Advances in Thermoregulating Textiles: Materials, Mechanisms, and Applications

Abstract

1. Introduction

2. Methods

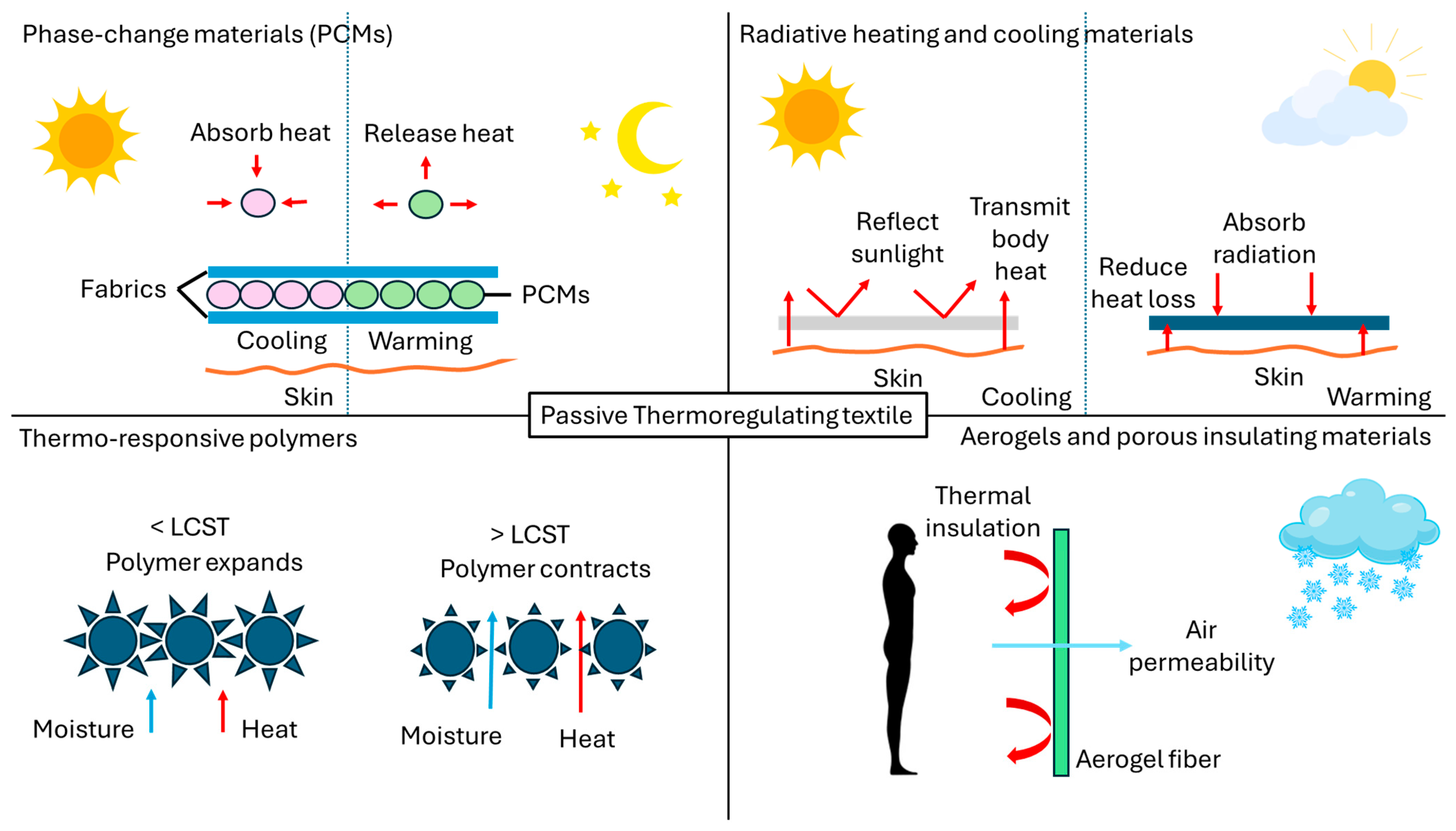

3. Passive Thermoregulating Textiles

3.1. Phase-Change Materials (PCMs)

3.2. Radiative Cooling and Heating Materials

3.3. Thermo-Responsive Polymers

3.4. Aerogels and Porous Insulating Materials

3.5. A Comparative Overview

4. Active Thermoregulating Textiles

4.1. Shape-Memory Fabrics

4.2. Other Active Thermoregulating Fabrics

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tyurin, I.N.; Getmantseva, V.V.; Andreeva, E.G. Analysis of Innovative Technologies of Thermoregulating Textile Materials. Fibre Chem. 2018, 50, 1–9. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2023: Synthesis Report. Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2023; pp. 35–115. [Google Scholar]

- Tang, K.H.D. Are we already in a climate crisis. Glob. J. Civ. Environ. Eng. 2019, 1, 25–32. [Google Scholar] [CrossRef]

- Tang, K.H.D. Climate change policies of the four largest global emitters of greenhouse gases: Their similarities, differences and way forward. J. Energy Res. Rev. 2022, 10, 19–35. [Google Scholar] [CrossRef]

- Tang, K.H.D. Climate change and its impacts on mental wellbeing. Glob. Acad. J. Humanit. Soc. Sci. 2021, 3, 144–151. [Google Scholar]

- Tang, K.H.D. The Effects of Climate Change on Occupational Safety and Health. Glob. J. Civ. Environ. Eng. 2018, 3, 1–10. [Google Scholar] [CrossRef]

- Tang, K.H.D. Abating biomechanical risks: A comparative review of ergonomic assessment tools. J. Eng. Res. Rep. 2020, 17, 41–51. [Google Scholar] [CrossRef]

- Wu, R.; Chen, T.-H.; Hsu, P.-C. Stay healthy under global warming: A review of wearable technology for thermoregulation. EcoMat 2023, 5, e12396. [Google Scholar] [CrossRef]

- Santamouris, M.; Cartalis, C.; Synnefa, A.; Kolokotsa, D. On the impact of urban heat island and global warming on the power demand and electricity consumption of buildings—A review. Energy Build. 2015, 98, 119–124. [Google Scholar] [CrossRef]

- Tang, K.H.D. Urban Solutions to Climate Change: An Overview of Latest Progress. Acad. Environ. Sci. Sustain. 2024, 1. [Google Scholar] [CrossRef]

- Hossain, J.; Kadir, A.F.A.; Hanafi, A.N.; Shareef, H.; Khatib, T.; Baharin, K.A.; Sulaima, M.F. A Review on Optimal Energy Management in Commercial Buildings. Energies 2023, 16, 1609. [Google Scholar] [CrossRef]

- Li, X.; Guo, W.; Hsu, P.-C. Personal Thermoregulation by Moisture-Engineered Materials. Adv. Mater. 2024, 36, 2209825. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Wang, Y.; Fan, W.; Zou, J.; Yu, X.; Liu, Y.; Zhi, C. Adaptive dynamic smart textiles for personal thermal-moisture management. Eur. Polym. J. 2024, 206, 112777. [Google Scholar] [CrossRef]

- Shao, S.; Yuan, L.; Li, X.; Guo, W. Personal thermoregulation by mid-infrared engineered materials. Next Energy 2024, 2, 100083. [Google Scholar] [CrossRef]

- Fang, Y.; Chen, G.; Bick, M.; Chen, J. Smart textiles for personalized thermoregulation. Chem. Soc. Rev. 2021, 50, 9357–9374. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Cheng, H.; Zhang, S.; Li, Y.; Li, Z.; Ma, J.; Liu, X. Advancements and challenges in thermoregulating textiles: Smart clothing for enhanced personal thermal management. Chem. Eng. J. 2024, 488, 151040. [Google Scholar] [CrossRef]

- Lee, S.; Leung, E.M.; Badshah, M.A.; Strzelecka, A.A.; Gorodetsky, A.A. Manufacturing of breathable, washable, and fabric-integrated squid skin-inspired thermoregulatory materials. APL Bioeng. 2024, 8, 046101. [Google Scholar] [CrossRef]

- Chen, M.; Liu, Y.; Zhao, X. Emerging passive thermoregulatory textiles through tailoring different heat transfer routes. Text. Res. J. 2023, 93, 3414–3439. [Google Scholar] [CrossRef]

- Prajapati, D.G.; Kandasubramanian, B. A Review on Polymeric-Based Phase Change Material for Thermo-Regulating Fabric Application. Polym. Rev. 2020, 60, 389–419. [Google Scholar] [CrossRef]

- Pakdel, E.; Naebe, M.; Sun, L.; Wang, X. Advanced Functional Fibrous Materials for Enhanced Thermoregulating Performance. ACS Appl. Mater. Interfaces 2019, 11, 13039–13057. [Google Scholar] [CrossRef]

- Habibi, P.; Moradi, G.; Moradi, A.; Golbabaei, F. A review on advanced functional photonic fabric for enhanced thermoregulating performance. Environ. Nanotechnol. Monit. Manag. 2021, 16, 100504. [Google Scholar] [CrossRef]

- Lei, L.; Shi, S.; Wang, D.; Meng, S.; Dai, J.-G.; Fu, S.; Hu, J. Recent Advances in Thermoregulatory Clothing: Materials, Mechanisms, and Perspectives. ACS Nano 2023, 17, 1803–1830. [Google Scholar] [CrossRef] [PubMed]

- Kizildag, N. 11—Smart textiles with PCMs for thermoregulation. In Multifunctional Phase Change Materials; Pielichowska, K., Pielichowski, K., Eds.; Woodhead Publishing: Cambridge, UK, 2023; pp. 445–505. [Google Scholar]

- Umair, M.M.; Zhang, Y.; Iqbal, K.; Zhang, S.; Tang, B. Novel strategies and supporting materials applied to shape-stabilize organic phase change materials for thermal energy storage–A review. Appl. Energy 2019, 235, 846–873. [Google Scholar] [CrossRef]

- De Castro, P.F.; Minko, S.; Vinokurov, V.; Cherednichenko, K.; Shchukin, D.G. Long-Term Autonomic Thermoregulating Fabrics Based on Microencapsulated Phase Change Materials. ACS Appl. Energy Mater. 2021, 4, 12789–12797. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Chen, P.; Xiao, C.; Ge, Y.; Gao, H. Recent advances in dynamic dual mode systems for daytime radiative cooling and solar heating. RSC Adv. 2023, 13, 31738–31755. [Google Scholar] [CrossRef]

- Sun, S.; Nie, L.; Yang, N.; Okoro, O.V.; Shavandi, A. 13—Breathable and adaptive thermo-responsive personal protective clothing. In Protective Textiles from Natural Resources; Mondal, M.I.H., Ed.; Woodhead Publishing: Cambridge, UK, 2022; pp. 377–394. [Google Scholar]

- Azam, F.; Ahmad, F.; Ulker, Z.; Zafar, M.S.; Ahmad, S.; Rasheed, A.; Nawab, Y.; Erkey, C. The Role and Applications of Aerogels in Textiles. Adv. Mater. Sci. Eng. 2022, 2022, 2407769. [Google Scholar] [CrossRef]

- Ali, M.A.; Hassabo, A.G.; Seddik, K.M.; Yahia, S.; Aly, N.M. Characterization of the thermal and Physico-Mechanical properties of cotton and polyester yarns treated with phase change materials composites. Egypt. J. Chem. 2022, 65, 21–37. [Google Scholar] [CrossRef]

- Zeighampour, F.; Khoddami, A.; Dolez, P.I. Innovative flexible thermal storage textile using nanocomposite shape-stabilized phase change materials. Fash. Text. 2023, 10, 43. [Google Scholar] [CrossRef]

- Yan, Y.; Li, W.; Zhu, R.; Lin, C.; Hufenus, R. Flexible Phase Change Material Fiber: A Simple Route to Thermal Energy Control Textiles. Materials 2021, 14, 401. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Chen, Z.; Zhu, F.; Zhu, C.; Wang, C.; Gu, C. Effect of Polyvinyl Chloride Microplastics on Bacterial Community and Nutrient Status in Two Agricultural Soils. Bull. Environ. Contam. Toxicol. 2021, 107, 602–609. [Google Scholar] [CrossRef]

- Liang, C.; Zhang, W.; Liu, C.; He, J.; Xiang, Y.; Han, M.; Tong, Z.; Liu, Y. Multifunctional phase change textiles with electromagnetic interference shielding and multiple thermal response characteristics. Chem. Eng. J. 2023, 471, 144500. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, F.; Shi, X.; Sun, K.; Kou, Y.; Das, P.; Li, Y.; Zhang, X.; Mateti, S.; Chen, Y.; et al. A Thermoregulatory Flexible Phase Change Nonwoven for All-Season High-Efficiency Wearable Thermal Management. Nano-Micro Lett. 2023, 15, 29. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Xue, T.; Tian, J.; Yang, Y.; Fan, W.; Liu, T. Polyimide/boron nitride composite aerogel fiber-based phase-changeable textile for intelligent personal thermoregulation. Compos. Sci. Technol. 2022, 226, 109541. [Google Scholar] [CrossRef]

- El Majd, A.; Sair, S.; Ousaleh, H.A.; Bouhaj, Y.; Belouaggadia, N.; Younsi, Z.; El Bouari, A. Advancing tent thermoregulation: Integrating shape-stabilized PCM into fabric design. J. Energy Storage 2024, 95, 112681. [Google Scholar] [CrossRef]

- Lu, Y.; Xiao, X.; Fu, J.; Huan, C.; Qi, S.; Zhan, Y.; Zhu, Y.; Xu, G. Novel smart textile with phase change materials encapsulated core-sheath structure fabricated by coaxial electrospinning. Chem. Eng. J. 2019, 355, 532–539. [Google Scholar] [CrossRef]

- Shahid, M.A.; Hossain, M.T.; Hossain, I.; Limon, M.G.M.; Rabbani, M.; Rahim, A. Research and development on phase change material-integrated cloth: A review. J. Ind. Text. 2024, 54, 15280837241262518. [Google Scholar] [CrossRef]

- Xue, S.; Huang, G.; Chen, Q.; Wang, X.; Fan, J.; Shou, D. Personal Thermal Management by Radiative Cooling and Heating. Nano-Micro Lett. 2024, 16, 153. [Google Scholar] [CrossRef]

- Jiang, S.; Zhang, K.; Wang, C.-F.; Li, Q.; Zhu, L.; Chen, S. Recent advancements in radiative cooling textiles for personal thermal management. J. Mater. Chem. A 2024, 12, 14866–14884. [Google Scholar] [CrossRef]

- Zhu, F.L.; Feng, Q.Q. Recent advances in textile materials for personal radiative thermal management in indoor and outdoor environments. Int. J. Therm. Sci. 2021, 165, 106899. [Google Scholar] [CrossRef]

- Wu, R.; Sui, C.; Chen, T.-H.; Zhou, Z.; Li, Q.; Yan, G.; Han, Y.; Liang, J.; Hung, P.-J.; Luo, E.; et al. Spectrally engineered textile for radiative cooling against urban heat islands. Science 2024, 384, 1203–1212. [Google Scholar] [CrossRef]

- Wu, X.-E.; Wang, Y.; Liang, X.; Zhang, Y.; Bi, P.; Zhang, M.; Li, S.; Liang, H.; Wang, S.; Wang, H.; et al. Durable Radiative Cooling Multilayer Silk Textile with Excellent Comprehensive Performance. Adv. Funct. Mater. 2024, 34, 2313539. [Google Scholar] [CrossRef]

- Miao, D.; Cheng, N.; Wang, X.; Yu, J.; Ding, B. Integration of Janus Wettability and Heat Conduction in Hierarchically Designed Textiles for All-Day Personal Radiative Cooling. Nano Lett. 2022, 22, 680–687. [Google Scholar] [CrossRef] [PubMed]

- Zhu, B.; Li, W.; Zhang, Q.; Li, D.; Liu, X.; Wang, Y.; Xu, N.; Wu, Z.; Li, J.; Li, X.; et al. Subambient daytime radiative cooling textile based on nanoprocessed silk. Nat. Nanotechnol. 2021, 16, 1342–1348. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Yan, Z.; Fan, D. Flexible Radiative Cooling Textiles Based on Composite Nanoporous Fibers for Personal Thermal Management. ACS Appl. Mater. Interfaces 2023, 15, 17848–17857. [Google Scholar] [CrossRef]

- Cheng, N.; Wang, Z.; Lin, Y.; Li, X.; Zhang, Y.; Ding, C.; Wang, C.; Tan, J.; Sun, F.; Wang, X.; et al. Breathable Dual-Mode Leather-Like Nanotextile for Efficient Daytime Radiative Cooling and Heating. Adv. Mater. 2024, 36, 2403223. [Google Scholar] [CrossRef]

- Chen, C.; Jia, X.; Li, X.; Shi, M.; Hu, J.; Song, M.; Wu, S.; Dai, H.; Wang, X.; Geng, H. Scalable wet-spinning of wearable chitosan-silica textile for all-day radiative cooling. Chem. Eng. J. 2023, 475, 146307. [Google Scholar] [CrossRef]

- Zhang, S.; Cui, C.; Zhang, F.; Lu, J.; Su, J.; Han, J. Flexible coated textile with remarkable passive daytime radiative cooling, UV resistance and hydrophobicity performance. Prog. Org. Coat. 2024, 186, 108005. [Google Scholar] [CrossRef]

- Pillai, R.R.; Appavoo, K.; Lungu, C.T.; Behura, S.K.; Thomas, V. Plasma-Corona-Processed Nanostructured Coating for Thermoregulative Textiles. ACS Appl. Polym. Mater. 2024, 6, 14047–14056. [Google Scholar] [CrossRef]

- Liang, J.; Ding, L.; Yu, Z.; Zhang, X.; Chen, S.; Wang, Y. Smart and programmed thermo-wetting yarns for scalable and customizable moisture/heat conditioning textiles. J. Colloid Interface Sci. 2023, 651, 612–621. [Google Scholar] [CrossRef]

- Yang, Y.; Bao, X.; Wang, Q.; Wang, P.; Zhou, M.; Yu, Y. Thermo-responsive cotton fabric prepared by enzyme-initiated “graft from” polymerization for moisture/thermal management. Cellulose 2021, 28, 1795–1808. [Google Scholar] [CrossRef]

- Xue, T.; Ma, R.; Zhang, X.; Tao, W.; Wang, C.; Yin, Y. Preparation of thermoresponsive cotton fabric by grafting P(MEO2MA-co-OEGMA475-co-GMA) polymer for personal thermal management. Cellulose 2024, 31, 4007–4023. [Google Scholar] [CrossRef]

- Qiu, H.; Yang, Q.; Tao, S.; Zhou, W.; Zhu, J.; Xu, L.; Pan, H.; Zhang, H.; Wang, J. Asymmetrical surface-modified polyester/cotton fabrics for temperature-adaptive moisture and thermal management of human body. Colloids Surf. A Physicochem. Eng. Asp. 2024, 701, 134934. [Google Scholar] [CrossRef]

- Ji, Y.; Sun, Y.; Javed, M.; Xiao, Y.; Li, X.; Jin, K.; Cai, Z.; Xu, B. Skin inspired thermoresponsive polymer for constructing self-cooling system. Energy Convers. Manag. 2022, 254, 115251. [Google Scholar] [CrossRef]

- Memiş, N.K.; Kaplan, S. Smart polyester fabric with comfort regulation by temperature and moisture responsive shape memory nanocomposite treatment. J. Ind. Text. 2020, 51, 7920S–7941S. [Google Scholar] [CrossRef]

- He, Y.; Guo, S.; Zuo, X.; Tian, M.; Zhang, X.; Qu, L.; Miao, J. Smart Green Cotton Textiles with Hierarchically Responsive Conductive Network for Personal Healthcare and Thermal Management. ACS Appl. Mater. Interfaces 2024, 16, 59358–59369. [Google Scholar] [CrossRef]

- McNeil, S.J.; Gupta, H. Emerging applications of aerogels in textiles. Polym. Test. 2022, 106, 107426. [Google Scholar] [CrossRef]

- Xue, T.; Zhu, C.; Feng, X.; Wali, Q.; Fan, W.; Liu, T. Polyimide Aerogel Fibers with Controllable Porous Microstructure for Super-Thermal Insulation Under Extreme Environments. Adv. Fiber Mater. 2022, 4, 1118–1128. [Google Scholar] [CrossRef]

- Wu, M.; Shao, Z.; Zhao, N.; Zhang, R.; Yuan, G.; Tian, L.; Zhang, Z.; Gao, W.; Bai, H. Biomimetic, knittable aerogel fiber for thermal insulation textile. Science 2023, 382, 1379–1383. [Google Scholar] [CrossRef]

- Li, M.; Gan, F.; Dong, J.; Fang, Y.; Zhao, X.; Zhang, Q. Facile Preparation of Continuous and Porous Polyimide Aerogel Fibers for Multifunctional Applications. ACS Appl. Mater. Interfaces 2021, 13, 10416–10427. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Peng, Y.; Dong, J.; Pu, L.; Chang, K.; Yan, X.-P.; Qian, H.-L.; Li, L.; Huang, Y.; Liu, T. Hierarchically porous polyimide aerogel fibers based on the confinement of Ti3C2Tx flakes for thermal insulation and fire retardancy. Compos. Commun. 2023, 37, 101429. [Google Scholar] [CrossRef]

- Sai, H.; Wang, M.; Miao, C.; Song, Q.; Wang, Y.; Fu, R.; Wang, Y.; Ma, L.; Hao, Y. Robust Silica-Bacterial Cellulose Composite Aerogel Fibers for Thermal Insulation Textile. Gels 2021, 7, 145. [Google Scholar] [CrossRef]

- Xue, R.; Liu, G.; Liu, F. A simple and efficient method for the preparation of SiO2/PI/AF aerogel composite fabrics and their thermal insulation performance. Ceram. Int. 2023, 49, 210–215. [Google Scholar] [CrossRef]

- Zhao, Y.; Fang, F. A Biomimetic Textile with Self-Assembled Hierarchical Porous Fibers for Thermal Insulation. ACS Appl. Mater. Interfaces 2022, 14, 25851–25860. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Cheng, H.; Gao, J.; Xue, Y.; Han, G.; Zhou, B.; Liu, C.; Feng, Y.; Shen, C. Air-Drying for Rapid Manufacture of Flexible Aramid Nanofiber Aerogel Fibers with Robust Mechanical Properties and Thermal Insulation in Harsh Environments. Small 2025, 21, 2409408. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, C.; Tao, S.; Chai, H.; Xu, D.; Li, X.; Qi, H. High-performance smart cellulose nanohybrid aerogel fibers as a platform toward multifunctional textiles. Chem. Eng. J. 2023, 466, 143153. [Google Scholar] [CrossRef]

- Peng, Y.; Cui, Y. Advanced Textiles for Personal Thermal Management and Energy. Joule 2020, 4, 724–742. [Google Scholar] [CrossRef]

- Amadi, A.; Mohyaldinn, M.; Ridha, S.; Ola, V. Advancing engineering frontiers with NiTi shape memory alloys: A multifaceted review of properties, fabrication, and application potentials. J. Alloys Compd. 2024, 976, 173227. [Google Scholar] [CrossRef]

- Fu, C.; Xia, Z.; Hurren, C.; Nilghaz, A.; Wang, X. Textiles in soft robots: Current progress and future trends. Biosens. Bioelectron. 2022, 196, 113690. [Google Scholar] [CrossRef]

- Granberry, R.; Barry, J.; Holschuh, B.; Abel, J. Kinetically Tunable, Active Auxetic, and Variable Recruitment Active Textiles from Hierarchical Assemblies. Adv. Mater. Technol. 2021, 6, 2000825. [Google Scholar] [CrossRef]

- Ruckdashel, R.R.; Venkataraman, D.; Park, J.H. Smart textiles: A toolkit to fashion the future. J. Appl. Phys. 2021, 129, 130903. [Google Scholar] [CrossRef]

- Mirvakili, S.M.; Hunter, I.W. Artificial Muscles: Mechanisms, Applications, and Challenges. Adv. Mater. 2018, 30, 1704407. [Google Scholar] [CrossRef]

- Chatterjee, K.; Ghosh, T.K. Thermoelectric Materials for Textile Applications. Molecules 2021, 26, 3154. [Google Scholar] [CrossRef] [PubMed]

- Choe, A.; Yeom, J.; Kwon, Y.; Lee, Y.; Shin, Y.-E.; Kim, J.; Ko, H. Stimuli-responsive micro/nanoporous hairy skin for adaptive thermal insulation and infrared camouflage. Mater. Horiz. 2020, 7, 3258–3265. [Google Scholar] [CrossRef]

- Lyu, S.; LaBat, K.L. Posture modification effects using soft materials structures. Int. J. Ind. Ergon. 2021, 84, 103125. [Google Scholar] [CrossRef]

- Roach, D.J.; Yuan, C.; Kuang, X.; Li, V.C.-F.; Blake, P.; Romero, M.L.; Hammel, I.; Yu, K.; Qi, H.J. Long Liquid Crystal Elastomer Fibers with Large Reversible Actuation Strains for Smart Textiles and Artificial Muscles. ACS Appl. Mater. Interfaces 2019, 11, 19514–19521. [Google Scholar] [CrossRef]

- Wei, J.; Ma, Y.; Liu, C.; Li, J.; Shen, J.; Zhang, K.Y.; Liu, S.; Zhao, Q. Dynamic tuning of metal–ligand coordination through water molecules to induce multicolor fluorescence variations for humidity monitoring and anti-counterfeiting applications. J. Mater. Chem. C 2021, 9, 5945–5951. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhang, F.; Wang, M.; Gardner, C.J.; Kim, G.; Liu, Y.; Leng, J.; Jin, S.; Chen, R. Reversible Humidity Sensitive Clothing for Personal Thermoregulation. Sci. Rep. 2017, 7, 44208. [Google Scholar] [CrossRef]

- Sroysee, W.; Chairam, S.; Amatatongchai, M.; Jarujamrus, P.; Tamuang, S.; Pimmongkol, S.; Chaicharoenwimolkul, L.; Somsook, E. Poly(m-ferrocenylaniline) modified carbon nanotubes-paste electrode encapsulated in nafion film for selective and sensitive determination of dopamine and uric acid in the presence of ascorbic acid. J. Saudi Chem. Soc. 2018, 22, 173–182. [Google Scholar] [CrossRef]

- Mu, J.; Wang, G.; Yan, H.; Li, H.; Wang, X.; Gao, E.; Hou, C.; Pham, A.T.C.; Wu, L.; Zhang, Q.; et al. Molecular-channel driven actuator with considerations for multiple configurations and color switching. Nat. Commun. 2018, 9, 590. [Google Scholar] [CrossRef]

- Wang, W.; Yao, L.; Cheng, C.-Y.; Zhang, T.; Atsumi, H.; Wang, L.; Wang, G.; Anilionyte, O.; Steiner, H.; Ou, J.; et al. Harnessing the hygroscopic and biofluorescent behaviors of genetically tractable microbial cells to design biohybrid wearables. Sci. Adv. 2017, 3, e1601984. [Google Scholar] [CrossRef]

- Peng, Y.; Sun, F.; Xiao, C.; Iqbal, M.I.; Sun, Z.; Guo, M.; Gao, W.; Hu, X. Hierarchically Structured and Scalable Artificial Muscles for Smart Textiles. ACS Appl. Mater. Interfaces 2021, 13, 54386–54395. [Google Scholar] [CrossRef]

- Zhang, M.; Li, Z.; Xu, Y.; Wang, J. Design and research of liquid cooling garments in thermal environment. Int. J. Refrig. 2022, 139, 136–147. [Google Scholar] [CrossRef]

- Fan, Q.; Fan, H.; Han, H.; Bai, Z.; Wu, X.; Hou, C.; Zhang, Q.; Li, Y.; Li, K.; Wang, H. Dynamic Thermoregulatory Textiles Woven from Scalable-Manufactured Radiative Electrochromic Fibers. Adv. Funct. Mater. 2024, 34, 2310858. [Google Scholar] [CrossRef]

- Bai, Y.; Li, H.; Gan, S.; Li, Y.; Liu, H.; Chen, L. Flexible heating fabrics with temperature perception based on fine copper wire and fusible interlining fabrics. Measurement 2018, 122, 192–200. [Google Scholar] [CrossRef]

- Wang, Y.; Gordon, S.; Yu, W.; Wang, F. Structural architecture of wearable materials based on tri-component elastic-conductive composite yarn: Toward a Joule heating application. Text. Res. J. 2018, 89, 3303–3311. [Google Scholar] [CrossRef]

- Chai, J.; Kang, Z.; Yan, Y.; Lou, L.; Zhou, Y.; Fan, J. Thermoregulatory clothing with temperature-adaptive multimodal body heat regulation. Cell Rep. Phys. Sci. 2022, 3, 100958. [Google Scholar] [CrossRef]

- Zhang, R.; He, Z.-Z. Wearable active-cooling garment for personalized thermoregulation in vehicle. Energy Build. 2024, 310, 114064. [Google Scholar] [CrossRef]

- Zhang, M.; Li, Z.; Wang, Q.; Xu, Y.; Hu, P.; Zhang, X. Performance investigation of a portable liquid cooling garment using thermoelectric cooling. Appl. Therm. Eng. 2022, 214, 118830. [Google Scholar] [CrossRef]

| Material | Solar Reflectance | IR Emittance | Cooling Performance | Heating Performance | Reference |

|---|---|---|---|---|---|

| SSHF | 97% | High (mid-IR selective) | 2.3 °C lower vs. typical solar-reflecting textile | N/A | [42] |

| MST | 96.5% | 97.1% | −5.1 °C (892.4 W/m2); −6.0 °C vs. silk; −8.3 °C vs. cotton | N/A | [43] |

| Janus PU/Si3N4 membrane | 91% | 93% | −21.9 °C (day); −2.8 °C (night) vs. cotton | N/A | [44] |

| Nanoprocessed silk | >90% | >85% | −3.5 °C (≈900 W/m2); −8 °C on skin model vs. natural silk | N/A | [45] |

| Porous-fiber textile | 98.8% | 97% | −4.5 °C (day); −5.5 °C (night); −7.1 °C vs. bare skin | N/A | [46] |

| Dual-mode nano-leather | N/A | N/A | −22.0 °C (sun) | +22.1 °C (sun) | [47] |

| Chitosan/SiO2 spectrally selective fabric | 82.3% | 95.6% | 95.7 W/m2 (day); 103.3 W/m2 (night) | N/A | [48] |

| Flexible PDRC (P(VDF-HFP) + Al2O3) | 95% | 98% | −12.5 °C (peak, day); −5 °C (night) | N/A | [49] |

| LTP-treated fabrics | Higher IR reflectivity | N/A | ≈15 °C cooler vs. untreated | N/A | [50] |

| Criteria | PCMs | Radiative Cooling and Heating Materials | Thermo-Responsive Polymers | Aerogels and Porous Insulating Materials |

|---|---|---|---|---|

| Working mechanism | Stores/releases latent heat via phase change (solid ↔ liquid); regulates temperature by absorbing/releasing heat | Controls heat via IR radiation: radiative cooling (emits body heat) or heating (absorbs/retains IR radiation) | Changes between hydrophilic and hydrophobic states based on temperature (LCST/UCST), modulating breathability and moisture retention | Traps air/gases within nanoporous structures to reduce heat transfer and provide insulation |

| Energy requirement | Passive (no external energy); responsive to environmental temperature | Passive (uses ambient light/heat); does not require external power | Passive; relies on ambient or body temperature changes | Passive; utilizes physical structure, no external energy needed |

| Cooling/heating performance | Effective; can buffer up to 14 °C (cooling) and rise by 9 °C (heating); maintains temperatures for prolonged periods | Cooling up to 21.9 °C (extreme solar conditions); temperature drops of 4–8 °C typically observed | Moderately effective; ~1.0–2.8 °C heating/cooling; up to ~13 °C in composite hydrogel-based systems | Effective insulation over a wide range (−196 to 400 °C); comparable to down or fat-based insulation |

| Durability | High: >100–1000 thermal cycles; performance sustained over 4 years; resistant to washing and abrasion | High: Washable, UV-resistant, hydrophobic; retains function after repeated exposure to sun/wear | Proven washability (e.g., >60 washes); some wear-off over cycles; mechanical properties can degrade | High: Very high mechanical strength, flexibility, stretchability (up to 1000%); survives extreme conditions and strain cycles (e.g., 10,000 cycles) |

| Scalability/manufacturing feasibility | Variable: some methods (e.g., microfluidic, coaxial electrospinning) are complex; others, like dip-coating or vacuum impregnation, are scalable | High: Many radiative materials use scalable techniques (e.g., roll-to-roll electrospinning, dip-coating, self-assembly) | High: Scalable grafting methods (e.g., in situ, UV polymerization); compatible with cotton and synthetic blends | High: Improved with wet spinning, freeze-drying, in situ polymerization; recent developments allow large-scale production with biodegradable, low-cost materials |

| Comfort and breathability | Improved via nanomaterials/aerogels, but high PCM load can reduce flexibility/breathability | High: Nanofibrous and porous structures enhance breathability, air/moisture permeability, and wearer comfort | High: Designed to modulate moisture/air permeability dynamically; good compatibility with natural fibers like cotton | May limit breathability depending on fiber structure; newer core–shell and porous structures improve comfort |

| Integration with textiles | Microencapsulation, core–sheath fibers, dip-coating, etc.; compatible with cotton, polyester, etc. | Nanofibers and coatings applied to silk, cotton, polyurethane, and synthetic fabrics | Can be grafted directly onto cotton, polyester, blended yarns; compatible with weaving/knitting processes | Integrated as fibers into yarns or fabrics (e.g., polyimide, aramid, cellulose aerogels); compatible with weaving and coating processes |

| Leakage risk | Can be an issue (liquid PCMs), but can be mitigated via microencapsulation, core–sheath design, solid-to-solid PCMs | No leakage; materials are solid-state or vapor-based systems | Low; polymers are chemically bonded or grafted onto fabric surfaces | Low; typically dry-state solid structures; minimal risk compared to PCMs |

| Cost and material availability | Moderate to high: PEG, paraffin, and composite carriers vary in cost; nanomaterials increase cost | Varies: Metal oxides, silica, and carbon-based coatings may increase costs, though mass production could reduce them | Moderate: Uses commonly available monomers/polymers; increasing feasibility | Traditionally costly and brittle but now cost-effective due to scalable methods and the use of abundant natural polymers |

| Best use cases | Outdoor clothing, sportswear, bedding, emergency blankets, smart textiles for thermal comfort | Daytime wear, desert or urban applications, hats, summer apparel, building materials for passive cooling | Sportswear, daily wear, smart clothing, adaptive clothing, moisture management | Extreme environments (space, arctic, firefighting), outdoor gear, thermal underwear, multifunctional smart textiles |

| Limitations | Leakage risk in liquid PCMs, phase separation, and stiffness at high loadings; some methods are not yet cost-effective for mass production | May not retain heat effectively at night; cooling is more effective than heating; visual appearance may be limited | Requires precise LCST/UCST matching to user comfort; performance may decline with repeated washing or abrasion | Historically brittle; breathability can be a concern; thermal insulation may not be actively responsive like smart polymers |

| Material | Stimulus | Actuation Performance | Activation Conditions | Durability/Cycles | Key Benefits | Ref. |

|---|---|---|---|---|---|---|

| SMP-based composite arrays | Temperature | Thermal insulation change ≈ 61.4% (hairs stand vs. lie flat) | ΔT across body comfort range | Not specified | Fast, reversible tuning of insulation via micro-hair morphology | [75] |

| LCE fibers (two-way SMP) | Temperature | Reversible actuation strain of up to 51%; cylinder diameter Δ ≈ 40% | Heating to ~120 °C/cooling to root temperature | Reversible over many heating/cooling cycles | Large, reversible shape change built into textile structure | [77] |

| Nafion bending film | Moisture (humidity) | Bends toward lower-humidity side in <1 s | Ambient moisture/sweat uptake | Rapid, repeatable | Ultra-fast moisture-driven actuation without external heating | [79] |

| Nafion “sweat-pore” flaps | Humidity | Flaps open/close to modulate evaporation | Wearer’s sweat/decreased humidity | Excellent stability over many cycles | Sweat-responsive ventilation for dynamic thermal comfort | [80] |

| Nafion ribbon inserts | Humidity | Thickness decreases when wet, causing higher thermal conductivity; reverses when dry | Wearer’s sweat/drying | ≥50 rubbing cycles demonstrated | Adjustable thermal conductivity via reversible ribbon geometry | [80] |

| Kirigami-inspired actuator | Moisture (vapor) | Semilunar cuts curl outward with increased humidity, opening vents | Skin humidity increases | Not specified | Integrated vents that autonomously open/close for heat and moisture | [81] |

| Biohybrid microbial-cell flaps | Sweat | Ventilated flaps shift from flat to curved for adjustable skin exposure | Physical activity, e.g., induced perspiration | Not specified | Self-powered moisture-actuated flaps for sports garments | [82] |

| Artificial-muscle yarns | Moisture | Fiber contraction on wetting/extension on drying | Ambient humidity changes | Not specified | Switchable pores in garment sleeves: expand in dry conditions, contract in humidity | [83] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, K.H.D. Advances in Thermoregulating Textiles: Materials, Mechanisms, and Applications. Textiles 2025, 5, 22. https://doi.org/10.3390/textiles5020022

Tang KHD. Advances in Thermoregulating Textiles: Materials, Mechanisms, and Applications. Textiles. 2025; 5(2):22. https://doi.org/10.3390/textiles5020022

Chicago/Turabian StyleTang, Kuok Ho Daniel. 2025. "Advances in Thermoregulating Textiles: Materials, Mechanisms, and Applications" Textiles 5, no. 2: 22. https://doi.org/10.3390/textiles5020022

APA StyleTang, K. H. D. (2025). Advances in Thermoregulating Textiles: Materials, Mechanisms, and Applications. Textiles, 5(2), 22. https://doi.org/10.3390/textiles5020022