Rapid Fabrication of Pineapple Leaf Fibers from Discarded Leaves by Using Electrolysis of Brine

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Formation of PALF

2.2. Characterization of PALF

2.2.1. Scanning Electron Microscopy and Visual Appearance

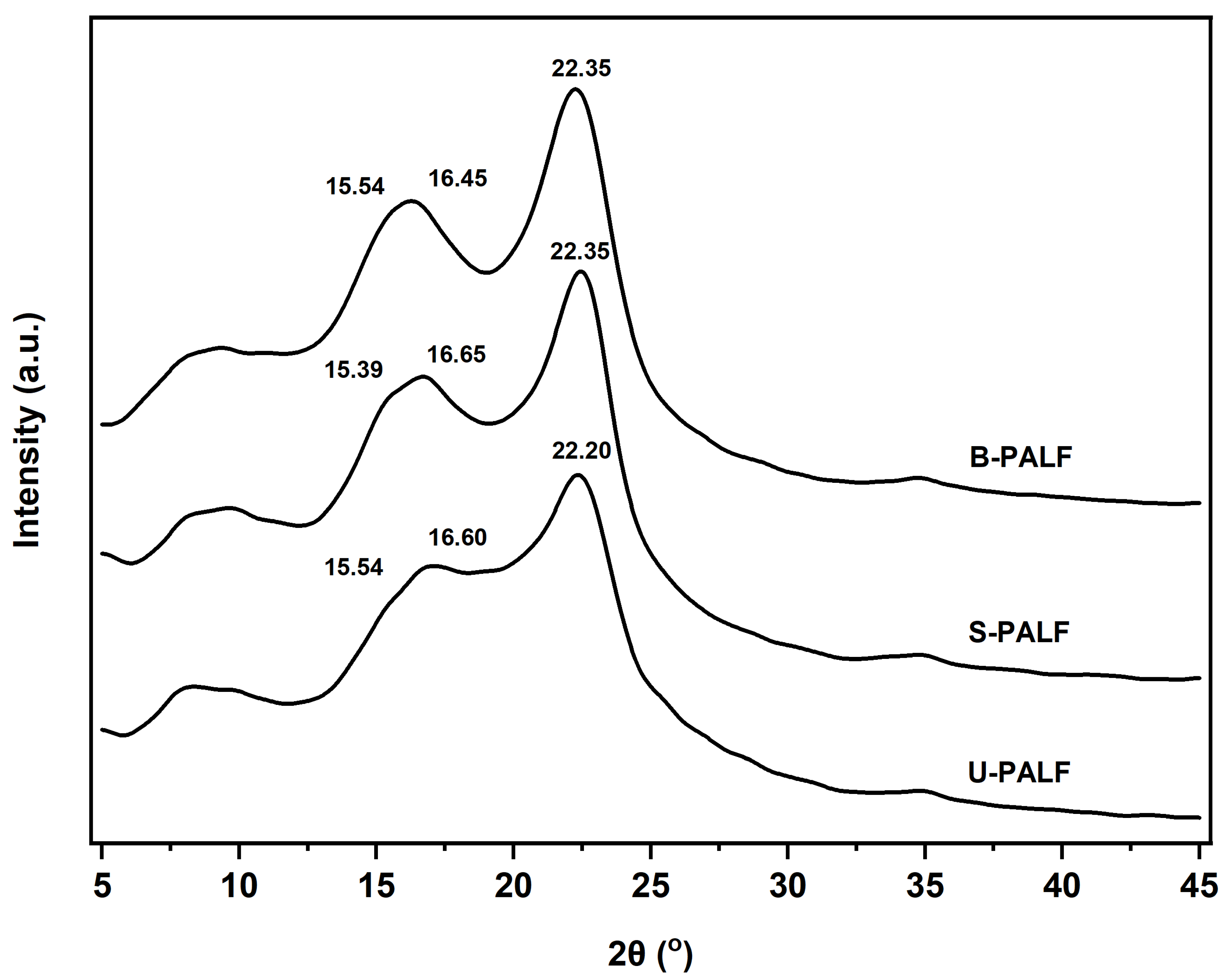

2.2.2. X-ray Diffraction

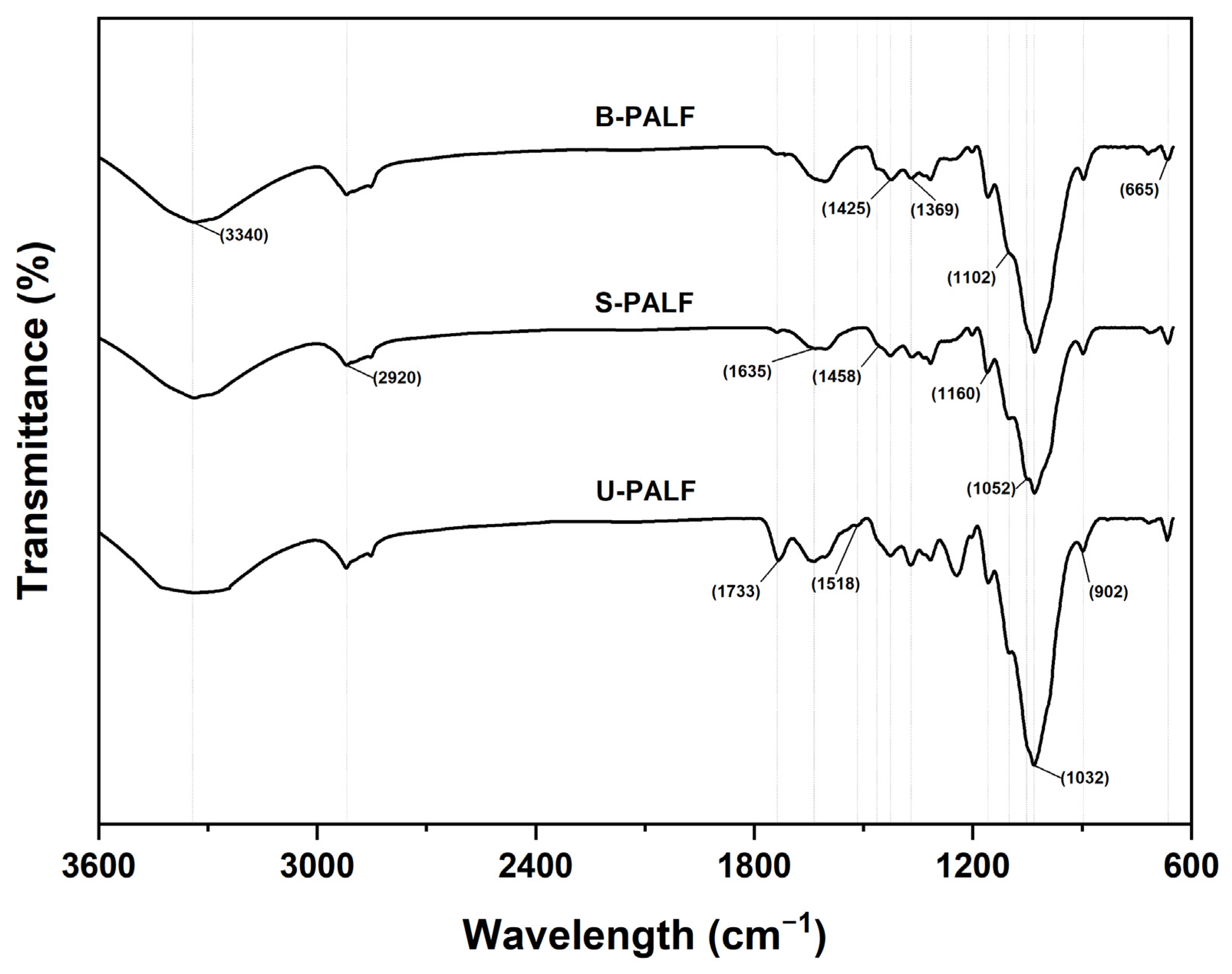

2.2.3. Fourier Transform Infrared Spectroscopy

2.3. Gas Chromatography

3. Results and Discussion

3.1. Hypochorite Production

3.2. Surface Morphology

3.3. Crystallinity Index

3.4. Functional Groups

3.5. The Presence of Hydrogen

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pandit, P.; Pandey, R.; Singha, K.; Shrivastava, S.; Gupta, V.; Jose, S. Pineapple Leaf Fibre: Cultivation and Production. In Pineapple Leaf Fibers: Processing, Properties and Applications; Jawaid, M., Asim, M., Tahir, P.M., Nasir, M., Eds.; Springer: Singapore, 2020; pp. 1–20. [Google Scholar] [CrossRef]

- Todkar, S.S.; Patil, S.A. Review on mechanical properties evaluation of pineapple leaf fibre (PALF) reinforced polymer composites. Compos. Part B Eng. 2019, 174, 106927. [Google Scholar] [CrossRef]

- Ferreira, L.E.; Muniz, B.V.; Bittar, T.O.; Berto, L.A.; Figueroba, S.R.; Groppo, F.C.; Pereira, A.C. Effect of particles of ashes produced from sugarcane burning on the respiratory system of rats. Environ. Res 2014, 135, 304–310. [Google Scholar] [CrossRef] [PubMed]

- Gabrielli, P.; Gazzani, M.; Mazzotti, M. The Role of Carbon Capture and Utilization, Carbon Capture and Storage, and Biomass to Enable a Net-Zero-CO2 Emissions Chemical Industry. Ind. Eng. Chem. Res. 2020, 59, 7033–7045. [Google Scholar] [CrossRef] [Green Version]

- Mwaikambo, L. Review of the history, properties and application of plant fibres. Afr. J. Sci. Technol. 2006, 7, 120–133. [Google Scholar]

- Daochalermwong, A.; Chanka, N.; Songsrirote, K.; Dittanet, P.; Niamnuy, C.; Seubsai, A. Removal of Heavy Metal Ions Using Modified Celluloses Prepared from Pineapple Leaf Fiber. ACS Omega 2020, 5, 5285–5296. [Google Scholar] [CrossRef]

- Putra, A.; Prasetiyo, I.; Selamat, Z. Green Acoustic Absorber from Pineapple Leaf Fibers. In Pineapple Leaf Fibers: Processing, Properties and Applications; Jawaid, M., Asim, M., Tahir, P.M., Nasir, M., Eds.; Springer: Singapore, 2020; pp. 143–165. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Ramakrishnan, S.; Pugalenthi, T.; Ravikumar, P. Performance of Surface Modified Pineapple Leaf Fiber and Its Applications. In Pineapple Leaf Fibers: Processing, Properties and Applications; Jawaid, M., Asim, M., Tahir, P.M., Nasir, M., Eds.; Springer: Singapore, 2020; pp. 309–321. [Google Scholar] [CrossRef]

- Ramli, S.; Sheikh Md Fadzullah, S.; Mustafa, Z. The effect of alkaline treatment and fiber length on pineapple leaf fiber reinforced poly lactic acid biocomposites. J. Teknol. 2017, 79, 111–115. [Google Scholar] [CrossRef] [Green Version]

- Jose, S.; Salim, R.; Ammayappan, L. An Overview on Production, Properties, and Value Addition of Pineapple Leaf Fibers (PALF). J. Nat. Fibers 2016, 13, 362–373. [Google Scholar] [CrossRef]

- Adam, A.; Yusof, Y.; Yahya, A. Extraction of pineapple leaf fibre: Josapine and moris. J. Eng. Appl. Sci. 2016, 11, 161–165. [Google Scholar]

- Das, P.; Nag, D.; Debnath, S.; Nayak, L. Machinery for extraction and traditional spinning of plant fibres. Indian J. Tradit. Knowl. 2010, 9, 2. [Google Scholar]

- Asim, M.; Abdan, K.; Jawaid, M.; Nasir, M.; Dashtizadeh, Z.; Ishak, M.R.; Hoque, M.E. A Review on Pineapple Leaves Fibre and Its Composites. Int. J. Polym. Sci. 2015, 2015, 950567. [Google Scholar] [CrossRef]

- Gaba, E.W.; Asimeng, B.O.; Kaufmann, E.E.; Katu, S.K.; Foster, E.J.; Tiburu, E.K. Mechanical and Structural Characterization of Pineapple Leaf Fiber. Fibers 2021, 9, 51. [Google Scholar] [CrossRef]

- Zin, M.H.; Abdan, K.; Mazlan, N.; Zainudin, E.S.; Liew, K.E. The effects of alkali treatment on the mechanical and chemical properties of pineapple leaf fibres (PALF) and adhesion to epoxy resin. Iop Conf. Ser. Mater. Sci. Eng. 2018, 368, 012035. [Google Scholar] [CrossRef]

- Gedik, G.; Avinc, O. Bleaching of Hemp (Cannabis Sativa L.) Fibers with Peracetic Acid for Textiles Industry Purposes. Fibers Polym. 2018, 19, 82–93. [Google Scholar] [CrossRef]

- Khaliq, A.D.; Chafidz, A.; Maddun, F.R.; Herimawan, H.R.; Yusuf, G.M.; Rahmillah, F.I. The use of hydrogen peroxide and sky stabilizer agent in bleaching process of textile fabrics. Aip Conf. Proc. 2019, 2138, 050011. [Google Scholar] [CrossRef]

- Tanpichai, S.; Witayakran, S. All-cellulose composite laminates prepared from pineapple leaf fibers treated with steam explosion and alkaline treatment. J. Reinf. Plast. Compos. 2017, 36, 1146–1155. [Google Scholar] [CrossRef]

- Gadzama, S.W.; Sunmonu, O.K.; Isiaku, U.S.; Danladi, A. Isolation and characterization of nanocellulose from pineapple leaf fibres via chemo-mechanical method. Sci. World J. 2020, 15, 100–105. [Google Scholar]

- Cordeiro, N.; Gouveia, C.; John, M.J. Investigation of surface properties of physico-chemically modified natural fibres using inverse gas chromatography. Ind. Crop. Prod. 2011, 33, 108–115. [Google Scholar] [CrossRef]

- Bommaraju, T.V.; Orosz, P.J.; Sokol, E.A. Brine electrolysis. Electrochem. Encycl. 2007, 1–17. [Google Scholar]

- Tennakone, K. Hydrogen from brine electrolysis: A new approach. Int. J. Hydrog. Energy 1989, 14, 681–682. [Google Scholar] [CrossRef]

- Banik, S.; Nag, D.; Debnath, S. Utilization of pineapple leaf agro-waste for extraction of fibre and the residual biomass for vermicomposting. Indian J. Fibre Text. Res. 2011, 36, 2. [Google Scholar]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- French, A.D.; Santiago Cintrón, M. Cellulose polymorphy, crystallite size, and the Segal Crystallinity Index. Cellulose 2013, 20, 583–588. [Google Scholar] [CrossRef]

- Nam, S.; French, A.D.; Condon, B.D.; Concha, M. Segal crystallinity index revisited by the simulation of X-ray diffraction patterns of cotton cellulose Iβ and cellulose II. Carbohydr. Polym. 2016, 135, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Fukuzaki, S. Mechanisms of Actions of Sodium Hypochlorite in Cleaning and Disinfection Processes. Biocontrol Sci. 2006, 11, 147–157. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, A.R.; Sapuan, S.M.; Shahjahan, M.; Khalina, A. Effects of Simple Abrasive Combing and Pretreatments on the Properties of Pineapple Leaf Fibers (Palf) and Palf-Vinyl Ester Composite Adhesion. Polym.-Plast. Technol. Eng. 2010, 49, 972–978. [Google Scholar] [CrossRef]

- He, T.; Kar, M.; McDaniel, N.D.; Randolph, B.B. Electrochemical Hydrogen Production. In Springer Handbook of Electrochemical Energy; Breitkopf, C., Swider-Lyons, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 897–940. [Google Scholar] [CrossRef]

- Saleem, M.; Chakrabarti, B.; Hasan, D.u.; Islam, M.S.; Yussof, R.; Hajimolana, Y.S.; Hussain, M.; Khan, G.M.; Si Ali, B. On site Electrochemical Production of Sodium Hypochlorite Disinfectant for a Power Plant utilizing Seawater. Int. J. Electrochem. Sci. 2012, 7, 3929–3938. [Google Scholar]

- Fareez, I.M.; Ibrahim, N.A.; Wan Yaacob, W.M.H.; Mamat Razali, N.A.; Jasni, A.H.; Abdul Aziz, F. Characteristics of cellulose extracted from Josapine pineapple leaf fibre after alkali treatment followed by extensive bleaching. Cellulose 2018, 25, 4407–4421. [Google Scholar] [CrossRef]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Komuraiah, A.; Kumar, N.S.; Prasad, B.D. Chemical Composition of Natural Fibers and its Influence on their Mechanical Properties. Mech. Compos. Mater. 2014, 50, 359–376. [Google Scholar] [CrossRef]

- Masahisa, W. Synchrotron-radiated X-ray and neutron diffraction study of native cellulose. Cellulose 1997, 4, 221–232. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulase performance. Biotechnol. Biofuels 2010, 3, 10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Benini, K.C. Chemical modification effect on the mechanical properties of HIPS/ coconut fibers composites. Bioresources 2010, 5, 1143–1155. [Google Scholar]

- Mtibe, A.; Linganiso, L.Z.; Mathew, A.P.; Oksman, K.; John, M.J.; Anandjiwala, R.D. A comparative study on properties of micro and nanopapers produced from cellulose and cellulose nanofibres. Carbohydr Polym 2015, 118, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Rambabu, N.; Panthapulakkal, S.; Sain, M.; Dalai, A.K. Production of nanocellulose fibers from pinecone biomass: Evaluation and optimization of chemical and mechanical treatment conditions on mechanical properties of nanocellulose films. Ind Crop Prod 2016, 83, 746–754. [Google Scholar] [CrossRef]

- Revol, J.; Dietrich, A.; Goring, D. Effect of mercerization on the crystallite size and crystallinity index in cellulose from different sources. Can. J. Chem. 2011, 65, 1724–1725. [Google Scholar] [CrossRef]

- Samal, R.K.; Ray, M.C. Effect of chemical modifications on FTIR spectra. II. Physicochemical behavior of pineapple leaf fiber (PALF). J. Appl. Polym. Sci. 1997, 64, 2119–2125. [Google Scholar] [CrossRef]

- Mopoung, S. Microporous Activated Carbon Fiber from Pineapple Leaf Fiber by H3PO4 Activation. Asian J. Sci. Res. 2016, 9, 24–33. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.H.; Khalina, A.; Lee, S.H.; Padzil, F.N.M.; Ainun, Z.M.A. Physical, Morphological, Structural, Thermal and Mechanical Properties of Pineapple Leaf Fibers. In Pineapple Leaf Fibers: Processing, Properties and Applications; Jawaid, M., Asim, M., Tahir, P.M., Nasir, M., Eds.; Springer: Singapore, 2020; pp. 91–121. [Google Scholar] [CrossRef]

- Sugiyama, J.; Persson, J.; Chanzy, H. Combined infrared and electron diffraction study of the polymorphism of native celluloses. Macromolecules 1991, 24, 2461–2466. [Google Scholar] [CrossRef]

- Ojaomo, K.; Erinle, T.; Oladebeye, D.H.; Olakolegan, D. Hydrogen Generation through Electrolysis of Brine for Clean Energy Development in a Depressed Economy. IARJSET Int. Adv. Res. J. Sci. Eng. Technol. 2020, 7, 94–101. [Google Scholar] [CrossRef]

- Kraft, A.; Stadelmann, M.; Blaschke, M.; Kreysig, D.; Sandt, B.; Schröder, F.; Rennau, J. Electrochemical water disinfection Part I: Hypochlorite production from very dilute chloride solutions. J. Appl. Electrochem. 1999, 29, 859–866. [Google Scholar] [CrossRef]

| PALF | Crystallinity Index (%) | Crystallite Size (nm) |

|---|---|---|

| Untreated | 28.12 | 2.28 |

| Softened | 36.9 | 2.56 |

| Bleached | 44.26 | 2.49 |

| Gas | Percentage in 1 mL of Gas (%) | |||

|---|---|---|---|---|

| 15 min | 1 h | 2 h | 3 h | |

| Hydrogen (H2) | 98.68 ± 0.15 | 99.23 ± 0.23 | 99.15 ± 0.18 | 99.28 ± 0.21 |

| Others (N2, CO2) | 1.31 ± 0.15 | 0.77 ± 0.23 | 0.85 ± 0.18 | 0.72 ± 0.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phan, H.N.Q.; Leu, J.H.; Tran, K.T.; Nguyen, V.N.D.; Nguyen, T.T. Rapid Fabrication of Pineapple Leaf Fibers from Discarded Leaves by Using Electrolysis of Brine. Textiles 2023, 3, 1-10. https://doi.org/10.3390/textiles3010001

Phan HNQ, Leu JH, Tran KT, Nguyen VND, Nguyen TT. Rapid Fabrication of Pineapple Leaf Fibers from Discarded Leaves by Using Electrolysis of Brine. Textiles. 2023; 3(1):1-10. https://doi.org/10.3390/textiles3010001

Chicago/Turabian StylePhan, Huy N. Q., Jyh Hoang Leu, Khanh Thien Tran, Vi N. D. Nguyen, and Trung Tan Nguyen. 2023. "Rapid Fabrication of Pineapple Leaf Fibers from Discarded Leaves by Using Electrolysis of Brine" Textiles 3, no. 1: 1-10. https://doi.org/10.3390/textiles3010001

APA StylePhan, H. N. Q., Leu, J. H., Tran, K. T., Nguyen, V. N. D., & Nguyen, T. T. (2023). Rapid Fabrication of Pineapple Leaf Fibers from Discarded Leaves by Using Electrolysis of Brine. Textiles, 3(1), 1-10. https://doi.org/10.3390/textiles3010001