Last-Mile Logistics Network Design under E-Cargo Bikes

Abstract

1. Introduction

2. Materials and Methods

2.1. Problem Description

2.2. Solution Method

2.2.1. Solution Representation and Initialization

2.2.2. Fitness Function Value

2.2.3. Genetic Operators

2.2.4. Route Extraction

2.2.5. Genetic Algorithm Termination

3. Results

3.1. Overview

3.2. GA Parameters and Fine Tuning

3.3. Results

3.4. Sensitivity Analysis

3.5. GA Performance Validation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Melo, S.; Baptista, P. Evaluating the impacts of using cargo cycles on urban logistics: Integrating traffic, environmental and operational boundaries. Eur. Transp. Res. Rev. 2017, 9, 30. [Google Scholar] [CrossRef]

- Nocerino, R.; Colorni, A.; Lia, F.; Lue, A. E-bikes and E-scooters for smart logistics: Environmental and economic sustainability in pro-E-bike Italian pilots. Transp. Res. Procedia 2016, 14, 2362–2371. [Google Scholar] [CrossRef]

- Narayanan, S.; Antoniou, C. Electric cargo cycles-A comprehensive review. Transp. Policy 2021, 116, 278–303. [Google Scholar] [CrossRef]

- Aiello, G.; Quaranta, S.; Certa, A.; Inguanta, R. Optimization of urban delivery systems based on electric assisted cargo bikes with modular battery size, taking into account the service requirements and the specific operational context. Energies 2021, 14, 4672. [Google Scholar] [CrossRef]

- Lee, K.; Chae, J.; Kim, J. A courier service with electric bicycles in an Urban Area: The case in Seoul. Sustainability 2019, 11, 1255. [Google Scholar] [CrossRef]

- Choubassi, C.; Seedah, D.P.; Jiang, N.; Walton, C.M. Economic analysis of cargo cycles for urban mail delivery. Transp. Res. Rec. 2016, 2547, 102–110. [Google Scholar] [CrossRef]

- Arnold, F.; Cardenas, I.; Sorensen, K.; Dewulf, W. Simulation of B2C e-commerce distribution in Antwerp using cargo bikes and delivery points. Eur. Transp. Res. Rev. 2017, 10, 2. [Google Scholar] [CrossRef]

- Sárdi, D.L.; Bóna, K. A geometrical structure-based new approach for city logistics system planning with cargo bikes and its application for the shopping malls of Budapest. Appl. Sci. 2021, 11, 3300. [Google Scholar] [CrossRef]

- Temporelli, A.; Brambilla, P.C.; Brivio, E.; Girardi, P. Last Mile Logistics Life Cycle Assessment: A Comparative Analysis from Diesel Van to E-Cargo Bike. Energies 2022, 15, 7817. [Google Scholar] [CrossRef]

- Dalla Chiara, G.; Alho, A.R.; Cheng, C.; Ben-Akiva, M.; Cheah, L. Exploring benefits of cargo-cycles versus trucks for urban parcel delivery under different demand scenarios. Transp. Res. Rec. 2020, 2674, 553–562. [Google Scholar] [CrossRef]

- Fikar, C.; Hirsch, P.; Gronalt, M. A decision support system to investigate dynamic last-mile distribution facilitating cargo-bikes. Int. J. Logist. Res. Appl. 2018, 21, 300–317. [Google Scholar] [CrossRef]

- Perboli, G.; Rosano, M. Parcel delivery in urban areas: Opportunities and threats for the mix of traditional and green business models. Transp. Res. Part C Emerg. Technol. 2019, 99, 19–36. [Google Scholar] [CrossRef]

- Llorca, C.; Moeckel, R. Study of Cargo Bikes for Parcel Deliveries under Different Supply, Demand and Spatial Conditions. In Proceedings of the 2020 Forum on Integrated and Sustainable Transportation Systems (FISTS), Delft, The Netherlands, 3–5 November 2020. [Google Scholar]

- Caggiani, L.; Colovic, A.; Prencipe, P.L.; Ottomanelli, M. A green logistics solution for last-mile deliveries considering e-vans and e-cargo bikes. Transp. Res. Procedia 2020, 52, 75–82. [Google Scholar] [CrossRef]

- Enthoven, D.L.; Jargalsaikhan, B.; Roodbergen, K.J.; Uit het Broek, M.A.; Schrotenboer, A.H. The two-echelon vehicle routing problem with covering options: City logistics with cargo bikes and parcel lockers. Comp. Oper. Res. 2020, 118, 104919. [Google Scholar] [CrossRef]

- Büttgen, A.; Turan, B.; Hemmelmayr, V. Evaluating Distribution Costs and CO2-Emissions of a Two-Stage Distribution System with Cargo Bikes: A Case Study in the City of Innsbruck. Sustainability 2021, 13, 13974. [Google Scholar] [CrossRef]

- Niels, T.; Hof, M.T.; Bogenberger, K. Design and Operation of an Urban Electric Courier Cargo Bike System. In Proceedings of the 2018 21st International Conference on Intelligent Transportation Systems, Maui, HI, USA, 4–7 November 2018. [Google Scholar]

- Naumov, V.; Pawluś, M. Identifying the optimal packing and routing to improve last-mile delivery using cargo bicycles. Energies 2021, 14, 4132. [Google Scholar] [CrossRef]

- Fontaine, P. The vehicle routing problem with load-dependent travel times for cargo bicycles. Eur. J. Oper. Res. 2022, 300, 1005–1016. [Google Scholar] [CrossRef]

- Naumov, V. Substantiation of Loading Hub Location for Electric Cargo Bikes Servicing City Areas with Restricted Traffic. Energies 2021, 14, 839. [Google Scholar] [CrossRef]

- Robichet, A.; Nierat, P.; Combes, F. First and Last Miles by Cargo Bikes: Ecological Commitment or Economically Feasible? The Case of a Parcel Service Company in Paris. Transp. Res. Rec. 2022, 2676, 269–278. [Google Scholar] [CrossRef]

- Caggiani, L.; Prencipe, L.P.; Colovic, A.; Dell’Orco, M. An Eco-Friendly Decision Support System for Last-Mile Delivery Using E-Cargo Bikes. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6. [Google Scholar]

- Vasiutina, H.; Szarata, A.; Rybicki, S. Evaluating the Environmental Impact of Using Cargo Bikes in Cities: A Comprehensive Review of Existing Approaches. Energies 2021, 14, 6462. [Google Scholar] [CrossRef]

- Anderluh, A.; Hemmelmayr, V.C.; Nolz, P.C. Sustainable Logistics with Cargo Bikes—Methods and Applications. In Sustainable Transportation and Smart Logistics; Faulin, J., Juan, A.A., Grasman, S.E., Hirsch, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 207–232. [Google Scholar]

- Boysen, N.; Fedtke, S.; Schwerdfeger, S. Last-mile delivery concepts: A survey from an operational research perspective. OR Spectr. 2021, 43, 1–58. [Google Scholar] [CrossRef]

- Iliopoulou, C.; Kepaptsoglou, K.; Karlaftis, M.G. Route planning for a seaplane service: The case of the Greek Islands. Comp. Oper. Res. 2015, 59, 66–77. [Google Scholar] [CrossRef]

- Lenstra, J.K.; Rinnooy Kan, A.H.G. Complexity of vehicle routing and scheduling problems. Networks 1981, 11, 221–227. [Google Scholar] [CrossRef]

- Charisis, A.; Iliopoulou, C.; Kepaptsoglou, K. DRT route design for the first/last mile problem: Model and application to Athens, Greece. Public Transp. 2018, 10, 499–527. [Google Scholar] [CrossRef]

- Liu, L.; Suzuki, T. Quantifying e-bike applicability by comparing travel time and physical energy expenditure: A case study of Japanese cities. J. Transp. Health 2019, 13, 150–163. [Google Scholar] [CrossRef]

- Liazos, A.; Iliopoulou, C.; Kepaptsoglou, K.; Bakogiannis, E. Geofence planning for electric scooters. Transp. Res. Part D Transp. Environ. 2022, 102, 103149. [Google Scholar] [CrossRef]

- Arango, I.; Lopez, C.; Ceren, A. Improving the autonomy of a mid-drive motor electric bicycle based on system efficiency maps and its performance. World Electr. Veh. J. 2021, 12, 59. [Google Scholar] [CrossRef]

- Iliopoulou, C.; Kepaptsoglou, K.; Vlahogianni, E. Metaheuristics for the transit route network design problem: A review and comparative analysis. Public Transp. 2019, 11, 487–521. [Google Scholar] [CrossRef]

- Bell, J.E.; McMullen, P.R. Ant colony optimization techniques for the vehicle routing problem. Adv. Eng. Inform. 2004, 18, 41–48. [Google Scholar] [CrossRef]

- Alpos, T.; Iliopoulou, C.; Kepaptsoglou, K. Nature-Inspired Optimal Route Network Design for Shared Autonomous Vehicles. Vehicles 2023, 5, 24–40. [Google Scholar] [CrossRef]

- Eslamipoor, R. A fuzzy multi-objective model for supplier selection to mitigate the impact of vehicle transportation gases and delivery time. J. Data Inf. Manag. 2022, 4, 231–241. [Google Scholar] [CrossRef]

- Eslamipoor, R. A two-stage stochastic planning model for locating product collection centers in green logistics networks. Clean. Logist. Supply Chain 2023, 6, 100091. [Google Scholar] [CrossRef]

| Description | |

|---|---|

| Sets | |

| V | |

| Set of delivery points including depot 0 and depot N+1 (starting and ending point), | |

| B | |

| Q | Set of packages for delivery |

| Parameters | |

| N | Number of delivery points |

| qi | Number of packages to be delivered at point i |

| C | Capacity of the e-cargo bike (in packages) |

| b | Ε-cargo bike |

| dij | Distance between delivery points (i,j) (km) |

| eij | Energy consumption for link (i,j) |

| L | Battery Capacity for each e-cargo bike |

| r | Usable capacity factor |

| α | Tolerance for workload allocation |

| Decision Variable | |

| xijb | Binary variable equal to 1 if the vehicle b is traveling on arc (i,j), |

| Set of Experiments | POP | CR | MR | Best Objective Function Value (Wh) | Average | Standard Deviation |

|---|---|---|---|---|---|---|

| 1 | 25 | 0.2 | 0.05 | 685.25 | 782.75 | 58.12 |

| 2 | 0.15 | 828.46 | 889.904 | 77.01 | ||

| 3 | 0.25 | 835.36 | 866.548 | 25.77 | ||

| 4 | 0.6 | 0.05 | 790.24 | 842.862 | 44.12 | |

| 5 | 0.15 | 771.81 | 907.45 | 99.96 | ||

| 6 | 0.25 | 877.54 | 905.056 | 31.30 | ||

| 7 | 0.8 | 0.05 | 678.71 | 779.924 | 92.43 | |

| 8 | 0.15 | 816.55 | 845.22 | 20.19 | ||

| 9 | 0.25 | 838.55 | 909.574 | 102.79 | ||

| 10 | 50 | 0.2 | 0.05 | 784.98 | 891.39 | 78.83 |

| 11 | 0.15 | 888.74 | 929.058 | 43.19 | ||

| 12 | 0.25 | 867.45 | 893.08 | 19.63 | ||

| 13 | 0.6 | 0.05 | 836.39 | 855.262 | 13.45 | |

| 14 | 0.15 | 832.02 | 890.702 | 36.36 | ||

| 15 | 0.25 | 941.46 | 1018.814 | 57.91 | ||

| 16 | 0.8 | 0.05 | 834.1 | 834.56 | 57.87 | |

| 17 | 0.15 | 849.77 | 876.99 | 42.07 | ||

| 18 | 0.25 | 942.1 | 1013.29 | 194.39 |

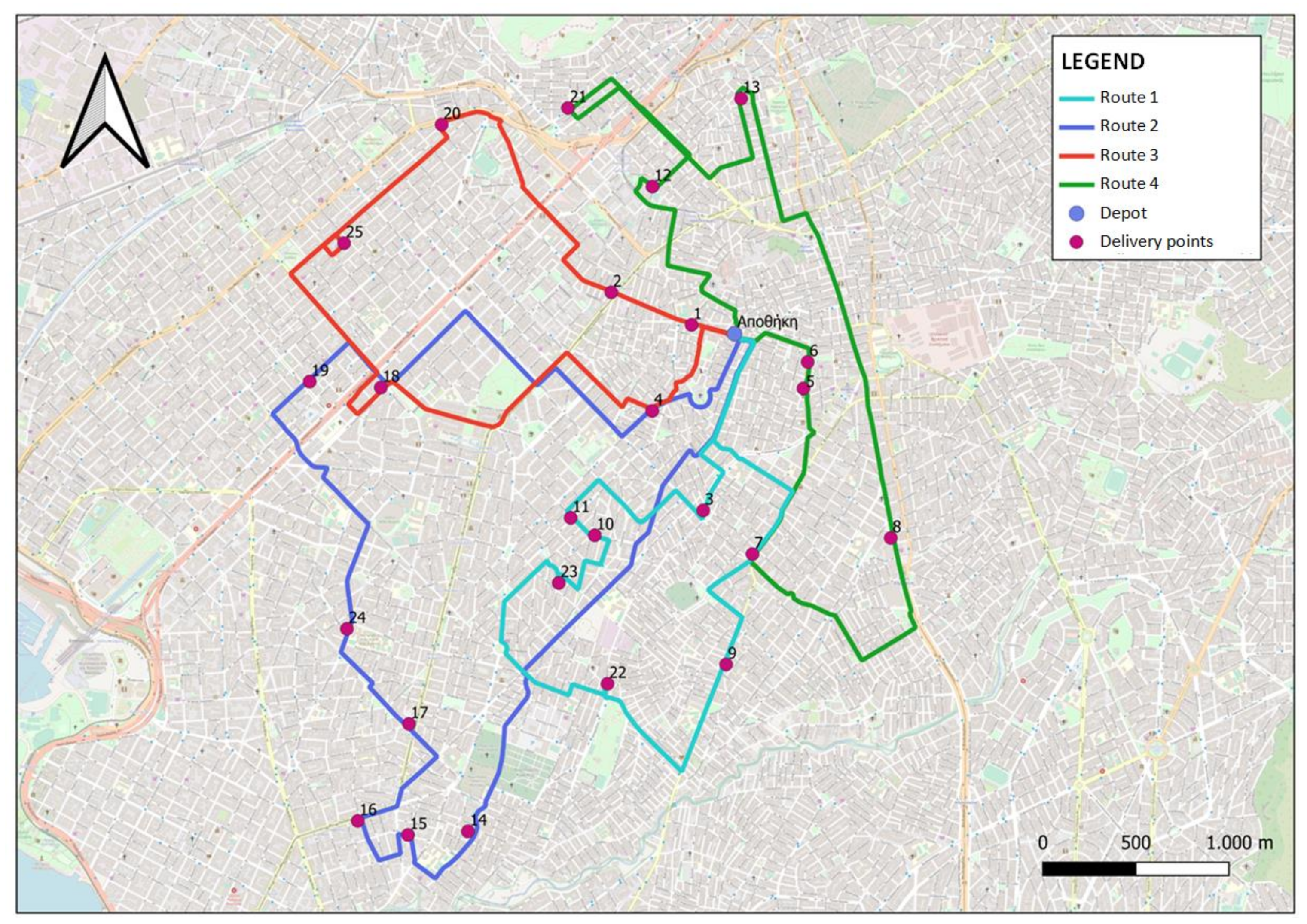

| Travelled Distance (m) | Packages Per Route | Delivery Points Per Route | |

|---|---|---|---|

| Route 1 | 14,689 | 20 | 7 |

| Route 2 | 18,581 | 18 | 6 |

| Route 3 | 16,856 | 19 | 6 |

| Route 4 | 14,351 | 19 | 6 |

| Objective Function | 634 Wh | ||

| Algorithm | Best Objective Function Value (Wh) | Average | Standard Deviation |

|---|---|---|---|

| GA | 678.71 | 779.924 | 92.43 |

| ACO | 699.12 | 740.818 | 24.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papaioannou, E.; Iliopoulou, C.; Kepaptsoglou, K. Last-Mile Logistics Network Design under E-Cargo Bikes. Future Transp. 2023, 3, 403-416. https://doi.org/10.3390/futuretransp3020024

Papaioannou E, Iliopoulou C, Kepaptsoglou K. Last-Mile Logistics Network Design under E-Cargo Bikes. Future Transportation. 2023; 3(2):403-416. https://doi.org/10.3390/futuretransp3020024

Chicago/Turabian StylePapaioannou, Eleni, Christina Iliopoulou, and Konstantinos Kepaptsoglou. 2023. "Last-Mile Logistics Network Design under E-Cargo Bikes" Future Transportation 3, no. 2: 403-416. https://doi.org/10.3390/futuretransp3020024

APA StylePapaioannou, E., Iliopoulou, C., & Kepaptsoglou, K. (2023). Last-Mile Logistics Network Design under E-Cargo Bikes. Future Transportation, 3(2), 403-416. https://doi.org/10.3390/futuretransp3020024