Lyocell-Based Nonwovens: Mechanical Performance and Biodegradation Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Fibres Characterization

2.1.1. Linear Density Test

2.1.2. Breaking Force and Elongation at Break

2.1.3. Differential Scanning Calorimetry (DSC)

2.2. Nonwoven Production

2.2.1. Carded and Needle-Punched Nonwovens

2.2.2. Carded Needle-Punched and Thermal-Bonded Nonwovens

2.3. Nonwoven Characterization

2.3.1. Mechanical Properties

2.3.2. Biodegradability and Soil’s Toxicity

3. Results and Discussion

3.1. Characterization of the Fibres

3.1.1. Linear Density and Mechanical Properties

3.1.2. Analysis of Fibres’ Differential Scanning Calorimetry (DSC)

3.2. Characterization of the Nonwovens

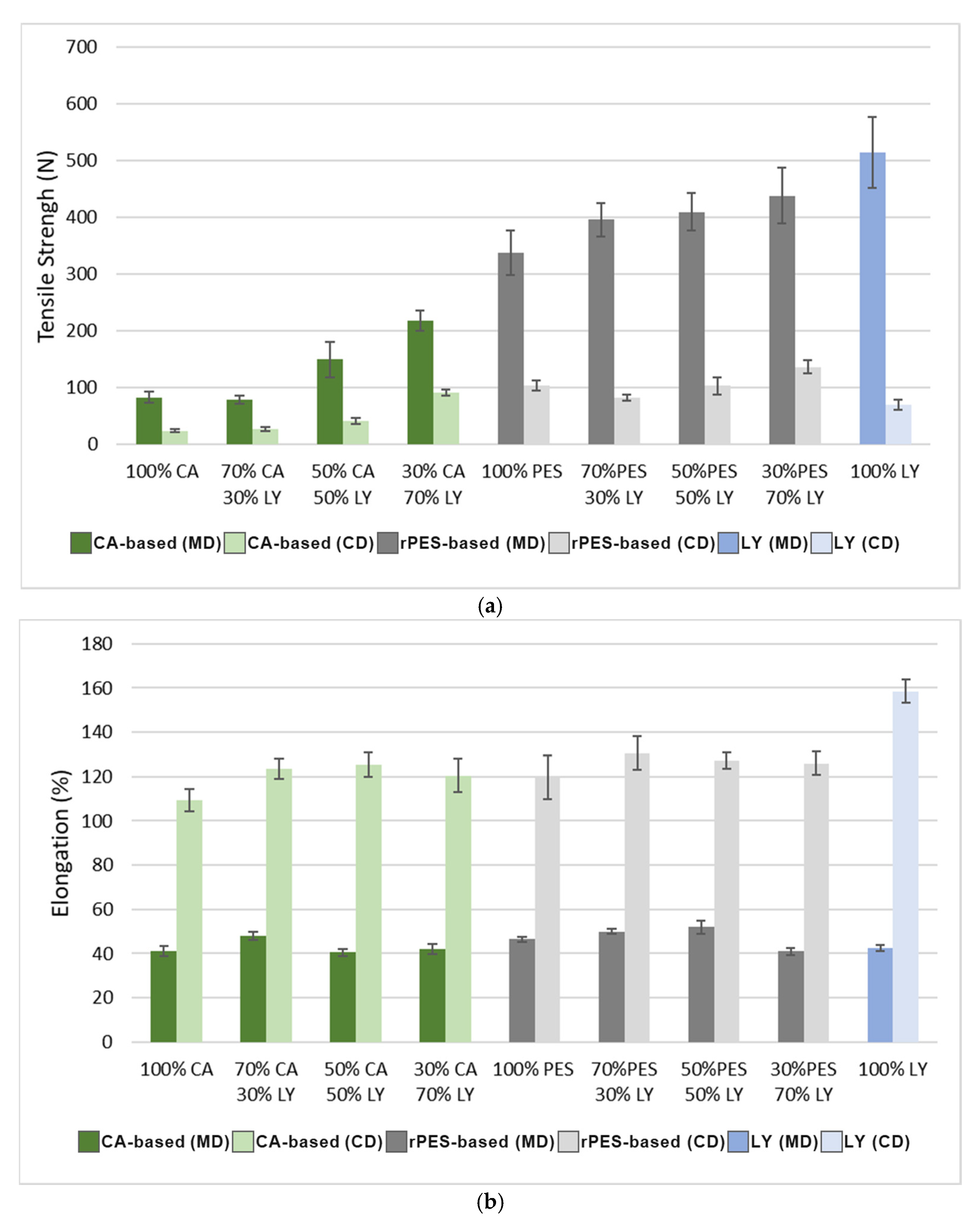

3.2.1. Mechanical Characterization of Carded and Needle-Punched Nonwovens

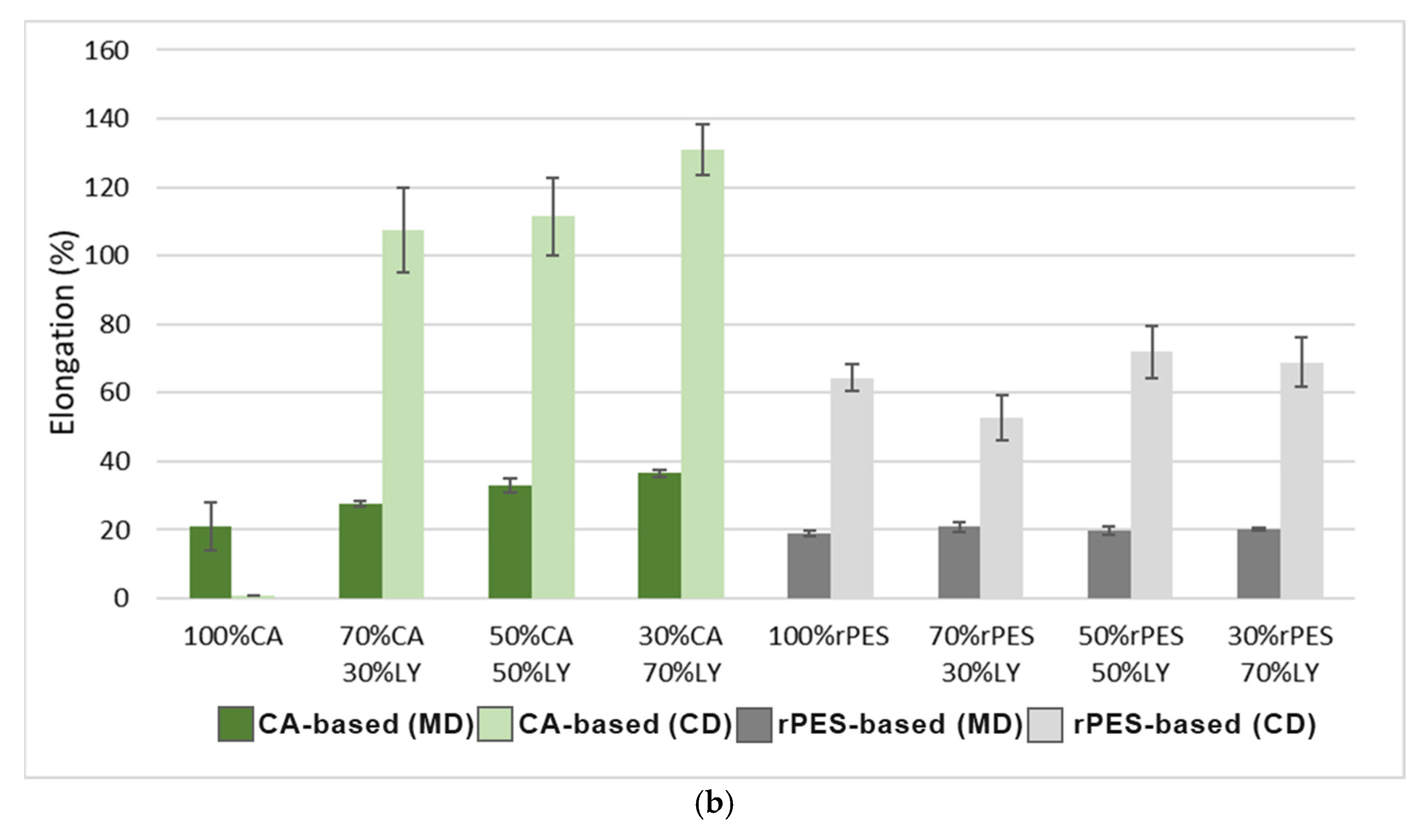

3.2.2. Mechanical Characterization of Carded Needle-Punched and Thermal-Bonded Nonwovens

3.3. Impacts of Using Two Consolidation Methods

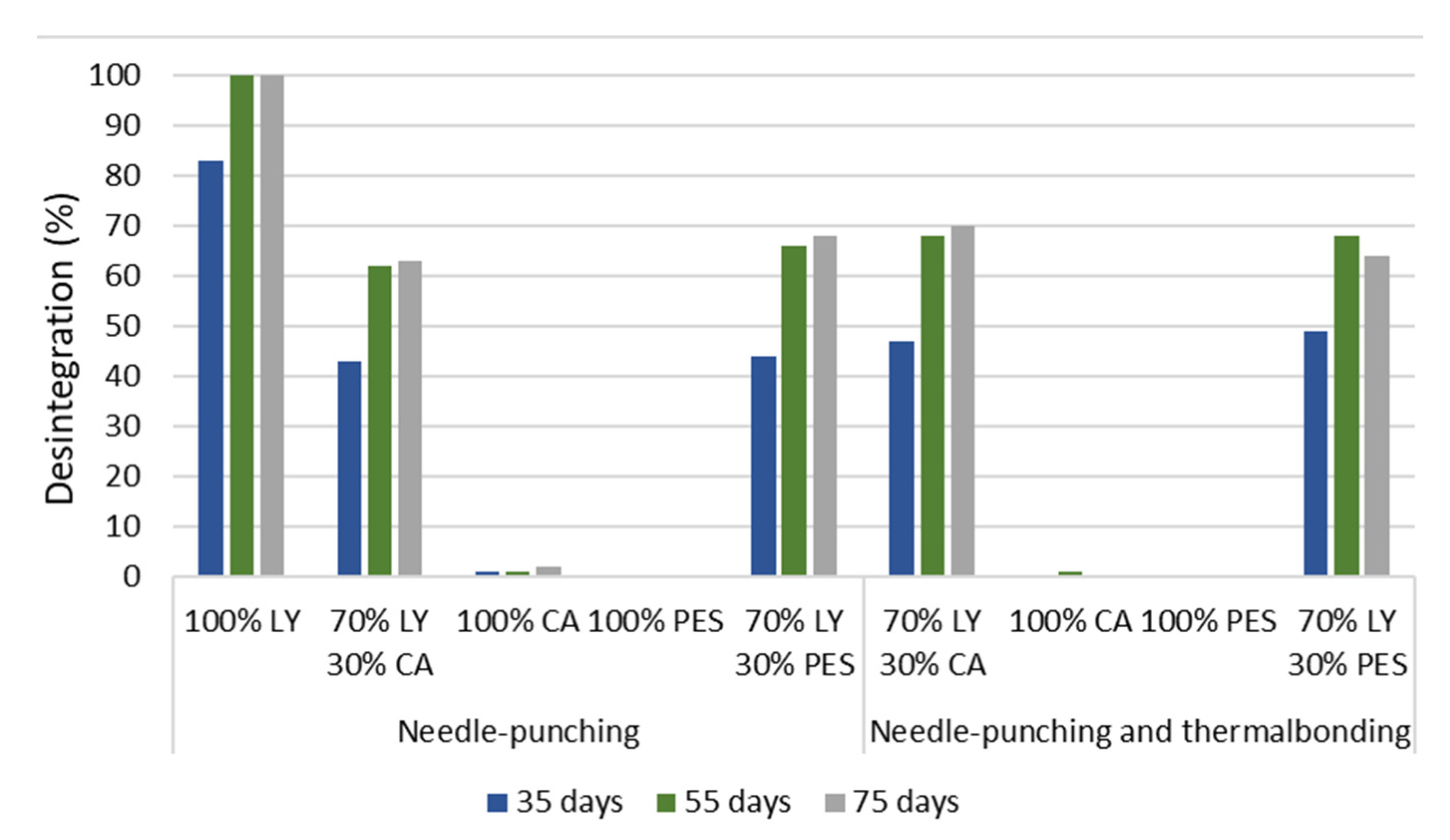

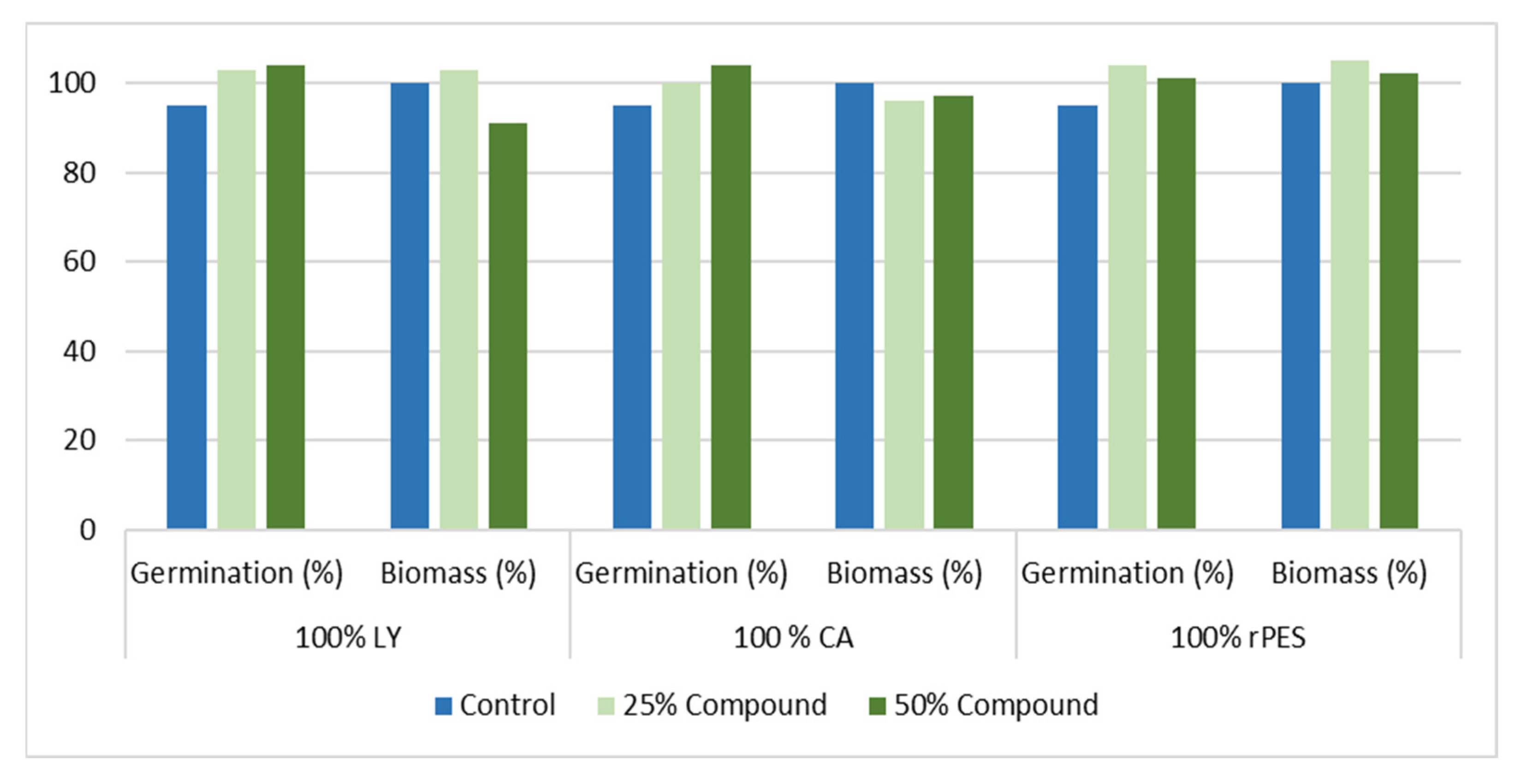

3.4. Biodegradability Assessment

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nonwoven Fabrics Market. Available online: https://www.reportsanddata.com/report-detail/nonwoven-fabrics-market (accessed on 24 March 2025).

- Wysokińska, Z.; Czajkowski, T.; Grabowska, K. Nonwovens: Global Trends in World Economy, European Foreign Trade, and Selected Case Studies from Poland and Asian Brics Countries. Autex Res. J. 2020, 20, 382–414. [Google Scholar] [CrossRef]

- Kalil, B. Worldwide Staple Fiber-Based Nonwoven Consumption | International Fiber Journal. Available online: https://www.fiberjournal.com/worldwide-staple-fiber-based-nonwoven-consumption/ (accessed on 24 March 2025).

- Nonwoven Fabrics Market Size, Share, Growth Report, 2030. Available online: https://www.grandviewresearch.com/industry-analysis/nonwoven-fabrics-market (accessed on 20 February 2025).

- Dhaka, V.; Singh, S.; Anil, A.G.; Sunil Kumar Naik, T.S.; Garg, S.; Samuel, J.; Kumar, M.; Ramamurthy, P.C.; Singh, J. Occurrence, toxicity and remediation of polyethylene terephthalate plastics. A review. Environ. Chem. Lett. 2022, 20, 1777–1800. [Google Scholar] [CrossRef] [PubMed]

- Santos, A.S.; Ferreira, P.J.T.; Maloney, T. Bio-based materials for nonwovens. Cellulose 2021, 28, 8939–8969. [Google Scholar] [CrossRef]

- Othman, H.; Almouregi, M.; Awad, E.; Zaher, S.; Mohamed, L.; Dabour, E.; Youssif, E.; Hassabo, A. Nonwoven Fabrics: Manufacturing, Finishing, Applications, and Possibilities. J. Text. Color. Polym. Sci. 2025, 22, 23–30. [Google Scholar] [CrossRef]

- Liu, M.; Ma, C.; Chen, Y.; Wang, Y.; Xu, J.; Li, Z.; Deng, L.; Zou, L.; Wu, J.; Wang, H. Cellulose nonwoven with fast liquid-discharging and anti-return properties: A microplastic-free surface layer for disposable absorbent hygiene products. Chem. Eng. J. 2024, 490, 151291. [Google Scholar] [CrossRef]

- Gao, X.; Duckett, K.E.; Bhat, G.; Rong, H. Effects of Water on Processing and Properties of Thermally Bonded Cotton/Cellulose Acetate Nonwovens. Int. Nonwovens J. 2001, 10, 21–25. [Google Scholar] [CrossRef]

- Yadav, N.; Hakkarainen, M. Degradable or not? Cellulose acetate as a model for complicated interplay between structure, environment and degradation. Chemosphere 2021, 265, 128731. [Google Scholar] [CrossRef]

- Zhang, S.; Fu, L.; Yang, Z.; Jing, M.; Zhang, Z.; Xiang, S.; Wang, R. Response Surface Methodology for Optimizing the Preparation Process of Cellulose Acetate/Polylactic Acid Nonwoven Surgical Gown Material. Fibers Polym. 2021, 22, 928–935. [Google Scholar] [CrossRef]

- Badara, O.; Rämö, V.; Rissanen, M.; Tehrani-Bagha, A. Mechanically recycled textile fibers in carded and needle-punched non-wovens: Implications on processability, structure, and performance. Text. Res. J. 2024, 95, 00405175241302482. [Google Scholar] [CrossRef]

- Gaminian, H.; Ahvazi, B.; Vidmar, J.J.; Ekuere, U.; Regan, S. Revolutionizing Sustainable Nonwoven Fabrics: The Potential Use of Agricultural Waste and Natural Fibres for Nonwoven Fabric. Biomass 2024, 4, 363–401. [Google Scholar] [CrossRef]

- Orasugh, J.T.; Botlhoko, O.J.; Temane, L.T.; Ray, S.S. Progress in polymer nonwoven textile materials in electromagnetic interference shielding applications. Funct. Compos. Mater. 2024, 5, 5. [Google Scholar] [CrossRef]

- Marques, R.; Oliveira, C.; Araújo, J.C.; Chaves, D.M.; Ferreira, D.P.; Fangueiro, R.; Silva, C.J.; Rodrigues, L. Planting Sustainability: A Comprehensive Review of Plant Fibres in Needle-Punching Nonwovens. Textiles 2024, 4, 530–548. [Google Scholar] [CrossRef]

- Tapia-Picazo, J.C.; Luna-Bárcenas, J.G.; García-Chávez, A.; Gonzalez-Nuñez, R.; Bonilla-Petriciolet, A.; Alvarez-Castillo, A. Polyester fiber production using virgin and recycled PET. Fibers Polym. 2014, 15, 547–552. [Google Scholar] [CrossRef]

- ISO 1973:2021; Textile Fibres—Determination of Linear Density—Gravimetric Method and Vibroscope Method. ISO: Geneva, Switzerland, 2021.

- ISO 5079:2020; Textile Fibres—Determination of Breaking Force and Elongation at Break of Individual Fibres. ISO: Geneva, Switzerland, 2020.

- ISO 9073-3:2023; Part 3: Determination of Tensile Strength and Elongation at Break Using the Strip Method. ISO: Geneva, Switzerland, 2023.

- Egan, J.; Salmon, S. Strategies and progress in synthetic textile fiber biodegradability. SN Appl. Sci. 2022, 4, 22. [Google Scholar] [CrossRef]

- ISO 20200:2023; Plastics—Determination of the Degree of Disintegration of Plastic Materials Under Composting Conditions in a Laboratory-Scale Test. ISO: Geneva, Switzerland, 2023.

- EN 13432:2000; Packaging—Requirements for Packaging Recoverable Through Composting and Biodegradation—Test Scheme And Evaluation Criteria for the Final Acceptance of Packaging. EN: Brussels, Belgium, 2000.

- OECD. Test No. 208: Terrestrial Plant Test: Seedling Emergence and Seedling Growth Test, OECD Guidelines for the Testing of Chemicals, Section 2; OECD Publishing: Paris, France, 2006. [Google Scholar] [CrossRef]

- Dadashian, F.; Yaghoobi, Z.; Wilding, M.A. Thermal behaviour of lyocell fibres. Polym. Test. 2005, 24, 969–977. [Google Scholar] [CrossRef]

- Sąsiadek, M.; Dobrzańska-Danikiewicz, A.D.; Niedziela, M.; Woźniak, W.; Szota, M. Mechanical Properties of Spunlace Non-Wovens with a Porous Structure. Coatings 2024, 14, 1342. [Google Scholar] [CrossRef]

- Chandra, R. Biodegradable polymers. Prog. Polym. Sci. 1998, 23, 1273–1335. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, S.; Galluzzi, M.; Li, F.; Zhang, X.; Yang, X.; Liu, X.; Cai, X.; Zhu, X.; Du, B.; et al. Insight into multifunctional polyester fabrics finished by one-step eco-friendly strategy. Chem. Eng. J. 2019, 358, 634–642. [Google Scholar] [CrossRef]

- Chand, S.; Bhat, G.S.; Spruiell, J.E.; Malkan, S. Role of Fiber Morphology in Thermal Bonding. Int. Nonwovens J. 2002, os-11, 12–20. [Google Scholar] [CrossRef]

- Shibata, M.; Oyamada, S.; Kobayashi, S.; Yaginuma, D. Mechanical properties and biodegradability of green composites based on biodegradable polyesters and lyocell fabric. J. Appl. Polym. Sci. 2004, 92, 3857–3863. [Google Scholar] [CrossRef]

- Zhijiang, C.; Yi, X.; Haizheng, Y.; Jia, J.; Liu, Y. Poly(hydroxybutyrate)/cellulose acetate blend nanofiber scaffolds: Preparation, characterization and cytocompatibility. Mater. Sci. Eng. C 2016, 58, 757–767. [Google Scholar] [CrossRef] [PubMed]

- Zambrano, M.C.; Pawlak, J.J.; Venditti, R.A. Effects of chemical and morphological structure on biodegradability of fibers, fabrics, and other polymeric materials. BioResources 2020, 15, 9786–9833. [Google Scholar] [CrossRef]

- Brunšek, R.; Kopitar, D.; Schwarz, I.; Marasović, P. Biodegradation Properties of Cellulose Fibers and PLA Biopolymer. Polymers 2023, 15, 3532. [Google Scholar] [CrossRef] [PubMed]

- Sülar, V.; Devrim, G. Biodegradation Behaviour of Different Textile Fibres: Visual, Morphological, Structural Properties and Soil Analyses. Fibres Text. East. Eur. 2019, 27, 100–111. [Google Scholar] [CrossRef]

| Fibres | Lyocell (LY) | Cellulose Acetate (CA) | Recycled Polyester (rPES) |

|---|---|---|---|

| Linear density (dtex) | 1.30 | 1.49 | 1.49 |

| Length (mm) | 38 | 38 | 38 |

| Breaking force (cN) | 5.73 ± 0.16 | 1.99 ± 0.07 | 8.05 ± 0.30 |

| Elongation at break (%) | 16.0 ± 0.07 | 30.0 ± 0.09 | 24 ± 1.7 |

| Tenacity (cN/dtex) | 4.20 | 1.30 | 5.4 |

| Fibres | Glass Transition (°C) | Melting Point (°C) | ||||

|---|---|---|---|---|---|---|

| Tonset | Tendset | Tglass | Tonset | Tendset | Tmelting | |

| Cellulose Acetate (CA) | 181.08 | 190.69 | 185.39 | 220.68 | 235.19 | 227.58 |

| Recycled Polyester (rPES) | 68.88 | 83.24 | 76.06 | 227.85 | 272.47 | 250.16 |

| Nonwoven Composition | Carded and Needle-Punched | Carded, Needle-Punched, and Thermal-Bonded | ||

|---|---|---|---|---|

| Basis Weight (gsm) | Thickness (mm) | Basis Weight (gsm) | Thickness (mm) | |

| 100% LY | 220 | 2.85 | - | - |

| 100% CA | 230 | 3.72 | 207 | 0.47 |

| 70% CA/30% LY | 220 | 2.91 | 200 | 0.54 |

| 50% CA/50% LY | 220 | 3.04 | 228 | 0.86 |

| 30% CA/70% LY | 230 | 2.80 | 246 | 1.16 |

| 100% rPES | 197 | 3.16 | 232 | 0.74 |

| 70% rPES/30% LY | 198 | 3.00 | 231 | 1.20 |

| 50% rPES/50% LY | 193 | 2.80 | 185 | 1.20 |

| 30% rPES/70% LY | 200 | 2.82 | 205 | 1.61 |

| Sample | Biodegradability over Time | ||||

|---|---|---|---|---|---|

| Day 0 | Day 35 | Day 55 | Day 75 | ||

| Needle-punched | 100% LY |  |  |  |  |

| 100% CA |  |  |  |  | |

| 100% rPES |  |  |  |  | |

| 70% LY/30% CA |  |  |  |  | |

| 70% LY/30% rPES |  |  |  |  | |

| Needle-Punched + Thermal bonded | 100% CA |  |  |  |  |

| 100% rPES |  |  |  |  | |

| 70% LY/30% CA |  |  |  |  | |

| 70% LY/30% rPES |  |  |  |  | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodrigues, L.; Medeiros, J.; Marques, R.; Silva, C.J. Lyocell-Based Nonwovens: Mechanical Performance and Biodegradation Analysis. Textiles 2025, 5, 20. https://doi.org/10.3390/textiles5020020

Rodrigues L, Medeiros J, Marques R, Silva CJ. Lyocell-Based Nonwovens: Mechanical Performance and Biodegradation Analysis. Textiles. 2025; 5(2):20. https://doi.org/10.3390/textiles5020020

Chicago/Turabian StyleRodrigues, Lúcia, João Medeiros, Rita Marques, and Carla J. Silva. 2025. "Lyocell-Based Nonwovens: Mechanical Performance and Biodegradation Analysis" Textiles 5, no. 2: 20. https://doi.org/10.3390/textiles5020020

APA StyleRodrigues, L., Medeiros, J., Marques, R., & Silva, C. J. (2025). Lyocell-Based Nonwovens: Mechanical Performance and Biodegradation Analysis. Textiles, 5(2), 20. https://doi.org/10.3390/textiles5020020