Abstract

The rapid production and disposal of synthetic textiles, driven by fast fashion and overconsumption, contribute significantly to environmental pollution and human health risks. Functional finishes often contain toxic substances that leach into aquatic systems. Laundering and abrasion release microplastic fibers (MPFs), commonly called microplastics, and anthropogenic microfibers (MFs) which degrade into nanoplastics (NPs) through mechanical stress, heat, and UV radiation. These particles bypass wastewater treatment and accumulate in human organs, including the liver, lungs, and brain. This review highlights the limitations of current waste management systems, the role of textile design in particle release, and the need for further research on airborne emissions and environmental interactions. Mitigating textile-derived plastic pollution will require biodegradable finishes, pre-consumer filtration systems, and circular consumption models supported by interdisciplinary collaboration.

Keywords:

fashion; textiles; pollution; plastics; microplastics; nanoplastics; waste; laundering; abrasion; finishing; environment; fibers 1. Introduction

Textile scientists broadly classify fibers used in apparel as either natural (plant-based/animal/protein) or manufactured (man-made/synthetic). Within the manufactured classification are fibers created from regenerated materials: cellulose, proteins, and synthetic fibers created from virgin feedstock (petrochemicals or biomass). In regenerated cellulosic textiles, wood pulp, taken from mature forests, soaks in a chemical solution and is treated to form a viscose, which is then treated with other chemicals to form the fiber, rayon, for use in textile spinning [1,2], whereas synthetics, nylon and polyester, undergo many processes of combining petrochemical-based monomers to form a solution, which is then heated to form a polymer. Chemical baths and other additives extrude the solution into a usable fiber. Based on the chemical processes, regenerated manufactured and synthetic fibers are made of similar chemical solutions and polymers to consumer-grade plastics. The end-use textiles of both types of manufactured fibers, no matter the feedstock, can produce microplastics (MPs) and, through various means, further degrade to form nanoplastics (NPs) [3,4]. To ensure clarity and consistency, this review adopts the definition of microplastics established by the European Chemicals Agency (ECHA). According to ECHA, microplastics are defined as

“A material consisting of a solid polymer containing particles, to which additives or other substances may have been added, and where a weight fraction of ≥1% particles meet one of the following criteria:

- (a)

- All sizes ranging from 100 nm to 5 mm;

- (b)

- For fibers, a length of 300 nm to 15 mm with a length-to-diameter ratio greater than 3.

Polymers that occur in nature and have not been chemically modified (except by hydrolysis), as well as those that are (bio)degradable, are excluded [5]”.

This definition is particularly relevant for the textiles sector, where synthetic polymer-based fibers—such as polyester, nylon, and acrylic—are a major source of microplastic and microplastic fiber (MPF) pollution throughout the product lifecycle. Additionally, anthropogenic microfibers (MFs) can contain microplastics as well as other fibers including cotton, rayon, or other man-made bio-cellulosic fibers [6,7]. Additionally, the International Standards Organization (ISO) defines MP as any solid plastic particle insoluble in water with dimensions between 1 µm and 1000 µm (=1 mm). MPs also meet the following conditions:

- (a)

- “Primary microplastics object represents a particle intentionally added to end-user products for example cosmetic means, coatings, paints etc.

- (b)

- Secondary microplastics object can also result as a fragment of the respective item. Microplastics have regular and irregular shapes.

- (c)

- The defined dimension is related to the longest length of the particle. [8]”

More importantly, a concern raised by environmentalists is the difficulty in clearly determining the amount of clothing produced each year using manufactured fibers, namely synthetic polyester, the most common fiber in modern clothing [9]. Manufactured fiber mills use an estimated 342 million barrels of oil to generate the virgin feedstock to produce synthetic fibers every year. More concerningly, estimations suggest that 35–40% of ocean MP and NP pollution is attributed to synthetic fibers from clothing and textiles. Despite the capacity and ability, consumers recycle or reuse less than 20% of clothing and textiles produced from synthetic fibers [10]. Beyond the fibers, industry professionals estimate that upwards of 100 billion garments are made annually, and about 30% of those are never worn and immediately sent to landfills, where they will take decades, even up to a century, to biodegrade [10]. These discarded never-worn garments are not directly contributing to the MP or NP problems found in wastewater and aquatic environments; however, due to the slow biodegradation and leeching, their impacts on the environment are not yet fully understood, nor has sufficient research been completed.

Once the clothing and/or textiles reach the disposal stage within the fashion cycle, those not sent to landfills are sent to be incinerated, releasing greenhouse gases that contribute to global warming [11,12]. While greenhouse gases occur naturally, human activity and artificial production, including the breakdown of MPs and NPs into atmospheric particles and the subsequent release of chemicals, contribute to further environmental concerns [11]. The increased MP and NP presence can significantly raise nitrous oxide, carbon dioxide, and methane emissions—all byproducts harmful to both the atmosphere and human health. Polyethylene terephthalate (PET), the most widely used virgin feedstock in the textile industry, has significantly contributed to environmental and human health concerns through common textile disposal practices [11].

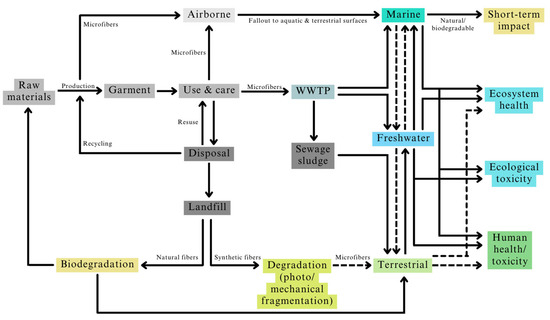

Manufactured fiber producers often claim that natural fibers, throughout their production process, use approximately 713 gallons of water compared to the 157 gallons of water for a single synthetic t-shirt [1,12]. With these claims, synthetics might be seen as a more sustainable option for the fashion industry, but compared to the lack of degradability, MP and NP effluence, and chemicals used in finishing to reduce unwanted fabrication issues, the environmental aftereffects offset the water consumption saving comparisons [9]. A reduction in the production of all fibers and fabrics combined with recycling/repurposing of existing fibers and fabrics is a foreseeable bandage for the overconsumption and textile pollution pandemic—and more importantly the rising crisis of MP and NP effects on environmental and human health [13]. Therefore, the purpose of this content review is to examine emerging research on the human health impacts of microplastics (MPs), microplastic fibers (MPFs), and nanoplastics (NPs) specifically linked to the lifecycle of textiles—from manufacturing and wear to laundering and disposal. By bridging environmental pollution with health science, this review highlights how synthetic fibers contribute to plastic particle exposure and identifies critical gaps in understanding their biological interactions and long-term health effects in both animals and humans. This interdisciplinary synthesis underscores the urgent need for sustainable textile production and care practices across the supply chain informed by health-focused research. The role of the textile supply chain in the release and environmental integration of synthetic particles—along with their potential downstream health impacts—is illustrated in Figure 1 [14].

Figure 1.

Textile supply chain, release of microfibers, and their impacts on ecological and human health. The dotted lines represent indirect or minor pathways of entry into the environment [14].

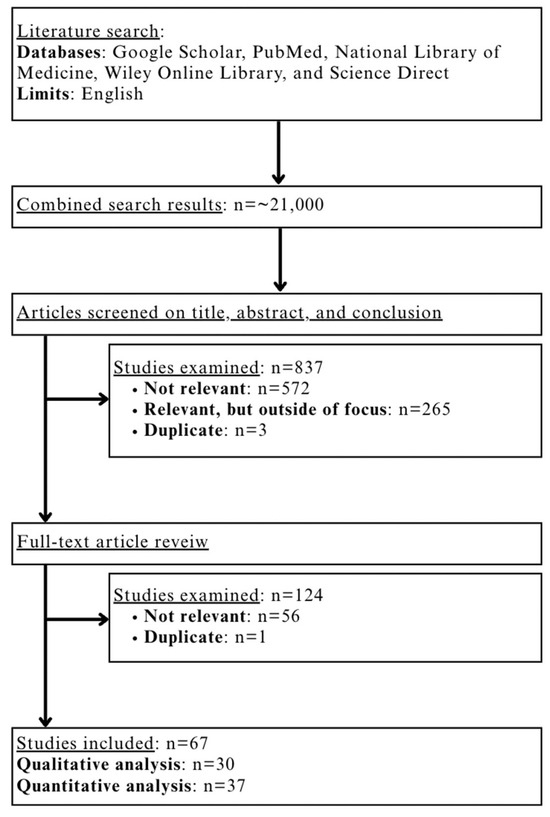

With the review of existing literature concerning the impacts of MPFs, MPs, NPs, and fabric finishing chemicals, the scope of the pollution crisis is vast. Touching physiological disruption, neurological dysregulation, and disruptions between key axes in the body, synthetic clothing and subsequent emissions reach far wider than the natural environment and land/marine species. The sources reviewed spanned far greater than the direct subject of this content review and provided a deeper understanding of the intimate relationship of plastics and the natural world. The breakdown of the relevant sources and the selection process of the articles to the content of this review are seen in Figure 2.

Figure 2.

Process of source selection and review.

The current research into the particulate plastic pollution is singularly focused, meaning that often factors like fashion are not considered as they are not the main polluter of this specific pollutant. Although many see the industry as vapid and shallow in terms of beauty, the industry is not held accountable for the role it plays in the global pollution pandemic. With that, the aim of this content review is to shed light on the role the industry plays and the importance of ethical and sustainable fashion on the environment and its inhabitants both in the short and long term.

2. Textiles and the Age of Plastics

Due to the prevalence of plastic pollution of all sizes, environmental scientists within multiple fields have stated that we are no longer in the Anthropocene but have entered a new epoch categorized by the assimilation of plastic into the environment called The Plasticene or The Age of Plastics [15,16]. The Plasticene is defined by the plastic fragments that scientists now use as stratigraphic markers from archeological field studies. With the main methods of uptake for MPs, MPFs, and NPs being identified as inhalation, ingestion, and dermal contact, it is important to state that multiple studies and sources have found that plastic fibers are one of the most abundant types of MPs, at 70.6%, ingested by fish [15].

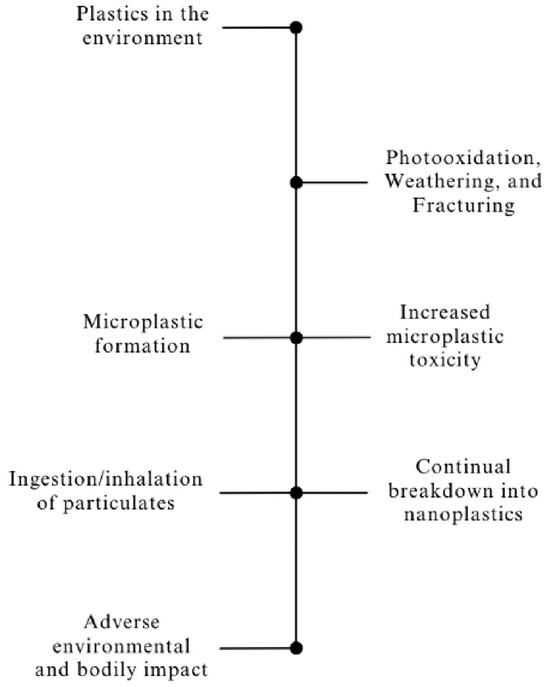

Plastic fragments are found in remote areas such as Antarctic snowpacks and as close as the human placenta [17]. Through ingestion, inhalation, and dermal contact, MPs and NPs, including those from synthetic fibers, have been found throughout the human body. From breast milk and blood to the placenta, lungs, and brain, MPs and NPs not only bioaccumulate but bio magnify in susceptible areas of the human body. The plastic degradation cycle, seen in Figure 3, is used to understand the process of how existing plastic in the environment undergoes degradation, leading to eventual uptake into the human body and marine/land species, supporting the need for research into the pollutant and its effects [18,19].

Figure 3.

Degradation of MPs to NPs in the environment [18,19].

With global changes and increased solar ultraviolet (UV) radiation, plastics in the environment undergo more intense photo-oxidation, which leads to fragmentation [19,20,21]. As some biodegrade with continual fracturing, many also mineralize, transforming from MPs to NPs, and uptake and biological impact are inevitable [20,21]. The increasing UV radiation is not the only concern, as increased and unpredictable natural events cause mechanical stress to the plastics and MPs already present in the environment, furthering their degradation into NPs [3,20,21,22]. A study into the enhancement of the internalization of MPs due to environmental exposure tested the internalization of MPs from fresh and salt water. Results showed that MPs exposed to fresh water for two to four weeks attached and became internalized by cells around ten times more often than control particles [23]. This increase in internalization was due to an eco-corona, making this an important factor in the cellular internalization of MPs [23]. With the findings and the understanding that heat influences the uptake of MPs and NPs into the body, the impacts of the climate crisis only grow more concerning with the large amount of plastic waste. When MPs are present in the environment, they can develop a layered structure of biomolecules on the surface: eco-corona. After interacting with organic matter in the environment, this eco-corona enhances the internalization capability of MPs [23].

The main entry point of MPs and other particulates is the gastrointestinal tract, but MPs can translocate into the circulatory systems and tissues, inducing inflammatory responses and necrosis (the death of most or all cells in tissue due to disease, injury, or failure of blood supply) [15,23]. A study aimed to quantify plastic particle pollution in human blood to further understand the global implications of the plastic crisis on humanity’s health [24]. Of the 22 participants involved, 17, or 77%, were found to have a quantifiable mass of plastic particles in their blood, PET being the most present [24]. PS, PE, and PMMA were the most present modes [24]. The uptake routes of plastic particles detected in the human bloodstream will likely be via mucosal contact, either through ingestion or inhalation [18,24]. With these findings, questions concerning a predisposition to diseases with an immunological base arise and warrant investigation [24].

Anxiety, a disorder that approximately over 15% of Americans will suffer from, has differing categorizations as they differ in terms of the real or imagined stimuli that produce anxiety; however, these disorders have the pathological expression of fear in common [25]. A study conducted concerning PS-MPs and the induction of anxiety and accumulation in mice is one of this first of its kind [26]. Through methods of Golgi staining of the dendritic spines and neurons, data showed that there was a significant lowering of dendritic spine density in mice exposed to PS-MPs compared to controls [26]. The significant inflammation seen in the study contributed to the connection between humans and MP consumption and inflammatory responses in the central nervous system (CNS) [22,26,27].

There have been two notable studies of the neurotoxic effects of MPs and NPs in rodents, the first of which found that exposure to PS-MPs resulted in presence in the gut, liver, and kidneys, and particle concentration in the tissues increased rapidly during the first week of exposure [22]. Acetylcholine (ACh) activity, a neurotransmitter (NT), was found to increase; however, metabolic changes suggest potential changes in neurotransmitter (NT) levels [9]. This study did not examine brain tissue; however, an in vitro rodent study showed that NPs can affect mitochondrial activity [22,28,29]. The in vitro study found that aged NPs stored for more than 6 months had increased toxicity while also revealing that microglia were able to internalize PS-NPs, suggesting the possibility for neuroinflammation [22].

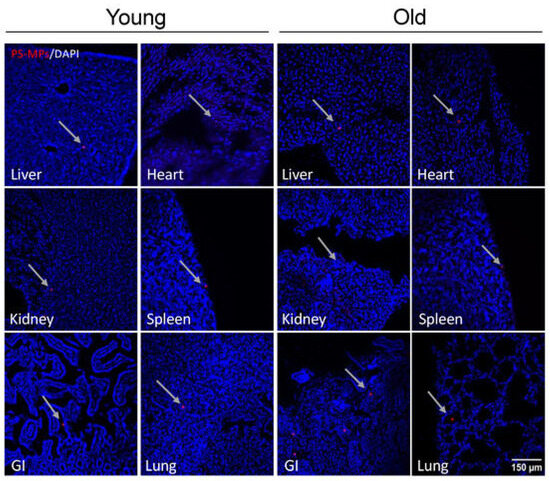

The aforementioned analysis found across species the presence of alterations in gene expression, inflammation of the gut, gills, liver, kidney, and/or muscle, and particle accumulation in tissues of the gills, intestines, liver, kidneys, gallbladder and/or gonads, as seen in Figure 4 [30]. Findings also added evidence of oxidative damage in the body and organs, disturbed metabolism, alterations in cell motion capabilities (motility) and behavior, and alterations in intestinal barrier function and gut microbiome [22,31]. Strikingly, in all species covered in the analysis, it was found that an overall reduction in fitness and increased mortality was present, which warrants immediate and thorough investigation into the impacts of MP and NP pollutants in regard to the human population as plastic is increasingly incorporated into every aspect of the modern human experience [22]. With systematic uptake of MPs and NPs eventually leading to passage into the brain, this causes ACh inhibition, altered NT levels, and oxidative stress [31,32,33]. ACh inhibition has been identified to be responsible for behavioral changes [9,32]. ACh is an NT that mediates fast synaptic transmission at neuromuscular junctions involved in neuroplasticity, motor functions, attention, memory, and arousal [22,30,34].

Figure 4.

The accumulation of PS-MPs in young and old mouse tissue samples. Images include the liver, heart, kidney, spleen, GI tract, and lung from 4-month-old and 21-month-old mice [30]. Arrow indicates PS-MPS.

Investigating bioaccumulation of MPs in the human brain and organs is extremely limited. A recent study compared concentrations of MPs by isolating and quantifying them using gas chromatography–mass spectrometry [35]. Results found that the brains exhibited higher concentrations than both liver and kidney samples; however, all organs had significantly increased concentrations from 2016 to 2024 [35]. PE-MPs were the predominant polymer found in organs and had the highest levels in brain samples. Results demonstrate that MPs are selectively accumulating in the human brain and concentrations are rising over time without filtering. More concerningly, MP concentrations in samples ranged from 7 to 30 times the concentration seen in the liver or kidneys [35].

3. Health Impacts of the Production of Synthetic Fibers

It is important to note that although cellulosic and other natural fibers release microfibers, these are not classified as MPs [36]. This distinction is important when understanding and correctly assessing the scope of pollution and its impacts on human health. In fabric production, the finishing of the textile is crucial to give it desired qualities such as water repellency or anti-static functioning. Polymeric NPs are plastic debris emitted from the finishes (coatings), and are within the nanometric scale [36]. The most common finishes include water repellents, antimicrobials, flame retardants, softeners, crease recovery, and UV protectants [36]. These polymeric finish coatings involve polymers such as Polyamide (PA), Polypropylene (PP), Polystyrene (PS), Polyethylene (PE), Polyvinyl chloride (PVC), and PET, but MPs and NPs can also come from less commonly used plastics such as Polycarbonate (PC) [2,36].

Finishes protect against various mechanical, physical, and chemical stresses, and while important, they produce micro and nano debris along with fiber fragments produced by wear and laundering. Table 1 shows different functional finishes, their performed function, and the specific polymer(s) used in the production [36]. Other finishing categories are aesthetic or mechanical and chemical finishes [2]. Functional finishes improve performance characteristics, mechanical/aesthetic finishes improve the look and feel, and chemical finishes can modify fabric qualities [2]. During the finishing stages, applied residues, including plasticizers, dyes, antioxidants, flame retardants, and UV stabilizers, increase health concerns through dermal contact prior to laundering [20,21,37]. Synthetic dyes, phthalates, flame retardants, and UV stabilizers are commonly used in clothing, from children’s sleepwear to fast fashion, in a variety of product assortments [36,38,39]. Many of these ultra-consumeristic, fashion-focused, and low-price-driven companies not only commit environmental and ethical violations but have also been identified as using hazardous chemicals in their products like phthalates, formaldehyde, heavy metals, and many others [39,40,41]. PET, PA, and Polyurethane (PU) are commonly used in coating textiles, and all have the potential to release MPs, which is of concern as they can act in a wide variety of functional finishes, as seen in Table 1, including durability, breathability, wind proofing, elasticity, and stretch recovery [36,42].

Table 1.

Finishes, functions, and polymers used in the production and application of coating textiles [2,35].

Formaldehyde, a known human carcinogen, was investigated to determine the presence of the chemical in eco-friendly clothing in addition to washed and unwashed conditions [40,41]. Surprisingly, the study found higher concentrations of the chemical in eco-friendly clothing than in non-eco-friendly options made up of synthetic or synthetic blend fibers, but this was only the case for undergarments. This brings greenwashing into the picture, a deceptive practice within, but not limited to, the fashion industry whereby brands frame their identities to be sustainable, hiding non-sustainable practices in company supply chains. A study explored dermal exposure to three vulnerable groups, pregnant women, babies, and toddlers, among which they found babies to be exposed to the highest amount of formaldehyde. The study makes it a point to note that clothing containing other chemicals increases health risks, but no detectable amounts of formaldehyde were found in washed clothing, which is an excellent practice for consumers to protect their dermis from exposure in their clothing [40].

Chemicals involved in the finishing of garments include antimony (Sb), aluminum (Al), zinc (Zn), cadmium (Cd), tin (Sn), arsenic (As), lead (Pb), titanium (Ti), and other chemicals that can all have adverse bodily reactions [38,43]. In terms of use in flame retardancy, Sb, Al, and Zn are used and later mentioned to have harmful effects [38]. As for UV stabilizers, Cd, Sn, Pb, and Ti are involved [38,43,44]. Specifically discussing Pb, a study investigated the blood lead levels concerning major depressive disorder, panic disorder, and generalized anxiety disorder [44]. The results showed that in young adults, higher blood lead levels were associated with increased odds of major depression and panic disorders, and the study made it a point to note that exposure to lead levels generally considered safe could result in adverse mental health outcomes [25,44]. Within the sustainability conversation, working rights and ethical regulations for employees are often glazed over. The results of a multitude of studies beg further investigation on the impacts these chemicals are having on finishing and garment laborers [25,38,44].

Hydrophobic surfaces are highly valued when producing fabrics for end-use: outdoor gear, protective gear, sportswear, stain-resistant garments, and rain gear [2]. PE is the most common polymer used for hydrophobic finishing surfaces, but this polymer and the release of NPs generated can have potential health impacts on nutrient digestion and absorption [36]. With studies mentioned in [36], the consensus moving forward with the results is to first make alterations to the design and production components of fabrics by using natural fibers, finding alternative manufacturing processes, and utilizing a pre-washing procedure at the textile manufacturing center. In addition to the suggested design and production changes, it is also stated that replacing polymeric finishes with biodegradable finishes could be highly beneficial to the environment and human health. The manufacturing and production suggestions also involve the disposal processing of textiles and clothing as it is necessary to have better textile management, wastewater treatment, wastewater treatment sludge, and removal of MPs from the environment [36].

Another key factor is the chemicals used in the finishing and dyeing of both cellulosic and synthetic fibers. As previously noted, finishes can range from crease recovery and water repellency to flame retardancy and antimicrobial, all of which significantly reduce the biodegradability of textile fibers and can further contaminate the environment [19,45]. Most dyes, pigments, chemicals, and other components of finishes and dyes for textiles and garments have mutagenic potential, which can damage DNA [46,47]. MPs have been shown to possess a Trojan Horse ability whereby they carry pollutants such as endocrine-disrupting chemicals (EDCs), heavy metals, and neurologically impacting chemicals into the body [4,48].

The methods of reducing MPs and NPs in the environment and human bodily systems are important moving forward for the fashion industry and its consumers, as NPs have been identified as posing several risks to humans and ecology [22,36,46]. Although the toxicity of NPs has not even begun to be fully explored, they are widely detected in the food chain and environment, suggesting the hazardous nature of this pollutant. Findings show that cell internalization and impacts on intracellular systems are both hazardous qualities NPs have shown to possess [22]. There are many challenges to studying the impacts of NPs, such as difficulty in detecting NPs, elimination of pollutants, recycling procedures, and aged NPs and their subsequent effects.

4. Production of Microplastics and Nanoplastics by Consumers

Domestic laundering releases around half a million tons of MPs and NPs into wastewater systems yearly, equivalent to almost three billion polyester shirts [37]. The primary source of MPs in aquatic environments is directly connected to microfibers in the wastewater released after a domestic washing cycle [49]. These synthetic MPs in sizes and dimensions ranging from 1 μm to 5 mm easily pass through the sophisticated filtration systems of urban WWTPs and are distributed into natural water systems in treated effluents [7,12]. These MP fibers then seep into aquatic environments and affect ecosystems along coastlines as well as inland regions. It has been estimated that upwards of 70% of plastic-based marine pollutants are predicted to originate from inland sources, such as migrating through rivers [12,38,50,51]. Sources have also found that MPs ingested by zooplankton could cause increased mortality rates of the species. As ecosystems function in tandem, this increased mortality could lead to unknown effects as zooplankton are vital, providing a link between phytoplankton and larger predators such as fish, marine mammals, and seabirds [7,33].

During each washing cycle, finishes degrade, releasing MPs and NPs into the environment, potentially impacting human health [36,51]. During washing, two types of effluents are produced, the first being MPs and NPs released from the coatings and the second being the MPs and NPs from fragments of synthetic fibers which can bond with the coatings [36,49]. Primary MPs are directly released into the environment as small plastic particles less than 5 mm in size. This includes the fragments released during the home laundering process. Other sources of primary MPs include cosmetics and many industrial applications such as tires, marine coatings, and road markings. Secondary MPs are the byproducts of plastics and/or primary MPs already present in the environment, which can arise from numerous weathering sources [38,47]. It is important to note that cellulosic fibers are also present in global water sources; however, they biodegrade.

Saravanja et al. (2022) reported that synthetic clothing contributes approximately 35% of the MPs to the world’s oceans, which is expected as synthetic fibers make up upwards of 60% of global fiber consumption. Researchers investigated MP release by comparing polyester, recycled polyester, and polyester blended garments using household laundering practices [52]. Results confirm, despite the differences in fiber blends, that domestic washing of textiles and garments is a widespread source of the emission of MP fibers (MPFs) into the environment [52]. Across multiple studies, when looking into the volume of MPs released during home laundering practices, release volume was dependent on and influenced by factors such as type of washed garment, fiber content, type of yarns, yarn twists, and pore size of microfibers [6,12,52]. Other factors that have been noted as contributors to increased releases of MPs are the temperature of the wash and dry cycles, the detergent used, and the physical characteristics, such as shear and tensile strength, bending, and compression [6,53].

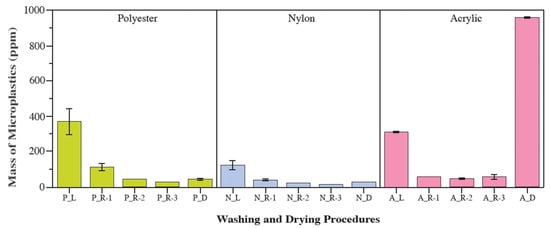

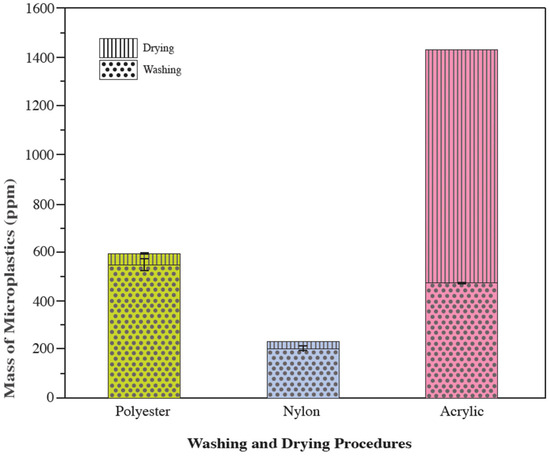

Ref. [6] quantified the release of MPs across polyester, nylon, and acrylic garments and assessed them on three physical properties: fuzziness and pilling, tensile strength, and elongation [6]. The physical characteristic of fuzziness and pilling was artificially generated using friction on the fabric’s surface with a grading scale of 1 to 5 [6,54]. The tensile strength was measured with swatches from the weft and warp directions. Wastewater was also collected and analyzed to determine the quantity of MPs present after the laundering procedure [48,55]. Results were consistent with similar studies in that the washing procedures were repeated and progressed as seen in Figure 5 and Figure 6 [6,54,55]. The specimens showed a decrease in the overall MPF release; however, continual washing procedures increased the shedding of MPFs [11,12]. The total amount of MPs released during the experiment was highest for acrylic, followed by polyester and nylon. The release was higher for polyester and nylon during washing, while acrylic released more during drying, as seen in Figure 5 [6,54,55]. An investigation into the possible relationship between dryer sheets and MP fiber release is needed to better understand the scope of MPFs and MPs released during drying. Findings indicated that fabrics with a higher yarn-breaking strength, abrasion resistance, and flexural stiffness showed a lower tendency to pill and produce fuzz, thus releasing fewer MPs during the mechanical process of washing and drying [53].

Figure 5.

The mass of MPs generated during washing and drying procedures (P, N, and A represent polyester, nylon, and acrylic; L refers to the laundering process; R-1, R-2, and R-3 correspond with the rinsing processes; D refers to the drying process) [6,54,55].

Figure 6.

The total mass of MPs released during washing and drying [6,54,55].

Related studies investigated MPFs released from polyester and polyester blends during domestic laundering [51,56]. In addition to the impact of MPs on the environment, MPFs from domestic laundering wastewater can be ingested by environmental organisms and act as contaminant transporters [56]. Many apparel manufacturers will blend polyester with cotton to increase the value of the garment as the qualities of polyester, durability and affordability, are enhanced by the qualities of cotton, softness and breathability [2]. When comparing MPF release from polyester–cotton, 100% polyester, and 100% acrylic samples from domestic laundering, findings indicated that the polyester–cotton fabric consistently shed fewer MP fibers when compared to the 100% polyester and 100% acrylic samples [54,55,57]. Researchers estimate that over 700,000 fibers could be released from an average wash load of 100% polyester or 100% acyclic clothing, compared to significantly less amounts with cellulosic/synthetic blends limiting serious threats to the aquatic environment and overall human health [57].

MPFs released into the wastewater systems are not the only concern to researchers. During the domestic laundering process, MPFs are also released into the air as part of the mechanical drying process. To quantify airborne emissions of MPs from domestic laundry dryers, researchers repeatedly washed and dried a blue polyester fleece blanket using the normal dry program on the dryer, which operated for twenty minutes per session [42,54,58]. Findings indicated that mechanical drying is a source of MPF emission, specifically that polyester drying emits MPs into the surrounding indoor air [59]. As inhalation is a form of MP and NP entry into the body, airborne MP fibers from dryers should be further investigated to explore impacts on human health as well as procedures to reduce MPF release from domestic drying of synthetic fibers.

Beyond the physical characteristics of synthetic textiles, powder detergents contain an inorganic component called zeolite, which increases the friction between the clothing in the machine and increases the emission of MPs due to abrasion [47,58]. Interestingly, using detergent acted as a catalyst for an increase in the release of MPs in the laundering process [47]. Studies have shown that the garment-to-washing liquid ratio factors in when looking into the volume of MPs generated. Findings explain that a higher water volume increases the mechanical stress on garments during the washing process, contributing to higher amounts of MPFs released [47].

Shedding involves the release of fibers from textiles due to wear, washing, and drying. All fabrics shed, but polyester produces the most significant volume of MPFs [60]. Findings showed that loosely knitted textiles shed more, especially when worn, and that highly twisted yarns are more effective in reducing shed [60]. The degree of shedding and the potential harm of the MPFs released must be acknowledged, particularly regarding synthetics and their finishes, which often contain harmful chemicals [61].

Although laundering has traditionally been considered a primary source of MP emission from textiles, textile-to-textile abrasion during wear has been shown to release over 10 times more MPs and fibrils than washing alone. Fibrils are produced when MP fibers fragment, forming small thread-like plastic particles. A study that examined synthetic textiles, specifically 12 polyester textiles, found that one gram of textile released between 4900 and 640,000 MPFs and 0 to 350,000 fibrils [62]. The average ratio of fibrils to MPs was 0.8. The formation of pilling on the textile’s surface was identified as a key indicator of MP and fibril release [62,63]. Pilling is commonly observed in cotton, polyester, nylon, and acrylic fabrics, as well as their blends.

Typically, microplastics (MPs) range from 5 millimeters (mm) to 1 micrometer (µm), but nanoparticles (NPs) are even smaller—less than 1 micrometer (μm) [3]. Nanoparticles—whether engineered for specific functions or naturally occurring in the environment—can impart desirable properties to products due to their unique surface characteristics, often in a cost-effective way [64]. In textiles, NPs are used to enhance performance. For instance, because synthetic fibers such as polyamide and polyester are highly flammable, nanoparticles are often applied as fabric finishes to mitigate this trait [64,65]. However, the emergence of NPs in the environment raises new concerns about their toxicity and long-term impact.

Fabric finishes are an essential component of synthetic textiles and can range from antimicrobial to UV stabilizers, but these often contain harmful chemicals like phthalates and polyfluoroalkyl substances (PFASs) [61,66]. PFASs are a large class of manufactured chemicals known for their heat, grease, and water resistance, making them ideal for finishing textiles with specific functions [67]. When textiles experience mechanical stress from wash or wear, fibers rub against each other, causing friction that leads to the breaking and release of tiny particles less than 500 µm in length [66].

To limit MP release, researchers have explored filtration improvements in washing machines to prevent MPF entry into sewage systems. However, these solutions often overlook fiber release due to wear and friction. One promising development involves applying a low-friction coating to polyester and nylon fabrics. Tests showed that coated fabrics, after five one-hour wash cycles at 104 °F, released 84–96% fewer MPs [61,66]. Despite this success, environmental experts caution that the use of PFASs in these coatings still poses ecological threats [33,66].

5. Discussion

Despite increasing evidence of global environmental degradation, climate- and fashion-related waste research remains underfunded and underprioritized. While public discourse may be divided on climate change, the proliferation of waste—especially from the fashion industry—is a visible and measurable crisis. Landfills are overwhelmed, natural fibers fail to biodegrade due to compaction, and synthetic fabrics add to toxic buildup through chemical leaching and greenhouse gas emissions during decomposition or incineration [68]. These issues demand innovative interventions in textile waste management, including the potential development of wastewater treatment systems for synthetic textiles to capture and process MPFs before they enter aquatic ecosystems.

Laundering and textile abrasion are leading sources of MPF pollution, with estimates suggesting that over 500,000 tons of MPFs are released into aquatic environments annually [63]. Although wastewater treatment plants (WWTPs) can filter out some MPs, they are not designed to handle this scale or type of pollutant. Additionally, abrasion during wear can release more than ten times the MP volume of laundering alone, especially in synthetic fabrics prone to pilling [63].

Textile characteristics such as fiber type, knit structure, and yarn twist influence the degree of shedding, with polyester shedding the most during washing and acrylic during drying [6,60]. The problem is compounded by the use of powder detergents containing zeolite, which increases mechanical friction and MPF release [47]. Airborne emissions from dryers, though understudied, are an emerging concern, particularly due to the potential for MP inhalation [42]. These airborne pathways need further investigation, especially for commonly used synthetic fabrics such as nylon, acrylic, and polyester.

Fabric finishes designed to improve functionality—such as antimicrobial coatings, UV resistance, or flame retardancy—often contain substances like PFASs and phthalates. These chemicals contribute to environmental toxicity and present risks to human health through dermal exposure or particulate release during laundering and wear. While low-friction textile coatings have shown promise in reducing MPF shedding, the trade-off of introducing other harmful compounds must be carefully evaluated [66].

Broader environmental factors, such as rising global temperatures and increased UV radiation, accelerate the degradation of plastics into NPs, increasing their bioavailability and toxicity [3,38,58]. Ocean salinity changes due to warming and evaporation further complicate the potential uptake of MPs and NPs by marine species. These interactions represent critical gaps in current research and could have cascading impacts on biodiversity and human health.

Ultimately, addressing this systemic problem requires a fundamental shift in how the fashion industry engages with sustainability. From investing in regenerative materials and localizing waste treatment to rethinking overproduction, fashion must take responsibility for its environmental impact. Similarly, consumers must be supported in adopting circular practices such as buying second-hand, upcycling, reducing consumption, and exchanging goods between each other. The relationship between overproduction, overconsumption, and environmental harm is not just a matter of industry ethics—it is a global health imperative.

6. Conclusions and Research Outlook

This review consolidates current research on the environmental and human health impacts of microplastic fibers (MPFs), microplastics (MPs), and nanoplastics (NPs) originating from the production, use, and disposal of synthetic textiles. It is evident that the fashion industry, particularly through the widespread use of polyester, nylon, acrylic, and blended synthetic fabrics, is a significant contributor to particulate plastic pollution. Laundering, textile-to-textile abrasion, and chemical finishing treatments further exacerbate the release and fragmentation of these particles, which are increasingly found in both environmental systems and human biological tissues.

Key findings emphasize the inadequacy of current waste management and water treatment systems to mitigate the release and accumulation of MPs, MPFs, and NPs. Additionally, the chemical complexity of textile coatings—many of which include harmful substances such as PFASs, phthalates, and heavy metals—introduces further ecological and physiological risks. With documented evidence of MPs in blood, placenta, and vital organs, and a growing understanding of their potential to bioaccumulate and disrupt immune and endocrine function, the urgency for reform is clear.

Looking forward, several areas require immediate attention. These include the development of pre-consumer interventions such as pre-washing systems and fiber-engineering solutions to reduce shedding, as well as the replacement of polymeric finishes with biodegradable alternatives. Research must also address the knowledge gap surrounding airborne MPF emissions from domestic drying and their implications for indoor air quality. The interaction between MPs and environmental variables such as temperature and salinity also presents a critical avenue for future study, particularly in the context of climate change and marine biodiversity.

To mitigate the multifaceted consequences of particulate plastic pollution, the fashion industry must adopt systemic reforms grounded in sustainability, material innovation, and transparency. Equally, consumers must be prepared to shift toward circular consumption models. Continued interdisciplinary collaboration across fashion, environmental science, public health, and engineering will be essential in advancing the understanding and resolution of this global issue.

As the discovery of MPFs, MPs, and NPs is relatively nascent, along with corresponding research, this offers the opportunity for a dedicated field of study examining the relationship between textile and fashion consumerism, environmental impacts, and bodily harm. Preliminary studies have investigated the possibility of a number of solutions aimed at mitigating future pollution: firstly, regenerative agriculture, which involves utilizing cotton fibers and fabric waste to develop agricultural applications for crop maintenance and production [65]. Secondly is the gasification of MPs, MPFs, and NPs gathered from WWTPs, but there are only two current investigations into this possibility [69]. This solution, however, would involve a specific collection system for the separation of plastic pollutants from water, requiring large investigations to produce logistical solutions.

Other avenues to explore would be to work with other forms of waste disposal such as the meat packing industry to use leathers and skins that are designated for disposal, creating a feedback loop for the leather and skins sector of the fashion industry. Applications in mushrooms, seaweed, and algae could provide interesting advancements in both fabrication and finishing of textiles. Additionally, the continual evolution of recycling polyester and other synthetic fibers, if more efficient and widespread, could also create a fashion feedback loop whereby production coincides with reprocessing into another textile. Lastly, the industry itself, along with consumers, must acknowledge and accept that not only is the supply chain timeline far too fast, resulting in overproduction, but that this haste has compromised the quality of the textiles and garments, massively decreasing the textile’s lifecycle. If the focal point of the fashion industry, across price and product classifications, was on quality and sustainability, likely, overproduction, overconsumption, and pollution would all decrease.

From reviewing sources pertaining to the subject of this review, beyond the concern of the impacts of the particulate pollutants produced from synthetic textiles, is the opportunity to innovate for the fashion industry. It is vital to move forward with an interdisciplinary approach to fully eradicate the plastic pollutant crisis. Creativity and ingenuity are some of humanity’s redeeming qualities, and with the ever expanding scientific, technological, and design-focused advancements, the future of fashion, if it adopts bio-technology, could lead to new applications and discoveries outside of the main vein of the industry. The current research compiled for this review highlights that a cascade of innovations throughout the supply chain are necessary for the fashion industry to repair the harm it has set in motion and to ensure that the future industry is transparent, sustainable, and ethical above all else.

Author Contributions

Conceptualization, A.P.L. and C.F.; methodology, A.P.L.; software, A.P.L.; validation, C.F. and L.B.-S.; formal analysis, A.P.L.; investigation, A.P.L.; resources, C.F.; data curation, L.B.-S.; writing—original draft preparation, A.P.L.; writing—review and editing, C.F. and L.B.-S.; visualization, A.P.L. and L.B.-S.; supervision, C.F. and L.B.-S.; project administration, C.F. and L.B.-S.; funding acquisition, C.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| MPs | Microplastics |

| MPFs | Microplastic fibers |

| NPs | Nanoplastics |

| PA | Polyamide |

| PC | Polycarbonate |

| PE | Polyethylene |

| PET | Polyethylene terephthalate |

| PFAS | Polymethyl methacrylate |

| PP | Polypropylene |

| PS | Polystyrene |

| PU | Polyurethane |

| PVC | Polyvinyl chloride |

| UV | Ultraviolet |

| WWTP | Wastewater treatment plant |

References

- Common Objective. (2021, December 10). Synthetics & Sustainable Synthetics: Global Production. Common Objective. Available online: https://www.commonobjective.co/article/synthetics-sustainable-synthetics-global-production (accessed on 10 February 2025).

- Kadolph, S.J.; Marcketti, S.B. Textiles, 12th ed.; Pearson: London, UK, 2017. [Google Scholar]

- Gigault, J.; Halle A ter Baudrimont, M.; Pascal, P.-Y.; Gauffre, F.; Phi, T.-L.; El Hadri, H.; Grassl, B.; Reynaud, S. Current opinion: What is a nanoplastic? Environ. Pollut. 2018, 235, 1030–1034. [Google Scholar] [CrossRef] [PubMed]

- Toxicity of Synthetic Fibres Health. (n.d.). Austinpublishinggroup.com. Available online: https://austinpublishinggroup.com/textile-engineering/fulltext/arte-v2-id1012.php (accessed on 4 February 2025).

- Directorate-General for Research and Innovation; European Commission; CEU. SAM_ADV. Environmental and Health Risks of Microplastic Pollution: A Scientific Opinion. Publications Office of the European Union: Brussels, Belgium, 2019. Available online: https://coilink.org/20.500.12592/5tf18p (accessed on 19 May 2025).

- Choi, S.; Kim, J.; Kwon, M. The Effect of the Physical and Chemical Properties of Synthetic Fabrics on the Release of Microplastics during Washing and Drying. Polymers 2022, 14, 3384. [Google Scholar] [CrossRef]

- De Falco, F.; Di Pace, E.; Cocca, M.; Avella, M. The contribution of washing processes of synthetic clothes to microplastic pollution. Sci. Rep. 2019, 9, 6633. [Google Scholar] [CrossRef] [PubMed]

- ISO 24187:2023; Principles for the Analysis of Microplastics Present in the Environment. International Organization for Standardization: Geneva, Switzerland, 2023.

- Wang, S.; Han, Q.; Wei, Z.; Wang, Y.; Xie, J.; Chen, M. Polystyrene microplastics affect learning and memory in mice by inducing oxidative stress and decreasing the level of acetylcholine. Food Chem. Toxicol. 2022, 162, 112904. [Google Scholar] [CrossRef]

- Igini, M. 10 Concerning Fast Fashion Waste Statistics. Earth.org. 2023. Available online: https://earth.org/statistics-about-fast-fashion-waste/ (accessed on 17 March 2025).

- Chen, X.; Xie, Y.; Wang, J.; Shi, Z.; Zhang, J.; Wei, H.; Ying, M. Presence of different microplastics promotes greenhouse gas emissions and alters the microbial community composition of farmland soil. Sci. Total Environ. 2023, 879, 162967. [Google Scholar] [CrossRef]

- Ullah, S.; Ahmad, S.; Guo, X.; Ullah, S.; Ullah, S.; Nabi, G.; Wanghe, K. A review of the endocrine disrupting effects of micro and nano plastic and their associated chemicals in mammals. Front. Endocrinol. 2023, 13, 1084236. [Google Scholar] [CrossRef]

- Thompson, R.C.; Courtene-Jones, W.; Boucher, J.; Pahl, S.; Raubenheimer, K.; Koelmans, A.A. Twenty years of microplastic pollution research—What have we learned? Science 2024, 386, eadl2746. [Google Scholar] [CrossRef] [PubMed]

- Henry, B.; Laitala, K.; Klepp, I.G. Microfibres from apparel and home textiles: Prospects for including microplastics in environmental sustainability assessment. Sci. Total Environ. 2019, 652, 483–494. [Google Scholar] [CrossRef]

- Lim, K.P.; Lim, P.E.; Yusoff, S.; Sun, C.; Ding, J.; Loh, K.H. A Meta-Analysis of the Characterisations of Plastic Ingested by Fish Globally. Toxics 2022, 10, 186. [Google Scholar] [CrossRef]

- Rangel-Buitrago, N.; Neal, W.J.; Nicoll, K. Is Earth in a new time period: The plasticene? Front. Young Minds 2023, 11, 1210561. [Google Scholar] [CrossRef]

- Aves, A.R.; Revell, L.E.; Gaw, S.; Ruffell, H.; Schuddeboom, A.; Wotherspoon, N.E.; LaRue, M.; McDonald, A.J. The first evidence of microplastics in Antarctic snow. Cryosphere 2022, 16, 2127–2145. [Google Scholar] [CrossRef]

- Barceló, D.; Picó, Y.; Alfarhan, A.H. Microplastics: Detection in human samples, cell line studies, and health impacts. Environ. Toxicol. Pharmacol. 2023, 101, 104204. [Google Scholar] [CrossRef] [PubMed]

- Suran, M. A planet too rich in fibre: Microfibre pollution may have major consequences on the environment and human health. EMBO Rep. 2018, 19, e46701. [Google Scholar] [CrossRef]

- Andrady, A.L. The plastic in microplastics: A review. Mar. Pollut. Bull. 2017, 119, 12–22. [Google Scholar] [CrossRef] [PubMed]

- Andrady, A.L.; Barnes, P.W.; Bornman, J.F.; Gouin, T.; Madronich, S.; White, C.C.; Zepp, R.G.; Jansen, M.A.K. Oxidation and fragmentation of plastics in a changing environment, from UV-radiation to biological degradation. Sci. Total Environ. 2022, 851, 158022. [Google Scholar] [CrossRef]

- Prüst, M.; Meijer, J.; Westerink, R.H.S. The plastic brain: Neurotoxicity of micro- and nanoplastics. Part. Fibre Toxicol. 2020, 17, 24. [Google Scholar] [CrossRef] [PubMed]

- Ramsperger, A.F.; Narayana, V.K.; Gross, W.; Mohanraj, J.; Thelakkat, M.; Greiner, A.; Schmalz, H.; Kress, H.; Laforsch, C. Environmental exposure enhances the internalization of microplastic particles into cells. Sci. Adv. 2020, 6, eabd1211. [Google Scholar] [CrossRef] [PubMed]

- Leslie, H.A.; van Velzen, M.J.M.; Brandsma, S.H.; Vethaak, A.D.; Garcia-Vallejo, J.J.; Lamoree, M.H. Discovery and quantification of plastic particle pollution in human blood. Environ. Int. 2022, 163, 107199. [Google Scholar] [CrossRef]

- Kolb, B.; Whishaw, I.Q. Fundamentals of Human Neuropsychology, 8th ed.; Macmillan Education: Midrand, South Africa, 2021. [Google Scholar]

- Li, G.; Liu, X.; Sun, X.; Huang, L.; Kuang, W.; Ou, J.; Zhang, J.; Zhang, Z.; Li, H.; Tang, H.; et al. Polystyrene microplastics induce anxiety via HRAS derived PERK-NF-κB pathway. Environ. Int. 2024, 185, 108543. [Google Scholar] [CrossRef]

- Bear, M.F.; Connors, B.W.; Paradiso, M.A. Neuroscience: Exploring the Brain, 4th ed.; Wolters Kluwer, Cop.: Baltimore, MD, USA, 2015. [Google Scholar]

- Banerjee, A.; Shelver, W.L. Micro- and nanoplastic induced cellular toxicity in mammals: A review. Sci. Total Environ. 2021, 755, 142518. [Google Scholar] [CrossRef]

- Barboza, L.G.A.; Otero, X.L.; Fernández, E.V.; Vieira, L.R.; Fernandes, J.O.; Cunha, S.C.; Guilhermino, L. Are microplastics contributing to pollution-induced neurotoxicity? A pilot study with wild fish in a real scenario. Heliyon 2023, 9, e13070. [Google Scholar] [CrossRef] [PubMed]

- Gaspar, L.; Bartman, S.; Coppotelli, G.; Ross, J.M. Acute Exposure to Microplastics Induced Changes in Behavior and Inflammation in Young and Old Mice. Int. J. Mol. Sci. 2023, 24, 12308. [Google Scholar] [CrossRef] [PubMed]

- Mills, B. Can Plastic Harm the Brain? Cognitive Vitality. Alzdiscovery.org. 2023. Available online: https://www.alzdiscovery.org/cognitive-vitality/blog/can-plastic-harm-the-brain (accessed on 3 March 2025).

- Prins, R. Microplastics Appear to Promote Dementia. Plastic Soup Foundation. 2023. Available online: www.plasticsoupfoundation.org/en/2023/09/microplastics-appear-to-promote-dementia/ (accessed on 4 February 2025).

- Gaylarde, C.; Baptista-Neto, J.A.; da Fonseca, E.M. Plastic microfibre pollution: How important is clothes’ laundering? Heliyon 2021, 7, e07105. [Google Scholar] [CrossRef]

- Farmer, T.A.; Matlin, M.W. Cognition, 11th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2023. [Google Scholar]

- Campen, M.; Nihart, A.; Garcia, M.; Liu, R.; Olewine, M.; Castillo, E.; Bleske, B.; Scott, J.; Howard, T.; Gonzalez-Estrella, J.; et al. Bioaccumulation of microplastics in decedent human brains assessed by pyrolysis gas chromatography-mass spectrometry. Res. Sq. 2024, 3, rs-4345687. [Google Scholar] [CrossRef]

- Ali, A.; Qamer, S.; Shahid, M.; Tomkova, B.; Zaman Khan, M.; Militky, J.; Wiener, J.; Venkataraman, M. Micro- and nanoplastics produced from textile finishes: A review. Langmuir 2024, 40, 17849–17867. [Google Scholar] [CrossRef]

- UNEP. Fashion’s Tiny Hidden Secret. UN Environment. 2019. Available online: https://www.unep.org/news-and-stories/story/fashions-tiny-hidden-secret (accessed on 25 February 2025).

- Campanale, C.; Massarelli, C.; Savino, I.; Locaputo, V.; Uricchio, V.F. A Detailed Review Study on Potential Effects of Microplastics and Additives of Concern on Human Health. Int. J. Environ. Res. Public Health 2020, 17, 1212. [Google Scholar] [CrossRef]

- Greenpeace International. Taking the Shine off Shein: Hazardous Chemicals in Shein Products Break EU Regulations, New Report Finds. 2022. Available online: https://www.greenpeace.org/international/press-release/56979/taking-the-shine-off-shein-hazardous-chemicals-in-shein-products-break-eu-regulations-new-report-finds/ (accessed on 11 March 2025).

- Herrero, M.; González, N.; Rovira, J.; Marquès, M.; Domingo, J.L.; Nadal, M. Early-life exposure to formaldehyde through clothing. Toxics 2022, 10, 361. [Google Scholar] [CrossRef]

- Herrero, M.; Rovira, J.; Esplugas, R.; Nadal, M.; Domingo, J.L. Human exposure to trace elements, aromatic amines and formaldehyde in swimsuits: Assessment of the health risks. Environ. Res. 2020, 181, 108951. [Google Scholar] [CrossRef]

- O’Brien, S.; Okoffo, E.D.; O’Brien, J.W.; Ribeiro, F.; Wang, X.; Wright, S.L.; Samanipour, S.; Rauert, C.; Toapanta, T.Y.A.; Albarracin, R.; et al. Airborne emissions of microplastic fibres from domestic laundry dryers. Sci. Total Environ. 2020, 747, 141175. [Google Scholar] [CrossRef]

- Shi, Y.; Zheng, L.; Huang, H.; Tian, Y.-C.; Gong, Z.; Liu, P.; Wu, X.; Li, W.; Gao, S. Formation of Nano- and Microplastics and Dissolved Chemicals During Photodegradation of Polyester Base Fabrics with Polyurethane Coating. Environ. Sci. Technol. 2023, 57, 1894–1906. [Google Scholar] [CrossRef]

- Bouchard, M.F.; Bellinger, D.C.; Weuve, J.; Matthews-Bellinger, J.; Gilman, S.E.; Wright, R.O.; Schwartz, J.; Weisskopf, M.G. Blood lead levels and major depressive disorder, panic disorder, and generalized anxiety disorder in US young adults. Arch. Gen. Psychiatry 2009, 66, 1313–1319. [Google Scholar] [CrossRef]

- Proykova, A. Opinion on Nanosilver: Safety, Health and Environmental Effects and Role in Antimicrobial Resistance; European Commission: Luxembourg, 2014. [Google Scholar] [CrossRef]

- Estrela, F.N.; Guimarães, A.T.B.; Araújo, A.P.d.C.; Silva, F.G.; Luz TM da Silva, A.M.; Pereira, P.S.; Malafaia, G. Toxicity of polystyrene nanoplastics and zinc oxide to mice. Chemosphere 2021, 271, 129476. [Google Scholar] [CrossRef] [PubMed]

- Periyasamy, A.P.; Tehrani-Bagha, A. A review on microplastic emission from textile materials and its reduction techniques. Polym. Degrad. Stab. 2022, 199, 109901. [Google Scholar] [CrossRef]

- Encarnação, T.; Pais, A.A.; Campos, M.G.; Burrows, H.D. Endocrine disrupting chemicals: Impact on human health, wildlife and the environment. Sci. Prog. 2019, 102, 3–42. [Google Scholar] [CrossRef]

- ISO 4484-1:2023; Textiles and Textile Products—Microplastics from Textile Sources—Part 1: Determination of Material Loss from Fabrics During Washing. International Organization for Standardization: Geneva, Switzerland, 2023.

- Acharya, S.; Rumi, S.S.; Hu, Y.; Abidi, N. Microfibers from synthetic textiles as a major source of microplastics in the environment: A review. Text. Res. J. 2021, 91, 004051752199124. [Google Scholar] [CrossRef]

- Akyildiz, S.H.; Fiore, S.; Bruno, M.; Sezgin, H.; Yalcin-Enis, I.; Yalcin, B.; Bellopede, R. Release of microplastic fibers from synthetic textiles during household washing. Environ. Pollut. 2024, 357, 124455. [Google Scholar] [CrossRef] [PubMed]

- Saravanja, A.; Pusic, T.; Dekanic, T. Microplastics in Wastewater by Washing Polyester Fabrics. Materials 2022, 15, 2683. [Google Scholar] [CrossRef]

- Miller, M.E.; Hamann, M.; Kroon, F.J. Bioaccumulation and biomagnification of microplastics in marine organisms: A review and meta-analysis of current data. PLoS ONE 2020, 15, e0240792. [Google Scholar] [CrossRef]

- ISO 4484-2:2023; Textiles and Textile Products—Microplastics from Textile Sources—Part 2: Qualitative and Quantitative Analysis of Microplastics. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 4484-3:2023; Textiles and Textile Products—Microplastics from Textile Sources—Part 3: Measurement of Collected Material Mass Released from Textile end Products by Domestic Washing Method. International Organization for Standardization: Geneva, Switzerland, 2023.

- Sizmur, T.; Frost, H.; Felipe-Sotelo, M.; Bond, T.; Mallory, M.L.; O’Driscoll, N.J. Methylmercury sorption to polyethylene terephthalate (PET) fibers and relevance to environmental exposure. Environ. Toxicol. Chem. 2025, 44, 335–343. [Google Scholar] [CrossRef]

- Napper, I.E.; Thompson, R.C. Release of synthetic microplastic plastic fibres from domestic washing machines: Effects of fabric type and washing conditions. Mar. Pollut. Bull. 2016, 112, 39–45. [Google Scholar] [CrossRef]

- Pirc, U.; Vidmar, M.; Mozer, A.; Kržan, A. Emissions of microplastic fibers from microfiber fleece during domestic washing. Environ. Sci. Pollut. Res. 2016, 23, 22206–22211. [Google Scholar] [CrossRef] [PubMed]

- Lionetto, M.G.; Caricato, R.; Calisi, A.; Giordano, M.E.; Schettino, T. Acetylcholinesterase as a biomarker in environmental and occupational medicine: New insights and future perspectives. BioMed Res. Int. 2013, 2013, 321213. [Google Scholar] [CrossRef] [PubMed]

- Carney Almroth, B.M.; Åström, L.; Roslund, S.; Petersson, H.; Johansson, M.; Persson, N.-K. Quantifying shedding of synthetic fibers from textiles, a source of microplastics released into the environment. Environ. Sci. Pollut. Res. Int. 2018, 25, 1191–1199. [Google Scholar] [CrossRef] [PubMed]

- Tedesco, M.C.; Fisher, R.M.; Stuetz, R.M. Emission of fibres from textiles: A critical and systematic review of mechanisms of release during machine washing. Sci. Total Environ. 2024, 955, 177090. [Google Scholar] [CrossRef]

- Yang, T.; Gao, M.; Nowack, B. Formation of microplastic fibers and fibrils during abrasion of a representative set of 12 polyester textiles. Sci. Total Environ. 2023, 862, 160758. [Google Scholar] [CrossRef]

- Wicker, A. Are Your Clothes Making You Sick? The Opaque World of Chemicals in Fashion. The Guardian. 2023. Available online: https://www.theguardian.com/fashion/2023/jul/02/fashion-chemicals-pfas-bpa-toxic (accessed on 6 February 2025).

- Rivero, P.J.; Urrutia, A.; Goicoechea, J.; Arregui, F.J. Nanomaterials for Functional Textiles and Fibers. Nanoscale Res. Lett. 2015, 10, 501. [Google Scholar] [CrossRef]

- Thordsson, J. Investigating How Textile Waste Could Become Nutrients for Cotton Crops. Better Cotton. 2022. Available online: https://bettercotton.org/investigating-how-textile-waste-could-become-nutrients-for-cotton-crops/ (accessed on 23 March 2025).

- Surana, D.; Patel, P.; Ghosh, P.; Sharma, S.; Kumar, V.; Kumar, S. Microplastic fibers in different environmental matrices from synthetic textiles: Ecotoxicological risk, mitigation strategies, and policy perspective. J. Environ. Chem. Eng. 2024, 12, 112333. [Google Scholar] [CrossRef]

- National Institute of Environmental Health Sciences. Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS). 2023. Available online: https://www.niehs.nih.gov/health/topics/agents/pfc (accessed on 17 March 2025).

- Sustainability For All. Landfills: A Serious Problem for the Environment. 2019. Available online: https://www.activesustainability.com/environment/landfills-serious-problem-environment/ (accessed on 4 February 2025).

- Rittfors, J. Thermochemical Textile Recycling Investigation of Pyrolysis and Gasification of Cotton and Polyester Master’s Thesis in Innovative and Sustainable Chemical Engineering. Available online: https://odr.chalmers.se/server/api/core/bitstreams/b2fe2eac-ba3c-4400-9718-0cf4f86ad13a/content (accessed on 25 February 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).