Enhancing Thermal Efficiency in Power Electronics: A Review of Advanced Materials and Cooling Methods

Abstract

1. Introduction

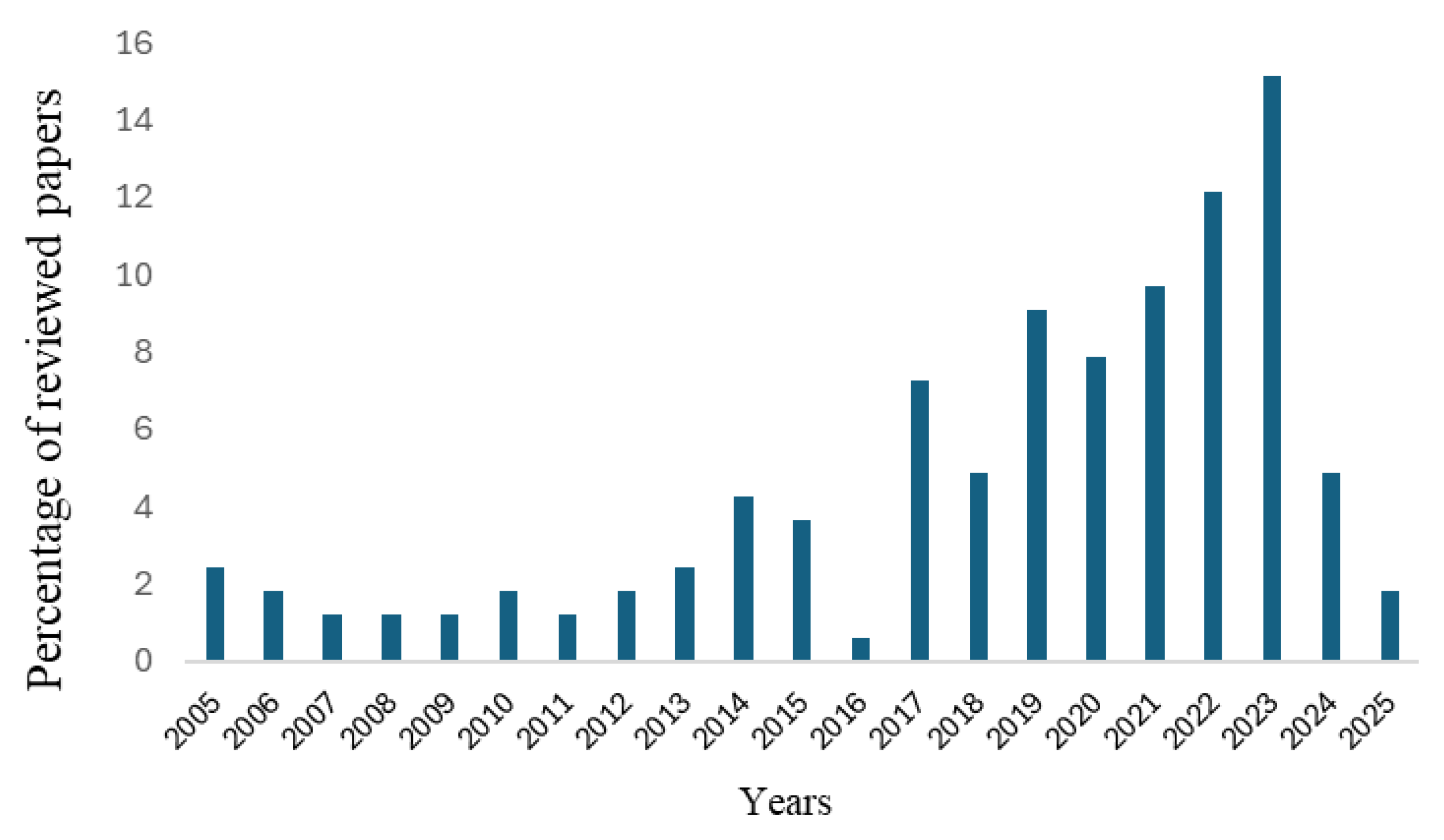

2. Methodology

3. Power Module Major Components

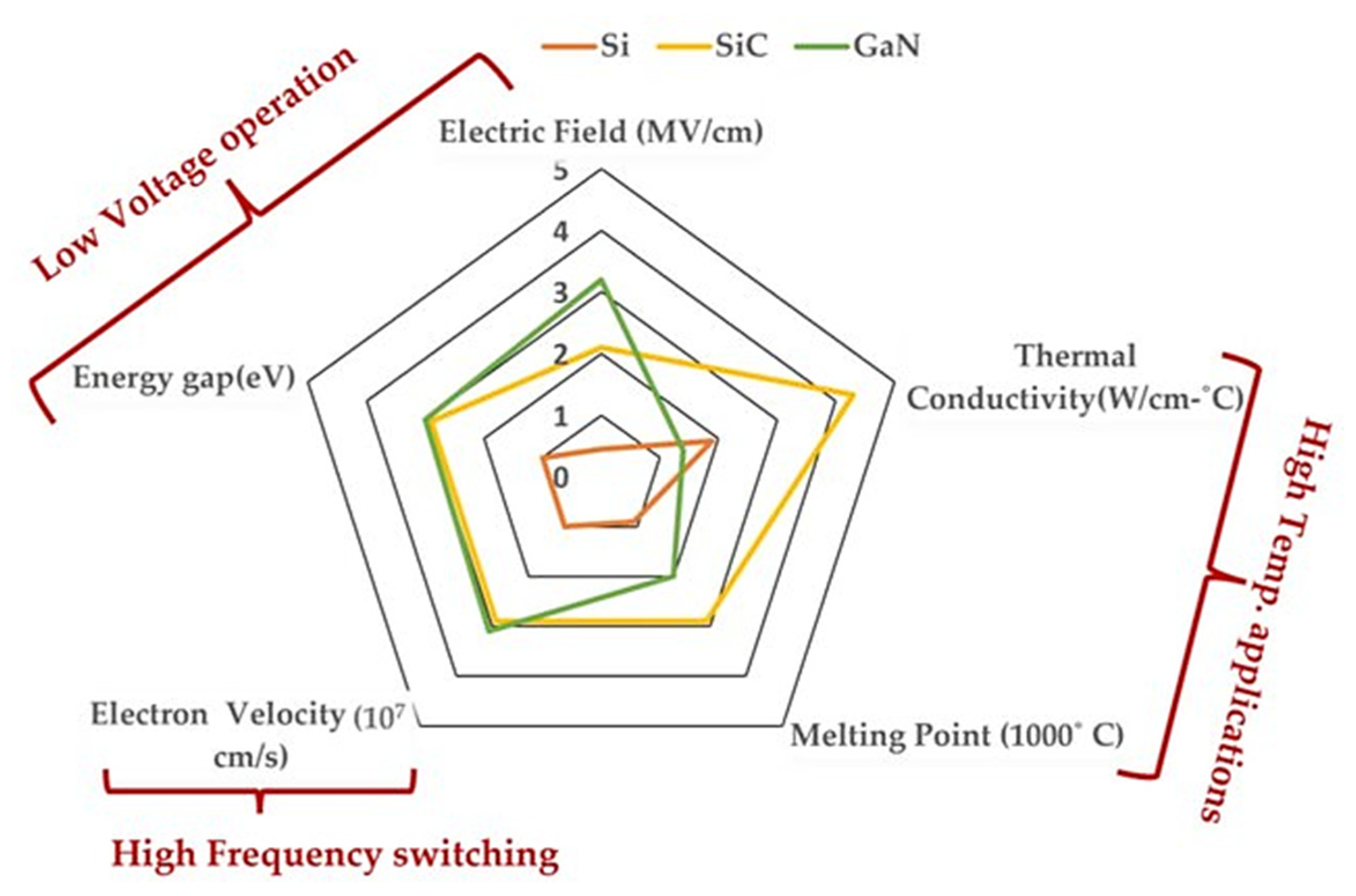

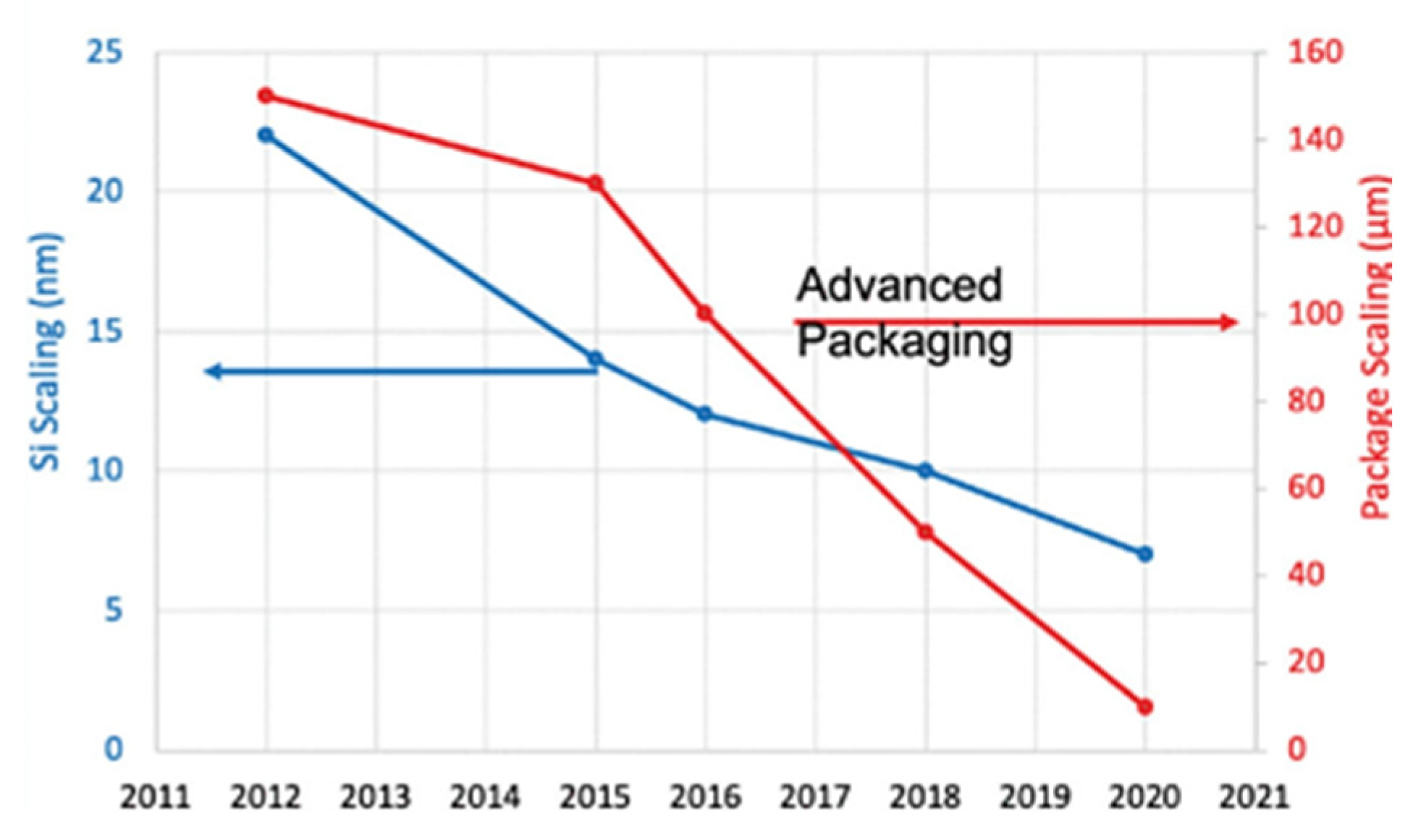

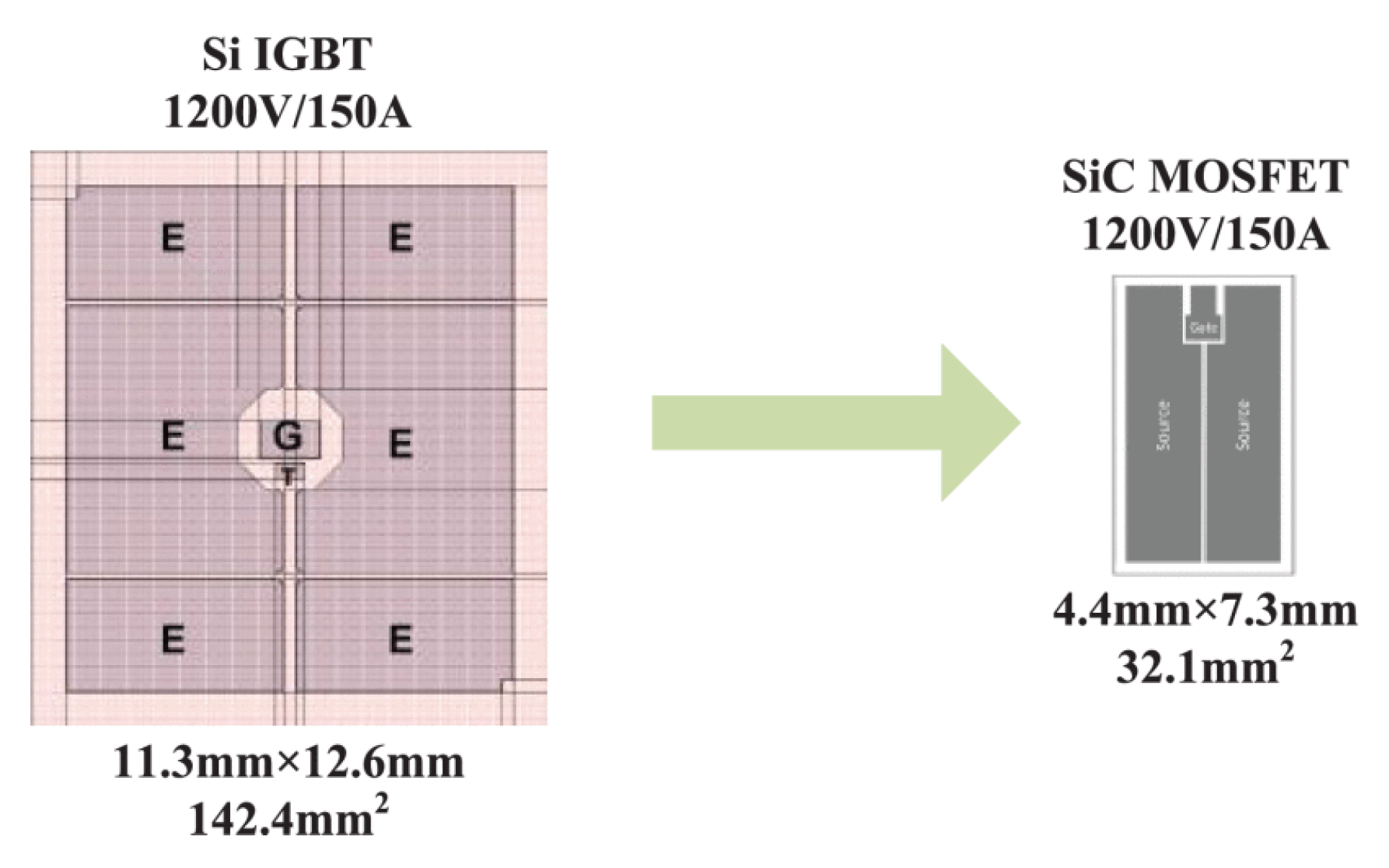

3.1. Power Semiconductor Device

3.2. Spacer

3.3. Substrate

3.4. Thermal Interface Material

3.5. Heat Sink

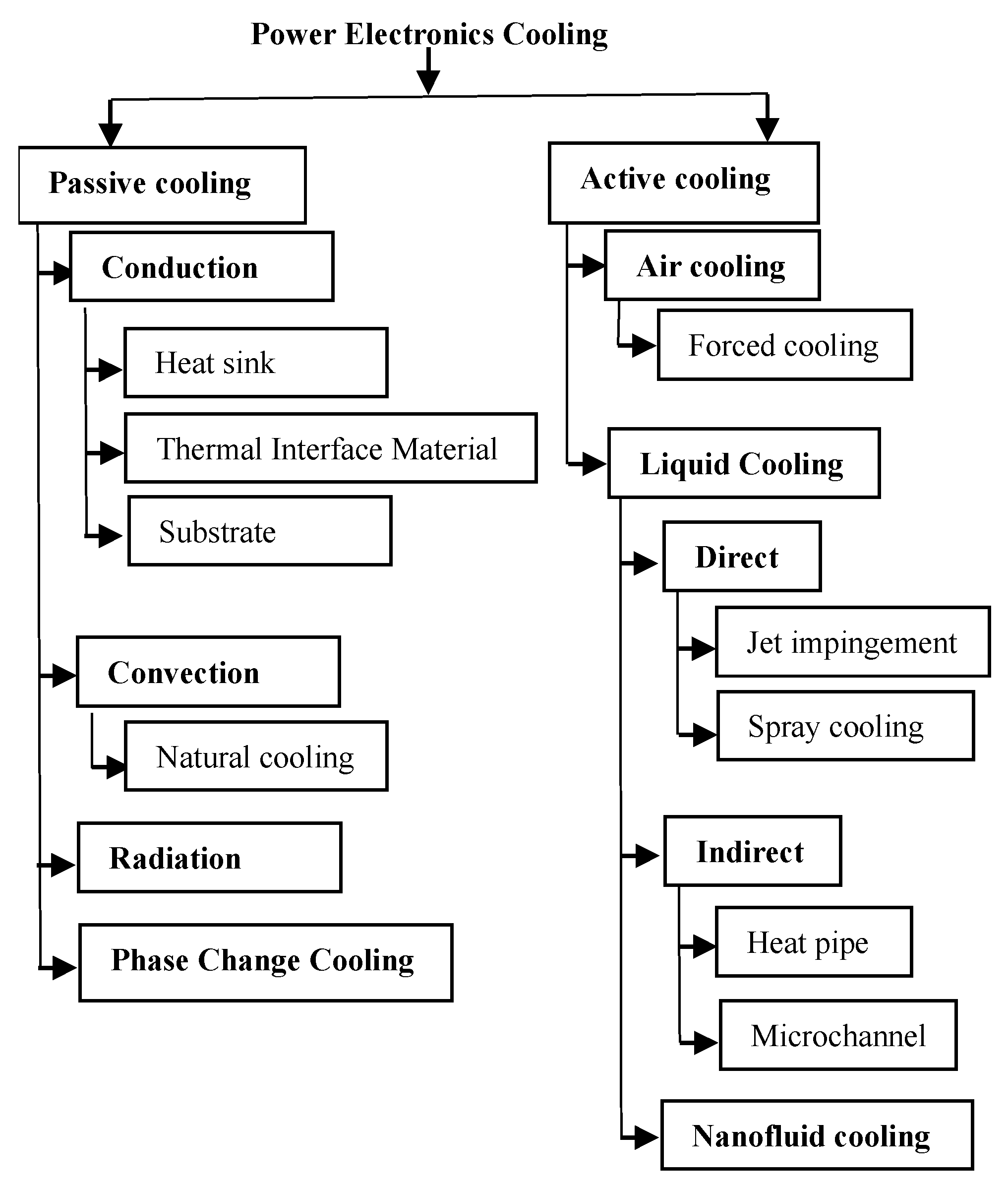

4. Cooling Techniques

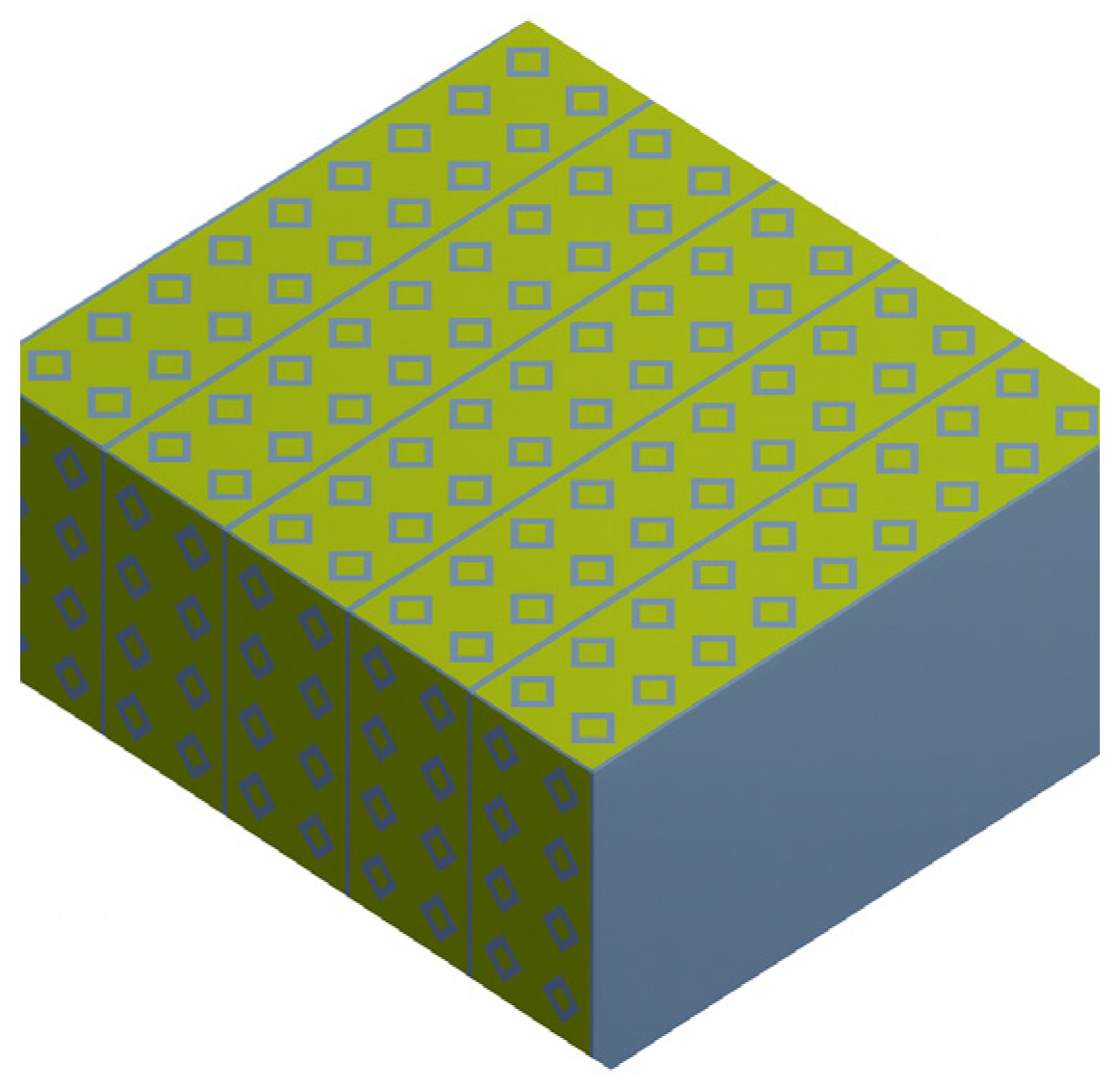

4.1. Fin

4.2. Microchannel

| Ref. | Method | Analysis | Fluid | Outcome |

|---|---|---|---|---|

| [78] | Numerical | Manifold microchannel heat sink optimization. | 50/50 water/ethylene-glycol |

|

| [67] | Numerical | Optimization of the heat sink with single-layer, double-layer, and double-sided channels with working fluid water and Aluminum oxide. | Water, Water-based Al2O3 |

|

| [68] | Experimental | Hierarchical microchannel heat sink. | HFE-7100 |

|

| [69] | Numerical | Self-adaptive microchannel pin fin heat sink. | Deionized Water |

|

| [70] | Numerical | Addition of pillar structure in the microchannel. | Deionized Water |

|

| [71] | Experimental and Numerical | Topology optimization of spider web heat sink. | Water |

|

| [72] | Numerical | Modification of microchannel heat sink incorporating secondary flow channels. | Water |

|

| [73] | Experimental and Numerical | Microchannel heat sink with rhombus fractal network. | Water |

|

| [79] | Experimental | Unidirectional porous heat sink. | Distilled Water |

|

| [80] | Numerical | Rectangular microchannel modification in three ways (Front loose back compact, uniformly distributed, and Front compact back loose) with internal spoiler cavities. | Water |

|

| [81] | Numerical | Interrupted microchannel heat sink with no ribs, rectangle ribs, triangle ribs, and trapezoid ribs. | Water |

|

| [82] | Experimental and Numerical | Addition of a combined delta winglet composed of three delta winglets in a rectangular channel. | Water |

|

| [83] | Experimental | Additive Manufacturing-based multi-passed microchannel heat sink. | Water |

|

| [84] | Numerical | Application of side wall staggered ribs in the microchannel. | Water |

|

| [85] | Experimental and Numerical | Combining the Si-glass microchannel heat sink. | Deionized Water |

|

| [86] | Numerical | Implementation of Y-shaped symmetric and asymmetric bionic fractal networks. | Deionized Water |

|

| [87] | Experimental and Numerical | Implementation of V-shaped rib with different cross-sections in rectangular low channel. | Water |

|

| [88] | Numerical | Transverse ribs (rectangular shape) in open microchannel. | Deionized Water |

|

| [89] | Numerical | Circular re-entrant cavity microchannels and sinusoidal wavy microchannels. | Water |

|

| [90] | Numerical | Addition of different types of ribs and cavities in microchannel heat sink. | Deionized Water |

|

| [91] | Numerical | Initialization of decreasing height bifurcated plate in microchannel. | Water |

|

| [74] | Numerical | Wavy microchannel with varying wavelength. | Water |

|

| [92] | Experimental and Numerical | SiC microchannels with high aspect ratio and decreased hydraulic diameter. | Deionized Water |

|

| [93] | Experimental and Numerical | Embedded cooling with Si fabricated 3D manifold microchannel. | Water |

|

| [66] | Experimental | Integration of straight microchannel and unit cell microchannel with jet impingement. | Water |

|

| [94] | Experimental | CTE-matched two-phase mini-channel heat Sink. | R-245fa |

|

| [95] | Experimental | Two-pass diverging microchannel and skived microchannel heat sink. | HFC-245fa |

|

| [96] | Experimental | Two-phase additively manufactured MCHS with multiple geometric features. | Water |

|

| [76] | Experimental | Embedded microchannels with 3D manifold. | Water, R-245fa |

|

4.3. Jet Impingement

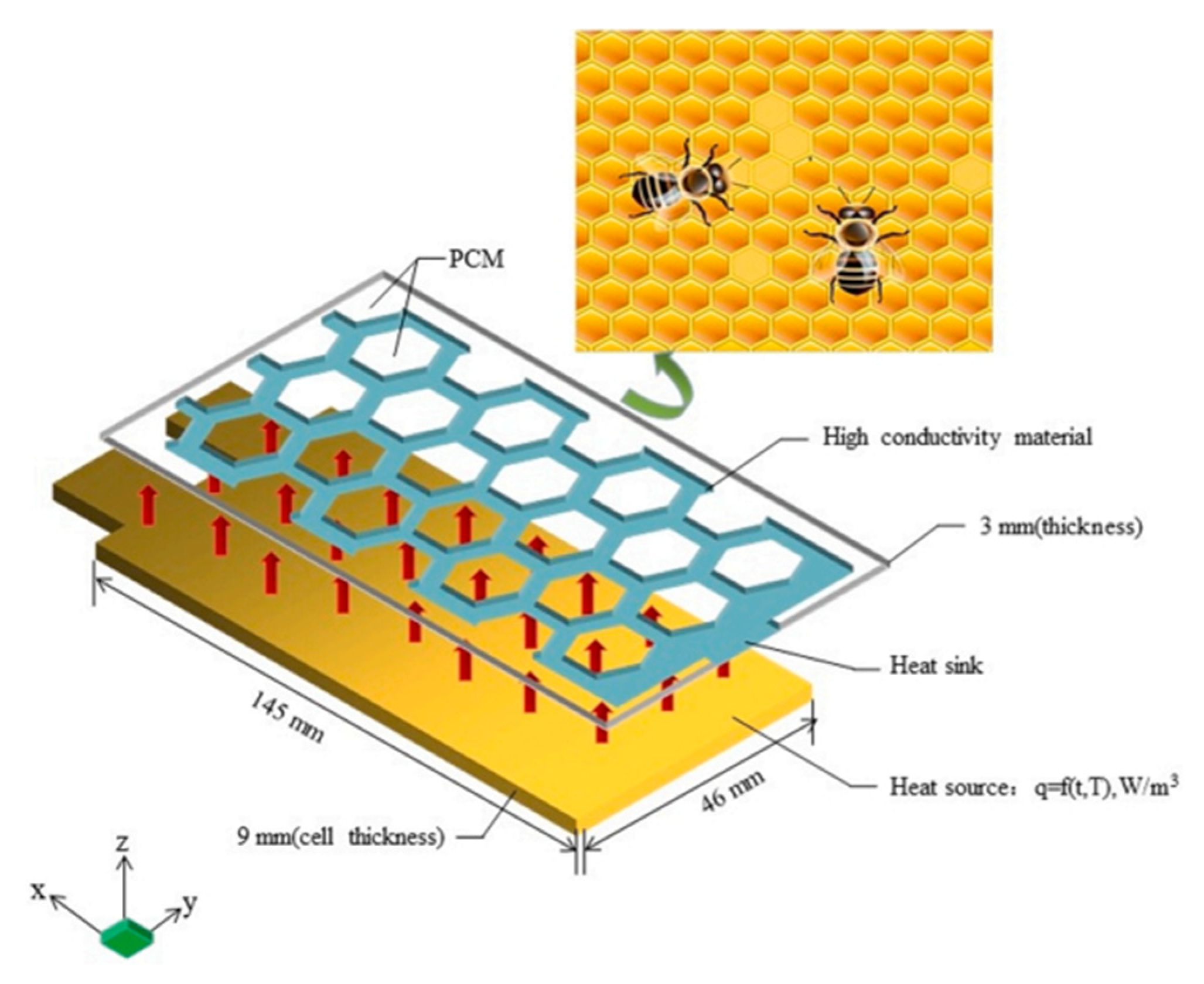

4.4. Phase Change Material

4.5. Nanofluid

4.6. Pool Boiling

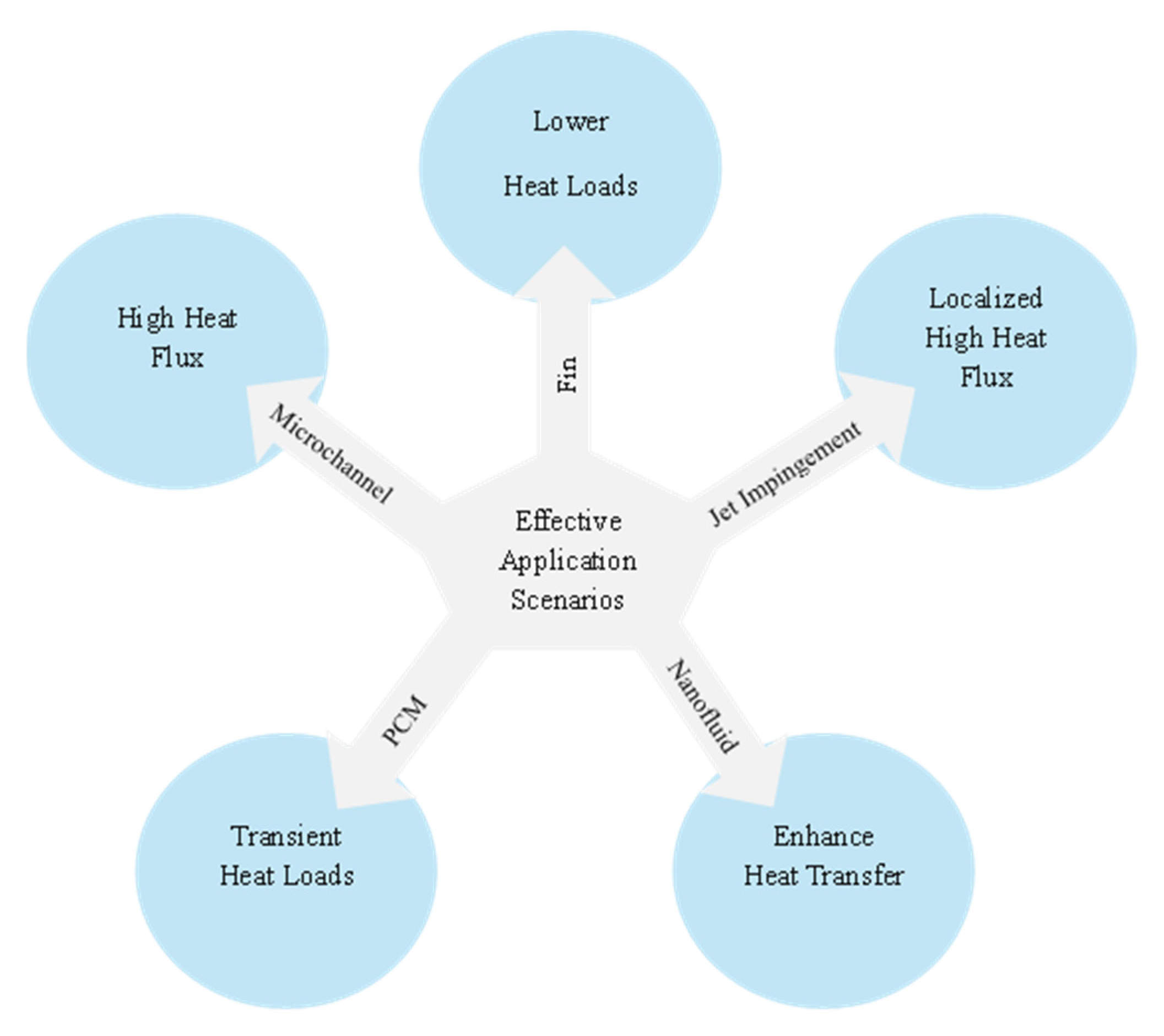

5. Performance of Cooling Solutions

6. Qualitative Comparison of Cooling Techniques

7. Challenges in Quantitative Analysis

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jones, J.S.; Rodriguez, R.; Yang, Y.; Lopera, L.; Emadi, A. Overview of Current Thermal Management of Automotive Power Electronics for Traction Purposes and Future Directions. IEEE Trans. Transp. Electrif. 2022, 8, 2412–2428. [Google Scholar] [CrossRef]

- Hanif, A.; Yu, Y.; DeVoto, D.; Khan, F. A Comprehensive Review Toward the State-of-the-Art in Failure and Lifetime Predictions of Power Electronic Devices. IEEE Trans. Power Electron. 2018, 34, 4729–4746. [Google Scholar] [CrossRef]

- Gabriel, O.E.; Huitink, D.R. Failure Mechanisms Driven Reliability Models for Power Electronics: A Review. J. Electron. Packag. 2022, 145, 020801. [Google Scholar] [CrossRef]

- Wang, H.; Ma, K.; Blaabjerg, F. Design for reliability of power electronic systems. In Proceedings of the IECON 2012-38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; pp. 33–44. [Google Scholar] [CrossRef]

- Qin, Y.; Albano, B.; Spencer, J.; Lundh, J.S.; Wang, B.; Buttay, C.; Tadjer, M.; DiMarino, C.; Zhang, Y. Thermal management and packaging of wide and ultra-wide bandgap power devices: A review and perspective. J. Phys. D Appl. Phys. 2023, 56, 093001. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; de Castro, C.A.N. A critical review of traditional and emerging techniques and fluids for electronics cooling. Renew. Sustain. Energy Rev. 2017, 78, 821–833. [Google Scholar] [CrossRef]

- Acharya, P.V.; Bahadur, V.; Hebner, R.; Ouroua, A.; Strank, S. Assessing the Performance of Advanced Cooling Techniques on Thermal Management of Next-Generation Power Electronics. In ASME 2019 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems; American Society of Mechanical Engineers: New York, NY, USA, 2019. [Google Scholar] [CrossRef]

- Cengel, Y.; Ghajar, A. Heat and Mass Transfer: Fundamentals and Applications, 6th ed.; McGraw-Hill: Columbus, OH, USA, 2020. [Google Scholar]

- McPherson, B.; McGee, B.; Simco, D.; Olejniczak, K.; Passmore, B. Direct liquid cooling of high performance Silicon Carbide (SiC) power modules. In Proceedings of the 2017 IEEE International Workshop on Integrated Power Packaging (IWIPP), Delft, The Netherlands, 5–7 April 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Lad, A.A.; Hoque, M.J.; Christian, S.; Zhao, Y.; Balda, J.C.; King, W.P.; Miljkovic, N. High power density thermal management of discrete semiconductor packages enabled by additively manufactured hybrid polymer-metal coolers. Appl. Therm. Eng. 2023, 220, 119726. [Google Scholar] [CrossRef]

- Sung, M.K.; Mudawar, I. Effects of jet pattern on two-phase performance of hybrid micro-channel/micro-circular-jet-impingement thermal management scheme. Int. J. Heat Mass Transf. 2009, 52, 3364–3372. [Google Scholar] [CrossRef]

- Ramesh, K.N.; Sharma, T.K.; Rao, G.A.P. Latest Advancements in Heat Transfer Enhancement in the Micro-channel Heat Sinks: A Review. Arch. Comput. Methods Eng. 2020, 28, 3135–3165. [Google Scholar] [CrossRef]

- Zuckerman, N.; Lior, N. Jet impingement heat transfer: Physics, correlations, and numerical modeling. Adv. Heat Transf. 2006, 39, 565–631. [Google Scholar] [CrossRef]

- Osman, A.; Moreno, G.; Myers, S.; Narumanchi, S.V.J.; Joshi, Y. Single-Phase Jet Impingement Cooling for a Power-Dense Silicon Carbide Power Module. IEEE Trans. Compon. Packag. Manuf. Technol. 2023, 13, 615–627. [Google Scholar] [CrossRef]

- Deng, Z.; Zhang, C.; Sun, Q.; Wu, L.; Yao, F.; Xu, D. Experimental study on melting performance of phase change material-based finned heat sinks by a comprehensive evaluation. J. Therm. Anal. Calorim. 2020, 144, 869–882. [Google Scholar] [CrossRef]

- Barua, H.; Chowdhury, S.; Wilkins, J.; Ozpineci, B. Single and Double-Sided Jet Impingement Cooling for SiC-Based Power Modules. In Proceedings of the 2023 IEEE 10th Workshop on Wide Bandgap Power Devices and Applications, WiPDA, Charlotte, NC, USA, 4–6 December 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Tang, G.; Chai, T.C.; Zhang, X. Thermal optimization and characterization of sic-based high power electronics packages with advanced thermal design. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 9, 854–863. [Google Scholar] [CrossRef]

- Lamichhane, R.R.; Ericsson, N.; Frank, S.; Britton, C.; Marlino, L.; Mantooth, A.; Francis, M.; Shepherd, P.; Glover, M.; Perez, S.; et al. A wide bandgap silicon carbide (SiC) gate driver for high-temperature and high-voltage applications. In Proceedings of the 2014 IEEE 26th International Symposium on Power Semiconductor Devices & IC’s (ISPSD), Waikoloa, HI, USA, 15–19 June 2014; IEEE: New York, NY, USA, 2014; pp. 414–417. [Google Scholar] [CrossRef]

- Qian, C.; Gheitaghy, A.M.; Fan, J.J.; Tang, H.Y.; Sun, B.; Ye, H.Y.; Zhang, G.Q. Thermal Management on IGBT Power Electronic Devices and Modules. IEEE Access 2018, 6, 12868–12884. [Google Scholar] [CrossRef]

- Jeon, J.; Seong, J.; Lim, J.; Kim, M.K.; Kim, T.; Yoon, S.W. Finite Element and Experimental Analysis of Spacer Designs for Reducing the Thermomechanical Stress in Double-Sided Cooling Power Modules. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 9, 3883–3891. [Google Scholar] [CrossRef]

- Rafin, S.M.S.H.; Ahmed, R.; Haque, M.A.; Hossain, M.K.; Haque, M.A.; Mohammed, O.A. Power Electronics Revolutionized: A Comprehensive Analysis of Emerging Wide and Ultrawide Bandgap Devices. Micromachines 2023, 14, 2045. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, A.Q. High Performance SiC Power Module Based on Repackaging of Discrete SiC Devices. IEEE Trans. Power Electron. 2023, 38, 9306–9310. [Google Scholar] [CrossRef]

- Wang, B.; Xiao, M.; Zhang, Z.; Wang, Y.; Qin, Y.; Song, Q.; Lu, G.-Q.; Ngo, K.; Zhang, Y. Chip Size Minimization for Wide and Ultrawide Bandgap Power Devices. IEEE Trans. Electron. Devices 2023, 70, 633–639. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, X.; Wu, X.; Shi, C.; Zhang, J.; Zhang, Y. Performance Evaluation of High-Power SiC MOSFET Modules in Comparison to Si IGBT Modules. IEEE Trans. Power Electron. 2019, 34, 1181–1196. [Google Scholar] [CrossRef]

- Wang, B.; Wang, L.; Wu, S.; Hou, Z.; Mu, W.; Yang, F.; Liu, J.; Gan, Y. An Evaluation on Thermal Performance Improvements for SiC Power Module Integrated with Vapor Chamber in MMC. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 5214–5225. [Google Scholar] [CrossRef]

- Kim, H.; Hwang, J.Y.; Kim, S.E.; Joo, Y.C.; Jang, H. Thermomechanical Challenges of 2.5-D Packaging: A Review of Warpage and Interconnect Reliability. IEEE Trans. Compon. Packag. Manuf. Technol. 2023, 13, 1624–1641. [Google Scholar] [CrossRef]

- Alharbi, S.S.; Alharbi, S.S.; Al-Bayati, A.M.S.; Matin, M. A Comparative Performance Evaluation of Si IGBT, SiC JFET, and SiC MOSFET Power Devices for a Non-Isolated DC-DC Boost Converter. In Proceedings of the 2017 North American Power Symposium (NAPS), Morgantown, WV, USA, 17–19 September 2017. [Google Scholar]

- Liu, M.; Coppola, A.; Alvi, M.; Anwar, M. Comprehensive Review and State of Development of Double-Sided Cooled Package Technology for Automotive Power Modules 2022; Institute of Electrical and Electronics Engineers: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Hsieh, M.-C.; Yu, C.-K.; Wu, S.-T. Thermo-mechanical Simulative study for 3D vertical stacked IC packages with spacer structuresWaterfront Hotel 2010. In Proceedings of the 2010 26th Annual IEEE Semiconductor Thermal Measurement and Management Symposium (SEMI-THERM), Santa Clara, CA, USA, 21–25 February 2010. [Google Scholar]

- Lin, Y.-S.; Liu, Y. Automotive High Power Module with Spacer on Die Bottom (Flip Chip) or Die Top (Wire Bond). In Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 7–8 July 2020; pp. 1–6. [Google Scholar]

- Cao, J.; Li, J.; Mei, Y.H. A Double-Sided Bidirectional Power Module with Low Heat Concentration and Low Thermomechanical Stress. IEEE Trans. Power Electron. 2021, 36, 9763–9766. [Google Scholar] [CrossRef]

- Adak, S.; Swain, S.K.; Pardeshi, H.; Rahman, H.; Sarkar, C.K. Effect of AlN spacer layer thickness on device performance of AIInN/AlN/GaN MOSHEMT. In Proceedings of the 1st International Conference on Computing, Communication, Control and Automation, Pune, India, 26–27 February 2015; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2015; pp. 902–905. [Google Scholar] [CrossRef]

- Fukumoto, A.; Berry, D.; Ngo, K.D.T.; Lu, G.Q. Effects of extreme temperature swings (−55 °C to 250 °C) on silicon nitride active metal brazing substrates. IEEE Trans. Device Mater. Reliab. 2014, 14, 751–756. [Google Scholar] [CrossRef]

- Gurpinar, E.; Chowdhury, S.; Ozpineci, B.; Fan, W. Graphite-Embedded High-Performance Insulated Metal Substrate for Wide-Bandgap Power Modules. IEEE Trans. Power Electron. 2021, 36, 114–128. [Google Scholar] [CrossRef]

- Kovacevic-Badstuebner, I.; Mengotti, E.; Natzke, P.; Race, S.; Bianda, E.; Jormanainen, J.; Grossner, U. Power Cycling of Sintered SiC Power MOSFET Baseplate-less Modules with Aluminum Oxide and Silicon Nitride Substrates. In Proceedings of the International Symposium on Power Semiconductor Devices and ICs, Hong Kong, China, 28 May–1 June 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023; pp. 60–63. [Google Scholar] [CrossRef]

- Yu, C.; Buttay, C.; Laboure, E. Thermal management and electromagnetic analysis for GaN devices packaging on DBC substrate. IEEE Trans. Power Electron. 2017, 32, 906–910. [Google Scholar] [CrossRef]

- Mouane, O.; Sideras-Haddad, E.; Nkadimeng, E.; Mckenzie, R.; Van Rensburg, R.; Sandrock, C.; Mellado, B.; Coville, N.J. Heat Conduction Enhancement of a Thermal Interface Material for Heat Sink Applications Using Carbon Nanomaterials. IEEE Trans. Nanotechnol. 2022, 21, 352–359. [Google Scholar] [CrossRef]

- Burzo, M.G.; Li, M. Investigation of Pressure Dependence of Interface Thermal Resistance in Thermal Greases by Transient Thermoreflectance. In Proceedings of the 34th SEMI-THERM Symposium, San Jose, CA, USA, 19–23 March 2018; IEEE: New York, NY, USA, 2018. [Google Scholar]

- Wen, H.; Ji, Y.; Zhang, K.; Yuen, M.M.; Lee, S.R.; Fu, X.-Z.; Sun, R.; Wong, C.-P. Low Melting Alloy Composites as Thermal Interface Materials with Low Thermal Resistance. In Proceedings of the 2016 17th International Conference on Electronic Packaging Technology, Wuhan, China, 16–19 August 2016. [Google Scholar]

- Hansson, J.; Nilsson, T.M.J.; Ye, L.; Liu, J. Effect of Fiber Concentration on Mechanical and Thermal Properties of a Solder Matrix Fiber Composite Thermal Interface Material. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 1045–1053. [Google Scholar] [CrossRef]

- Idris, J.; Hon, T.W. High-Performance Carbon Nanotubes Thermal Interface Materials. In Proceedings of the 36th International Electronics Manufacturing Technology Conference, Johor Bahru, Malaysia, 11–13 November 2014. [Google Scholar]

- Prinzi, L.F.; Green, C.E.; Cola, B.A. Investigation of the Mechanical Compliance of Highly Conductive and Durable Carbon NanotubePolymer Composite Thermal Interface Material. In Proceedings of the 16th IEEE ITHERM Conference, Orlando, FL, USA, 20 May–2 June 2017. [Google Scholar]

- Wang, X.; Li, H.; Yao, R.; Lai, W.; Liu, R.; Yu, R.; Chen, X.; Li, J. Thermal Contact Resistance Optimization of Press-Pack IGBT Device Based on Liquid Metal Thermal Interface Material. IEEE Trans. Power Electron. 2022, 37, 5411–5421. [Google Scholar] [CrossRef]

- Jiang, H.; Zhou, H.; Robertson, S.; Zhou, Z.; Zhao, L.; Liu, C. Further enhancement of thermal conductivity through optimal uses of h-BN fillers in polymer-based thermal interface material for power electronics. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA; pp. 1569–1574. [Google Scholar] [CrossRef]

- Barako, M.T.; Gao, Y.; Won, Y.; Marconnet, A.M.; Asheghi, M.; Goodson, K.E. Reactive metal bonding of carbon nanotube arrays for thermal interface applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 1906–1913. [Google Scholar] [CrossRef]

- Zhang, C.; Ren, L.; Zeng, X.; Sun, R. Effects of Rheological Properties on the Thermal Resistance of Gel Thermal Interface Materials. In Proceedings of the 23rd International Conference on Electronic Packaging Technology (ICEPT), Dalian, China, 10–13 August 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Dan, B.; Sammakia, B.G.; Subbarayan, G.; Kanuparthi, S.; Mallampati, S. The study of the polydispersivity effect on the thermal conductivity of particulate thermal interface materials by finite element method. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 2068–2074. [Google Scholar] [CrossRef]

- Yi, M.; Wu, P.; Qiu, Y.; Wen, J.; Zhu, W.; Wang, L. Reducing thermal interface resistance by Oxygen plasma treatment for FCBGA advanced package. IEEE Trans. Compon. Packag. Manuf Technol. 2024, 14, 251–256. [Google Scholar] [CrossRef]

- Kemerli, U.; Joshi, Y. Performance Comparison of Various Thermal Interface Materials Used with Metal Foams. In Proceedings of the InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Orlando, FL, USA, 20 May–2 June 2023; IEEE Computer Society: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, X.; Li, J.; Zhang, F.; Zhao, W.; Zhang, Y.; Gerada, D.; Zhang, H. Effectiveness of Thermal Interface Materials on Electrical Machines Thermal Performance with Heat Pipes. IEEE Trans. Transp. Electrif. 2023, 10, 1274–1285. [Google Scholar] [CrossRef]

- Wang, Y. Thermal Resistance Modeling and Heat Dissipation Improvement of Press-Pack IGBT. Master’s Thesis, Chong Qing University, Chongqing, China, 2021. [Google Scholar]

- Zhang, K.; Liu, H.; Du, F.; Chen, X.; Li, B.; Hong, J. MMC-based heat sink topology optimization design for natural convection problems. Int. J. Therm. Sci. 2023, 192, 108376. [Google Scholar] [CrossRef]

- See, Y.S.; Ho, J.Y.; Leong, K.C.; Wong, T.N. Experimental investigation of a topology-optimized phase change heat sink optimized for natural convection. Appl. Energy 2022, 314, 118984. [Google Scholar] [CrossRef]

- Gopi, M. Design Modification and Analysis of Cooling Fins in Motor Cycle Engine. J. Emerg. Technol. Innov. Res. JETIR 2019, 6, 660–665. [Google Scholar]

- Zahari, N.A.B.; Husaini, Y.B.; Yaakub, T.N.B.T. Fin Configuration Affects under Natural Convection Heat Transfer for Rectangular Fin Heatsink Using Steady-State Thermal Analysis. In Proceedings of the 2023 IEEE Symposium on Industrial Electronics and Applications (ISIEA), Helsinki-Espoo, Finland, 19–21 June 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Feng, S.; Shi, M.; Yan, H.; Sun, S.; Li, F.; Lu, T.J. Natural convection in a cross-fin heat sink. Appl. Therm. Eng. 2018, 132, 30–37. [Google Scholar] [CrossRef]

- Liu, J.; Li, Z.; Yan, C.; Ding, X.; Yu, B. A Temperature Self-Adapting Heat Sink For Improving The Heat Dissipation Ability by Weakening The Dust Accumulation. In Proceedings of the 21st International Conference on Electronic Packaging Technology (ICEPT), Guangzhou, China, 12–15 August 2020; IEEE: New York, NY, USA. [Google Scholar] [CrossRef]

- Rao, A.K.; Somkuwar, V. Heat transfer of a tapered fin heat sink under natural convection. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; pp. 7886–7891. [Google Scholar] [CrossRef]

- Chen, H.-L.; Wang, C.-C. Analytical and Experimental Verification of Interleaved Trapezoidal Heat Sink. In Proceedings of the 33rd SEMI-THERM Symposium, San Jose, CA, USA, 13–17 March 2017; IEEE: New York, NY, USA, 2017. [Google Scholar]

- Robinson, A.J.; Tan, W.; Kempers, R.; Colenbrander, J.; Bushnell, N.; Chen, R. A New Hybrid Heat Sink with Impinging Micro-Jet Arrays and Microchannels Fabricated using High Volume Additive Manufacturing. In Proceedings of the 33rd SEMI-THERM Symposium, San Jose, CA, USA, 13–17 March 2017; IEEE: New York, NY, USA, 2017. [Google Scholar]

- Noh, W.; Kim, K.J. Optimization of Hollow Hybrid Fin Heat Sinks under Natural Convection. In Proceedings of the 2023 29th International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), Budapest, Hungary, 27–29 September 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Paul, B.; Mathew, M.; Govind, P. Modelling and Thermal Analysis of Honey Comb Heat Sink for LEDs in Street Lighting Applications in International Conference on Inventive Systems and Control (ICISC-2017); IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Li, Y.; Gong, L.; Xu, M.; Joshi, Y. Thermal Performance of Metal Foam Heat Sink with Pin Fins for Non Uniform Heat Flux Electronics Cooling. In Proceedings of the 35th SEMI-THERM Symposium, San Jose, CA, USA, 18–22 March 2019. [Google Scholar]

- Liu, F.; Wang, J.; Liu, Y.; Wang, F.; Yang, N.; Liu, X.; Liu, H.; Li, W.; Liu, H.; Huang, B. Performance analysis of phase change material in battery thermal management with biomimetic honeycomb fin. Appl. Therm. Eng. 2021, 196, 117296. [Google Scholar] [CrossRef]

- Kumar, A.; Mondal, M.K. Optimizing Heat Sink Size for a Given Heat Source. In Proceedings of the 2023 2nd International Conference on Futuristic Technologies (INCOFT), Karnataka, India, 24–26 November 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Zhou, F.; Joshi, S.N.; Liu, Y.; Dede, E.M. Near-junction cooling for next-generation power electronics. Int. Commun. Heat Mass Transf. 2019, 108, 104300. [Google Scholar] [CrossRef]

- Sakanova, A.; Yin, S.; Zhao, J.; Wu, J.M.; Leong, K.C. Optimization and comparison of double-layer and double-side micro-channel heat sinks with nanofluid for power electronics cooling. Appl. Therm. Eng. 2014, 65, 124–134. [Google Scholar] [CrossRef]

- Back, D.; Drummond, K.P.; Sinanis, M.D.; Weibel, J.A.; Garimella, S.V.; Peroulis, D.; Janes, D.B. Design, Fabrication, and Characterization of a Compact Hierarchical Manifold Microchannel Heat Sink Array for Two-Phase Cooling. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 1291–1300. [Google Scholar] [CrossRef]

- Li, X.; Xuan, Y. Embedded Cooling of High-Heat-Flux Hotspots Using Self-Adaptive Microchannel/Pin-Fin Hybrid Heat Sink. IEEE Trans. Compon. Packag. Manuf. Technol. 2022, 12, 1627–1635. [Google Scholar] [CrossRef]

- Hongyue, W.; Xingxian, X.; Pengfei, W.; Bin, Z.; Si, C.; Yijun, S. Study on the pillars structure impacts on the embedded microchannel heat sink. In Proceedings of the 23rd International Conference on Electronic Packaging Technology, Dalian, China, 9–11 August 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Han, X.H.; Liu, H.L.; Xie, G.; Sang, L.; Zhou, J. Topology optimization for spider web heat sinks for electronic cooling. Appl. Therm. Eng. 2021, 195, 117154. [Google Scholar] [CrossRef]

- Memon, S.A.; Cheema, T.A.; Kim, G.M.; Park, C.W. Hydrothermal investigation of a microchannel heat sink using secondary flows in trapezoidal and parallel orientations. Energies 2020, 13, 5616. [Google Scholar] [CrossRef]

- Zhuang, D.; Yang, Y.; Ding, G.; Du, X.; Hu, Z. Optimization of Microchannel Heat Sink with Rhombus Fractal-like Units for Electronic Chip Cooling. Int. J. Refrig. 2020, 116, 108–118. [Google Scholar] [CrossRef]

- Kieger, T. Computational analysis of changing wavelength on bottom rib and side rib wavy microchannel heat sinks. In Proceedings of the 38th SEMI-THERM Symposium, San Jose, CA, USA, 21–25 March 2022. [Google Scholar]

- Alugoju, U.K.; Dubey, S.K.; Javed, A. Optimization of converging and diverging microchannel heat sink for electronic chip cooling. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 817–827. [Google Scholar] [CrossRef]

- Jung, K.W.; Kharangate, C.R.; Lee, H.; Palko, J.; Zhou, F.; Asheghi, M.; Dede, E.M.; Goodson, K.E. Microchannel Cooling Strategies for High Heat Flux (1 kW/cm2) Power Electronic Applications. In Proceedings of the 2017 16th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 30 May–2 June 2017. [Google Scholar]

- Liu, W.; Torsten, H.; Drobnik, J. Effective Thermal Simulation of Power Electronics in Hybrid and Electric Vehicles. World Electr. Veh. J. 2012, 5, 574–580. [Google Scholar] [CrossRef]

- Zhou, Y.; Nomura, T.; Dede, E.M. Topology Optimization of Manifold Microchannel Heat Sinks. In Proceedings of the 19th IEEE ITHERM Conference, Orlando, FL, USA, 26–29 May 2020. [Google Scholar]

- Takai, K.; Yuki, K.; Yuki, K.; Kibushi, R.; Unno, N. Heat Transfer Performance of Uni-directional Porous Heat Sink for Cooling of Next Generation on-vehicle Inverter. In Proceedings of the International Conference on Electronics Packaging (ICEP), Yamagata, Japan, 19–22 April 2017. [Google Scholar]

- Li, F.; Zhu, W.; He, H. Numerical study on a novel microchannel structure towards high efficient heat dissipation in high power electronics. In Proceedings of the 19th International Conference on Electronic Packaging Technology, Shanghai, China, 8–11 August 2018. [Google Scholar]

- Wang, W.; Li, Y.; Zhang, Y.; Li, B.; Sundén, B. Analysis of laminar flow and heat transfer in an interrupted microchannel heat sink with different shaped ribs. J. Therm. Anal. Calorim. 2019, 140, 1259–1266. [Google Scholar] [CrossRef]

- Liu, H.L.; Fan, C.C.; He, Y.L.; Nobes, D.S. Heat transfer and flow characteristics in a rectangular channel with combined delta winglet inserts. Int. J. Heat Mass Transf. 2019, 134, 149–165. [Google Scholar] [CrossRef]

- Joshi, S.N.; Yu, Z.; Sennoun, H.; Hampshire, J.; Dede, E.M. Single-phase Cooling Performance of a Topology Optimized and Additively-Manufactured Multi-Pass Branching Microchannel Heat Sink. In Proceedings of the 19th IEEE ITHERM Conference, Orlando, FL, USA, 26–29 May 2020. [Google Scholar]

- Thaher, A.; Mathew, B. Heat Sink Employing Straight Microchannels with Sidewall Ribs in Staggered Arrangement for Liquid Based Cooling of Microelectronic Chips. In Proceedings of the IEEE 23rd Electronics Packaging Technology Conference, Singapore, 1–3 December 2021; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2021; pp. 519–523. [Google Scholar] [CrossRef]

- Du, J.; Li, W.; Gao, X.; Zheng, D.; Yang, Y.; Wang, Z.; Zhao, H.; Kang, J.; Wang, W. Design. Fabrication, and Test of an Embedded Si-Glass Microchannel Heat Sink for High-power RF Application. In Proceedings of the 22nd International Conference on Electronic Packaging Technology, Xiamen, China, 11–14 August 2021; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2021. [Google Scholar] [CrossRef]

- He, Z.; Yan, Y.; Feng, S.; Yang, Z.; Zhang, L.; Zhang, Z. Multi-objective optimizations on thermal and hydraulic performance of symmetric and asymmetric bionic Y-shaped fractal networks by genetic algorithm coupled with CFD simulation. Int. Commun. Heat Mass Transf. 2021, 124, 105261. [Google Scholar] [CrossRef]

- Jiang, W.; Zhao, J.; Rao, Z. Heat transfer performance enhancement of liquid cold plate based on mini V-shaped rib for battery thermal management. Appl. Therm. Eng. 2021, 189, 116729. [Google Scholar] [CrossRef]

- Liu, C.; Zhou, J.; Zhao, Q.; Chen, X. Numerical Investigation of Heat Transfer in Open Microchannel Heat Sinks with Transverse Ribs for High Heat Flux Dissipation. IEEE Trans. Plasma Sci. 2022, 50, 4220–4225. [Google Scholar] [CrossRef]

- Jovin, D.; Jie, J.; Hui, H.; Ooi, K.T. Numerical Analysis of Passive Manifold Microchannel Heat Exchanger Enhancements. In Proceedings of the InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, San Diego, CA, USA, 31 May–3 June 2022; IEEE Computer Society: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Liu, S.; Pan, Z. Numerical Study on Cavities Shape for the Hydrothermal Performance of Microchannel Heat Sinks with Elliptical Ribs and Secondary Channels. In Proceedings of the International Conference on Electrical Engineering and Informatics, Banda Aceh, Indonesia, 27–28 September 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022; pp. 20–25. [Google Scholar] [CrossRef]

- Fathi, M.; Heyhat, M.M.; Targhi, M.Z. Thermal performance enhancement of microchannel heat sinks with a decreasing-height bifurcation plate. In Proceedings of the 8th International Conference on Technology and Energy Management, ICTEM, Babol, Iran, 8–9 February 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Cassada, N.; Anderson, C.; Kubicek, L.; Hobby, D.; Frye, C.; Baxamusa, S.; Kotovsky, J.; Jackson, K.; Ladner, I.; Bandhauer, T. SiC Microchannel Heat Sinks for High Heat Flux Dissipation of 1 kW/cm2. IEEE Trans. Compon. Packag. Manuf. Technol. 2023, 13, 655–665. [Google Scholar] [CrossRef]

- Jung, K.W.; Kharangate, C.R.; Lee, H.; Palko, J.; Zhou, F.; Asheghi, M.; Dede, E.M.; Goodson, K.E. Embedded cooling with 3D manifold for vehicle power electronics application: Single-phase thermal-fluid performance. Int. J. Heat Mass Transf. 2019, 130, 1108–1119. [Google Scholar] [CrossRef]

- Shaeri, M.R.; Chen, C.H.; Bonner, R.W.; Demydovych, M. Demonstration of CTE-Matched Two-Phase Minichannel Heat Sink. In Proceedings of the InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Orlando, FL, USA, 30 May–2 June 2023; IEEE Computer Society: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Lin, F.-C.; Liu, C.-F.; Yang, M.-T.; Lee, S.-W.; Hsu, C.-H.; Sung, K.-F.; Yang, C.-Y. Flow Boiling Heat Transfer Performance Comparison of Skived Straight and CNC Diverging Microchannels Heat Sinks. In Proceedings of the 39th Annual Semiconductor Thermal Measurement, Modeling and Management Symposium (SEMI-THERM), San Jose, CA, USA, 13–16 March 2023. [Google Scholar]

- Chen, N.; Chen, Y.; Zhao, I. Study of Two-phase Microchannel Heat Sink Fabricated by Additive Manufacturing Technologies. In Proceedings of the THERMINIC 28th International Workshop on Thermal Investigations of ICs and Systems, Dublin, Ireland, 28–30 September 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Leena, R.; Renjith, R.V.; Prakash, M.J. Experimental and Numerical Investigations on Steady and Unsteady Jet Impingement Cooling for High-Power Electronics. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 636–640. [Google Scholar] [CrossRef]

- Wei, T.-W.; Oprins, H.; Cherman, V.; Yang, Z.; Rivera, K.; Van der Plas, G.; Pawlak, B.J.; England, L.; Beyne, E.; Baelmans, M. Demonstration of Package Level 3D-printed Direct Jet Impingement Cooling applied to High power, Large Die Applications. In Proceedings of the Electronic Components and Technology Conference, Orlando, FL, USA, 3–30 June 2020; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2020; pp. 1422–1429. [Google Scholar] [CrossRef]

- Chu, W.X.; Chiou, P.H.; Wang, C.C. Experimental and numerical study upon uniformity of impingement cooling with pin-fin heat sink. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 10, 88–98. [Google Scholar] [CrossRef]

- Henry, M.A.; Reid, K.E.; Maddox, J.F.; Knight, R.W.; Bhavnani, S.H. A Numerical and Experimental Study of Staggered Submerged Liquid Jet Arrays Using Variable Angle Discharge Manifolds. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 2168–2176. [Google Scholar] [CrossRef]

- Mudawar, I. Assessment of High-Heat-Flux Thermal Management Schemes. IEEE Trans. Compon. Packag. Technol. 2001, 24, 122–141. [Google Scholar] [CrossRef]

- Gould, K.; Cai, S.Q.; Neft, C.; Bhunia, A. Liquid jet impingement cooling of a silicon carbide power conversion module for vehicle applications. IEEE Trans. Power Electron. 2014, 30, 2975–2984. [Google Scholar] [CrossRef]

- Zing, C.; Mahjoob, S. Numerical Investigation of Thermal Transport in Confined Single and Multiple Jet Impingements Through Porous Filled Non-Uniform Cross Section Channels. In Proceedings of the 17th IEEE ITHERM Conference, San Diego, CA, USA, 29 May–1 June 2018. [Google Scholar]

- Kuraan, A.M.; Choo, K. The Influence of Nozzle to Plate Spacing on the Circular Hydraulic Jump of Water Jet Impingement. In Proceedings of the 16th IEEE ITHERM Conference, San Diego, CA, USA, 29 May–1 June 2017. [Google Scholar]

- Zielinski, A.J.; Embury, M.C.; Solovitz, S.A. Impingement Cooling Using a Variable-Diameter Synthetic Jet. In Proceedings of the 17th IEEE ITHERM Conference, San Diego, CA, USA, 29 May–1 June 2018. [Google Scholar]

- Clark, M.D.; Weibel, J.A.; Garimella, S.V. Identification of the Dominant Heat Transfer Mechanisms during Confined Two-phase Jet Impingement. In Proceedings of the 17th IEEE ITHERM Conference, San Diego, CA, USA, 29 May–June 1 2018. [Google Scholar]

- Corvera, C.; Mahjoob, S. Analysis of Jet and Cross Flow Interaction with Application in Hotspot Electronics Cooling. In Proceedings of the InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, San Diego, CA, USA, 31 May–3 June 2022; IEEE Computer Society: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Jahnes, M.; Owen, M.; Pennington, W.W.; Preindl, M. Direct Contact Jet Impingement Cooling with Non-conductive Fluid for Power Converters that Enables Increased Power Density. In Proceedings of the IEEE Transportation Electrification Conference and Expo, ITEC, Anaheim, CA, USA, 15–17 June 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022; pp. 807–812. [Google Scholar] [CrossRef]

- Corvera, C.; Mahjoob, S. Thermal-Fluid Study of Jet-in-Crossflow Cooling in Comparison with Pure Jet Impingement and Pure Crossflow Cooling Methods Applicable in Hotspot Treatment. In Proceedings of the InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Orlando, FL, USA, 30 May–2 June 2023; IEEE Computer Society: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Smith, A.H.; Bhavnani, S.H.; Knight, R.W. Improving fluid-thermal performance of impinging jet arrays with small-scale engineered surface augmentations in the fountain regions. In Proceedings of the InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Orlando, FL, USA, 30 May–2 June 2023; IEEE Computer Society: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Agbim, K.A.; Pahinkar, D.G.; Graham, S. Integration of Jet Impingement Cooling with Direct Bonded Copper Substrates for Power Electronics Thermal Management. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 9, 226–234. [Google Scholar] [CrossRef]

- Behera, R.C.; Dutta, P.; Srinivasan, K. Numerical study of interrupted impinging jets for cooling of electronics. IEEE Trans. Compon. Packag. Technol. 2007, 30, 275–284. [Google Scholar] [CrossRef]

- Oró, E.; de Gracia, A.; Castell, A.; Farid, M.M.; Cabeza, L.F. Review on phase change materials (PCMs) for cold thermal energy storage applications. Appl. Energy 2012, 99, 513–533. [Google Scholar] [CrossRef]

- Lone, M.I.; Jilte, R. A review on phase change materials for different applications. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; pp. 10980–10986. [Google Scholar] [CrossRef]

- Hasan, M.I.; Tbena, H.L. Enhancing the cooling performance of micro pin fin heat sink by using the phase change materials with different configurations. In Proceedings of the 2018 International Conference on Advances in Sustainable Engineering and Applications (ICASEA), Wasit University, Kut, Iraq, 14–15 March 2018. [Google Scholar]

- Kumar, M.G.; Balaji, C. Experimental and Numerical Investigations on a Phase Change Material Based Heat Sink with Symbiotically Joined Heat Pipe. Heat Transf. Eng. 2019, 42, 23–40. [Google Scholar] [CrossRef]

- Qureshi, Z.A.; Elnajjar, E.; Al-Ketan, O.; Al-Rub, R.A.; Al-Omari, S.B. Heat transfer performance of a finned metal foam-phase change material (FMF-PCM) system incorporating triply periodic minimal surfaces (TPMS). Int. J. Heat Mass Transf. 2021, 170, 121001. [Google Scholar] [CrossRef]

- Angayarkanni, S.A.; Philip, J. Review on thermal properties of nanofluids: Recent developments. Adv. Colloid Interface Sci. 2015, 225, 146–176. [Google Scholar] [CrossRef] [PubMed]

- Tan, Z.; Li, F.; Liu, Z.; Wu, Y. Numerical Study of Microchannel Heat Sink Using Water-Al2O3Nanofluids for Heat Dissipation of High-power Devices. In Proceedings of the 23rd International Conference on Electronic Packaging Technology, ICEPT, Dalian, China, 9–11 August 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Zhang, W.; Li, G.J.; Ren, B.; Chong, Y.C.; Michon, M. Investigation of Ferrofluid Cooling for High Power Density Permanent Magnet Machines. IEEE Trans. Magn. 2022, 59, 1–11. [Google Scholar] [CrossRef]

- Olmo, C.; Mendez, C.; Ortiz, F.; Delgado, F.; Valiente, R.; Werle, P. Maghemite Nanofluid Based on Natural Ester: Cooling and Insulation Properties Assessment. IEEE Access 2019, 7, 145851–145860. [Google Scholar] [CrossRef]

- Vaishnav, H.; Navin, K.; Kurchania, R.; Ball, R.J. Synthesis of ZrO2 Based Nanofluids for Cooling and Insulation of Transformers. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 199–205. [Google Scholar] [CrossRef]

- Sakanova, A.; Zhao, J.; Tseng, K.J. Investigation on the Influence of Nanofluids in Wavy Microchannel Heat Sink. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 956–970. [Google Scholar] [CrossRef]

- Tharayil, T.; Asirvatham, L.G.; Rajesh, S.; Wongwises, S. Thermal Management of Electronic Devices Using Combined Effects of Nanoparticle Coating and Graphene-Water Nanofluid in a Miniature Loop Heat Pipe. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 8, 1241–1253. [Google Scholar] [CrossRef]

- Kumar, V.; Sarkar, J. Particle ratio optimization of Al2O3-MWCNT hybrid nanofluid in minichannel heat sink for best hydrothermal performance. Appl. Therm. Eng. 2020, 165. [Google Scholar] [CrossRef]

- Patel, D.; Mishra, A.; Nabeel, M. Heat Transfer Characteristics of Nanofluids of Silicon Oxides (SiO2) with Conventional Fluid. In Proceedings of the 2nd International Conference on Innovative Practices in Technology and Management, ICIPTM, Nodia, India, 23–25 February 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022; pp. 420–423. [Google Scholar] [CrossRef]

- Mansour, D.-E.A.; Emara, R.F.; El Nemr, M.K. Heat Transport Characteristics of Oil-Based Nanofluids with Different Types of Nanoparticles. In Proceedings of the 19th IEEE International Conference on Dielectric Liquids (ICDL), Manchester, UK, 25–29 June 2017. [Google Scholar]

- Shill, D.C.; Das, A.K.; Chatterjee, S. Insulation and Cooling Performance of Transformer Oil Based Nanofluid. In Proceedings of the 2020 International Conference on Computer, Electrical & Communication Engineering (ICCECE), Kolkata, India, 17–18 January 2020. [Google Scholar]

- Turgut, A.; Elbasan, E. Nanofluids for Electronics Cooling. In Proceedings of the 2014 IEEE 20th International Symposium for Design and Technology in Electronic Packaging (SIITME), Bucharest, Romania, 23–26 October 2014; p. 344. [Google Scholar]

- Aglawe, K.R.; Yadav, R.K.; Thool, S.B. Preparation, applications and challenges of nanofluids in electronic cooling: A systematic review. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; pp. 366–372. [Google Scholar] [CrossRef]

- Aksoy, Y.T.; Cornelissen, H.; Eneren, P.; Vetrano, M.R. Spray Cooling Investigation of TiO2–Water Nanofluids on a Hot Surface. Energies 2023, 16, 2938. [Google Scholar] [CrossRef]

- Aksoy, Y.T.; Enayati, F.; Eneren, P.; Vetrano, M.R. Experimental study on enhanced heat transfer via nanoparticle depositions using TiO2-water nanofluid sprays. Appl. Therm. Eng. 2025, 264, 125450. [Google Scholar] [CrossRef]

- Eneren, P.; Aksoy, Y.T.; Vetrano, M.R. Practical Challenges in Nanofluid Convective Heat Transfer Inside Silicon Microchannels. Energies 2023, 16, 7885. [Google Scholar] [CrossRef]

- Hadžić, A.; Može, M.; Zupančič, M.; Golobič, I. Superbiphilic Laser-Microengineered Surfaces with A Self-Assembled Monolayer Coating for Exceptional Boiling Performance. Adv. Funct. Mater. 2023, 34, 2310662. [Google Scholar] [CrossRef]

- Sun, Y.; Tang, Y.; Zhang, S.; Yuan, W.; Tang, H. A review on fabrication and pool boiling enhancement of three-dimensional complex structures. Renew. Sustain. Energy Rev. 2022, 162, 112437. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, Y.; Bai, J.; Qiu, H.; Li, Y.; Yang, Z.; Yan, C. Pool Boiling Enhancement via Surface Engineering for Thermal Management. In Proceedings of the 25th International Conference on Electronic Packaging Technology, Tianjin, China, 7–9 August 2024; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, Y.; Bai, J.; Qiu, H.; Li, Y.; Yang, Z.; Yan, C. Pool Boiling Enhancement of Copper Powder-Mesh Composite Surface Based on Screen Printing for High-Power Electronics Cooling. In Proceedings of the 25th International Conference on Electronic Packaging Technology, ICEPT, Tianjin, China, 7–9 August 2024; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024. [Google Scholar] [CrossRef]

- Katarkar, A.; Pingale, A.; Madgule, M.; Belgamwar, S.; Bhaumik, S. Pool boiling heat transfer enhancement on micro- and nano-structured copper surface. JMST Adv. 2025, 7, 131–141. [Google Scholar] [CrossRef]

- Ma, X.; Song, G.; Chen, H.; Zhang, Y.; Xu, N.; Wei, J. Experimental investigation and correlation analysis of pool boiling heat transfer on the array surfaces with micro-fins using FC-72 for the electronic thermal management. Appl. Therm. Eng. 2023, 236, 121755. [Google Scholar] [CrossRef]

- Prasher, R.S.; Chang, J.Y.; Sauciuc, I.; Narasimhan, S.; Chau, D.; Chrysler, G.; Myers, A.; Prstic, S.; Hu, C. Nano and Micro Technology-Based Next-Generation Package-Level Cooling Solutions. Intel Technol. J. 2005, 9, 285–296. [Google Scholar] [CrossRef]

- Dede, E.M.; Liu, Y. Experimental and numerical investigation of a multi-pass branching microchannel heat sink. Appl. Therm. Eng. 2013, 55, 51–60. [Google Scholar] [CrossRef]

- Rimbault, B.; Nguyen, C.T.; Galanis, N. Experimental investigation of CuO-water nanofluid flow and heat transfer inside a microchannel heat sink. Int. J. Therm. Sci. 2014, 84, 275–292. [Google Scholar] [CrossRef]

- Stevanovic, L.D.; Beaupre, R.A.; Gowda, A.V.; Pautsch, A.G.; Solovitz, S.A. Integral Micro-channel Liquid Cooling for Power Electronics. In Proceedings of the Twenty-Fifth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Palm Springs, CA, USA, 21–25 February 2010. [Google Scholar]

- Nascimento, F.J.D.; Leão, H.L.S.L.; Ribatski, G. An experimental study on flow boiling heat transfer of R134a in a microchannel-based heat sink. Exp. Therm. Fluid Sci. 2013, 45, 117–127. [Google Scholar] [CrossRef]

- Lee, J.; Mudawar, I. Critical heat flux for subcooled flow boiling in micro-channel heat sinks. Int. J. Heat Mass Transf. 2009, 52, 3341–3352. [Google Scholar] [CrossRef]

- Zimmermann, S.; Tiwari, M.K.; Meijer, I.; Paredes, S.; Michel, B.; Poulikakos, D. Hot water cooled electronics: Exergy analysis and waste heat reuse feasibility. Int. J. Heat Mass Transf. 2012, 55, 6391–6399. [Google Scholar] [CrossRef]

- Madhour, Y.; Olivier, J.; Costa-Patry, E.; Paredes, S.; Michel, B.; Thome, J.R. Flow boiling of R134a in a multi-microchannel heat sink with hotspot heaters for energy-efficient microelectronic CPU cooling applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2011, 1, 873–883. [Google Scholar] [CrossRef]

- Colgan, E.G.; Furman, B.; Gaynes, M.; Graham, W.S.; LaBianca, N.C.; Magerlein, J.H.; Polastre, R.J.; Rothwell, M.B.; Bezama, R.J.; Choudhary, R.; et al. A Practical Implementation of Silicon Microchannel Coolers for High Power Chips. In Proceedings of the 21st IEEE SEMI-THERM Symposium, San Jose, CA, USA, 15 March 2005. [Google Scholar]

- Lee, Y.J.; Singh, P.K.; Lee, P.S. Fluid flow and heat transfer investigations on enhanced microchannel heat sink using oblique fins with parametric study. Int. J. Heat Mass Transf. 2015, 81, 325–336. [Google Scholar] [CrossRef]

- Fu, B.R.; Lee, C.Y.; Pan, C. The effect of aspect ratio on flow boiling heat transfer of HFE-7100 in a microchannel heat sink. Int. J. Heat Mass Transf. 2013, 58, 53–61. [Google Scholar] [CrossRef]

- Colgan, E.G.; Furman, B.; Gaynes, M.; LaBianca, N.; Magerlein, J.; Polastre, R.; Bezama, R.J.; Choudhary, R.; Marston, K.; Toy, H.; et al. Silicon microchannel cooling for high power chips. HVAC R Res. 2006, 12, 1031–1045. [Google Scholar] [CrossRef]

- Agostini, B.; Thome, J.R.; Fabbri, M.; Michel, B. High heat flux two-phase cooling in silicon multimicrochannels. IEEE Trans. Compon. Packag. Technol. 2008, 31, 691–701. [Google Scholar] [CrossRef]

- Chien, L.H.; Chang, C.Y. An experimental study of two-phase multiple jet cooling on finned surfaces using a dielectric fluid. Appl. Therm. Eng. 2011, 31, 1983–1993. [Google Scholar] [CrossRef]

- Fabbri, M.; Dhir, V.K. Optimized heat transfer for high power electronic cooling using arrays of microjets. J. Heat Transf. 2004, 127, 760–769. [Google Scholar] [CrossRef]

- Mahmoudi, S.R.; Adamiak, K.; Castle, G.S.P. Two-phase cooling characteristics of a saturated free falling circular jet of HFE7100 on a heated disk: Effect of jet length. Int. J. Heat Mass Transf. 2012, 55, 6181–6190. [Google Scholar] [CrossRef]

- Sung, M.K.; Mudawar, I. Single-phase hybrid micro-channel/micro-jet impingement cooling. Int. J. Heat Mass Transf. 2008, 51, 4342–4352. [Google Scholar] [CrossRef]

- Fabbri, M.; Jiang, S.; Dhir, V.K. A comparative study of cooling of high power density electronics using sprays and microjets. J. Heat Transf. 2005, 127, 38–48. [Google Scholar] [CrossRef]

- Natarajan, G.; Bezama, R.J. Microjet cooler with distributed returns. Heat Transf. Eng. 2007, 28, 779–787. [Google Scholar] [CrossRef]

- Brunschwiler, T.; Rothuizen, H.; Fabbri, M.; Kloter, U.; Michel, B.; Bezama, R.J.; Natarajan, G. Direct liquid jet-impingement cooling with micron-sized nozzle array and distributed return architecture. In Proceedings of the Thermal and Thermomechanical Proceedings 10th Intersociety Conference on Phenomena in Electronics Systems, 2006, ITHERM, San Diego, CA, USA, 30 May–2 June 2006. [Google Scholar]

- Wei, T.; Oprins, H.; Cherman, V.; Qian, J.; De Wolf, I.; Beyne, E.; Baelmans, M. High-Efficiency Polymer-Based Direct Multi-Jet Impingement Cooling Solution for High-Power Devices. IEEE Trans. Power Electron. 2018, 34, 6601–6612. [Google Scholar] [CrossRef]

- Joshi, S.N.; Dede, E.M. Two-phase jet impingement cooling for high heat flux wide band-gap devices using multi-scale porous surfaces. Appl. Therm. Eng. 2017, 110, 10–17. [Google Scholar] [CrossRef]

- Escher, W.; Brunschwiler, T.; Michel, B.; Poulikakos, D. Experimental investigation of an ultrathin manifold microchannel heat sink for liquid-cooled chips. J. Heat Transf. 2010, 132, 081402. [Google Scholar] [CrossRef]

- Ramaraju, R.G.V.; Passandideh-Fard, M.; Chandra, S. High Heat Flux Removal by Water Jet Impingement Using 3D Printed Nozzles. In Proceedings of the THERMINIC 2022-28th International Workshop on Thermal Investigations of ICs and Systems, Proceedings, Dublin, Ireland, 28–30 September 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Han, Y.; Lau, B.L.; Zhang, X. Package-level microjet-based hotspot cooling solution for microelectronic devices. IEEE Electron. Device Lett. 2015, 36, 502–504. [Google Scholar] [CrossRef]

| Parameter | Si IGBT | SiC MOSFET |

|---|---|---|

| Low | High | |

| Switching Frequency | Slow | Fast |

| Tail Current | Present | Absent |

| Low | High | |

| Switching Loss | High | Low |

| Operating Junction Temperature | Low | High |

| Power Density | Low | High |

| Heat Flux | Low | High |

| Material | Thickness (µm) | Thermal Conductivity (W/mK) | Coefficient of Thermal Expansion, α (10−6/°C) |

|---|---|---|---|

| Al2O3 | 381 | 20 | 8.1 |

| AlN | 635 | 180 | 4.5 |

| Si3N4 | 635 | 30 | 3.3 |

| HT-07006 | 152 | 24 | 7.5 |

| Type | Material | Thermal Conductivity (W/mK) |

|---|---|---|

| Gap Filler | h-BN | 300 |

| IC-diamond | 2000 | |

| Kryonaut | 12.5 | |

| GT-2 | 9.8 | |

| MX-4 | 8.5 | |

| Kafuter k-705 | 2 | |

| Epoxy resin | 0.8 | |

| Silicone oil | 0.165 | |

| Artic Silver 5 | 0.96 | |

| Nickel oxide | 12 | |

| Thermal epoxy | 2.5 | |

| Gap Pad | TFX | 14.3 |

| Rocket | 7.5 | |

| Kafuter k-5205 | 2 | |

| Shin-Etsu G751 | 4.5 | |

| TF 400 | 2.8 | |

| Thermal gap pad | 13.1 | |

| eGraf | 10.15 | |

| PCM | SY G1000 | 6 |

| Solder | SAC305 | 34 |

| Metal Based | Indium | 36 |

| PC alloy with 50% Cu | 54 | |

| Bismuth-based liquid metal | 70 |

| Ref. | Method | Analysis | Outcome |

|---|---|---|---|

| [55] | Numerical | Rectangular, in-line, and staggered fin configurations. |

|

| [56] | Experimental and Numerical | Cross-fin heat sink composed of a sequence of long fins and short fins configured perpendicularly. |

|

| [57] | Experimental and Numerical | Temperature self-adaptive fin integration. |

|

| [58] | Numerical | Tapered fin heat sink. |

|

| [59] | Experimental and Numerical | Two different geometrical perimeter-shaped fin additions. |

|

| [60] | Experimental and Numerical | Hybrid heat sink with microchannel and microjet arrays. |

|

| [61] | Numerical | Hollow hybrid fin optimization. |

|

| [62] | Numerical | Introduction of Honeycomb structure heat sink. |

|

| [63] | Numerical | Integration of metal foam heat sink with pin fins. |

|

| [64] | Experimental and Numerical | PCM with honeycomb fin. |

|

| [65] | Experimental and Numerical | Optimization of heat sink size. |

|

| Ref. | Method | Analysis | Outcome |

|---|---|---|---|

| [99] | Experimental | Bare die 3D printed thermal packaging with jet impingement. |

|

| [100] | Experimental and Numerical | Submerged staggered liquid jet arrays featuring various discharge manifolds. |

|

| [102] | Experimental and Numerical | Jet impingement cooled heat exchanger designed by subjecting the module base plate to an array of nozzles with a diameter of 200 µm. |

|

| [103] | Numerical | Utilization of porous inserts (metal foam). |

|

| [104] | Experimental | Heat transfer and fluid flow characteristics of water jet impingement on a flat plate. |

|

| [105] | Experimental | Synthetic jet impingement with four different aperture cases. |

|

| [106] | Experimental | Confined two-phase jet impingement. |

|

| [107] | Numerical | Combination of air jet impingement and cross-coolant flow. |

|

| [108] | Numerical | Direct contact jet impingement with ATF (Automatic Transmission Fluid). |

|

| [16] | Numerical | Implementation of single-side and double-side jet impingement cooling with manifold design. |

|

| [109] | Numerical | Jet in cross flow for hotspot cooling. |

|

| [110] | Experimental and Numerical | Surface augmentation in jet impingement fountain region. |

|

| [13] | Experimental and Numerical | Investigation of different outlet arrangements and pin-fin layouts. |

|

| [111] | Experimental and Numerical | Implementation of single-phase jet impingement cooling directly at the power electronic substrate layer to enhance thermal management. |

|

| [112] | Numerical | Effect of flow pulsations on local, time-averaged Nusselt number of an impinging air jet. |

|

| [98] | Experimental and Numerical | Influence of geometric and flow factors on the heat transfer properties of both steady and unsteady jets. |

|

| PCM | Melting Temperature (°C) | Thermal Conductivity (W/mK) | Heat of Fusion (KJ/kg) |

|---|---|---|---|

| RT 11 | 10–12 | 0.2 | 160 |

| Capric acid + Lauric acid | 18 | 0.143 | 120 |

| Paraffin C16–C18 | 20–22 | 0.2 | 152 |

| RT 27 | 25–28 | 0.2 | 149 |

| Paraffin (RT44HC) | 41–44 | 0.2 | 250 |

| Sodium Acetate Trihydrate | 58–62 | 0.82 | 269 |

| RT 70 | 70 | 0.2 | 230 |

| Ref. | Fluid | Feature | heff (W/cm2K) |

|---|---|---|---|

| [140] | Water | Nano- and micro-technology-based packaging optimization. | 1.05 |

| [141] | Ethylene glycol water | Multi-pass branching microchannel. | 1.25 |

| [142] | CuO | Rectangular microchannel with varying CuO nanoparticle concentration. | 1.85 |

| [143] | Water | Submillimeter channels directly manufactured in the ceramic substrate’s back-metallization layer. | 1.96 |

| [144] | R134a | Heat transmission during flow boiling in micro-channels with a rectangular cross-section. | 1.97 |

| [145] | HFE 7100 | Critical heat flux (CHF) limit in sub-cooled flow boiling in the microchannel. | 2.16 |

| [146] | Water | Cooling system with hot water coolant. | 2.39 |

| [147] | R134a | Heat transmission during boiling in microchannels with two-phase flow. | 2.48 |

| [148] | Water | A chip connected to a single-phase Si microchannel cooler. | 3.57 |

| [149] | Water | Microchannel equipped with oblique fins. | 3.61 |

| [150] | HFE 7100 | Investigation of microchannel heat sink aspect ratio regarding flow boiling heat transfer. | 4.40 |

| [151] | Water | Chip-attached Si microchannel cooler using Ag epoxy. | 4.63 |

| [152] | R236fa | Cooling of a high heat flux in a Si microchannel via two phases. | 6.07 |

| Ref. | Fluid | Feature | heff (W/cm2K) |

|---|---|---|---|

| [11] | HFE 7100 | Two-phase hybrid microchannel jet impingement. | 1.67 |

| [153] | FC-72 | Two-phase jet cooling with a smooth surface. | 1.82 |

| [154] | FC 40 | Single-phase heat transfer under circular microjet arrays. | 2.39 |

| [155] | HFE 7100 | Two-phase free-faller circular jet. | 2.5 |

| [156] | HFE 7100 | Single-phase hybrid microchannel jet impingement. | 2.82 |

| [157] | Water | Single-phase heat transfer using droplet sprays. | 3.94 |

| [153] | FC-72 | Two-phase jet cooling with finned surface. | 3.95 |

| [14] | Water-Ethylene glycol | Pin fins in the DBC substrate using laser powder bed fusion additive manufacturing. | 4.1 |

| [153] | FC-72 | Two-phase jet cooling with pin-finned surface. | 5 |

| [158] | Water | Microjet array cooling with distributed return network. | 5.2 |

| [159] | Water | Single-phase distributed return submerged direct liquid jet impingement cold plate having nozzle pitch of 100 µm. | 5.87 |

| [154] | Water | Single-phase heat transfer under circular microjet arrays. | 6.1 |

| [160] | Water | 4 × 4 array jet impingement PVC cooler with direct cooling. | 6.25 |

| [161] | R-245fa | Two-phase jet impingement using closed tunnel porous coated surface. | 6.93 |

| [161] | R-245fa | Two-phase jet impingement using open tunnel porous coated surface. | 6.93 |

| [161] | R-245fa | Two-phase jet impingement using flat porous coated surface. | 8.6 |

| [157] | Water | Two-phase heat transfer using arrays of microjets. | 9.68 |

| [161] | R-245fa | Two-phase jet impingement using pin fins with porous coating. | 9.78 |

| [162] | Water | Ultrathin manifold microchannel heat sink with impinging liquid slot-jets. | 10.8 |

| [163] | Water | Polymer nozzles with nine staggered orifices. | 12 |

| [164] | Water | Si hybrid heat sink and diamond heat spreader with microchannel flow, microjet array impingement. | 18.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orville, T.; Tajwar, M.; Bihani, R.; Saha, P.; Hannan, M.A. Enhancing Thermal Efficiency in Power Electronics: A Review of Advanced Materials and Cooling Methods. Thermo 2025, 5, 30. https://doi.org/10.3390/thermo5030030

Orville T, Tajwar M, Bihani R, Saha P, Hannan MA. Enhancing Thermal Efficiency in Power Electronics: A Review of Advanced Materials and Cooling Methods. Thermo. 2025; 5(3):30. https://doi.org/10.3390/thermo5030030

Chicago/Turabian StyleOrville, Tahmid, Monem Tajwar, Raghav Bihani, Parnab Saha, and Mohammed Abdul Hannan. 2025. "Enhancing Thermal Efficiency in Power Electronics: A Review of Advanced Materials and Cooling Methods" Thermo 5, no. 3: 30. https://doi.org/10.3390/thermo5030030

APA StyleOrville, T., Tajwar, M., Bihani, R., Saha, P., & Hannan, M. A. (2025). Enhancing Thermal Efficiency in Power Electronics: A Review of Advanced Materials and Cooling Methods. Thermo, 5(3), 30. https://doi.org/10.3390/thermo5030030