Heat Treatment Effects on β Ti-10Mo-xMn Alloys for Biomedical Applications

Abstract

1. Introduction

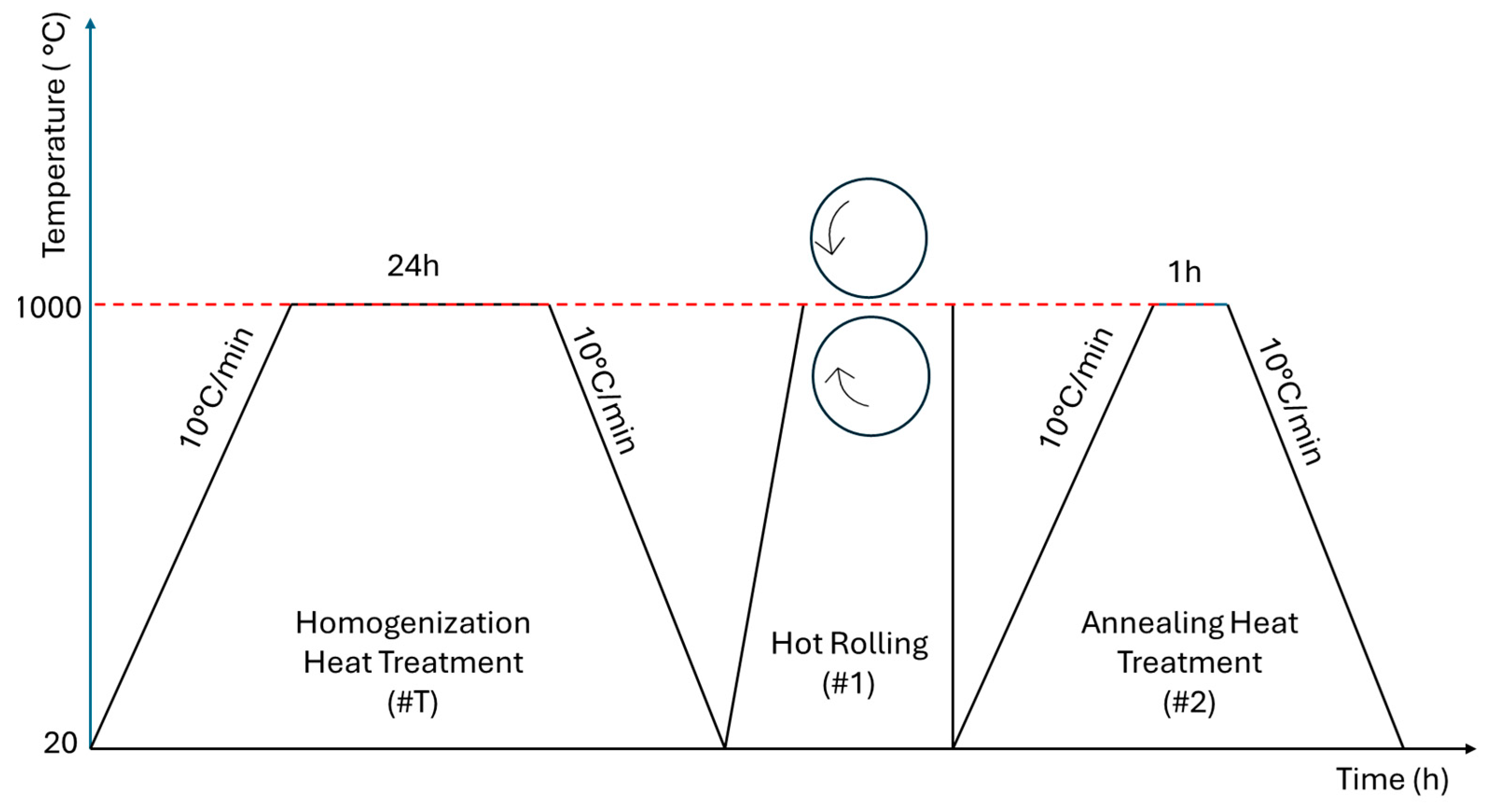

2. Materials and Methods

3. Results and Discussion

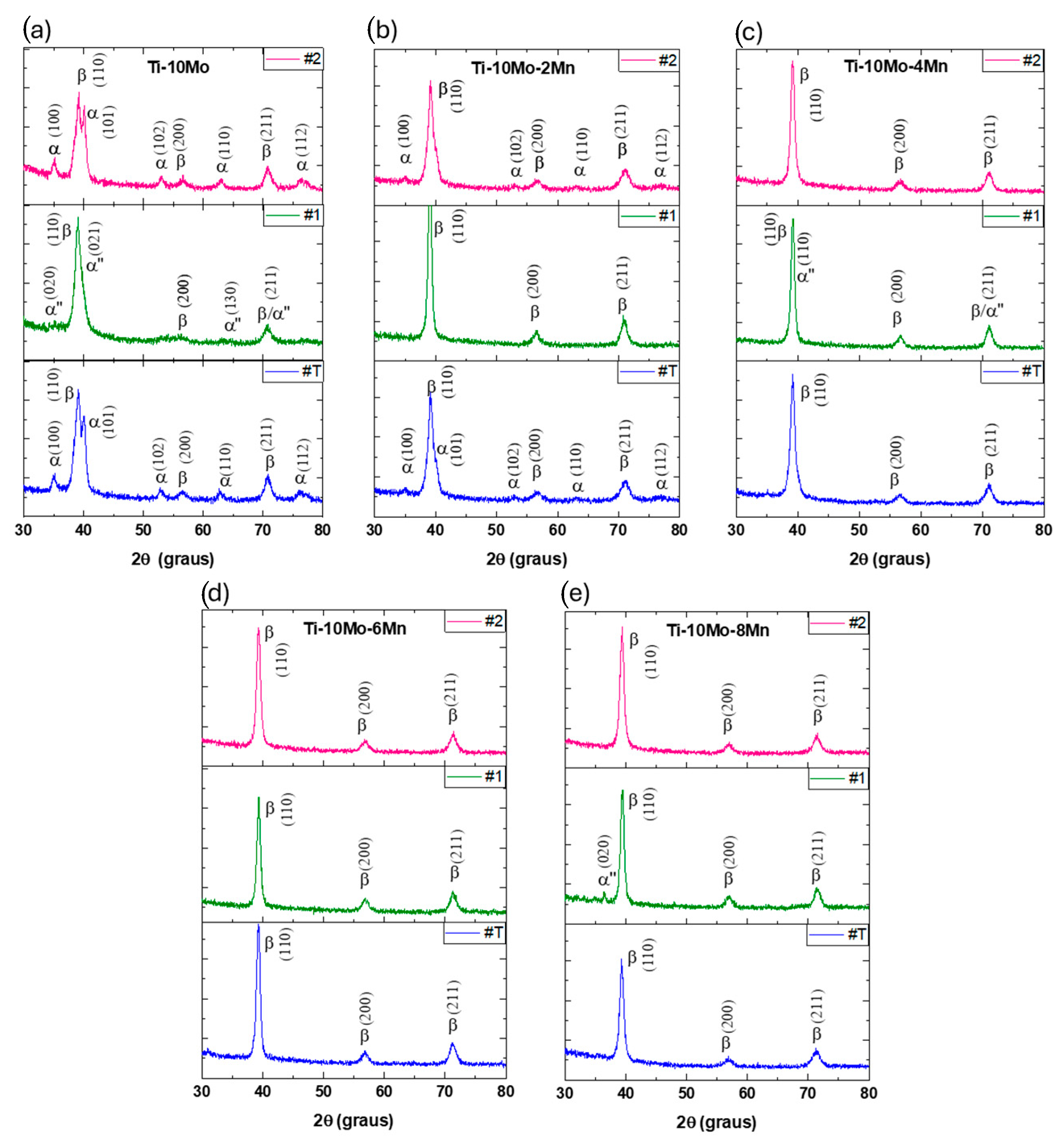

3.1. X-Ray Results

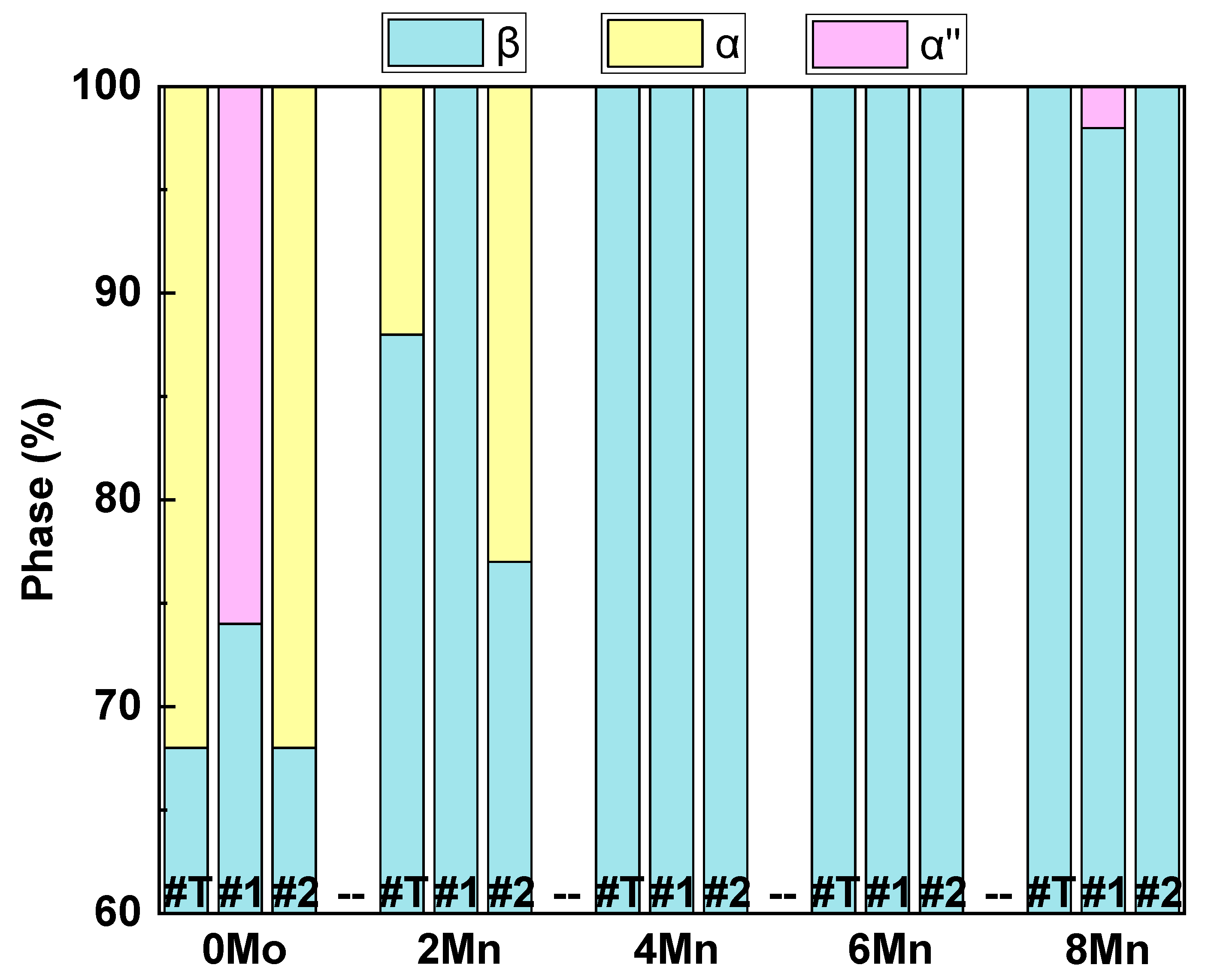

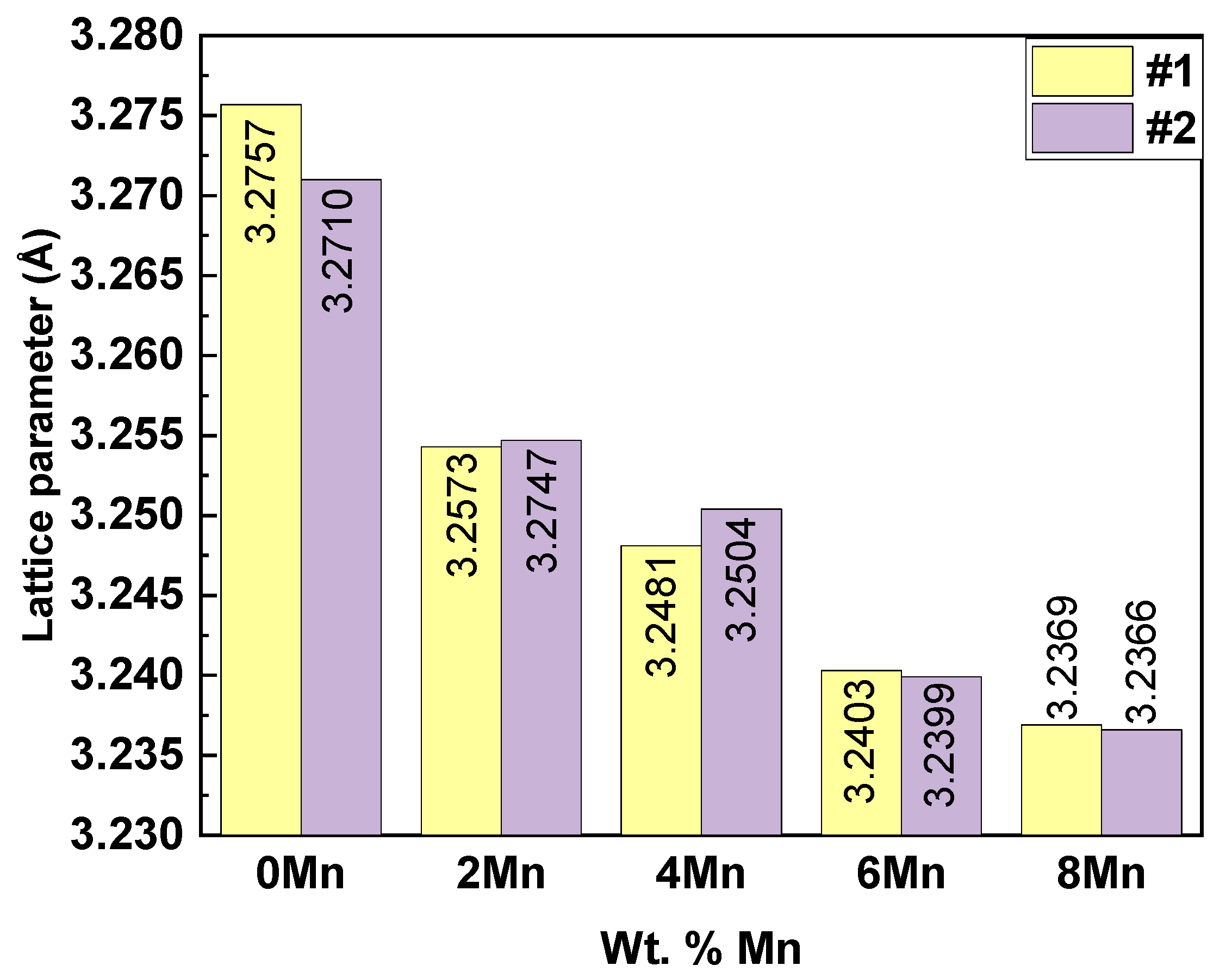

3.2. Rietveld Refinement Results

3.3. Microscopic Analysis

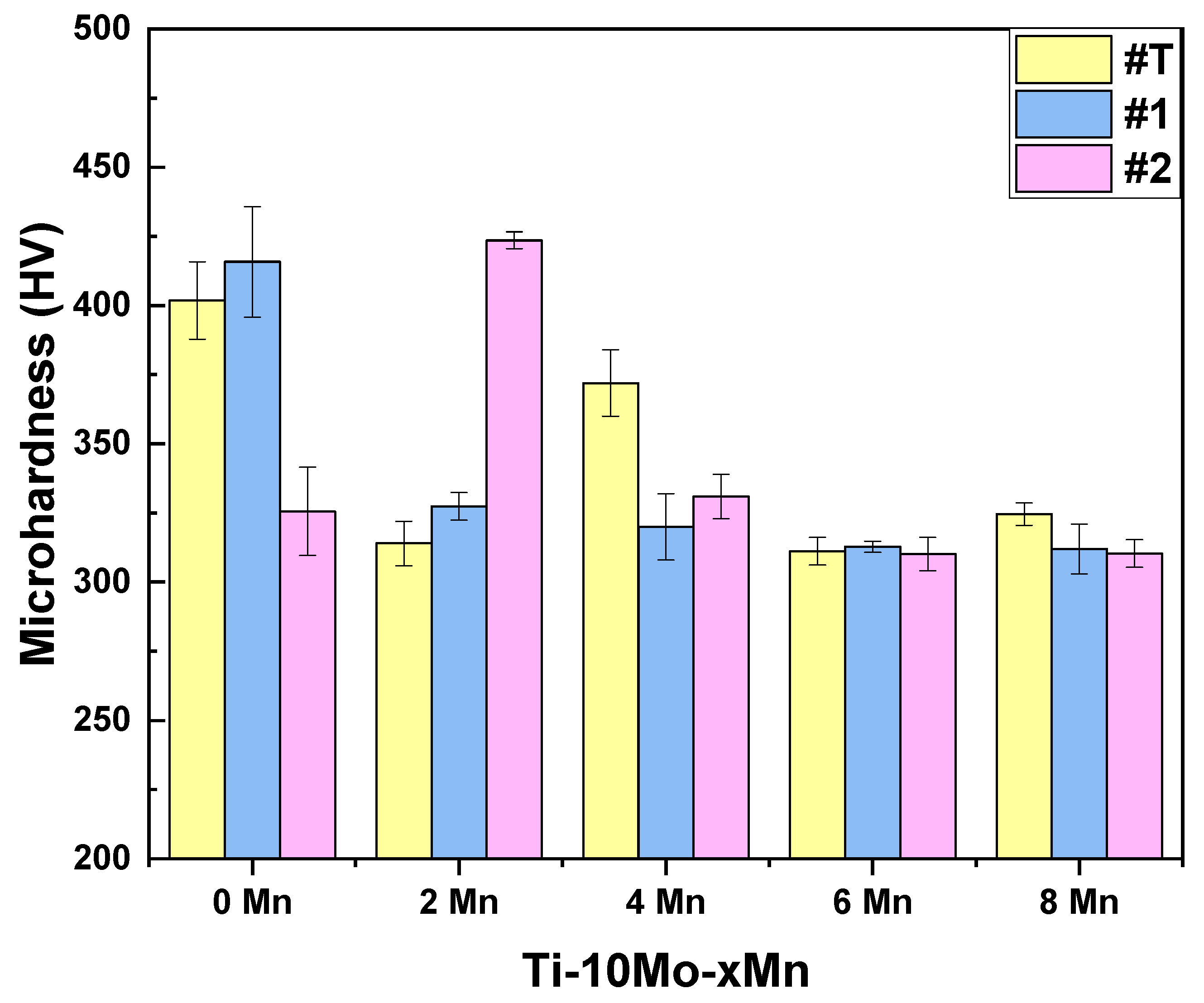

3.4. Vickers Hardness

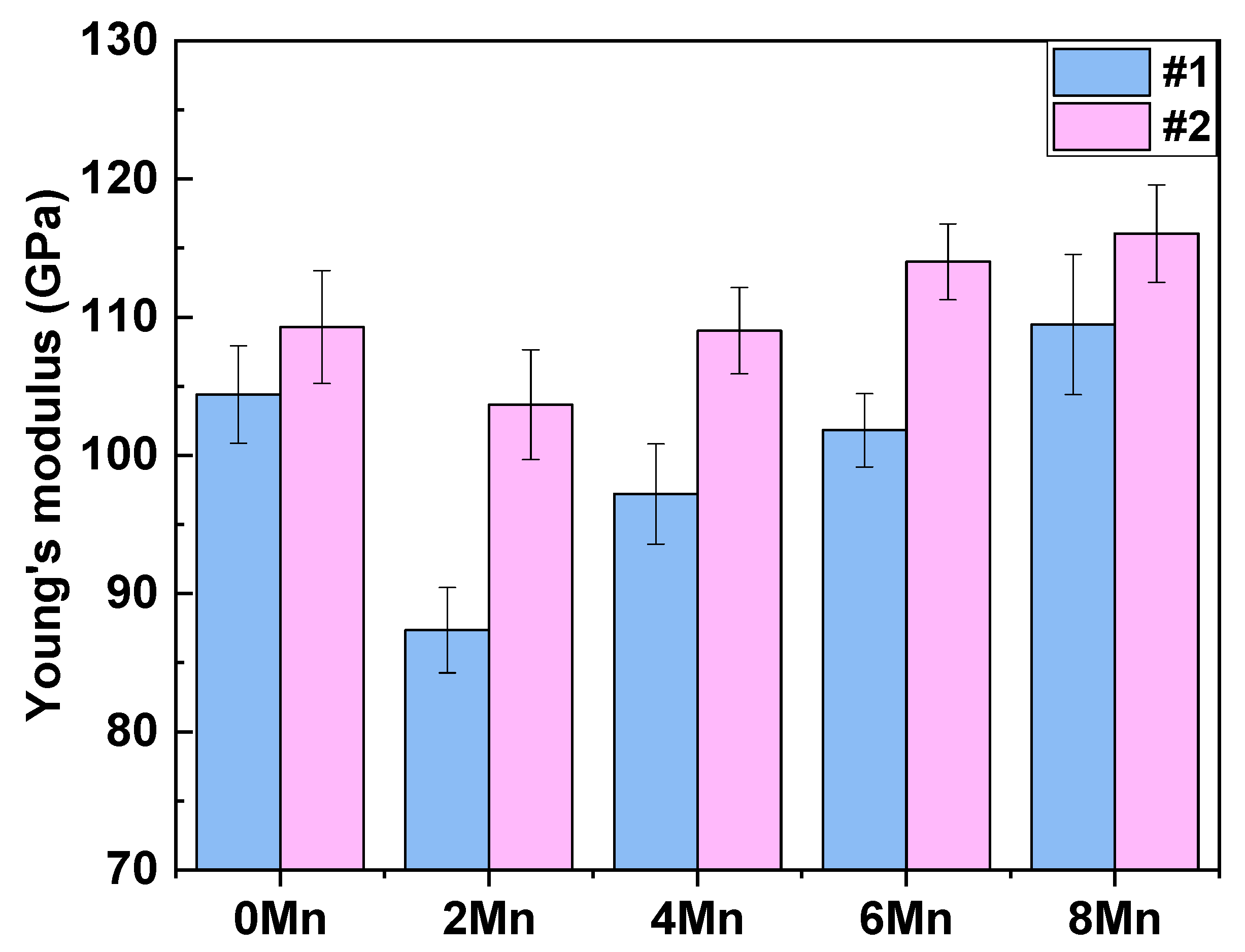

3.5. Elastic Modulus

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Y.; Yan, S.; Qu, S.; Yi, M.; Chen, Z.; Zhou, T.; Xu, C. Microstructure of titanium alloy in additive/subtractive hybrid manufacturing: A review. J. Alloys Compd. 2025, 1014, 178769. [Google Scholar] [CrossRef]

- Yadav, P.; Saxena, K.K. Effect of heat-treatment on microstructure and mechanical properties of Ti alloys: An overview. Mater. Today Proc. 2020, 26, 2546–2557. [Google Scholar] [CrossRef]

- Lourenço, M.L.; Pontes, F.M.L.; Grandini, C.R. The Influence of Thermomechanical Treatments on the Structure, Microstructure, and Mechanical Properties of Ti-5Mn-Mo Alloys. Metals 2022, 12, 527. [Google Scholar] [CrossRef]

- Sarma, J.; Kumar, R.; Sahoo, A.K.; Panda, A. Enhancement of material properties of titanium alloys through heat treatment process: A brief review. Mater. Today Proc. 2020, 23, 561–564. [Google Scholar] [CrossRef]

- Gupta, J.; Jha, I.K.; Khatirkar, R.K.; Singh, J. Microstructure Evolution During Aging Heat Treatment of Metastable Ti-15V-3Cr-3Al-3Sn β Titanium Alloy. J. Mater. Eng. Perform. 2025, 34, 19945–19956. [Google Scholar] [CrossRef]

- Xavier, C.C.; Correa, D.R.N.; Grandini, C.R.; Rocha, L.A. Low temperature heat treatments on Ti-15Zr-xMo alloys. J. Alloys Compd. 2017, 727, 246–253. [Google Scholar] [CrossRef]

- Kuroda, P.A.B.; Quadros, F.d.F.; Afonso, C.R.M.; Grandini, C.R. The Effect of Solution Heat Treatment Time on the Phase Formation and Selected Mechanical Properties of Ti-25Ta-xZr Alloys for Application as Biomaterials. J. Mater. Eng. Perform. 2021, 30, 5905–5913. [Google Scholar] [CrossRef]

- Lourenço, M.L.; Correa, M.R.; de Almeida, G.S.; Kuroda, P.A.B.; Zambuzzi, W.F.; Grandini, C.R. Development of new β Ti-10-Mo-Mn alloys for biomedical applications. J. Alloys Compd. 2024, 1008, 176524. [Google Scholar] [CrossRef]

- Kuroda, P.A.B.; Carvalho, A.P.; Caram, R.; Figueiredo, R.B.; Afonso, C.R.M. Nanostructured bulk HPT β Ti-42Nb alloy as biomaterial for implants obtained directly from micrometric powders. Mater. Lett. 2025, 378, 137572. [Google Scholar] [CrossRef]

- Correa, D.R.N.; Kuroda, P.A.B.; Grandini, C.R.; Rocha, L.A.; Oliveira, F.G.M.; Alves, A.C.; Toptan, F. Tribocorrosion behavior of β-type Ti-15Zr-based alloys. Mater. Lett. 2016, 179, 118–121. [Google Scholar] [CrossRef]

- Kuroda, P.A.B.; Pedroso, B.L.T.; Pontes, F.M.L.; Grandini, C.R. Effect of Titanium Addition on the Structure, Microstructure, and Selected Mechanical Properties of As-Cast Zr-25Ta-xTi Alloys. Metals 2021, 11, 1507. [Google Scholar] [CrossRef]

- de Mattos, F.; da Silva, A.; Sangali, M.; Rodrigues, J.; Caram, R.; Afonso, C. Unraveling composition graded microstructure of in-situ alloyed Ti-15Nb alloy through laser powder bed fusion. Mater. Lett. 2024, 358, 135776. [Google Scholar] [CrossRef]

- Larson, A.C.; Dreele, R.B.V. General Structure Analysis System (GSAS); Los Alamos National Laboratory Report LAUR; Los Alamos National Laboratory (LANL): Los Alamos, NM, USA, 2004. [Google Scholar]

- Toby, B.H. R factors in Rietveld analysis: How good is good enough? Powder Diffr. 2012, 21, 67–70. [Google Scholar] [CrossRef]

- Kuroda, P.A.B.; Grandini, C.R.; Afonso, C.R. Development of new β Ti and Zr-based alloys in the Ta-(75-x)Ti-xZr system. J. Mater. Res. Technol. 2024, 29, 4579–4587. [Google Scholar] [CrossRef]

- E92-16, A.D.; Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- E384-16, A.D.; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Rossi, M.C.; Bayerlein, D.L.; Gouvêa, E.d.S.; Haro Rodríguez, M.V.; Escuder, A.V.; Borrás, V.A. Evaluation of the influence of low Mg content on the mechanical and microstructural properties of β titanium alloy. J. Mater. Res. Technol. 2021, 10, 916–925. [Google Scholar] [CrossRef]

- Elhadad, A.A.; Romero-Resendiz, L.; Rossi, M.C.; Rodríguez-Albelo, L.M.; Lascano, S.; Afonso, C.R.M.; Alcudia, A.; Amigó, V.; Torres, Y. Findings and perspectives of β-Ti alloys with biomedical applications: Exploring beyond biomechanical and biofunctional behaviour. J. Mater. Res. Technol. 2024, 33, 3550–3618. [Google Scholar] [CrossRef]

- Cardoso, G.C.; de Almeida, G.S.; Corrêa, D.O.G.; Zambuzzi, W.F.; Buzalaf, M.A.R.; Correa, D.R.N.; Grandini, C.R. Preparation and characterization of novel as-cast Ti-Mo-Nb alloys for biomedical applications. Sci. Rep. 2022, 12, 11874. [Google Scholar] [CrossRef] [PubMed]

- Martins Júnior, J.R.S.; Nogueira, R.A.; Araújo, R.O.d.; Donato, T.A.G.; Arana-Chavez, V.E.; Claro, A.P.R.A.; Moraes, J.C.S.; Buzalaf, M.A.R.; Grandini, C.R. Preparation and characterization of Ti-15Mo alloy used as biomaterial. Mater. Res. 2011, 14, 107–112. [Google Scholar] [CrossRef]

- Hanada, S.; Izumi, O. Deformation and Fracture of Metastable Beta Titanium Alloys (Ti–15Mo–5Zr and Ti–15Mo–5Zr–3Al). Trans. Jpn. Inst. Met. 1982, 23, 85–94. [Google Scholar] [CrossRef][Green Version]

- Nunes, A.R.V.; Borborema, S.; Malet, L.; Dille, J.; de Almeida, L.H. Microstructural Evolution of Cold-Rolled β Metastable Ti-29Nb-2Mo-6Zr Alloy. Microsc. Microanal. 2019, 25, 2634–2635. [Google Scholar] [CrossRef]

- Collings, E.W. The Physical Metallurgy of Titanium Alloys; ASM: Novelty, OH, USA, 1984. [Google Scholar]

- Kuroda, P.A.B.; Quadros, F.d.F.; Araújo, R.O.d.; Afonso, C.R.M.; Grandini, C.R. Effect of Thermomechanical Treatments on the Phases, Microstructure, Microhardness and Young’s Modulus of Ti-25Ta-Zr Alloys. Materials 2019, 12, 3210. [Google Scholar] [CrossRef] [PubMed]

- Abbaschian, R.; Reed-Hill, R.E. Physical Metallurgy Principles—SI Version; Cengage Learning: Boston, MA, USA, 2009. [Google Scholar]

- Callister, W.D., Jr.; Rethwisch, D.G. Materials Science and Engineering: An Introduction; John Wiley & Sons: Hoboken, NY, USA, 2020. [Google Scholar]

- Kaur, M.; Singh, K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C 2019, 102, 844–862. [Google Scholar] [CrossRef] [PubMed]

| Symbol | Condition |

|---|---|

| #T | Heat treatment homogenization |

| #1 | Hot rolling |

| #2 | Heat treatment annealing |

| x2 | Ti-10Mo | Ti-10Mo-2Mn | Ti-10Mo-4Mn | Ti-10Mo-6Mn | Ti-10Mo-8Mn |

|---|---|---|---|---|---|

| #T | 1.279 | 1.203 | 1.309 | 1.094 | 1.262 |

| #1 | 1.125 | 1.540 | 1.143 | 1.148 | 1.104 |

| #2 | 1.337 | 1.278 | 1.226 | 1.174 | 1.147 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lourenço, M.L.; Kuroda, P.A.B.; Grandini, C.R. Heat Treatment Effects on β Ti-10Mo-xMn Alloys for Biomedical Applications. Thermo 2025, 5, 46. https://doi.org/10.3390/thermo5040046

Lourenço ML, Kuroda PAB, Grandini CR. Heat Treatment Effects on β Ti-10Mo-xMn Alloys for Biomedical Applications. Thermo. 2025; 5(4):46. https://doi.org/10.3390/thermo5040046

Chicago/Turabian StyleLourenço, Mariana Luna, Pedro Akira Bazaglia Kuroda, and Carlos Roberto Grandini. 2025. "Heat Treatment Effects on β Ti-10Mo-xMn Alloys for Biomedical Applications" Thermo 5, no. 4: 46. https://doi.org/10.3390/thermo5040046

APA StyleLourenço, M. L., Kuroda, P. A. B., & Grandini, C. R. (2025). Heat Treatment Effects on β Ti-10Mo-xMn Alloys for Biomedical Applications. Thermo, 5(4), 46. https://doi.org/10.3390/thermo5040046