Smart Fabric Textiles: Recent Advances and Challenges

Abstract

1. Introduction

2. Brief History

3. Fabrication Methods

4. The Main Types of Smart Fabric Textiles

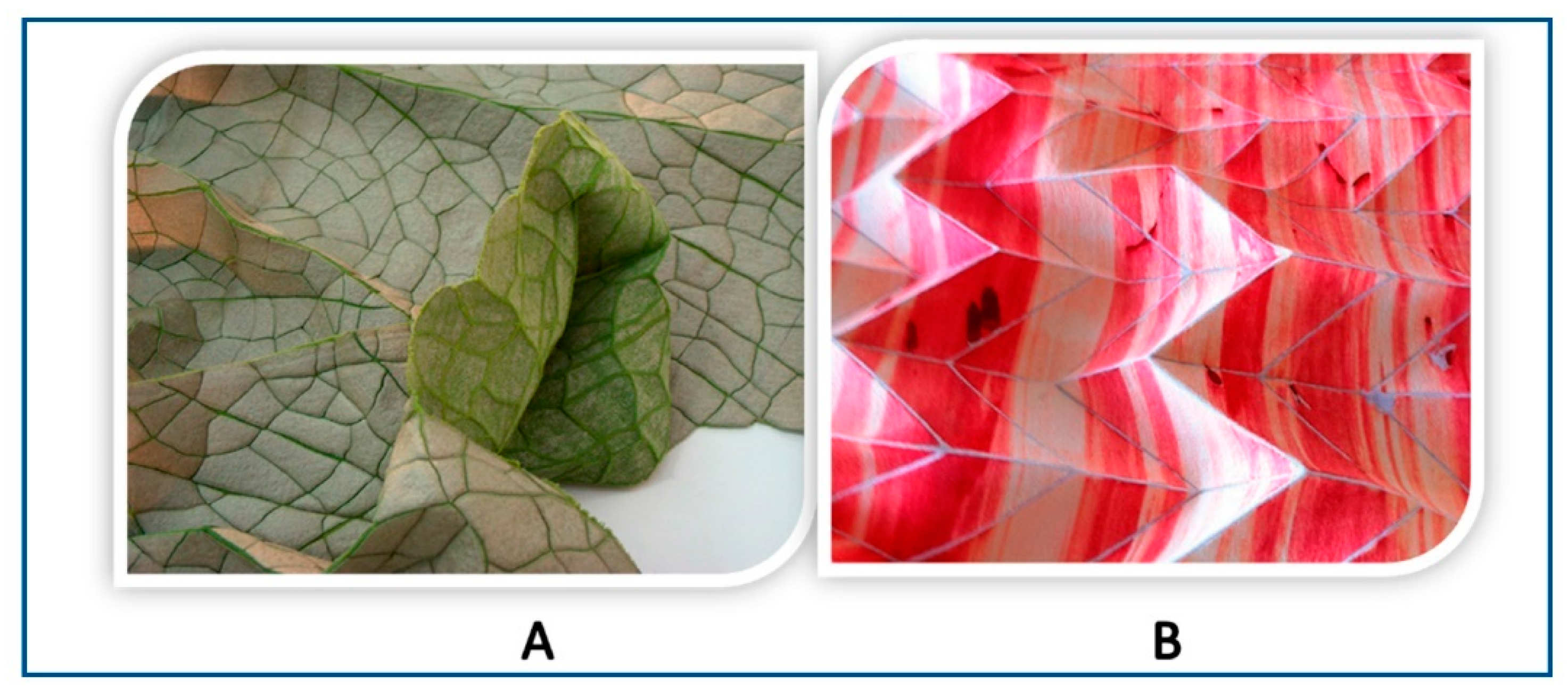

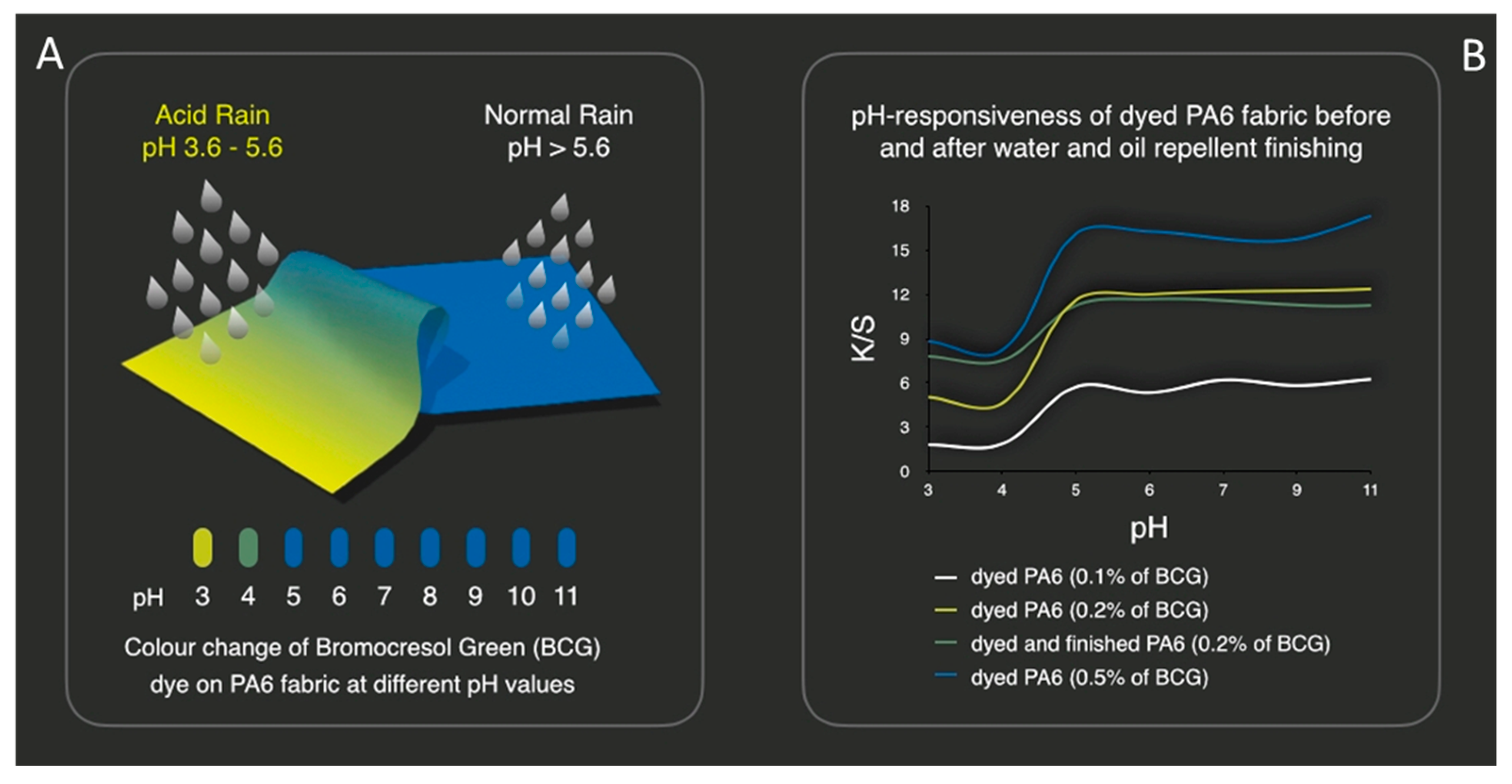

4.1. Smart Color-Changing Fabric Textiles

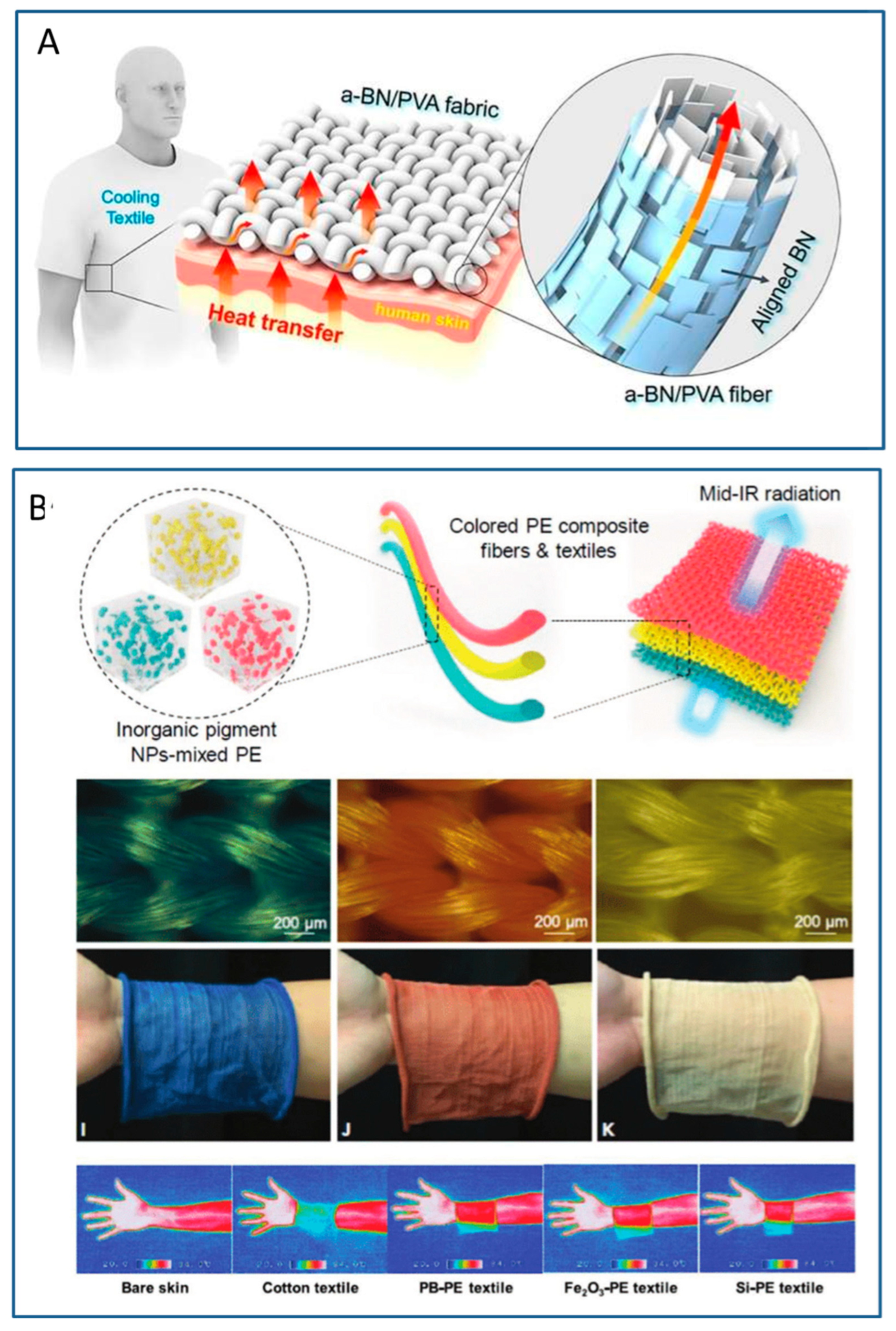

4.2. Temperature-Controlling Fabric Textiles

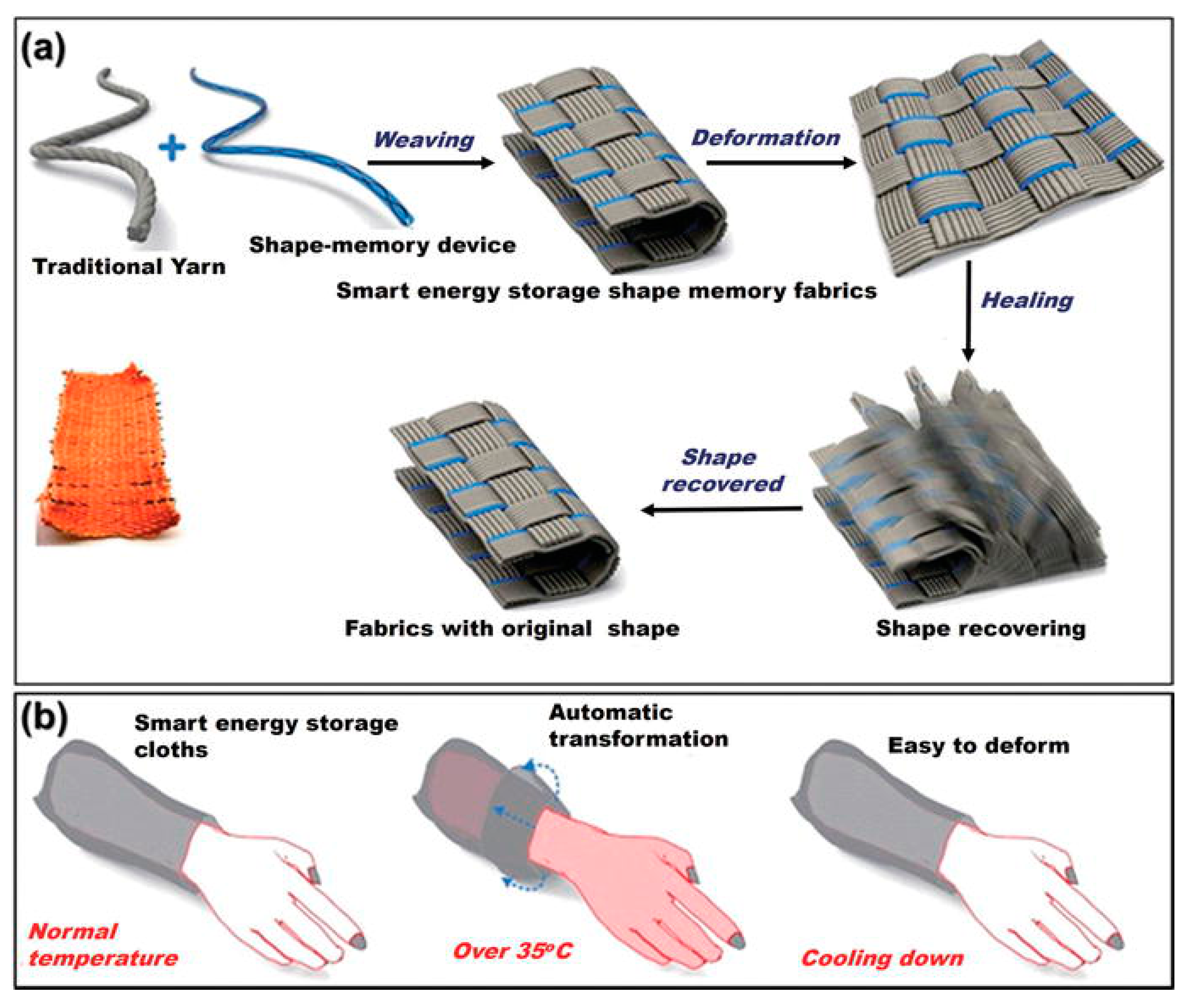

4.3. Shape Memory Fabric Textiles

4.4. Waterproof and Breathable Fabric Textiles

- Optimum heat and moisture regulation.

- Absorption of surplus heat.

- Waterproofness.

- Good air and water vapor permeability.

- Rapid drying to prevent catching cold, durable, easy care/launderability.

- Dimensional stability even when it comes in contact with water.

- Lightweight, soft, and pleasant to the touch.

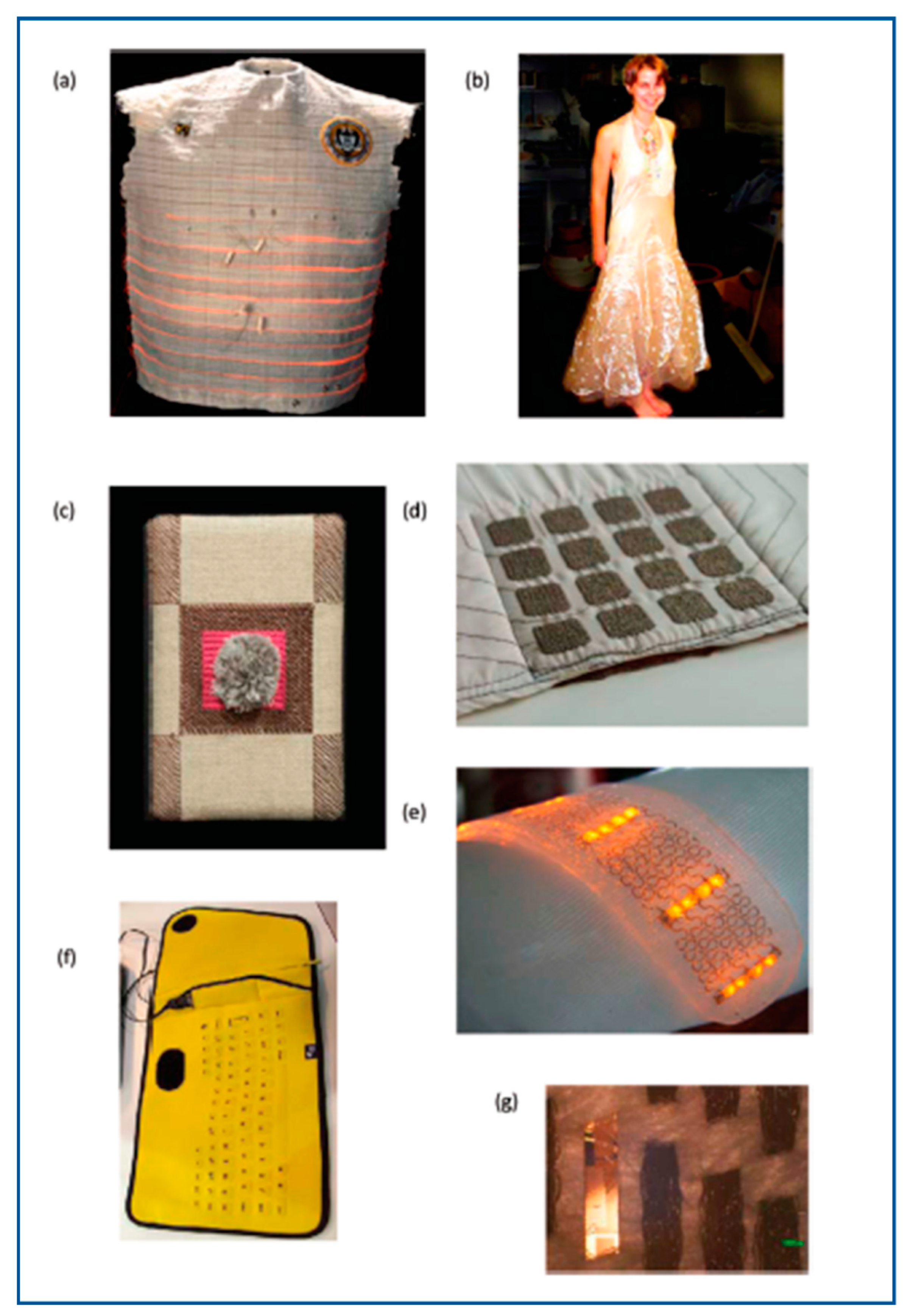

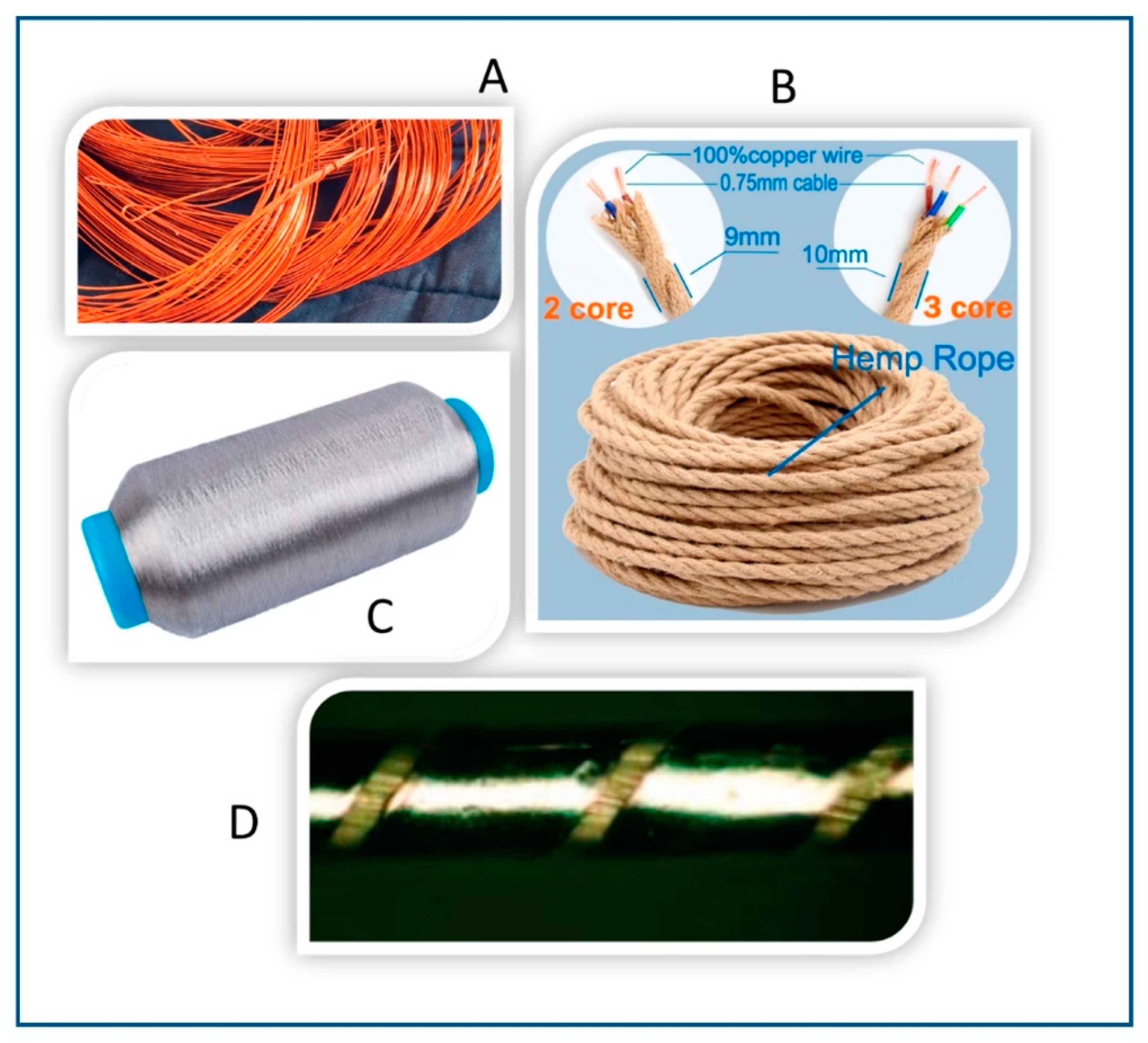

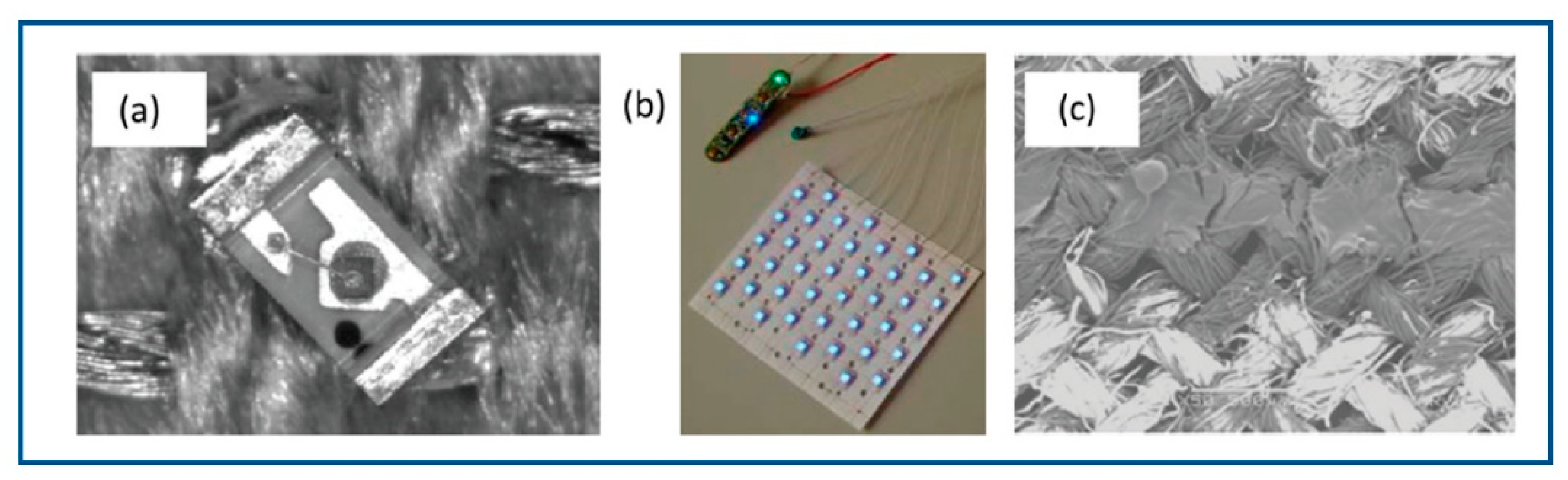

4.5. Wearable Electronics Smart Textile

4.6. Phase-Changing Textiles

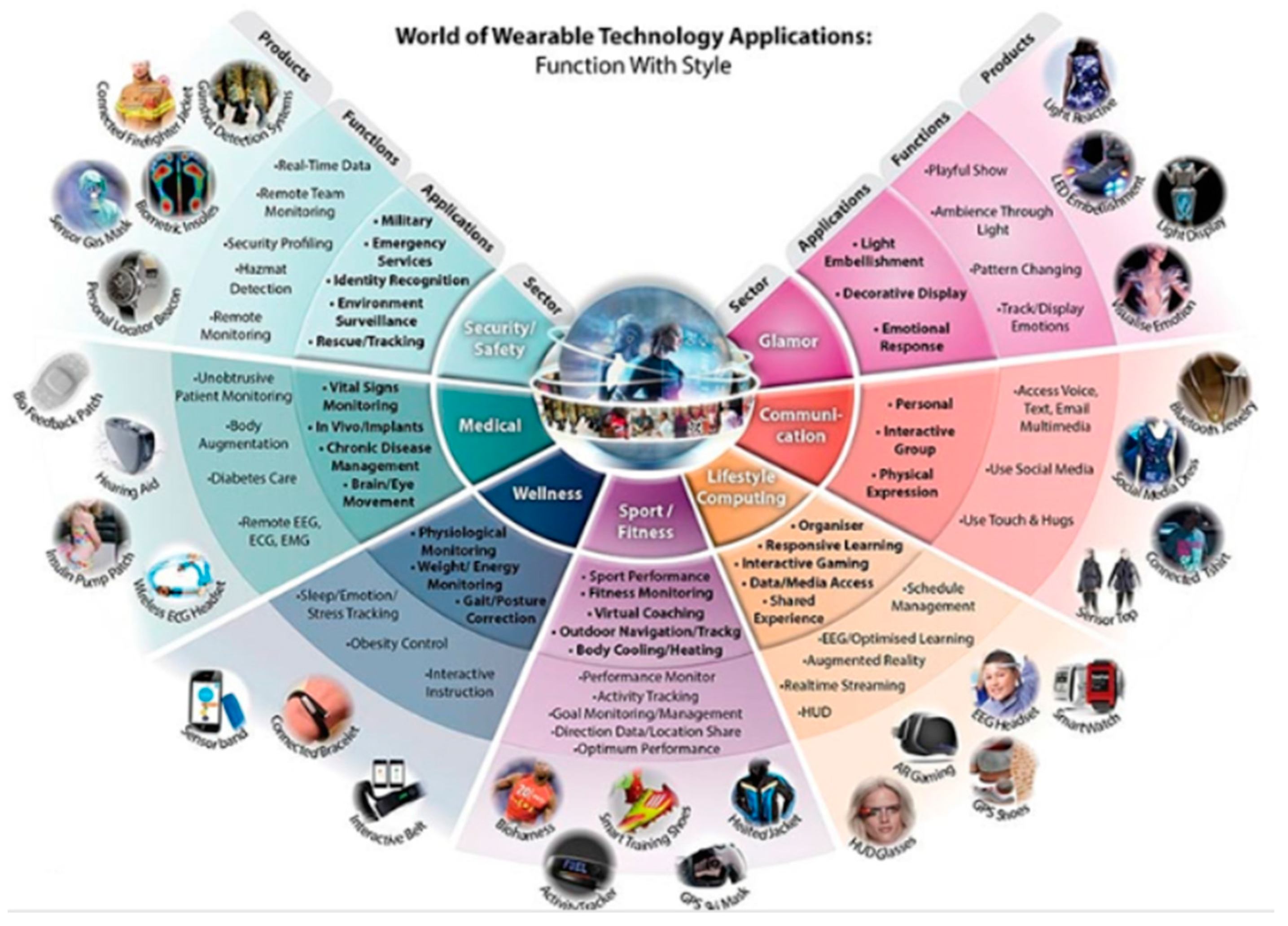

5. Today’s Applications

6. Recent Advances and Challenges

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cherenack, K.; van Pieterson, L. Smart textiles: Challenges and opportunities. J. Appl. Phys. 2012, 112, 091301. [Google Scholar] [CrossRef]

- van Langenhove, L.; Hertleer, C. Smart clothing: A new life. Int. J. Cloth. Sci. Technol. 2004, 16, 63–72. [Google Scholar] [CrossRef]

- Stanković, S.B.; Novaković, M.; Popović, D.M.; Poparić, G.B.; Bizjak, M. Novel engineering approach to optimization of thermal comfort properties of hemp containing textiles. J. Text. Inst. 2019, 110, 1271–1279. [Google Scholar] [CrossRef]

- Wei, D.W.; Wei, H.; Gauthier, A.C.; Song, J.; Jin, J.; Xiao, H. Superhydrophobic modification of cellulose and cotton textiles: Methodologies and applications. J. Bioresour. Bioprod. 2020, 5, 1–15. [Google Scholar] [CrossRef]

- van Rijwikj, K.; Teuwen, J.J.E.; Bersee, H.E.N.; Beukers, A. Textile fiber-reinforced anionic polyamide-6 composites. Part I: The vacuum infusion process. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1–10. [Google Scholar] [CrossRef]

- Pigatto, C.; Santos Almeida, J.H.; Luiz Ornaghi, H.; Rodríguez, A.L.; Mählmann, C.M.; Amico, S.C. Study of polypropylene/ethylene-propylene-diene monomer blends reinforced with sisal fibers. Polym. Compos. 2012, 33, 2262–2270. [Google Scholar] [CrossRef]

- Júnior, H.L.; Zattera, A.J.; Amico, S.C. Dynamic mechanical properties and correlation with dynamic fragility of sisal reinforced composites. Polym. Compos. 2015, 36, 161–166. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, H.; Seo, J.; Shin, S.; Koo, J.H.; Pang, C.; Son, S.; Kim, J.H.; Jang, Y.H.; Kim, D.E.; et al. Conductive fiber-based ultrasensitive textile pressure sensor for wearable electronics. Adv. Mater. 2015, 27, 2433–2439. [Google Scholar] [CrossRef]

- Edgar, K.J.; Zhang, H. Antibacterial modification of Lyocell fiber: A review. Carbohydr. Polym. 2020, 250, 116932. [Google Scholar] [CrossRef]

- Shi, Q.; Sun, J.; Hou, C.; Li, Y.; Zhang, Q.; Wang, H. Advanced functional fiber and smart textile. Adv. Fiber Mater. 2019, 1, 3–31. [Google Scholar] [CrossRef]

- Huang, L.; Lin, S.; Xu, Z.; Zhou, H.; Duan, J.; Hu, B.; Zhou, J. Fiber-based energy conversion devices for human-body energy harvesting. Adv. Mater. 2020, 32, 1902034. [Google Scholar] [CrossRef] [PubMed]

- Liao, M.; Yer, L.; Zhang, Y.; Chen, T.; Peng, H. The recent advance in fiber-shaped energy storage devices. Adv. Electron. Mater. 2019, 5, 1800456. [Google Scholar] [CrossRef]

- Floris, I.; Adam, J.M.; Calderón, P.A.; Sales, S. Fiber optic shape sensors: A comprehensive review. Opt. Lasers Eng. 2021, 139, 106508. [Google Scholar] [CrossRef]

- Smart Textiles in Fashion: What They Are, Types & Exciting Examples. Available online: https://thetechfashionista.com/what-are-smart-textiles-and-examples/ (accessed on 20 October 2022).

- Smart Textile. Available online: https://www.technicaltextile.net/articles/smart-textile-2592 (accessed on 20 October 2022).

- Patwary, M.S.U.; Syduzzaman, M. Smart Textiles and Nano-Technology: A General Overview. J. Text. Sci. Eng. 2015, 5, 1–7. [Google Scholar] [CrossRef]

- Gasparini, K. Digital Hybridisation in Adaptive Textiles for Public Space. Textiles 2022, 2, 436–446. [Google Scholar] [CrossRef]

- Giglio, A.; Neuwerk, K.; Haupt, M.; Conti, G.M.; Paoletti, I. Textile-Based Sound Sensors (TSS): New Opportunities for Sound Monitoring in Smart Buildings. Textiles 2022, 2, 296–306. [Google Scholar] [CrossRef]

- Chandler, D.L. 3 Questions: The Rapidly Unfolding Future of Smart Fabrics. Available online: https://news.mit.edu/2020/smart-fabrics-future-0508 (accessed on 15 October 2022).

- Aouf, R.S. Scientists Create Temperature-Regulating Fabric. Available online: https://www.dezeen.com/2019/02/26/temperature-regulating-fabric-university-of-maryland/ (accessed on 15 October 2022).

- Polyester Shape Memory. Available online: https://www.leantex.com/memory-fabric/ (accessed on 15 October 2022).

- Sharma, S. Waterproof Breathable Fabrics: Product Modification and Recent Developments. Available online: https://textilelearner.net/waterproof-breathable-fabrics/ (accessed on 15 October 2022).

- Hart, M. Scientists Develop Electronic Textiles for Interactive Gear. Available online: https://nerdist.com/article/scientists-develop-electronic-textiles-interactive-gear-smart-clothes/ (accessed on 15 October 2022).

- Çelikel, D.C. Smart E-Textile Materials. In Advanced Functional Materials; IntechOpen: London, UK, 2020; pp. 1–16. [Google Scholar] [CrossRef]

- Peng, Y.; Cui, Y. Advanced textiles for personal thermal management and energy. Joule 2020, 4, 724–742. [Google Scholar] [CrossRef]

- Chen, G.; Li, Y.; Bick, M.; Chen, J. Smart textiles for electricity generation. Chem. Rev. 2020, 120, 3668–3720. [Google Scholar] [CrossRef]

- Massaroni, C.; Saccomandi, P.; Schena, E. Medical smart textiles based on fiber optic technology: An overview. J. Funct. Mater. 2015, 6, 204–221. [Google Scholar] [CrossRef]

- Revaiah, R.G.; Kotresh, T.M.; Kandasubramanian, B. Technical textiles for military applications. J. Text. Inst. 2020, 111, 273–308. [Google Scholar] [CrossRef]

- Huand, C.-T.; Tang, C.-F.; Lee, M.-C.; Chang, S.-H. Parametric design of yarn-based piezoresistive sensors for smart textiles. Sens. Actuators A Phys. 2008, 148, 10–15. [Google Scholar]

- van Langenhove, L. Smart Textiles for Medicine and Healthcare: Materials, Systems and Applications; CRC Press: Cambridge, UK, 2007; ISBN 9781845692933. [Google Scholar]

- Smart Textiles in Europe: The Next Tech Disruption—Interview with Andreas. Available online: https://www.smartx-europe.eu/smart-textiles-europe-next-tech-disruption-interview-lymberis-1/ (accessed on 5 November 2022).

- Bhisey, R. Smart Textile Market to Expand at a CAGR of 25% from 2021 to 2031. Open PR Worldwide Public Relations. 2022. Available online: https://www.openpr.com/news/2651325/smart-textile-market-to-expand-at-a-cagr-of-25-from-2021-to-2031 (accessed on 25 August 2022).

- Smart and Interactive Textiles Market to Thrive at a CAGR of 25.88% during 2022–2032 | Future Market Insights, Inc. Available online: https://www.globenewswire.com/news-release/2022/08/08/2493665/0/en/Smart-and-Interactive-Textiles-Market-to-Thrive-at-a-CAGR-of-25-88-during-2022-2032-Future-Market-Insights-Inc.html (accessed on 25 September 2022).

- Gauvreau, B.; Guo, N.; Schicker, K.; Stoeffler, K.; Boismenu, F.; Ajji, A.; Wingfield, R.; Dubois, C.; Skorobogatiy, M. Color-changing and color-tunable photonic bandgap fiber textiles. Opt. Express 2008, 16, 15677–15693. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; He, S.; Liu, L.; Guan, G.; Lu, X.; Sun, X.; Peng, H. The continuous fabrication of mechanochromic fibers. J. Mater. Chem. C Mater. 2016, 4, 2127–2133. [Google Scholar] [CrossRef]

- Moretti, C.; Tao, X.; Koehl, L.; Koncar, V. Electrochromic textile displays for personal communication. In Smart Textiles and Their Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 539–568. [Google Scholar] [CrossRef]

- Fishlock, D. Doctor volts [Electrotherapy]. IEEE Rev. 2001, 47, 23–28. [Google Scholar] [CrossRef]

- Thorpe, E.O. The invention of the first wearable computer. In Proceedings of the 2nd International Symposium on Wearable Computers 1998, Washington, DC, USA, 19–20 October 1998; pp. 4–8. [Google Scholar]

- Juanga-Labayen, J.P.; van Labayen, I.V.; Yaun, Q. A review on textile recycling practices and challenges. Textiles 2022, 2, 174–188. [Google Scholar] [CrossRef]

- Krifa, M. Electrically conductive textile materials—Application in flexible sensors and antennas. Textiles 2021, 1, 239–257. [Google Scholar] [CrossRef]

- Axisa, F.; Dittmar, A.; Delhomme, G. Smart clothes for the monitoring in real time and conditions of physiological, emotional and sensorial reactions of human. In Proceedings of the 25th Annual International Conference, Riverton, NJ, USA, 2–4 November 2015. [Google Scholar]

- Cottet, D.; Grzyb, J.; Kirstein, T.; Troster, G. Electrical characterization of textile transmission line. IEEE Trans. Adv. Packag. 2003, 26, 182–190. [Google Scholar] [CrossRef]

- Locher, I.; Troster, G. Fundamental building blocks for circuits on textiles. IEEE Trans. Adv. Packag. 2007, 30, 541–550. [Google Scholar] [CrossRef]

- Martin, T.; Jones, M.; Chong, J.; Quirk, M.; Baumann, K.; Passauer, L. Design and implementation of an electronic textile jumpsuit. In Proceedings of the 2009 International Symposium on Wearable Computers (ISWC ‘09), Linz, Austria, 4–7 September 2009; pp. 157–168. [Google Scholar]

- Randell, S.; Baurley, M.C.; Muller, H. Textile tools for wearable computing. In Proceedings of the 1st International Forum on Applied Wearable Computing (IFAWC 2004), Bremen, Germany, 30 August–1 September 2004. [Google Scholar]

- Textile Trend: 3D Fabric. Available online: https://startupfashion.com/textile-trend-3d-fabric (accessed on 20 October 2022).

- About Copper. Available online: https://copperalliance.org/sustainable-copper/about-copper/ (accessed on 20 October 2022).

- 2 Núcleo 3 Núcleo Torcido Cabo Corda de Cânhamo Fio Elétrico Estilo Retro Cobre Cabo da Lâmpada Do Vintage Tecido Fio Têxtil Pingente de Cabo de Luz. Available online: https://pt.aliexpress.com/item/1005002134805048.html?gatewayAdapt=glo2bra (accessed on 20 October 2022).

- Highly Conductive Pure Silver-Coated Nylon Thread/Yarn for E-Textiles Electronic. Available online: https://www.ebay.ca/itm/274894080543 (accessed on 20 October 2022).

- Kevlar Yarn 6 *6mm Aramid Fiber Rope Used on Tamglass Tempering Furnace Kevlar Rope. Available online: https://leverjimmy.en.made-in-china.com/product/nvbmQGhEIBYo/China-Kevlar-Yarn-6-6mm-Aramid-Fiber-Rope-Used-on-Tamglass-Tempering-Furnace-Kevlar-Rope.html (accessed on 20 October 2022).

- Kramer, J. Color-Changing Ink Turns Clothes into Giant Chemical Sensors American. Scientific American. 2020. Available online: https://www.scientificamer9ican.com/article/color-changing-ink-turns-clothes-into-giant-chemical-sensors/ (accessed on 25 August 2022).

- Stojkoski, V.; Kert, M. Design of pH responsive textile as a sensor material for acid rain. Polymers 2020, 12, 2251. [Google Scholar] [CrossRef]

- Notman, N.; Turner, K. Temperature-Controlling Textiles. Royal Society of Chemistry—Education in Chemistry. 2020. Available online: https://edu.rsc.org/feature/temperature-controlling-textiles/4011183.article (accessed on 25 August 2022).

- Service, R.F. This Fabric Can Give You Your Own Personal Climate-Control System. Science (1979). 2017. Available online: https://www.science.org/content/article/fabric-can-give-you-your-own-personal-climate-control-system (accessed on 25 August 2022).

- Gao, T.; Yang, Z.; Chen, C.; Li, Y.; Fu, K.; Dai, J.; Hitz, E.M.; Xie, H.; Liu, B.; Song, J.; et al. Three-Dimensional Printed Thermal Regulation Textiles. ACS Nano 2017, 11, 11513–11520. [Google Scholar] [CrossRef]

- Ru, H.; Liu, Y.; Huang, S.; Ren, X.; Shu, W.; Cheng, J.; Tao, G.; Xu, W.; Chen, R.; Luo, X. Emerging Materials and Strategies for Personal Thermal Management. Adv. Energy Mater. 2020, 10, 1903921. [Google Scholar] [CrossRef]

- Gök, M.O.; Bilir, M.Z.; Gürcüm, B.H. Shape-Memory Applications in Textile Design. Procedia Soc. Behav. Sci. 2015, 195, 2160–2169. [Google Scholar] [CrossRef]

- Thakur, S. Shape Memory Polymers for Smart Textile Applications. In Textiles for Advanced Applications; InTech: Tokyo, Japan, 2017. [Google Scholar] [CrossRef]

- New Cloth Market. Development of Shape Memory Fabrics/Garments. Fibre2Fashion. 2009. Available online: https://www.fibre2fashion.com/industry-article/3983/development-of-shape-memory-fabrics-garments (accessed on 25 August 2022).

- Huang, Y.; Zhu, M.; Pei, Z.; Xue, Q.; Huang, Y.; Zhi, C. A shape memory supercapacitor and its application in smart energy storage textiles. J. Mater. Chem. A Mater. 2016, 4, 1290–1297. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Midha, V.K. Waterproof breathable fabrics. In Handbook of Technical Textiles, 2nd ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 27–55. [Google Scholar] [CrossRef]

- Interactive Led Fabrics. Available online: https://br.pinterest.com/pin/1137370080867857745/?mt=login (accessed on 10 October 2022).

- Ganapati, P. Smart Textiles Blend LEDs, Circuits and Sensors. Available online: https://www.wired.com/2010/06/gallery-smart-textiles/ (accessed on 10 October 2022).

- Zulqarnain, M.; Stanzione, S.; Rathinavel, G.; Smout, S.; Willegems, M.; Myny, K.; Cantatore, E. A flexible ECG patch compatible with NFC RF communication. NPJ Flex. Electron. 2020, 4, 13. [Google Scholar] [CrossRef]

- My Heart Project—Ist 507816. Available online: http://www.hitech-projects.com/euprojects/myheart/ (accessed on 25 October 2022).

- Create the Change. Available online: https://www.biotexfuture.de/ (accessed on 25 October 2022).

- Advanced E-Textiles for Firefighters and Civilian Victims. Available online: http://www.proetex.org/ (accessed on 25 October 2022).

- Innovation in Materials and Substrate Technology. Available online: http://www.stella-project.de/Innovations/tabid/54/Default.aspx (accessed on 25 October 2022).

- Microflex Dissemination—Details of the Publications and Events Related to the Microflex Project. Available online: http://microflex.ecs.soton.ac.uk/ (accessed on 25 October 2022).

- Application of Sensor Technology in Textiles. Available online: https://textilelearner.net/sensor-technology-in-textile-industry/#:~:text=Sensor%20is%20an%20instrument%20that,(today%20mostly%20electronic)%20instrument (accessed on 25 October 2022).

- Eurecat Centre Tecnologic de Catalunya. Available online: https://eurecat.org/en/portfolio-items/dephotex/ (accessed on 25 October 2022).

- McQuarrie, L. Wearable X Is Launching Smart Yoga Pants for Men and a Redesigned App. Available online: https://www.trendhunter.com/trends/smart-yoga-pants (accessed on 5 October 2022).

- Sensoria Smart Socks Win ‘Best New Wearable Technology Device’ Award by IDTechEx. Available online: https://www.innovationintextiles.com/sensoria-smart-socks-win-best-new-wearable-technology-device-award-by-idtechex/ (accessed on 5 October 2022).

- Rubenov, E. Send Somone a Hug via Text Message. Available online: https://www.trendhunter.com/trends/hug-shirt-send-somone-a-hug-via-text-message (accessed on 5 October 2022).

- Smart Textiles and Smart Clothing—The New Black for the Internet of Things. Available online: https://www.nanowerk.com/smart/smart-clothing.php (accessed on 5 October 2022).

- Levi’s® Trucker Jacket. Available online: https://atap.google.com/jacquard/products/levi-trucker/ (accessed on 5 October 2022).

- Top Performance Sportswear Smart Textiles to Watch Out for in 2019. Available online: https://butlertechnologies.com/performance-sportswear-smart-textiles/ (accessed on 5 October 2022).

- Nadi X Mesh. Available online: https://www.wearablex.com/products/nadi-x-mesh (accessed on 5 October 2022).

- Ministry of Supply Heated Jacke. Available online: https://eshopu.tk/products.aspx?cname=ministry+of+supply+heated+jacket&cid=69 (accessed on 5 October 2022).

- Rajandran, S.; Anand, S.C. Developments in medical textiles. Text. Prog. 2002, 32, 1–42. [Google Scholar] [CrossRef]

- Shirvan, A.R.; Nouri, A. Chapter 13—Medical textiles. In Advances in Functional and Protective Textiles; Woodhead Publishing: Sawston, UK, 2020; pp. 291–333. [Google Scholar] [CrossRef]

- Liposuction Garments. Available online: https://www.indiamart.com/proddetail/liposuction-garments-16709847491.html (accessed on 7 October 2022).

- The Best Cloth Diaper Inserts for Absorbency and Comfort. Available online: https://nickisdiapers.com/blogs/switch-to-sustainable/most-absorbent-cloth-diaper-fabrics (accessed on 7 October 2022).

- Kiron, M.I. Medical Textiles: Features, Types and Applications. Available online: https://textilelearner.net/medical-textiles/ (accessed on 7 October 2022).

- LIVMOA™ 5000 for Infection Control. Available online: https://www.livmoa.toray/en/infection/5000_001.html (accessed on 7 October 2022).

- Non-Woven Cotton Sanitary Pads Wholesale. Available online: https://www.purcotton.net/oem-service/sanitary-pads/ (accessed on 7 October 2022).

- McDavid Knee Brace Com Dobradiças Laterais. Suporte Máximo do Joelho & Compressão Para Estabilidade & Recuperação, Suporte ao Tendão da Patela, Alívio. Available online: https://www.extra.com.br/mcdavid-knee-brace-com-dobradicas-laterais-suporte-maximo-do-joelho-compressao-para-estabilidade-recuperacao-suporte-ao-tendao-da-patela-alivio/p/1538337866 (accessed on 7 October 2022).

- A Guide to Cosmetic Prosthetic Devices. Available online: https://www.biotechpossibilities.com/possibilities/a-guide-to-cosmetic-prosthetic-devices (accessed on 7 October 2022).

- Peng, L.; Su, B.; Yu, A.; Jiang, X. Review of clothing for thermal management with advanced materials. Cellulose 2019, 26, 6415–6448. [Google Scholar] [CrossRef]

- Guo, Y.; Li, K.; Hou, C.; Li, Y.; Zhang, Q.; Wang, H. Fluoroalkylsilane-modified textile-based personal energy management device for multifunctional wearable applications. ACS Appl. Mater. Interfaces 2016, 8, 4676–4683. [Google Scholar] [CrossRef]

- Peng, L.; Fan, W.; Li, D.; Wang, S.; Yu, A.; Jiang, X. Smart thermal management textiles with anisotropic and thermoresponsive electrical conductivity. Adv. Mater. Tech. 2019, 5, 1900599. [Google Scholar] [CrossRef]

- Fang, Y.; Chen, G.; Bick, M.; Chen, J. Smart textiles for personalized thermoregulation. Chem. Soc. Rev. 2021, 50, 9357–9374. [Google Scholar] [CrossRef]

- Ünsal, Ö.F.; Hiçyilmaz, A.S.; Yilmaz, A.N.Y.; ALtin, Y.; Borazan, I.; Bedeloğlu, A. Chapter 17—Energy-generating textiles. In Advances in Functional and Protective Textiles; Woodhead Publishing: Sawston, UK, 2020; pp. 415–455. [Google Scholar] [CrossRef]

- Tao, X. Smart Fibers, Fabrics and Clothing; CRC Press: Cambridge, UK, 2000; Volume 34. [Google Scholar]

- Military Textiles: The Scope and Future. Available online: https://textilevaluechain.in/in-depth-analysis/military-textilesthe-scope-and-future/ (accessed on 28 September 2022).

- Medical Smart Textile Market Valuation Worth USD 2.10 Billion by 2027 at 7.51% CAGR—Report by Market Research Future (MRFR). Available online: https://www.globenewswire.com/en/news-release/2022/06/21/2465760/0/en/Medical-Smart-Textile-Market-Valuation-Worth-USD-2-10-Billion-by-2027-at-7-51-CAGR-Report-by-Market-Research-Future-MRFR.html (accessed on 28 September 2022).

- Rajendran, S. Advanced Textiles for Wound Care; Woodhead Publishing: Sawston, UK, 2018; ISBN 978-0-08-102192-7. [Google Scholar]

- Peng, Y.; Sun, F.; Xiao, C.; Iqbal, M.I.; Sun, Z.; Guo, M.; Gao, W.; Hu, X. Hierarchically structured and scalable artificial muscles for smart textiles. ACS Appl. Mater. Interfaces 2021, 14, 45. [Google Scholar] [CrossRef]

- Libanori, A.; Chen, G.; Zhao, X.; Zhou, Y.; Chen, J. Smart textiles for personalized healthcare. Nat. Electron. 2022, 5, 142–156. [Google Scholar] [CrossRef]

- Global Nanotechnology Clothing Market (2022 to 2031)—Featuring Nano Textile, Colmar and Shanghai Hu Zheng. Nano Technology among Others. Available online: https://www.globenewswire.com/en/news-re%20lease/2022/04/22/2427164/28124/en/Global-Nanotechnology-Clothing-Market-2022-to-2031-Featuring-Nano-Textile-Colmar-and-Shanghai-Huzheng-Nano-Technology-Among-Others.html#:~:text=The%20global%20nanotechnology%20clothing%20market%20is%20expected%20to%20grow%20from,(CAGR)%20of%2024.6%25 (accessed on 20 September 2022).

- Shah, M.A.; Pirzada, B.M.; Price, G.; Shibiru, A.L.; Qurashi, A. Applications of nanotechnology in smart tetile industry: A critical review. J. Adv. Res. 2022, 38, 55–75. [Google Scholar] [CrossRef] [PubMed]

- Kao, H.L.; Chuang, C.H.; Chang, L.C.; Cho, C.L.; Chiu, H.C. Inkjet-printed silver films on textiles for wearable electronics applications. Surf. Coat. Technol. 2019, 362, 328–332. [Google Scholar] [CrossRef]

- Chen, W.D.; Lin, Y.H.; Chang, C.P.; Sung, Y.; Liu, Y.M.; Ger, M.D. Fabrication of high-resolution conductive line via inkjet printing of nano-palladium catalyst onto PET substrate. Surf. Coat. Technol. 2011, 205, 4750. [Google Scholar] [CrossRef]

- Wang, M.W.; Liu, T.Y.; Pang, D.C.; Hung, J.C.; Tseng, C.C. Inkjet printing of a pH sensitive palladium catalyst patterns of ITO glass for electroless copper. Surf. Coat. Technol. 2014, 259, 340–345. [Google Scholar] [CrossRef]

- Ghahremani Honarvar, M.; Latifi, M. Overview of wearable electronics and smart textiles. J. Text. Inst. 2017, 108, 631–652. [Google Scholar] [CrossRef]

- Park, S.; Sundaresan, J. Smart textiles: Wearable electronic systems. MRS Bull. 2003, 28, 585–591. [Google Scholar] [CrossRef]

- Qiu, Q.; Zhu, M.; Li, Z.; Qiu, K.; Liu, X.; Yu, J.; Ding, B. Highly flexible, breathable, tailorable and washable power generation fabrics for wearable electronics. Nano Energy 2019, 58, 750–758. [Google Scholar] [CrossRef]

- Niu, Z.; Qi, S.; Shuaib, S.S.A.; Yuan, W. Flexible, stimuli-responsive and self-cleaning phase change fiber for thermal energy storage and smart textiles. Compos. Part B Eng. 2022, 228, 109431. [Google Scholar] [CrossRef]

- Nigusse, A.B.; Mengistie, D.A.; Malengier, B.; Tseghai, G.B.; van Langenhove, L. Wearable smart textiles for long-term electrocardiography monitoring—A review. Sensors 2021, 21, 4174. [Google Scholar] [CrossRef]

- Yin, Z.; Lu, H.; Gan, L.; Zhang, Y. Electronic fibers/textiles for health-monitoring: Fabrication and application. Adv. Mater. Technol. 2022, 2200654. [Google Scholar] [CrossRef]

- Guo, L.; Bresky, E.; Persson, N.-K. Electroconductive textiles and textile-based electromechanical sensors—Integration in as an approach for smart textiles. In Smart Textiles and their Applications; Woodhead Publishing: Sawston, UK, 2016; pp. 657–693. [Google Scholar] [CrossRef]

- Vanĉo, M.; Krmela, J.; Pešlová, F. The use of PVD coating on natural textile fibers. Proc. Eng. 2016, 136, 341–345. [Google Scholar] [CrossRef]

- Maity, S.; Catterjee, A. Conductive polymer-based electro-conductive textile composites for electromagnetic interference shielding: A review. J. Ind. Text. 2016, 47, 2228–2252. [Google Scholar] [CrossRef]

- Kim, H.K.; Byun, S.W.; Jeong, S.H.; Ki Hong, Y.; Joo, J.S.; Song, K.; Park, Y.H.; Lee, J.Y. Environmental staility of EMI shielding PET fabric/polypyrrole composite. Mol. Cryst. Liq. Cryst. 2002, 377, 369–372. [Google Scholar] [CrossRef]

- Wilson, J.I.B. Textile surface functionalization by chemical vapour deposition (CVD). In Surface Modification of Textiles; Woodhead Publishing: Sawston, UK, 2009; pp. 126–138. [Google Scholar] [CrossRef]

- Stempien, Z.; Khalid, M.; Koanecki, M.; Filipczak, P.; Wrzesińska, A.; Korzeniewska, E.; Sasiadek, E. Inkjet Printing of Polypyrrole Electroconductive Layers Based on Direct Inks Freezing and Their Use in Textile Solid-State Supercapacitors. Materials 2021, 14, 3577. [Google Scholar] [CrossRef]

- Chen, D.; Jiang, K.; Huang, T.; Shen, G. Recent advances in fiber supercapacitors: Materials, device configurations, and applications. Adv. Mater. 2019, 32, 1901806. [Google Scholar] [CrossRef]

- Weng, W.; Yang, J.; Zhang, Y.; Li, Y.; Yang, S.; Zhu, L.; Zhu, M. A route toward smart system integration: From fiber design to device construction. Adv. Mater. 2020, 32, 1902301. [Google Scholar] [CrossRef]

- Rotzler, S.; Kallmayer, C.; Dils, C.; von Krshiwobloski, M.; Bauer, U.; Schneider-Ramelow, M. Improving the washbility of smart textiles: Influence of different washing conditions on textile integrated conductor tracks. J. Text. Inst. 2020, 111, 1766–1777. [Google Scholar] [CrossRef]

- Sinner, H. €Uber das Waschen Mit Haushaltswaschmaschinen; HausþHeim Verlag: Hamburg, Germany, 1960. [Google Scholar]

- Rotzler, S. Einfluss der Sinnerschen Faktoren Sowie der Textile Substrate Auf die Waschbarkeit Textilintegrierter Leiterbahnen. Master’s Thesis, Hochschule f€ur Technik und Wirtschaft Berlin, Berlin, Germany, 2018. [Google Scholar]

- Textile Recycling—CTDEEP. Available online: https://portal.ct.gov/-/media/DEEP/waste_management_and_disposal/Solid_Waste_Management_Plan/June2013/SMARTTextileRecyclingGroipenSWACJune2013pdf.pdf (accessed on 5 November 2022).

- Chowdhury, P.; Samanta, K.K.; Basak, S. Recent development in textile for sportswear application. Int. J. Eng. Res. Technol. 2014, 3, 1905–1910. [Google Scholar]

- Veske, P.; Ilen, E. Review of the end-of-life solutions in electronics-based smart textiles. J. Text. Inst. 2021, 112, 1500–1513. [Google Scholar] [CrossRef]

- Gulati, R.; Sharma, S.; Sharma, R.K. Antimicrobial textile: Recent developments and functional perspective. Polym. Bull. 2022, 79, 5747–5771. [Google Scholar] [CrossRef] [PubMed]

- Snari, R.M.; Alsahag, M.; Alisaac, A.; Bayazeed, A.; Alsoliemy, A.; Khalifa, M.E.; El-Metwaly, N.M. Smart textiles immobilized with hydrazone probe for colorimetric recognition of bacteria. J. Mol. Liq. 2022, 366, 120149. [Google Scholar] [CrossRef]

- Nie, X.; Wu, S.; Huang, F.; Wang, Q.; Wei, Q. Smart textiles with self-disinfetion and photothermochromic effects. ACS Appl. Mater. Interfaces 2021, 13, 2245–2255. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Júnior, H.L.O.; Neves, R.M.; Monticeli, F.M.; Dall Agnol, L. Smart Fabric Textiles: Recent Advances and Challenges. Textiles 2022, 2, 582-605. https://doi.org/10.3390/textiles2040034

Júnior HLO, Neves RM, Monticeli FM, Dall Agnol L. Smart Fabric Textiles: Recent Advances and Challenges. Textiles. 2022; 2(4):582-605. https://doi.org/10.3390/textiles2040034

Chicago/Turabian StyleJúnior, Heitor Luiz Ornaghi, Roberta Motta Neves, Francisco Maciel Monticeli, and Lucas Dall Agnol. 2022. "Smart Fabric Textiles: Recent Advances and Challenges" Textiles 2, no. 4: 582-605. https://doi.org/10.3390/textiles2040034

APA StyleJúnior, H. L. O., Neves, R. M., Monticeli, F. M., & Dall Agnol, L. (2022). Smart Fabric Textiles: Recent Advances and Challenges. Textiles, 2(4), 582-605. https://doi.org/10.3390/textiles2040034