1. Introduction

Among the various forms of energy currently being used, a significant portion is generated into or by heat. In most industrial systems, heat is the main energy input for a system or accounts for most of the energy generated by a system. Due to the sharp growth in demand for energy throughout the world, techniques to enhance heat transfer performance and reduce energy loss by adopting more efficient processes have attracted a great deal of attention. The recent leap in heat dissipation rates of emerging advanced applications, coupled with the need for size reduction in cooling hardware, has made typical single-phase systems unable to meet this level of cooling requirements even with their maximum exploitable performance, which spurs a transition to phase-change thermal systems [

1,

2]. This trend encompasses applications generating high heat fluxes, such as thermal management in space, power electronics and microelectronics, heat exchangers for water desalination and hydrogen storage in vehicles, rocket engine nozzles, particle accelerators, nuclear fusion reactors, defense-sector laser and radar systems, and the advanced material processing [

3,

4,

5,

6]. The tremendous advantages of phase-change heat transfer systems are attributed to their ability to utilize both sensible and latent heats compared to the single-phase systems, which only exploit the sensible heat [

7]. Condensation and boiling are typical forms of phase-change heat transfer processes by which enormous amounts of heat can be transferred from/to a fluid with a small temperature difference during these processes due to the use of latent heat. Given the combined effects of buoyant forces and surface tension, the systems with boiling and condensation processes exhibit dramatically higher heat transfer coefficients and performances than those with a single-phase process [

8].

Horizontal flow boiling is commonly applied to shell-and-tube boilers, vapor-compression refrigeration systems, and fuel channels of pressurized heavy water nuclear reactors (PHWR). In the event of loss of coolant in pressurized heavy water reactors, the core fuel channels would face low mass velocity, flow stagnation, and reversal, posing a serious safety concern in terms of thermal management. Accordingly, investigating the horizontal flow boiling in PHWRs under low-pressure low-flow (LPLF) conditions plays a crucial role in understanding and predicting their nuclear core behavior to ensure thermal safety in unfavorable case scenarios such as the loss of coolant accidents [

9,

10]. The LPLF conditions are also widely applied to plate-type freshwater generators, used for desalination systems of marine plants and vessels [

11]. Furthermore, these conditions can be applied to natural-circulation passive systems and compact cooling systems for thermal management purposes. LPLF conditions in thermal management systems are often referred to operating conditions where pressure ranges from subatmospheric to a few bars while the mass flux is often lower than 200 kg/m

2-s, accompanied by a laminar or transitional flow regime.

To date, many studies have been undertaken empirically and numerically, focusing on the heat transfer characteristics of internal flow boiling for various working fluids, ranging from water to different refrigerants, at different tube sizes and orientations under operating pressures and mass fluxes, often varying from a medium to high range [

12,

13,

14,

15]. However, there are very limited experimental studies in the literature, mostly conducted under low-pressure or low-flow conditions. A large difference in density between steam and liquid at LPLF conditions causes a high slip ratio and fast gas expansion, leading to behaviors and mechanisms different from those of medium-to-high-pressure and flow conditions.

Baburajan et al. [

9] measured the local boiling heat transfer coefficient (BHTC) and pressure drop in a horizontal tube under low-pressure low-flow conditions for the subcooled boiling region. They employed infra-red thermography to measure local wall temperature in order to estimate local single-phase and two-phase heat transfer coefficients of water at atmospheric pressure for a range of mass fluxes and inlet subcooling temperatures, ranging from 450 kg/m

2-s to 935 kg/m

2-s and from 29 °C to 70 °C, respectively. They found that for a given vapor quality, the subcooled boiling heat transfer coefficient and the wall temperature increase with the increase in heat flux. However, the fluid temperature remains constant. In addition, it was observed that as mass flux increased, both the single- and two-phase pressure drops increased.

Changhong et al. [

16] conducted an experimental study on two-phase flow boiling heat transfer of distilled water in two vertical narrow annuli at high-pressure conditions and low-flow rates. It was revealed that the boiling heat transfer coefficients were independent of mass quality and mass flux, but were strongly dependent on the heat flux, indicating that the nucleate boiling regime has been the dominant mechanism. In addition, it was observed that the BHTC grew with the increase in heat flux. In another experimental study, Yan et al. [

17,

18] investigated the heat transfer of subcooled water flow boiling in a uniformly heated vertical circular tube with an ID of 9 mm under high heat flux and high mass flux (HHHM) operating conditions, which is commonly employed to the divertor cooling systems of the “international thermonuclear experimental reactors” (ITER).

In an empirical study conducted by Santini et al. [

3], 1575 measurements (points) of peripherally averaged and axially local heat transfer coefficients during forced convection boiling of water in a 24 m long full-scale helically coiled tube were collected with experimental uncertainties between 5% and 20%. The experiments were performed under a pressure range between 2 MPa and 6 MPa, low mass flux, and low heat flux which are typical to the steam generators employed to the small modular reactors of nuclear power plants. As a result, BHTCs were found to depend on the heat flux and mass flux, implying that both nucleate boiling and convection contributed to the heat transfer process. In addition, it was concluded that the curvature effect on the flow boiling heat transfer has been negligible, so that BHTC in helical coils can be estimated through the existing correlations of straight tubes in practical applications. Nonetheless, most of correlations for straight tubes slightly underpredicted experimental data of helical coils.

Hardik and Prabhu [

19,

20] conducted experiments to characterize heat transfer performance of a diabatic two-phase water flow boiling under pressures above atmospheric (1 bar to 3 bar) with a mass flux ranging over 200 kg/m

2-s and vapor qualities varying from 0% and 40%. Experiments were implemented with eight test sections composed of horizontal thin-walled stainless steel tubes with different tube IDs varying from 5.5 mm to 12 mm and different tube length ranging from 550 mm to 1000 mm. The effects of tube diameter, mass flux, and heat flux on the local BHTC and two-phase pressure drop were then studied. As reported, no change was observed in the slope of boiling curve during subcooled region. BHTCs in subcooled and nucleate boiling regimes were dependent on heat flux and independent of mass flux. However, mass flux influenced the convective boiling region as the higher mass fluxes contributed to higher BHTCs. It was also reported that tube diameter did not affect the wall and bulk fluid temperatures as well as BHTCs. In contrast, tube diameter was shown to have a significant impact on the two-phase pressure drop as it decreased remarkably with the increase in tube diameter for the same heat flux at a constant mass flux.

Due to the limited studies and insufficient experimental data, the vast majority of the existing empirical correlations are not capable of properly predicting BHTC in LPLF conditions, underscoring the need for further experimental investigations. The present study aims to experimentally investigate the effect of vapor quality and mass flux on the local heat transfer coefficient for two-phase flow boiling of water in a horizontal conventional tube at a constant wall heat flux under LPLF conditions where the operating pressure is set to be subatmospheric and the mass flux ranges below 20 kg/m2-s. The experimental results will then be compared with several well-known empirical correlations in the literature to identify those with least deviations for the LPLF conditions operated in this study.

2. Experimental Methodology

2.1. Test Apparatus

The experimental setup consists of copper tubes with an outer diameter of 0.5 inches (i.e., 12.7 mm). The test section is also composed of a horizontal copper tube of 98 cm long with inner and outer diameters of 0.43 inches (i.e., 10.9 mm) and 0.5 inches (i.e., 12.7 mm), respectively, wrapped around by a heating tape. The test section as well as the other parts of the test setup involved with heaters are fully insulated using three layers of different insulators to minimize the heat gain or heat loss during the experiments.

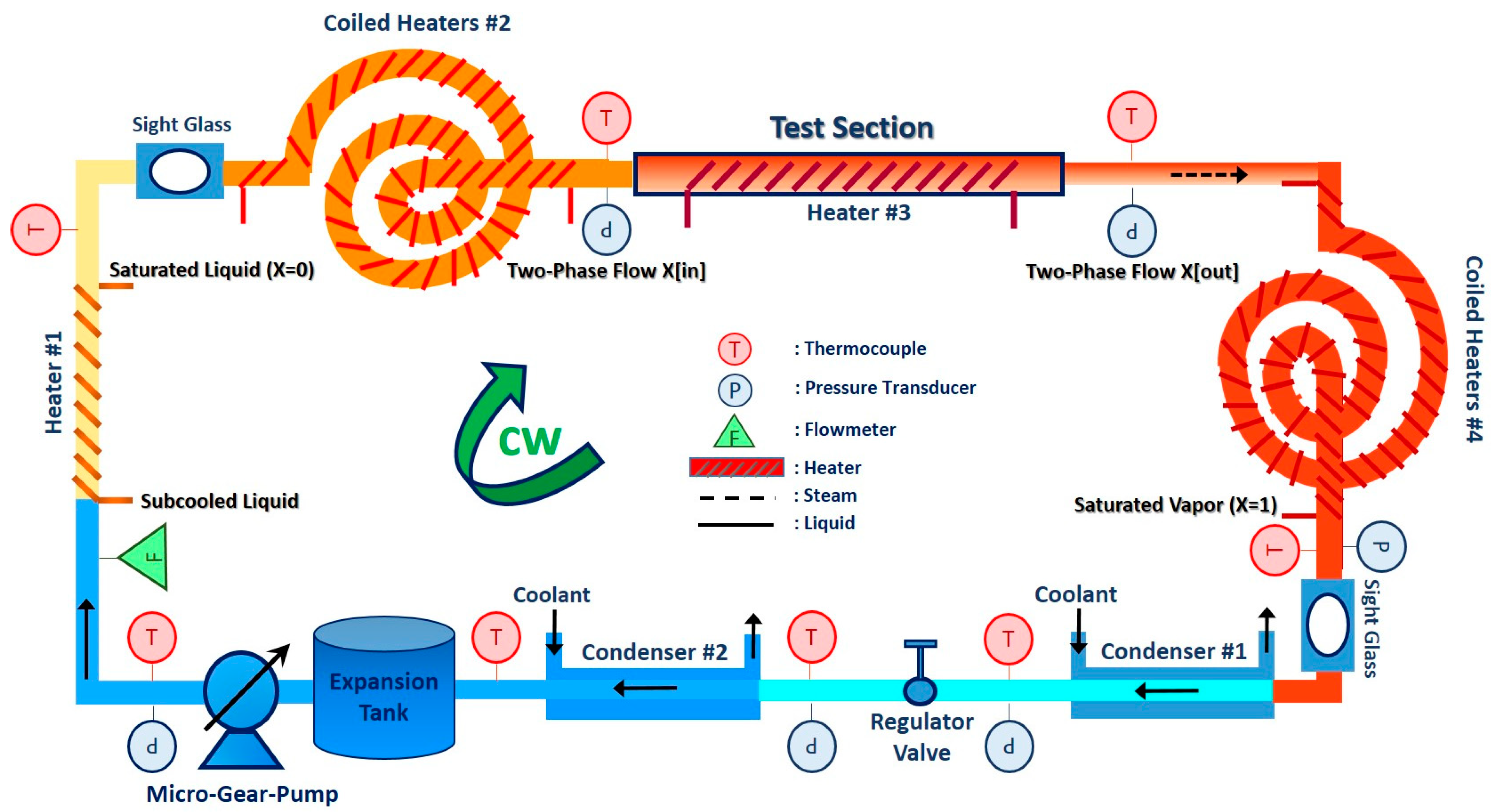

The compression and Yor-Lok fittings were utilized, along with Teflon tape and proper sealant, to connect and seal tubes, adapters and connectors—major components of the setup—and sensing instruments. The entire test apparatus was then evacuated using a vacuum pump to conduct long-term leak-check tests to examine if the system is air-leak-tight. The system was then charged with the distilled water under a rough vacuum to perform single-phase and two-phase flow experiments at pressures below the atmospheric pressure. The test apparatus is illustrated in

Figure 1, whereas

Figure 2 depicts its schematic, accompanied by the designated states of the working fluid in the cycle as well as by the mounted locations of sensing devices. A micro-gear pump equipped with an inverter motor is used to control the flow rate. Two customized tube-in-tube condensers and a pressure regulator are also utilized for the test apparatus to maintain steady-flow operating conditions in the cycle. Power controllers and monitors were engaged in the test apparatus to control heat supplies to reach the desired operating conditions as well as to adjust the vapor quality at the inlet and outlet of the test section, pre- and after-test sections. The auxiliary items such as shut-off valves and sight glasses were also added to the connecting tubes at various locations in the setup to enable a direct observation of flow states as well as to ease further modifications, disassembly, and reassembly of the setup.

A range of sensing instruments including thermocouples, pressure transducers, and a turbine flowmeter were also mounted to monitor and control the operating conditions within the tests through measuring the tube surface and fluid temperatures, pressures, and flow rate. All the precision instruments were then connected to a power supply and a data acquisition system to monitor and compile real-time data for further analysis.

Table 1 represents a breakdown of the sensing devices, accompanied by their quantity in use, accuracy, and operating range.

2.2. Operating Conditions and Test Procedures

Table 2 summarizes the geometry of the test section, and the operating conditions set to perform the tests. As shown in

Figure 2, the test apparatus can be tuned for both configurations in single-phase and two-phase flow. To ensure the results’ reliability and reproducibility, the tests were subject to be repeated three times for the given range of operating conditions.

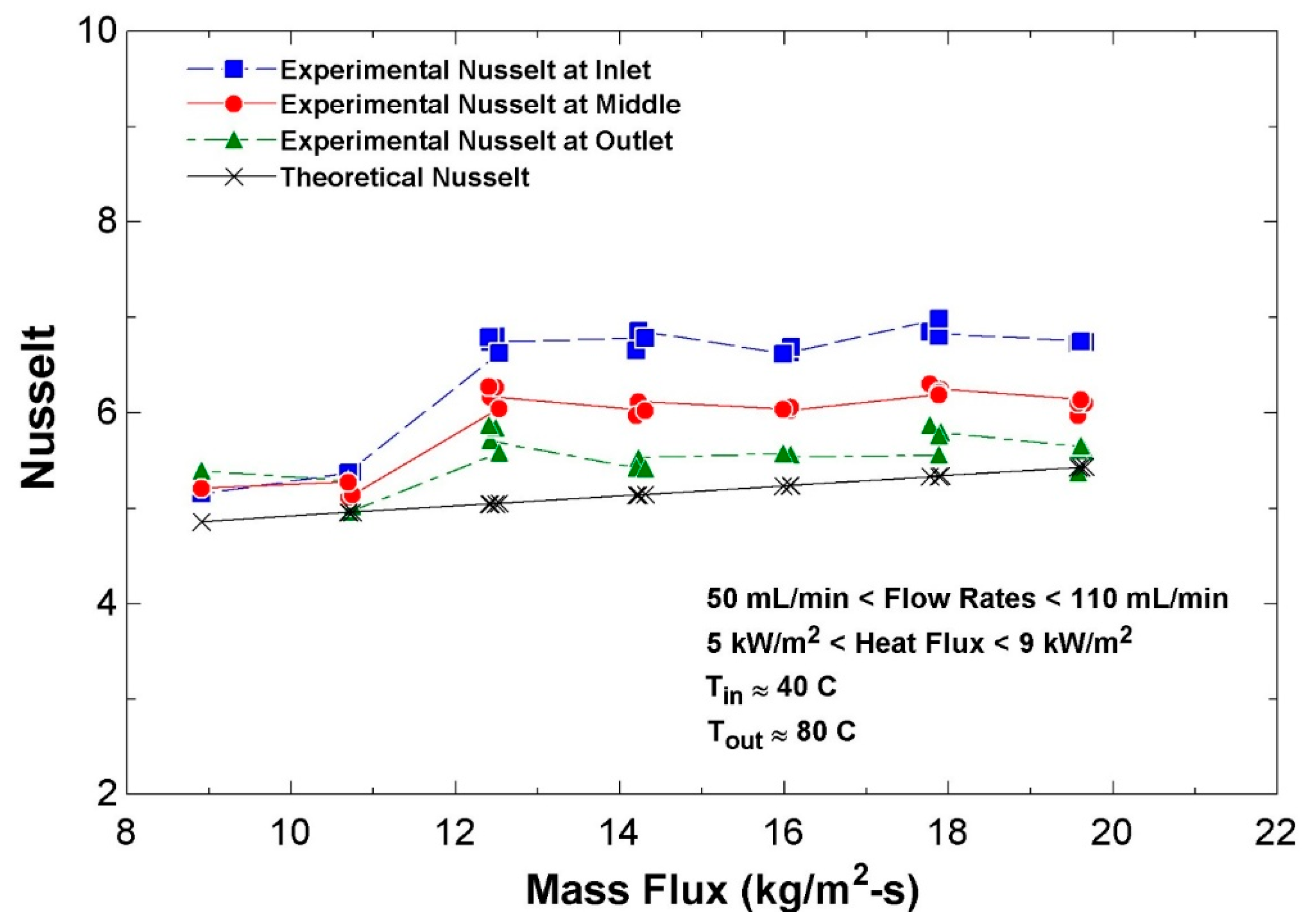

The single-phase tests were conducted at the inlet pressure of 88 kPa for volumetric flow rates in the range of 50–110 mL/min, equivalent to mass fluxes in the range of 8–20 kg/m2-s. Using heater unit#1, the single-phase flow temperature at the inlet of the test article is set for 40 °C. Using heater unit#3, a range of constant heat fluxes proportional to mass fluxes are supplied to the compressed liquid flow to heat it up to 80 °C at the exit of the test section. This exit temperature was set to be securely lower than the saturation temperature at 88 kPa (i.e., 96 °C) to avoid any transition of single-phase flow into the saturation state.

The two-phase flow tests were then performed under the same range of pressure and mass fluxes as those for the single-phase flow. The mass flux range for both configurations lies within the laminar flow regime. At the outlet of the test section, the fluid is a two-phase flow with unknown vapor quality at the saturation temperature of 96 °C and the corresponding saturation pressure of 88 kPa, passing through the coiled heaters#4 to reach the known state of saturated vapor with quality of 1 (i.e., x = 100%) in order to measure unknown vapor quality at the outlet of the test section. The saturated vapor is then condensed in a tube-in-tube heat exchanger using cooling water to turn it to the state of saturated liquid (i.e., x = 0%). The flow temperature and pressure are set to drop through a regulator valve as well as a second tube-in-tube condenser to take the working fluid to the subcooled/compressed liquid state at the cycle’s low-pressure and low-temperature points of 76 kPa and 40 °C, respectively, prior to entering the pump in order to avoid cavitation. After having the liquid flow squeezed in the pump to the high-pressure of the cycle (i.e., 88 kPa), it is warmed up by heater#1 until reaching the saturated liquid state. Using coiled heater#2 located just before the test section, the saturated liquid flow turns to a two-phase flow with a vapor quality in the range of 30–60% at the inlet of the test section and is afterwards exposed to a constant wall heat flux supplied by heater#3 to reach higher vapor qualities at the outlet, and then keeps recirculated.

2.3. Data Reduction—Heat Transfer Parameters

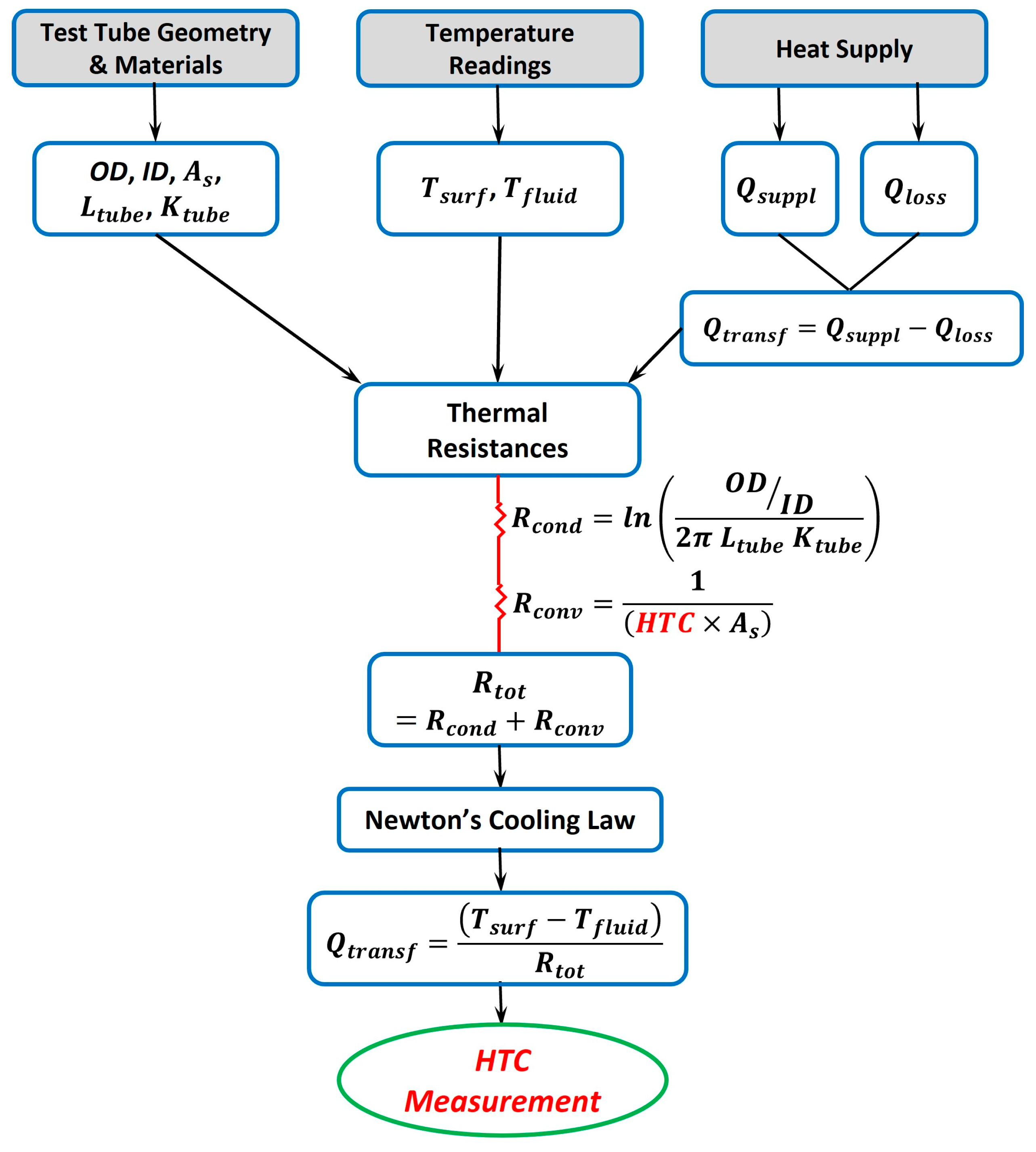

By collecting raw data for surface temperatures (), fluid temperatures (), fluid pressure (P), flow rate (), and heating power supplied (), the heat transfer performance parameters at different locations of the test section—including the inlet, middle, and the outlet–can be measured.

According to Newton’s cooling law, the following can be expressed:

where

stands for the actual amount of heat transferred to the flow,

is the amount of heat loss to be estimated, and

accounts for the total local thermal resistance at the test section.

Due to sensible heat, the energy balance for the liquid single-phase flow configuration is expressed as follows:

whereas the latent heat exchanged in the test section for the configuration with the two-phase flow boiling is expressed as follows:

in which

and

refer to the enthalpies of the two-phase flow for the vapor qualities at the inlet and outlet of the test section, respectively.

The total thermal resistance at different locations of the test section (i.e., the inlet, middle, and outlet) is composed of the conductive thermal resistance

and the convective thermal resistance

for either of the configurations, as shown below:

where

HTC stands for an unknown value of the heat transfer coefficient at different locations of the test section for either of the configurations with single-phase flow or two-phase flow boiling.

After calculating the heat transfer coefficient, the Nusselt number (

Nu) can be obtained as below:

The Reynolds number (

Re) for the single-phase flow can also be computed as follows:

The flow regime for the liquid phase or the gas phase of the internal two-phase flow boiling is determined by the Reynolds numbers for the liquid phase (

) and the gas phase (

), respectively, defined as follows:

where

Gl and

Gg stand for liquid-phase and gas-phase mass fluxes, and

and

accounts for liquid-phase and gas-phase dynamic viscosities, respectively.

The flowchart represented in

Figure 3 summarizes data reduction process to experimentally measure heat transfer coefficients at each mass flux tested.

2.4. Heat Loss Estimation

The measurement of local heat transfer coefficient in single-phase flow is not affected by heat loss estimation given the presence of sensible heat, influencing the local bulk fluid temperature where the actual heat transferred to the fluid is realized by executing an energy balance through flow rate and fluid temperature readings regardless of measuring the heat loss and calibrating the heat supplies. By contrast, the accurate estimation of heat loss in two-phase flow boiling plays a crucial role in reliable and accurate measurements of local vapor quality and the boiling heat transfer coefficient [

10,

21]. This is associated with the existence of latent heat in the phase-change heat transfer process, occurring at a constant saturation temperature while the fluid enthalpy increases proportionally with the increase in local vapor quality resulting from heat acquisition. Hence, inaccurate heat loss estimation and imprecise latent heat supply calibration compromises the reliability of heat transfer data and poses large uncertainties in the results.

In the present study, two experimental approaches are conducted to estimate heat loss and calibrate heat supply within flow boiling tests. In the first common approach, single-phase experiments are executed under a range of mass and heat fluxes to estimate a fixed average percentage of heat loss and calibrate heat supply for two-phase flow tests. In the second approach, the heat loss estimation and the correlation of heat supply calibration are extracted directly from the flow boiling tests.

2.4.1. Single-Phase-Based Heat Loss Approach

In the first approach, extensively applied in the literature [

19,

22,

23], heating powers supplied experimentally (

) to the test article are observed to increase the liquid flow temperature between the inlet and outlet from 40 °C to 80 °C for a range of volumetric flow rates of 50–110 mL/min, which is equivalent to the range of mass fluxes 8–20 kg/m

2-s. On the other hand, the actual or effective heat transferred to the single-phase flow

can be computed using Equation (2). Accordingly, the heat losses corresponding to mass fluxes are the differences between

and

. As represented in

Figure 4, a correlation is thus developed by plotting

versus

to calibrate heat supplies later for measurements of local vapor quality and boiling heat transfer coefficient.

2.4.2. Two-Phase-Based Heat Loss Approach

In the next approach, first introduced by Kabir, heat loss estimation and heat supply calibration are directly implemented through flow boiling experiments, providing more accuracy compared to the first common technique [

10].

As depicted in

Figure 2, the heat supplying units#2, 3, and 4 are engaged to provide the heat required to take the working fluid from the known saturated liquid state (

x ≈ 0%) at the saturation temperature of 96 °C to another known state at the end of phase-change process, that is, saturated vapor (

x ≈ 100%). To locate the saturated liquid state, the compressed liquid flow is slowly warmed up through heater#1 until a temperature reaches too close to the desired saturation temperature at the corresponding pressure. Similarly, to locate the saturated vapor state, heaters 2 to 4 are set to supply the latent heat for the saturated liquid until the two-phase flow reaches a slightly greater temperature than the saturation temperature, which is, indeed, the starting point of the superheated vapor state. In addition, by taking advantage of direct observations through sight glasses as well as a high-speed IR camera, the saturated liquid and vapor states are ensured by checking the lack of presence of vapor bubbles in the liquid stream and liquid droplet in the gas stream, respectively. The tests are then performed for a range of flow rates the same as those in the first approach. The total experimental latent heats supplied

to turn the saturated liquid flow to the saturated vapor are known for a range of flow rates whereas the theoretical latent heats required

at the corresponding flow rates can be computed via Equation (3). The differences between these two parameters indicate the heat losses corresponding to the flow rates, from which a correlation is achieved to calibrate the experimental latent heat supplies for further measurements of two-phase flow boiling, as illustrated in

Figure 5.

2.5. Local Vapor Quality Measurement

One of the parameters which remarkably impacts the local flow boiling heat transfer coefficient is vapor quality [

21], underscoring the crucial role of vapor quality measurement in accurately and reliably characterizing the two-phase heat transfer coefficients.

After having the heat supplies calibrated for all the heaters in the test apparatus, local vapor qualities along the test section are measured by conducting the energy balance on the change in enthalpy of vaporization. The inlet vapor quality can therefore be measured and controlled via heater#2, positioned just prior to the test section in

Figure 2, taking the fluid flow from the known state of saturated liquid (

x = 0%) to the two-phase flow of a desired vapor quality at the inlet. However, the local vapor quality at the outlet can be measured either from heater#3 located at the test section using Equation (3) or from coiled heater#4 situated immediately after the test section, also called “after-heaters” in

Figure 6, where the two-phase flow of unknown quality at the outlet is turned to the known state of saturated vapor (

x = 1), using the following expression:

This is important to note that the outlet quality measured from the test section using Equation (3) incorporates accumulated errors arising from the earlier measurement of inlet quality [

21]. The outlet quality measurement through Equation (3) reflects uncertainties due to measurements of fluid temperature and pressure, flow rate, and heat supply calibration for the test section heater, accompanied additionally by the earlier error in measurement of vapor quality at the inlet (

x[in]), leading to error accumulation in the outlet quality measurement. Accordingly, Equation (9) is preferred to measuring the outlet quality with the aid of calibrated coiled heater#4 (i.e., after-heaters).

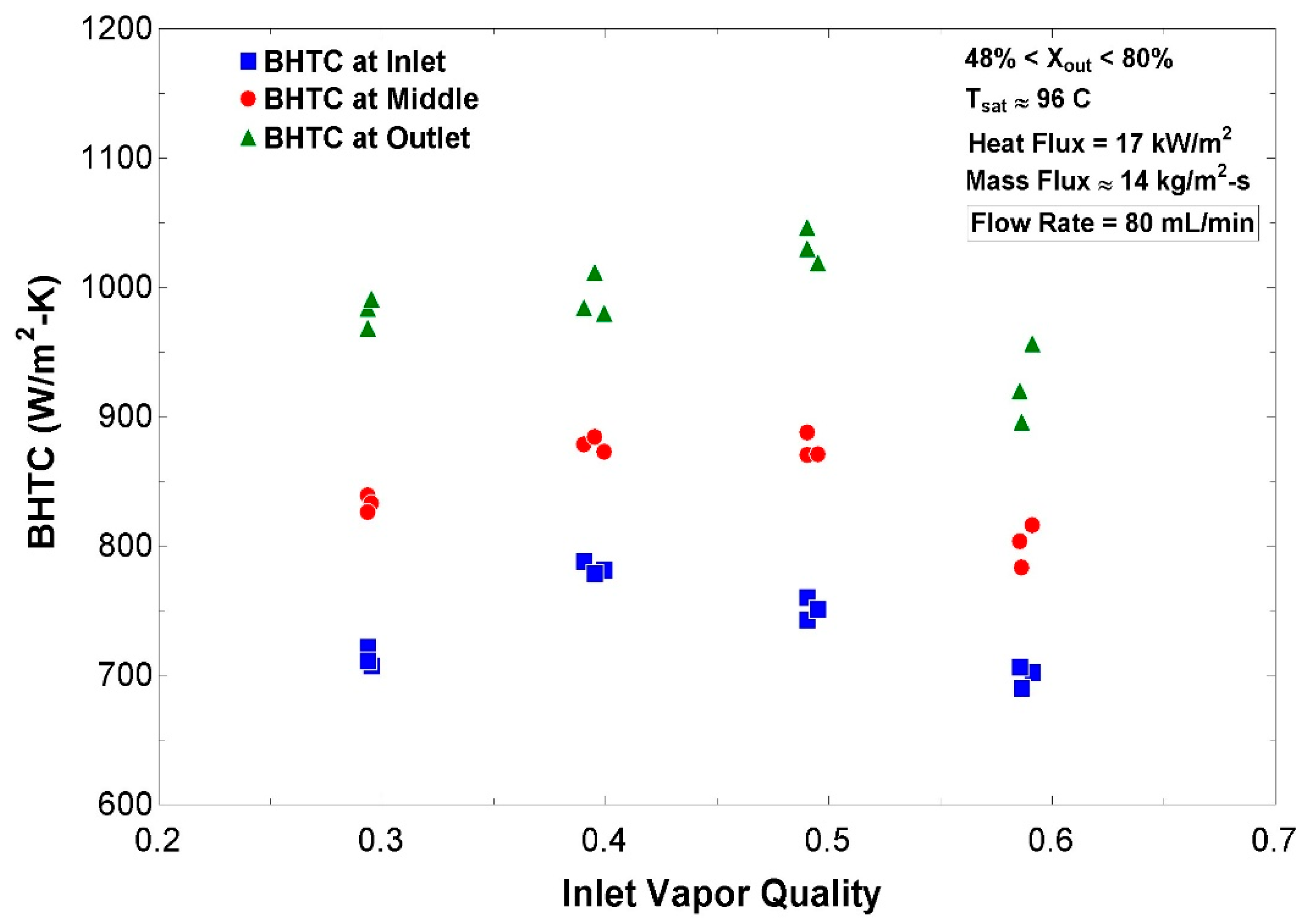

Figure 6 illustrates the local quality measured at the test section outlet against mass flux for a given range of inlet vapor qualities from 30% to 50% at a constant saturation temperature under a constant wall heat flux of 17 kW/m

2. As clearly shown in this figure, the outlet quality decreases with the increase in mass flux at the same inlet quality and heat flux. By contrast, the outlet quality increases as the inlet quality increases from 30% to 50% at the same mass and heat fluxes.

Additionally,

Figure 6 concurrently represents the measured outlet vapor qualities derived both from the test section heater using Equation (3) and the after-heaters using Equation (9) where the quality measurements differ up to virtually 3% for the same operating conditions. As discussed earlier, the outlet quality measurements through the after-heaters (upper curves) are found to be more accurate due to the absence of error accumulation from the earlier measurements of inlet qualities.

2.6. Experimental Uncertainty Propagation

To investigate the uncertainty propagation analysis, the following correlation is employed [

10]:

where

UR and

UVi represent the uncertainties affiliated with the parameter

R and the independent variable

Vi, respectively. In addition, “

n” accounts for the number of independent variables.

Accordingly, Equations (11) and (12) are developed based on Equation (10) to compute the overall experimental uncertainties for the main heat transfer parameters, including heat transfer coefficient and Nusselt, sourced in the inherent measurement errors for tube diameter, test section length, mass flow rate, fluid flow pressure, bulk fluid temperature, surface temperature, and heat transferred to the fluid.

Table 3 summarizes the uncertainty propagation for the experimental results reported in this study. Taking the cumulative effect of random and systematic errors into account for calculating uncertainties as well as considering the test reproducibility, the attained range of uncertainties reflects acceptable reliability of the tests performed in the present study.

4. Conclusions and Future Work

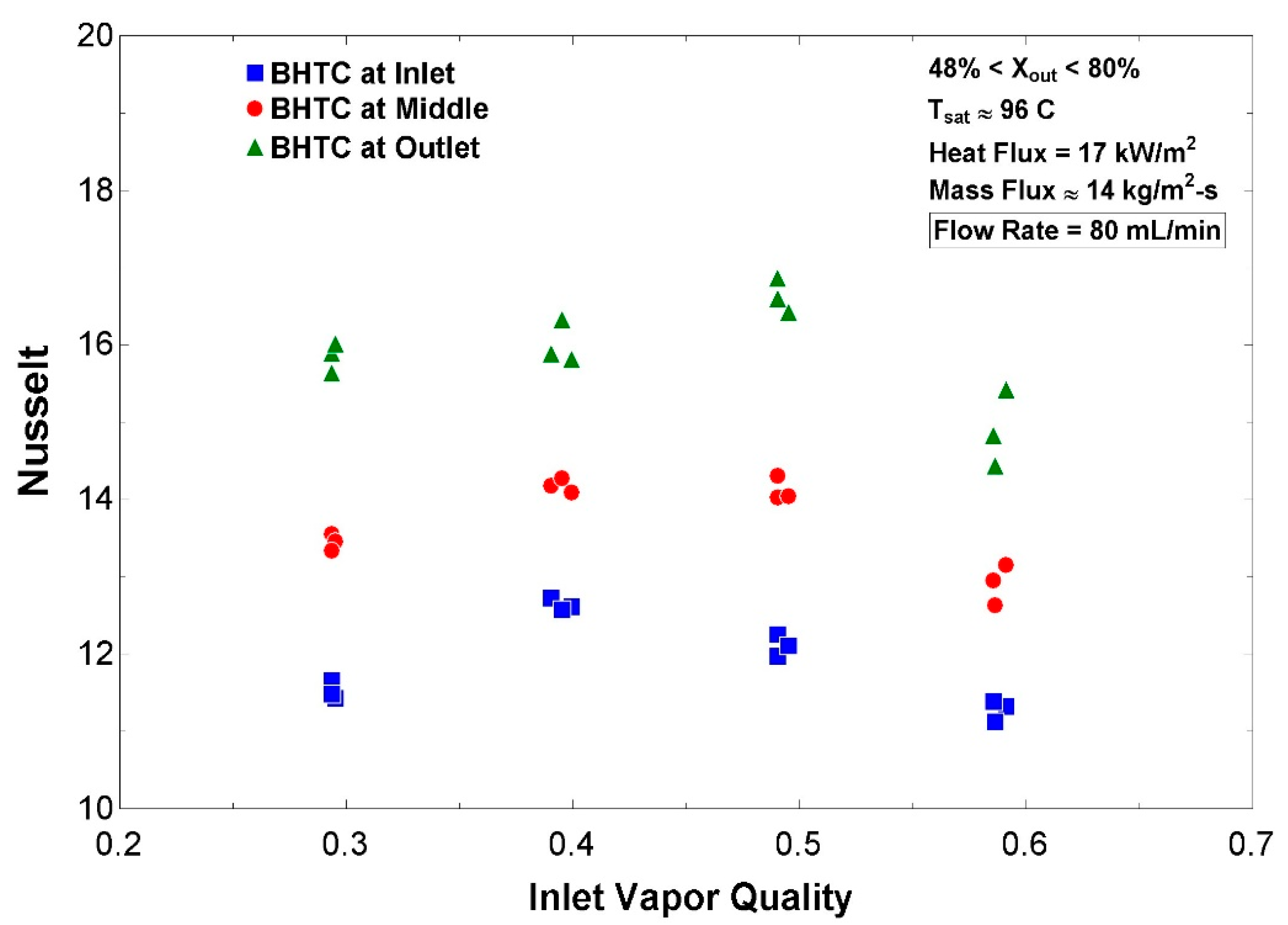

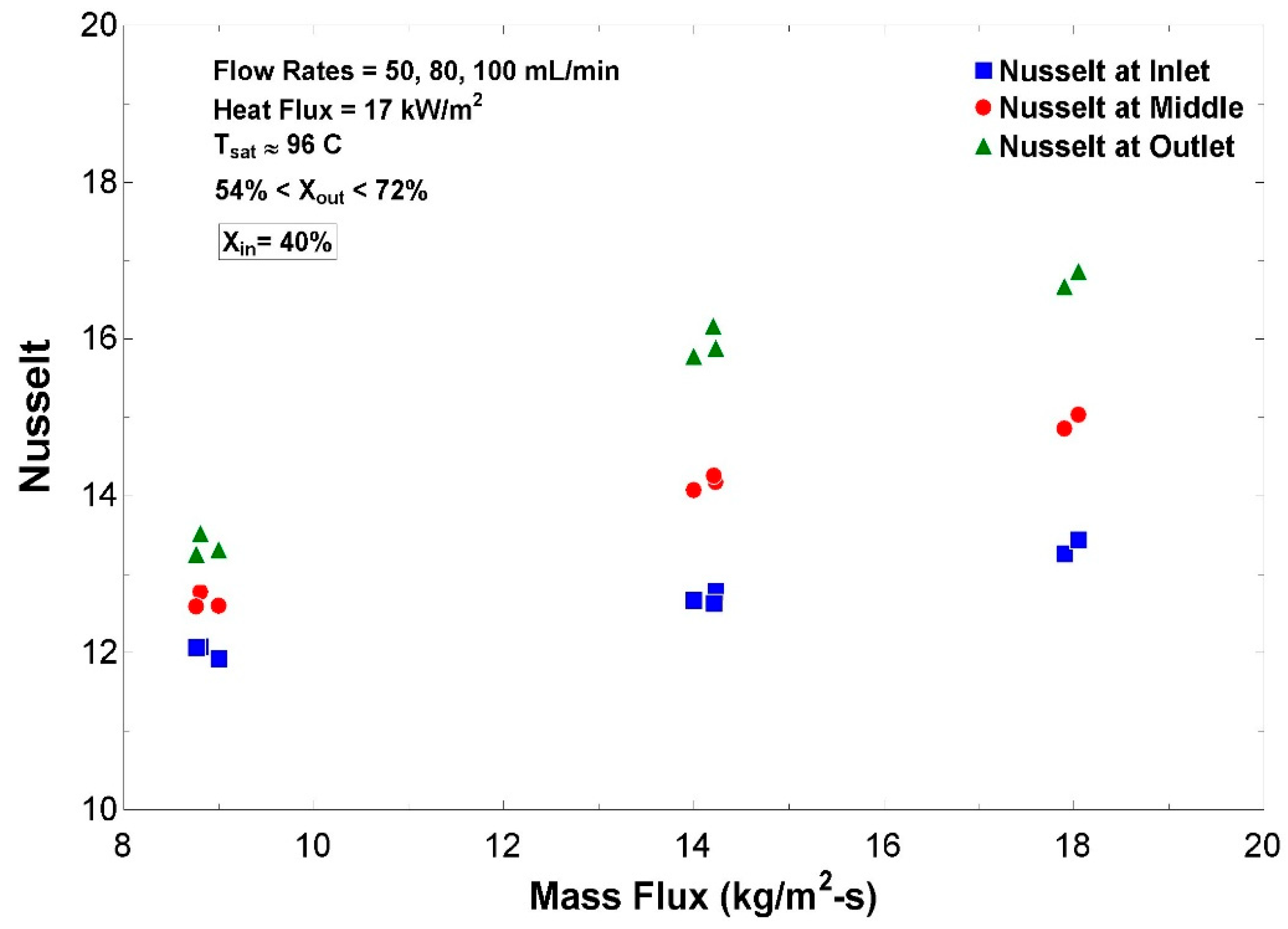

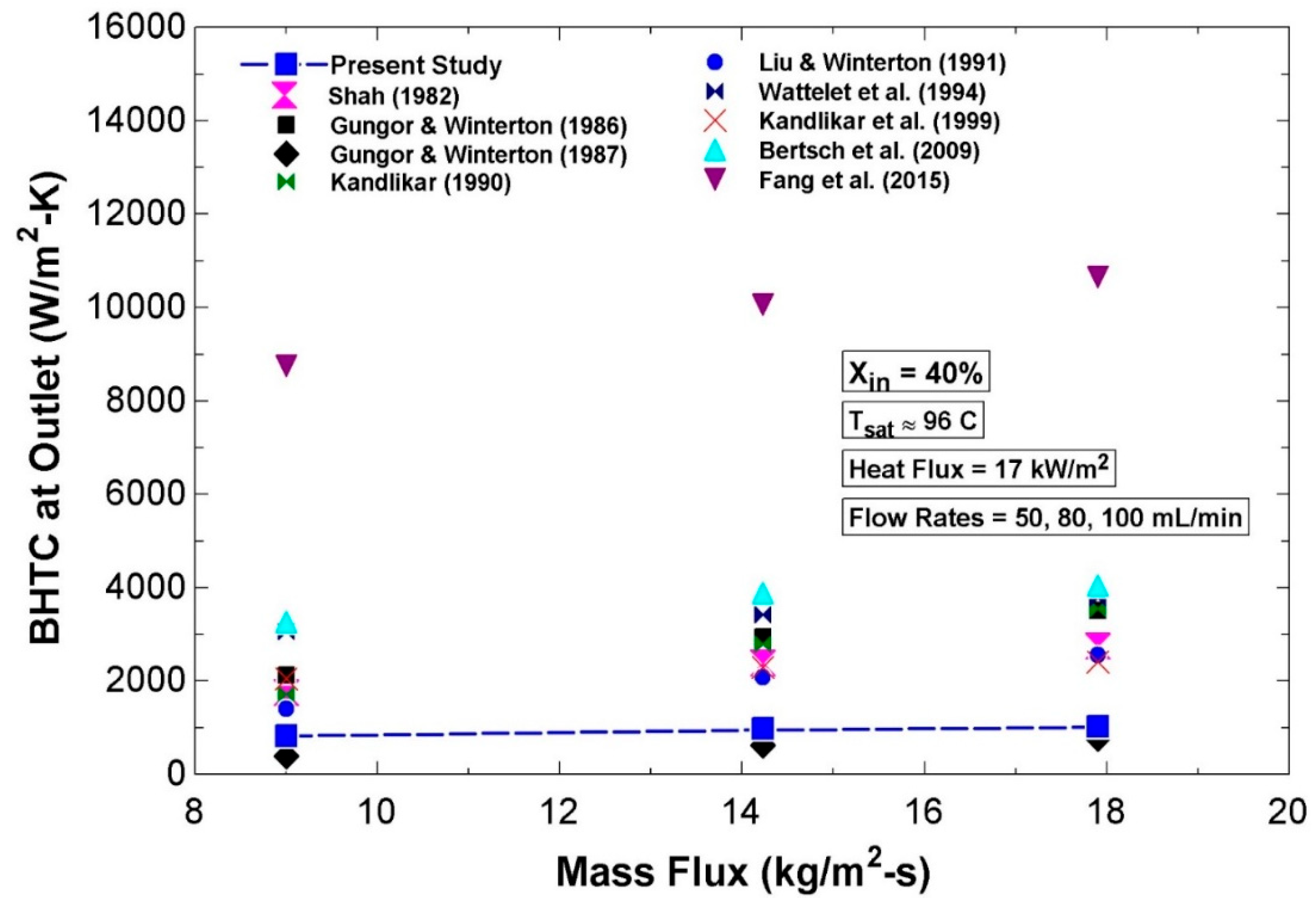

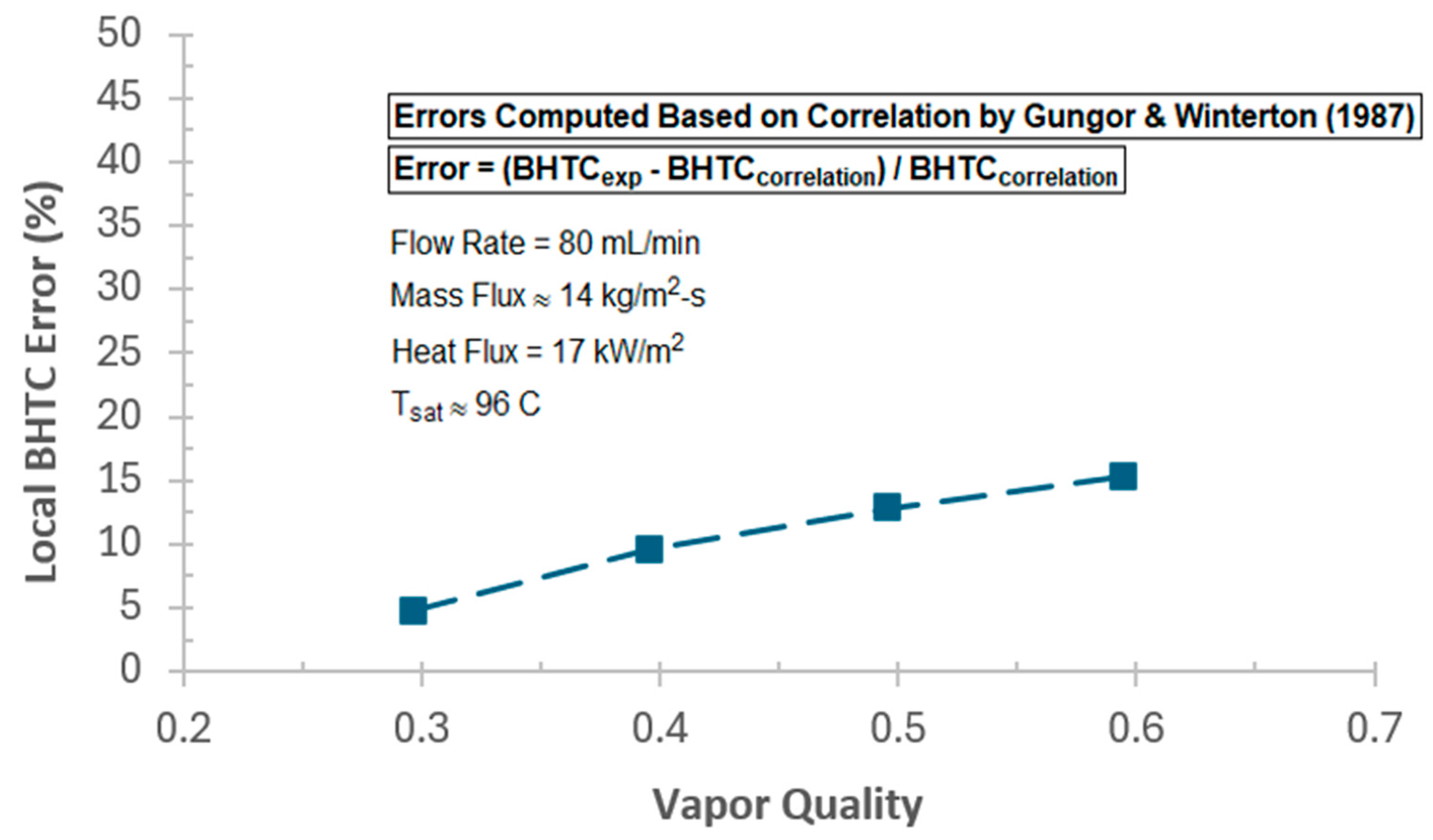

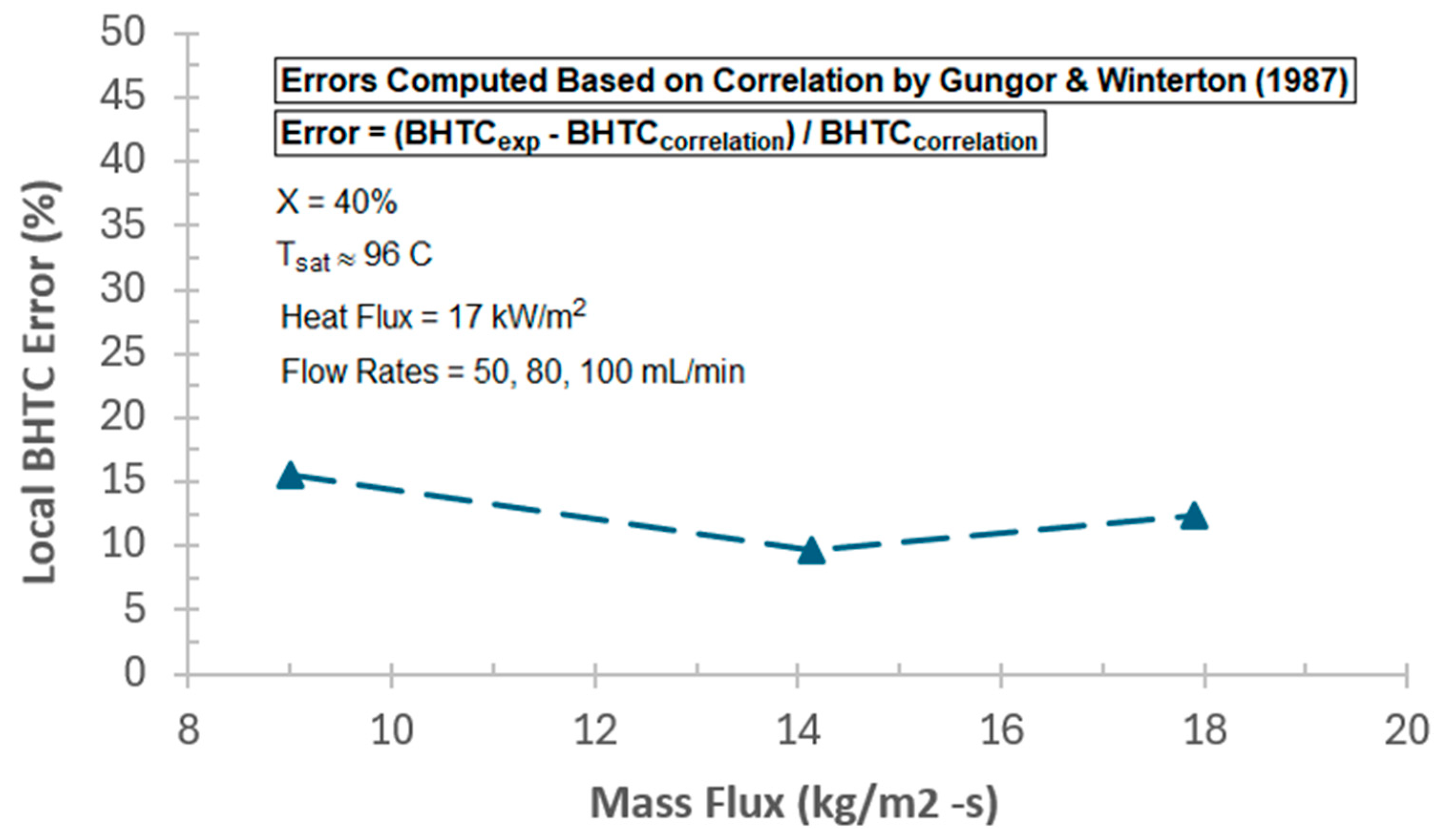

In the present study, heat transfer performance of single-phase and two-phase flow boiling of water in a horizontal conventional tube was experimentally characterized under low-pressure low-flow (LPLF) conditions, where limited studies have been conducted to date. For ranges of local vapor qualities from 30% to 80% and mass flux from 8 to 20 kg/m2-s, it was found that local boiling heat transfer coefficient (BHTC) and Nusselt at the test section exit reached a peak at a certain range of local qualities between 55% and 75%. A similar trend of BHTC variations was also predicted by several empirical correlations in the literature, reaching a peak at local qualities between 45% and 85%. It was also observed that local BHTCs and local Nusselt increased with the increase in mass flux, and the impact of mass flux was stronger than that of vapor quality. For the same mass flux and the same inlet vapor quality, local BHTCs increased along the test section as local quality increased, so that BHTCs at the outlet were always found to be greater than those at the middle and inlet. In contrast, heat transfer coefficient (HTC) for the liquid single-phase flow at the test section inlet was found to be larger than those at the middle and outlet for a range of mass fluxes, which is rooted in the entrance effect at the inlet of the test section where the liquid flow is still neither thermally nor hydrodynamically fully developed. While local HTCs and Nusselt at the inlet and middle increased slightly with the increase in mass flux, they remained fairly constant with the change in mass flux at the outlet where the laminar flow was fully developed. Furthermore, the present work investigated the suitability of the existing BHTC correlations for the experimented range of LPLF conditions, disclosing that most fail to properly estimate BHTC, except the correlation proposed by Gungor and Winterton in 1987.

It is important to point out that the present work studies a narrow, but extreme, range of mass fluxes lying in LPLF conditions at constant wall heat flux. The effect of heat flux variations, lower operating pressures towards high vacuum, and a wider range of mass fluxes up to 200 kg/m2-s are subject to be investigated further. Local BHTC of water was experimentally shown to vary with vapor quality, reaching a peak. However, possible mechanisms underlying this phenomenon are not clear or well investigated in the literature. Therefore, further efforts are required to better appreciate the mechanisms of flow boiling heat transfer in LPLF conditions for developing more reliable and accurate prediction tools and empirical correlations. To address this, vapor bubble formation, growth, and departure from the heated surface along with the boiling flow patterns are subject to further studies through modifying the experimental setup to allow direct high-speed camera observations in a transparent test section. Additionally, a computational fluid dynamic (CFD) simulation of the two-phase flow dynamics is a great help in understanding the governing mechanisms deeper.