High-Impact Resistance of Textile/Fiber-Reinforced Cement-Based Composites: Experiment and Theory Analysis

Abstract

1. Introduction

2. Experiment Program

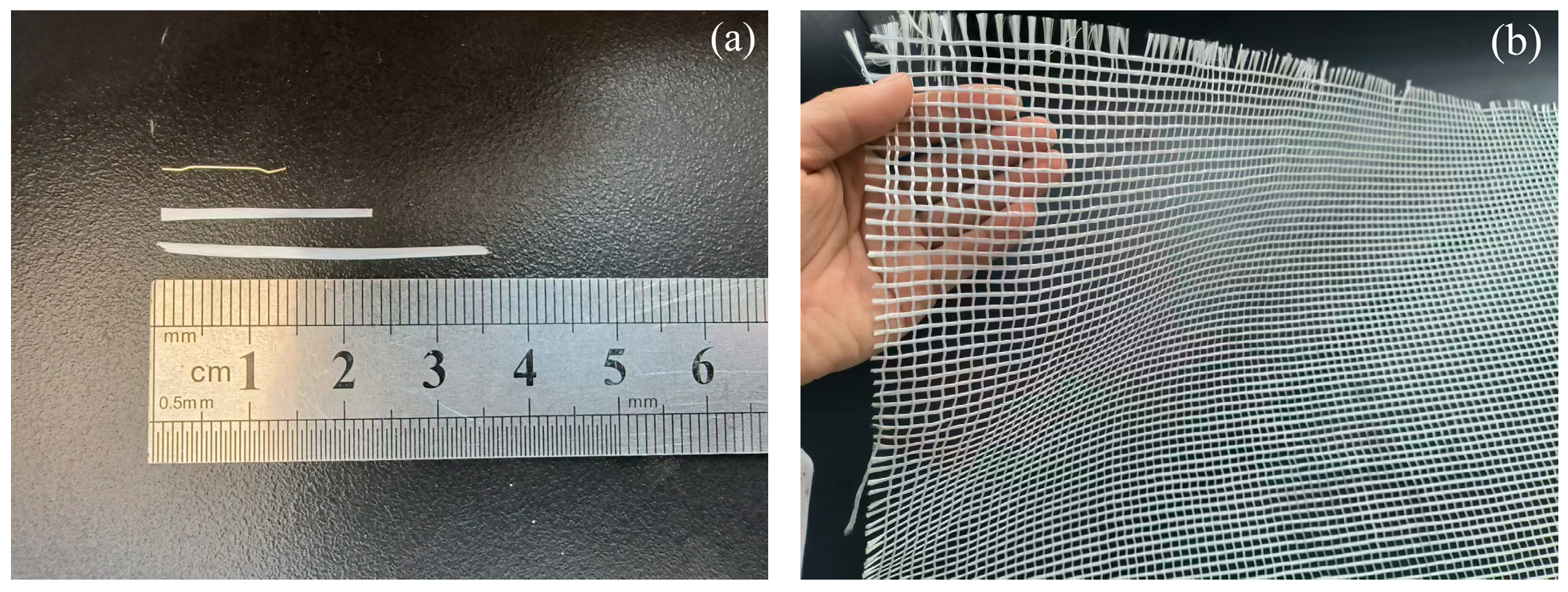

2.1. Material Properties and Mix Proportions

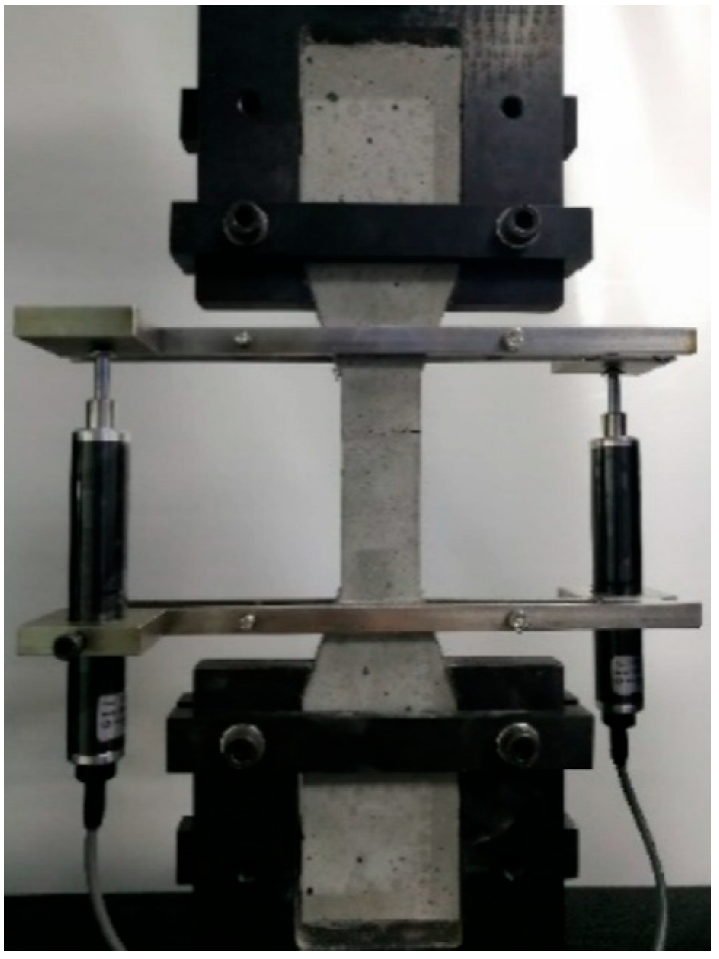

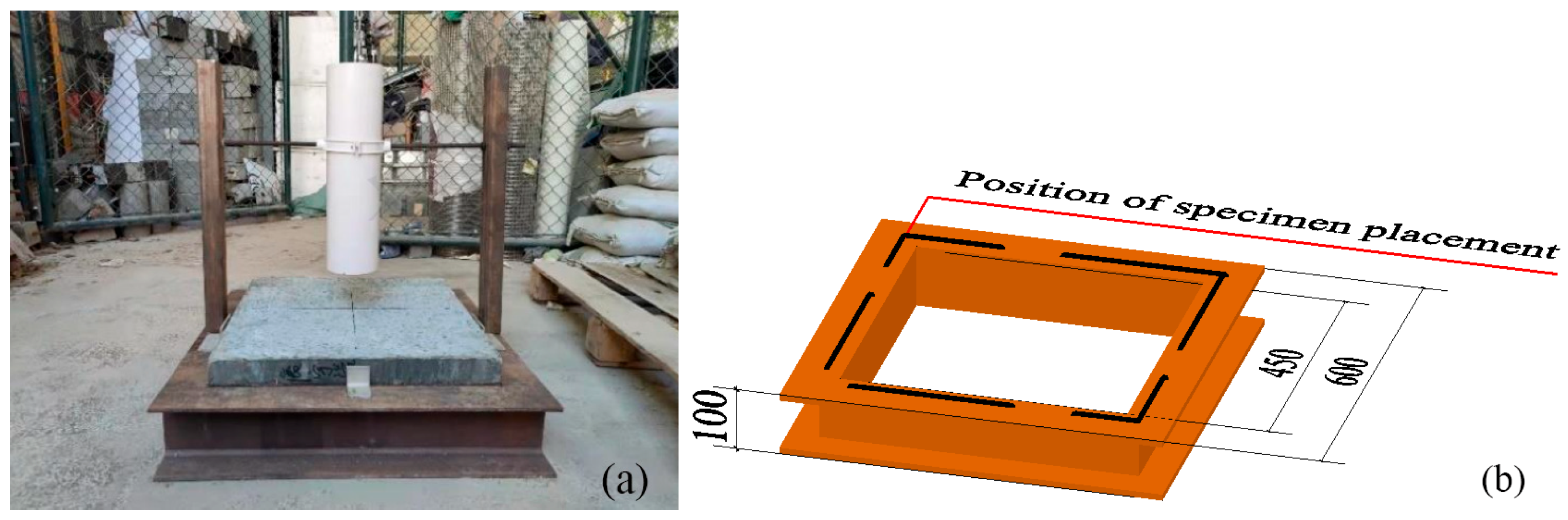

2.2. Testing Methods

2.2.1. Fabrication and Maintenance of the Specimen

2.2.2. Compression Test

2.2.3. Tension Test

2.2.4. Drop Weight Impact Tests

3. Results and Analysis

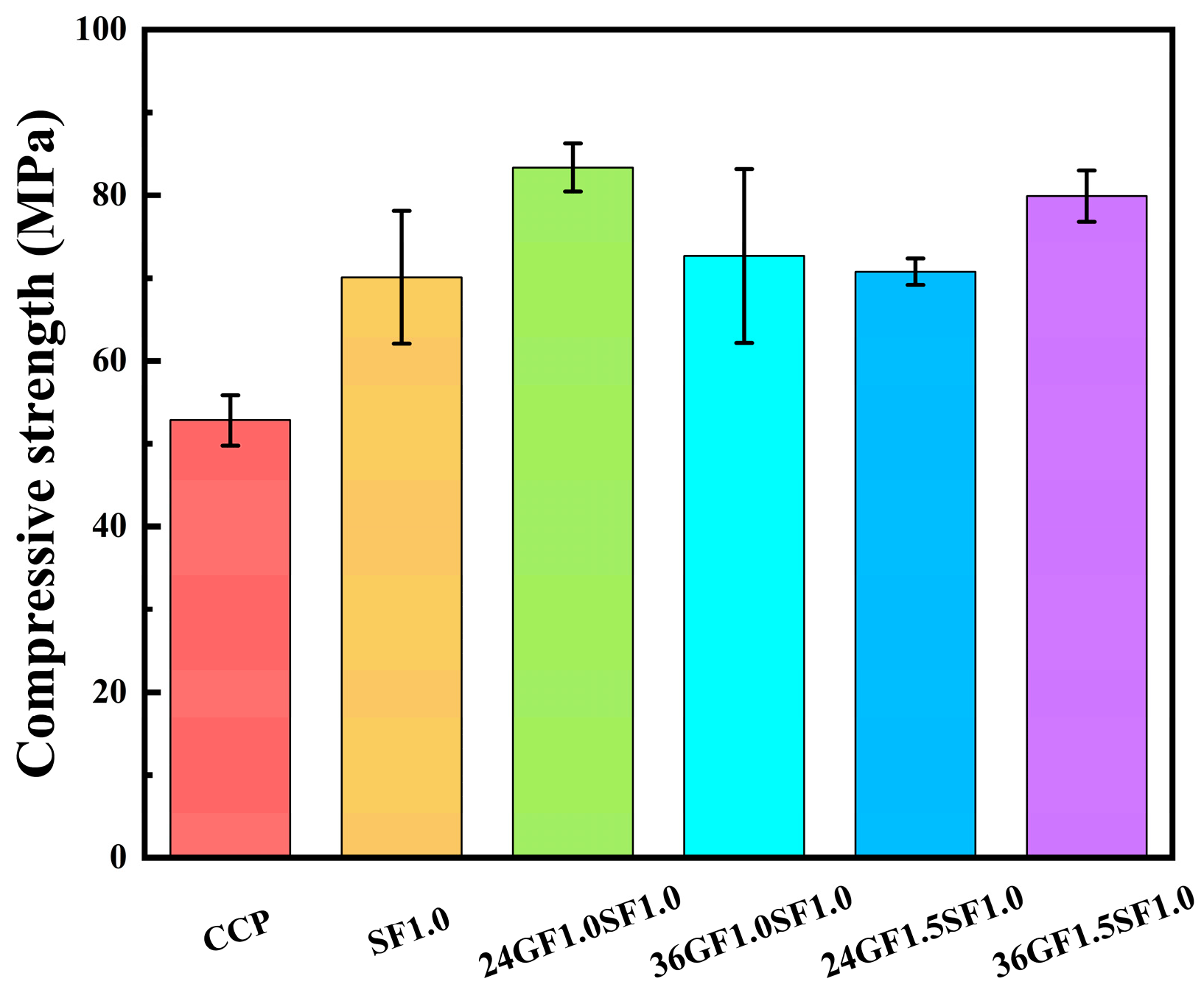

3.1. Explore the Mechanical Properties of Glass Fiber- and Steel Fiber-Reinforced Specimens

3.2. Impact Resistance

3.2.1. The Development Process of Impact Cracks

- Crack initiation stage: as the number of impacts increases, the bottom surface of the specimen transitions from having no cracks to developing the first visible crack.

- Stable crack development stage: with further increases in the number of impacts, cracks on the bottom surface of the specimen develop stably.

- Accelerated crack development stage: as the number of impacts increases, new cracks appear less frequently, while existing cracks lengthen rapidly, leading to final specimen failure.

3.2.2. The Effect of Glass Fiber Volume on the Impact Resistance of the Specimen

3.2.3. The Effect of Short Glass Fiber Length on the Impact Resistance of the Specimen

3.2.4. The Effect of the Number of Glass Fiber Textile Layers on the Impact Resistance of the Specimen

3.2.5. Testing the Addition of the Same Volume Fraction of Glass Fiber Fabric and Glass Fiber to Compare the Impact Resistance of the Sample

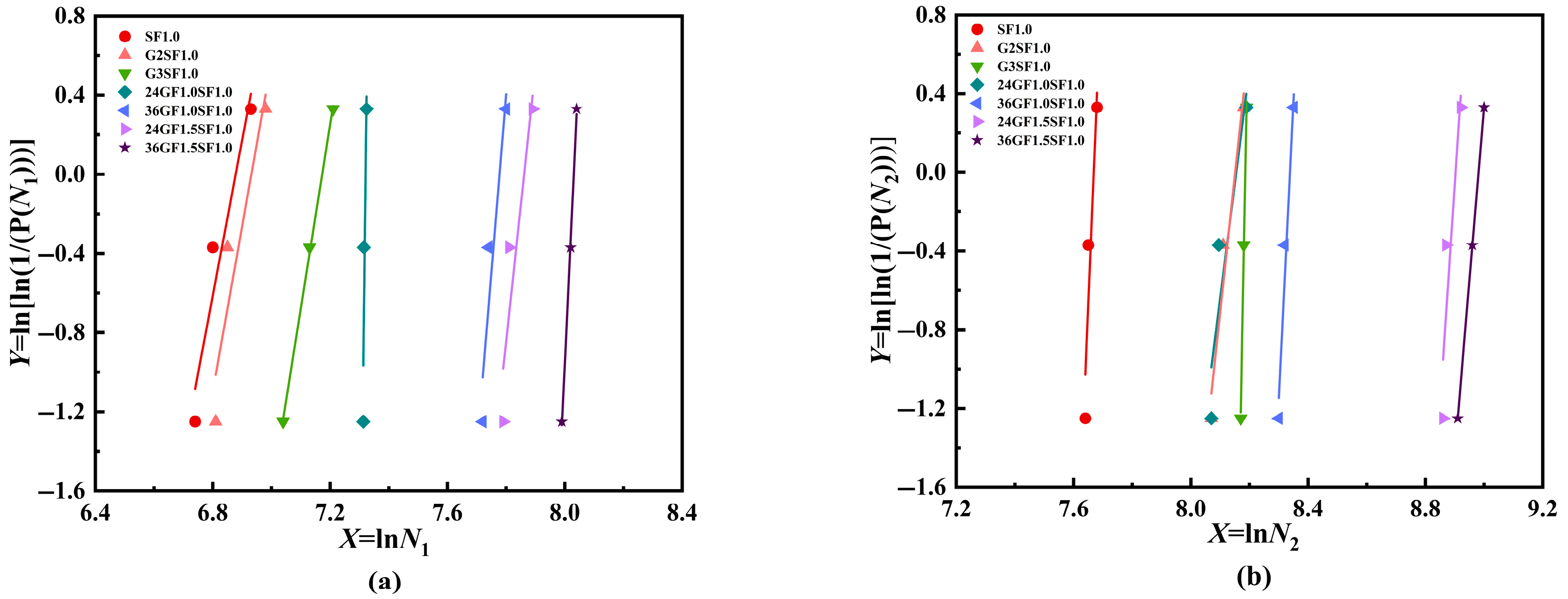

4. Impact Life and Damage Analysis Based on the Weibull Distribution

4.1. Distribution of the Impact Number

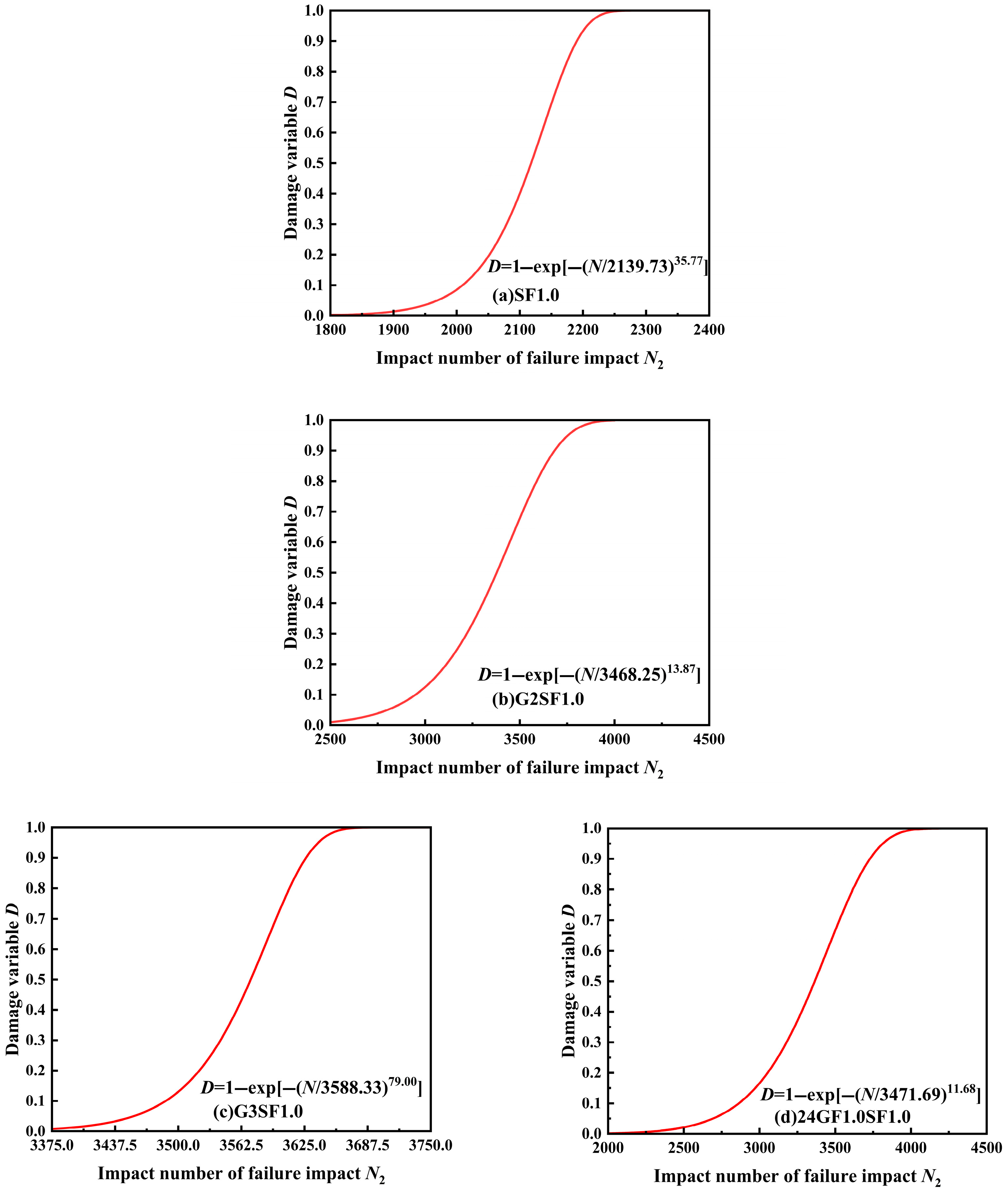

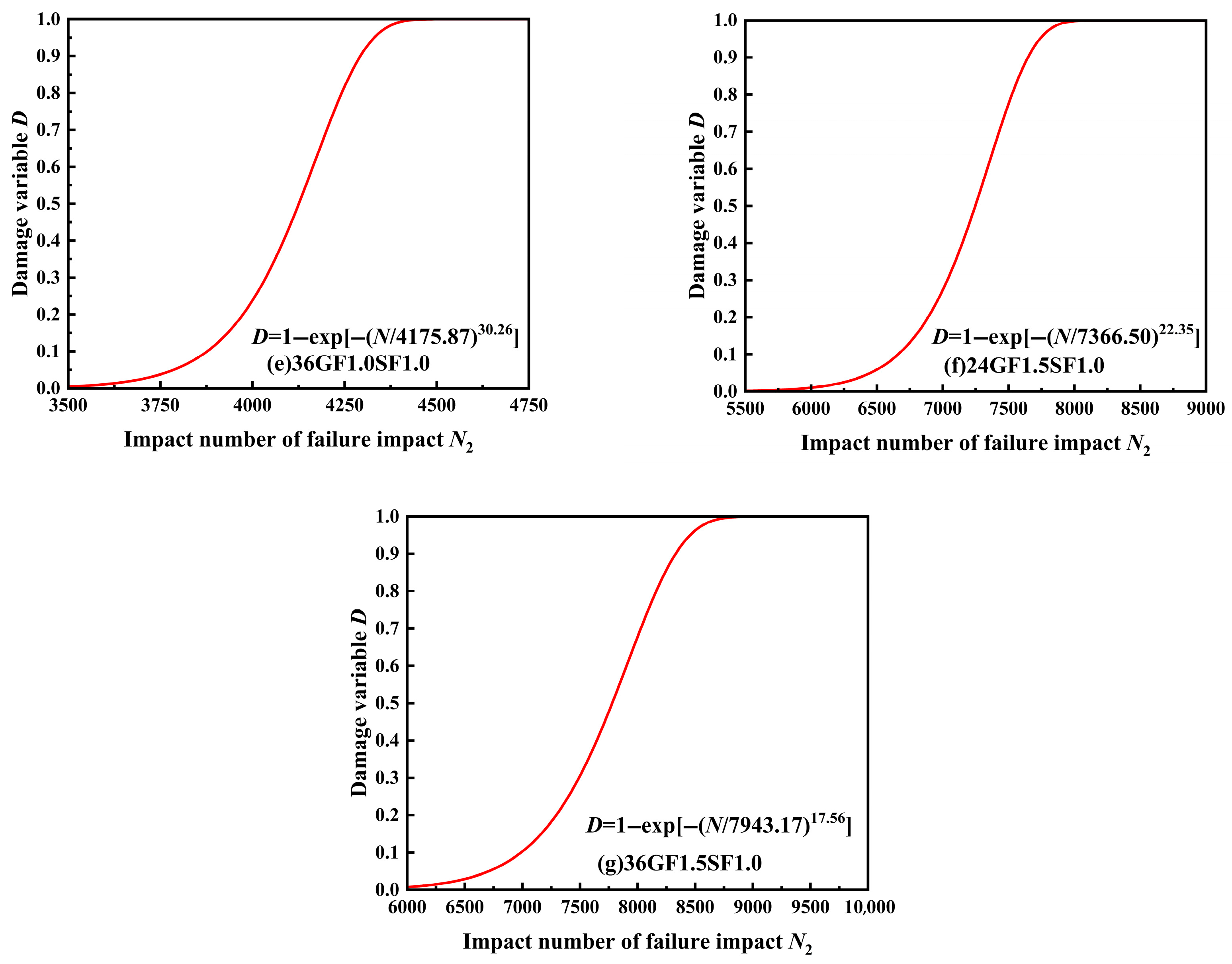

4.2. Impact Damage Evolution Equation

5. Conclusions

- High-modulus fibers dissipate more impact energy under the same deformation compared to low-modulus fibers, leading to better utilization of the spring effect and restraining crack propagation. As a result, the failure mode of the fiber-reinforced specimens in this experiment is characterized by localized punching shear damage occurring only in the impacted site, without the specimen fracturing into multiple pieces.

- The impact resistance of specimens increases with the increase in glass fiber volume fraction, length, and the number of textile layers. A specimen combined with 1.5 vol% 36 mm length glass fibers and 1.0 vol% steel fibers exhibited ultra-high impact resistance, achieving a failure impact energy of 114 kJ.

- At the same volume fraction, compared with the combination of glass fiber textile and steel fiber, the combination of glass fiber and steel fiber can better improve the impact resistance of the specimen. This is because glass fibers and steel fibers form a network structure in the matrix, while the glass fiber textile only reinforces the lower part of the specimen.

- The damage evolution equation established based on a two-parameter Weibull distribution accurately describes the distribution characteristics of the impact numbers of fiber reinforced specimens, guiding structural design under different failure probabilities.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Gemeel, A.N.; Zhuge, Y.; Youssf, O. Experimental investigation of basalt textile reinforced engineered cementitious composite under apparent hoop tensile loading. J. Build. Eng. 2019, 23, 270–279. [Google Scholar] [CrossRef]

- Yu, K.Q.; Wang, Y.C.; Yu, J.T.; Xu, S.L. A strain-hardening cementitious composites with the tensile capacity up to 8%. Constr. Build. Mater. 2017, 137, 410–419. [Google Scholar] [CrossRef]

- Yu, J.; Leung, C.K.Y. Strength improvement of strain-hardening cementitious composites with ultrahigh-volume fly ash. J. Mater. Civ. Eng. 2017, 9, 05017003. [Google Scholar] [CrossRef]

- Lu, C.; Yu, J.; Leung, C.K.Y. Tensile performance and impact resistance of strain hardening cementitious composites (SHCC) with recycled fibers. Constr. Build. Mater. 2018, 171, 566–576. [Google Scholar] [CrossRef]

- Huang, B.T.; Zhu, J.X.; Weng, K.F.; Li, V.C.; Dai, J.G. Ultra-high-strength engineered/strain-hardening cementitious composites (ECC/SHCC): Material design and effect of fiber hybridization. Cem. Concr. Res. 2022, 129, 104464. [Google Scholar] [CrossRef]

- Yu, K.Q.; Zhu, W.J.; Ding, Y.; Lu, Z.D.; Yue, J.T.; Xiao, J.Z. Micro-structural and mechanical properties of ultra-high performance engineered cementitious composites (UHP-ECC) incorporation of recycled fine powder (RFP). Cem. Concr. Res. 2019, 124, 125–134. [Google Scholar] [CrossRef]

- Zhou, J.; Qian, S.Z.; Beltran, M.G.S.; Ye, G.; Breugel, K.; Li, V.C. Development of engineered cementitious composites with limestone powder and blast furnace slag. Mater. Struct. 2010, 6, 803–814. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Wang, Y.C.; Xu, D.L.; Li, S. Mechanical performance and hydration mechanism of geopolymer composite reinforced by resin. Mater. Sci. Eng. A 2010, 527, 24–25. [Google Scholar] [CrossRef]

- Akcay, B. Experimental investigation on uniaxial tensile strength of hybrid fibre concrete. Compos. Part B Eng. 2012, 2, 766–778. [Google Scholar] [CrossRef]

- Li, V.C. Tailoring ECC for special attributes: A review. Int. J. Concr. Struct. Mater. 2012, 3, 135–144. [Google Scholar] [CrossRef]

- Singh, M.; Saini, B.; Chalak, H.D. Performance and composition analysis of engineered cementitious composite (ECC)—A review. J. Build. Eng. 2019, 26, 100851. [Google Scholar] [CrossRef]

- Liao, Q.; Su, Y.R.; Yu, J.T.; Yao, Q.Y.; Meng, D.; Yu, K.Q. Experimental and theoretical investigation on compression-shear properties of high-strength engineered cementitious composites (HS-ECC). J. Build. Eng. 2023, 67, 106015. [Google Scholar] [CrossRef]

- Xu, S.L.; Cai, X.R. Experimental study and theoretical models on compressive properties of ultrahigh toughness cementitious composites. J. Mater. Civ. Eng. 2010, 10, 1067–1077. [Google Scholar] [CrossRef]

- Ding, Z.D.; Wen, J.C.; Li, X.Q.; Fu, J.; Ji, X.F. Mechanical behaviour of polyvinyl alcohol-engineered cementitious composites (PVA-ECC) tunnel linings subjected to vertical load. Tunneling Undergr. Space Technol. 2020, 95, 103151. [Google Scholar] [CrossRef]

- Maalej, M.; Quek, S.T.; Zhang, J. Behavior of hybrid-fiber engineered cementitious composites subjected to dynamic tensile loading and projectile impact. J. Mater. Civ. Eng. 2005, 2, 143–152. [Google Scholar] [CrossRef]

- Li, Q.H.; Zhao, X.; Xu, S.L.; Gao, X. Influence of steel fiber on dynamic compressive behavior of hybrid fiber ultra high toughness cementitious composites at different strain rates. Constr. Build. Mater. 2016, 125, 490–500. [Google Scholar] [CrossRef]

- Zhu, D.; Mobasher, B.; Rajan, S.D. Non-contacting strain measurement for cement-based composites in dynamic tensile testing. Cem. Concr. Compos. 2012, 2, 147–155. [Google Scholar] [CrossRef]

- Truong, V.D.; Noh, H.W.; Kim, D.J. Effects of adding short fibers on impact resistance of glass textile reinforced cementitious composites under direct tension. Constr. Build. Mater. 2023, 379, 131220. [Google Scholar] [CrossRef]

- Heravi, A.A.; Fuchs, A.; Gong, T. Mechanical characterization of textile reinforced cementitious composites under impact tensile loading using the split Hopkinson tension bar. Cem. Concr. Compos. 2020, 114, 103769. [Google Scholar] [CrossRef]

- Truong, V.D.; Noh, H.W.; Kim, D.J. Rate-sensitive tensile resistance of glass textile reinforced cementitious composites. Constr. Build. Mater. 2022, 360, 129553. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, D.; Ou, Y. Impact response of basalt textile reinforced concrete subjected to different velocities and temperatures. Constr. Build. Mater. 2018, 175, 381–391. [Google Scholar] [CrossRef]

- Zeng, X.D. Research on impact resistance of modified bamboo fiber cement-based composites. Cent. South Univ. For. Technol. 2022, 12, 000344. [Google Scholar]

- Wang, D.H.; Ju, Y.Z.; Shen, H.; Xu, L.B. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Fu, Q.; Niu, D.T.; Zhang, J.; Huang, D.G.; Hong, M.S. Impact response of concrete reinforced with hybrid basalt-polypropylene fibers. Powder Technol. 2018, 326, 411–424. [Google Scholar] [CrossRef]

- Lin, J.X.; Song, Y.; Xie, Z.H.; Guo, Y.C.; Yuan, B.; Zeng, J.J.; Wei, X. Static and dynamic mechanical behavior of engineered cementitious composites with PP and PVA fibers. J. Build. Eng. 2020, 29, 101097. [Google Scholar] [CrossRef]

- CECS 13-2009; Standard Test Methods for Fiber Reinforced Concrete. CECS: Beijing, China, 2009.

- JC/T 2461-2018; MIIT Standard Test Method for the Mechanical Properties of Ductile Fiber Reinforced Cementitious Composites. MIIT: Beijing, China, 2018.

- ACI544.2R-89; American Concrete Institute Measurement of Properties of Fiber Reinforced Concrete. American Concrete Institute: Farmington Hills, MI, USA, 1989.

- Singh, S.P.; Kaushik, S.K. Flexural fatigue life distributions and failure probability of steel fibrous concrete. ACI Mater. J. 2000, 6, 658–667. [Google Scholar]

- Chen, X.D.; Liu, Z.H.; Guo, S.S.; Huang, Y.B.; Xu, W.L. Experimental study on fatigue properties of normal and rubberized self-compacting concrete under bending. Constr. Build. Mater. 2019, 205, 10–20. [Google Scholar] [CrossRef]

- Asrani, N.P.; Murali, G.; Parthiban, K. A feasibility of enhancing the impact resistance of hybrid fibrous geopolymer composites: Experiments and modelling. Constr. Build. Mater. 2019, 203, 56–68. [Google Scholar] [CrossRef]

- Rahmani, T.; Kiani, B.; Shekarchi, M.; Safari, A. Statistical and experimental analysis on the behavior of fiber reinforced concretes subjected to drop weight test. Constr. Build. Mater. 2012, 37, 360–369. [Google Scholar] [CrossRef]

- Chang, T.P. Performance comparison of six numerical methods in estimating weibull parameters for wind energy application. Appl. Energy 2011, 1, 272–282. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Karthikeyan, K.; Haridharan, M.K.; Amran, M.; Siva, A. Low-velocity impact response of novel prepacked expanded clay aggregate fibrous concrete produced with carbon nano tube, glass fiber mesh and steel fiber. Constr. Build. Mater. 2021, 284, 122749. [Google Scholar] [CrossRef]

- Mahesh, S.; Phoenix, S.L.; Beyerlein, I.J. Strength distributions and size effects for 2D and 3D composites with weibull fibers in an elastic matrix. Int. J. Fract. 2002, 1, 41–85. [Google Scholar] [CrossRef]

| Fiber | Density/(g·cm−3) | Length/mm | Diameter/μm | Tensile Strength/MPa | Elastic Modulus/GPa |

|---|---|---|---|---|---|

| Glass Fiber | 2.68 | 24/36 | 14/19 | 1700 | 72 |

| Steel Fiber | 7.85 | 13 | 22 | 2500 | 200 |

| Product Single Weight/(g/m2) | Textile Size/mm | Tensile Fracture Force/(N/50 mm) | |

|---|---|---|---|

| Warp Tarn | Weft Yarn | ||

| 220 | 6 × 6 | ≥1600 | ≥1600 |

| Cement | GGBFS | Sand | Water | Water Reducer |

|---|---|---|---|---|

| 235 | 941 | 424 | 203 | 17 |

| Group | Textile Layers | Steel Fiber/% | Glass Fiber/% |

|---|---|---|---|

| CCP | 0 | 0 | 0 |

| SF1.0 | 0 | 1.0 | 0 |

| G2SF1.0 | 2 | 1.0 | 0 |

| G3SF1.0 | 3 | 1.0 | 0 |

| 24GF1.0SF1.0 | 0 | 1.0 | 1.0 |

| 36GF1.0SF1.0 | 0 | 1.0 | 1.0 |

| 24GF1.5SF1.0 | 0 | 1.0 | 1.5 |

| 36GF1.5SF1.0 | 0 | 1.0 | 1.5 |

| Group | Tensile Strength/MPa | cov1/% | Peak Strain/% | cov2/% |

|---|---|---|---|---|

| SF1.0 | 5.69 | 3.74 | 0.61 | 2.15 |

| 24GF1.0SF1.0 | 6.09 | 5.21 | 1.10 | 6.59 |

| 24GF1.5SF1.0 | 7.07 | 7.65 | 1.39 | 5.98 |

| 36GF1.0SF1.0 | 6.32 | 2.13 | 1.24 | 3.13 |

| 36GF1.5SF1.0 | 7.18 | 9.21 | 1.45 | 6.75 |

| Group | CV1/% | CV2/% | /kJ | kJ | ||

|---|---|---|---|---|---|---|

| CCP | 1 | 0.00 | 1 | 0.00 | 0.01 | 0.01 |

| SF1.0 | 923 | 9.89 | 2116 | 2.42 | 13.6 | 31.1 |

| G2SF1.0 | 1250 | 8.52 | 3366 | 5.68 | 18.4 | 49.5 |

| G3SF1.0 | 975 | 9.14 | 3560 | 1.15 | 14.3 | 52.3 |

| 24GF1.0SF1.0 | 1506 | 0.56 | 3276 | 2.18 | 22.1 | 48.2 |

| 36GF1.0SF1.0 | 2335 | 4.46 | 4113 | 2.72 | 34.3 | 60.5 |

| 24GF1.5SF1.0 | 2521 | 5.37 | 7211 | 3.52 | 37.1 | 106 |

| 36GF1.5SF1.0 | 3026 | 2.53 | 7752 | 4.50 | 44.5 | 114 |

| Group | ||||||

|---|---|---|---|---|---|---|

| SF1.0 | 7.84 | 35.77 | 53.96 | 274.30 | 0.9774 | 0.8845 |

| G2SF1.0 | 9.30 | 13.87 | 66.74 | 113.06 | 0.9990 | 0.9516 |

| G3SF1.0 | 8.33 | 79.00 | 57.73 | 646.65 | 0.8744 | 0.9957 |

| 24GF1.0SF1.0 | 123.50 | 11.68 | 904.09 | 95.22 | 0.8354 | 0.8563 |

| 36GF1.0SF1.0 | 17.88 | 30.26 | 139.10 | 252.28 | 0.9986 | 0.9645 |

| 24GF1.5SF1.0 | 13.79 | 22.35 | 108.37 | 199.02 | 0.8489 | 0.8239 |

| 36GF1.5SF1.0 | 31.42 | 17.56 | 252.32 | 157.69 | 0.9976 | 0.9999 |

| SF1.0 | G2SF1.0 | G3SF1.0 | 24GF1.0SF1.0 | 36GF1.0SF1.0 | 24GF1.5SF1.0 | 36GF1.5SF1.0 | |

|---|---|---|---|---|---|---|---|

| 0.1 | 2009 | 2949 | 3488 | 2863 | 3877 | 6661 | 6988 |

| 0.2 | 2052 | 3113 | 3521 | 3053 | 3974 | 6888 | 7293 |

| 0.3 | 2079 | 3220 | 3542 | 3178 | 4036 | 7034 | 7490 |

| 0.4 | 2100 | 3304 | 3558 | 3278 | 4084 | 7148 | 7645 |

| 0.5 | 2118 | 3378 | 3572 | 3364 | 4126 | 7247 | 7779 |

| 0.6 | 2135 | 3446 | 3584 | 3446 | 4164 | 7338 | 7904 |

| 0.7 | 2150 | 3515 | 3597 | 3527 | 4202 | 7428 | 8028 |

| 0.8 | 2168 | 3589 | 3610 | 3616 | 4242 | 7525 | 8161 |

| 0.9 | 2190 | 3683 | 3626 | 3729 | 4293 | 7647 | 8330 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Z.; Liu, D. High-Impact Resistance of Textile/Fiber-Reinforced Cement-Based Composites: Experiment and Theory Analysis. Textiles 2025, 5, 26. https://doi.org/10.3390/textiles5030026

Deng Z, Liu D. High-Impact Resistance of Textile/Fiber-Reinforced Cement-Based Composites: Experiment and Theory Analysis. Textiles. 2025; 5(3):26. https://doi.org/10.3390/textiles5030026

Chicago/Turabian StyleDeng, Zongcai, and Dongyue Liu. 2025. "High-Impact Resistance of Textile/Fiber-Reinforced Cement-Based Composites: Experiment and Theory Analysis" Textiles 5, no. 3: 26. https://doi.org/10.3390/textiles5030026

APA StyleDeng, Z., & Liu, D. (2025). High-Impact Resistance of Textile/Fiber-Reinforced Cement-Based Composites: Experiment and Theory Analysis. Textiles, 5(3), 26. https://doi.org/10.3390/textiles5030026