Improving Cocoa Drying Efficiency with a Mixed Forced Convection Solar Dryer in an Equatorial Climate

Abstract

1. Introduction

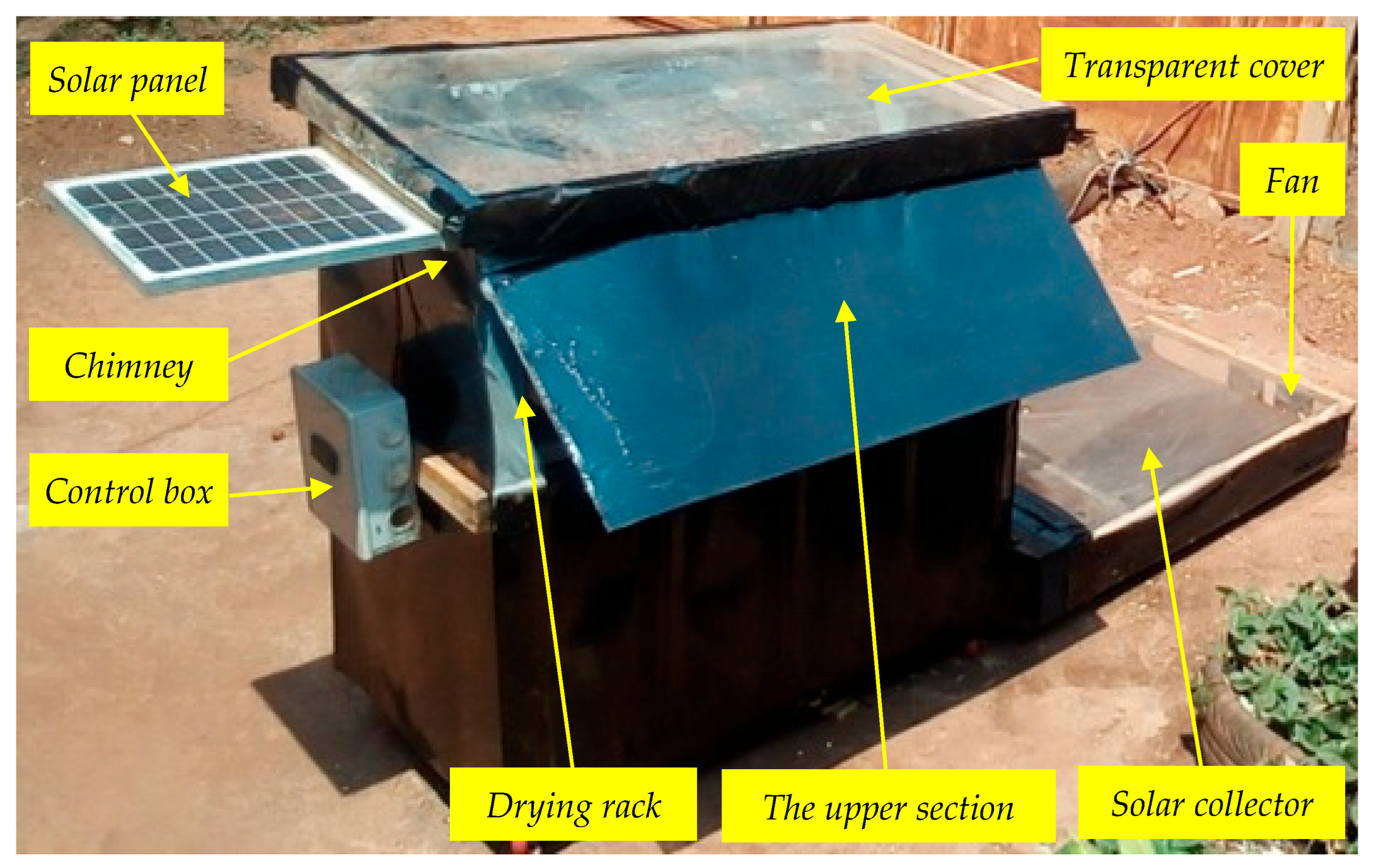

2. Dryer Description and Technical Specification

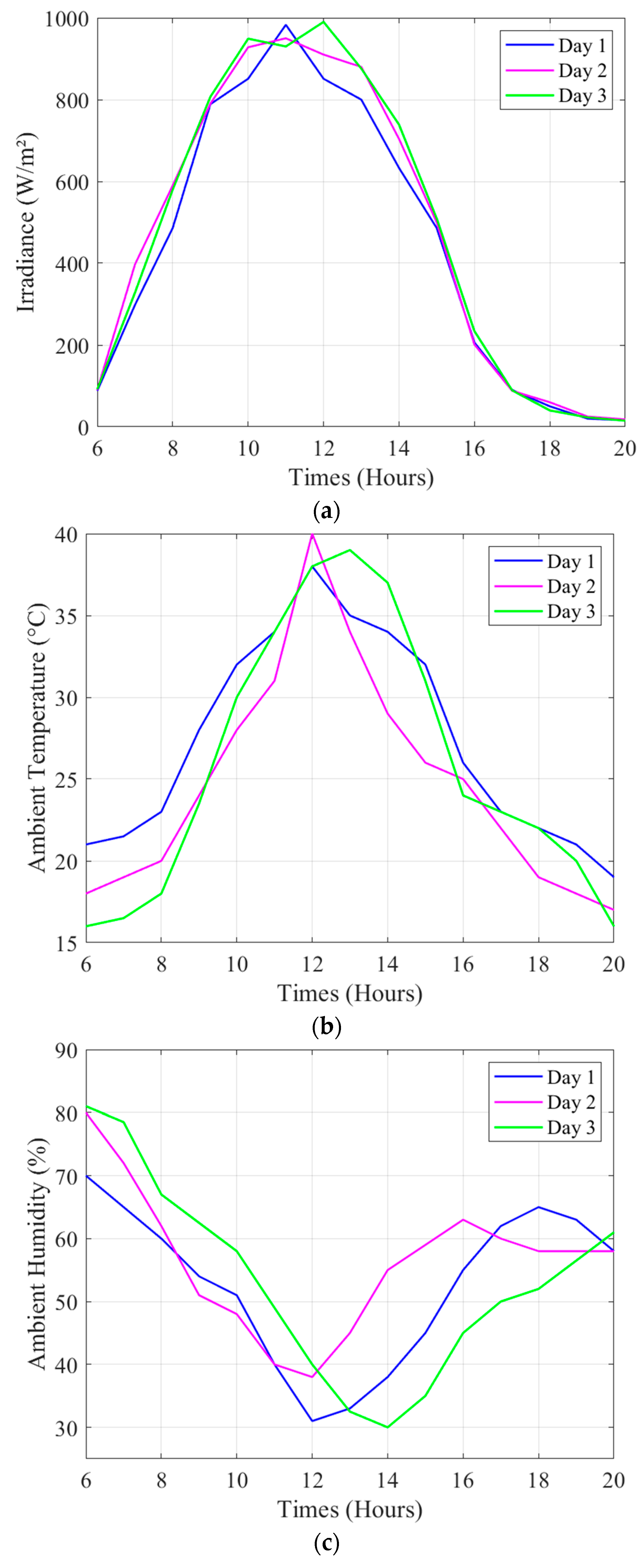

2.1. Environmental Conditions at the Study Site

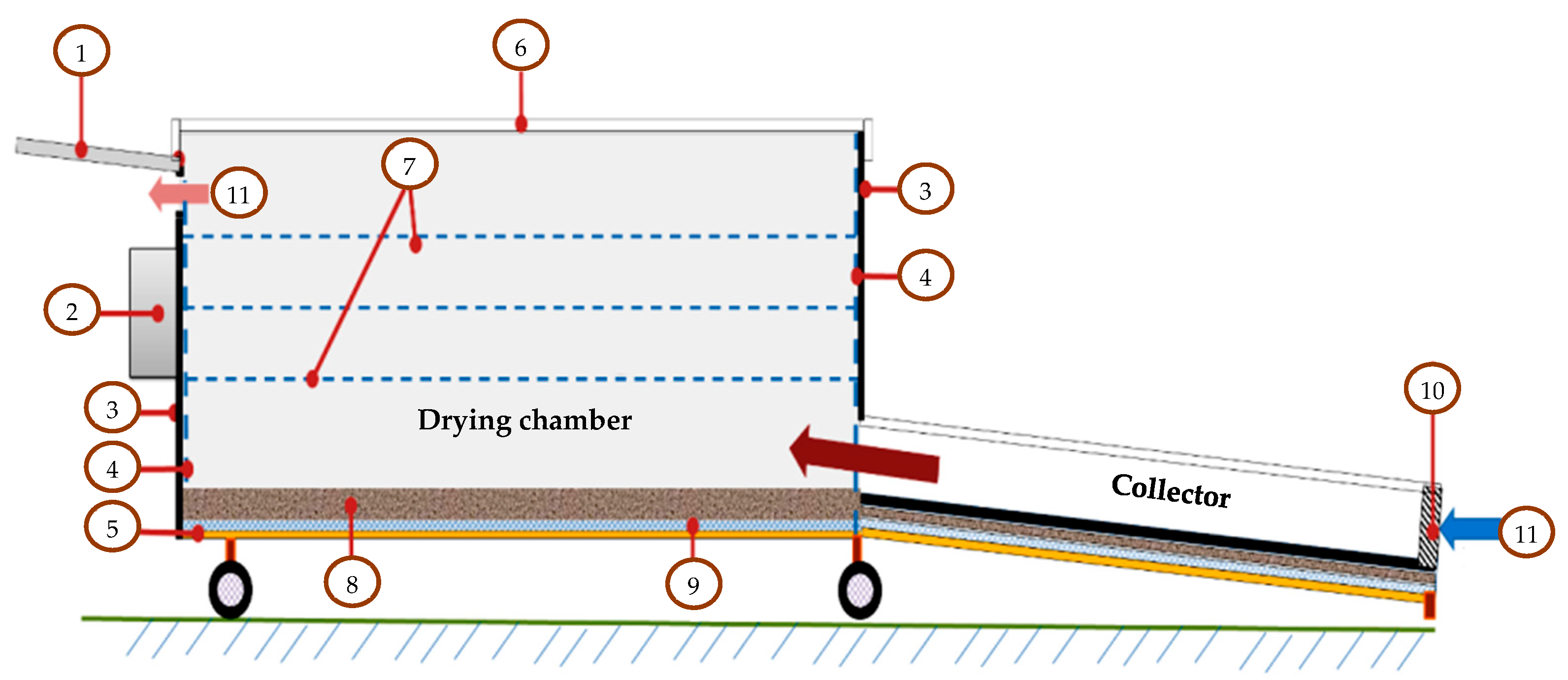

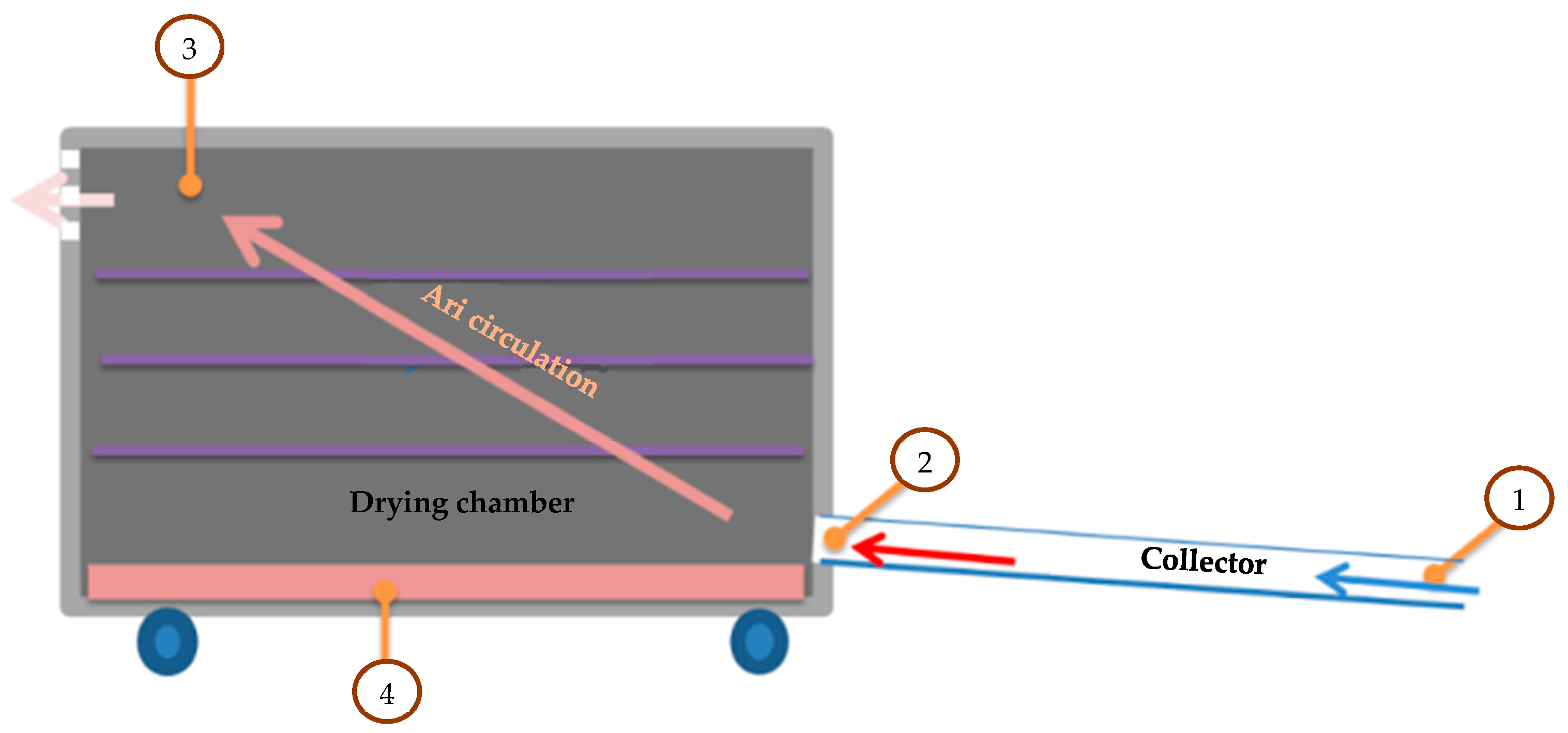

2.2. Schematic Diagram of the Proposed Dryer

2.3. Operating Principle of the Proposed Dryer

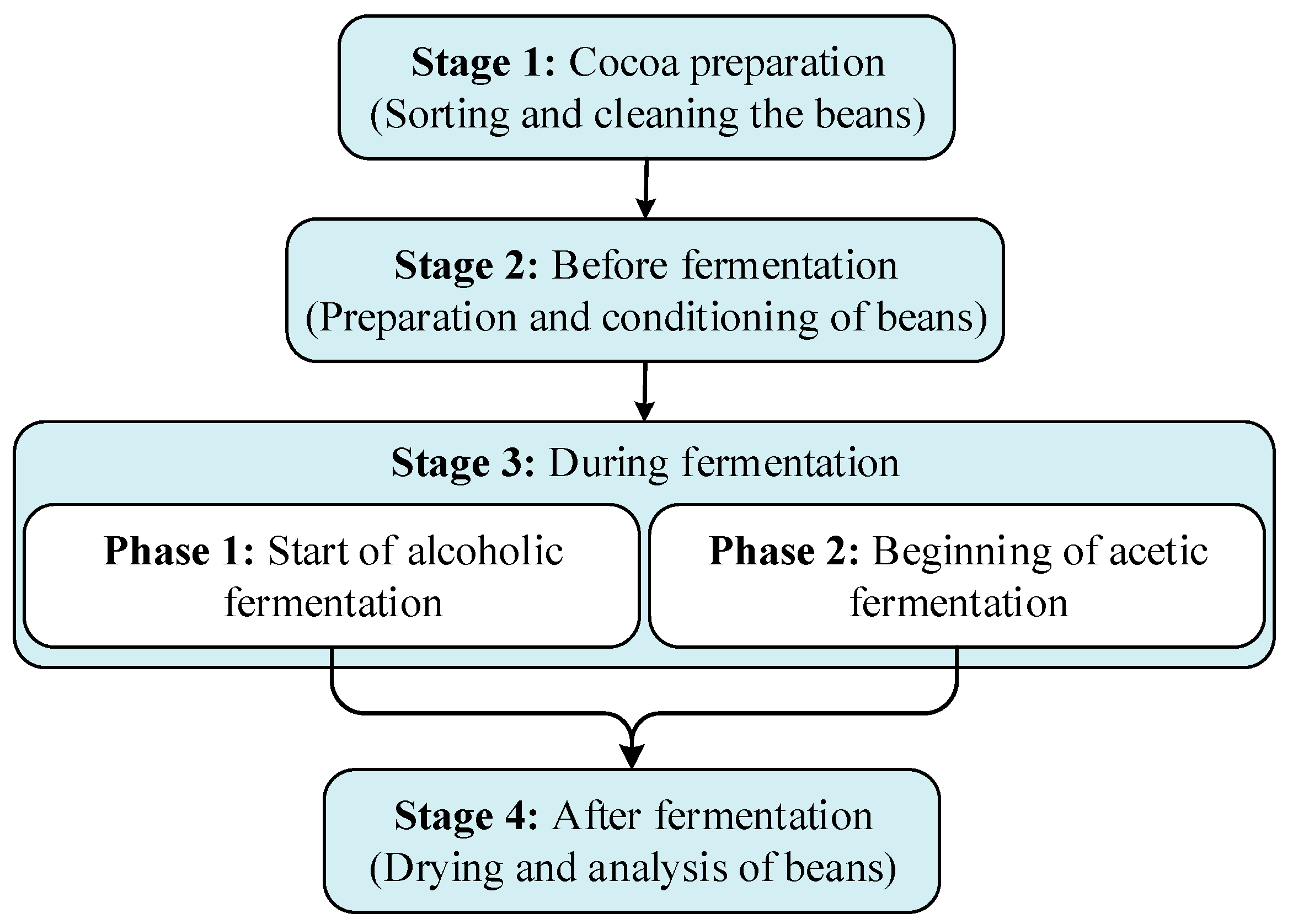

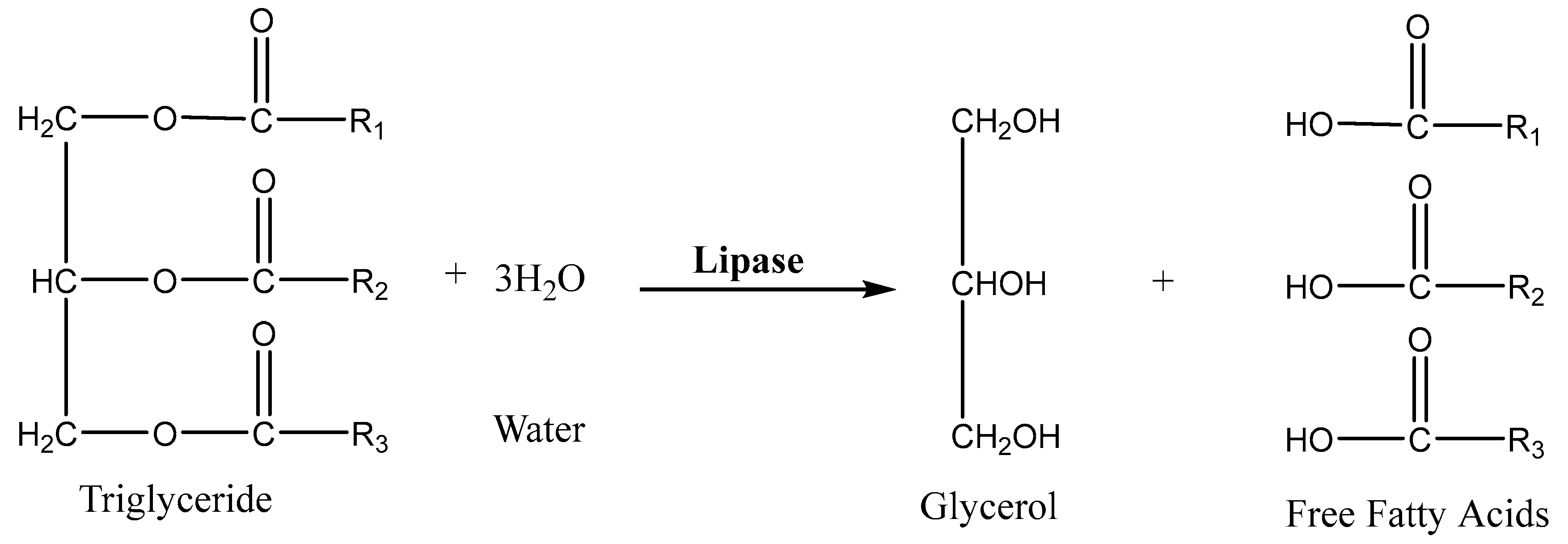

3. Cocoa Drying Process

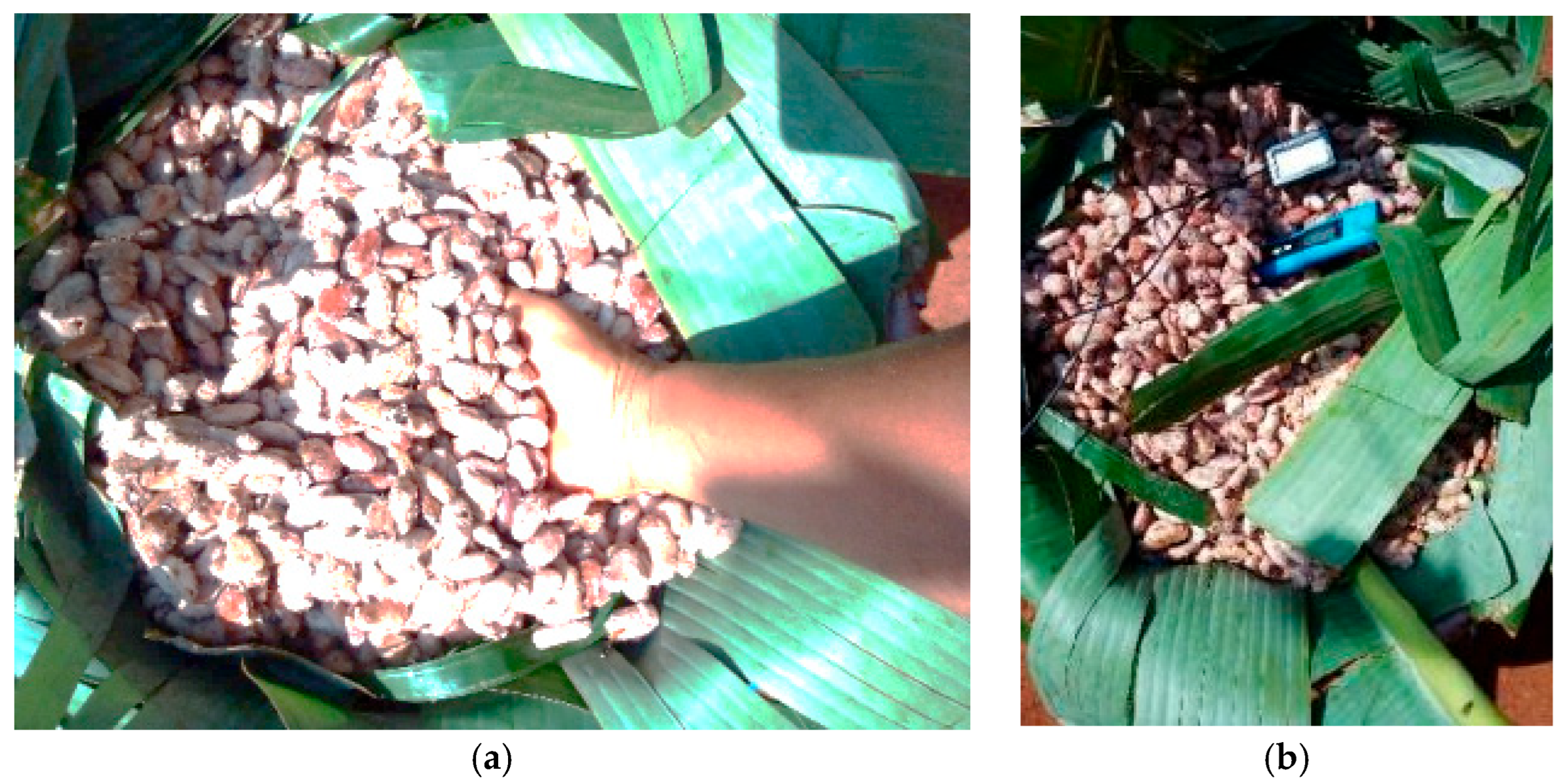

3.1. Selection of Plant Material and Test Sample

3.2. Plant Material Preparation Stages

3.2.1. Stage 1: Preparation of Plant Material

3.2.2. Stage 2: Before Fermentation

3.2.3. Stage 3: During Fermentation

- Phase 1: Start of Alcoholic Fermentation

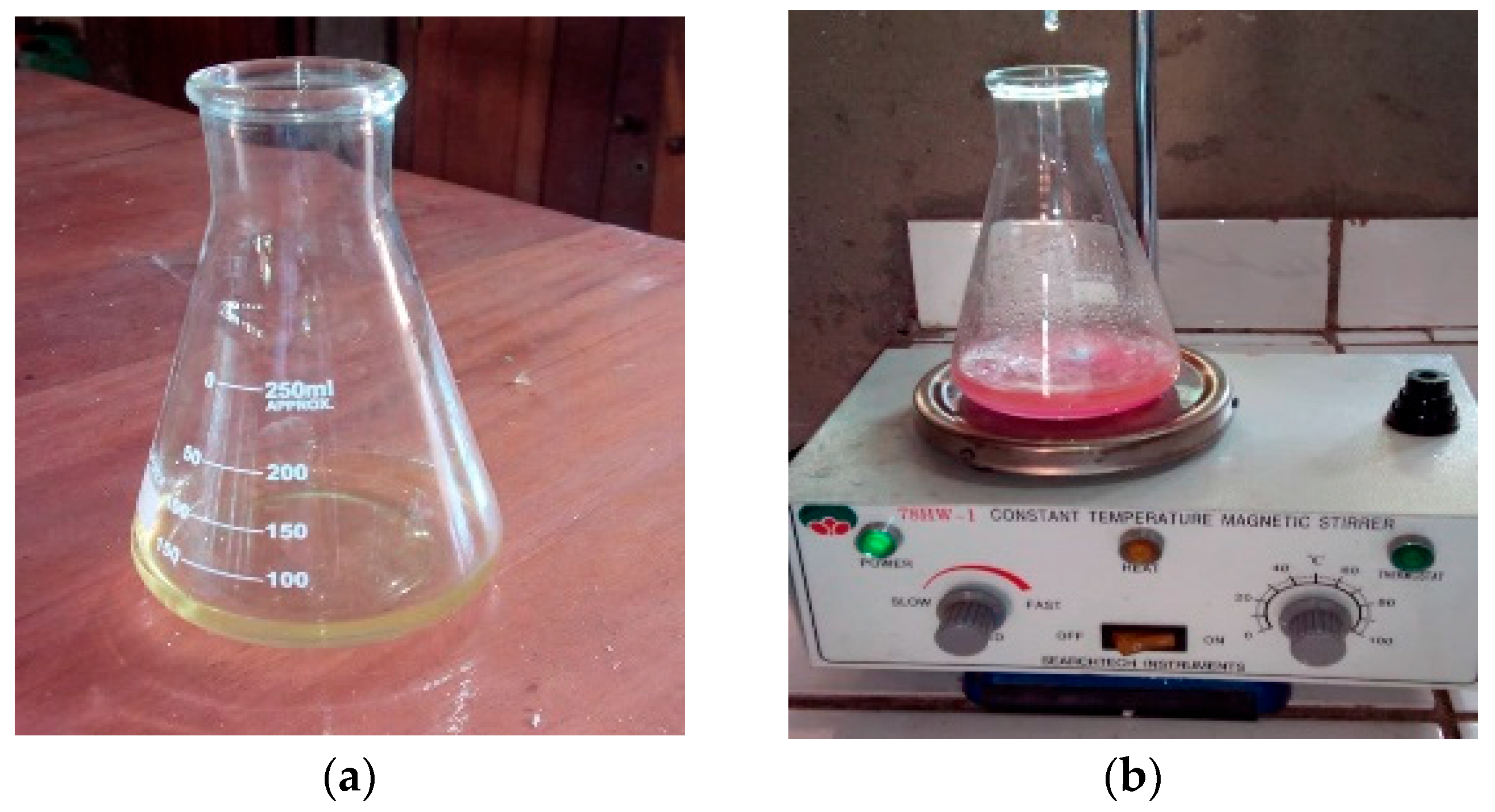

- Phase 2: Beginning of acetic fermentation

3.2.4. Stage 4: After Fermentation

3.3. Drying Processes

3.4. Analysis of Characteristic Parameters

3.4.1. Product Water Content

3.4.2. Water Mass to Be Extracted from Product

3.4.3. Product Water Removal Rate

3.4.4. Moisture Content Estimation

3.4.5. Assessment of Water Content

3.4.6. The Amount of Water to Be Removed from the Product

3.4.7. Experiment Size

3.4.8. Analysis of Cocoa Quality

3.4.9. Analytical Methods for Cocoa Analysis

3.4.10. pH Assessment

4. Experimental Results and Discussion

4.1. Prototype and Dimensions of the Solar Dryer

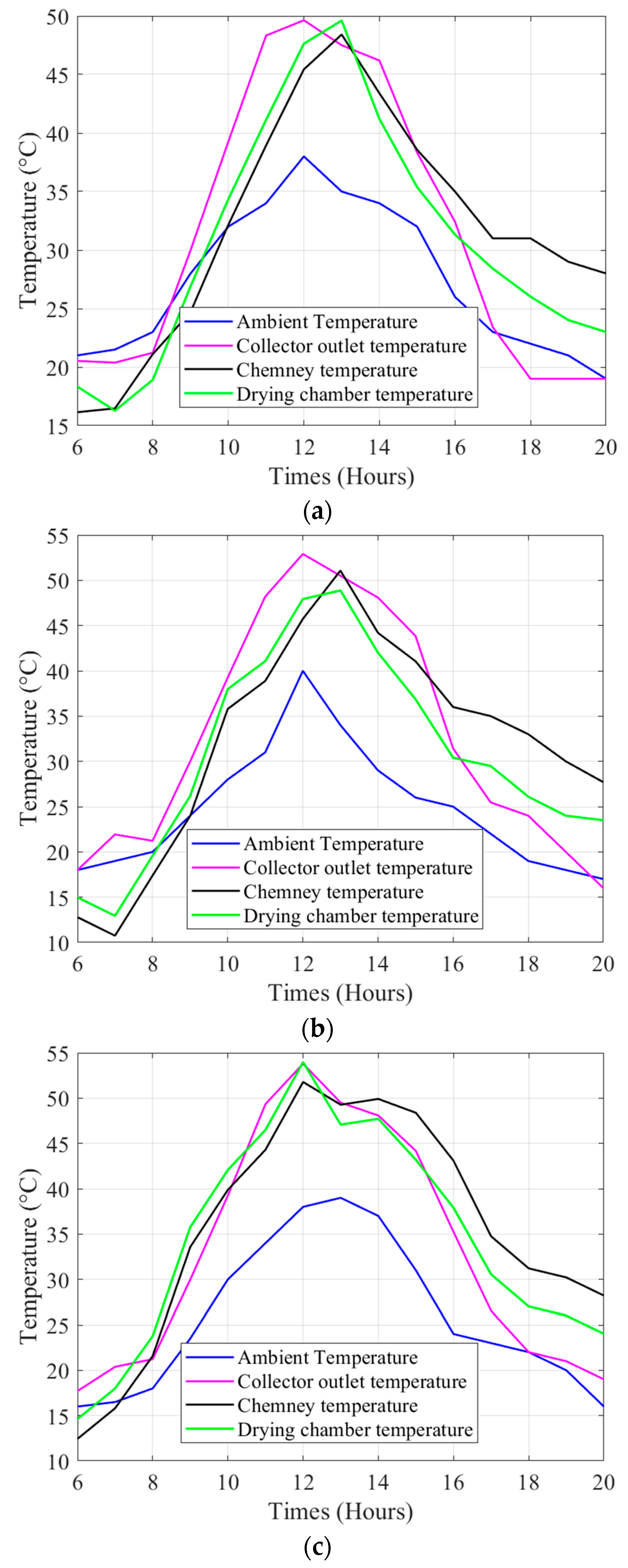

4.2. Environmental Parameters

4.3. Results of Evaluation of the Load Dryer

4.4. Drying Time and Number of Experiment Replicates

- -

- t1 is the z-score for a significance level of 5%, corresponding to 1.96;

- -

- t2 is the z-score for a statistical power of 80%, corresponding to 0.84.

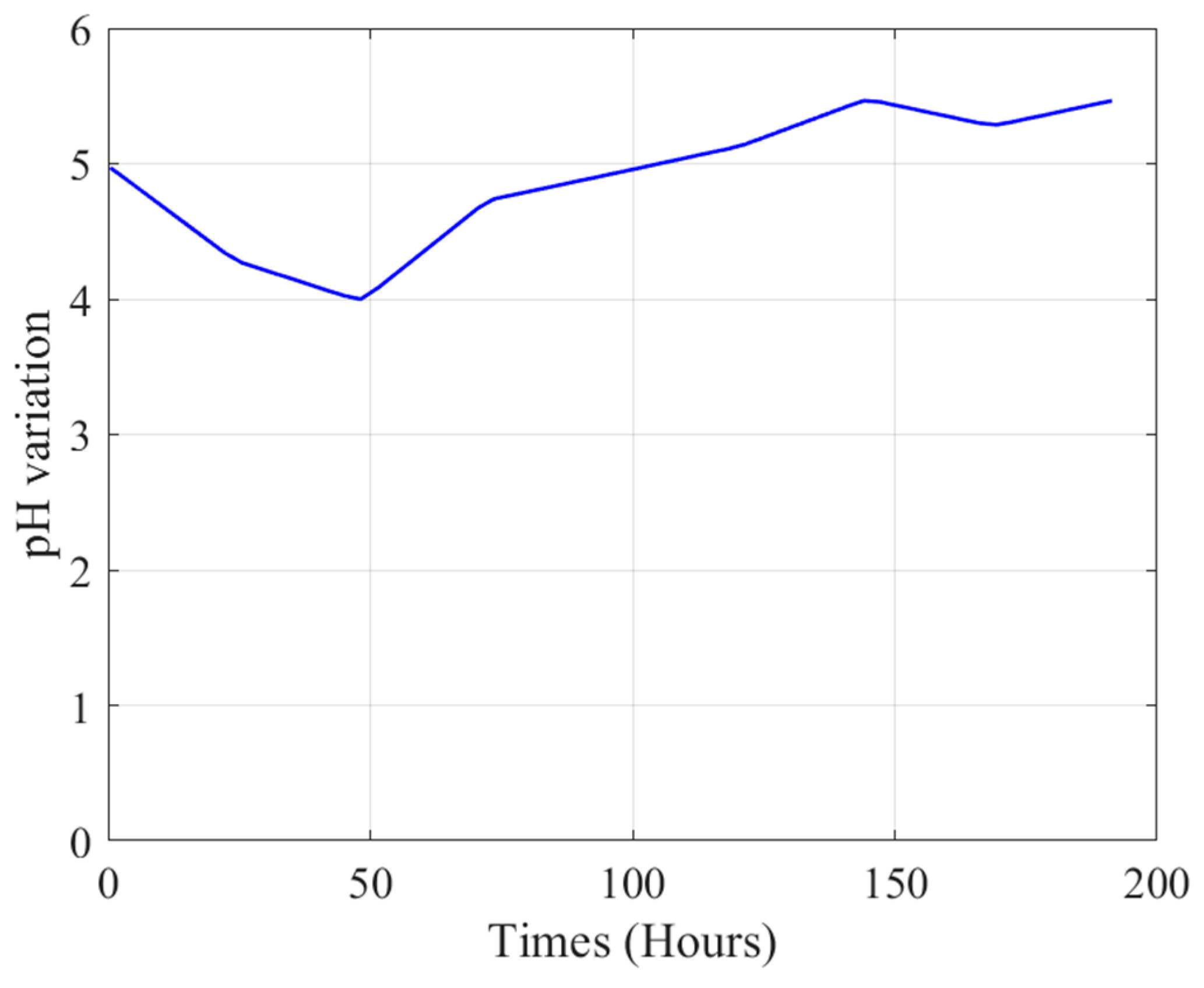

4.5. Results of pH Analysis

4.5.1. Control of pH During Fermentation

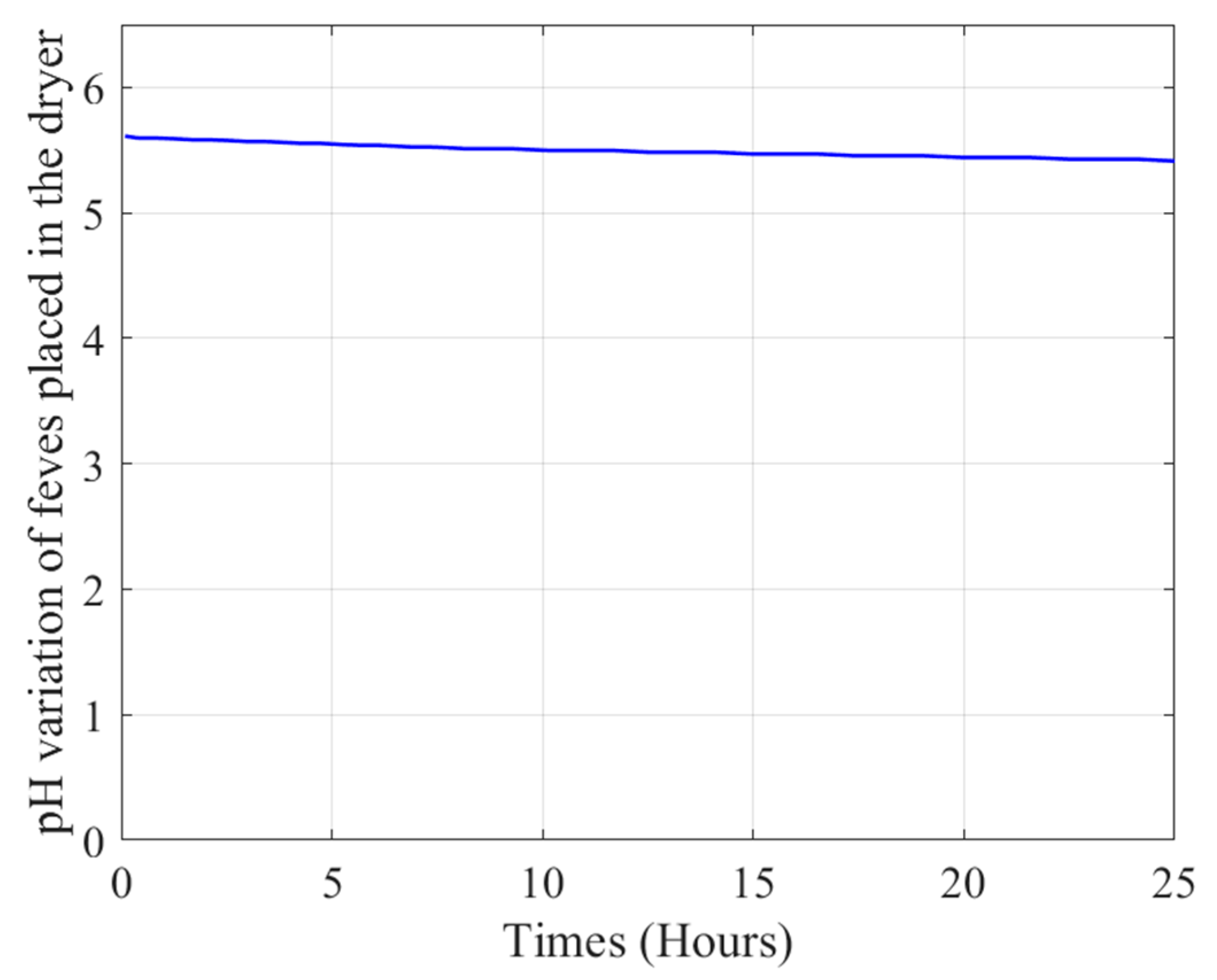

4.5.2. Control pH During Drying

- For air-drying

- For the proposed dryer

4.6. Cutting Test Results

4.7. Results of Laboratory Analysis of Product Quality

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kongor, J.E.; Owusu, M.; Oduro-Yeboah, C. Cocoa production in the 2020s: Challenges and solutions. CABI Agric. Biosci. 2024, 5, 102. [Google Scholar] [CrossRef]

- Chen-Yen-Su, A. Analyse Morphologique et Profils Aromatique, Sensoriel du Cacao du Sambirano. Ph.D. Thesis, Université de la Réunion, Saint-Denis, France, 2014. [Google Scholar]

- Mbakouop, A.N.; Tchakounté, H.; Ankungha, A.I.; Fapi, C.B.N. Design, fabrication and performance assessment of a mixed solar dryer for cocoa beans. Appl. Sol. Energy 2022, 58, 767–776. [Google Scholar] [CrossRef]

- Streule, S.; Freimüller Leischtfeld, S.; Chatelain, K.; Miescher Schwenninger, S. Effect of pod storage and drying temperature on fermentation dynamics and final bean quality of Cacao Nacional in Ecuador. Foods 2024, 13, 1536. [Google Scholar] [CrossRef] [PubMed]

- Afoakwa, E.O. Cocoa Production and Processing Technology; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Mohapatra, D.; Kumar, S.; Kotwaliwale, N.; Singh, K.K. Critical factors responsible for fungi growth in stored food grains and non-Chemical approaches for their control. Ind. Crops Prod. 2017, 108, 162–182. [Google Scholar] [CrossRef]

- Mbakouop, A.N.; Tchakounté, H.; Ankungha, A.I.; Nzoundja Fapi, C.B. Experimental performance analysis of a mixed forced convection solar dryer: Application to cocoa bean drying. Sol. Energy 2023, 257, 110–124. [Google Scholar] [CrossRef]

- Moreno-Miranda, C.; Jordán, J.; Moreno, R.; Moreno, P.; Solis, J. Protected Designation of Origin and Sustainability Characterization: The Case of PDO Cocoa Arriba. Agriculture 2019, 9, 229. [Google Scholar] [CrossRef]

- Guehi, T.S.; Zahouli, I.B.; Ban-Koffi, L.; Fae, M.A.; Nemlin, J.G. Performance of different drying methods and their effects on the chemical quality attributes of raw cocoa material. Int. J. Food Sci. Technol. 2010, 45, 1564–1571. [Google Scholar] [CrossRef]

- Kongor, J.E.; Hinneh, M.; Van de Walle, D.; Afoakwa, E.O.; Boeckx, P.; Dewettinck, K. Factors influencing quality variation in cocoa (Theobroma cacao) bean flavour profile—A review. Food Res. Int. 2016, 82, 44–52. [Google Scholar] [CrossRef]

- Dzelagha, B.F.; Ngwa, N.M.; Nde Bup, D. A review of cocoa drying technologies and the effect on bean quality parameters. Int. J. Food Sci. 2020, 2020, 8830127. [Google Scholar] [CrossRef]

- Jiménez-Rodríguez, D.J.; García-Alamilla, P.; Márquez-Rocha, F.J.; Vázquez-Medina, R.; Carrera-Lanestosa, A.; González-Alejo, F.A.; González-Alejo, F.A.; Sánchez-Ramos, C.A.; Ruiz-Santiago, F.L. Temperature Effect of Cocoa (Theobroma cacao L.) Drying on Energy Consumption, Bioactive Composition and Vibrational Changes. Processes 2024, 12, 2523. [Google Scholar] [CrossRef]

- Komolafe, C.A.; Waheed, M.A. Design and fabrication of a forced convection solar dryer integrated with heat storage materials. Ann. Chim. Sci. Matériaux (ACSM) 2018, 42, 23–39. [Google Scholar] [CrossRef]

- Santander, M.; Chica, V.; Correa, H.A.M.; Rodríguez, J.; Villagran, E.; Vaillant, F.; Escobar, S. Unravelling Cocoa Drying Technology: A Comprehensive Review of the Influence on Flavor Formation and Quality. Foods 2025, 14, 721. [Google Scholar] [CrossRef] [PubMed]

- Djikeng, F.T.; Teyomnou, W.T.; Tenyang, N.; Tiencheu, B.; Morfor, A.T.; Touko, B.A.H.; Houketchang, S.N.; Boungo, G.T.; Karuna, M.S.L.; Ngoufack, F.Z.; et al. Effect of traditional and oven roasting on the physicochemical properties of fermented cocoa beans. Heliyon 2018, 4, e00533. [Google Scholar] [CrossRef]

- Sianipar, C.P. Environmentally-appropriate technology under lack of resources and knowledge: Solar-powered cocoa dryer in rural Nias, Indonesia. Clean. Eng. Technol. 2022, 8, 100494. [Google Scholar] [CrossRef]

- VijayaVenkataRaman, S.; Iniyan, S.; Goic, R. A review of solar drying technologies. Renew. Sustain. Energy Rev. 2012, 16, 2652–2670. [Google Scholar] [CrossRef]

- Ilustre, E.J.; Mantile, J.T.F.; Antonio, C.D.; Recio, S.A.M.; Melendres, K.W.B.; Arguelles, A.S.A.; Bautista, J.N.; Limos-Galay, J.A. Automated rice grain dryer with sun-tracking solar panel using Arduino Uno. Int. J. Res. 2024, 8, 75–83. [Google Scholar] [CrossRef]

- Bagnaka, I.C. Memoire Online—Amélioration du Système de Séchage Artificiel des Fèves de Cacao dans les Régions à Forte Pluviométrie au CAMEROUN: Cas du Bassin de Production du Sud-Ouest.—Ignace Christian Bagnaka. 2017. Available online: https://www.memoireonline.com/09/21/12192/m_Amelioration-du-systeme-de-sechage-artificiel-des-feves-de-cacao-dans-les-regions--forte-pluv11.html (accessed on 9 July 2024).

- Saunshia, Y.; Sandhya, M.V.S.; Lingamallu, J.M.R.; Padela, J.; Murthy, P. Improved fermentation of cocoa beans with enhanced aroma profiles. Food Biotechnol. 2018, 32, 257–272. [Google Scholar] [CrossRef]

- Simo-Tagne, M.; Etala, H.D.T.; Tagne, A.T.; Ndukwu, M.C.; El Marouani, M. Energy, environmental and economic analyses of an indirect cocoa bean solar dryer: A comparison between natural and forced convections. Renew. Energy 2022, 187, 1154–1172. [Google Scholar] [CrossRef]

- Pandey, S.; Kumar, A.; Sharma, A. Sustainable solar drying: Recent advances in materials, innovative designs, mathematical modeling, and energy storage solutions. Energy 2024, 308, 132725. [Google Scholar] [CrossRef]

- Villagran, E.; Espitia, J.J.; Velázquez, F.A.; Rodriguez, J. Solar Dryers: Technical Insights and Bibliometric Trends in Energy Technologies. AgriEngineering 2024, 6, 4041–4063. [Google Scholar] [CrossRef]

- Alibas, I.; Yilmaz, A. Microwave and convective drying kinetics and thermal properties of orange slices and effect of drying on some phytochemical parameters. J. Therm. Anal. Calorim. 2022, 147, 8301–8321. [Google Scholar] [CrossRef] [PubMed]

- Białobrzewski, I.; Zielińska, M.; Mujumdar, A.S.; Markowski, M. Heat and mass transfer during drying of a bed of shrinking particles–Simulation for carrot cubes dried in a spout-fluidized-bed drier. Int. J. Heat Mass Transf. 2008, 51, 4704–4716. [Google Scholar] [CrossRef]

- Photovoltaic Geographical Information System (PVGIS). Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/tools.html (accessed on 10 December 2023).

- Batteix, F. Utiliser un Capteur de Température et D’humidité DHT11/DHT22 Avec une Carte Arduino/Genuino. Available online: https://www.carnetdumaker.net/articles/utiliser-un-capteur-de-temperature-et-dhumidite-dht11-dht22-avec-une-carte-arduino-genuino (accessed on 9 July 2024).

- Komolafe, C.A.; Waheed, M.A.; Kuye, S.I.; Adewumi, B.A.; Adejumo, A.O.D. Thermodynamic analysis of forced convective solar drying of cocoa with black coated sensible thermal storage material. Case Stud. Therm. Eng. 2021, 26, 101140. [Google Scholar] [CrossRef]

- Gbogbri, G.F. Impact de la Fermentation sur les Propriétés Antioxydantes, Anti-Inflammatoires et Immunomodulatrices du Cacao. Ph.D. Thesis, Université Montpellier, Montpellier, France, 2019. [Google Scholar]

- Jannot, Y.; Kanmogne, A.; Talla, A.; Monkam, L. Experimental determination and modelling of water desorption isotherms of tropical woods: Afzelia, ebony, iroko, moabi and obeche. Holz Als Roh-Und Werkstoff 2006, 64, 121–124. [Google Scholar] [CrossRef]

- García-Moreira, D.P.; Hernández-Guzmán, H.; Pacheco, N.; Cuevas-Bernardino, J.C.; Herrera-Pool, E.; Moreno, I.; López-Vidaña, E.C. Solar and Convective Drying: Modeling, Color, Texture, Total Phenolic Content, and Antioxidant Activity of Peach (Prunus persica (L.) Batsch) Slices. Processes 2023, 11, 1280. [Google Scholar] [CrossRef]

- Rozis, J.-F.; Alain Guinebault, A. Sécher des Produits Alimentaires. Techniques, Procédés, Équipements; Éditions du Gret, Ministère de la Coopération, CTA: Paris, France, 1995; 344p, ISBN 978-2-8684-4072-X. Available online: https://gret.org/publication/secher-des-produits-alimentaires/ (accessed on 9 July 2024).

- García-Moreira, D.P.; Pacheco, N.; Hernández-Guzmán, H.; Bahammou, Y.; Tagnamas, Z.; Moreno, I.; López-Vidaña, E.C. Evaluation of Various Drying Methods for Mexican Yahualica chili: Drying Characteristics and Quality Assessment. Processes 2024, 12, 1969. [Google Scholar] [CrossRef]

- Randa, L.; Ahlem, T.H. Optimisation du Séchage par Microonde par Modèles Mathématiques des Ombellifères. Ph.D. Thesis, B.B.A. Ibrahimi El Bachir El Mohamed Université, El Anceur, Algeria, 2020. [Google Scholar]

- Garti, N.; Widlak, N.R. Cocoa Butter and Related Compounds; Elsevier: Amsterdam, The Netherlands; AOCS Press: Champaign, IL, USA, 2015; pp. 497–501. ISBN 9780983079125. [Google Scholar] [CrossRef]

- Campos, R.; Marangoni, A.G. Molecular composition dynamics and structure of cocoa butter. In Cocoa Butter and Related Compounds; AOCS Press: Champaign, IL, USA, 2012; pp. 103–150. [Google Scholar] [CrossRef]

- Oliveira, M.M.; Cerqueira, B.V.; Barbon Jr, S.; Barbin, D.F. Classification of fermented cocoa beans (cut test) using computer vision. J. Food Compos. Anal. 2021, 97, 103771. [Google Scholar] [CrossRef]

- End, M.J.; Dand, R. CAOBISCO/ECA/FCC. Fèves de cacao: Exigences de qualité de l’industrie du chocolat et du cacao. Septembre 2015, ISBN: 978-2-9601817-1-5. Available online: https://www.cocoaquality.eu/ (accessed on 14 April 2025).

- Ruesgas-Ramón, M.; Figueroa-Espinoza, M.C.; Durand, E.; Suárez-Quiroz, M.L.; González-Ríos, O.; Rocher, A.; Reversat, G.; Vercauteren, J.; Oger, C.; Galano, J.-M.; et al. Identification and quantification of phytoprostanes and phytofurans of coffee and cocoa by-and co-products. Food Funct. 2019, 10, 6882–6891. [Google Scholar] [CrossRef]

- Streule, S.; Freimüller Leischtfeld, S.; Galler, M.; Motzer, D.; Poulose-Züst, M.; Miescher Schwenninger, S. Variations in Ecuadorian cocoa fermentation and drying at two locations: Implications for quality and sensory. Foods 2023, 13, 137. [Google Scholar] [CrossRef]

- Mougang, N.N.; Tene, S.T.; Zokou, R.; Kohole, H.A.F.; Solefack, E.N.; Mboukap, A.N.; Abaoabo, A.A.F.; Womeni, H.M. Influence of fermentation time, drying time and temperature on cocoa pods (Theobroma cacao L.) marketability. Appl. Food Res. 2024, 4, 100460. [Google Scholar] [CrossRef]

- Selamat, J.; Hamid, M.A.; Mohamed, S.; Man, C.Y. Physical and chemical characteristics of Malaysian cocoa butter. In Proceedings of the Malaysian International Cocoa Conference Kuala Lumpur, Kuala Lumpur, Malaysia, 20–21 October 1994; Selamat, J., Lian, B.C., Lai, T.K., Ishak, W.R.W., Mansor, M., Eds.; pp. 351–357. [Google Scholar]

- Sabariah, S.; Md Ali, A.R.; Chong, C.L. Chemical and physical characteristics of cocoa butter substitutes, milk fat and Malaysian cocoa butter blends. J. Am. Oil Chem. Soc. 1998, 75, 905–910. [Google Scholar] [CrossRef]

- Ejike, U.D.I.; Liman, M.L.; Olonishuwa, P.T. Application of lipases and phospholipases in bioremediation of oil-contaminated environments/habitats. In Phospholipases in Physiology and Pathology; Academic Press: Cambridge, MA, USA, 2023; pp. 405–422. [Google Scholar] [CrossRef]

- EEC. Directive 73/241/EEC by European Parliament and the European Council Relating to Cocoa and Chocolate Products Intended for Human Consumption. Off. J. Eur. Communities L 1973, 228, 23–35. [Google Scholar]

| Moldy (%) | Slate (%) | Attacked by Insects, Sprouted, or Flat (%) |

|---|---|---|

| 3 | 3 | 3 |

| 4 | 8 | 6 |

| Product Name | Materials | Specifications (Width × Length × Thickness) | Units |

|---|---|---|---|

| Dryer | Wood | 0.80 × 2.60 × 0.70 | m |

| Collector | 0.70 × 1.40 × 0.09 | m | |

| Solar drying room | 0.75 × 1.30 × 0.55 | m | |

| Drying rack | Plastic mesh | 0.65 × 1 × 1.20 | m |

| Absorber material | Stainless steel sheet | 0.004 | m |

| Transparent cover | Flexible polycarbonate | 0.003 | m |

| Insulating materials | Polystyrene and plywood | 0.015 | m |

| Electrical characteristics of fans | DC Voltage | 12 | V |

| Power | 7 and 5 | W | |

| Battery | Li-ion | 10 | Ah |

| Solar module | Monocrystalline semiconductor | 30 | W |

| Test | Solar Dryer (Days) | Free Air (Days) |

|---|---|---|

| Test 1 | 2 | 5 |

| Test 2 | 3 | 4.5 |

| Test 3 | 2.5 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mbakouop, A.N.; Nzoundja Fapi, C.B.; Siéwé, A.D.; Tchakounté, H.; Ankungha, A.I. Improving Cocoa Drying Efficiency with a Mixed Forced Convection Solar Dryer in an Equatorial Climate. Thermo 2025, 5, 18. https://doi.org/10.3390/thermo5020018

Mbakouop AN, Nzoundja Fapi CB, Siéwé AD, Tchakounté H, Ankungha AI. Improving Cocoa Drying Efficiency with a Mixed Forced Convection Solar Dryer in an Equatorial Climate. Thermo. 2025; 5(2):18. https://doi.org/10.3390/thermo5020018

Chicago/Turabian StyleMbakouop, Arnaud Nzendjang, Claude Bertin Nzoundja Fapi, André Désire Siéwé, Hyacinthe Tchakounté, and Awoh Innocentia Ankungha. 2025. "Improving Cocoa Drying Efficiency with a Mixed Forced Convection Solar Dryer in an Equatorial Climate" Thermo 5, no. 2: 18. https://doi.org/10.3390/thermo5020018

APA StyleMbakouop, A. N., Nzoundja Fapi, C. B., Siéwé, A. D., Tchakounté, H., & Ankungha, A. I. (2025). Improving Cocoa Drying Efficiency with a Mixed Forced Convection Solar Dryer in an Equatorial Climate. Thermo, 5(2), 18. https://doi.org/10.3390/thermo5020018