An Overview on Methods for Producing Side-Emitting Polymer Optical Fibers

Abstract

1. Introduction

- -

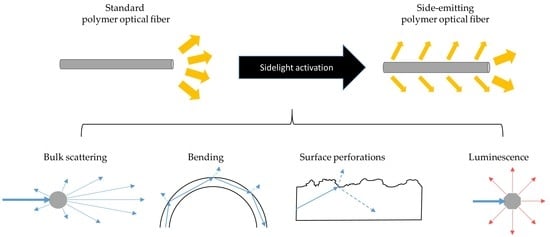

- Bulk scattering (cf. Figure 1c): Scattering centers can be intentionally integrated into the POF to change the light ray path. The scattering can be induced by adding substances or dopants such as microparticles or nanoparticles where the particles’ number, shape and refractive index influence the side emission. Scattering can also be inherent to the material, e.g., in case of Rayleigh scattering due to molecular irregularities [2,38,39].

- -

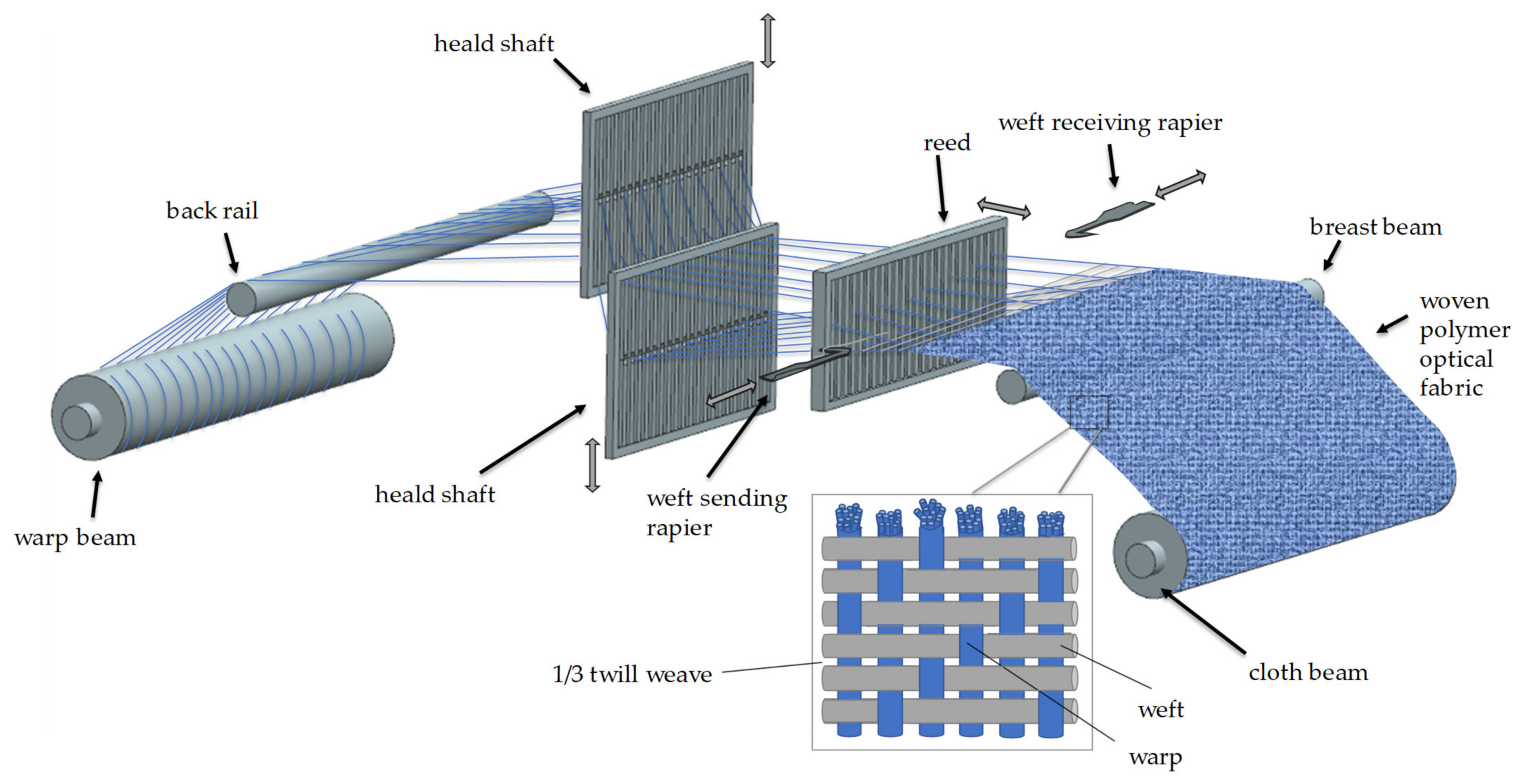

- Bending (cf. Figure 1d): Bends induce a displacement of the core–cladding interface, which again can cause a light ray to drop below the critical angle. Most of the light is emitted from the convex surface of the bent fiber. Side emission can be induced by both microbends where the bending radius R is in the range of the POF radius r or smaller, as in many textiles such as woven or knitted fabrics, or macrobends with R >> r [40,41,42].

- -

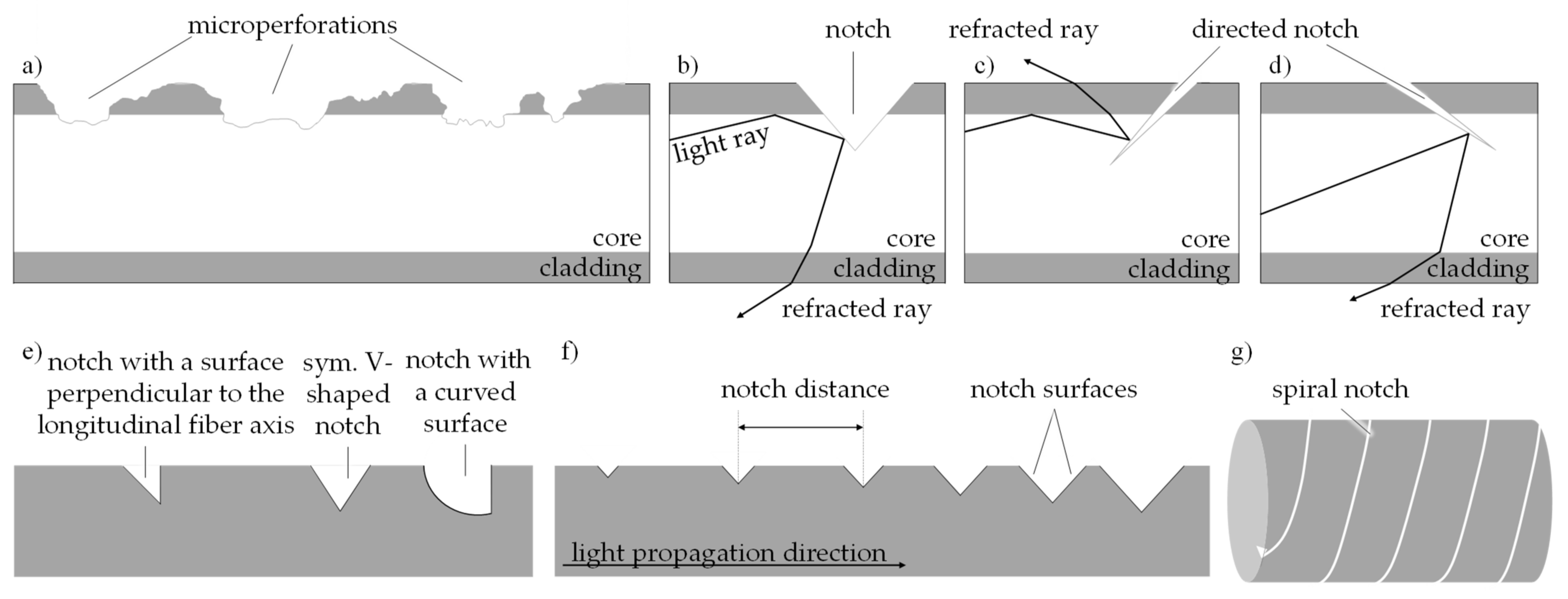

- Surface perforations (cf. Figure 1e): Irregularities at the core–cladding interface change the angle at which a light ray hits the reflective surface leading to refraction. The surface irregularities can vary from microperforations to even notches or grooves. The depth, number and geometry of the perforations influence the intensity and direction of the emitted light [43,44,45,46].

- -

- Luminescence (cf. Figure 1f): Unlike scattering particles, luminescent materials can change a light ray’s path by isotropically reemitting light that has previously been absorbed. With regard to POF, this means that a part of the light fulfils the condition of TIR and propagates further in the fiber core. Another part of the light rays does not fulfil the condition and is refracted [33,47].

2. Methodology

3. Fabrication Methods for Side-Emitting Polymer Optical Fibers

3.1. Bulk Scattering

3.1.1. Doping of the Fiber

3.1.2. Laser Modification by In-Volume Processing

3.2. Surface Perforation

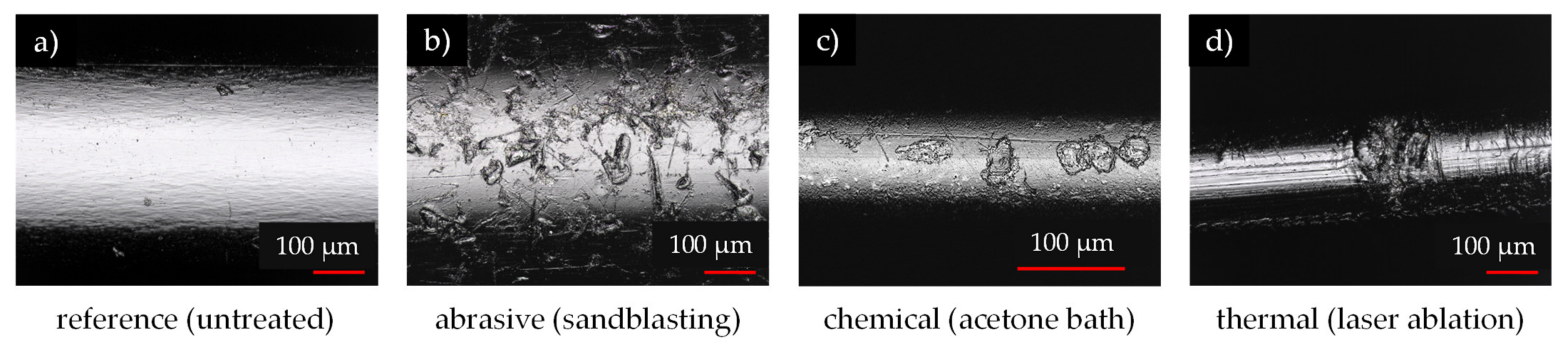

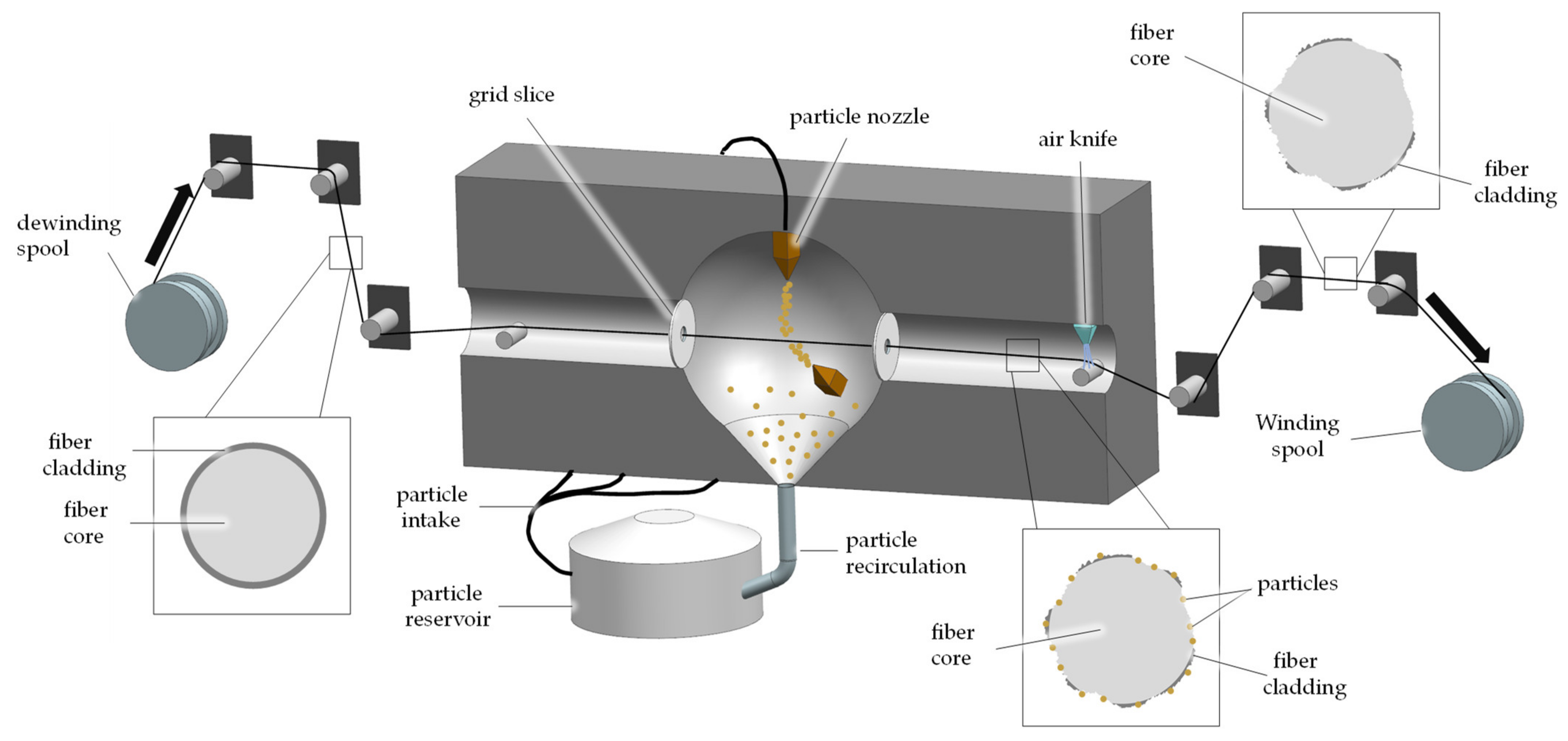

3.2.1. Abrasive Material Removal

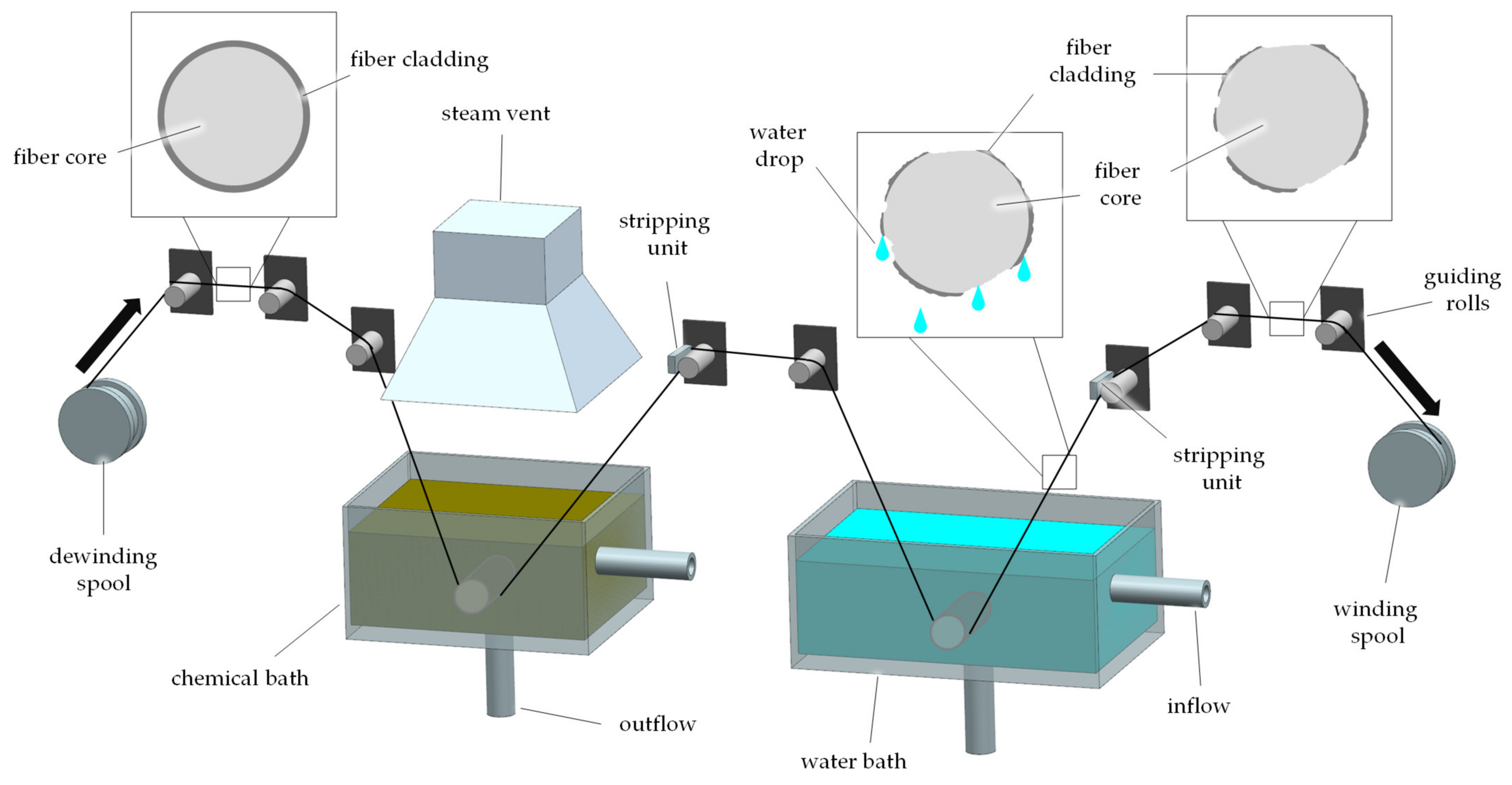

3.2.2. Chemical Surface Perforation

3.2.3. Thermal Surface Perforation

- Laser ablation;

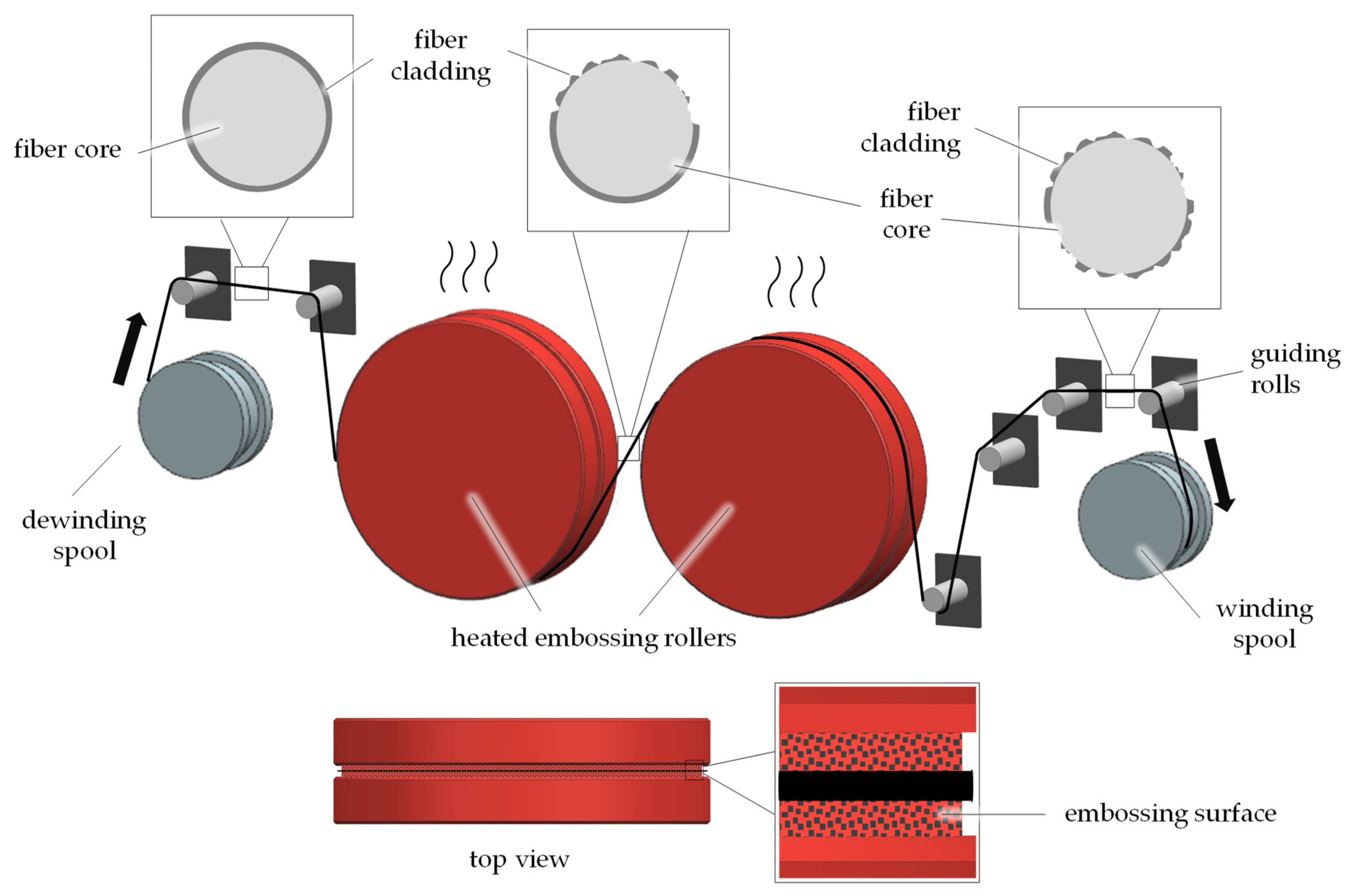

- Methods with heated embossing devices.

3.3. Bending

- Bending radius rB (if increased: emission decreases);

- Fiber diameter d (if increased: emission increases) [115].

3.4. Luminescence

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koike, Y. Fundamentals of Plastic Optical Fibers; Wiley-VCH: Weinheim, Germany, 2015; ISBN 978-3-527-41006-4. [Google Scholar]

- Bunge, C.-A.; Bremer, K.; Lustermann, B.; Woyessa, G. Special fibres and components. In Polymer Optical Fibres: Fibre Types, Materials, Fabrication, Characterisation and Applications; Bunge, C.-A., Gries, T., Beckers, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 119–151. ISBN 9780081000397. [Google Scholar]

- MENTOR GmbH & Co. Präzisions-Bauteile KG. M-Fibre—Innovative Side Light Fibre for Product-Integrated Light Solutions. Available online: https://www.mentor.de.com/bauelemente/en/m-fibre-innovative-side-light-fibre-for-product-integrated-light-solutions/ (accessed on 11 June 2021).

- Selm, B.; Gürel, E.A.; Rothmaier, M.; Rossi, R.M.; Scherer, L.J. Polymeric Optical Fiber Fabrics for Illumination and Sensorial Applications in Textiles. J. Intell. Mater. Syst. Struct. 2010, 21, 1061–1071. [Google Scholar] [CrossRef]

- Aeroflow, I. Biliblankets. Available online: https://aeroflowinc.com/biliblankets/ (accessed on 11 June 2021).

- Conneely, A.J.; Bennett, C.; O’Connor, G.M.; Vollmerhausen, T.; O’Byrne, C.; Spence, G.; Rowe, D.; Victor, J. Generation of side-emitting polymer optical fibres by laser ablation for use in antimicrobial applications. In International Congress on Applications of Lasers & Electro-Optics, Proceedings of the ICALEO® 2016: 35th International Congress on Applications of Lasers & Electro-Optics, San Diego, CA, USA, 16–20 October 2016; Laser Institute of America: Orlando, FL, USA, 2016; p. M604. ISBN 978-1-940168-17-3. [Google Scholar]

- Quandt, B.M.; Pfister, M.S.; Lübben, J.F.; Spano, F.; Rossi, R.M.; Bona, G.-L.; Boesel, L.F. POF-yarn weaves: Controlling the light out-coupling of wearable phototherapy devices. Biomed. Opt. Express 2017, 8, 4316–4330. [Google Scholar] [CrossRef] [PubMed]

- Mordon, S.; Thécua, E.; Ziane, L.; Lecomte, F.; Deleporte, P.; Baert, G.; Vignion-Dewalle, A.-S. Light emitting fabrics for photodynamic therapy: Technology, experimental and clinical applications. Transl. Biophotonics 2020, 2, 76. [Google Scholar] [CrossRef]

- Kuhlmann, C.; Groeneveld, R.; van Rees, H.; Timmerman, L.; Ebberink, G.; Timmermans, M.; Bottenberg, E.; Mahy, J. Smart textile based remote identification system. In Proceedings of the AUTEX2019, 19th World Textile Conference on Textiles at the Crossroads, Ghent, Belgium, 11–15 June 2019. [Google Scholar]

- Bunge, C.-A.; Kallweit, J.P.; Houri, M.A.; Mohr, B.; Bērziòš, A.; Grauberger, C.; Adi, P.; Gries, T. Textile Multitouch Force-Sensor Array Based on Circular and Non-Circular Polymer Optical Fibers. IEEE Sens. J. 2020, 20, 7548–7555. [Google Scholar] [CrossRef]

- Zhao, C.; Ye, L.; Yu, X.; Ge, J.; Liu, D. Continuous Fuel Level Sensor Based on Spiral Side-Emitting Optical Fiber. J. Control Sci. Eng. 2012, 2012, 267519. [Google Scholar] [CrossRef]

- Gausepohl, T.; Pennig, D.; Heck, S.; Gick, S.; Vegt, P.A.; Block, J.E. Effective Management of Bone Fractures with the Illuminoss® Photodynamic Bone Stabilization System: Initial Clinical Experience from the European Union Registry. Orthop. Rev. 2017, 9, 6988. [Google Scholar] [CrossRef]

- Seewald, R.; Kallweit, J.; Weiland, J.; Schiebahn, A.; Gries, T.; Reisgen, U. Use of UV-Curing Adhesive Systems on Non-transparent Joining Parts by Using Sidelight Activated Polymer Optical Fibres. In Industrial Applications of Adhesives; Da Silva, L., Adams, R.D., Sato, C., Dilger, K., Eds.; Springer: Singapore, 2021; pp. 1–14. ISBN 978-981-15-6767-4. [Google Scholar]

- Pan, H. Introduction: Why Plastic Optical Fibers? In Plastic Optical Fiber Sensors, 1st ed.; Werneck, M.M., Allil, R.C.D.S.B., Eds.; CRC Press: Boca Raton, FL, USA, 2019; pp. 1–20. ISBN 9781315098593. [Google Scholar]

- Kröplin, P.; Dieling, C.; Beckers, M.; Schrank, V.; Beer, M.; Gries, T.; Seide, G.; Bunge, C.-A. Overview of the POF market. In Polymer Optical Fibres: Fibre Types, Materials, Fabrication, Characterisation and Applications; Bunge, C.-A., Gries, T., Beckers, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 349–400. ISBN 9780081000397. [Google Scholar]

- Zubia, J.; Arrue, J. Plastic Optical Fibers: An Introduction to Their Technological Processes and Applications. Opt. Fiber Technol. 2001, 7, 101–140. [Google Scholar] [CrossRef]

- Emslie, C. Polymer optical fibres. J. Mater. Sci. 1988, 23, 2281–2293. [Google Scholar] [CrossRef][Green Version]

- Beckers, M.; Schlüter, T.; Vad, T.; Gries, T.; Bunge, C.-A. An overview on fabrication methods for polymer optical fibers. Polym. Int. 2015, 64, 25–36. [Google Scholar] [CrossRef]

- Arrue, J.; Jiménez, F.; Ayesta, I.; Illarramendi, M.A.; Zubia, J. Polymer-Optical-Fiber Lasers and Amplifiers Doped with Organic Dyes. Polymers 2011, 3, 1162–1180. [Google Scholar] [CrossRef]

- Xia, H.; Chen, T.; Hu, C.; Xie, K. Recent Advances of the Polymer Micro/Nanofiber Fluorescence Waveguide. Polymers 2018, 10, 1086. [Google Scholar] [CrossRef]

- Jakubowski, K.; Huang, C.-S.; Boesel, L.F.; Hufenus, R.; Heuberger, M. Recent advances in photoluminescent polymer optical fibers. Curr. Opin. Solid State Mater. Sci. 2021, 25, 100912. [Google Scholar] [CrossRef]

- Min, R.; Ortega, B.; Marques, C. Latest Achievements in Polymer Optical Fiber Gratings: Fabrication and Applications. Photonics 2019, 6, 36. [Google Scholar] [CrossRef]

- Koike, Y.; Asai, M. The future of plastic optical fiber. NPG Asia Mater 2009, 1, 22–28. [Google Scholar] [CrossRef]

- Zubia, J.; Aldabaldetreku, G.; Durana, G.; Arrue, J.; Jiménez, F. Light propagation in multi-step index optical fibres. Laser Photonics Rev. 2008, 2, 182–202. [Google Scholar] [CrossRef]

- Peters, K. Polymer optical fiber sensors—A review. Meas. Sci. Technol. 2011, 20, 13002. [Google Scholar] [CrossRef]

- Bilro, L.; Alberto, N.; Pinto, J.L.; Nogueira, R. Optical sensors based on plastic fibers. Sensors 2012, 12, 12184–12207. [Google Scholar] [CrossRef]

- Soge, A.O.; Dairo, O.F.; Sanyaolu, M.E.; Kareem, S.O. Recent developments in polymer optical fiber strain sensors: A short review. J. Opt. 2021, 50, 299–313. [Google Scholar] [CrossRef]

- Broadway, C.; Min, R.; Leal-Junior, A.G.; Marques, C.; Caucheteur, C. Toward Commercial Polymer Fiber Bragg Grating Sensors: Review and Applications. J. Lightwave Technol. 2019, 37, 2605–2615. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Z.; Tam, H.-Y.; Tao, X. Multifunctional Smart Optical Fibers: Materials, Fabrication, and Sensing Applications. Photonics 2019, 6, 48. [Google Scholar] [CrossRef]

- Yamada, Y. Textile-integrated polymer optical fibers for healthcare and medical applications. Biomed. Phys. Eng. Express 2020, 6, 62001. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Diaz, C.A.R.; Avellar, L.M.; Pontes, M.J.; Marques, C.; Frizera, A. Polymer Optical Fiber Sensors in Healthcare Applications: A Comprehensive Review. Sensors 2019, 19, 3156. [Google Scholar] [CrossRef] [PubMed]

- Cinquino, M.; Prontera, C.T.; Pugliese, M.; Giannuzzi, R.; Taurino, D.; Gigli, G.; Maiorano, V. Light-Emitting Textiles: Device Architectures, Working Principles, and Applications. Micromachines 2021, 12, 652. [Google Scholar] [CrossRef]

- Spigulis, J.; Pfafrods, D.; Stafeckis, M.; Jelinska-Platace, W. Glowing optical fiber designs and parameters. In Optical Inorganic Dielectric Materials and Devices; International Society for Optics and Photonics: Bellingham, DC, USA, 1997; Volume 2967, pp. 231–236. [Google Scholar]

- Bisyarin, M.A.; Eronyan, M.A.; Kulesh, A.Y.; Meshkovskiy, I.K.; Reutsky, A.A.; Shcheglov, A.A.; Ustinov, S.V. Light-emitting optical fibers with controllable anomalous small-angle scattering. J. Opt. Soc. Am. B 2017, 34, 2396–2399. [Google Scholar] [CrossRef]

- Spigulis, J. Side-Emitting Fibers Brighten Our World. Opt. Photon. News 2005, 16, 34–39. [Google Scholar] [CrossRef]

- Corless, R.M.; Gonnet, G.H.; Hare, D.E.G.; Jeffrey, D.J.; Knuth, D.E. On the LambertW function. Adv. Comput. Math. 1996, 5, 329–359. [Google Scholar] [CrossRef]

- Endruweit, A.; Alobaidani, A.D.; Furniss, D.; Seddon, A.B.; Benson, T.; Johnson, M.S.; Long, A.C. Spectroscopic experiments regarding the efficiency of side emission optical fibres in the UV-A and visible blue spectrum. Opt. Lasers Eng. 2008, 46, 97–105. [Google Scholar] [CrossRef]

- Bunge, C.-A.; Kruglov, R.; Poisel, H. Rayleigh and Mie scattering in polymer optical fibers. J. Lightwave Technol. 2006, 24, 3137–3146. [Google Scholar] [CrossRef]

- Huang, J.; Křemenáková, D.; Militký, J.; Zhu, G. Evaluation of Illumination Intensity of Plastic Optical Fibres with Tio2 Particles by Laser Treatment. Autex Res. J. 2015, 15, 13–18. [Google Scholar] [CrossRef][Green Version]

- Jiménez, F.; Arrue, J.; Aldabaldetreku, G.; Zubia, J. Numerical Simulation of Light Propagation in Plastic Optical Fibres of Arbitrary 3D Geometry. In WSEAS Transactions on Mathematics; World Scientific and Engineering Academy and Society: Corfu, Greece, 2004; Volume 13, pp. 824–829. [Google Scholar]

- Wang, J.; Huang, B.; Yang, B. Effect of weave structure on the side-emitting properties of polymer optical fiber jacquard fabrics. Text. Res. J. 2013, 83, 1170–1180. [Google Scholar] [CrossRef]

- Lustermann, B.; Quandt, B.M.; Ulrich, S.; Spano, F.; Rossi, R.M.; Boesel, L.F. Experimental determination and ray-tracing simulation of bending losses in melt-spun polymer optical fibres. Sci. Rep. 2020, 10, 11885. [Google Scholar] [CrossRef]

- Shen, J.; Tao, X.; Ying, D.; Hui, C.; Wang, G. Light-emitting fabrics integrated with structured polymer optical fibers treated with an infrared CO2 laser. Text. Res. J. 2012, 83, 730–739. [Google Scholar] [CrossRef]

- Shen, J.; Chui, C.; Tao, X. Luminous fabric devices for wearable low-level light therapy. Biomed. Opt. Express 2013, 4, 2925–2937. [Google Scholar] [CrossRef] [PubMed]

- Koncar, V. Optical Fiber Fabric Displays. Opt. Photon. News 2005, 16, 40–44. [Google Scholar] [CrossRef]

- Im, M.H.; Park, E.J.; Kim, C.H.; Lee, M.S. Modification of Plastic Optical Fiber for Side-Illumination. In Human-Computer Interaction. Interaction Platforms and Techniques; Jacko, J.A., Ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 1123–1129. ISBN 978-3-540-73107-8. [Google Scholar]

- La Rosa-Cruz, E.d.; Dirk, C.W.; RodrÍguez, O.; Castaño, V.M. Characterization of Fluorescence Induced by Side Illumination of Rhodamine B Doped Plastic Optical Fibers. Fiber Integr. Opt. 2001, 20, 457–464. [Google Scholar] [CrossRef]

- Bunge, C.-A.; Kallweit, J.P.; Al Houri, M.; Gries, T.; Mohr, B. Directed Illumination by Side-Emitting Fibers with Trilobal Cross Section. J. Lightwave Technol. 2019, 37, 5714–5721. [Google Scholar] [CrossRef]

- Buelow, R.; Jenson, C.; Davenport, J. Light Pipe with Side-Light Extraction. US Patent 20040179777A1, 10 March 2003. [Google Scholar]

- Chen, P.; Chen, M.; Hu, W.; Lin, G.; Xu, Z. Polymer Sidelight Optical Fiber and Preparation Device Thereof. CN Patent 111061006A, 4 January 2020. [Google Scholar]

- Joseph, E.; Franklin, J.; Smith, G. Side-Scattering Light Guides. US Patent 20060140562A1, 6 September 2002. [Google Scholar]

- Kokhanovsky, A.A. Light Scattering Reviews 10; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 978-3-662-46761-9. [Google Scholar]

- Lockwood, D.J. Rayleigh and Mie Scattering. In Encyclopedia of Color Science and Technology; Luo, M.R., Ed.; Springer: New York, NY, USA, 2016; pp. 1097–1107. ISBN 978-1-4419-8070-0. [Google Scholar]

- Sasho, S. Optical Fiber Sensor. JP Patent 2009115976A, 5 November 2007. [Google Scholar]

- Sasho, S. Multi-Core Plastic Coated Optical Fiber and Cable. JP Patent 2010266720A, 15 May 2009. [Google Scholar]

- Blumenstock, T.; Zimmermann, T. Producing Optical Fiber Useful for Manufacturing Light-Emitting Element, Comprises Providing Mixture Deducible Through Nozzle, Comprising First and Second Materials, Discharging Mixture, and Altering Mixing Ratio between Materials. DE Patent 102012012795A1, 28 June 2012. [Google Scholar]

- Franklin, J.B.; Smith, G.B.; Joseph, E.K. Side Scattering Polymer Light Guide and Method of Manufacture. CA Patent 002486643A, 22 May 2001. [Google Scholar]

- Orcutt, D.E. Optical Distribution System Including Light Guide. US Patent 4422719A, 7 May 1981. [Google Scholar]

- Ritter, S.; Henze, I.; Wolff, D.; Alkemper, J.; Hoppe, B.; Schultheis, B. Side-Emitting Step Index Fiber. DE Patent 102008009137B4, 14 February 2008. [Google Scholar]

- Sugiyama, H.; Sugimachi, M.; Ishiharada, M.; Morimura, Y.; Terahama, T.; Fukuyama, H.; Tanuma, I. Optical Transmission Tube, Method for Making It and Linear Illuminant System. EP Patent 0874191A2, 24 April 1997. [Google Scholar]

- Guay, J.-M.; Villafranca, A.; Baset, F.; Popov, K.; Ramunno, L.; Bhardwaj, V.R. Polarization-dependent femtosecond laser ablation of poly-methyl methacrylate. New J. Phys. 2012, 14, 85010. [Google Scholar] [CrossRef]

- Zheng, C.; Hu, A.; Kihm, K.D.; Ma, Q.; Li, R.; Chen, T.; Duley, W.W. Femtosecond Laser Fabrication of Cavity Microball Lens (CMBL) inside a PMMA Substrate for Super-Wide Angle Imaging. Small 2015, 11, 3007–3016. [Google Scholar] [CrossRef] [PubMed]

- Reupert, A.; Heck, M.; Nolte, S.; Wondraczek, L. Side-emission properties of femtosecond laser induced scattering centers in optical fibers. Opt. Mater. Express 2019, 9, 2497. [Google Scholar] [CrossRef]

- Roth, G.-L.; Esen, C.; Hellmann, R. Femtosecond laser direct generation of 3D-microfluidic channels inside bulk PMMA. Opt. Express 2017, 25, 18442–18450. [Google Scholar] [CrossRef]

- Appeldorn, R.H.; Hulme-Lowe, A.G.; Lea, M.C. Illumination Device Comprising an Optical Fibre. EP Patent 0594089B1, 19 October 1992. [Google Scholar]

- Wördenweber, B.; Boyce, P.; Hoffman, D.D.; Wallaschek, J. Automotive Lighting and Human Vision, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 978-3-540-36696-6. [Google Scholar]

- Zarian, J.R.; Robbins, J.A.; Sitar, D.; Holme, J.A. Side Lighting Optical Conduit. US Patent 6289150B1, 19 June 1996. [Google Scholar]

- Zheng, J.; Pei, L.; Adumbratio, N.; Latus, F.; Wei, H.; Feng, S.C. A Kind of Side Emitting Optical Fiber with Spiral Grooves. CN Patent 207752175U, 1 February 2018. [Google Scholar]

- Zeng, J.; Kong, L.; Su, L.; Fan, X.; Wang, S.; He, J.; Dong, X.; Chen, H. Study on Glowing Uniformity of Side Glowing Optical Fiber. Appl. Phys. 2019, 9, 287–293. [Google Scholar] [CrossRef]

- Jensen, M.F.; Noerholm, M.; Christensen, L.H.; Geschke, O. Microstructure fabrication with a CO2 laser system: Characterization and fabrication of cavities produced by raster scanning of the laser beam. Lab Chip 2003, 3, 302–307. [Google Scholar] [CrossRef] [PubMed]

- Zaremba, D.; Evert, R. Materials, chemical properties and analysis. In Polymer Optical Fibres: Fibre Types, Materials, Fabrication, Characterisation and Applications; Bunge, C.-A., Gries, T., Beckers, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 153–186. ISBN 9780081000397. [Google Scholar]

- Allemand, L.-R.; Calvet, J.; Cavan, J.-C.; Thevenin, J.-C. Optical Fibers with Plastic Core and Polymer Cladding. US Patent 4552431A, 23 September 1982. [Google Scholar]

- Uyor, U.O.; Popoola, A.P.I.; Popoola, O.M.; Aigbodion, V.S. Polymeric cladding materials under high temperature from optical fibre perspective: A review. Polym. Bull. 2020, 77, 2155–2177. [Google Scholar] [CrossRef]

- Bernasson, A.; Peuvergne, H. Optical Fiber with Multiple Point Lateral Illumination. JP Patent 2004264826A, 22 December 2003. [Google Scholar]

- George, R.; Walsh, L.J. Performance assessment of novel side firing flexible optical fibers for dental applications. Lasers Surg. Med. 2009, 41, 214–221. [Google Scholar] [CrossRef]

- Lockwood, R.; Mezei, G.A. Method and Device for Scratching Surface of Optical Fiber Substrate and Method of Manufacturing Optical Fiber Lighting System. JP Patent 2002283238A, 27 December 2001. [Google Scholar]

- Kluth, M. Illumination Device with Light Conductors Has Light Conductors with Output Coupling Arrangements and/or Reflectors so Light Can Be Coupled Out at Least Through Part of Side Surfaces. DE Patent 10206613A1, 15 February 2002. [Google Scholar]

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A Review of the Properties and Applications of Poly (Methyl Methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Hilleringmann, U. Ätztechnik. In Silizium-Halbleitertechnologie; Hilleringmann, U., Ed.; Vieweg+Teubner Verlag: Wiesbaden, Germany, 2004; pp. 65–90. ISBN 978-3-519-30149-3. [Google Scholar]

- Inglev, R.; Woyessa, G.; Bang, O.; Janting, J. Polymer Optical Fiber Modification by Etching Using Hansen Solubility Parameters—A Case Study of TOPAS, Zeonex, and PMMA. J. Lightwave Technol. 2019, 37, 4776–4783. [Google Scholar] [CrossRef]

- Hu, X.; Yang, K.; Zhang, C. Optimization of Preparation Conditions for Side-Emitting Polymer Optical Fibers Using Response Surface Methodology. Polymers 2020, 12, 3062. [Google Scholar] [CrossRef]

- Yong, L.K.; Park, J.E.; Seong, M.-L.; Youngjin, L.; Joo-hyun, L. Method of Forming a Pattern on Optical Fiber Textiles. KR Patent 20090018410A, 14 August 2007. [Google Scholar]

- Dyer, P.E. Excimer laser polymer ablation: Twenty years on. Appl. Phys. A Mater. Sci. Process. 2003, 77, 167–173. [Google Scholar] [CrossRef]

- Prakash, S.; Kumar, S. Experimental investigations and analytical modeling of multi-pass CO2 laser processing on PMMA. Precis. Eng. 2017, 49, 220–234. [Google Scholar] [CrossRef]

- Klank, H.; Kutter, J.P.; Geschke, O. CO2-laser micromachining and back-end processing for rapid production of PMMA-based microfluidic systems. Lab Chip 2002, 2, 242–246. [Google Scholar] [CrossRef] [PubMed]

- Silfvast, W.T. Laser Fundamentals, 1st ed.; Cambridge University Press: Cambridge, UK, 2012; ISBN 9780521541053. [Google Scholar]

- Radovanovic, M.; Madic, M. Experimental investigations of CO2 laser cut quality: A review. Nonconv. Technol. Rev. 2011, 4, 35–42. [Google Scholar]

- Shih, W.-C. Fabrication and Applications of Multiple Side-Window, Side-Firing Optical Fiber. US Patent 20200123053A1, 31 August 2016. [Google Scholar]

- Esteves, F.; Alonso, H. Effect of CO2 Laser Radiation on Surface and Dyeing Properties of Synthetic Fibres. Text. Appar. 2007, 11, 42–47. [Google Scholar] [CrossRef]

- Fujigaki, T.; Fujinaga, Y.; Tokuda, S.; Furukawa, N.; Ichimura, K.; Shibuya, Y.; Iuchi, S. Working Equipment for Roughening The Side of Optical fiber. US Patent 4929169A, 13 June 1988. [Google Scholar]

- Wehlage, D.; Herrmann, A.; Ehrmann, A. Integration of optical fibers in woven fabrics with position-dependent sidelight emission. In Proceedings of the LICHT2016, Karlsruhe, Germany, 25–27 September 2016; Deutsche Lichttechnische Gesellschaft e.V.: Berlin, Germany, 2016. [Google Scholar]

- Arrue, J.; Kalymnios, D.; Zubia, J.; Fuster, G. Light power behaviour when bending plastic optical fibres. IEE Proc. Optoelectron. 1998, 145, 313–318. [Google Scholar] [CrossRef]

- Arrue, J.; Zubia, J. Analysis of the decrease in attenuation achieved by properly bending plastic optical fibres. Electron. Lett. 1996, 143, 135. [Google Scholar] [CrossRef]

- Durana, G.; Zubia, J.; Arrue, J.; Aldabaldetreku, G.; Mateo, J. Dependence of bending losses on cladding thickness in plastic optical fibers. Appl. Opt. 2003, 42, 997–1002. [Google Scholar] [CrossRef]

- Jing, N.; Zheng, J.; Zhao, X.; Teng, C. Investigation of a macrobending micro-plastic optical fiber for refractive index sensing. Appl. Opt. 2014, 53, 8145–8150. [Google Scholar] [CrossRef]

- Křemenáková, D.; Meryová, B.; Militký, J.; Lédl, V. Illumination intensity changes of side emitting optical fibers. World J. Eng. 2013, 10, 217–222. [Google Scholar] [CrossRef]

- Babchenko, A.; Weinberger, Z.; Itzkovich, N.; Maryles, J. Plastic optical fibre with structural imperfections as a displacement sensor. Meas. Sci. Technol. 2006, 17, 1157–1161. [Google Scholar] [CrossRef]

- Babchenko, A.; Maryles, J. Graded-index plastic optical fiber for deformation sensing. Opt. Lasers Eng. 2007, 45, 757–760. [Google Scholar] [CrossRef]

- Chen, T.; Tu, J.; Song, X.; Li, Z. Sensor for measuring extremely large strain based on bending Polymer optical fiber. Instrum. Exp. Tech. 2017, 60, 301–306. [Google Scholar] [CrossRef]

- Wang, W.-C.; Ledoux, W.R.; Sangeorzan, B.J.; Reinhall, P.G. A shear and plantar pressure sensor based on fiber-optic bend loss. J. Rehabil. Res. Dev. 2005, 42, 315–325. [Google Scholar] [CrossRef]

- Vijayan, A.; Gawli, S.; Kulkarni, A.; Karekar, R.N.; Aiyer, R.C. An optical fiber weighing sensor based on bending. Trans. Inst. Meas. Control 2008, 19, 105302. [Google Scholar] [CrossRef]

- Guo, Z.; Chu, F.; Fan, J.; Zhang, Z.; Bian, Z.; Li, G.; Song, X. Study of macro-bending biconical tapered plastic optical fiber for relative humidity sensing. Sens. Rev. 2019, 39, 352–357. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Díaz, C.R.; Leitão, C.; Pontes, M.J.; Marques, C.; Frizera, A. Polymer optical fiber-based sensor for simultaneous measurement of breath and heart rate under dynamic movements. Opt. Laser Technol. 2019, 109, 429–436. [Google Scholar] [CrossRef]

- Sartiano, D.; Geernaert, T.; Torres Roca, E.; Sales, S. Bend-Direction and Rotation Plastic Optical Fiber Sensor. Sensors 2020, 20, 5405. [Google Scholar] [CrossRef]

- Azkune, M.; Ruiz-Rubio, L.; Aldabaldetreku, G.; Arrospide, E.; Pérez-Álvarez, L.; Bikandi, I.; Zubia, J.; Vilas-Vilela, J.L. U-Shaped and Surface Functionalized Polymer Optical Fiber Probe for Glucose Detection. Sensors 2017, 18, 34. [Google Scholar] [CrossRef]

- Kallweit, J.; Pätzel, M.; Gries, T. Lichtleitende Polymerfasern. Konstruktion 2020, 72, IW8–IW11. [Google Scholar] [CrossRef]

- Schrank, V.; Beer, M.; Beckers, M.; Gries, T. Polymer-optical fibre (POF) integration into textile fabric structures. In Polymer Optical Fibres: Fibre Types, Materials, Fabrication, Characterisation and Applications; Bunge, C.-A., Gries, T., Beckers, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 337–348. ISBN 9780081000397. [Google Scholar]

- Gries, T.; Veit, D.; Wulfhorst, B. Textile Technology: An Introduction, 2nd ed.; Carl Hanser Fachbuchverlag: Munich, Germany, 2015; ISBN 978-1-56990-565-4. [Google Scholar]

- Daniel, M. Light Emitting Fabric. US Patent 4234907A, 29 January 2021. [Google Scholar]

- Ge, L.; Tan, J. Development of three-dimensional effects and stretch for polymeric optical fiber (POF) textiles with double weave structure containing spandex. J. Text. Inst. 2021, 112, 398–405. [Google Scholar] [CrossRef]

- Wang, J.; Yang, B.; Huang, B.; Jin, Z. Design and development of polymeric optical fiber jacquard fabric with dynamic pattern display. Text. Res. J. 2012, 82, 967–974. [Google Scholar] [CrossRef]

- Parker, J.R. Fiber Optic Light Emitting Panel and Method of Making Same. US Patent 4885663A, 22 March 1988. [Google Scholar]

- Koukal, C.-E. Single or Multi-Ply, Preferably Two-Ply Textile. DE Patent 102004043193B4, 9 March 2004. [Google Scholar]

- Kobek, H.-J. Uniformly luminous textile fabric. EN Patent 102013020715, 10 December 2013. [Google Scholar]

- Alobaidani, A.D.; Furniss, D.; Endruweit, A.; Johnson, M.S.; Benson, T.; Seddon, A.B. Enhancement of the side emission efficiency of commercial PMMA optical fibres in the UV-A and visible blue spectrum for photocuring of epoxy resins. In Proceedings of the Thirteenth European Conference on Composite Materials (ECCM13), Stockholm, Sweden, 2–5 June 2008; Gibson, G., Ed.; Royal Institute of Technology: Stockholm, Sweden, 2008. [Google Scholar]

- Mitsubishi Rayon Co. Ltd. ESKA Optical Fiber Division. In Specification Sheet CK-40; Mitsubishi Rayon Co. Ltd.: Tokyo, Japan, 2001. [Google Scholar]

- Sojitz plc. DB-250: Display Type. 2017. Available online: https://www.sojitz.com/en/ (accessed on 6 September 2021).

- Tan, J. Photonic Patterns: Fashion Cutting with Illuminating Polymeric Optical Fibre (POF) textiles. In Proceedings of the The Second International Conference for Creative Pattern Cutting, Huddersfield, UK, 24–25 February 2016; ISBN 9781862181380. [Google Scholar]

- Cochrane, C.; Meunier, L.; Kelly, F.; Koncar, V. Flexible displays for smart clothing: Part I—Overview. Indian J. Fibre Text. Res. 2011, 36, 422–428. [Google Scholar]

- Fraga, H. Firefly luminescence: A historical perspective and recent developments. Photochem. Photobiol. Sci. 2008, 7, 146–158. [Google Scholar] [CrossRef]

- Schlotter, P.; Schmidt, R.; Schneider, J. Luminescence conversion of blue light emitting diodes. Appl. Phys. A Mater. Sci. Process. 1997, 64, 417–418. [Google Scholar] [CrossRef]

- Hutchison, S.G.; Hutchison, F.I. Radioactivity in Everyday Life. J. Chem. Educ. 1997, 74, 501. [Google Scholar] [CrossRef]

- Ronda, C.R. Luminescence: From Theory to Applications; Wiley-VCH: Weinheim, Germany, 2008; ISBN 978-3527314027. [Google Scholar]

- Poisel, H.; Klein, K.F.; Levin, V.M. Fluorescent Optical Fibers for Data Transmission. In Optical Polymers: Fibers and Waveguides; Harmon, J.P., Noren, G.K., Eds.; American Chemical Society: Washington, DC, USA, 2001; pp. 211–219. ISBN 9780841237063. [Google Scholar]

- Kamimura, S.; Furukawa, R. Strain sensing based on radiative emission-absorption mechanism using dye-doped polymer optical fiber. Appl. Phys. Lett. 2017, 111, 63301. [Google Scholar] [CrossRef]

- Guo, J.; Zhou, B.; Yang, C.; Dai, Q.; Kong, L. Stretchable and upconversion-luminescent polymeric optical sensor for wearable multifunctional sensing. Opt. Lett. 2019, 44, 5747–5750. [Google Scholar] [CrossRef]

- Miluski, P.; Dorosz, D.; Żmojda, J.; Kochanowicz, M.; Dorosz, J. Luminescent Polymer Optical Fibre Sensor for Temperature Measurement. Acta Phys. Pol. A 2015, 127, 730–733. [Google Scholar] [CrossRef]

- Inman, R.H.; Shcherbatyuk, G.V.; Medvedko, D.; Gopinathan, A.; Ghosh, S. Cylindrical luminescent solar concentrators with near-infrared quantum dots. Opt. Express 2011, 19, 24308–24313. [Google Scholar] [CrossRef]

- Jakubowski, K.; Huang, C.-S.; Gooneie, A.; Boesel, L.F.; Heuberger, M.; Hufenus, R. Luminescent solar concentrators based on melt-spun polymer optical fibers. Mater. Des. 2020, 189, 108518. [Google Scholar] [CrossRef]

- Moraitis, P.; Schropp, R.E.I.; van Sark, W.G.J.H.M. Nanoparticles for Luminescent Solar Concentrators—A review. Opt. Mater. 2018, 84, 636–645. [Google Scholar] [CrossRef]

- Vieira, A.; Arrue, J.; García-Ramiro, B.; Jiménez, F.; Illarramendi, M.A.; Zubia, J. POF-Based Solar Concentrators Incorporating Dyes and Europium Chelates. Materials 2021, 14, 2667. [Google Scholar] [CrossRef]

- Correia, S.F.H.; Lima, P.P.; Pecoraro, E.; Ribeiro, S.J.L.; André, P.S.; Ferreira, R.A.S.; Carlos, L.D. Scale up the collection area of luminescent solar concentrators towards metre-length flexible waveguiding photovoltaics. Prog. Photovolt Res. Appl. 2016, 24, 1178–1193. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Zhang, Y.; Dong, R.; Luscombe, C.K. Review on the Role of Polymers in Luminescent Solar Concentrators. J. Polym. Sci. Part A Polym. Chem. 2019, 57, 201–215. [Google Scholar] [CrossRef]

- Parola, I.; Illarramendi, M.A.; Jakobs, F.; Kielhorn, J.; Zaremba, D.; Johannes, H.-H.; Zubia, J. Characterization of Double-Doped Polymer Optical Fibers as Luminescent Solar Concentrators. Polymers 2019, 11, 1187. [Google Scholar] [CrossRef]

- Ikhlef, A.; Skowronek, M. Application of a plastic scintillating fiber array for low-energy x-ray imaging. Appl. Opt. 1998, 37, 8081–8084. [Google Scholar] [CrossRef]

- Park, J.W.; Kim, G.H. Detection of Gamma Rays Using Plastic Scintillating Fibers. J. Nucl. Sci. Technol. 2004, 41, 373–376. [Google Scholar] [CrossRef]

- Tang, S.; Ma, Q.; Fang, J.; Yin, Z.; Zhu, D.-M. Simulation Study of Energy Absorption of X- and γ-Rays in Plastic Scintillating Fiber Arrays. IEEE Trans. Nucl. Sci. 2007, 54, 1773–1778. [Google Scholar] [CrossRef]

- Miluski, P.; Dorosz, D.; Kochanowicz, M.; Żmojda, J. Fluorescent polymeric optical fibre illuminator. Electron. Lett. 2016, 52, 1550–1552. [Google Scholar] [CrossRef]

- Cennamo, N.; Mattiello, F.; Galatus, R.V.; Voiculescu, E.; Zeni, L. Plasmonic Sensing in D-Shaped POFs With Fluorescent Optical Fibers as Light Sources. IEEE Trans. Instrum. Meas. 2018, 67, 754–759. [Google Scholar] [CrossRef]

- Ding, W.; Sun, J.; Chen, G.; Zhou, L.; Wang, J.; Gu, X.; Wan, J.; Pu, X.; Tang, B.; Wang, Z.L. Stretchable multi-luminescent fibers with AIEgens. J. Mater. Chem. C 2019, 7, 10769–10776. [Google Scholar] [CrossRef]

- Slooff, L.H.; van Blaaderen, A.; Polman, A.; Hebbink, G.A.; Klink, S.I.; van Veggel, F.C.J.M.; Reinhoudt, D.N.; Hofstraat, J.W. Rare-earth doped polymers for planar optical amplifiers. J. Appl. Phys. 2002, 91, 3955–3980. [Google Scholar] [CrossRef]

- Deng, K.-L.; Olson, D.R.; Ye, Q. Optical Fibers Having A Surface Light Field Emulation (S-Life) Segment and Method of Making The Same. US Patent 2011188261A1, 1 February 2010. [Google Scholar]

- Arrue, J.; García-Ramiro, B.; Jiménez, F.; Illarramendi, M.A.; Ayesta, I.; Zubia, J.; Evert, R.; Zaremba, D. Gain in europium-chelate-doped polymer-optical-fiber amplifiers. J. Opt. Soc. Am. B 2018, 35, 2770. [Google Scholar] [CrossRef]

- Appollinaire Ltd. Fluorescent Fiber Optics. Available online: https://www.aengineers.com/scintillating%20optical%20fibers.htm (accessed on 30 July 2021).

- Bartlett, R.J.; Philip-Chandy, R.; Eldridge, P.; Merchant, D.F.; Morgan, R.; Scully, P.J. Plastic optical fibre sensors and devices. Trans. Inst. Meas. Control 2000, 22, 431–457. [Google Scholar] [CrossRef]

- Bunge, C.-A. Side Optical Fiber. DE Patent 102014110120A1, 18 July 2014. [Google Scholar]

- Guo, J.; Zhou, B.; Yang, C.; Dai, Q.; Kong, L. Stretchable and Temperature-Sensitive Polymer Optical Fibers for Wearable Health Monitoring. Adv. Funct. Mater. 2019, 29, 1902898. [Google Scholar] [CrossRef]

- Luo, J.; Gao, Q.; Zhang, K.; Ge, M.; Liu, J. Structure and luminescent properties of luminous polypropylene fiber based on Sr2MgSi2O7:Eu2+, Dy3+. J. Rare Earths 2014, 32, 696–701. [Google Scholar] [CrossRef]

- Erdman, A.; Kulpinski, P.; Gabor, J.; Stanula, A.; Swinarew, A.S. Luminescent Cellulose Fibers Modified with Poly((9-Carbazolyl) Methylthiirane). Polymers 2020, 12, 2296. [Google Scholar] [CrossRef] [PubMed]

- Jakobs, F.; Harms, K.; Kielhorn, J.; Zaremba, D.; Ang, P.Y.; Kowalsky, W.; Johannes, H.-H. Homogeneous Distribution of Polymerizable Coumarin Dyes for Active Few Mode POF. Materials 2020, 13, 1975. [Google Scholar] [CrossRef]

- Parola, I.; Arrospide, E.; Recart, F.; Illarramendi, M.; Durana, G.; Guarrotxena, N.; García, O.; Zubia, J. Fabrication and Characterization of Polymer Optical Fibers Doped with Perylene-Derivatives for Fluorescent Lighting Applications. Fibers 2017, 5, 28. [Google Scholar] [CrossRef]

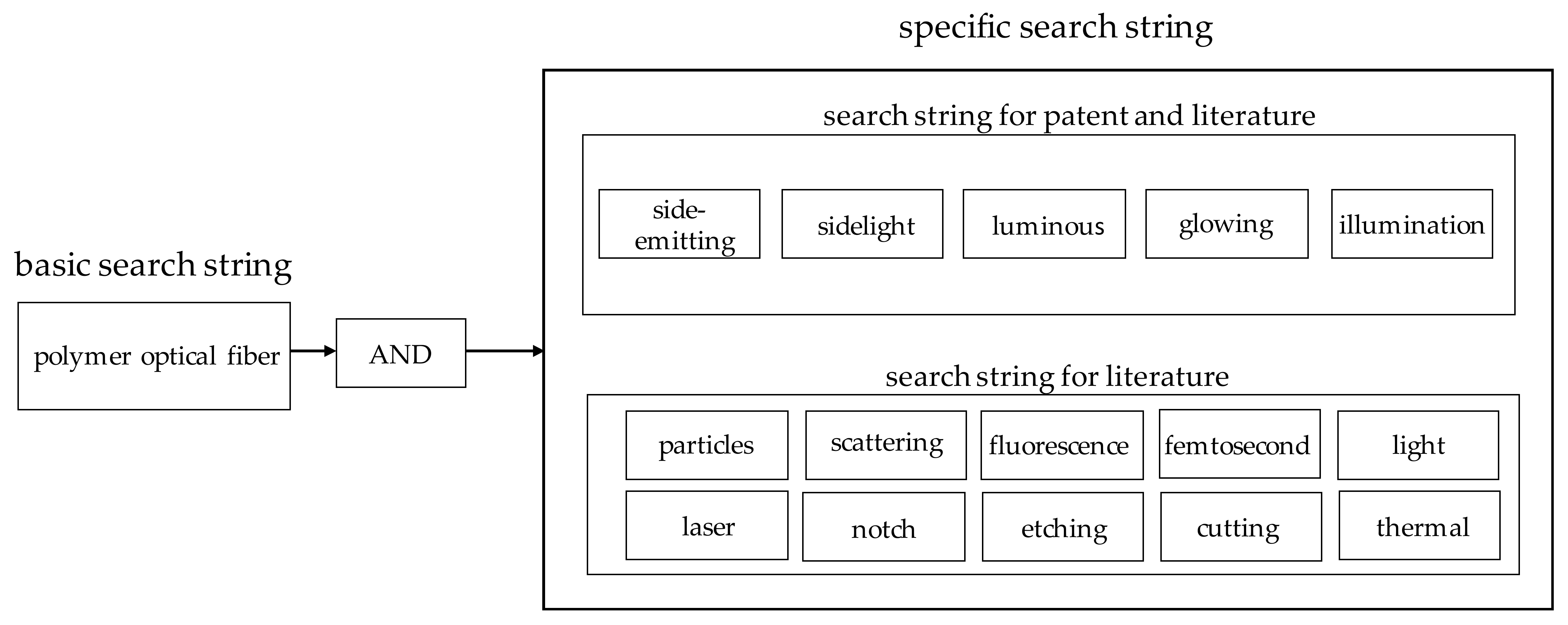

| Search results found based on the keywords | 1827 |

| Search results after scanning the titles and the journal names | 419 |

| Search results matching the covered topic | 186 |

| Search results used for this review paper | 106 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kallweit, J.; Pätzel, M.; Pursche, F.; Jabban, J.; Morobeid, M.; Gries, T. An Overview on Methods for Producing Side-Emitting Polymer Optical Fibers. Textiles 2021, 1, 337-360. https://doi.org/10.3390/textiles1020017

Kallweit J, Pätzel M, Pursche F, Jabban J, Morobeid M, Gries T. An Overview on Methods for Producing Side-Emitting Polymer Optical Fibers. Textiles. 2021; 1(2):337-360. https://doi.org/10.3390/textiles1020017

Chicago/Turabian StyleKallweit, Jan, Mark Pätzel, Franz Pursche, Junes Jabban, Mohamad Morobeid, and Thomas Gries. 2021. "An Overview on Methods for Producing Side-Emitting Polymer Optical Fibers" Textiles 1, no. 2: 337-360. https://doi.org/10.3390/textiles1020017

APA StyleKallweit, J., Pätzel, M., Pursche, F., Jabban, J., Morobeid, M., & Gries, T. (2021). An Overview on Methods for Producing Side-Emitting Polymer Optical Fibers. Textiles, 1(2), 337-360. https://doi.org/10.3390/textiles1020017