Other challenges included positioning the modules with minimal disruption to airport operations and ensuring the modules were installed safely with adequate distances maintained from critical infrastructure such as fueling systems. The design also required balancing the corridor width and location with the provision of exceptional passenger experience in the corridor, including optimal views and functionality [86]. The modular corridor is not completely straight, it is offset around the baggage system, as this adds visual interest and interrupts what would otherwise be a long straight run [86].

Clear objectives and decisive action, careful planning, timely decision making, and shared commitment are also identified as critical to the project success [86]. Benefits of the temporary corridors include improved passenger experience, including convenience, safety and flow; savings in terms of time and associated costs; and improved construction scheduling and phasing. The temporary modular corridor simplifies travel for passengers throughout construction and for the construction team since it eliminates the need for temporary corridors that would change throughout different phases of construction [84]. The larger project includes several sustainability features such as LEED Platinum certification, energy-efficient and water-saving equipment, and the use of sustainable materials [84].

4. Characteristics of Modular Construction at Airports in the US

The previous sections highlighted some airport construction projects that have utilized modular construction at US airports and showcased the versatility and efficiency of modular construction to support airport development. Some of the characteristics of these projects are summarized in Table 3 below. One of the first projects to utilize modular construction for terminal construction, the DFW High C Gates, utilized a hybrid approach, with prefabricated modules and traditional construction for connections. This project provided valuable lessons for DFW, with subsequent projects incorporating larger modules and additional components, as well as for other airports, such as ATL, which integrated a hybrid approach for their Terminal D expansion, with a combination of modular and traditional construction. The other examples all represent widely varying applications, with steel structures for the sterile corridor at IAH, precast concrete on the landside at ORD, and iconic design features of an elevated pedestrian bridge at SEA and a massive, locally sourced timber roof at PDX. The final project is also unique, with the use case of modular construction as a temporary corridor at SFO.

Table 3.

Module construction projects at US airports.

Transport was provided by the Dutch firm Mammoet and Italian firm Figiori for all projects, and all projects conducted transport activities at night, to minimize disruption to airport activities. Many of the projects used a combination of SPMTs, cranes, and strand jacks. The number of modules varied significantly, from six modules at DFW and ATL to over 6000 precast components at ORD. In all cases, transport played an important role in the design. Modules and components were designed to reflect size constraints, such as the need to fit under the Skylink train structure at Dallas, as well as financial considerations, such as the reduction in the size of double tees from 15 ft to 14 ft to reduce the need for expensive escort across state lines. Transport also was an important consideration in component design in terms of the need to stabilize and reinforce the modules for lifting, transport and placement. As airports and their partners gain experience, module sizes increase, include additional finishes, and can be transported more quickly.

The projects were often innovative beyond the construction method. The SEA walkway is the longest in the world over an active taxiway that can accommodate a large aircraft. The PDX roof reflects local pride and local sourcing in addition to being a one-of-a-kind interior finish on an incredibly dramatic scale. The SFO corridor provides safe passage for passengers and ensures the continued operation of gates, as well as large windows, local art and wayfinding, all of which support a higher passenger level of service.

In all cases, a strong motivator for modular construction was the need to maintain airport operations throughout construction. In some cases, all work was performed at night and there were no terminal closures. In other cases, there were limited closures, such as the limit of eight gate closures at a time at the ATL Terminal D. In all cases, modular construction reduced the disruption to passengers and airport operations.

Recurring themes for success were close collaborations, detailed planning and careful execution. Many of the projects utilized and CMAR and/or a design–build approach, which bring the constructors and subcontractors on board early in the design process. Detailed planning and careful execution often included the use of mock-ups, additional structural analysis, and computer modeling such as BIM and 4D modeling and simulation. The use of advanced surveying for the module and components, the on-site features and the pavement and environment along the travel route were all important to ensure a safe journey and placement within the required tolerances.

Modular construction can also meet stringent seismic requirements, as demonstrated at SEA and SFO, as well as support sustainability certifications, which were obtained for the projects at ATL, SEA, ORD, PDX and SFO. Overall, modular construction has been a good solution for many airports and it is likely to be increasingly used to allow airports to meet growing demands while minimizing disruption to airport operations.

5. How Modular Construction Contributes to Airport Sustainability

Many of the benefits of modular construction at airports directly relate to airport sustainability, and modular construction supports airport sustainability in a variety of ways, as illustrated in Table 4. One of the biggest advantages of modular construction is the reduced impact on airport operations, which is a primary driver for modular construction for many of the airport projects. At an airport where the proposed development is an expansion to meet a demand that already exceeds the current capacity, the airport cannot accommodate much disruption due to construction. Similarly, modular construction may also reduce disruption on the airside. In both cases, modular construction moves fabrication out of a congested and constrained area to a fabrication site that is more accessible. Ideally, fabrication can take place in an area where security protocols for construction workers are less burdensome, saving both the airport and the contractor time and money. Reduced disruption can also present financial gains if it reduces disruption to airport concessions, which provides non-aeronautical revenue and amenities and services for passengers.

Table 4.

Modular Construction and Airport Sustainability.

By moving fabrication off-site, the project schedule can be accelerated, and activities can occur in tandem at the site and the fabrication site. This saves time and money, and further reduces the impact on airport operations. Off-site fabrication also provides improved safety for construction workers, since workers may be able to work at a better height (consider the fabrication of the SEA roof on the ground rather than at an elevation of 85 ft) or otherwise configure the work for greater safety. Safety is also improved by selecting a fabrication site with fewer constraints in terms of adjacent buildings and activities and moving the activities away from passengers and ramps where aircraft and ground service equipment are moving. Quality control may also be enhanced using modular construction, since tighter tolerances require additional checks and oversight.

Modular construction can also increase safety and convenience for passengers, since more of the construction activities can occur on the fabrication site, reducing both the amount of disruption in the terminal and the length of the disruption. Modular projects have also demonstrated compliance with seismic and sustainability requirements. Overall, modular airport construction can play an important role in supporting airport sustainability.

One limitation of this research is that the analysis is descriptive and qualitative, and relies on secondary sources such as reports, press releases and some stakeholder consultation. This approach is limited since there are issues related to selection bias and data verification. This paper may understate the challenges of airport modular construction since airports and constructors may be more likely to discuss project benefits and less likely to discuss challenges.

6. Recommendations and Conclusions

Modular construction offers significant benefits and supports airport sustainability, based on the recent experience of US airports. Successful modular construction projects at airports require collaboration and strong commitment. Involving all stakeholders from the outset is crucial, and building a qualified team with the appropriate expertise ensures a multidisciplinary perspective, integrating input from constructors, transporters, and trades early on and throughout the process.