Optimized Solar-Powered Evaporative-Cooled UFAD System for Sustainable Thermal Comfort: A Case Study in Riyadh, KSA

Abstract

1. Introduction

2. Materials and Methods

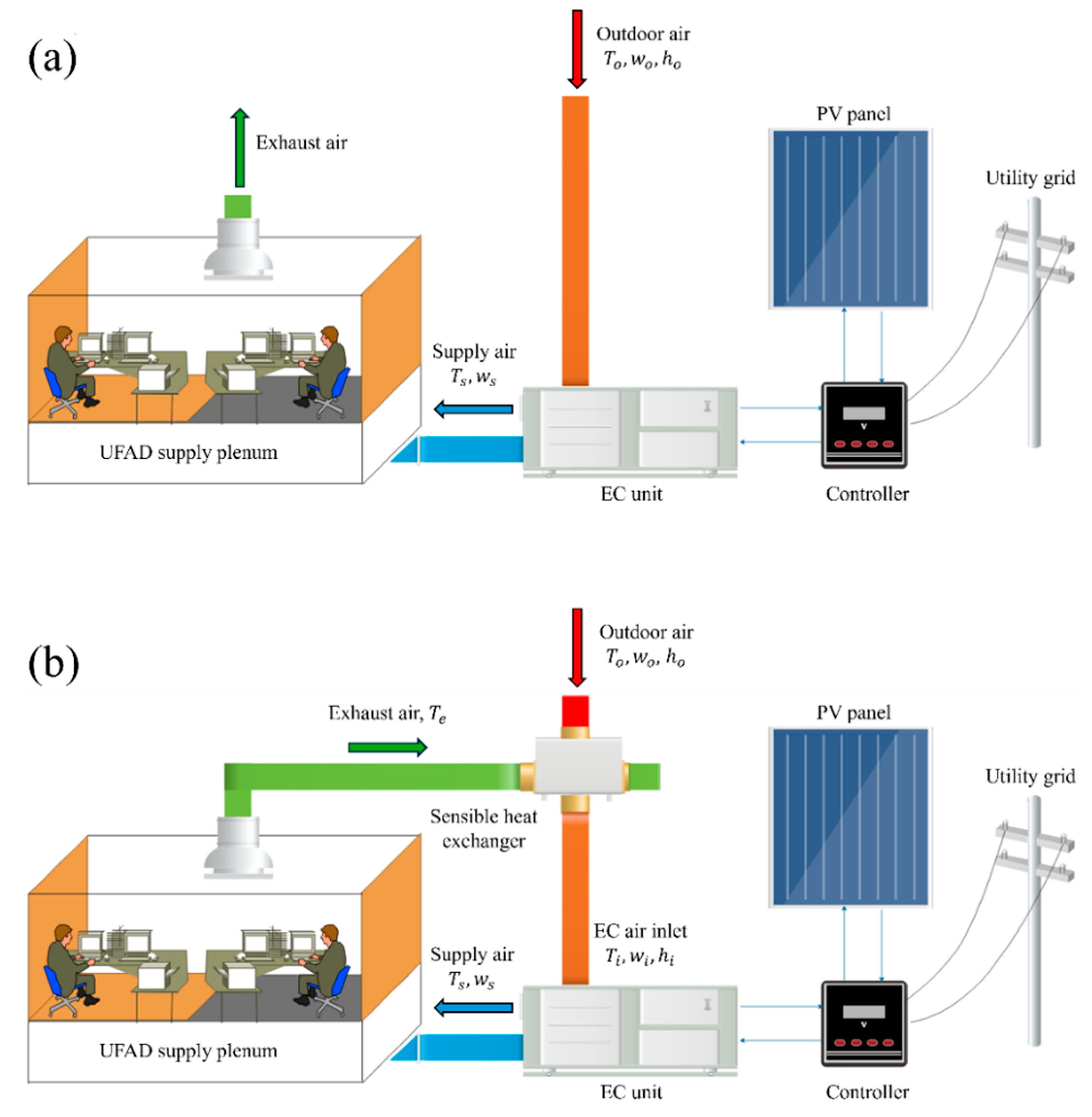

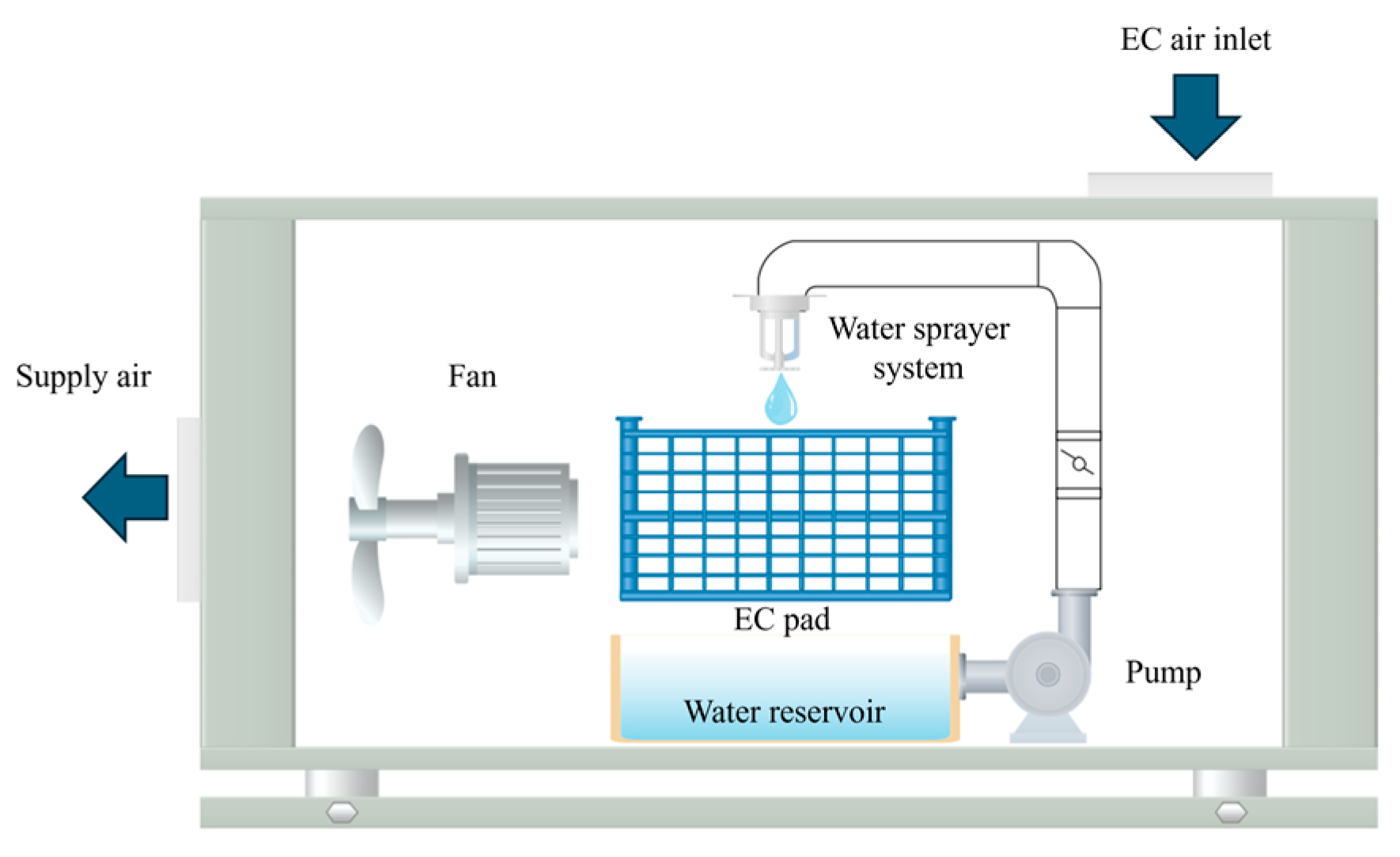

2.1. System Description

2.2. EC-UFAD Supply Conditions

2.3. Water Consumption

2.4. Energy Consumption

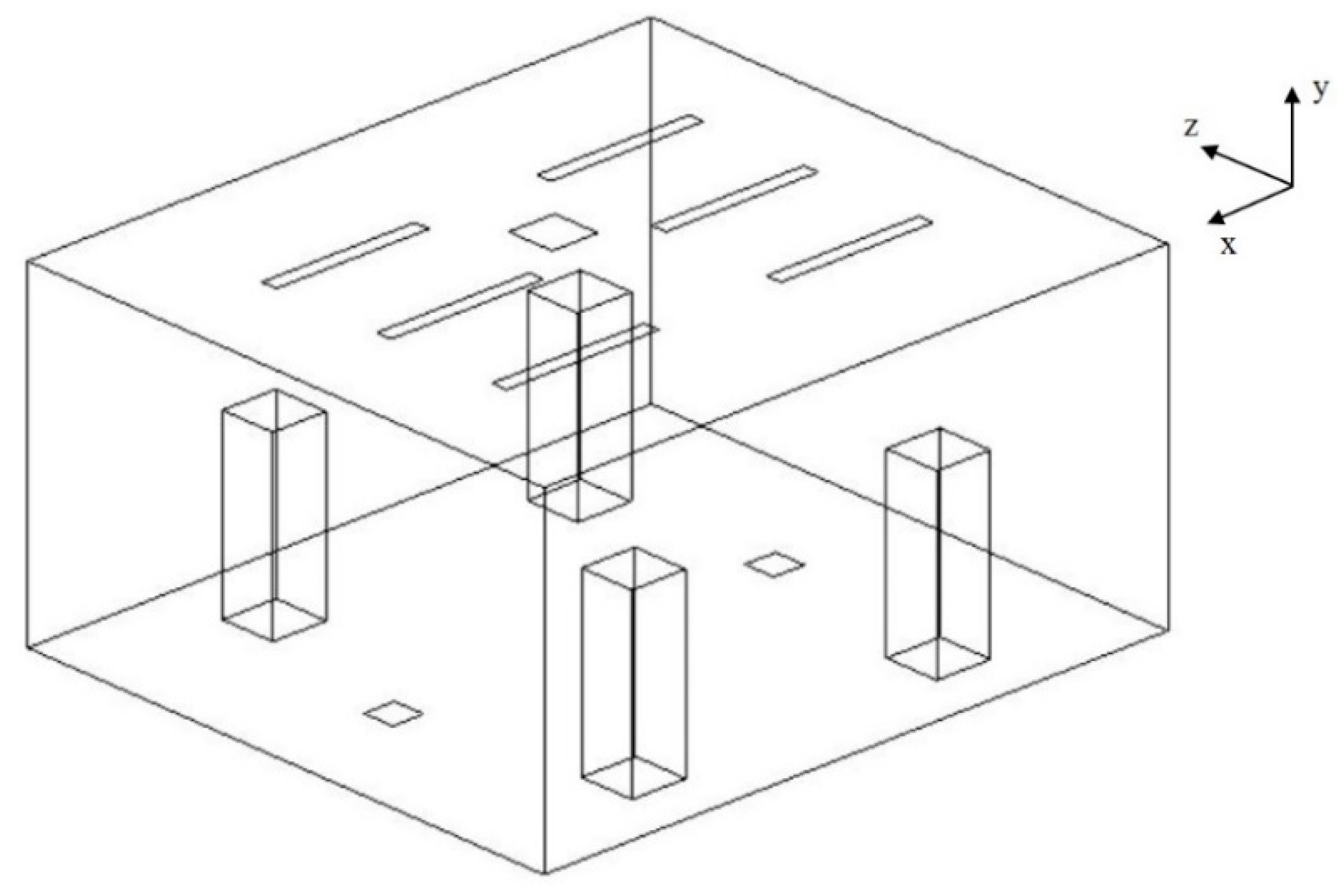

2.5. Simulation Parameters

2.6. CFD Methods

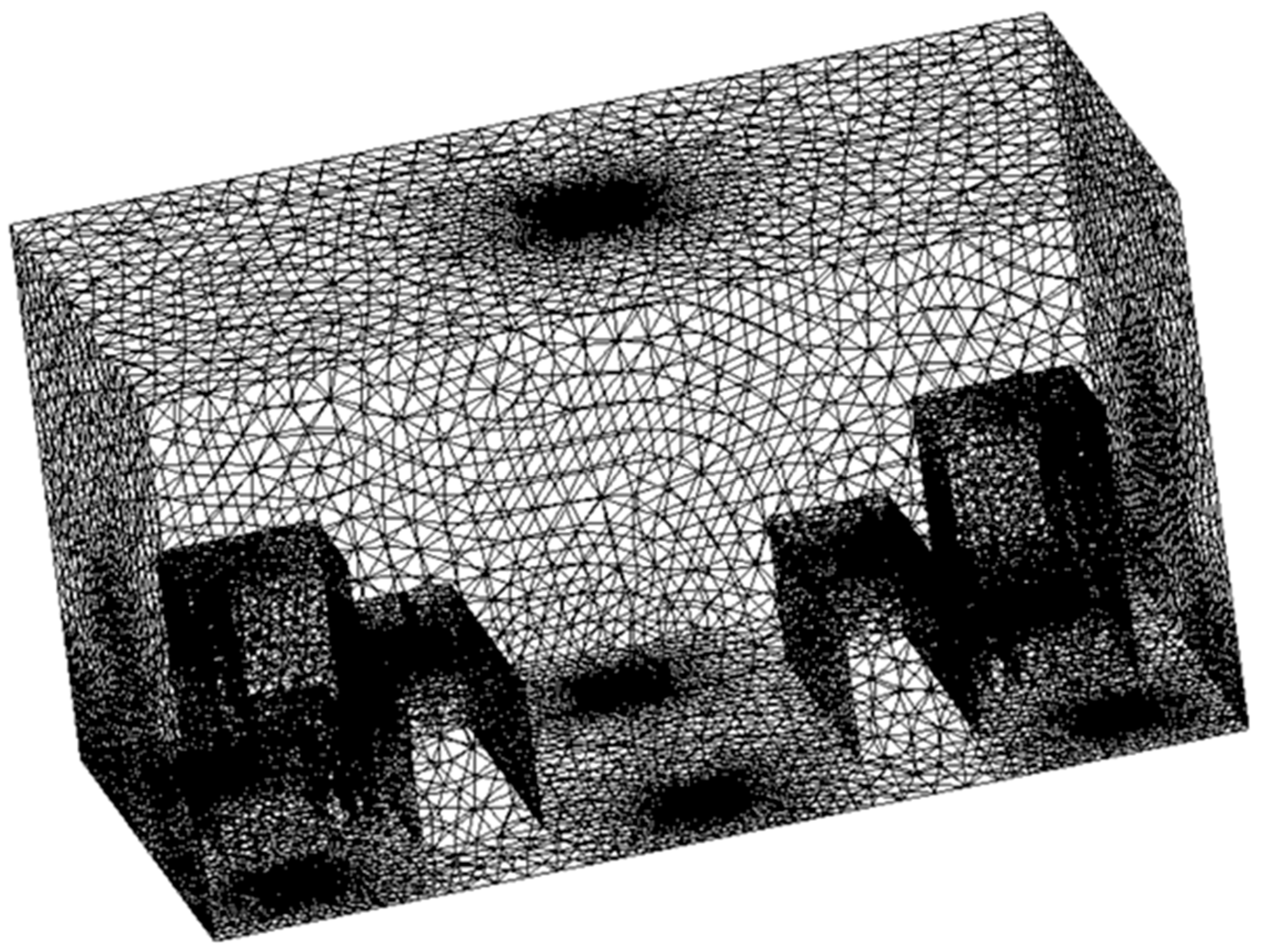

2.6.1. Mesh and Grid-Independence Analysis

2.6.2. Airflow Modeling

2.6.3. Boundary Conditions

2.6.4. Numerical Solution

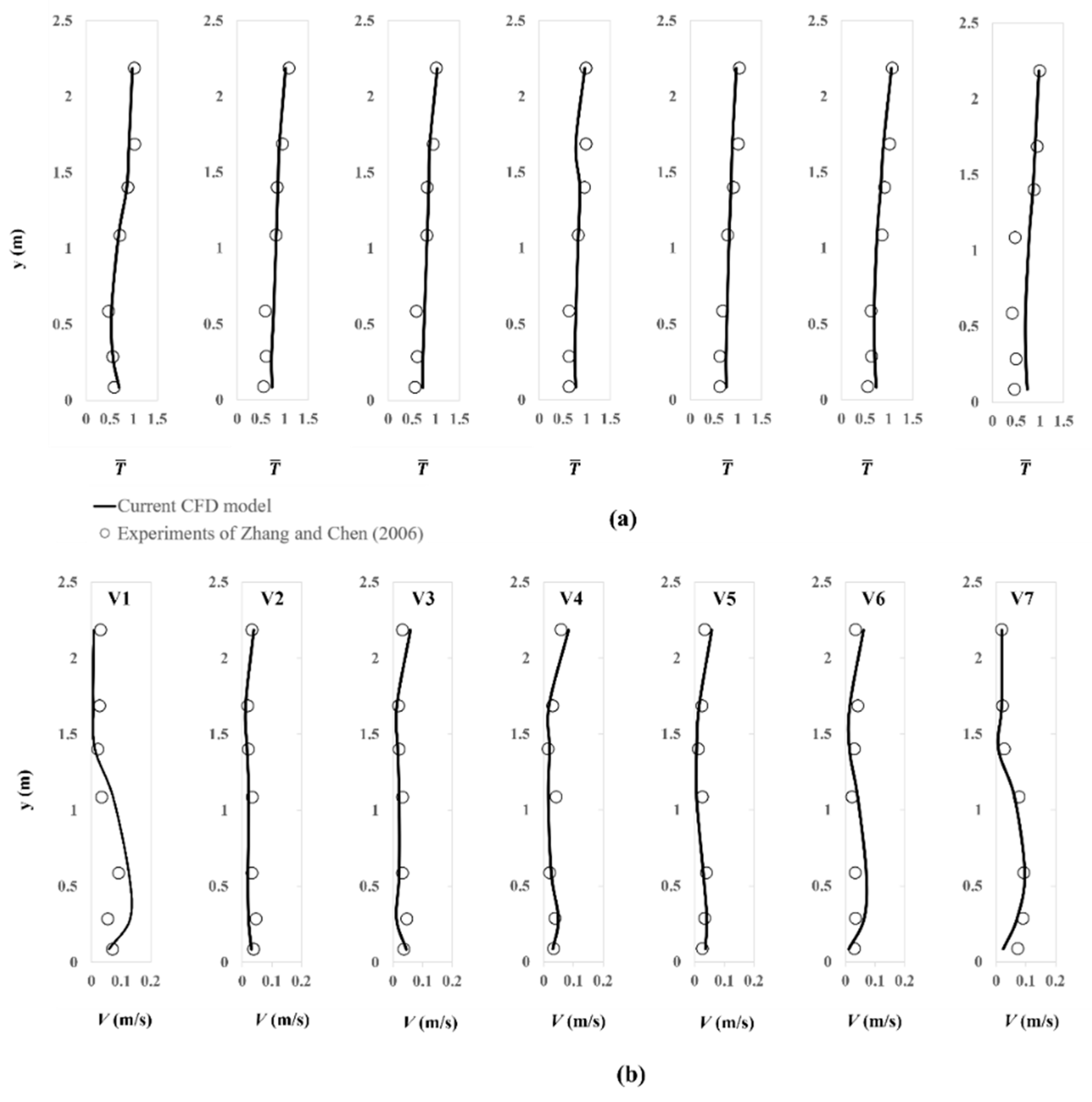

2.6.5. Validation of the CFD Model

2.7. Thermal Comfort Assessment

- The metabolic rate corresponds to that of a sedentary adult (1 Met = 58.15 W/m2).

- Mechanical work attributed to the occupant is assumed to be zero.

- A typical indoor clothing insulation value of 0.6 clo is used, corresponding to 0.093 m2·°C/W.

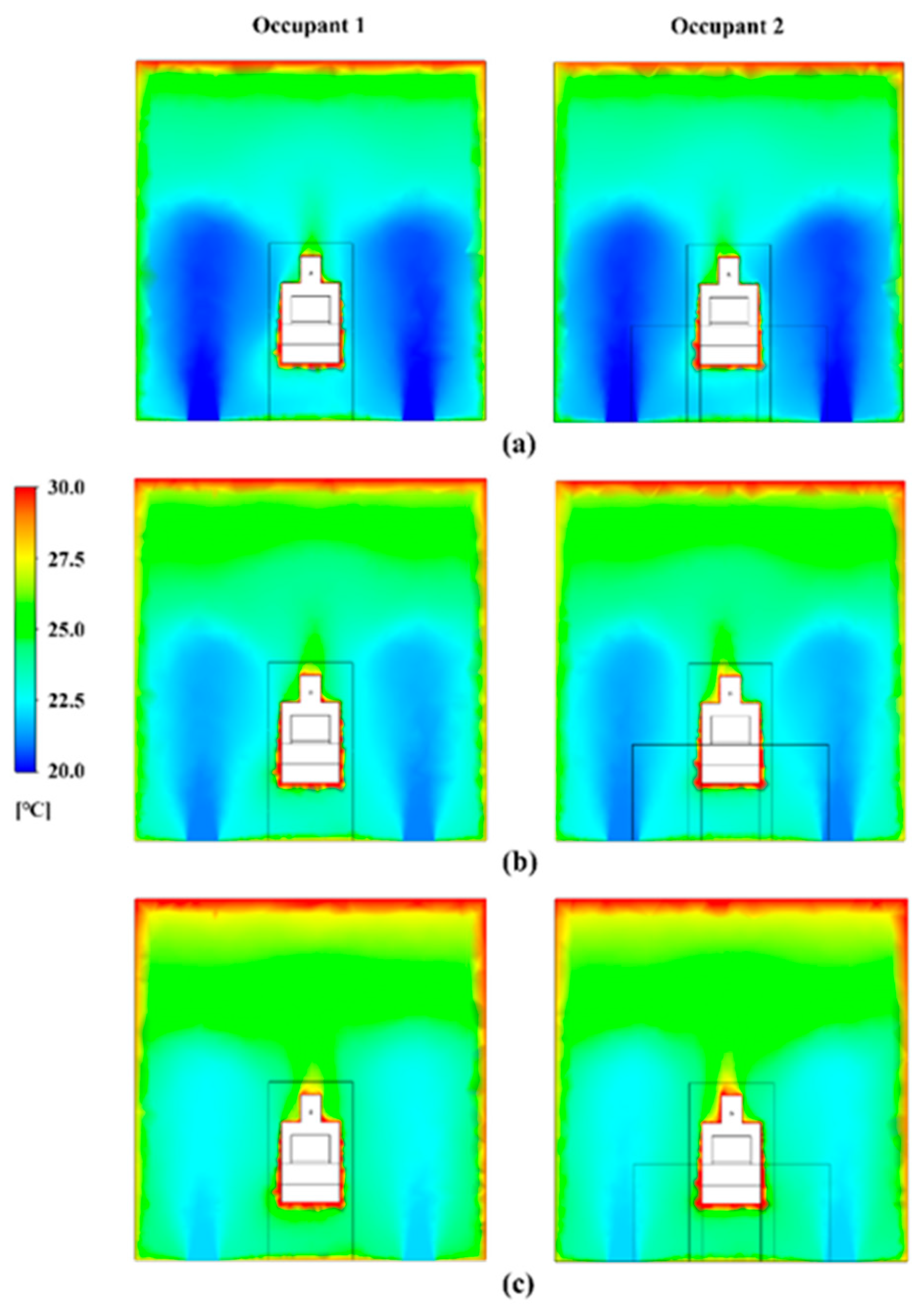

3. Results and Discussion

3.1. Performance Analysis Results

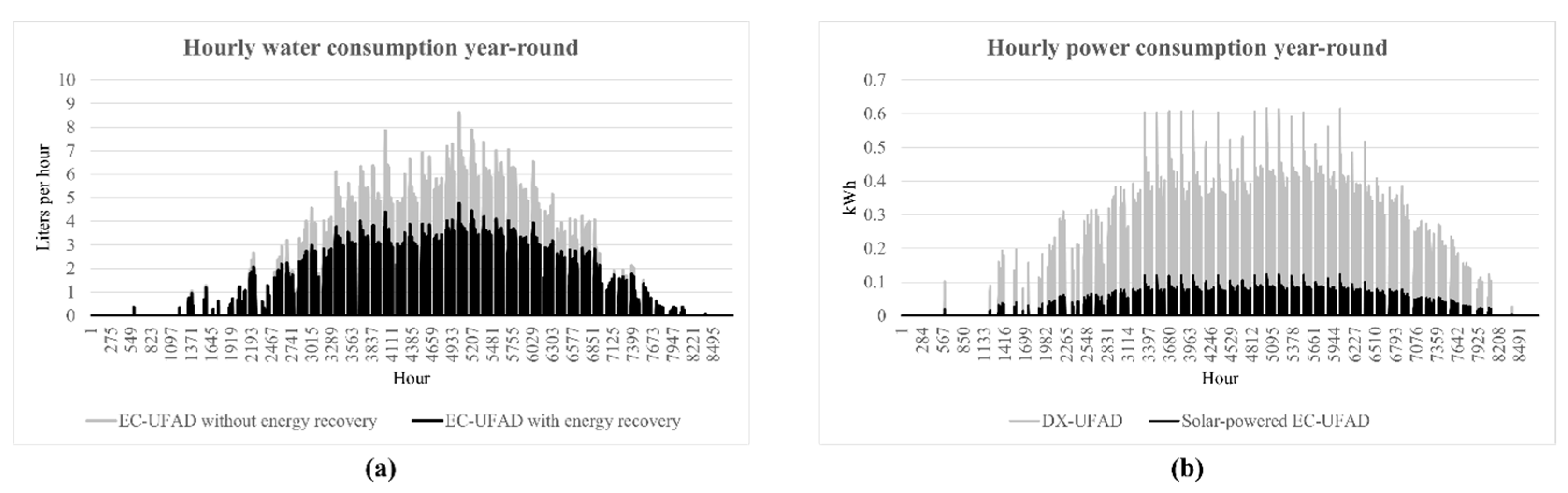

3.2. Hourly Analysis

3.3. Cost–Benefit Analysis

4. Conclusions

- For the temporary office under study, the EC-UFAD system achieved optimal thermal comfort and water efficiency when operated with energy recovery. The ideal conditions included a supply flow rate of 232 L/s at a temperature of 22 °C, with a corresponding humidity ratio of 9.47 g H2O/kg air. This finding aligns with the proposed UFAD design with six 25 × 25 cm supply diffusers, the number, placement, and size of which directly influence performance [46,47].

- The EC-UFAD system with energy recovery reduces water consumption by 31.3% compared to the system without energy recovery, while both configurations maintain occupant comfort.

- With 70% of its power sourced from solar energy, the optimized EC-UFAD system reduces grid electricity consumption by 93.5% compared to the DX-UFAD system under identical design conditions.

- Operational costs are reduced by 84–87% when transitioning from the DX-UFAD to the EC-UFAD system.

- The optimized EC-UFAD operation yields a 5-year payback period and a USD 375 net present value.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- The Future of Cooling. Available online: https://www.oecd.org/en/publications/the-future-of-cooling_9789264301993-en.html (accessed on 1 June 2025).

- Mastrucci, A.; Ruijven, B.; Byers, E.; Poblete-Cazenave, M.; Pachauri, S. Global Scenarios of Residential Heating and Cooling Energy Demand and CO2 Emissions. Clim. Change 2021, 168, 14. [Google Scholar] [CrossRef]

- Open Data Library|Open Data of the SEEC|SEEC. Available online: https://www.seec.gov.sa/en/media-center/open-data/open-data-library (accessed on 1 June 2025).

- Kapilan, N.; Isloor, A.M.; Karinka, S. A Comprehensive Review on Evaporative Cooling Systems. Results Eng. 2023, 18, 101059. [Google Scholar] [CrossRef]

- Hussain, I. Evaluating the Parameters Affecting the Direct and Indirect Evaporative Cooling Systems. Eng. Anal. Bound. Elem. 2022, 145, 211–223. [Google Scholar] [CrossRef]

- Yang, H.; Shi, W.; Chen, Y.; Min, Y. Research Development of Indirect Evaporative Cooling Technology: An Updated Review. Renew. Sustain. Energy Rev. 2021, 145, 111082. [Google Scholar] [CrossRef]

- Xue, T. A Comprehensive Review of the Applications of Hybrid Evaporative Cooling and Solar Energy Source Systems. Sustainability 2023, 15, 16907. [Google Scholar] [CrossRef]

- Tripathi, R.J.; Kumar, D. A Holistic Approach for Solar-Driven HVAC Evaporative Cooling System: Comparative Study of Dry and Wet Channel. J. Build. Eng. 2024, 83, 108465. [Google Scholar] [CrossRef]

- A/L Sambathan, S.; Ismail, F.B.; Nasif, M.S. Underfloor Air Distribution Technology: A Review. AIP Conf. Proc. 2018, 2035, 070004. [Google Scholar] [CrossRef]

- Matsunawa, K.; Iizuka, H.; Tanabe, S. Development and Application of an Underfloor Air-Conditioning System with Improved Outlets for a’smart’building in Tokyo. Ashrae Trans. 1995, 101 Pt 2, 887–901. [Google Scholar]

- LIU, Q.A.; LINDEN, P.F. The fluid dynamics of an underfloor air distribution system. J. Fluid Mech. 2006, 554, 323. [Google Scholar] [CrossRef]

- Lin, Y.J.P.; Linden, P.F. A Model for an under Floor Air Distribution System. Energy Build. 2005, 37, 399–409. [Google Scholar] [CrossRef]

- Alajmi, A.F.; Abou-Ziyan, H.Z.; El-Amer, W. Energy Analysis of Under-Floor Air Distribution (UFAD) System: An Office Building Case Study. Energy Convers. Manag. 2013, 73, 78–85. [Google Scholar] [CrossRef]

- Rahmati, B.; Heidarian, A.; Jadidi, A.M. Investigation in Performance of a Hybrid Under-Floor Air Distribution with Improved Desk Displacement Ventilation System in a Small Office. Appl. Therm. Eng. 2018, 138, 861–872. [Google Scholar] [CrossRef]

- Seok, Y.J.; Cho, H.J.; Han, S.K.; Jeong, J.W. Underfloor Air Distribution Integrated with an Indirect and Direct Evaporative Cooling Assisted 100% Outdoor Air System. 2011. Available online: https://www.aivc.org/resource/underfloor-air-distribution-integrated-indirect-and-direct-evaporative-cooling-assisted-100 (accessed on 17 July 2025).

- Jaber, S.; Ezzat, A.W. Investigation of Energy Recovery with Exhaust Air Evaporative Cooling in Ventilation System. Energy Build. 2017, 139, 439–448. [Google Scholar] [CrossRef]

- Chen, M.; Hao, S. Numerical Study on the Cutting off Performance of a Novel Personalized Air Curtain in a General Consulting Ward. Dev. Built Environ. 2023, 16, 100239. [Google Scholar] [CrossRef]

- Ameen, A.; Cehlin, M.; Yamasawa, H.; Kobayashi, T.; Karimipanah, T. Energy Saving, Indoor Thermal Comfort and Indoor Air Quality Evaluation of an Office Environment Using Corner Impinging Jet Ventilation. Dev. Built Environ. 2023, 15, 100179. [Google Scholar] [CrossRef]

- Asral, A. CFD Analysis of Coronavirus Dispersion through Breathing in Aircraft Cabin Environments. J. Adv. Fluid Heat Mater. Eng. 2025, 1, 49–59. [Google Scholar] [CrossRef]

- Singh, R.; Rawal, R. Effect of Surface Reflectance on Lighting Efficiency in Interiors. In Proceedings of the Building Simulation 2011: 12th Conference of International Building Performance Simulation Association (IBPSA), Sydney, Australia, 14–16 November 2011; Available online: https://publications.ibpsa.org/proceedings/bs/2011/papers/bs2011_1725.pdf (accessed on 17 July 2025).

- Ray, S.D.; Gong, N.-W.; Glicksman, L.R.; Paradiso, J.A. Experimental Characterization of Full-Scale Naturally Ventilated Atrium and Validation of CFD Simulations. Energy Build. 2014, 69, 285–291. [Google Scholar] [CrossRef]

- ASHRAE. ASHRAE Handbook—HVAC Systems and Equipment. In Air-to-Air Energy Recovery Equipment; ASHRAE: Peachtree Corners, GA, USA, 2020; p. 26. [Google Scholar]

- Franchini, G.; Brumana, G.; Perdichizzi, A. Performance Prediction of a Solar District Cooling System in Riyadh, Saudi Arabia—A Case Study. Energy Convers. Manag. 2018, 166, 372–384. [Google Scholar] [CrossRef]

- Mansour, R.B.; Khan, M.A.M.; Alsulaiman, F.A.; Mansour, R.B. Optimizing the Solar PV Tilt Angle to Maximize the Power Output: A Case Study for Saudi Arabia. IEEE Access 2021, 9, 15914–15928. [Google Scholar] [CrossRef]

- Bahrami, M. Refrigeration Cycle Notes. 2020. Available online: https://www.sfu.ca/~mbahrami/ENSC%20461/Notes/Refrigeration%20Cycle.pdf (accessed on 17 July 2025).

- Yoo, S.; Ito, K. Validation, Verification, and Quality Control of Computational Fluid Dynamics Analysis for Indoor Environments Using a Computer-simulated Person with Respiratory Tract. Jpn. Archit. Rev. 2022, 5, 714–727. [Google Scholar] [CrossRef]

- Lee, Y.-T.; Wen, C.-Y.; Shih, Y.-C.; Li, Z.; Yang, A.-S. Numerical and Experimental Investigations on Thermal Management for Data Center with Cold Aisle Containment Configuration. Appl. Energy 2022, 307, 118213. [Google Scholar] [CrossRef]

- Cheong, C.H.; Park, B.; Ryu, S.R. Effect of Under-Floor Air Distribution System to Prevent the Spread of Airborne Pathogens in Classrooms. Case Stud. Therm. Eng. 2021, 28, 101641. [Google Scholar] [CrossRef]

- Kanaan, M. Modelling of Contaminant Dispersion in Underfloor Air Distribution Systems: Comparison of Analytical and CFD Methods. J. Build. Perform. Simul. 2019, 12, 759–769. [Google Scholar] [CrossRef]

- Wan, M.P.; Chao, C.Y. Numerical and Experimental Study of Velocity and Temperature Characteristics in a Ventilated Enclosure with Underfloor Ventilation Systems. Indoor Air 2005, 15, 342–355. [Google Scholar] [CrossRef]

- Alsaad, H.; Voelker, C. Performance Assessment of a Ductless Personalized Ventilation System Using a Validated CFD Model. J. Build. Perform. Simul. 2018, 11, 689–704. [Google Scholar] [CrossRef]

- Liu, X.; Niu, J.; Perino, M.; Heiselberg, P. Numerical Simulation of Inter-Flat Air Cross-Contamination under the Condition of Single-Sided Natural Ventilation. J. Build. Perform. Simul. 2008, 1, 133–147. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, Q. Experimental Measurements and Numerical Simulations of Particle Transport and Distribution in Ventilated Rooms. Atmos. Env. 2006, 40, 3396–3408. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort; McGraw-Hill Book Company: New York, NY, USA, 1972. [Google Scholar]

- Kanaan, M.; Amine, S.; Gazo-Hanna, E. Optimizing Supply Conditions and Use of Return Air in UFAD System: Assessment of IAQ, Thermal Comfort and Energy Performance. Results Eng. 2024, 24, 103426. [Google Scholar] [CrossRef]

- Walikewitz, N.; Jänicke, B.; Langner, M.; Meier, F.; Endlicher, W. The Difference between the Mean Radiant Temperature and the Air Temperature within Indoor Environments: A Case Study during Summer Conditions. Build. Environ. 2015, 84, 151–161. [Google Scholar] [CrossRef]

- Kántor, N.; Unger, J. The Most Problematic Variable in the Course of Human-Biometeorological Comfort Assessment—The Mean Radiant Temperature. Open Geosci. 2011, 3, 90–100. [Google Scholar] [CrossRef]

- Ito, H.; Nakahara, N. Simplified Calculation Model of Room Air Temperature Profile in Under-Floor Air-Condition System. In Proceedings of the International Symposium on Room Convection and Ventilation Effectiveness, Tokyo, Japan, 22–24 July 1993. [Google Scholar]

- Liu, F.; Zhang, L.; Qian, H. The Penetration Phenomenon of the Expiratory Airflow from Thermal Plume of Human Body in the Microenvironment around People. Build. Environ. 2024, 259, 111656. [Google Scholar] [CrossRef]

- Gao, N.; Niu, J.; Morawska, L. Distribution of Respiratory Droplets in Enclosed Environments under Different Air Distribution Methods. Build. Simul. 2008, 1, 326–335. [Google Scholar] [CrossRef]

- ASHRAE. International Weather for Energy Calculations (IWEC). Version 2012; Volume 2. Available online: https://www.ashrae.org/technical-resources/bookstore/ashrae-international-weather-files-for-energy-calculations-2-0-iwec2 (accessed on 17 July 2025).

- Hmadi, M.; Mourtada, A.; Daou, R. Forecasting the Performance of a District Solar Thermal Smart Network in Desert Climate—A Case Study. Energy Convers. Manag. 2020, 207, 112521. [Google Scholar] [CrossRef]

- Javid, M. Assessing the Impact of Water Price and Water-Use Efficiency on Domestic Water Demand in Saudi Arabia. 2024. Available online: https://www.researchgate.net/publication/380053331_Assessing_the_Impact_of_Water_Price_and_Water-Use_Efficiency_on_Domestic_Water_Demand_in_Saudi_Arabia (accessed on 17 July 2025).

- Moya, D.; Paredes, J.; Kaparaju, P. Technical, Financial, Economic and Environmental Pre-Feasibility Study of Geothermal Power Plants by RETScreen—Ecuador’s Case Study. Renew. Sustain. Energy Rev. 2018, 92, 628–637. [Google Scholar] [CrossRef]

- Economics, T. Saudi Arabia Interest Rate. Available online: https://tradingeconomics.com/saudi-arabia/interest-rate (accessed on 17 July 2025).

- Zhang, K.; Zhang, X.; Li, S. Simplified Model for Desired Airflow Rate in Underfloor Air Distribution (UFAD) Systems. Appl. Therm. Eng. 2016, 93, 244–250. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Q.; Liu, Y. Investigation of the Quasi-Periodic Airflow Oscillation and Ventilation Performance of an Enclosed Environment with a Jet Air Supply. Energy Build. 2022, 265, 112104. [Google Scholar] [CrossRef]

| Case | Setpoint Temperature Below 1.8 m, °C | Supply Temperature, °C (db) | Supply Flow Rate, m3/s | Humidity Ratio, kg H2O/per kg Dry Air |

|---|---|---|---|---|

| With no energy recovery | ||||

| (a.1) | 23 | 20 | 0.229 | 0.014729 |

| (b.1) | 24 | 21 | 0.230 | 0.014309 |

| (c.1) | 25 | 22 | 0.232 | 0.013889 |

| With energy recovery | ||||

| (a.2) | 23 | 20 | 0.229 | 0.009710 |

| (b.2) | 24 | 21 | 0.230 | 0.009587 |

| (c.2) | 25 | 22 | 0.232 | 0.009465 |

| Nb. of Cells | Relative Difference in Predicted Values of Air Properties at the Exhaust with Previous Mesh Value (%) | ||

|---|---|---|---|

| Temperature | Velocity | ||

| Mesh 1 | 701,414 | - | - |

| Mesh 2 | 1,151,748 | 4.7 | 13.5 |

| Mesh 3 | 1,243,887 | 0.9 | 2.8 |

| Boundary | Type | Details |

|---|---|---|

| Supply diffuser | Velocity inlet | Temperature = 20–22 °C; velocity = 0.610; 0.613; 0.619 m/s; turbulent intensity = 5%; hydraulic diameter = 0.25 m. |

| Exhaust vent | Pressure outlet | Default values |

| Person simulator | No-slip condition | Heat flux = 58.15 W/m2 |

| Roof | No-slip condition | Heat flux = 16.96–17.67 W/m2 |

| North-oriented wall | No-slip condition | Heat flux = 10.99–11.68 W/m2 |

| West-oriented wall | No-slip condition | Heat flux = 11.81–13.12 W/m2 |

| Floor and other walls | No-slip condition | Zero heat flux |

| Case | MRT, °C | Microenvironment of Occupant 1 | Microenvironment of Occupant 2 | Water Usage, L/h | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T, °C | V, m/s | RH, % | PMV | T, °C | V, m/s | RH, % | PMV | |||

| 1. Simulations without energy recovery | ||||||||||

| (a.1) | 22.84 | 22.71 | 0.076 | 84.55 | −0.73 | 22.65 | 0.074 | 84.86 | −0.74 | 10.73 |

| (b.1) | 23.83 | 23.72 | 0.075 | 77.32 | −0.43 | 23.66 | 0.072 | 77.60 | −0.44 | 10.38 |

| (c.1) | 24.82 | 24.69 | 0.073 | 70.86 | −0.12 | 24.70 | 0.071 | 70.82 | −0.13 | 10.01 |

| 2. Simulations with energy recovery | ||||||||||

| (a.2) | 22.84 | 22.71 | 0.076 | 56.18 | −0.94 | 22.65 | 0.074 | 56.36 | −0.95 | 5.00 |

| (b.2) | 23.83 | 23.72 | 0.075 | 52.19 | −0.62 | 23.66 | 0.072 | 52.38 | −0.63 | 4.92 |

| (c.2) | 24.82 | 24.69 | 0.073 | 48.63 | −0.31 | 24.70 | 0.071 | 48.60 | −0.32 | 4.84 |

| Gross area of one panel, m2 | 2 |

| Tilted angle, degrees | 26 |

| Price of PV panel, USD | 150 |

| Installation cost, USD | 150 |

| Cost of controller, USD | 100 |

| Cost of ambiator, USD | 700 |

| Cost of the DX system, USD | 600 |

| Total initial investment cost, USD | 500 |

| Interest rate per period, % | 5% |

| Lifetime, years | 10% |

| Yearly earnings based on 2025 electrical tariff, USD | 113.3 |

| Discounted payback period based on 2025 tariff, years | 5 |

| Net present value (NPV), USD | 375 |

| Internal rate of return, % | 18.52% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kanaan, M.; Amine, S.; Hmadi, M. Optimized Solar-Powered Evaporative-Cooled UFAD System for Sustainable Thermal Comfort: A Case Study in Riyadh, KSA. Thermo 2025, 5, 26. https://doi.org/10.3390/thermo5030026

Kanaan M, Amine S, Hmadi M. Optimized Solar-Powered Evaporative-Cooled UFAD System for Sustainable Thermal Comfort: A Case Study in Riyadh, KSA. Thermo. 2025; 5(3):26. https://doi.org/10.3390/thermo5030026

Chicago/Turabian StyleKanaan, Mohamad, Semaan Amine, and Mohamed Hmadi. 2025. "Optimized Solar-Powered Evaporative-Cooled UFAD System for Sustainable Thermal Comfort: A Case Study in Riyadh, KSA" Thermo 5, no. 3: 26. https://doi.org/10.3390/thermo5030026

APA StyleKanaan, M., Amine, S., & Hmadi, M. (2025). Optimized Solar-Powered Evaporative-Cooled UFAD System for Sustainable Thermal Comfort: A Case Study in Riyadh, KSA. Thermo, 5(3), 26. https://doi.org/10.3390/thermo5030026