Design Innovation and Thermal Management Applications of Low-Dimensional Carbon-Based Smart Textiles

Abstract

1. Introduction

2. Thermal Conductivity and Flexibility of Low-Dimensional Carbon Materials

2.1. Flexibility and Mechanical Adaptability of Low-Dimensional Carbon Materials

2.2. Mechanisms of Heat Conduction

2.3. Factors Influencing Interfacial Thermal Conductance

2.3.1. Influence of Interfacial Defects

2.3.2. Strength of Interfacial Chemical Bonding

2.4. Size Effects

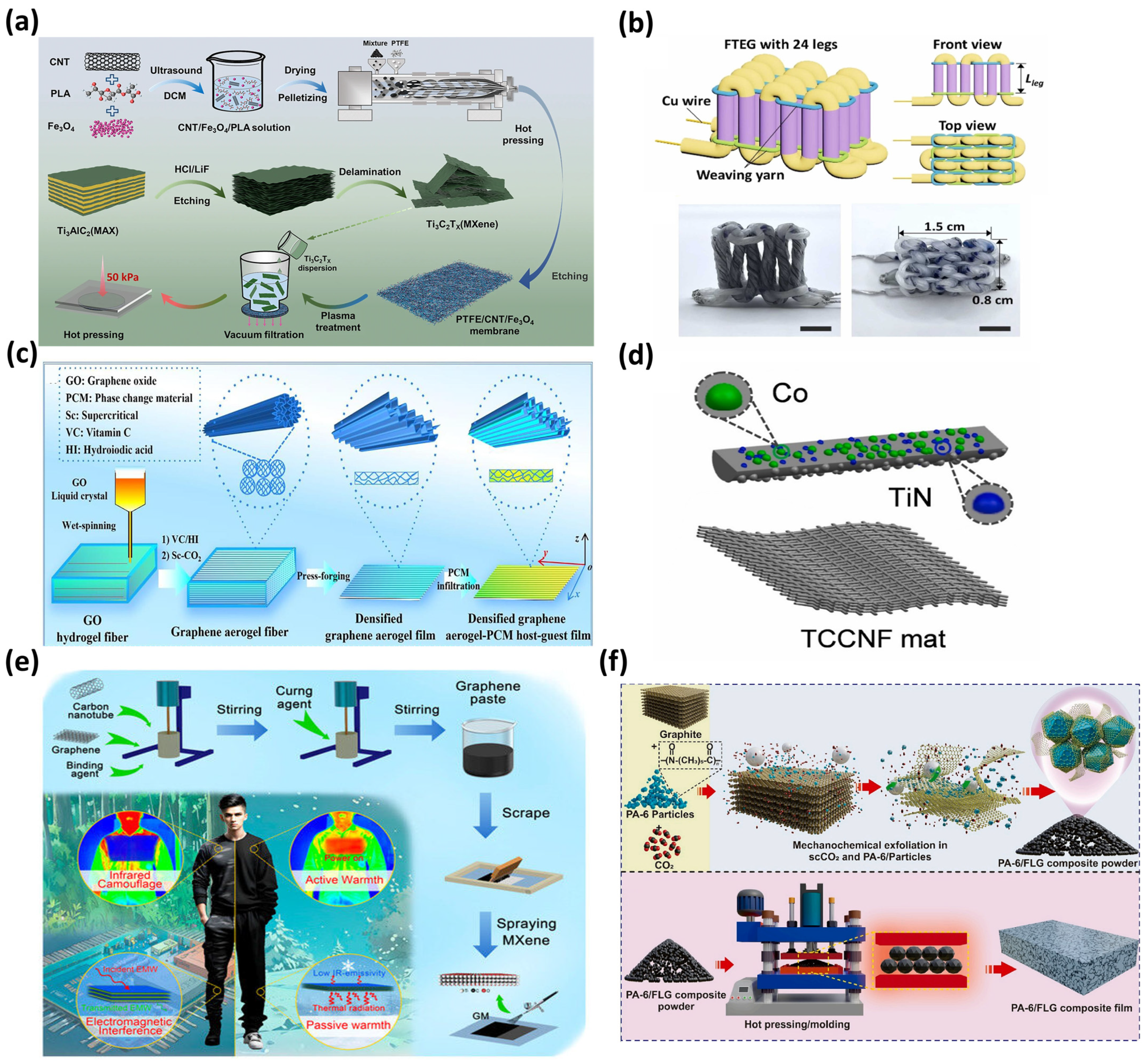

3. Textile Structural Design Strategies and Their Thermal Management Advantages

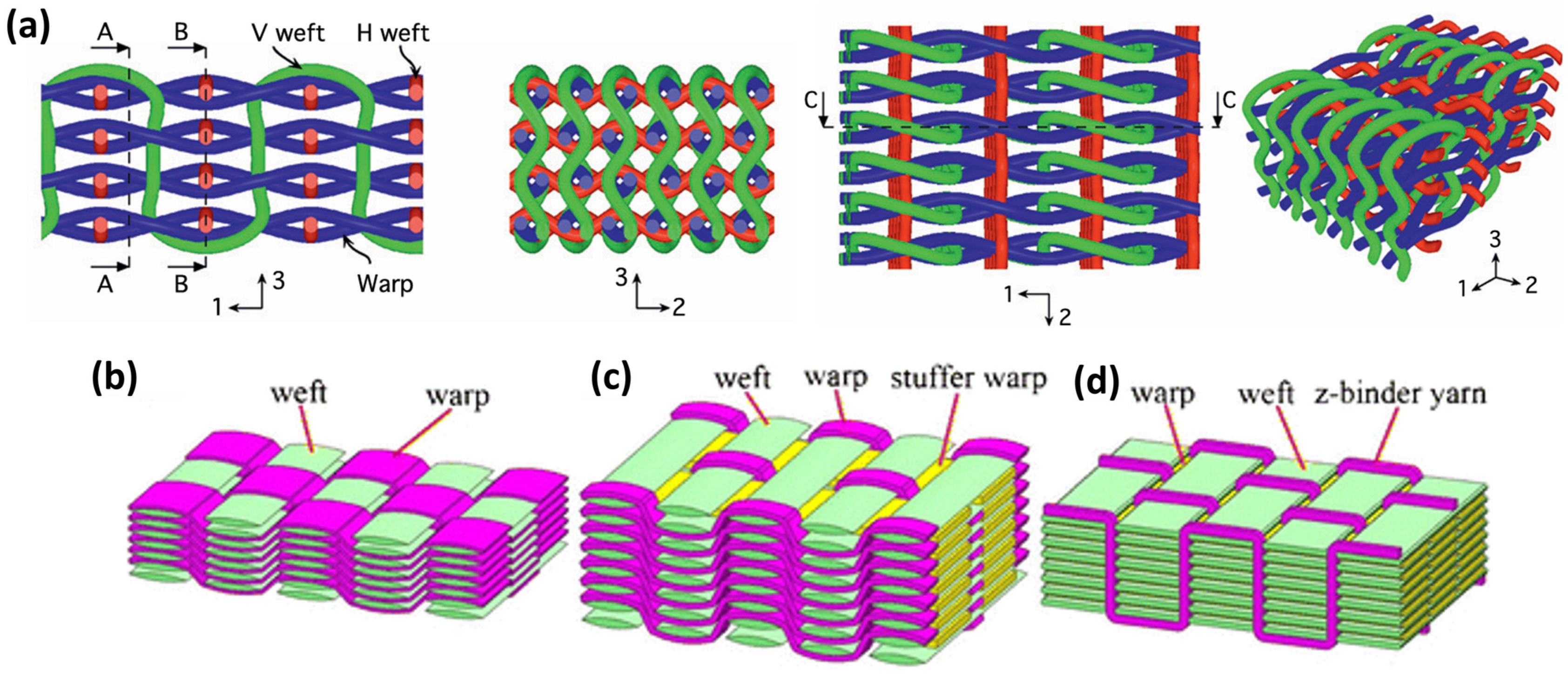

3.1. Classification of Textile Structures

| Structure Type | Representative Materials | Thermal Conductivity (W·m−1·K−1) | Mechanical Flexibility | Wearable Integration | Industrial Compatibility |

|---|---|---|---|---|---|

| 1D | CNT yarns, graphene fibers | ~500–1920 [47,97,98] | Excellent (axial), moderate in bundles | Easy (fiber spinning, coating) | Limited (lab-scale) |

| 2D | Graphene/CNT woven fabrics, ribbon-woven meshes | ~10–1480 [104,105,106,107] | High | Moderate to easy | Compatible with weaving/knitting |

| 3D | Angle-interlock, orthogonal woven composites | ~0.6 (Z-direction) [113] | Moderate | Moderate (requires 3D weaving) | Compatible with 3D textile manufacturing |

| Porous | Graphene foam, CNT sponge | 50–200 [116,117] | good | Low (requires template molding) | Low (complex processing) |

3.2. Performance Enhancement Mechanisms in Thermal Management

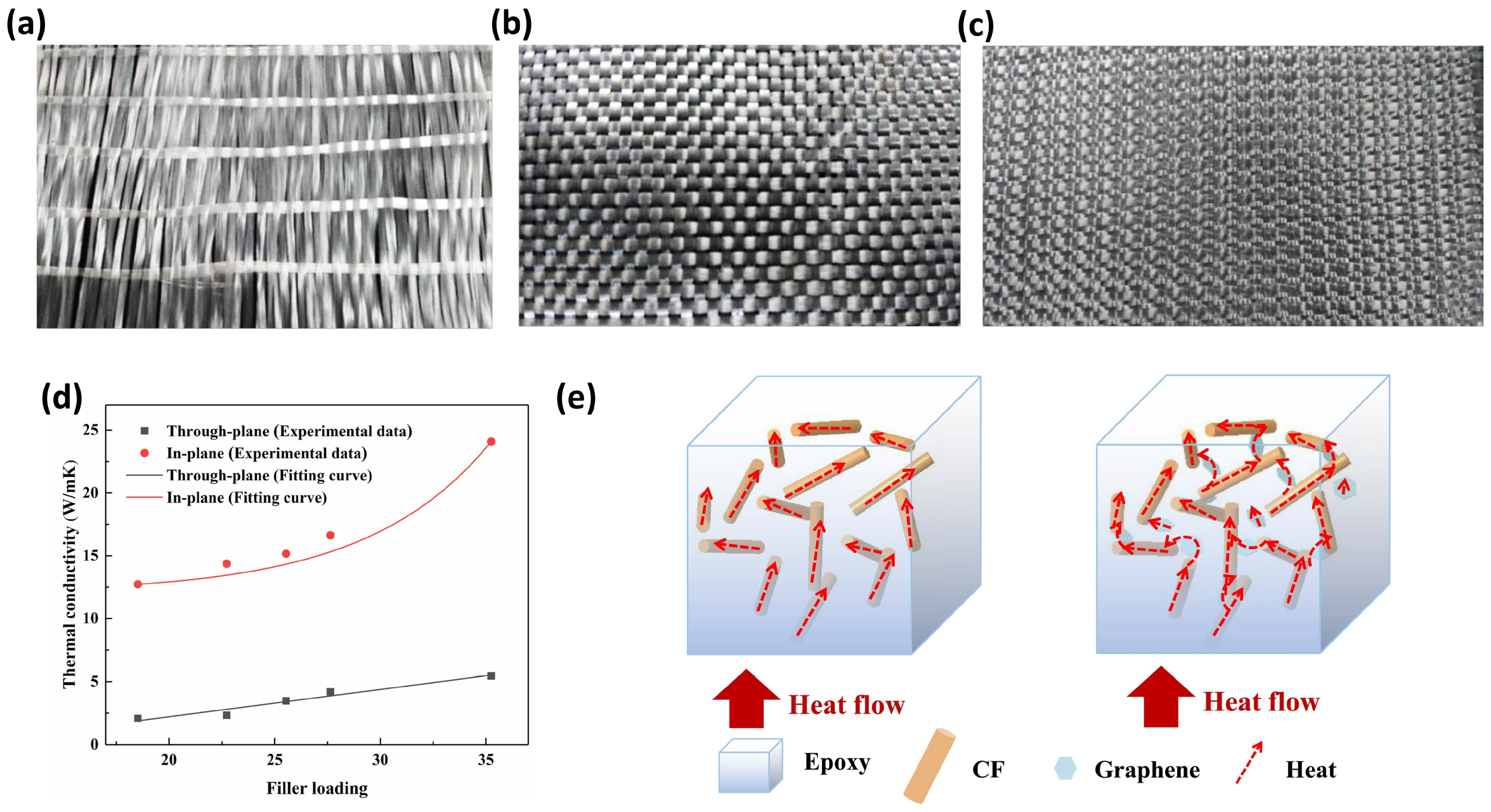

3.2.1. Construction of Multidimensional Heat Conduction Pathways

3.2.2. Pore Structure Regulation and Flexibility Matching

3.2.3. Stress Buffering Mechanisms

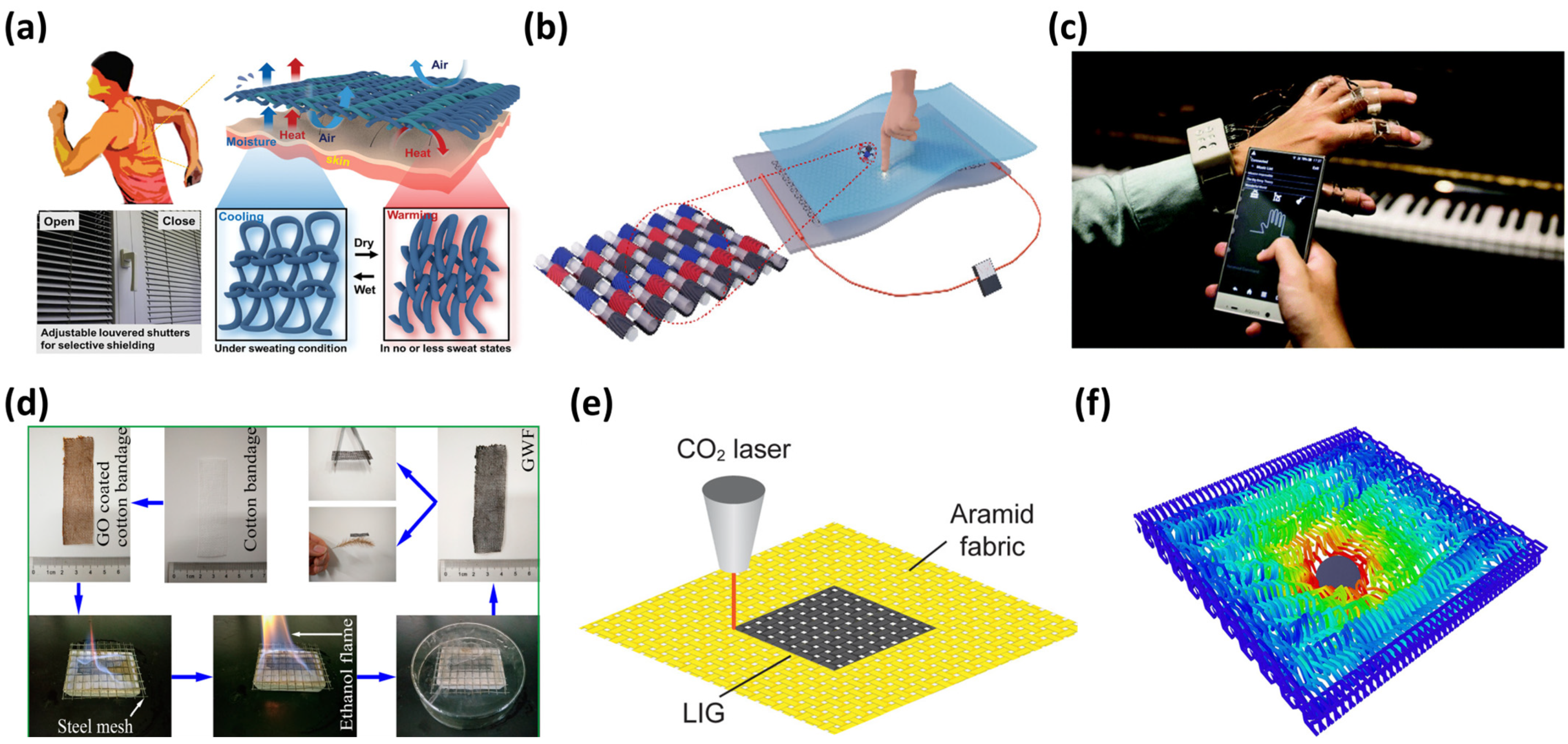

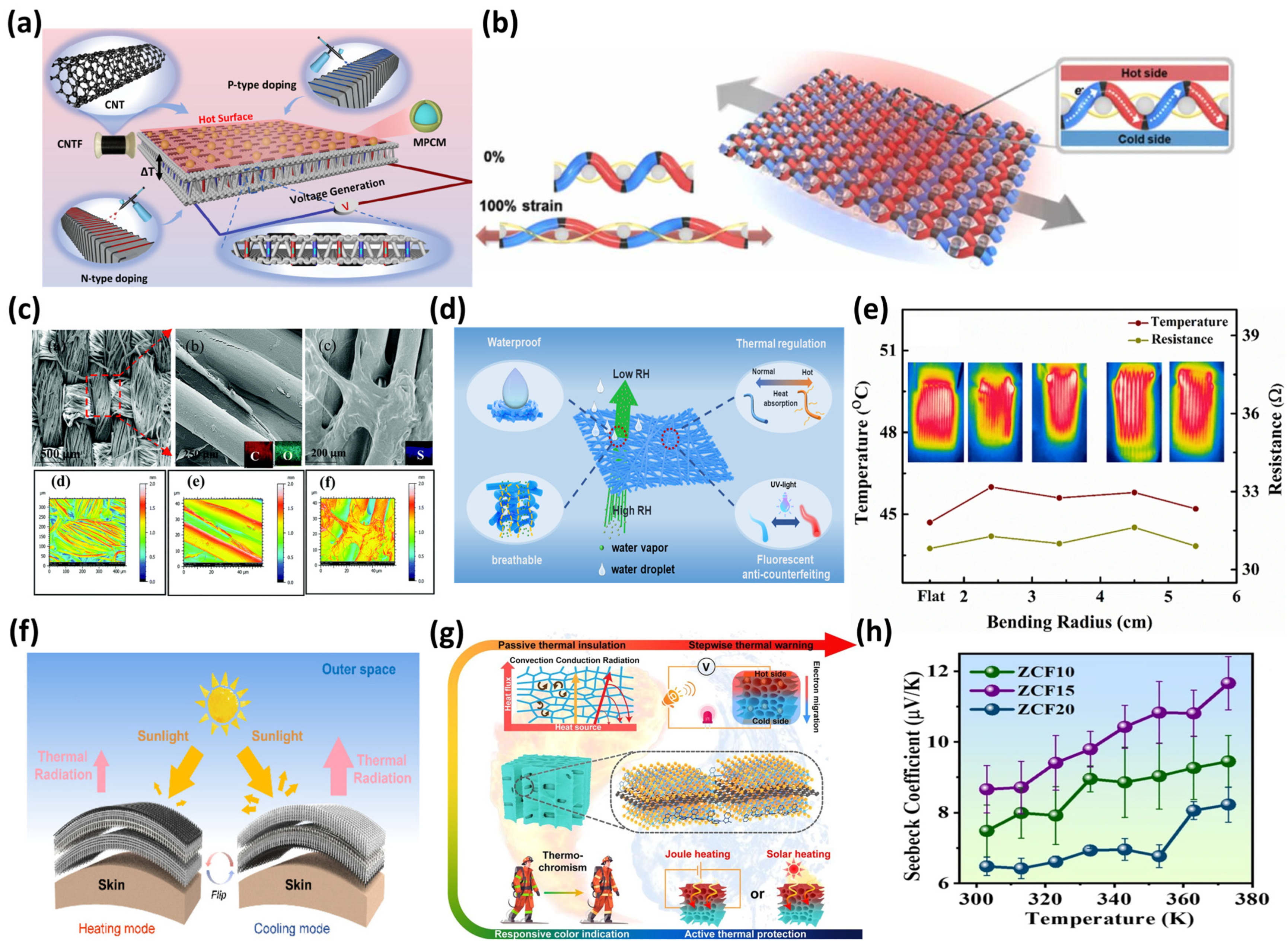

4. Applications of Flexible Thermal Management and Device Performance

4.1. Thermal Management Applications in Wearable Devices

4.2. Interfacial Thermal Regulation in Flexible Electronic Packaging

4.3. Thermal Control Coatings and the Expansion of Infrared Shielding Functions

5. Challenges and Future Prospects

5.1. Fundamental Challenges in Material Design and Multi-Property Integration

5.2. Critical Bottlenecks in Engineering Construction and Industrial Conversion

5.3. Data-Intelligence-Driven Innovations in Structural Design and Advanced Engineering Applications

5.4. Cost and Process Compatibility of Carbon-Based Materials

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Baeg, K.J.; Lee, J. Flexible Electronic Systems on Plastic Substrates and Textiles for Smart Wearable Technologies. Adv. Mater. Technol. 2020, 5, 2000071. [Google Scholar] [CrossRef]

- Rajan, K.; Garofalo, E.; Chiolerio, A. Wearable Intrinsically Soft, Stretchable, Flexible Devices for Memories and Computing. Sensors 2018, 18, 367. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Luo, D.; Li, Q.; Ma, X.; Liu, H.; Liu, L. OTFT Biosensor on Flexible Substrates for Human Health Monitoring: A Review. IEEE Sens. J. 2023, 23, 997–1011. [Google Scholar] [CrossRef]

- Zhao, J.; Lin, Y.; Wu, J.; Nyein, H.Y.Y.; Bariya, M.; Tai, L.; Chao, M.; Ji, W.; Zhang, G.; Fan, Z.; et al. A Fully Integrated and Self-Powered Smartwatch for Continuous Sweat Glucose Monitoring. ACS Sens. 2019, 4, 1925–1933. [Google Scholar] [CrossRef]

- Li, Q.; Xue, Z.; Wu, Y.; Zeng, X. The Status Quo and Prospect of Sustainable Development of Smart Clothing. Sustainability 2022, 14, 990. [Google Scholar] [CrossRef]

- Chang, J.; Meng, C.; Shi, B.; Wei, W.; Li, R.; Meng, J.; Wen, H.; Wang, X.; Song, J.; Hu, Z.; et al. Flexible, breathable, and reinforced ultra-thin Cu/PLLA porous-fibrous membranes for thermal management and electromagnetic interference shielding. J. Mater. Sci. Technol. 2023, 161, 150–160. [Google Scholar] [CrossRef]

- Song, H.; Liu, J.; Liu, B.; Wu, J.; Cheng, H.-M.; Kang, F. Two-dimensional materials for thermal management applications. Joule 2018, 2, 442–463. [Google Scholar] [CrossRef]

- Inagaki, M.; Kaburagi, Y.; Hishiyama, Y. Thermal management material: Graphite. Adv. Eng. Mater. 2014, 16, 494–506. [Google Scholar] [CrossRef]

- Atinafu, D.G.; Yun, B.Y.; Kim, Y.U.; Kim, S. Nanopolyhybrids: Materials, engineering designs, and advances in thermal management. Small Methods 2023, 7, 2201515. [Google Scholar] [CrossRef]

- Newcomb, B.A.; Chae, H.G. 21—The properties of carbon fibers. In Handbook of Properties of Textile and Technical Fibres, 2nd ed.; Bunsell, A.R., Ed.; Woodhead Publishing: Cambridge, UK, 2018; pp. 841–871. ISBN 978-0-08-101272-7. [Google Scholar]

- Xia, K.; Jian, M.; Zhang, Y. Advances in wearable and flexible conductors based on nanocarbon materials. Acta Phys.-Chim. Sin. 2016, 32, 2427–2446. [Google Scholar] [CrossRef]

- Li, Y.; Qian, Y.; Jiang, Q.; Haruna, A.Y.; Luo, Y.; Yang, J. Thermally conductive polymer-based composites: Fundamentals, progress and flame retardancy/anti-electromagnetic interference design. J. Mater. Chem. C 2022, 10, 14399–14430. [Google Scholar] [CrossRef]

- Salunke, D.R.; Gopalan, V. Thermal and Electrical behaviors of Boron Nitride/Epoxy reinforced polymer matrix composite—A review. Polym. Compos. 2021, 42, 1659–1669. [Google Scholar] [CrossRef]

- Hong, H.; Jung, Y.H.; Lee, J.S.; Jeong, C.; Kim, J.U.; Lee, S.; Ryu, H.; Kim, H.; Ma, Z.; Kim, T. Anisotropic Thermal Conductive Composite by the Guided Assembly of Boron Nitride Nanosheets for Flexible and Stretchable Electronics. Adv. Funct. Mater. 2019, 29, 1902575. [Google Scholar] [CrossRef]

- Sha, W.; Xiao, M.; Zhang, J.; Ren, X.; Zhu, Z.; Zhang, Y.; Xu, G.; Li, H.; Liu, X.; Chen, X. Robustly printable freeform thermal metamaterials. Nat. Commun. 2021, 12, 7228. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Peng, Z.; Wang, H.; Yang, L.; Zhang, L.; Li, C. Optimization of Flexible Nacre-like Cellulose Nanofiber Films by a Covalent Overlapping Method: Excellent Thermal Conductivity and Superior Flame Resistance. Ind. Eng. Chem. Res. 2023, 62, 5877–5888. [Google Scholar] [CrossRef]

- Dong, K.; Liu, K.; Pan, L.; Gu, B.; Sun, B. Experimental and numerical investigation on the thermal conduction properties of 2.5 D angle-interlock woven composites. Compos. Struct. 2016, 154, 319–333. [Google Scholar] [CrossRef]

- Dong, K.; Liu, K.; Zhang, Q.; Gu, B.; Sun, B. Experimental and numerical analyses on the thermal conductive behaviors of carbon fiber/epoxy plain woven composites. Int. J. Heat Mass Transf. 2016, 102, 501–517. [Google Scholar] [CrossRef]

- Dong, K.; Zhang, J.; Jin, L.; Gu, B.; Sun, B. Multi-scale finite element analyses on the thermal conductive behaviors of 3D braided composites. Compos. Struct. 2016, 143, 9–22. [Google Scholar] [CrossRef]

- Gou, J.; Fang, W.; Dai, Y.; Li, S.; Tao, W. Multi-size unit cells to predict effective thermal conductivities of 3D four-directional braided composites. Compos. Struct. 2017, 163, 152–167. [Google Scholar] [CrossRef]

- Fang, W.; Chen, L.; Gou, J.; Tao, W. Predictions of effective thermal conductivities for three-dimensional four-directional braided composites using the lattice Boltzmann method. Int. J. Heat Mass Transf. 2016, 92, 120–130. [Google Scholar] [CrossRef]

- Zhou, L.; Sun, X.; Chen, M.; Zhu, Y.; Wu, H. Multiscale modeling and theoretical prediction for the thermal conductivity of porous plain-woven carbonized silica/phenolic composites. Compos. Struct. 2019, 215, 278–288. [Google Scholar] [CrossRef]

- Dong, K.; Peng, X.; Zhang, J.; Gu, B.; Sun, B. Temperature-dependent thermal expansion behaviors of carbon fiber/epoxy plain woven composites: Experimental and numerical studies. Compos. Struct. 2017, 176, 329–341. [Google Scholar] [CrossRef]

- Peijian, D.; Li, C.; Xiang, D.; Junbo, X.; Junling, L.; Wei, J.; Xu, D.; Yifan, Z.; Ziyue, G.; Xi, W. Multiscale analysis on the anisotropic thermal conduction of laminated fabrics by finite element method. Compos. Struct. 2022, 292, 115672. [Google Scholar] [CrossRef]

- Kim, H.; Ji, W. Thermal conductivity of a thick 3D textile composite using an RVE model with specialized thermal periodic boundary conditions. Funct. Compos. Struct. 2021, 3, 015002. [Google Scholar] [CrossRef]

- Schuster, J.; Heider, D.; Sharp, K.; Glowania, M. Thermal conductivities of three-dimensionally woven fabric composites. Compos. Sci. Technol. 2008, 68, 2085–2091. [Google Scholar] [CrossRef]

- Shigang, A.; Rujie, H.; Yongmao, P. A Numerical Study on the Thermal Conductivity of 3D Woven C/C Composites at High Temperature. Appl. Compos. Mater. 2015, 22, 823–835. [Google Scholar] [CrossRef]

- Guo, X.; Cheng, S.; Cai, W.; Zhang, Y.; Zhang, X.-A. A review of carbon-based thermal interface materials: Mechanism, thermal measurements and thermal properties. Mater. Des. 2021, 209, 109936. [Google Scholar] [CrossRef]

- Das, C.M.; Kang, L.; Ouyang, Q.; Yong, K. Advanced low-dimensional carbon materials for flexible devices. InfoMat 2020, 2, 698–714. [Google Scholar] [CrossRef]

- Mandal, S.; Singh, R.; Roy, D.; Mukhopadhyay, K.; Dwivedi, M.; Joshi, M. Insights into the hierarchical geometries of hybrid low-dimensional carbons. Discov. Mater. 2024, 4, 21. [Google Scholar] [CrossRef]

- Islam, G.M.N.; Collie, S.; Gould, M.; Ali, M.A. Two-dimensional carbon material incorporated and PDMS-coated conductive textile yarns for strain sensing. J. Coat. Technol. Res. 2023, 20, 1881–1895. [Google Scholar] [CrossRef]

- Cui, Y.; Gong, H.; Wang, Y.; Li, D.; Bai, H. A Thermally Insulating Textile Inspired by Polar Bear Hair. Adv. Mater. 2018, 30, 1706807. [Google Scholar] [CrossRef]

- Lei, L.; Shi, S.; Wang, D.; Meng, S.; Dai, J.; Fu, S.; Hu, J. Recent advances in thermoregulatory clothing: Materials, mechanisms, and perspectives. ACS Nano 2023, 17, 1803–1830. [Google Scholar] [CrossRef] [PubMed]

- Leung, E.M.; Colorado Escobar, M.; Stiubianu, G.T.; Jim, S.R.; Vyatskikh, A.L.; Feng, Z.; Garner, N.; Patel, P.; Naughton, K.L.; Follador, M.; et al. A dynamic thermoregulatory material inspired by squid skin. Nat. Commun. 2019, 10, 1947. [Google Scholar] [CrossRef] [PubMed]

- Miao, D.; Wang, X.; Yu, J.; Ding, B. A Biomimetic Transpiration Textile for Highly Efficient Personal Drying and Cooling. Adv. Funct. Mater. 2021, 31, 2008705. [Google Scholar] [CrossRef]

- Banerjee, D.; Chattopadhyay, S.; Tuli, S. Infrared thermography in material research—A review of textile applications. Indian J. Fibre Text. Res. 2013, 38, 427–437. [Google Scholar]

- Nejman, A.; Gromadzińska, E.; Kamińska, I.; Cieślak, M. Assessment of Thermal Performance of Textile Materials Modified with PCM Microcapsules Using Combination of DSC and Infrared Thermography Methods. Molecules 2020, 25, 122. [Google Scholar] [CrossRef]

- Repon, M.R.; Mikučionienė, D. Progress in Flexible Electronic Textile for Heating Application: A Critical Review. Materials 2021, 14, 6540. [Google Scholar] [CrossRef]

- Gspann, T.S.; Juckes, S.M.; Niven, J.F.; Johnson, M.B.; Elliott, J.A.; White, M.A.; Windle, A.H. High thermal conductivities of carbon nanotube films and micro-fibres and their dependence on morphology. Carbon 2017, 114, 160–168. [Google Scholar] [CrossRef]

- Mu, B.; Li, M. Fabrication and thermal properties of tetradecanol/graphene aerogel form-stable composite phase change materials. Sci. Rep. 2018, 8, 8878. [Google Scholar] [CrossRef]

- Qi, G.; Yang, J.; Bao, R.; Xia, D.; Cao, M.; Yang, W.; Yang, M.; Wei, D. Hierarchical graphene foam-based phase change materials with enhanced thermal conductivity and shape stability for efficient solar-to-thermal energy conversion and storage. Nano Res. 2017, 10, 802–813. [Google Scholar] [CrossRef]

- Masoumi, K.; Mardani, H.; RoghaniMamaqani, H.; SalamiKalajahi, M. Reversible Thermochromic and Fluorescent Poly (methyl Methacrylate) Nanocapsules for Wearable Devices, Thermal Energy Regulation, and High-Security Anticounterfeiting Inks. ACS Appl. Mater. Interfaces 2025, 17, 18869–18886. [Google Scholar] [CrossRef] [PubMed]

- Bao, D.; Zhang, X.; Ji, X.; Xu, Y.; Guan, F.; Guo, J.; Zhang, S. Photo-thermal effects initiate multi-level energy conversion in “solid-solid” phase-changing fibers. Int. J. Biol. Macromol. 2024, 281, 135819. [Google Scholar] [CrossRef]

- Gu, B.; Xu, Q.; Wang, H.; Pan, H.; Zhao, D. A hierarchically nanofibrous self-cleaning textile for efficient personal thermal management in severe hot and cold environments. ACS Nano 2023, 17, 18308–18317. [Google Scholar] [CrossRef] [PubMed]

- Angelotti, A.; Alongi, A.; Augello, A.; Dama, A.; De Antonellis, S.; Ravidà, A.; Zinzi, M.; De Angelis, E. Thermal conductivity assessment of cotton fibers from apparel recycling for building insulation. Energy Build. 2024, 324, 114866. [Google Scholar] [CrossRef]

- Yu, S.; Kim, D.-K.; Park, C.; Hong, S.M.; Koo, C.M. Thermal conductivity behavior of SiC–Nylon 6,6 and hBN–Nylon 6,6 composites. Res. Chem. Intermed. 2014, 40, 33–40. [Google Scholar] [CrossRef]

- Yin, Q.; Wang, B.; Cai, G.; Wang, Z.; Li, P.; Gao, Y.; Li, K.; Ming, X.; Liu, Y.; Gao, C.; et al. Highly thermally conductive composites of graphene fibers. Compos. Part A Appl. Sci. Manuf. 2024, 185, 108290. [Google Scholar] [CrossRef]

- Cho, J.; Jang, E.; Kim, J.; Kim, J. Enhanced thermal conductivity and insulating properties of PBO fiber grafted AlN/BN/PBO films for electronic packaging. Ceram. Int. 2025, 51, 2155–2162. [Google Scholar] [CrossRef]

- Liu, Y.; Zou, W.; Zhao, N.; Xu, J. Electrically insulating PBO/MXene film with superior thermal conductivity, mechanical properties, thermal stability, and flame retardancy. Nat. Commun. 2023, 14, 5342. [Google Scholar] [CrossRef]

- Lee, S.-M.; Kim, J.; Ahn, J. Graphene as a flexible electronic material: Mechanical limitations by defect formation and efforts to overcome. Mater. Today 2015, 18, 336–344. [Google Scholar] [CrossRef]

- Wang, X.; Shi, G. Flexible graphene devices related to energy conversion and storage. Energy Environ. Sci. 2015, 8, 790–823. [Google Scholar] [CrossRef]

- Govindaraj, P.; Sokolova, A.; Salim, N.; Juodkazis, S.; Fuss, F.K.; Fox, B.; Hameed, N. Distribution states of graphene in polymer nanocomposites: A review. Compos. Part B Eng. 2021, 226, 109353. [Google Scholar] [CrossRef]

- Wang, Y.; Li, M.; Gu, Y.; Zhang, X.; Wang, S.; Li, Q.; Zhang, Z. Tuning carbon nanotube assembly for flexible, strong and conductive films. Nanoscale 2015, 7, 3060–3066. [Google Scholar] [CrossRef] [PubMed]

- Yim, Y.; Yoon, Y.; Kim, S.; Lee, J.; Chung, D.; Kim, B. Carbon Nanotube/Polymer Composites for Functional Applications. Polymers 2025, 17, 119. [Google Scholar] [CrossRef] [PubMed]

- Tarfaoui, M.; Lafdi, K.; El Moumen, A. Mechanical properties of carbon nanotubes based polymer composites. Compos. Part B Eng. 2016, 103, 113–121. [Google Scholar] [CrossRef]

- Di, J.; Zhang, X.; Yong, Z.; Zhang, Y.; Li, D.; Li, R.; Li, Q. Carbon-Nanotube Fibers for Wearable Devices and Smart Textiles. Adv. Mater. 2016, 28, 10529–10538. [Google Scholar] [CrossRef]

- Kim, H.; Ahn, J. Graphene for flexible and wearable device applications. Carbon 2017, 120, 244–257. [Google Scholar] [CrossRef]

- Torres Alonso, E.; Rodrigues, D.P.; Khetani, M.; Shin, D.; De Sanctis, A.; Joulie, H.; de Schrijver, I.; Baldycheva, A.; Alves, H.; Neves, A.I.S.; et al. Graphene electronic fibres with touch-sensing and light-emitting functionalities for smart textiles. Npj Flex. Electron. 2018, 2, 25. [Google Scholar] [CrossRef]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Zhou, W.-X.; Cheng, Y.; Chen, K.; Xie, G.; Wang, T.; Zhang, G. Thermal Conductivity of Amorphous Materials. Adv. Funct. Mater. 2020, 30, 1903829. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Shahil, K.M.F.; Balandin, A.A. Thermal properties of graphene and multilayer graphene: Applications in thermal interface materials. Solid State Commun. 2012, 152, 1331–1340. [Google Scholar] [CrossRef]

- Ghosh, S.; Calizo, I.; Teweldebrhan, D.; Pokatilov, E.P.; Nika, D.L.; Balandin, A.A.; Bao, W.; Miao, F.; Lau, C.N. Extremely high thermal conductivity of graphene: Prospects for thermal management applications in nanoelectronic circuits. Appl. Phys. Lett. 2008, 92, 151911. [Google Scholar] [CrossRef]

- Ghosh, S.; Bao, W.; Nika, D.L.; Subrina, S.; Pokatilov, E.P.; Lau, C.N.; Balandin, A.A. Dimensional crossover of thermal transport in few-layer graphene. Nat. Mater. 2010, 9, 555–558. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef]

- Yildiz, O.; Stano, K.; Faraji, S.; Stone, C.; Willis, C.; Zhang, X.; Jur, J.S.; Bradford, P.D. High performance carbon nanotube-polymer nanofiber hybrid fabrics. Nanoscale 2015, 7, 16744–16754. [Google Scholar] [CrossRef]

- Krasavin, S.E.; Osipov, V.A. Effect of Stone–Wales defects on the thermal conductivity of graphene. J. Phys. Condens. Matter 2015, 27, 425302. [Google Scholar] [CrossRef]

- Wu, W.; Yang, H.; Liu, Y.; Yang, S.; Yang, P. Effect of defects on heat transfer at the graphene/epoxy interface. Int. Commun. Heat Mass Transf. 2022, 131, 105846. [Google Scholar] [CrossRef]

- Chien, S.-K.; Yang, Y.-T.; Chen, C.-K. The effects of vacancy defects and nitrogen doping on the thermal conductivity of armchair (10, 10) single-wall carbon nanotubes. Solid State Commun. 2011, 151, 1004–1008. [Google Scholar] [CrossRef]

- Zhang, N.; Zhou, B.; Li, D.; Qi, D.; Wu, Y.; Zheng, H.; Yang, B. Near-Interface Defects in Graphene/H-BN In-Plane Heterostructures: Insights into the Interfacial Thermal Transport. Nanomaterials 2022, 12, 1044. [Google Scholar] [CrossRef]

- Mann, S.; Mudahar, I.; Sharma, H.; Jindal, V.K.; Dubey, G.S.; Gumbs, G.; Fessatidis, V. Lattice thermal conductivity of pure and doped (B, N) Graphene. Mater. Res. Express 2020, 7, 095003. [Google Scholar] [CrossRef]

- Rezania, H.; Yarmohammadi, M. Controlling dynamical thermal transport of biased bilayer graphene by impurity atoms. AIP Adv. 2016, 6, 075121. [Google Scholar] [CrossRef]

- Feng, T.; Qiu, B.; Ruan, X. Publisher’s Note: Coupling between phonon-phonon and phonon-impurity scattering: A critical revisit of the spectral Matthiessen’s rule. Phys. Rev. B 2016, 93, 159904. [Google Scholar] [CrossRef]

- Xiao, G.; Li, H.; Yu, Z.; Niu, H.; Yao, Y. Highly Thermoconductive, Strong Graphene-Based Composite Films by Eliminating Nanosheets Wrinkles. Nano-Micro Lett. 2023, 16, 17. [Google Scholar] [CrossRef]

- Lu, C.; Li, Z.; Sang, X.; Fan, Z.; Xu, X.; Zhang, Y.; Xu, K.; Cheng, Y.; Zhao, J.; Zheng, J.-C.; et al. Stress-Driven Grain Boundary Structural Transition in Diamond by Machine Learning Potential. Small 2025, 21, 2409092. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Qiao, D.; Yang, M. Effects of Structure Defects on Thermal Transport at the Graphene–Water Interface. Adv. Mater. Interfaces 2023, 10, 2202518. [Google Scholar] [CrossRef]

- Boi, F.S.; Wang, S.; Lei, L.; Guo, X.; Guo, J.; Gu, A.; Zhang, L.; Song, J.; He, Y. Local stabilization of body-centred tetragonal Fe and enhanced dislocation density in carbon nanotubes filled with μm-long nanowires. New J. Chem. 2024, 48, 5721–5732. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, C.; Mai, Y.; Zhang, Y. Effect of non-covalent functionalisation on thermal and mechanical properties of graphene-polymer nanocomposites. Carbon 2016, 102, 311–318. [Google Scholar] [CrossRef]

- Wang, B.; Shao, W.; Cao, Q.; Cui, Z. Investigation on the interfacial heat transport between epoxy and the edge of amino-functionalized graphene. Int. J. Heat Mass Transf. 2022, 191, 122850. [Google Scholar] [CrossRef]

- Gutierrez, D.M.; Di Pierro, A.; Pecchia, A.; Sandonas, L.M.; Gutierrez, R.; Bernal, M.; Mortazavi, B.; Cuniberti, G.; Saracco, G.; Fina, A. Thermal bridging of graphene nanosheets via covalent molecular junctions: A non-equilibrium Green’s functions–density functional tight-binding study. Nano Res. 2019, 12, 791–799. [Google Scholar] [CrossRef]

- Di Pierro, A.; Saracco, G.; Fina, A. Molecular junctions for thermal transport between graphene nanoribbons: Covalent bonding vs. interdigitated chains. Comput. Mater. Sci. 2018, 142, 255–260. [Google Scholar] [CrossRef]

- Zhang, Z.; Ouyang, Y.; Cheng, Y.; Chen, J.; Li, N.; Zhang, G. Size-dependent phononic thermal transport in low-dimensional nanomaterials. Phys. Rep. 2020, 860, 1–26. [Google Scholar] [CrossRef]

- Chen, J.; Liu, B.; Gao, X. Thermal properties of graphene-based polymer composite materials: A molecular dynamics study. Results Phys. 2020, 16, 102974. [Google Scholar] [CrossRef]

- Xu, X.; Pereira, L.F.C.; Wang, Y.; Wu, J.; Zhang, K.; Zhao, X.; Bae, S.; Tinh Bui, C.; Xie, R.; Thong, J.T.L.; et al. Length-dependent thermal conductivity in suspended single-layer graphene. Nat. Commun. 2014, 5, 3689. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; He, P.; Zheng, H.; Xiao, D.; Ding, G. Anomalous size effects of ultra-small graphene sheets on the thermal properties of macroscopic films. Chem. Eng. J. 2024, 493, 152803. [Google Scholar] [CrossRef]

- Lu, K.; Wang, Z.; Li, G.; Jiang, R.; Sui, G.; Yang, X.; Zhao, J. Enhanced longitudinal compressive strength of CFRP composites through matrix stiffening via flexible/rigid epoxide grafted silica: A combined analysis of simulation and experiments. Compos. Part B Eng. 2022, 235, 109756. [Google Scholar] [CrossRef]

- Najmi, L.; Hu, Z. Effects of Key Parameters on Thermal Conductivity of Carbon Nanotube–Epoxy Composites by Molecular Dynamics Simulations. J. Compos. Sci. 2025, 9, 159. [Google Scholar] [CrossRef]

- Zhang, C.; Bi, L.; Shi, S.; Wang, H.; Zhang, D.; He, Y.; Li, W. Two-Steps Method to Prepare Multilayer Sandwich Structure Carbon Fiber Composite with Thermal and Electrical Anisotropy and Electromagnetic Interference Shielding. Materials 2023, 16, 680. [Google Scholar] [CrossRef]

- Chen, Z.; Yu, C.; Ge, Y.; Ou, K.; Chen, J.; Lu, H. Interface phonon scattering suppression boosts heat conduction in thermal interface materials. Chem. Eng. J. 2024, 500, 156924. [Google Scholar] [CrossRef]

- Cui, L.; Guo, X.; Yu, Q.; Wei, G.; Du, X. Ultralow and anisotropic thermal conductivity in graphene phononic metamaterials. Int. J. Heat Mass Transf. 2022, 196, 123227. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, X.; Gu, B.-L.; Duan, W. Intrinsic anisotropy of thermal conductance in graphene nanoribbons. Appl. Phys. Lett. 2009, 95, 233116. [Google Scholar] [CrossRef]

- Marconnet, A.M.; Panzer, M.A.; Goodson, K.E.J.R.o.M.P. Thermal conduction phenomena in carbon nanotubes and related nanostructured materials. Rev. Mod. Phys. 2013, 85, 1295–1326. [Google Scholar] [CrossRef]

- Kamble, Z.; Mishra, R.K.; Behera, B.K.; Tichý, M.; Kolář, V.; Müller, M. Design, Development, and Characterization of Advanced Textile Structural Hollow Composites. Polymers 2021, 13, 3535. [Google Scholar] [CrossRef]

- Zou, R.; Liu, F.; Hu, N.; Ning, H.; Gong, Y.; Wang, S.; Huang, K.; Jiang, X.; Xu, C.; Fu, S. Graphene/graphitized polydopamine/carbon nanotube all-carbon ternary composite films with improved mechanical properties and through-plane thermal conductivity. ACS Appl. Mater. Interfaces 2020, 12, 57391–57400. [Google Scholar] [CrossRef]

- Luo, C.J.; Stoyanov, S.D.; Stride, E.; Pelan, E.; Edirisinghe, M. Electrospinning versus fibre production methods: From specifics to technological convergence. Chem. Soc. Rev. 2012, 41, 4708–4735. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, Y.; Li, J.; Hao, Y.; Ke, H.; Lv, P.; Wei, Q. Wet Spinning Technology for Aerogel Fiber: Pioneering the Frontier of High-Performance and Multifunctional Materials. Adv. Fiber Mater. 2024, 6, 1669–1709. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, Y.; Zhao, X.; Peng, L.; Sun, H.; Xu, Y.; Ren, X.; Jin, C.; Xu, P.; Wang, M. Ultrastiff and strong graphene fibers via full-scale synergetic defect engineering. Adv. Mater. 2016, 28, 6449–6456. [Google Scholar] [CrossRef]

- Xin, G.; Yao, T.; Sun, H.; Scott, S.M.; Shao, D.; Wang, G.; Lian, J. Highly thermally conductive and mechanically strong graphene fibers. Science 2015, 349, 1083–1087. [Google Scholar] [CrossRef]

- Rouf, K.; Denton, N.L.; French, R.M. Effect of fabric weaves on the dynamic response of two-dimensional woven fabric composites. J. Mater. Sci. 2017, 52, 10581–10591. [Google Scholar] [CrossRef]

- Jiao, T.; Han, B.; Zhao, L.; Zhang, Z.; Zeng, Y.; Li, D.; Zhang, K.; Deng, Q.; Zhao, Y.; Li, Z. Pie-rolling-inspired construction of vertical carbon fiber high thermal conductivity hybrid networks. Appl. Surf. Sci. 2023, 618, 156711. [Google Scholar] [CrossRef]

- Sarker, F.; Karim, N.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Potluri, P. High-performance graphene-based natural fiber composites. ACS Appl. Mater. Interfaces 2018, 10, 34502–34512. [Google Scholar] [CrossRef]

- Islam, M.R.; Afroj, S.; Karim, N. Scalable production of 2D material heterostructure textiles for high-performance wearable supercapacitors. ACS Nano 2023, 17, 18481–18493. [Google Scholar] [CrossRef]

- Deng, M.; Xu, Y.; Gao, K.; Zhao, C.; Sheng, N.; Zhu, C.; Rao, Z. A graphene nanoflake-based flexible composite phase change material for enhanced heat dissipation in chip cooling. Appl. Therm. Eng. 2024, 245, 122908. [Google Scholar] [CrossRef]

- Li, P.; Liu, Y.; Shi, S.; Xu, Z.; Ma, W.; Wang, Z.; Liu, S.; Gao, C. Highly Crystalline Graphene Fibers with Superior Strength and Conductivities by Plasticization Spinning. Adv. Funct. Mater. 2020, 30, 2006584. [Google Scholar] [CrossRef]

- Shi, S.; Jiang, T.; Cao, S.; Gui, X.; Wang, Y.; Li, Y.; Yu, W.; Lin, D.; Xie, H.; Li, X. Thermal conductivity and heat transfer mechanism of epoxy composites constructing by carbon fiber felt with three-dimensional layered structure. Polym. Compos. 2024, 45, 7633–7645. [Google Scholar] [CrossRef]

- Jiang, T.; Xu, K.; Wang, Y.; Xiang, L.; Tang, B.; Shi, S.; Li, Y.; Yu, W.; Xie, H.; Wu, X. In situ construction of high-thermal-conductivity and negative-permittivity epoxy/carbon fiber@carbon composites with a 3D network by high-temperature chemical vapor deposition. ACS Appl. Mater. Interfaces 2023, 15, 54027–54038. [Google Scholar] [CrossRef]

- Maiti, S.; Islam, M.R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable fiber-reinforced composites: A review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Shi, S.; Li, X.; Jiang, T.; Cao, S.; Gui, X.; Wang, Y.; Li, Y.; Yu, W.; Lin, D.; Xie, H. Ultra-High In-Plane Thermal Conductivity of Epoxy Composites Reinforced by Three-Dimensional Carbon Fiber/Graphene Hybrid Felt. J. Polym. Sci. 2025, 63, 1059–1069. [Google Scholar] [CrossRef]

- Stig, F.; Hallström, S. Spatial modelling of 3D-woven textiles. Compos. Struct. 2012, 94, 1495–1502. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, L.; Li, J.; Jiao, Y. Multi-Scale Finite Element Analyses of Thermal Conductivities of Three Dimensional Woven Composites. Appl. Compos. Mater. 2017, 24, 1525–1542. [Google Scholar] [CrossRef]

- Sharp, K.; Bogdanovich, A.E.; Tang, W.; Heider, D.; Advani, S.; Glowiana, M. High through-thickness thermal conductivity composites based on three-dimensional woven fiber architectures. AIAA J. 2008, 46, 2944–2954. [Google Scholar] [CrossRef]

- Cai, Y.; Yu, H.; Chen, C.; Feng, Y.; Qin, M.; Feng, W. Improved thermal conductivities of vertically aligned carbon nanotube arrays using three-dimensional carbon nanotube networks. Carbon 2022, 196, 902–912. [Google Scholar] [CrossRef]

- Joshi, V.; Rathod, M.K. Thermal transport augmentation in latent heat thermal energy storage system by partially filled metal foam: A novel configuration. J. Energy Storage 2019, 22, 270–282. [Google Scholar] [CrossRef]

- Wang, D.; Hu, S.; Křemenáková, D.; Militký, J.; Zhu, G. Effect of Textile Structure on Heat Transfer Performance. In Advanced Multifunctional Materials from Fibrous Structures, 1st ed.; Militký, J., Venkataraman, M., Eds.; Springer Nature: Singapore, 2023; pp. 163–198. ISBN 978-981-99-6002-6. [Google Scholar]

- Li, M.; Wang, P.; Boussu, F.; Soulat, D. A review on the mechanical performance of three-dimensional warp interlock woven fabrics as reinforcement in composites. J. Ind. Text. 2022, 51, 1009–1058. [Google Scholar] [CrossRef]

- Joshi, V.; Rathod, M.K. Thermal performance augmentation of metal foam infused phase change material using a partial filling strategy: An evaluation for fill height ratio and porosity. Appl. Energy 2019, 253, 113621. [Google Scholar] [CrossRef]

- Gao, J.; Xie, D.; Wang, X.; Zhang, X.; Yue, Y. High thermal conductivity of free-standing skeleton in graphene foam. Appl. Phys. Lett. 2020, 117, 251901. [Google Scholar] [CrossRef]

- Hasanzadeh, M.; Zadeh, S.M. Advanced Fibrous Composites for Aircraft Application. In Materials, Structures and Manufacturing for Aircraft, 1st ed.; Kuşhan, M.C., Gürgen, S., Sofuoğlu, M.A., Eds.; Springer: Eskişehir, Turkey, 2022; pp. 89–112. ISBN 978-3-030-91873-6. [Google Scholar]

- Fang, C.; Xu, B.; Li, M.; Han, J.; Yang, Y.; Liu, X. Advanced design of fibrous flexible actuators for smart wearable applications. Adv. Fiber Mater. 2024, 6, 622–657. [Google Scholar] [CrossRef]

- Pu, J.; Ma, K.; Luo, Y.; Tang, S.; Liu, T.; Liu, J.; Leung, M.; Yang, J.; Hui, R.; Xiong, Y. Textile electronics for wearable applications. Int. J. Extrem. Manuf. 2023, 5, 042007. [Google Scholar] [CrossRef]

- Wei, N.; Li, Z.; Li, Z.-H.; Zhang, C.; Wang, C.; Zhao, J.; Cai, K. A heat and force locating sensor with nanoscale precision: A knitted graphene sheet. Nanoscale 2021, 13, 5826–5833. [Google Scholar] [CrossRef]

- Alghamdi, A. Simulation-based evaluation of effects of fabric structure on thermal conductivity of various 2D woven composites. J. Ind. Text. 2024, 54, 15280837241247341. [Google Scholar] [CrossRef]

- Li, X.; Liu, M.; Chen, K.; Li, L.; Pei, G.; Zhao, B. Adaptive fabric with emissivity regulation for thermal management of humans. Nanophotonics 2024, 13, 3067–3075. [Google Scholar] [CrossRef]

- Wu, Y.; An, C.; Guo, Y.; Kang, L.; Wang, Y.; Wan, H.; Tang, H.; Ma, Q.; Yang, C.; Xu, M.; et al. Multiscale Structural Control by Matrix Engineering for Polydimethylsiloxane Filled Graphene Woven Fabric Strain Sensors. Small 2025, 21, 2410148. [Google Scholar] [CrossRef]

- Jang, Y.; Kim, J.-H.; Lee, D.; Chon, J.S.; Lee, S.; Kwon, D.-J. Comprehensive analysis of the effect of braiding angle on the wettability and mechanical properties of 3D braided carbon fiber fabric-reinforced composites. Mater. Today Commun. 2024, 41, 110798. [Google Scholar] [CrossRef]

- Yang, M.; Wang, Z.; Li, P.; Liu, Y.; Lin, J.; Wang, B.; Ming, X.; Gao, W.; Xu, Z.; Gao, C. Stress relaxation behaviors of graphene fibers. Carbon 2021, 182, 384–392. [Google Scholar] [CrossRef]

- Fu, Y.; Yao, X.; Gao, X. Micro-mesoscopic prediction of void defect in 3D braided composites. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106450. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, H.; Peng, Y.; Hu, J.; Sun, F. Hierarchically Programmed Meta-Louver Fabric for Adaptive Personal Thermal Management. Adv. Funct. Mater. 2024, 34, 2404721. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.-H.; Zhang, Y.; Xu, X.; Cheng, Y.; Zhang, Y.; Zhao, J.; Wei, N. Highly sensitive weaving sensor of hybrid graphene nanoribbons and carbon nanotubes for enhanced pressure sensing function. ACS Sens. 2024, 9, 2499–2508. [Google Scholar] [CrossRef]

- Liu, X.; Tang, C.; Du, X.; Xiong, S.; Xi, S.; Liu, Y.; Shen, X.; Zheng, Q.; Wang, Z.; Wu, Y.; et al. A highly sensitive graphene woven fabric strain sensor for wearable wireless musical instruments. Mater. Horiz. 2017, 4, 477–486. [Google Scholar] [CrossRef]

- Yin, B.; Wen, Y.; Hong, T.; Xie, Z.; Yuan, G.; Ji, Q.; Jia, H. Highly stretchable, ultrasensitive, and wearable strain sensors based on facilely prepared reduced graphene oxide woven fabrics in an ethanol flame. ACS Appl. Mater. Interfaces 2017, 9, 32054–32064. [Google Scholar] [CrossRef]

- Naseri, I.; Ziaee, M.; Nilsson, Z.N.; Lustig, D.R.; Yourdkhani, M. Electrothermal performance of heaters based on laser-induced graphene on aramid fabric. ACS Omega 2022, 7, 3746–3757. [Google Scholar] [CrossRef]

- Sang, Y.; Zhao, Y.; Hao, W.; Miao, L.; Li, J.; Zhao, G.; Li, J.; Sui, C.; He, X.; Wang, C. Ultrastretchable Helical Carbon Nanotube-Woven Film. ACS Appl. Mater. Interfaces 2024, 16, 10475–10484. [Google Scholar] [CrossRef]

- Li, Y.; He, T.; Shi, L.; Wang, R.; Sun, J. Strain Sensor with Both a Wide Sensing Range and High Sensitivity Based on Braided Graphene Belts. ACS Appl. Mater. Interfaces 2020, 12, 17691–17698. [Google Scholar] [CrossRef] [PubMed]

- Tsai, J.; Tzeng, S.; Tzou, Y. Characterizing the fracture parameters of a graphene sheet using atomistic simulation and continuum mechanics. Int. J. Solids Struct. 2010, 47, 503–509. [Google Scholar] [CrossRef][Green Version]

- Zhao, B.; Yan, Y.; Huang, Y.; Chen, Z.; Liang, Y.; Luo, Z.; Gao, C.; Wang, L. Achievement of high n-type thermoelectric performance and stretchability in single-walled carbon nanotubes/polyethyleneimine/polyvinylpyrrolidone composites: Enabling self-healing and sensitive self-powered temperature sensors. J. Power Sources 2025, 631, 236300. [Google Scholar] [CrossRef]

- Ryan, J.D.; Lund, A.; Hofmann, A.I.; Kroon, R.; Sarabia-Riquelme, R.; Weisenberger, M.C.; Müller, C. All-organic textile thermoelectrics with carbon-nanotube-coated n-type yarns. ACS Appl. Energy Mater. 2018, 1, 2934–2941. [Google Scholar] [CrossRef]

- Ding, D.; Wu, Q.; Li, Q.; Chen, Y.; Zhi, C.; Wei, X.; Wang, J. Novel Thermoelectric Fabric Structure with Switched Thermal Gradient Direction toward Wearable In-Plane Thermoelectric Generators. Small 2024, 20, 2306830. [Google Scholar] [CrossRef]

- Yu, L.; Liu, X.; Zhang, B.; Hu, H.; Chen, K.; Li, H.; Birch, D.J.S.; Chen, Y.; Qiu, H.; Gu, P. Phase-transition-promoted thermoelectric textiles based on twin surface-modified CNT fibers. ACS Appl. Mater. Interfaces 2024, 16, 18030–18039. [Google Scholar] [CrossRef]

- Sun, T.; Zhou, B.; Zheng, Q.; Wang, L.; Jiang, W.; Snyder, G.J. Stretchable fabric generates electric power from woven thermoelectric fibers. Nat. Commun. 2020, 11, 572. [Google Scholar] [CrossRef]

- Jang, D.; Park, K.T.; Lee, S.; Kim, H. Highly stretchable three-dimensional thermoelectric fabrics exploiting woven structure deformability and passivation-induced fiber elasticity. Nano Energy 2022, 97, 107143. [Google Scholar] [CrossRef]

- Khoso, N.A.; Xu, G.; Xie, J.; Sun, T.; Wang, J. The fabrication of a graphene and conductive polymer nanocomposite-coated highly flexible and washable woven thermoelectric nanogenerator. Mater. Adv. 2021, 2, 3695–3704. [Google Scholar] [CrossRef]

- Li, Z.; Ren, G.; Feng, Y.; Zhang, Y.; Cui, Z.; Lu, D.; Zhang, L.; Yu, H.; Li, W.; Liu, P. Electrospinning of Fluorine-Free Waterproof–Breathable Nanofiber Membranes with Thermal Regulation for Anticounterfeiting. ACS Appl. Nano Mater. 2023, 7, 919–927. [Google Scholar] [CrossRef]

- Pillai, P.S.; Athira, B.S.; Varghese, H.; Agarwal, S.; Kumar, B.; Alagirusamy, R.; Das, A.; Surendran, K.P.; Chandran, A. A resistive ink based all-printed fabric heater integrated wearable thermotherapy device. J. Mater. Sci. Mater. Electron. 2023, 34, 1261. [Google Scholar] [CrossRef]

- Luo, H.; Zhu, Y.; Xu, Z.; Hong, Y.; Ghosh, P.; Kaur, S.; Wu, M.; Yang, C.; Qiu, M.; Li, Q. Outdoor personal thermal management with simultaneous electricity generation. Nano Lett. 2021, 21, 3879–3886. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Li, B.-X.; Luo, Z.; Jin, M.; Quan, Q.; Ding, C.; Yu, Z.-Z.; Yang, D. Integrating and anisotropic MXene/reduced graphene oxide/PEDOT:PSS hybrid aerogel for active/passive thermal protection and stepwise thermal warning. Chem. Eng. J. 2024, 496, 153536. [Google Scholar] [CrossRef]

- Prasanna, C.S.; Harish, S.; Yamakawa, T.; Ikeda, K.; Hayakawa, Y.; Hamasaki, H.; Ikeda, H.; Navaneethan, M. Investigating the effect of microwave growth parameter regulation in the growth and thermoelectric properties of zinc oxide nanorods/carbon fabric for wearable thermoelectric application. Carbon Lett. 2025, 35, 1–15. [Google Scholar] [CrossRef]

- Xu, C.; Yang, S.; Li, P.; Wang, H.; Li, H.; Liu, Z. Wet-spun PEDOT:PSS/CNT composite fibers for wearable thermoelectric energy harvesting. Compos. Commun. 2022, 32, 101179. [Google Scholar] [CrossRef]

- Meng, F.; Li, X.; Zhang, M.; Zhao, Y.; Li, Z.; Zhang, S.; Li, H. Preparation of Thermal Conductivity-Enhanced, Microencapsulated Phase Change Materials Using Cellulose-Assisted Graphene Dispersion for Thermal Regulation in Textiles. Polymers 2024, 16, 3291. [Google Scholar] [CrossRef]

- Luo, Z.; Yang, D.; Liu, J.; Zhao, H.; Zhao, T.; Li, B.-X.; Yang, W.; Yu, Z. Nature-Inspired Solar-Thermal Gradient Reduced Graphene Oxide Aerogel-based Bilayer Phase Change Composites for Self-Adaptive Personal Thermal Management. Adv. Funct. Mater. 2023, 33, 2212032. [Google Scholar] [CrossRef]

- Su, H.; Lin, P.; Lu, H.; Chen, Y. Efficient solar-thermal conversion and thermal energy storage towards personal thermal management and thermoelectric power generation enabled by massive screen printing of carbon nanotube dopped energy storage gels. J. Energy Storage 2024, 76, 109782. [Google Scholar] [CrossRef]

- Kang, J.; Kim, H.; Kim, K.S.; Lee, S.; Bae, S.; Ahn, J.; Kim, Y.; Choi, J.; Hong, B.H. High-performance graphene-based transparent flexible heaters. Nano Lett. 2011, 11, 5154–5158. [Google Scholar] [CrossRef]

- Li, L.; Hong, S.K.; Jo, Y.; Tian, M.; Woo, C.Y.; Kim, S.H.; Kim, J.M.; Lee, H.W. Transparent, flexible heater based on hybrid 2D platform of graphene and dry-spun carbon nanotubes. ACS Appl. Mater. Interfaces 2019, 11, 16223–16232. [Google Scholar] [CrossRef]

- Olivieri, F.; Rollo, G.; De Falco, F.; Avolio, R.; Bonadies, I.; Castaldo, R.; Cocca, M.; Errico, M.E.; Lavorgna, M.; Gentile, G. Reduced graphene oxide/polyurethane coatings for wash-durable wearable piezoresistive sensors. Cellulose 2023, 30, 2667–2686. [Google Scholar] [CrossRef]

- Li, G.; Hong, G.; Dong, D.; Song, W.; Zhang, X. Multiresponsive Graphene-Aerogel-Directed Phase-Change Smart Fibers. Adv. Mater. 2018, 30, 1801754. [Google Scholar] [CrossRef]

- Hwang, J.; Lee, J.; Ryu, S.; Woo, Y.S. Role of graphene towards long-term stability of flexible heaters made of graphene-coated silver nanowire networks under repeated deformation. J. Mater. Sci. Mater. Electron. 2023, 34, 130. [Google Scholar] [CrossRef]

- Shao, R.; Wang, G.; Chai, J.; Lin, J.; Zhao, G.; Zeng, Z.; Wang, G. Multifunctional Janus-Structured Polytetrafluoroethylene-Carbon Nanotube-Fe3O4/MXene Membranes for Enhanced EMI Shielding and Thermal Management. Nano-Micro Lett. 2025, 17, 136. [Google Scholar] [CrossRef]

- Wang, N.; Li, X.; Cao, W.; Yang, X.; Zou, X.; Fang, Y.; Shen, X.; Li, Q.; Song, N.; Xu, T. Lightweight Polyimide Nanocomposites with 3D Cocarbonized MXene/Carbon Fiber Networks for Electromagnetic Interference Shielding and High-Temperature Stability. ACS Appl. Nano Mater. 2025, 8, 7347–7359. [Google Scholar] [CrossRef]

- Paleo, A.J.; MartinezRubi, Y.; Krause, B.; Pötschke, P.; Jakubinek, M.B.; Ashrafi, B.; Kingston, C. Carbon Nanotube–Polyurethane Composite Sheets for Flexible Thermoelectric Materials. ACS Appl. Nano Mater. 2023, 6, 17986–17995. [Google Scholar] [CrossRef]

- Kim, S.; Kim, Y.; Yu, W. Optimizing solvent properties to efficiently N-dope highly aligned wet-spun CNT fibers for advanced wearable thermoelectrics. Nano Energy 2025, 140, 111054. [Google Scholar] [CrossRef]

- Luo, Y.; Zhao, L.; Luo, G.; Dong, L.; Xia, Y.; Li, M.; Li, Z.; Wang, K.; Maeda, R.; Jiang, Z. Highly sensitive piezoresistive and thermally responsive fibrous networks from the in situ growth of PEDOT on MWCNT-decorated electrospun PU fibers for pressure and temperature sensing. Microsyst. Nanoeng. 2023, 9, 113. [Google Scholar] [CrossRef]

- Codau, T.C.; Codau, E. Synthesis of ultra-stretchable thermoelectric nanofibrous membrane based on wet-electrospun Polyurethane/MWCNTs composites. Mater. Today Sustain. 2024, 27, 100831. [Google Scholar] [CrossRef]

- Ka, D.; Jeong, K.; Jin, Y. Reduced graphene oxide coated cotton e-textile for wearable chemical warfare agent sensors. Adv. Compos. Mater. 2023, 32, 647–656. [Google Scholar] [CrossRef]

- Zhang, C.; Mao, Y.; Li, K.; Liu, Y.; Xu, Z.; Pang, K.; Cai, S.; Fan, L.; Gao, C. High power and energy density graphene phase change composite materials for efficient thermal management of Li-ion batteries. Energy Storage Mater. 2025, 75, 104003. [Google Scholar] [CrossRef]

- Li, G.; Wang, Y.; Zhang, X. Graphene aerogel-phase change material host-guest smart films. FlatChem 2021, 27, 100249. [Google Scholar] [CrossRef]

- Sun, K.; Dong, H.; Kou, Y.; Yang, H.; Liu, H.; Li, Y.; Shi, Q. Flexible graphene aerogel-based phase change film for solar-thermal energy conversion and storage in personal thermal management applications. Chem. Eng. J. 2021, 419, 129637. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, X.; Wu, Q.; Ni, Z.; Zhou, K.; Wen, C.; Yan, X.; Xie, T. Carbon nanotube sponge encapsulated Ag-MWCNTs/PW composite phase change materials with enhanced thermal conductivity, high solar-/electric-thermal energy conversion and storage. J. Energy Storage 2024, 84, 110925. [Google Scholar] [CrossRef]

- Cui, J.; Li, W.; Wang, Y.; Yu, H.; Feng, X.; Lou, Z.; Shan, W.; Xiong, Y. Ultra-Stable Phase Change Coatings by Self-Cross-Linkable Reactive Poly(ethylene glycol) and MWCNTs. Adv. Funct. Mater. 2022, 32, 2108000. [Google Scholar] [CrossRef]

- Alehosseini, M.; Kadumudi, F.B.; Revesz, S.; Karimi Reikandeh, P.; Henriksen, J.R.; Zsurzsan, T.G.; Spangenberg, J.; Dolatshahi-Pirouz, A. Self-Maintainable Electronic Materials with Skin-Like Characteristics Enabled by Graphene-PEDOT:PSS Fillers. Adv. Sci. 2025, 12, 2410539. [Google Scholar] [CrossRef]

- Wu, Q.; Hu, J. Waterborne polyurethane based thermoelectric composites and their application potential in wearable thermoelectric textiles. Compos. Part B Eng. 2016, 107, 59–66. [Google Scholar] [CrossRef]

- Ju, Z.; Li, P.; Zhao, X.; Ma, J.; Xu, H.; Liu, Y. Flexible TiN/Co@Carbon nanofiber mats for high-performance electromagnetic interference shielding and Joule heating applications. Carbon 2022, 196, 612–620. [Google Scholar] [CrossRef]

- Hou, X.; Zang, Z.; Meng, Y.; Wang, T.; Gao, S.; Liu, Q.; Qu, L.; Zhang, X. A Graphene/MXene-Modified Flexible Fabric for Infrared Camouflage, Electrothermal, and Electromagnetic Interference Shielding. Nanomaterials 2025, 15, 98. [Google Scholar] [CrossRef]

- Navik, R.; Tan, H.; Zhang, H.; Liu, Z.; Xiang, Q.; Shi, L.; Lu, S.; Zhao, Y. Scalable production of polyamide-6/graphene composites with enhanced electromagnetic shielding and thermal conductivity. Chem. Eng. J. 2023, 471, 144445. [Google Scholar] [CrossRef]

- Xie, L.; Min, P.; Ye, L.; He, P.; Yin, G.; Jin, M.; Zhang, H.-B.; Yu, Z.-Z. Interfacial enhancement enables highly conductive reduced graphene oxide-based yarns for efficient electromagnetic interference shielding and thermal regulation. Carbon 2024, 230, 119655. [Google Scholar] [CrossRef]

- Sun, Y.; Chang, H.; Hu, J.; Wang, Y.; Weng, Y.; Zhang, C.; Niu, S.; Cao, L.; Chen, Z.; Guo, N.; et al. Large-Scale Multifunctional Carbon Nanotube Thin Film as Effective Mid-Infrared Radiation Modulator with Long-Term Stability. Adv. Opt. Mater. 2021, 9, 2001216. [Google Scholar] [CrossRef]

- Mandriota, G.; Grandolfo, A.; Striani, R.; Panniello, A.; Bianco, G.V.; Milella, A.; Mele, C.; Comparelli, R.; Greco, A.; Striccoli, M.; et al. Novel thermally conductive coating for cotton fabrics based on reduced graphene oxide decorated with in situ synthesized silver nanoparticles. Appl. Surf. Sci. 2025, 684, 161884. [Google Scholar] [CrossRef]

- Wang, T.; Qiu, X.; Chen, X.; Lu, L.; Zhou, B. Sponge-like form-stable phase change materials with embedded graphene oxide for enhancing the thermal storage efficiency and the temperature response in transport packaging applications. Appl. Energy 2022, 325, 119832. [Google Scholar] [CrossRef]

- Lyu, J.; Liu, Z.; Wu, X.; Li, G.; Fang, D.; Zhang, X. Nanofibrous kevlar aerogel films and their phase-change composites for highly efficient infrared stealth. ACS Nano 2019, 13, 2236–2245. [Google Scholar] [CrossRef]

- Wu, W.; Zeng, Y.; Zhou, C.; Zhou, X.; Yang, S. Engineering graphene oxide and hydrogel coatings on fabrics for smart Janus textiles with superior thermal regulation. Chin. J. Chem. Eng. 2024, 74, 1–12. [Google Scholar] [CrossRef]

- Hekimoglu, G.; Sarı, A. Fly ash/octadecane shape-stabilized composite PCMs doped with carbon-based nanoadditives for thermal regulation applications. Energy Fuels 2021, 35, 1786–1795. [Google Scholar] [CrossRef]

- Sezer Hicyilmaz, A.; Teke, S.; Islek Cin, Z.; Celik Bedeloglu, A. Development of thermo-regulating fabrics with enhanced heat dissipation via graphene-modified n-octadecane microcapsules. Polym. Eng. Sci. 2022, 62, 210–219. [Google Scholar] [CrossRef]

- Akter, M.; Khalil, E.; Uddin, M.H.; Chowdhury, M.K.H.; Hasan, S.M.M. Artificial neural network and multiple linear regression modeling for predicting thermal transmittance of plain-woven cotton fabric. Text. Res. J. 2024, 94, 1279–1296. [Google Scholar] [CrossRef]

- Baghdadi, R.; Alibi, H.; Fayala, F.; Zeng, X. Investigation on air permeability of finished stretch plain knitted fabrics. I. Predicting air permeability using artificial neural networks. Fibers Polym. 2016, 17, 2105–2115. [Google Scholar] [CrossRef]

- Baghdadi, R.; Alibi, H.; Fayala, F.; Zeng, X. Investigation on Stiffness of Finished Stretch Plain Knitted Fabrics Using Fuzzy Decision Trees and Artificial Neural Networks. Fibers Polym. 2021, 22, 550–558. [Google Scholar] [CrossRef]

- Fayala, F.; Alibi, H.; Jemni, A.; Zeng, X. A new hybrid artificial intelligence approach to predicting global thermal comfort of stretch knitted fabrics. Fibers Polym. 2015, 16, 1417–1429. [Google Scholar] [CrossRef]

- Malik, S.A.; Kocaman, R.T.; Kaynak, H.K.; Gereke, T.; Aibibu, D.; Babaarslan, O.; Cherif, C. Analysis and prediction of air permeability of woven barrier fabrics with respect to material, fabric construction and process parameters. Fibers Polym. 2017, 18, 2005–2017. [Google Scholar] [CrossRef]

| Material Type | Thermal Conductivity (W/m·K) | Active Thermal Regulation | Flexibility | Wearability | Commercial Availability | Notes |

|---|---|---|---|---|---|---|

| Cotton | ~0.0381–0.0546 [45] | None | High | High | High | Natural cellulose fiber; low intrinsic thermal conductivity |

| Polyester | -- | None | High | High | High | Synthetic fiber (PET); widely used functional textile base |

| Nylon | ~0.25 [46] | None | High | High | High | Engineering plastic fiber |

| Graphene Textile | 363 (in-plane); 553 (axial) [47] | Yes | High | Relatively High | Fair | Textile modified with graphene or GO/rGO functional coating layers |

| CNT Textile | 110 (in-plane); 770 (axial) [39] | Yes | High | Relatively High | Fair | High-alignment structure; superior axial thermal conductivity |

| PBO Fiber | ~0.3 [48] | None | Relatively High | Relatively High | Moderate | High-strength, heat-resistant aromatic heterocyclic fiber |

| PBO/MXene Composite | 25.6–42.2 [49] | Yes | Relatively High | Moderate | Fair | Nanocomposite thermal interface film with enhanced flexibility and conductivity |

| Defect Type | Material System | Thermal Conductivity Change Δκ (%) | Interface Thermal Resistance Influence | Mechanism Description | Reference |

|---|---|---|---|---|---|

| Vacancy | CNT | Single vacancies, double vacancies, and triple vacancies cause the thermal conductivity of carbon nanotubes to decrease by 8.1%, 10.9%, and 11.7%, respectively. | Double-vacancy defects increased the Kapitza length corresponding to the interface thermal resistance from 0.7752 nm to 0.9476 nm. | Phonon scattering enhancement. | [69] |

| Dislocations | CNT | When the dislocation density increases by 10 times, the thermal conductivity of carbon nanotubes decreases by approximately 20%. | Dislocations cause lattice distortion and phase transformation, disrupting the path of phonons and increasing thermal resistance. | Local electronic structure distortion. | [77] |

| Impurity atoms (dopants) | Double-layer graphene (AA stacking) | Impurity concentration: when ni increases from 0 to 0.1 and = 0.6, the thermal conductivity of bilayer graphene increases by approximately 15%. | Impurity atoms alter the local mass distribution and electronic environment, thereby enhancing phonon scattering. In addition, the application of a bias voltage modulates the interaction strength between impurities and charge carriers, further influencing thermal transport behavior. | Covalent bond interference and interface scattering are severe. | [72] |

| Structural defects (Stone–Wales) | Graphene–water interface | A 2% Stone–Wales defect (SW) in the material reduces the thermal resistance at the graphene–water interface by 30%. | The SW defect increases the coupling of low-frequency phonons. A single vacancy enhances the aggregation of water molecules and strengthens hydrogen bonds. | Uneven contact, interruption of heat conduction path. | [76] |

| System Type | Representative Material | ΔT (K) | Power Output | Mechanical Durability | Reference |

|---|---|---|---|---|---|

| TE (π-type CNT yarn) | Interwoven p/n-CNT yarn array | ~44 | ~70 mW/m2 | Stretchable up to 80% without degradation | [140] |

| Organic TE yarn | PEDOT:PSS/MWCNT and PVP on polyester yarn | ~7.1 nW | Stable under ambient wear | [137] | |

| TE + PCM hybrid | CNT/AuNP composite with MPCM | ~6.6 | ~270 nW | Retains integrity after moderate deformation | [139] |

| PCM-enhanced | Graphene + MPCM in woven cotton matrix | 27–35 | Maintains phase retention in repeated cycles | [149] | |

| PCM bilayer textile | rGO aerogel with PCM bilayer | Maintains 32–34 °C at −5 °C | Solar-adaptive, stable over outdoor use | [150] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Y.; Lin, S.; Xue, Y.; Ou, B.; Li, Z.; Zhao, J.; Wei, N. Design Innovation and Thermal Management Applications of Low-Dimensional Carbon-Based Smart Textiles. Textiles 2025, 5, 27. https://doi.org/10.3390/textiles5030027

Pan Y, Lin S, Xue Y, Ou B, Li Z, Zhao J, Wei N. Design Innovation and Thermal Management Applications of Low-Dimensional Carbon-Based Smart Textiles. Textiles. 2025; 5(3):27. https://doi.org/10.3390/textiles5030027

Chicago/Turabian StylePan, Yating, Shuyuan Lin, Yang Xue, Bingxian Ou, Zhen Li, Junhua Zhao, and Ning Wei. 2025. "Design Innovation and Thermal Management Applications of Low-Dimensional Carbon-Based Smart Textiles" Textiles 5, no. 3: 27. https://doi.org/10.3390/textiles5030027

APA StylePan, Y., Lin, S., Xue, Y., Ou, B., Li, Z., Zhao, J., & Wei, N. (2025). Design Innovation and Thermal Management Applications of Low-Dimensional Carbon-Based Smart Textiles. Textiles, 5(3), 27. https://doi.org/10.3390/textiles5030027