Testing the Physical and Mechanical Properties of Polyacrylonitrile Nanofibers Reinforced with Succinite and Silicon Dioxide Nanoparticles

Abstract

1. Introduction

2. Materials and Methods

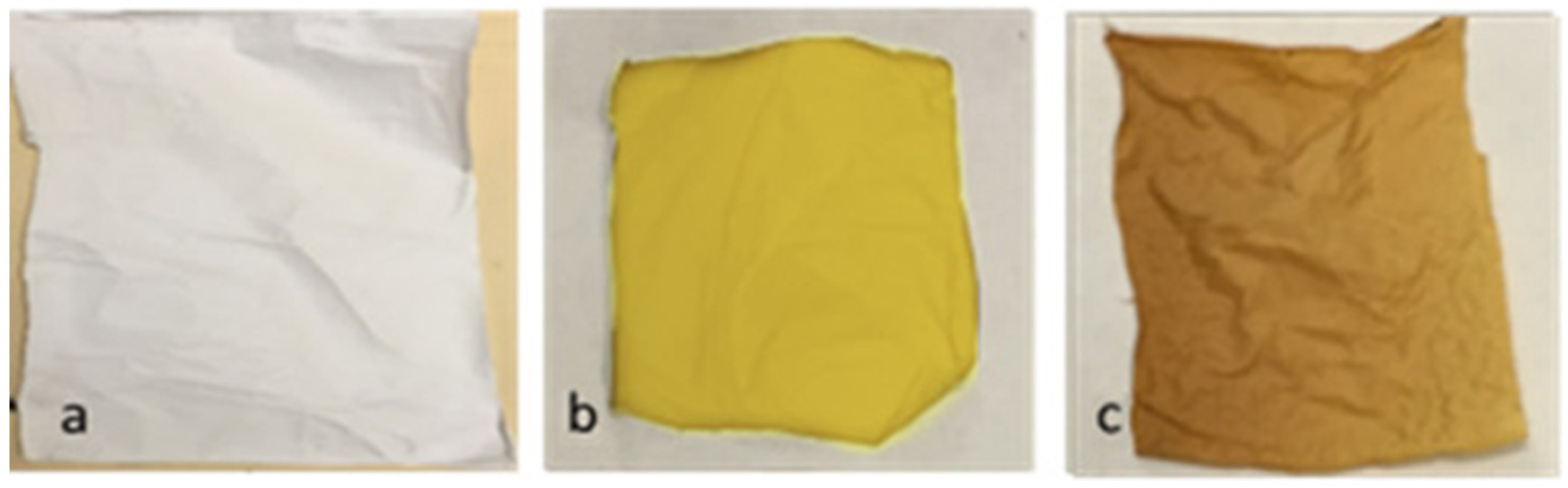

2.1. Materials and Fiber Fabrication

2.2. Preparation of Specimens and Mechanical Testing

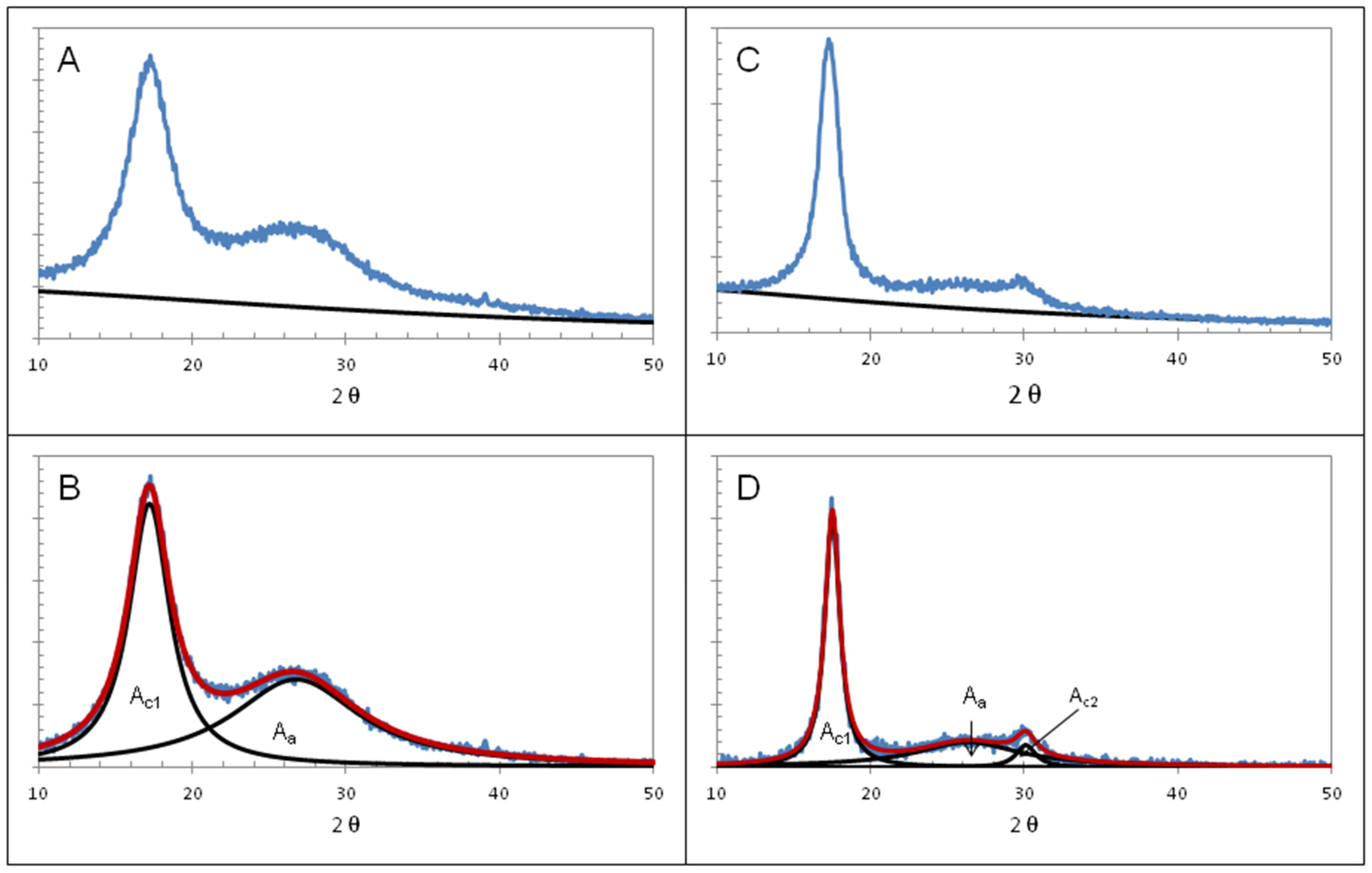

2.3. Structural Investigation

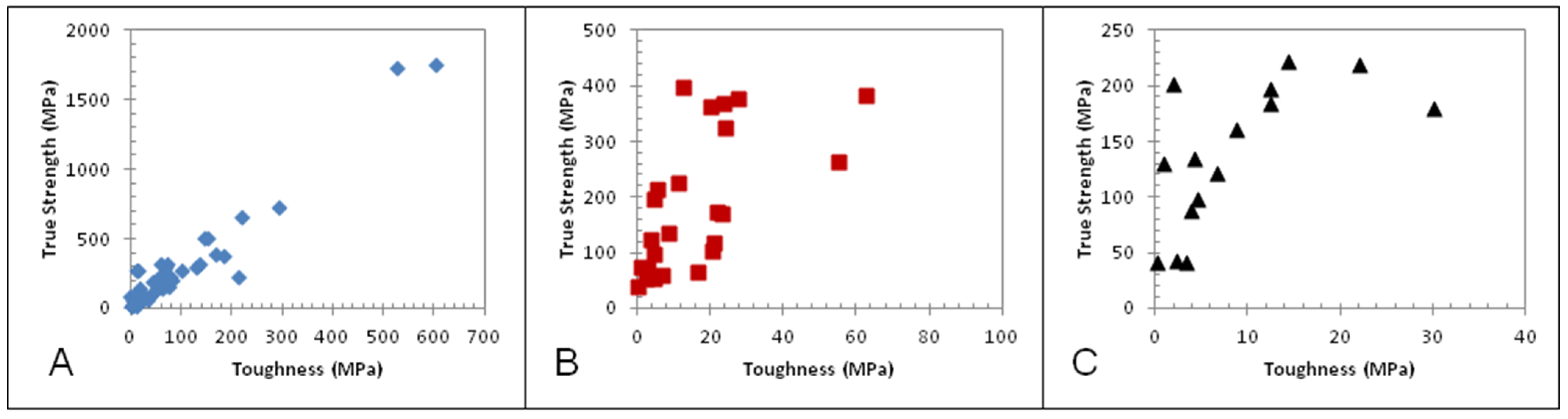

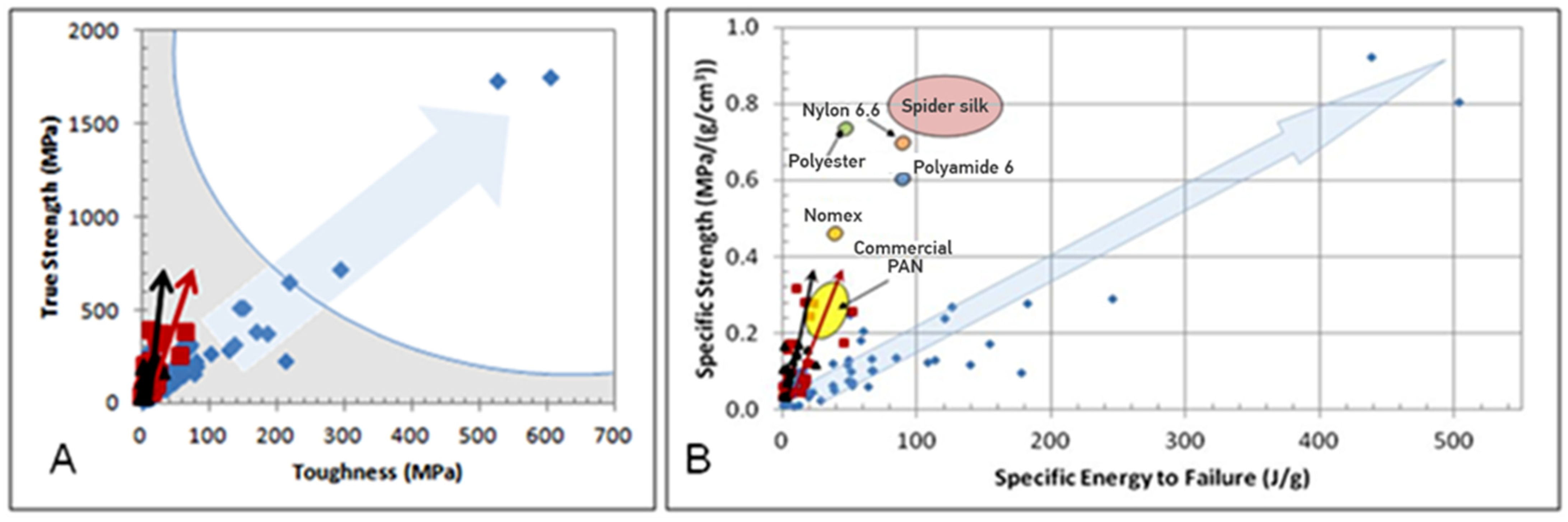

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benaoum, F.; Khelil, F.; Benhamena, A. Numerical analysis of reinforced concrete beams pre cracked reinforced by composite materials. Frat. Integrità Strutt. 2020, 14, 282–296. [Google Scholar] [CrossRef]

- Lusis, V.; Kononova, O.; Macanovskis, A.; Stonys, R.; Lasenko, I.; Krasnikovs, A. Experimental Investigation and Modelling of the Layered Concrete with Different Concentration of Short Fibers in the Layers. Fibers 2021, 9, 76. [Google Scholar] [CrossRef]

- Macanovskis, A.; Lukasenoks, A.; Krasnikovs, A.; Stonys, R.; Lusis, V. Composite Fibers in Concretes with Various Strengths. ACI Mater. J. 2018, 115, 647–652. [Google Scholar] [CrossRef]

- Bleive, L.L.; Lusis, V. Experimental study and numerical modelling for flexural capacity of FRC structural elements. Environ. Technol. Resour. Proc. Int. Sci. Pract. Conf. 2021, 3, 30–35. [Google Scholar] [CrossRef]

- Lusis, V.; Krasnikovs, A. Fiberconcrete with Non-Homogeneous Fibers Distribution. Environ. Technol. Resour. Proc. Int. Sci. Pract. Conf. 2013, 2, 67. [Google Scholar] [CrossRef][Green Version]

- Duy, N.P.; Anh, V.N.; Hiep, D.V.; Anh, N.M.T. Strength of concrete columns reinforced with Glass fiber reinforced polymer. Mag. Civ. Eng. 2021, 101, 10108. [Google Scholar] [CrossRef]

- Uslu, E.; Gavgali, M.; Erdal, M.O.; Yazman, Ş.; Gemi, L. Determination of mechanical properties of polymer matrix composites reinforced with electrospinning N66, PAN, PVA and PVC nanofibers: A comparative study. Mater. Today Commun. 2021, 26, 101939. [Google Scholar] [CrossRef]

- Kononova, O.; Krasnikovs, A.; Harjkova, G.; Lusis, V. Numerical simulation of mechanical properties for composite reinforced by knitted fabric. In Proceedings of the International Center for Numerical Methods in Engineering, Barcelona, Spain, 20–25 July 2014; Onate, E., Oliver, X., Huerta, A., Eds.; 2014; pp. 2925–2932. [Google Scholar]

- Kononova, O.; Krasnikovs, A.; Stonys, R.; Sahmenko, G.; Vitols, R. Investigation of influence of nano-reinforcement on the mechanical properties of composite materials. J. Civ. Eng. Manag. 2016, 22, 425–433. [Google Scholar] [CrossRef]

- Ahmadi, Z.; Ravandi, S.A.H.; Haghighat, F.; Dabirian, F. Enhancement of the Mechanical Properties of PAN Nanofiber/Carbon Nanotube Composite Mats Produced via Needleless Electrospinning System. Fibers Polym. 2020, 21, 1200–1211. [Google Scholar] [CrossRef]

- Viluma-Gudmona, A.; Lasenko, I.; Sanchaniya, J.V.; Abdelhadi, B. The amber nano fibers development prospects to expand the capabilites of textile 3D printing in the general process of fabrication methods. In Engineering for Rural Development, Proceedings of the 20th International Scientific Conference, Jelgava, Latvia, 26–28 May 2021; Latvia University of Life Sciences and Technologies: Jelgava, Latvia; pp. 248–257. [CrossRef]

- Storck, J.L.; Hellert, C.; Brockhagen, B.; Wortmann, M.; Diestelhorst, E.; Frese, N.; Grothe, T.; Ehrmann, A. Metallic Supports Accelerate Carbonization and Improve Morphological Stability of Polyacrylonitrile Nanofibers during Heat Treatment. Materials 2021, 14, 4686. [Google Scholar] [CrossRef]

- Vahle, D.; Böttjer, R.; Heyden, K.; Ehrmann, A. Conductive polyacrylonitrile/graphite textile coatings. AIMS Mater. Sci. 2018, 5, 551–558. [Google Scholar] [CrossRef]

- Lasenko, I.; Gaidukovs, S.; Rombovska, J. Manufacturing of amber particles suitable for composite fibre melt spinning. Proc. Latv. Acad. Sci. Sect. B Nat. Exact Appl. Sci. 2016, 70, 51–57. [Google Scholar] [CrossRef]

- Viluma-Gudmona, A.; Lasenko, I.; Sanchaniya, J.V.; Podgornovs, A. Electro-resistant biotextile development based on fiber reinforcement with nano particles. In Proceedings of the 20th International Scientific Conference Engineering for Rural Development, ERD 2021, Jelgava, Latvia, 26–28 May 2021; pp. 804–812. [Google Scholar] [CrossRef]

- Sadeghi, S.A.M.; Borhani, S.; Zadhoush, A.; Dinari, M. Single nozzle electrospinning of encapsulated epoxy and mercaptan in PAN for self-healing application. Polymer 2020, 186, 122007. [Google Scholar] [CrossRef]

- Mokhtari-Shourijeh, Z.; Langari, S.; Montazerghaem, L.; Mahmoodi, N.M. Synthesis of porous aminated PAN/PVDF composite nanofibers by electrospinning: Characterization and Direct Red 23 removal. J. Environ. Chem. Eng. 2020, 8, 103876. [Google Scholar] [CrossRef]

- Janushevskis, A.; Sanchaniya, J.; Vejanand, S. Designing of catamaran hull spine beam. In Proceedings of the 20th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 26–28 May 2021; pp. 1685–1691. [Google Scholar] [CrossRef]

- Dehghani, M.; Nadeem, H.; Raghuwanshi, V.S.; Mahdavi, H.; Holl, M.M.B.; Batchelor, W. ZnO/cellulose nanofiber composites for sustainable sunlight-driven dye degradation. ACS Appl. Nano Mater. 2020, 3, 10284–10295. [Google Scholar] [CrossRef]

- Gaidukovs, S.; Lyashenko, I.; Rombovska, J.; Gaidukova, G. Application of amber filler for production of novel polyamide composite fiber. Text. Res. J. 2016, 86, 2127–2139. [Google Scholar] [CrossRef]

- Xu, T.-C.; Han, D.-H.; Zhu, Y.-M.; Duan, G.-G.; Liu, K.-M.; Hou, H.-Q. High Strength Electrospun Single Copolyacrylonitrile (coPAN) Nanofibers with Improved Molecular Orientation by Drawing. Chin. J. Polym. Sci. 2020, 39, 174–180. [Google Scholar] [CrossRef]

- Grauda, D.; Bumbure, L.; Lyashenko, I.; Katashev, A.; Dekhtyar, Y.; Rashal, I. Amber Particles as Living Plant Cell Markers in Flow Cytometry / Dzintara Daļiņas Kā Dzīvu Augu Šūnu Marķieri Plūsmas Citometrijā. Proc. Latv. Acad. Sci. Sect. B Nat. Exact Appl. Sci. 2015, 69, 77–81. [Google Scholar] [CrossRef]

- Dadvar, S.; Tavanai, H.; Dadvar, H.; Morshed, M.; Ghodsi, F.E. UV-protection and photocatalytic properties of electrospun polyacrylonitrile nanofibrous mats coated with TiO2 nanofilm via sol–gel. J. Sol-Gel. Sci. Technol. 2011, 59, 269–275. [Google Scholar] [CrossRef]

- Dubova, I.; Apine, A.; Grauda, D.; Butkauskas, D.; Lasenko, I.; Jankevica, L. Adaptation of methods for the determination of biodegradation of bio-textiles with amber particles. In Proceedings of the International Scientific Conference of the University of Latvia, Innovative and Applied Research in Biology, Riga, Latvia, 5 February 2021; 2021; Volume 3, pp. 269–275. [Google Scholar] [CrossRef]

- Grauda, D.; Miķelsone, A.; Butkauskas, D.; Rašals, D.; Vilcāne, I.; Gobiņš, V.; Lasenko, I. Protective properties of biotextile indicated by immature gamete cells flow cytometry and Drosophila melanogaster survival tests. In Proceedings of the International Scientific Conference of the University of Latvia, Innovative and applied research in Biology, Riga, Latvia, 5 February 2021; Volume 3, pp. 26–33. [Google Scholar] [CrossRef]

- Wu, M.; Wang, Q.; Li, K.; Wu, Y.; Liu, H. Optimization of stabilization conditions for electrospun polyacrylonitrile nanofibers. Polym. Degrad. Stab. 2012, 97, 1511–1519. [Google Scholar] [CrossRef]

- Shrestha, R.; Li, P.; Chatterjee, B.; Zheng, T.; Wu, X.; Liu, Z.; Luo, T.; Choi, S.; Hippalgaonkar, K.; de Boer, M.P.; et al. Crystalline polymer nanofibers with ultra-high strength and thermal conductivity. Nat. Commun. 2018, 9, 1664. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Bang, S.H.; Malakooti, M.H.; Sodano, H.A. Isolation of Aramid Nanofibers for High Strength and Toughness Polymer Nanocomposites. ACS Appl. Mater. Interfaces 2017, 9, 11167–11175. [Google Scholar] [CrossRef] [PubMed]

- Zhu, K.; Duan, J.; Guo, J.; Wu, S.; Lu, A.; Zhang, L. High-Strength Films Consisted of Oriented Chitosan Nanofibers for Guiding Cell Growth. Biomacromolecules 2017, 18, 3904–3912. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Shao, Z.; Xu, L.; Wang, M. High throughput preparation of aligned nanofibers using an improved bubble-electrospinning. Polymers 2017, 9, 658. [Google Scholar] [CrossRef]

- Guan, Y.; Li, W.; Zhang, Y.; Shi, Z.; Tan, J.; Wang, F.; Wang, Y. Aramid nanofibers and poly (vinyl alcohol) nanocomposites for ideal combination of strength and toughness via hydrogen bonding interactions. Compos. Sci. Technol. 2017, 144, 193–201. [Google Scholar] [CrossRef]

- Ren, L.; Jiang, Q.; Chen, K.; Chen, Z.; Pan, C.; Jiang, L. Fabrication of a micro-needle array electrode by thermal drawing for bio-signals monitoring. Sensors 2016, 16, 908. [Google Scholar] [CrossRef]

- Wu, Y.-K.; Wang, L.; Fan, J.; Shou, W.; Liu, Y. A double-switching voltage: Controlling multiple jets in electrospinning. Mater. Lett. 2018, 233, 359–362. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, B.; Lu, X.; Wang, C.; Su, Z. Molecular Orientation in Individual Electrospun Nanofibers Studied by Polarized AFM-IR. Macromolecules 2019, 52, 9639–9645. [Google Scholar] [CrossRef]

- Kausar, A. Polyacrylonitrile-based nanocomposite fibers: A review of current developments. J. Plast. Film Sheeting 2019, 35, 295–316. [Google Scholar] [CrossRef]

- Jeon, I.; Yoon, J.; Kim, U.; Lee, C.; Xiang, R.; Shawky, A.; Xi, J.; Byeon, J.; Lee, H.M.; Choi, M.; et al. High-Performance Solution-Processed Double-Walled Carbon Nanotube Transparent Electrode for Perovskite Solar Cells. Adv. Energy Mater. 2019, 9, 1901204. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Kumar, R.; Pruncu, C.I. Recent progress of reinforcement materials: A comprehensive overview of composite materials. J. Mater. Res. Technol. 2019, 8, 6354–6374. [Google Scholar] [CrossRef]

- Barua, B.; Saha, M.C. Investigation on jet stability, fiber diameter, and tensile properties of electrospun polyacrylonitrile nanofibrous yarns. J. Appl. Polym. Sci. 2015, 132, 41918. [Google Scholar] [CrossRef]

- Jung, J.; Sodano, H.A. Aramid Nanofiber Reinforced Rubber Compounds for the Application of Tire Tread with High Abrasion Resistance and Fuel Saving Efficiency. ACS Appl. Polym. Mater. 2020, 2, 4874–4884. [Google Scholar] [CrossRef]

- Kaur, N.; Kumar, V.; Dhakate, S.R. Synthesis and characterization of multiwalled CNT—PAN based composite carbon nanofibers via electrospinning. SpringerPlus 2016, 5, 483. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Chawla, S.; Naraghi, M. Microstructural evolution and mechanics of hot-drawn CNT-reinforced polymeric nanofibers. Carbon 2016, 109, 813–822. [Google Scholar] [CrossRef]

- Wang, Q.; Yao, Q.; Chang, J.; Chen, L. Enhanced thermoelectric properties of CNT/PANI composite nanofibers by highly orienting the arrangement of polymer chains. J. Mater. Chem. 2012, 22, 17612–17618. [Google Scholar] [CrossRef]

- Mombini, S.; Mohammadnejad, J.; Bakhshandeh, B.; Narmani, A.; Nourmohammadi, J.; Vahdat, S.; Zirak, S. Chitosan-PVA-CNT nanofibers as electrically conductive scaffolds for cardiovascular tissue engineering. Int. J. Biol. Macromol. 2019, 140, 278–287. [Google Scholar] [CrossRef] [PubMed]

- Oberdörster, G.; Castranova, V.; Asgharian, B.; Sayre, P. Inhalation exposure to carbon nanotubes (CNT) and carbon nanofibers (CNF): Methodology and Dosimetry. J. Toxicol. Environ. Health Part B 2015, 18, 121–212. [Google Scholar] [CrossRef]

- Tan, E.P.S.; Lim, C.T. Physical properties of a single polymeric nanofiber. Appl. Phys. Lett. 2004, 84, 1603–1605. [Google Scholar] [CrossRef]

- Lim, C.T.; Tan, E.P.S.; Ng, S.Y. Effects of crystalline morphology on the tensile properties of electrospun polymer nanofibers. Appl. Phys. Lett. 2008, 92, 141908. [Google Scholar] [CrossRef]

- Wong, S.-C.; Baji, A.; Leng, S. Effect of fiber diameter on tensile properties of electrospun poly(ε-caprolactone). Polymer 2008, 49, 4713–4722. [Google Scholar] [CrossRef]

- Arinstein, A.; Burman, M.; Gendelman, O.; Zussman, E. Effect of supramolecular structure on polymer nanofibre elasticity. Nat. Nanotechnol. 2007, 2, 59–62. [Google Scholar] [CrossRef] [PubMed]

- Pai, C.-L.; Boyce, M.C.; Rutledge, G.C. Mechanical properties of individual electrospun PA 6(3)T fibers and their variation with fiber diameter. Polymer 2011, 52, 2295–2301. [Google Scholar] [CrossRef]

- Chew, S.Y.; Hufnagel, T.C.; Lim, C.T.; Leong, K.W. Mechanical properties of single electrospun drug-encapsulated nanofibres. Nanotechnology 2006, 17, 3880–3891. [Google Scholar] [CrossRef]

- Shin, M.K.; Kim, S.I.; Kim, S.J.; Kim, S.-K.; Lee, H.; Spinks, G.M. Size-dependent elastic modulus of single electroactive polymer nanofibers. Appl. Phys. Lett. 2006, 89, 231929. [Google Scholar] [CrossRef]

- Naraghi, M.; Arshad, S.N.; Chasiotis, I. Molecular orientation and mechanical property size effects in electrospun polyacrylonitrile nanofibers. Polymer 2011, 52, 1612–1618. [Google Scholar] [CrossRef]

- Qanati, M.V.; Rasooli, A.; Rezvani, M. Main structural and mechanical properties of electrospun PAN-based carbon nanofibers as a function of carbonization maximum temperature. Polym. Bull. 2022, 79, 331–355. [Google Scholar] [CrossRef]

- Yang, H.; Fan, F.R.; Xi, Y.; Wu, W. Bio-Derived Natural Materials Based Triboelectric Devices for Self-Powered Ubiquitous Wearable and Implantable Intelligent Devices. Adv. Sustain. Syst. 2020, 4, 2000108. [Google Scholar] [CrossRef]

| Polymer | Diameter Range, nm | Property Change with Diameter Decrease | Structure | |||

|---|---|---|---|---|---|---|

| Modulus (E) | Strength (σ) | Failure Strain (ε) | Orientation | Crystallinity | ||

| PLLA [45] | 270–420 | Increased slightly | - | - | - | - |

| PCL [46] | 250–1300 | Increased significantly for diameters <500 nm | Increased significantly for diameters <500 nm | Size effect not reported, but failure strain decreased with increasing crystallinity | Increased significantly with diameter decrease | Increased from 50–56% (XRD) with average diameter decrease |

| PCL [47] | 350–2500 | Increased slightly, faster for diameters <700 nm | Increased slightly, faster for diameters <700 nm | Limited data, but failure strain reported to decrease for diameters <700 nm | Increased with diameter decrease | Increased gradually from 42–50% (XRD) with average diameter decrease |

| Nylon 6,6 [48] | 400–900 | Increased significantly for diameters <600 nm | - | - | Increased gradually with average diameter decrease | Increased gradually from 35–47% (XRD) with average diameter decrease |

| PA6(3)T [49] | 170–3500 | Increased for diameters <500 nm | Yield strength increased for diameters <1000 nm | Decreased significantly with decrease in diameter (based on reported stress–strain diagrams) | Increased significantly with average diameter decrease <1000 nm (polarized FTIR) | Amorphous |

| PCL [50] and PCLEEP | 200/300–5000 | Increased considerably for diameters <700 nm | Increased dramatically for diameters <700 nm | Large strains to failure; unaffected by diameter | - | No measurable change in XRD crystallinity (bundles) |

| PA MPS [51] | 55–250 | Increased significantly; faster for diameters <70 nm | - | - | - | - |

| PAN [52] | 200–700 | Increased significantly, especially for longer spinning distance (increased crystallinity, orientation) | Yield strength increased significantly | Very large ultimate strain reported to depend weakly on fiber dia-meter; stress–strain diagram for a 250 nm fiber exhibited 150% strain | Increased significantly with increase in spinning distance (decrease in average diameter) | Low overall crystallinity, increased slightly with increase in spinning distance (decrease in average diameter) |

| PAN [53] | 140–3000 | Increased considerably for diameters <500 nm | Increased dramatically for diameters <500 nm | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lasenko, I.; Grauda, D.; Butkauskas, D.; Sanchaniya, J.V.; Viluma-Gudmona, A.; Lusis, V. Testing the Physical and Mechanical Properties of Polyacrylonitrile Nanofibers Reinforced with Succinite and Silicon Dioxide Nanoparticles. Textiles 2022, 2, 162-173. https://doi.org/10.3390/textiles2010009

Lasenko I, Grauda D, Butkauskas D, Sanchaniya JV, Viluma-Gudmona A, Lusis V. Testing the Physical and Mechanical Properties of Polyacrylonitrile Nanofibers Reinforced with Succinite and Silicon Dioxide Nanoparticles. Textiles. 2022; 2(1):162-173. https://doi.org/10.3390/textiles2010009

Chicago/Turabian StyleLasenko, Inga, Dace Grauda, Dalius Butkauskas, Jaymin Vrajlal Sanchaniya, Arta Viluma-Gudmona, and Vitalijs Lusis. 2022. "Testing the Physical and Mechanical Properties of Polyacrylonitrile Nanofibers Reinforced with Succinite and Silicon Dioxide Nanoparticles" Textiles 2, no. 1: 162-173. https://doi.org/10.3390/textiles2010009

APA StyleLasenko, I., Grauda, D., Butkauskas, D., Sanchaniya, J. V., Viluma-Gudmona, A., & Lusis, V. (2022). Testing the Physical and Mechanical Properties of Polyacrylonitrile Nanofibers Reinforced with Succinite and Silicon Dioxide Nanoparticles. Textiles, 2(1), 162-173. https://doi.org/10.3390/textiles2010009