1. Introduction

Some human activities, such as burning fossil fuels and cutting down forests, increase the amount of carbon dioxide in the atmosphere. As a greenhouse gas, carbon dioxide in the atmosphere retains heat and impedes its propagation into space. The burning of fossil fuels is still being used intensively in many countries around the world, which has a negative effect on the Earth’s climate.

Counteracting the ongoing environmental degradation resulting from energy production is possible by:

The rational energy use of energy, i.e., energy-efficient technologies in all manufacturing and living processes. In this way, the global demand for primary energy can be reduced;

Increasing the share of energy production from renewable sources to meet energy needs;

Use “clean” technologies when burning fossil fuels. Renewable sources will not wholly substitute conventional sources.

The energy used for heating and cooling a building’s spaces represents a significant share of global consumption. Therefore, preventing heat (or cold) loss in buildings will play an essential role in climate protection. One of the modern ways of protecting against such losses is active thermal insulation.

The most common approach to reducing heat loss from a building is to increase the thermal resistance of the walls. This operation, which usually involves increasing the thickness of insulation, is widely used but has limitations primarily related to the geometry of the building.

Heat loss from the building can also be reduced by heating the walls. This involves transferring heat outside of the room being heated, which may seem uneconomical. However, it should be considered that the cost of raising the temperature strongly depends on the temperature range in which it occurs. It makes sense if this involves using renewable energy from a low-temperature medium in its direct form (solar or geothermal energy). Thus, this forms the basis of active thermal insulation (ATI).

The main advantage of ATI is that the heat loss from a heated room is reduced during the heating season. This is synonymous with saving energy for heating, caring for the environment, and preventing climate change.

In the literature, ATI is also referred to as a thermal barrier (TB), a thermo-activated wall (TAW), and active thermal protection (ATP).

Active thermal insulation is the subject of many research papers and patents. One of the earlier reports on ATI concerns the Isomax Terrasol system [

1], which consists of a solar collector and a ground storage reservoir for storing solar energy. The insulated ground storage consists of several zones with different temperatures. A suitable control system transfers energy from the storage tank to the walls with embedded pipes. The ground is treated as a seasonal heat accumulator with great capacity.

The paper by Xu et al. [

2] reviews the methods for modeling heat transfer in systems with pipes located in a wall. The method for placing pipes in a wall is described, among other factors, in the patent [

3].

Romani et al. [

4] discussed the simulation and control of thermally active building systems (TABS). A review of the work on the use of phase-change materials (PCM) for radiant chilled ceilings was presented by Mousavi et al. in their paper [

5]. In the work of Hongn et al. [

6], two new models for active structures with embedded pipes were proposed.

Krzaczek and Kowalczuk [

7] suggested that a wall with ATI should consist of at least three layers: an external insulating layer, a core with installed pipes, and an internal layer with low thermal conductivity. They also recommended using a working liquid with a constant temperature of 17 °C throughout the year. This temperature provides an unchanging direction of heat transfer from the internal surface toward the ATI layer. Obtaining a constant medium temperature requires extracting the heat from different locations in the ground, depending on the season.

Barkanyi [

8] presented a method of arranging the different wall layers containing ATI. The ATI layer is placed between the layers of insulation, with the internal layer having a lower thermal conductivity coefficient than the external layer.

Meggers et al. [

9] presented a system that minimizes exergy demand and maximizes the use of renewable geothermal heat from the ground. The liquid is pumped into a pipe network in the building wall. The pipe network is connected to a ground source of heat. Steady-state analyses showed that at an outdoor temperature of −10 °C and a 6 cm-thick active insulation system has the equivalent performance of 11 cm-thick passive insulation. Furthermore, the location of the pipes in the wall was found to have a minor effect on the thermal effects.

Niu and Yu [

10] performed numerical calculations for a multilayer wall with an embedded capillary pipe network. In order to analyze the effect of the location of the pipe network embedded in the wall, a mathematical heat transfer model was created, and a simulation platform based on the Matlab application was developed to evaluate the system’s performance. Optimization of the location of the pipe network was performed. The net energy benefit, i.e., the direct energy benefit (difference in heat losses for passive insulation and active insulation) minus the power (related to the surface area) consumed to transport the working liquid flowing through the pipes in the ATI layer, was used as the objective function. No significant dependence of the energy benefit on the location of pipes in the wall was found.

Yu et al. [

11] studied the effect of water temperature and flow rate on the thermal performance of the envelope, while Li et al. [

12] studied the effect of external temperature (climate) on the energy savings resulting from the use of ATI. Shen and Li [

13] analyzed an ATI layer supplied with water that was heated by an air source heat pump, and Simko et al. [

14] studied the effect of geometric dimensions of the ATI layer on reducing heat losses.

Kisilewicz et al. [

15] studied a system constructed according to patents [

3,

8]. According to this system, the pipes are placed in a concrete core insulated from both sides. The bearing layer is located at the internal side of the wall, and the pipes are connected directly to the ground heat exchanger. The results showed that the heat losses through the building walls were reduced by 63% on average when compared to passive insulation (when the ATI layer is not working). During the hot summer period that was analyzed, positive wall-cooling effects were obtained. Under these conditions, the refrigerant circulation in the active insulation system needed to be turned off to allow for the natural cooling of the interior spaces.

In the paper by Krzaczek et al. [

16], an improved energy management technique for wall heating/cooling systems is described. The installed wall heating/cooling system is fully controlled by a special fuzzy logic program, which synchronizes the heat supply/receiving, considering the varying heat loads. The measurement results showed that the indoor air temperature variation did not exceed 0.8 °C throughout the year.

Computational fluid dynamics were used in the numerical study of the thermal performance of a wall with an embedded ATI layer, as described by Zhou and Li [

17]. The simulation data were in very good agreement with the laboratory-scale measurements. The effects of the inlet water temperature, mass flow rate, and the position of the embedded pipe were studied. The results showed that the wall with an embedded pipe achieves the best cooling or heating performance when the pipes are located in the middle of the wall. The mass flow rate has a slight effect on wall heat loss.

In [

18], Figiel and Leciej-Pirczewska carried out calculations concerning the impact of the location of a thermal envelope on its effectiveness. The results of the calculations involved three different locations of the thermal envelope and a wall without it. This analysis shows that the greatest reductions in heat losses are obtained with the ATI layer located outside the core. This location of the ATI layer is most common in thermally retrofitted buildings.

In a paper by Kalus et al. [

19], the design solutions of walls with pipes for heating or cooling were described. Krajcik et al. [

20] studied ATI with pipes attached to insulating bricks, while another paper by Krajcik et al. [

21] reviewed water wall systems.

Yang et al. [

22] conducted a global sensitivity analysis, which indicated that the heat source temperature, indoor temperature, charging duration, and thermal conductivity of the layer in which the pipes are embedded are the four most significant variables characterizing ATI performance. Furthermore, it was shown that pipe spacing has a major influence on heat accumulation (optimum spacing 100–250 mm). In contrast, pipe position has a minor influence on both the internal surface heat load and external surface heat losses.

Kalus et al. [

23] conducted an economic analysis comparing active insulation performance with passive insulation. Insulation costs, thermal costs, and gray energy costs were taken into account. They found the use of active insulation desirable, especially when powered by geothermal or waste energy.

Another paper by Kalus et al. [

24] considered the co-operation of ATI with heat storage in the form of a foundation slab that was 100 m

2 and 0.2 m thick and was powered by solar energy. It was found that this storage is insufficient to heat the house but is suitable for supplying active insulation during the heating season. At a working fluid temperature of 13 °C, the thermal resistance of a wall with ATI installed is equivalent to a thickness of 500 mm of insulation.

From the above review, it is clear that the optimal location of pipes in the building envelope with the ATI layer installed is of interest to researchers, but the results they obtain are inconclusive.

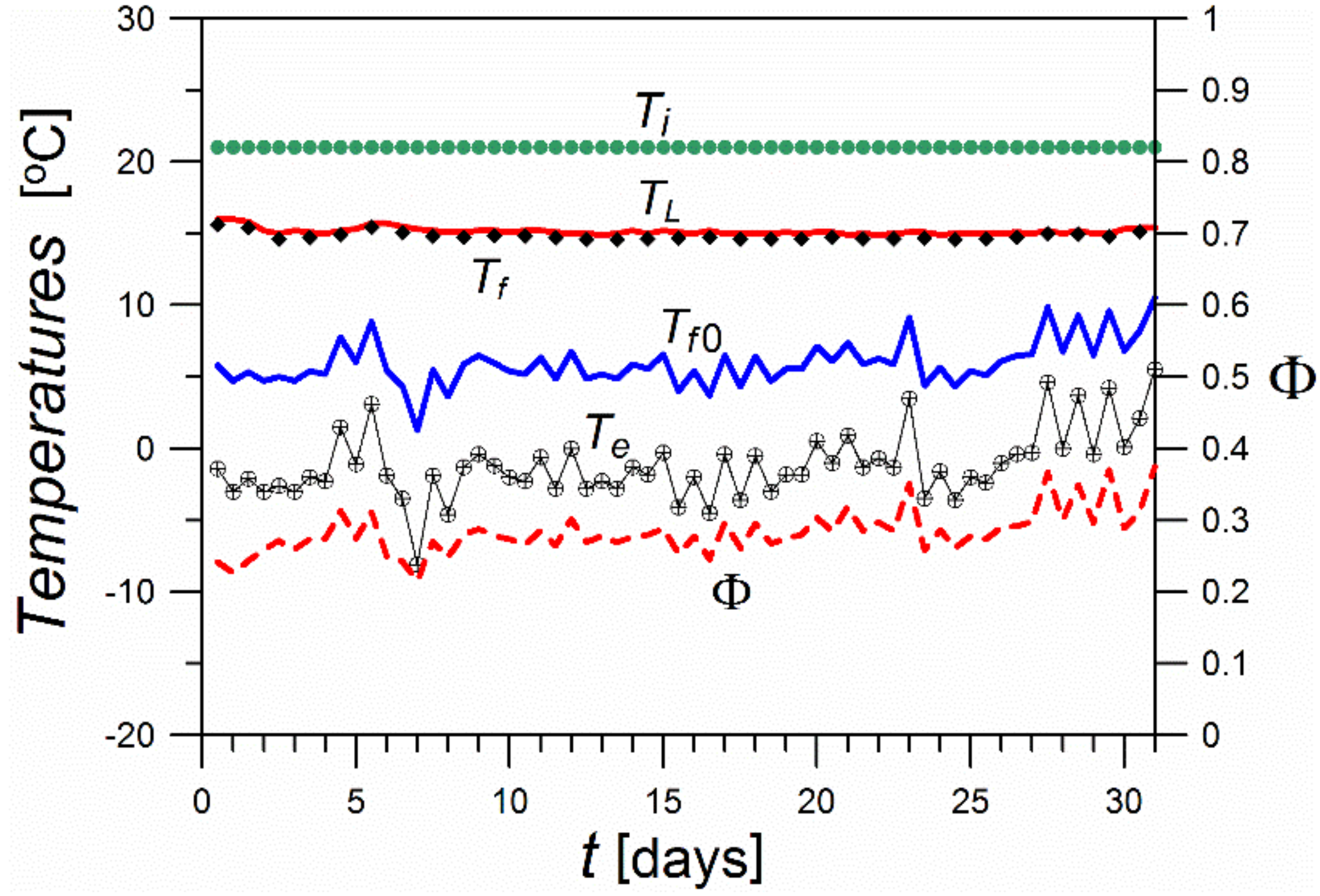

The primary role in the ATI layer heat transfer model is played by the temperature of the liquid flowing through the pipes. It is variable with time as well as with position. The difference in liquid temperature between the inlet and outlet of the layer is slight, which makes it possible to use the average liquid temperature (Tf). This is reasonable because the pipes in the ATI layer are arranged in a meandering manner such that the temperature of the ATI layer in the longitudinal section is equalized. For example, for a given circuit, the pipes in the inlet region are located near the outlet sections, which averages the temperature course in the longitudinal section of the ATI.

The basis for determining the temperature,

TL, is the temperature of the ground in which the ground exchanger is installed. In addition, the temperature

TL is affected by the heat transfer rate between the liquid and the ATI layer with

Tf. If the ground is not a heat store, the ground temperature as a function of position and time can be determined from the relationships presented in [

25,

26], among others.

This work aims to determine the optimal position of the ATI layer in the envelope. A heat transfer model through the envelope with the ATI layer was developed. The simplifying assumptions in the model were verified by numerical simulations. A relationship to determine the optimal location of the ATI layer was derived. Minimizing the summed cost of the heat energy delivered to the interior space and the ATI layer was used as the objective function. Only the operating costs were taken into account, and the unit price of energy supplied to the ATI layer is lower than the unit price of energy supplied to the internal space. Based on the results of the measurements carried out in the building facility with the ATI layer installed, the actual location of the ATI layer was compared with the location under optimal conditions.

2. Basic Relationships and Problem Description

For an envelope (e.g., building) with thermal resistance,

R, separating the environments with different temperatures,

T1 and

T2, the heat flux amounts to

When the temperature T1 is fixed, and T2 < T1, then in order to reduce the heat flux, the total thermal resistance through the envelope should be increased, or the temperature T2 should be increased. In the latter case, we are dealing with ATI.

The ATI is often located in the bearing layer of the building envelope in the form of a coil connected directly to the ground heat exchanger. The working liquid circulating in this system has a lower temperature than the indoor air of the building and a higher temperature than the outdoor air during the winter season. This reduces the heat flux transferring from the indoor space during this period. The direct energy benefit can be defined as the difference in heat losses for passive insulation

q0 and active insulation

qi:

This study paid special attention to applying the ATI layer under winter conditions.

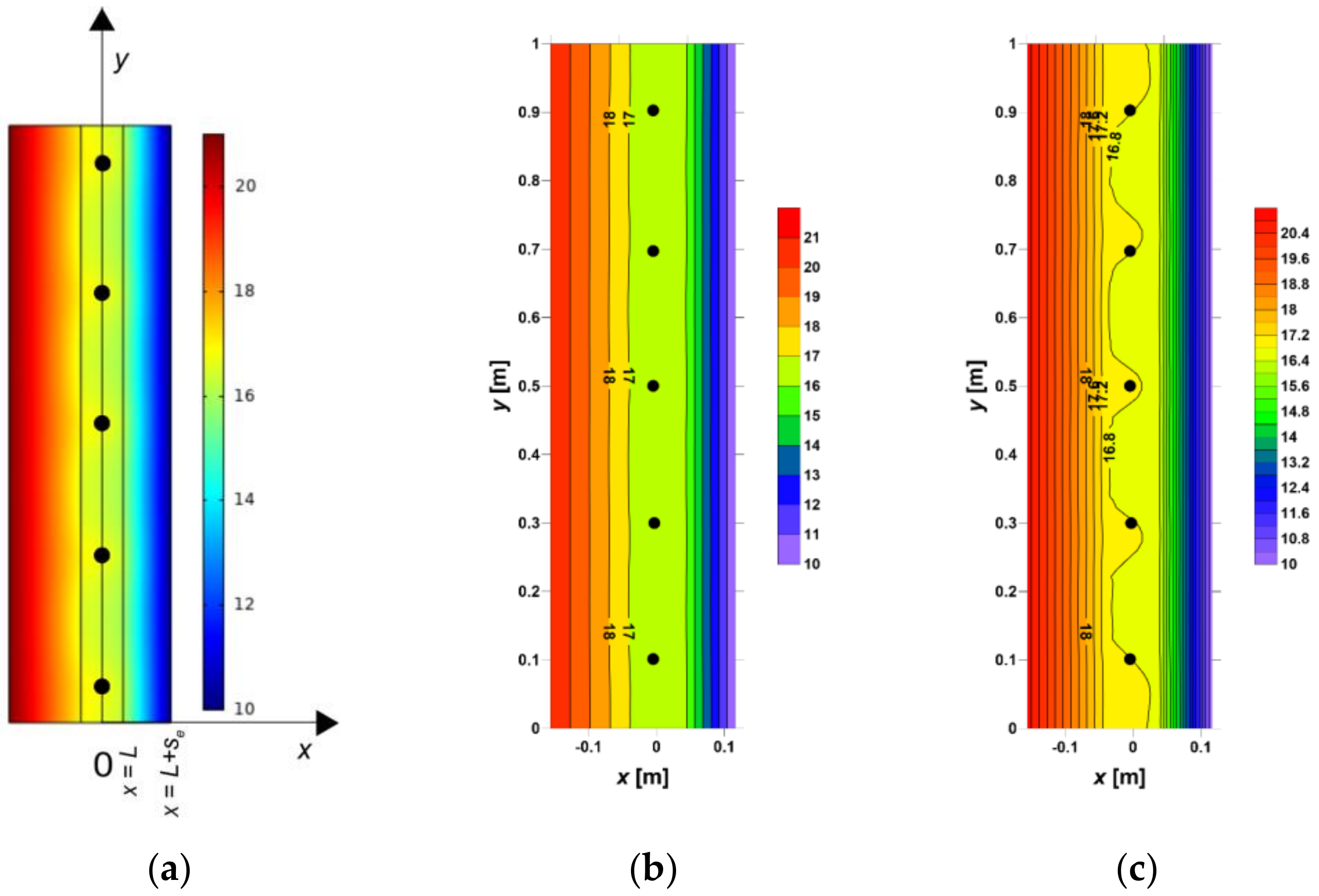

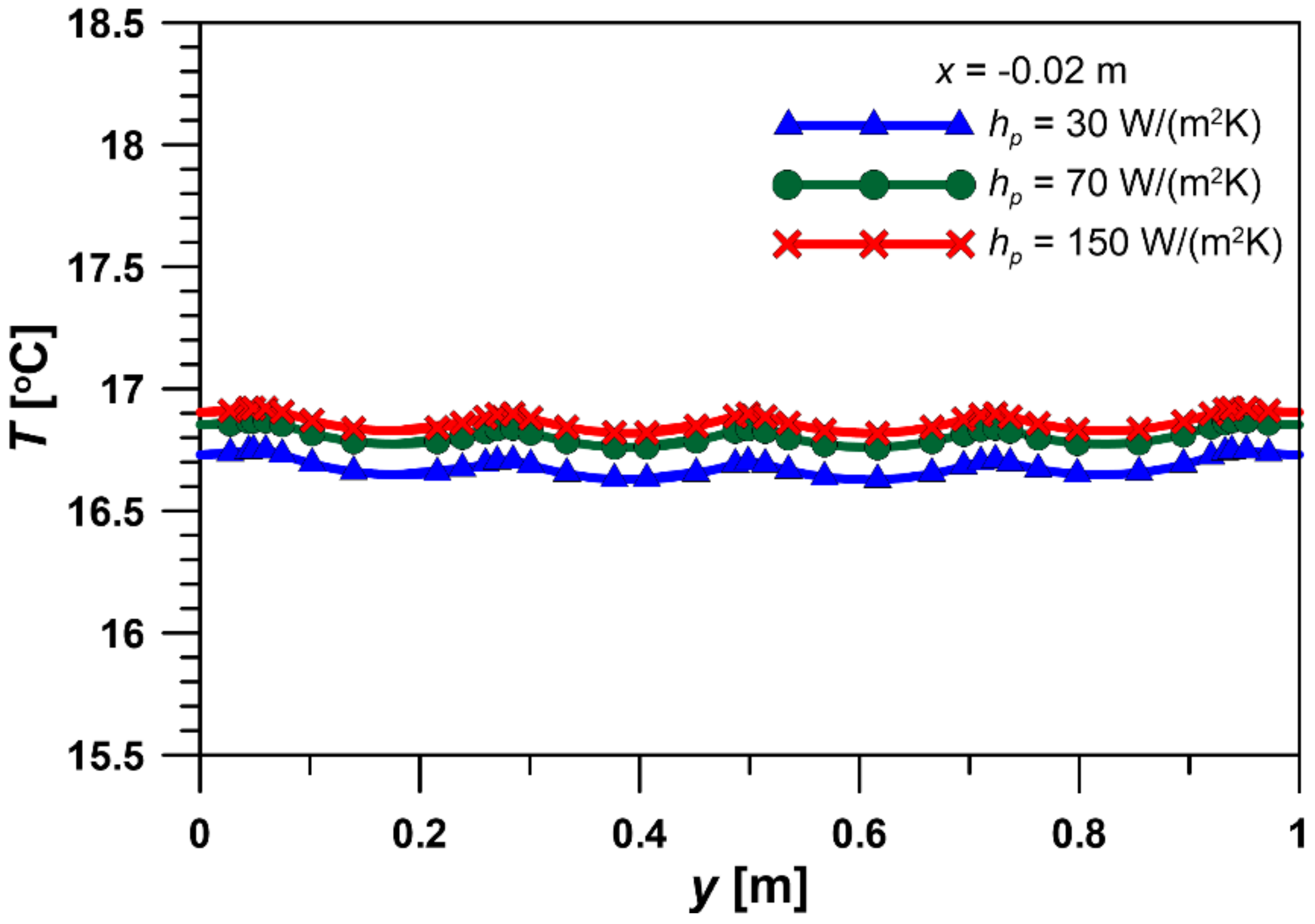

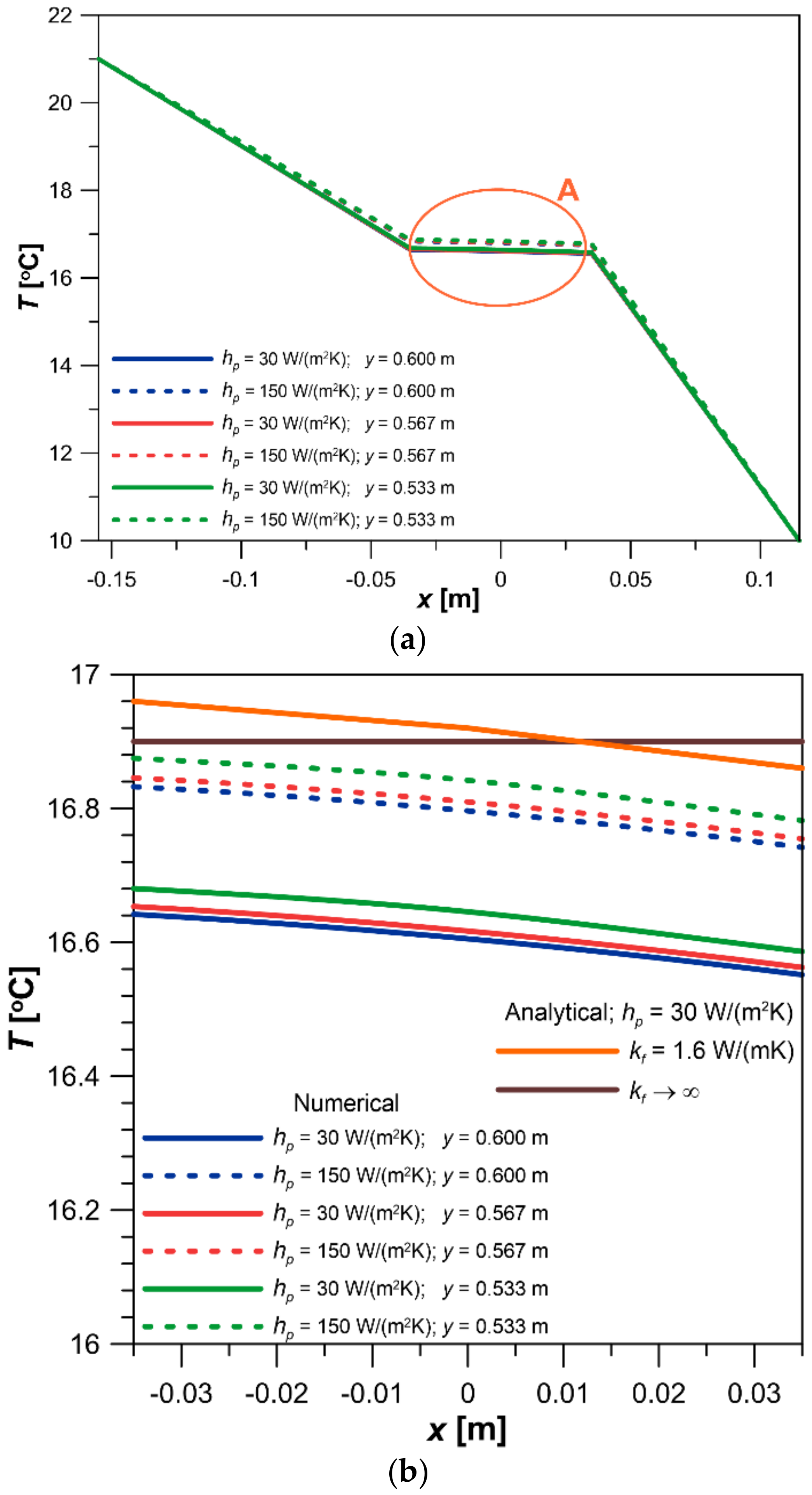

A simplified model of heat transport through an envelope with an active insulation layer is based on the assumption that the thermal resistance of the ATI layer is negligibly small, which causes the layer to have a uniform temperature,

Tf. The definition of a dimensionless, active insulation temperature was introduced (0 <

Φ <1):

where

Ti,

Te, and

Tf—internal temperature, external temperature, and ATI layer temperature [°C], respectively.

When Tf = Ti, then Φ = 0, while for Tf = Te, Φ = 1.

The ATI layer contains a heat source with heat generation

qv:

where

qf is the heat flux supplied to the ATI layer [W], while

L is half the thickness of this layer [m]. The active insulation layer separates the envelope into an internal part (i) and an external part (e). Each part is characterized by the summed thermal resistances:

Ri and

Re. These are the sum of the resistances of the individual layers (insulation, bearing partition, and plaster) and the convective heat transfer resistance at the internal/external surface. Therefore,

where

hi and

he—convective heat transfer coefficient at the internal and external surface [W/(m

2K)], respectively.

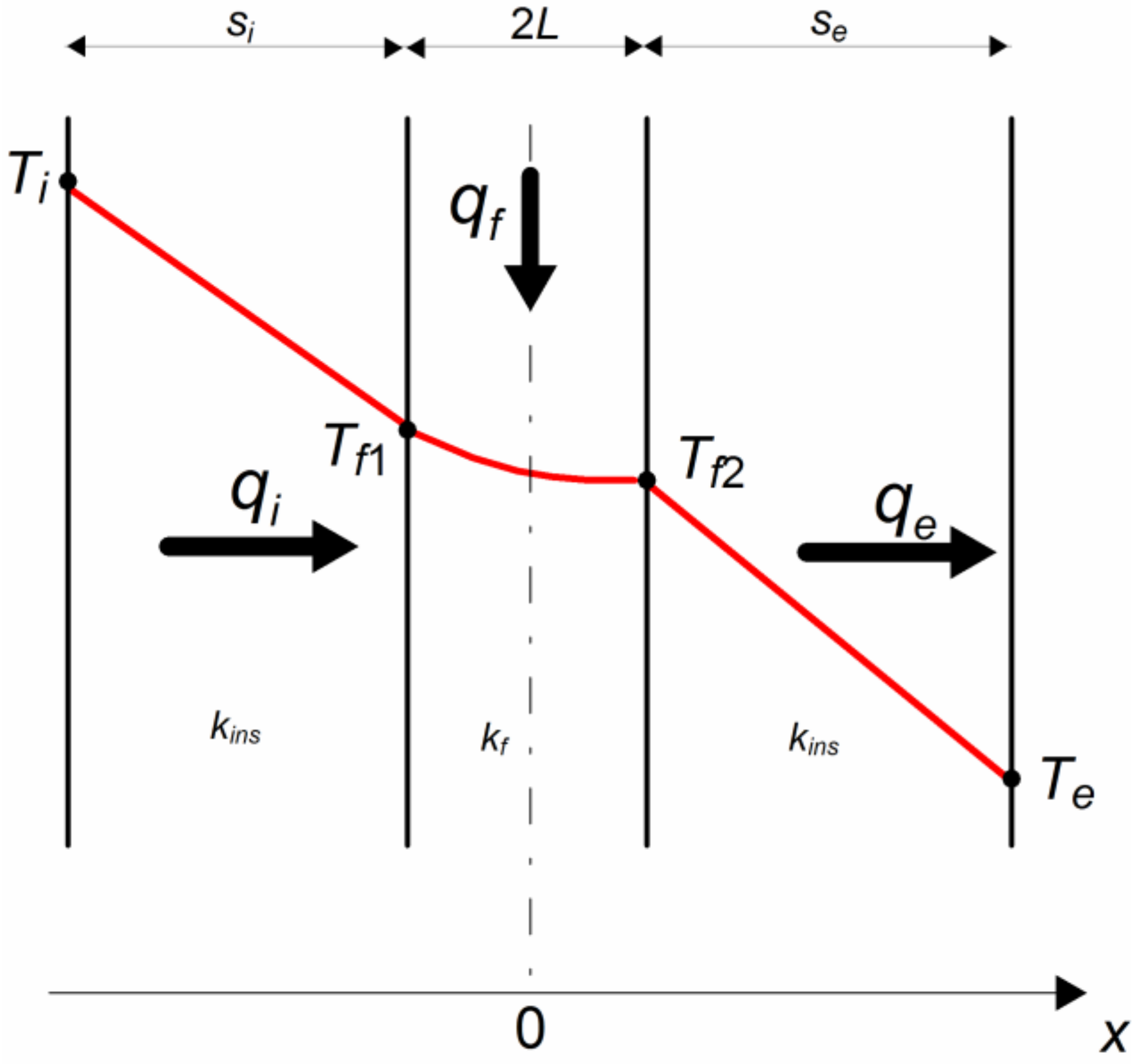

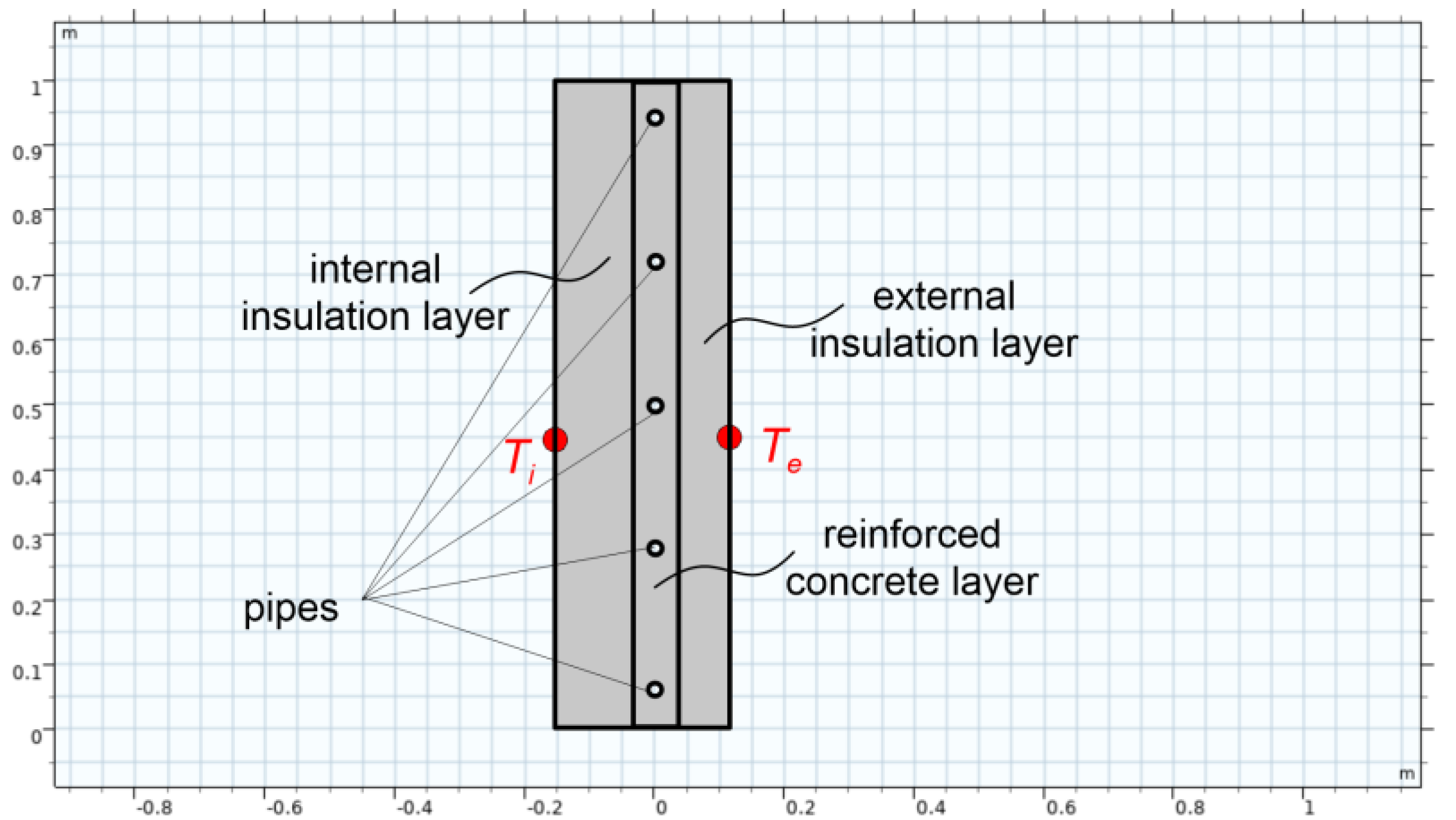

A schematic diagram of the considered envelope is shown in

Figure 1. The total thermal resistance of the envelope is

The envelope temperature on the side of the interior space is kept constant at

Ti, while the envelope temperature on the ambient side is

Te. In the special case of no heat source (

qf = 0), the insulation becomes passive. The heat fluxes in the internal and external insulation layers are then equal and amount to

q0. The heat flux for passive insulation becomes

In the presence of an active insulation layer, the heat fluxes transferred through the envelope are different: for the internal part (from the internal space to the active insulation layer), the heat flux is

qi, while for the external part (from the active insulation layer to the surroundings), the heat flux is

qe. The heat flux in the internal part is smaller than

q0 and equals

Whereas, in the external part, the heat flux is greater than

q0 and amounts to

The heat fluxes are related by the heat balance equation:

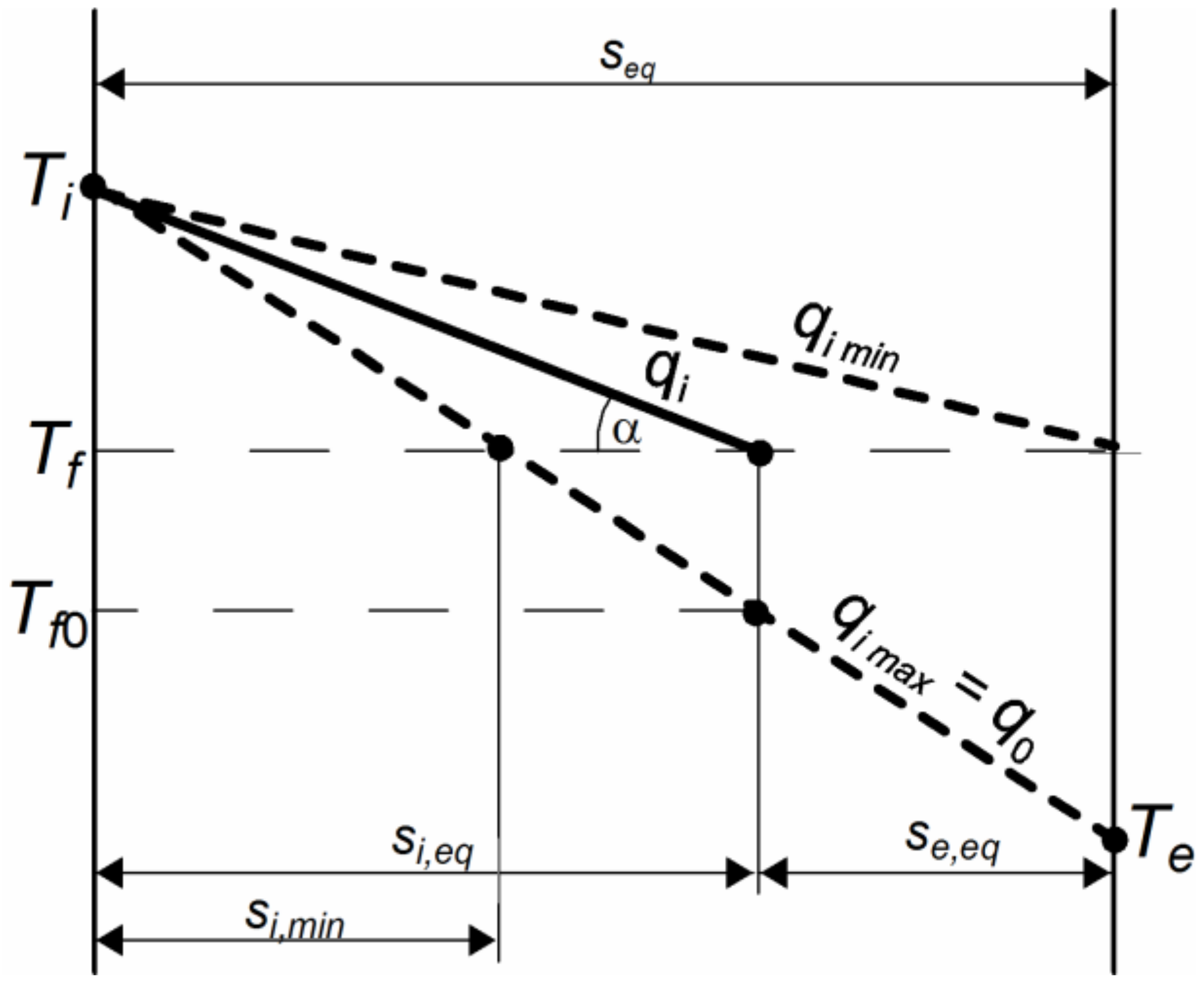

In

Figure 2, the limiting positions of the temperature profiles of the envelope with the active insulation layer are shown. The tangent of the angle of the temperature profile tan(

α) = −

dT/

dx, according to the Fourier equation, is

i.e., the higher the heat flux, the steeper the profile line is.

For a given value of

Tf, the minimum heat flux in the internal part corresponds to placing the ATI layer on the external surface of the envelope (

Ri,max =

R) and equals

The maximum heat flux in the internal part equals the value

q0, corresponding to passive insulation. Hence it follows that

Therefore, the minimum value of the internal thermal resistance is

The ratio of the resistance of the envelope’s internal part to the total resistance is denoted as

ρ (dimensionless internal resistance):

According to the above considerations, the values of the dimensionless internal resistance are in the range of

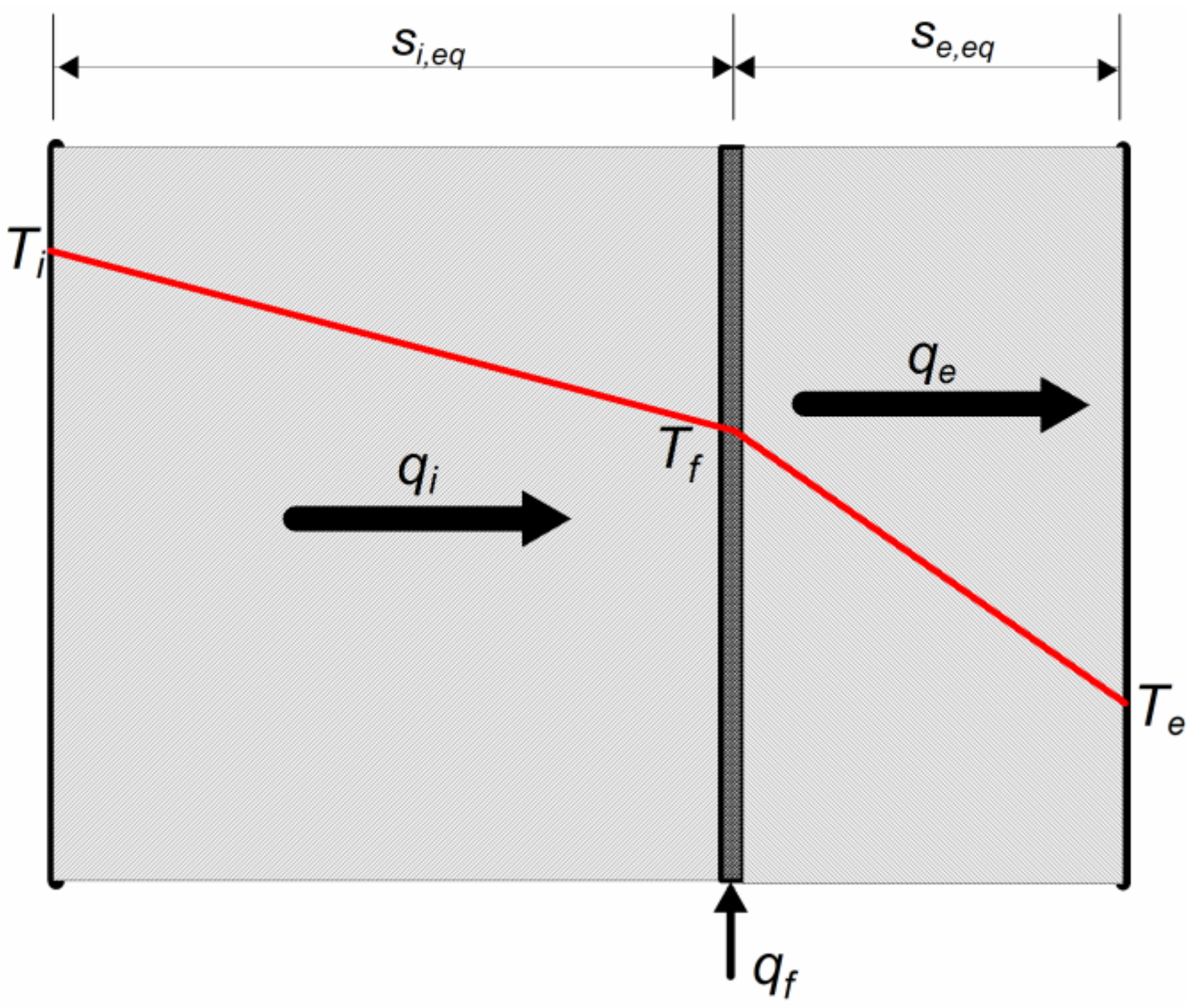

When considering (5) and (6) and the proportionality of the sum of the equivalent layer thicknesses,

seq, to the thermal resistances, it follows, from

Figure 2, that

For winter conditions, the temperature of the external surface of the envelope is lower than the internal space temperature and close to the ambient temperature,

Te. The envelope temperature varies linearly with position and decreases as one moves away from the internal envelope surface. The active insulation can be located at any section of the envelope, represented by the segment CD in

Figure 3. The location at point 1 causes the temperature profile in the internal part of the envelope to be segment A1, and the profile in the external part is segment 1B. The angle of inclination of segment A1 differs slightly from the slope angle of segment AC, corresponding to passive insulation. Thus, the heat losses from the internal space are slightly smaller than those for passive insulation. A greater reduction in heat losses will be achieved when the ATI layer is located at point 2, and an even greater reduction will be achieved for point 3 (

α1 >

α2 >

α3). However, the heat fluxes in the external part of the envelope are determined by the corresponding slope angles of the temperature profiles, which must also be considered. When the ATI layer is placed at point 1, the slope angle of segment 1B is slightly greater than the angle of inclination of segment CB, corresponding to passive insulation. The angle for segment 2B is greater than that for 1B, and the angle for segment 3B is more significant than that for 2B (

β1 <

β2 <

β3). The increase in the angle

β in the outer part of the envelope corresponds to a higher heat flux loss to the environment. Thus, the closer the ATI layer is located to point D, the less heat is transferred from the internal space to the ATI, but at the same time, more heat is transferred from the ATI layer to the surroundings. In the extreme case where the ATI layer is located at point C, the reduction in heat losses from the internal space is zero. In the other severe case where the ATI layer is located at point D, the heat flux lost to the surroundings is infinite (vertical profile course). Therefore, finding the most favorable position for the ATI layer in the envelope is desirable.

4. Optimal Location of the Active Insulation Layer

Space heating is associated with costs that depend on the unit price of energy. There are two energy streams when using an active insulation layer: the stream supplied to the interior space and the stream supplied to the active insulation layer. The unit prices of these streams are different; since the stream to the active layer is supplied directly from the ground without any transformation, its unit price, PW, is lower than the unit price of the heat stream supplied to the internal space, PR.

The price ratio is denoted by the pricing parameter

κ:For the given temperatures Ti, Te, and Tf, the total thermal resistance of envelope R, and the pricing parameter κ, the optimum location of the ATI layer can be determined. The problem consists in finding the thermal resistance of the internal part of the envelope Ri, and, more precisely, the fraction of this resistance in the total resistance ρ (Equation (15)).

The ratio of the heating costs of the interior space with active insulation

CATI to the costs of the heating space with passive insulation

C0 was used, with all other conditions remaining unchanged. Thus,

Taking into account formulae (3), (8)–(11), (15), (23), and (24), the relationship

η =

F (

ρ,

κ,

Φ) is obtained as a relationship between the dimensionless quantities:

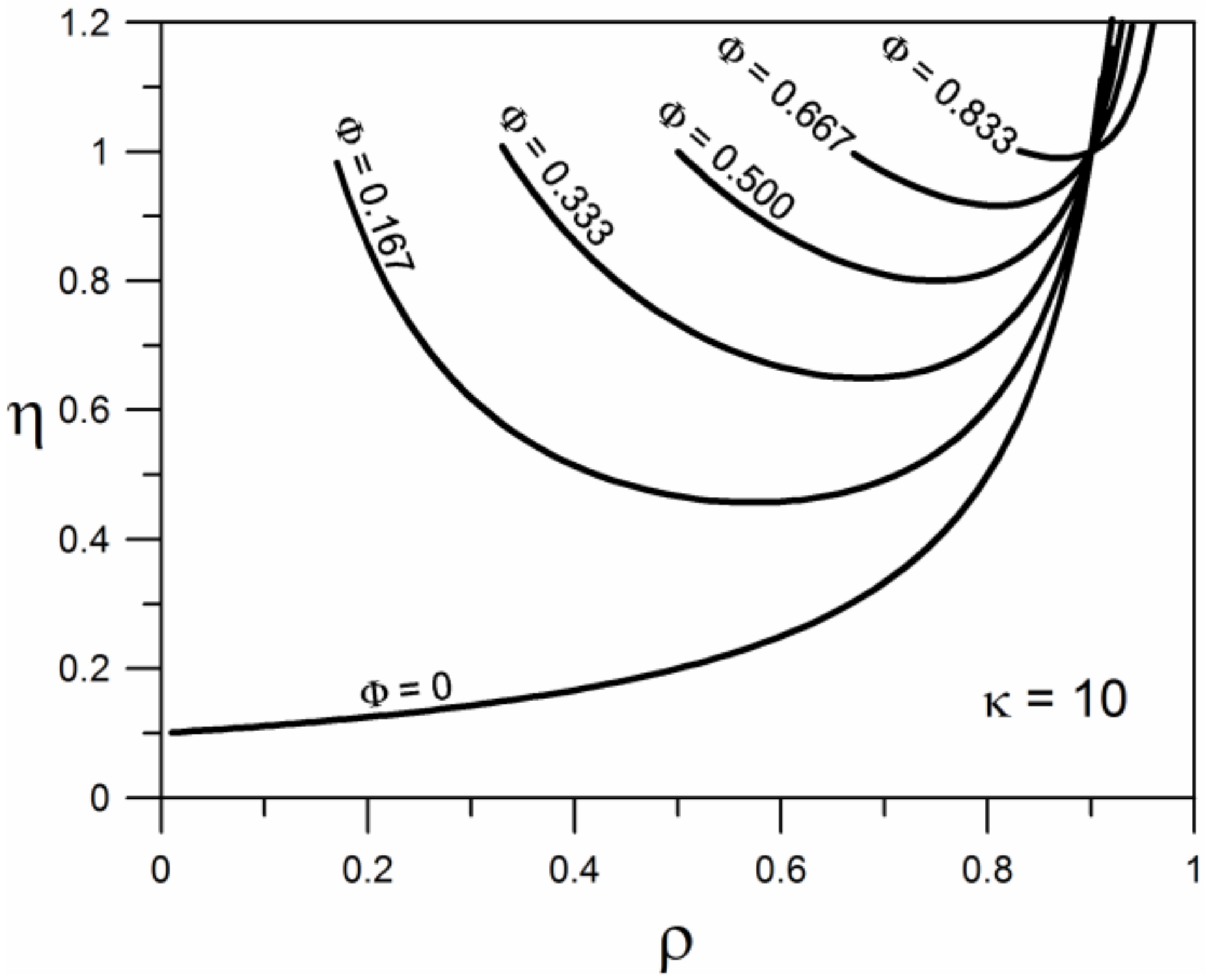

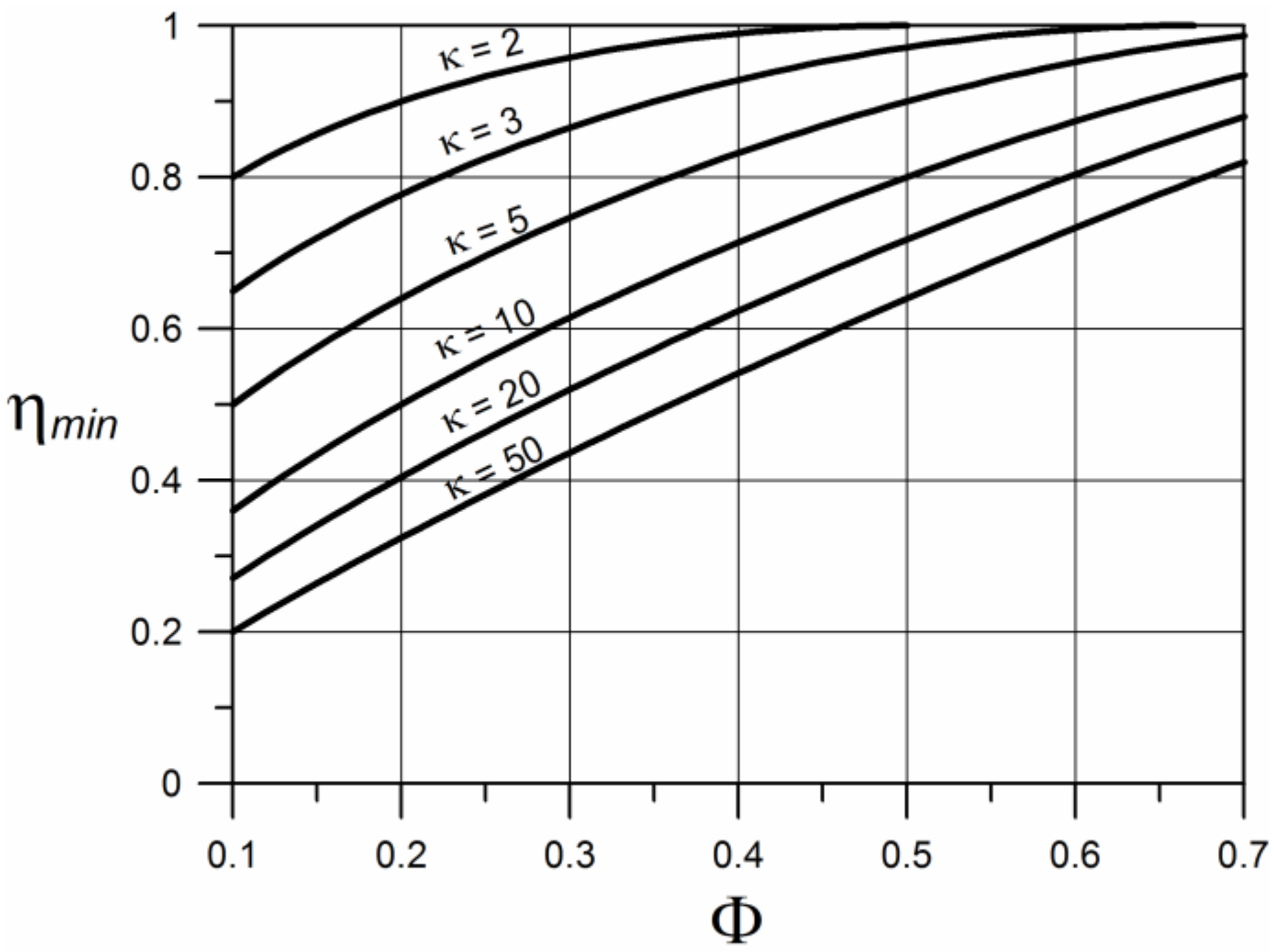

In

Figure 10, the courses of the function

η =

F1(

ρ,

κ) are shown for a constant value of the dimensionless temperature

Φ. In contrast, in

Figure 11, the courses of the function

η =

F2 (

ρ,

Φ) are depicted for a constant value of the pricing parameter

κ.The value of

ρopt, for which

η is minimal at fixed values of

κ and

Φ, was determined analytically. A necessary condition for the existence of an extremum of a function is the zeroing of the first derivative. The first derivative of the function

η =

f(

ρ) is

whereas the second derivative,

is always positive since

κ > 1; 0 <

Φ < 1 and

Φ < ρ < 1. By setting the first derivative to zero, the result is

from which it follows that the optimal position of the ATI layer corresponds to the following value of dimensionless resistance

ρ:

By substituting

ρopt into relationship (25), one obtains the value

η, corresponding to the extremum of the function:

This is the minimum value of η since the second derivative of the function η = f (ρ) is positive. The problem of determining the optimum ATI layer location is, therefore, reduced to the estimation of ρopt for specific values of Φ and κ. The economic effect of replacing passive insulation with an ATI layer is represented by ηmin, which can be determined from formula (30).

It can be seen from

Figure 12 and

Figure 13 that the smaller the

Φ (larger

Tf and/or smaller

Te), the lower the total heating costs and the closer to the inside surface of the envelope the ATI layer should be installed. The influence of the parameter

κ is evident as well. The greater the

κ (smaller unit cost of heat energy supplied to the ATI layer), the smaller the total heating costs are, and the closer to the environment the ATI layer should be installed.

5. Comparison with Experimental Results

Experimental results were taken from a publication [

15]. The research was conducted in a building located in Nyiregyhaza, Hungary. The building contains a variety of energy-efficient solutions, such as mechanical ventilation with heat recovery, a water–water heat pump, solar collectors, a fireplace with a water jacket, thermally insulated concrete energy storage under the building with a volume of 35 m

3, a horizontal ground exchanger under the building and around the building, and active insulation of the external walls and roof in the form of a coil connected to the ground exchanger located 1.75 m below ground level. The layer of active insulation in the form of pipes embedded in the envelope is located in the layer of reinforced concrete between the two layers of thermal insulation. The pipes with an internal diameter of 20 mm are made of polyethylene. The spacing between the pipes is 0.2 m. The circulation of the working liquid in the system is provided by a 21 W pump. A detailed description of the system can be found in [

15].

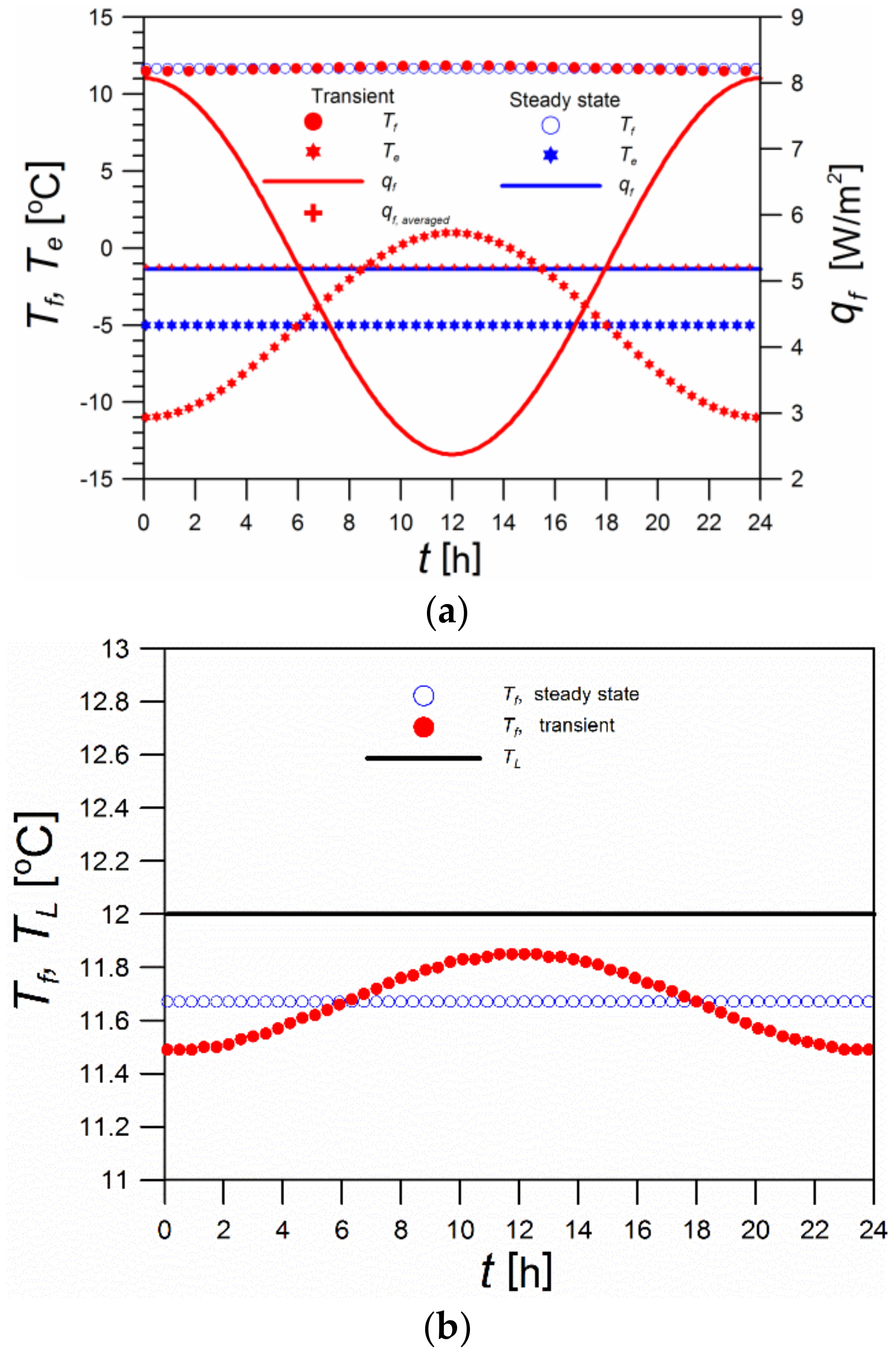

The heating system with active insulation was equipped with measuring devices and was adjusted for the continuous recording of the results. The internal space temperature,

Ti, the outdoor air temperature,

Te, and the temperature of the circulating liquid flowing through the active insulation pipes,

TL (mean value of the inlet and outlet temperatures), were measured. The measurements were performed using digital temperature sensors (DS18B20) with a one-wire interface. The measuring range was from −55 °C to 125 °C. The measuring accuracy was ±0.5 °C [

15]. The results are presented in

Figure 14. Apart from the measurement values, the diagram includes the calculated courses of the dimensionless temperature

Φ, and temperature,

Tf0, determined from relations (3) and (16), respectively.

The value of

ρ = Ri/R was determined based on adding up the thermal resistance of individual envelope layers. The dimensions and materials of the individual envelope layers are presented in [

15]. The following values are obtained:

Ri = 3.57 m

2K/W, and

R = 5.26 m

2K/W; thus,

ρ = 0.678.

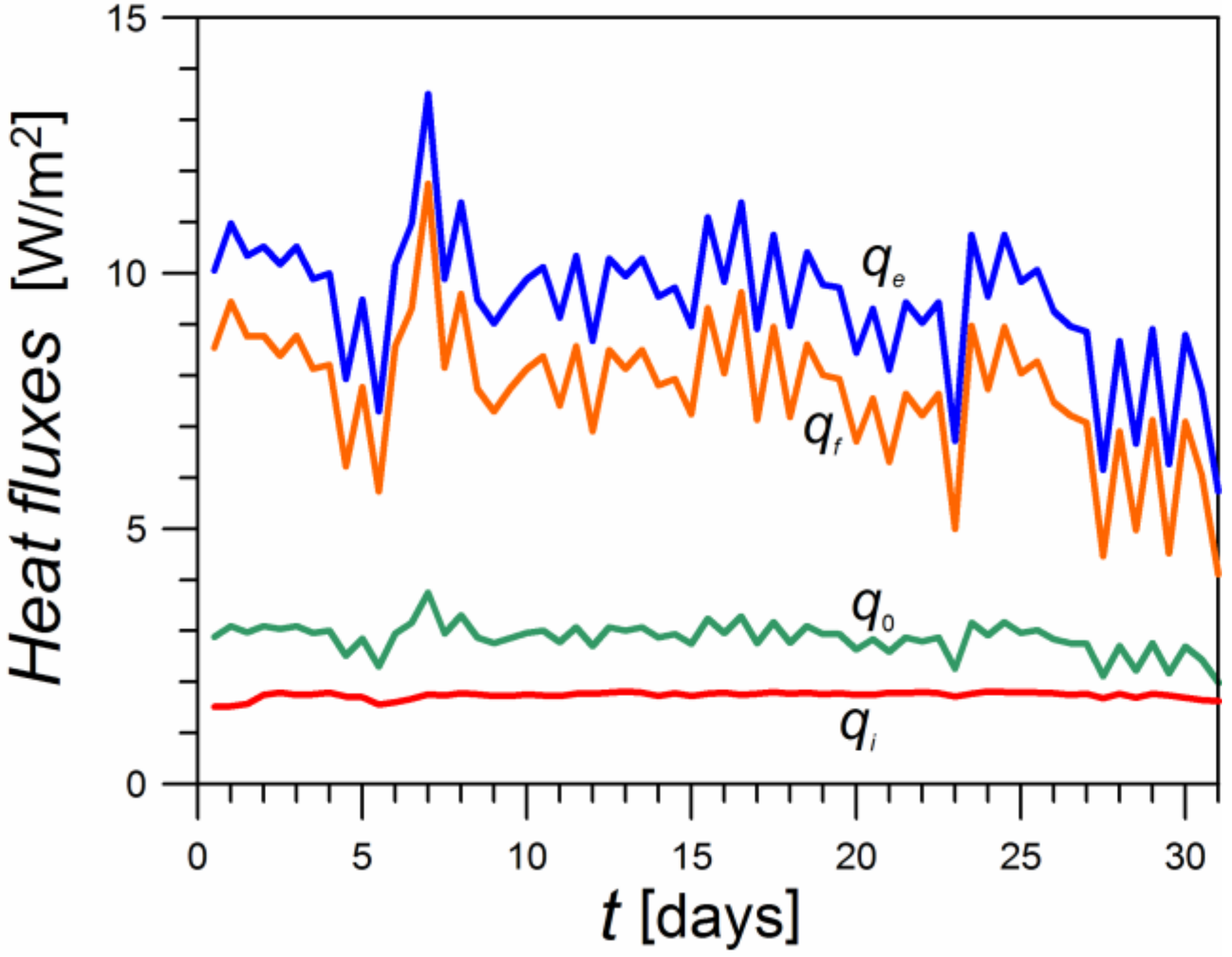

The values of the heat flux were calculated according to relations (8)–(11) and are presented in

Figure 15. The parameter

κ was determined from the formula (

Appendix B):

where

COP—coefficient of performance of the space heating heat pump;

Npump—the motor power of the pump transporting the working liquid (21 W);

Af—total wall surface area with the ATI layer (314 m2).

Figure 15.

Temporal courses of heat fluxes qi, qe, qf, and q0.

Figure 15.

Temporal courses of heat fluxes qi, qe, qf, and q0.

The calculations were carried out for the pump performance coefficient

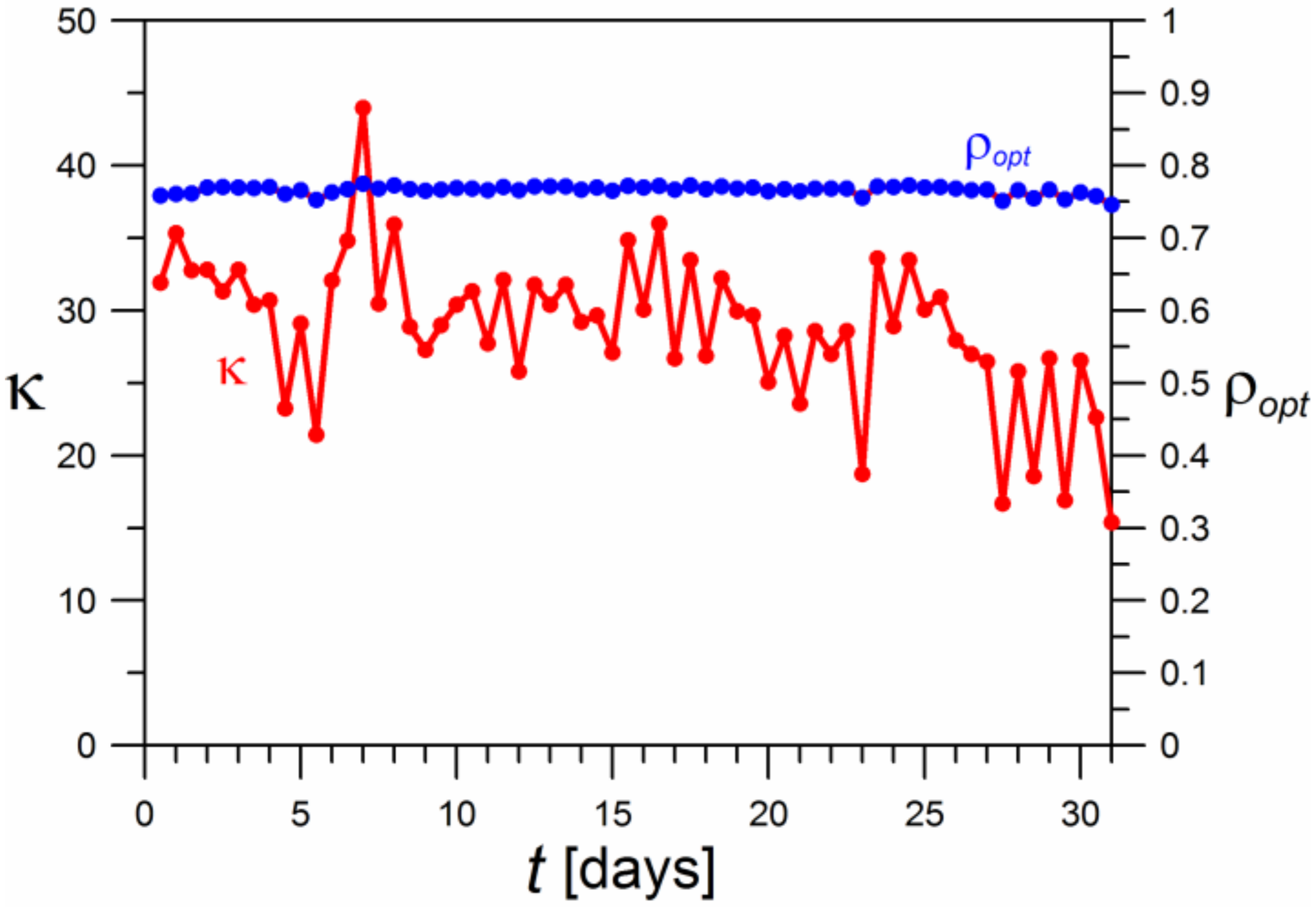

COP = 4.0. The obtained results are presented in

Figure 16. It was found that real

κ values show some scatter, but their average value can be estimated as approximately 25–30. For the

κ values estimated in this manner, the corresponding

ρopt values defining the optimum location of the ATI layer in the envelope were calculated according to formula (29). A value of

ρopt ≈ 0.77 was obtained.

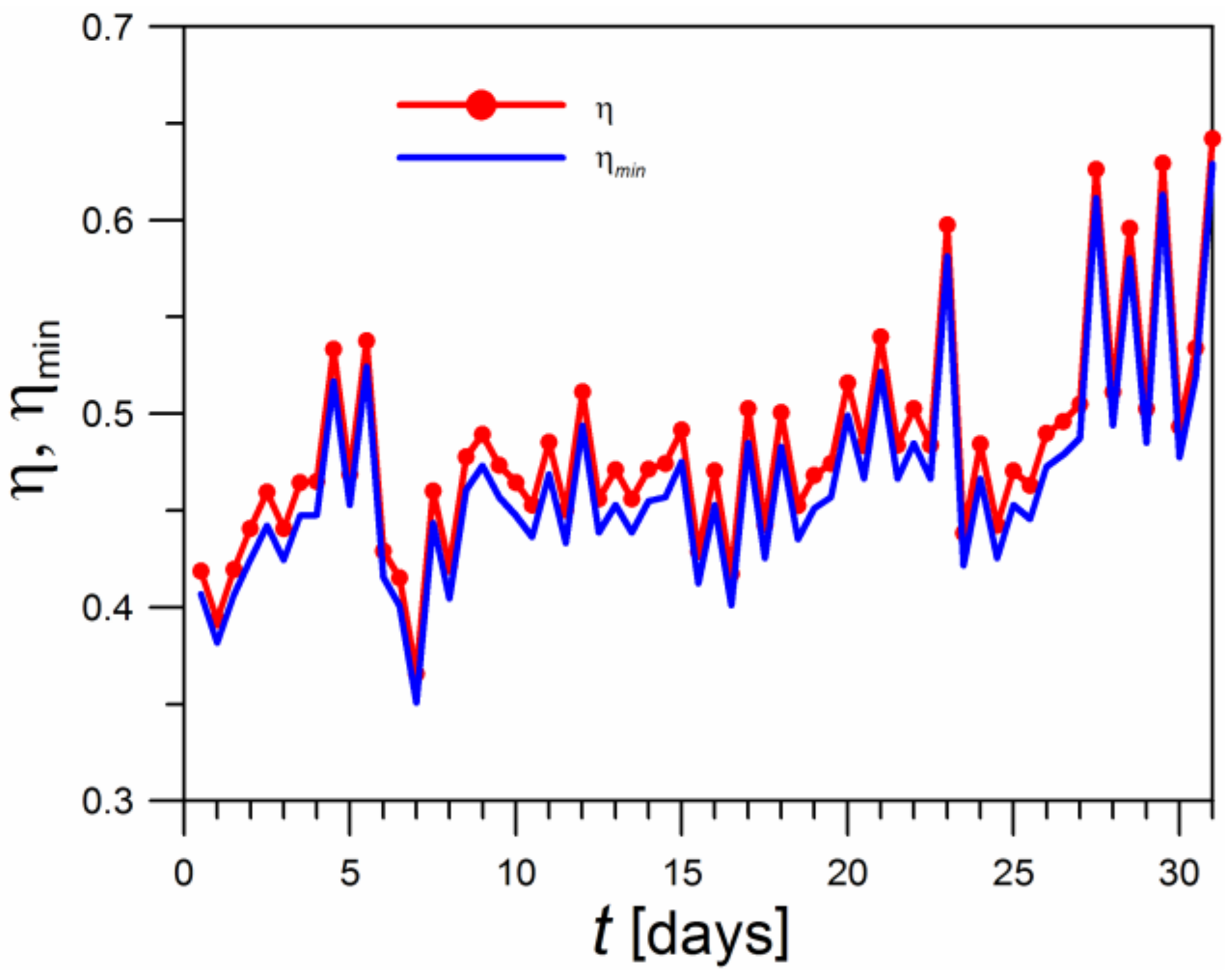

In

Figure 17, the results of calculating the economic benefits of using an active insulation layer are shown. The economic factor

η was used for this assessment. Its actual values have been determined according to Equation (25) and are depicted as symbols. Values of

η in the range of 0.4–0.6 were obtained. If instead of the actual value of the resistance ratio

ρ = 0.678, the values of

ρopt corresponding to the optimal location of the ATI layer (shown in

Figure 16) are used, the

ηmin values, calculated according to Equation (30), are slightly lower (the energy saving would be higher). Consequently, it should be considered that the value of

ρ = 0.678, which determines the location of the ATI layer under the measurement conditions, is somewhat underestimated. The placement of the pipes corresponding to a value of

ρ = 0.77, i.e., closer to the external surface of the envelope, would be more beneficial. However, the expected differences in savings due to a location change would be slight.