Sustainable Engineering of Recycled Aggregate Concrete: Structural Performance and Environmental Benefits Under Circular Economy Frameworks

Abstract

1. Introduction

Scope and Novelty of the Study

2. Methodological Framework for Literature Synthesis

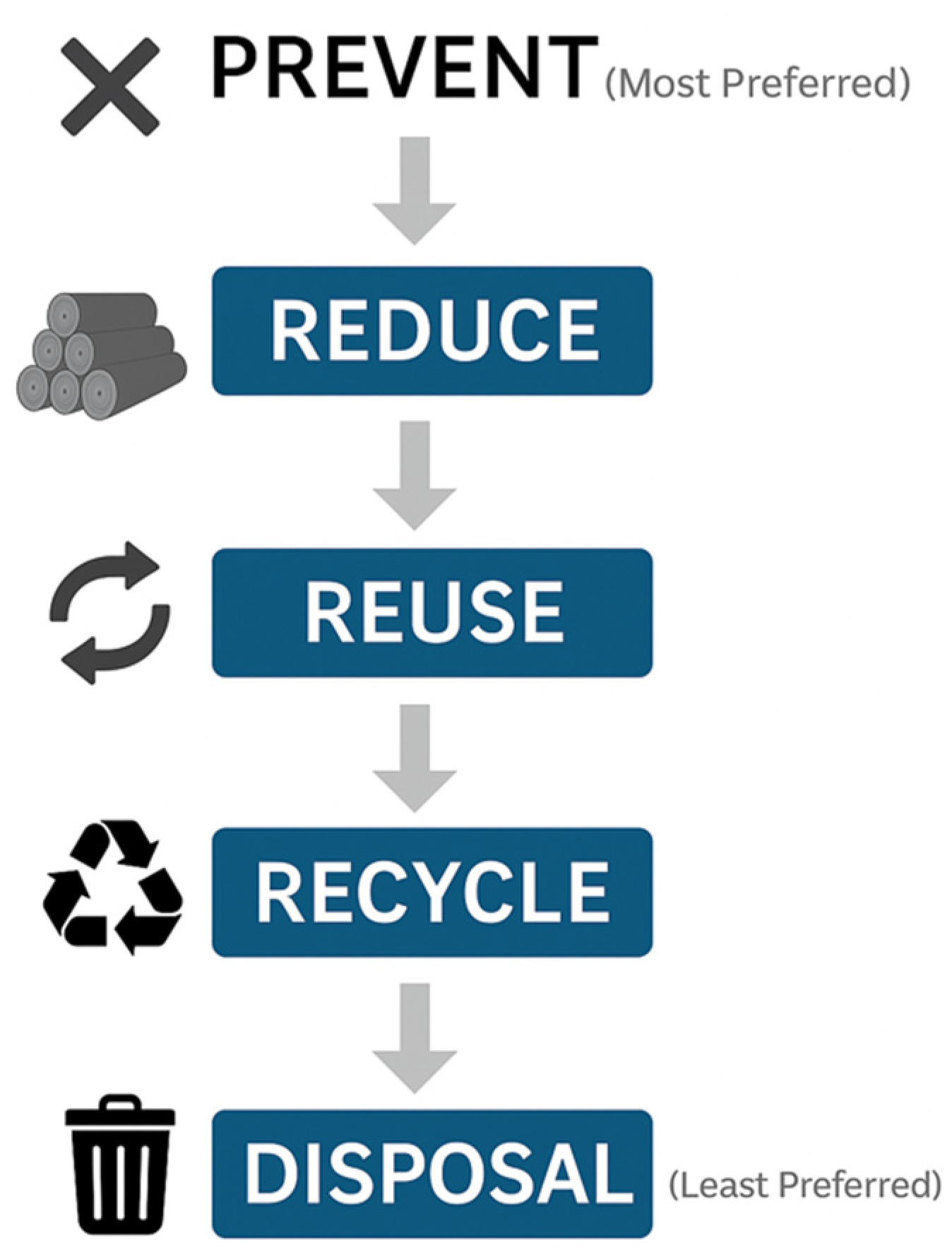

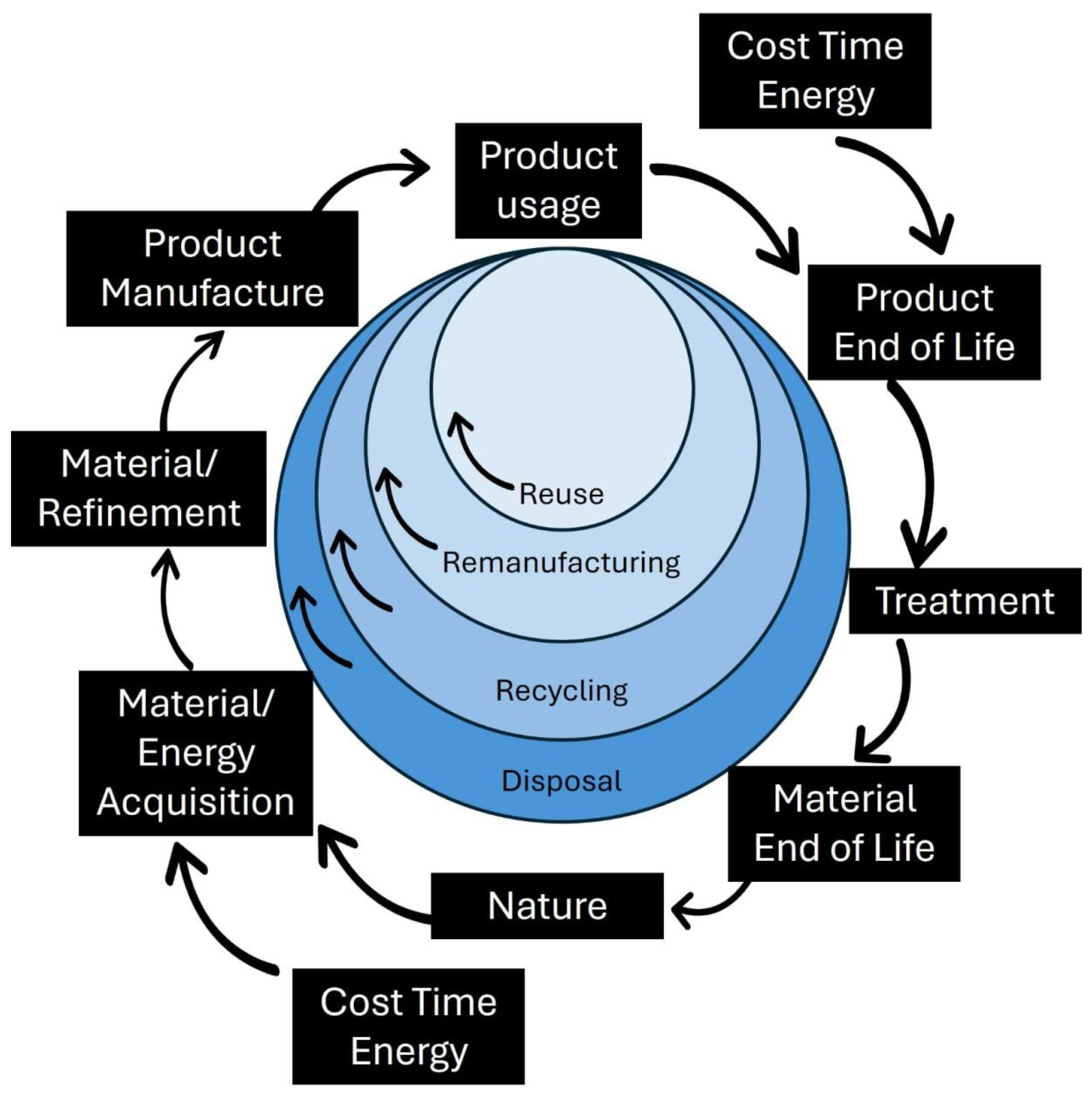

3. Circular Economy: Concepts and Evolution

4. Justification and Performance Evaluation of PET Polymer in Recycled Concrete Applications

5. Integrating Circular Economy Principles in Concrete Engineering

5.1. Reuse and Recycling of Construction Materials in Concrete

Quantitative Correlation Between Recycled Material Type, Dosage, and Mechanical Properties

5.2. Applications of Circular Economy in Reinforced Concrete and Material Recovery

5.3. Emerging Technologies for Construction Waste Recycling

5.4. Economic Viability and Waste Minimization Strategies

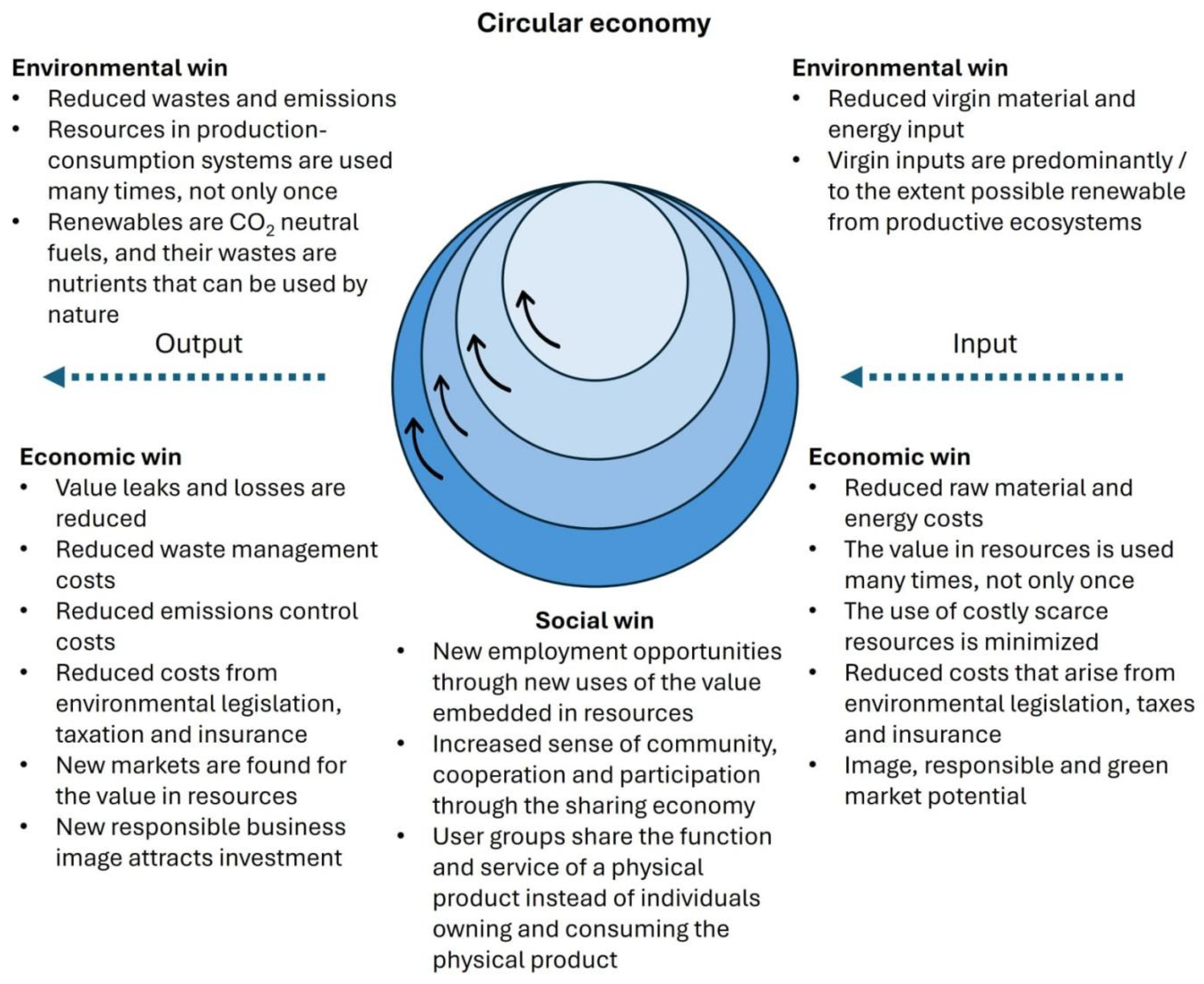

5.5. Multidimensional Benefits and Design Intent for Recycling in Construction

- Environmental Benefits—Prolonging landfill capacity and minimizing environmental degradation are direct outcomes of optimized reuse and recycling. Many construction materials include chemical additives that contribute to groundwater contamination when disposed of. Recycling mitigates such risks and, by reducing material transport to landfills, also contributes to CO2 emission reductions.

- Economic Advantages—While concerns exist regarding employment shifts from landfill operations; they are often counterbalanced by emerging job opportunities in recycling; material recovery; and green construction sectors. Recycled materials—distinct from simply reused ones—are processed to meet performance standards. This processing industry fosters new skill demands and economic activity, turning waste into valuable resources.

- Societal Benefits—The increasing demand for urban land necessitates the preservation of available space for infrastructure; housing; and ecological buffers. Effective recycling practices reduce the need for new landfills. Moreover, recycling reduces the uncontrolled dispersion of hazardous substances into ecosystems, thus safeguarding public health and improving urban living conditions.

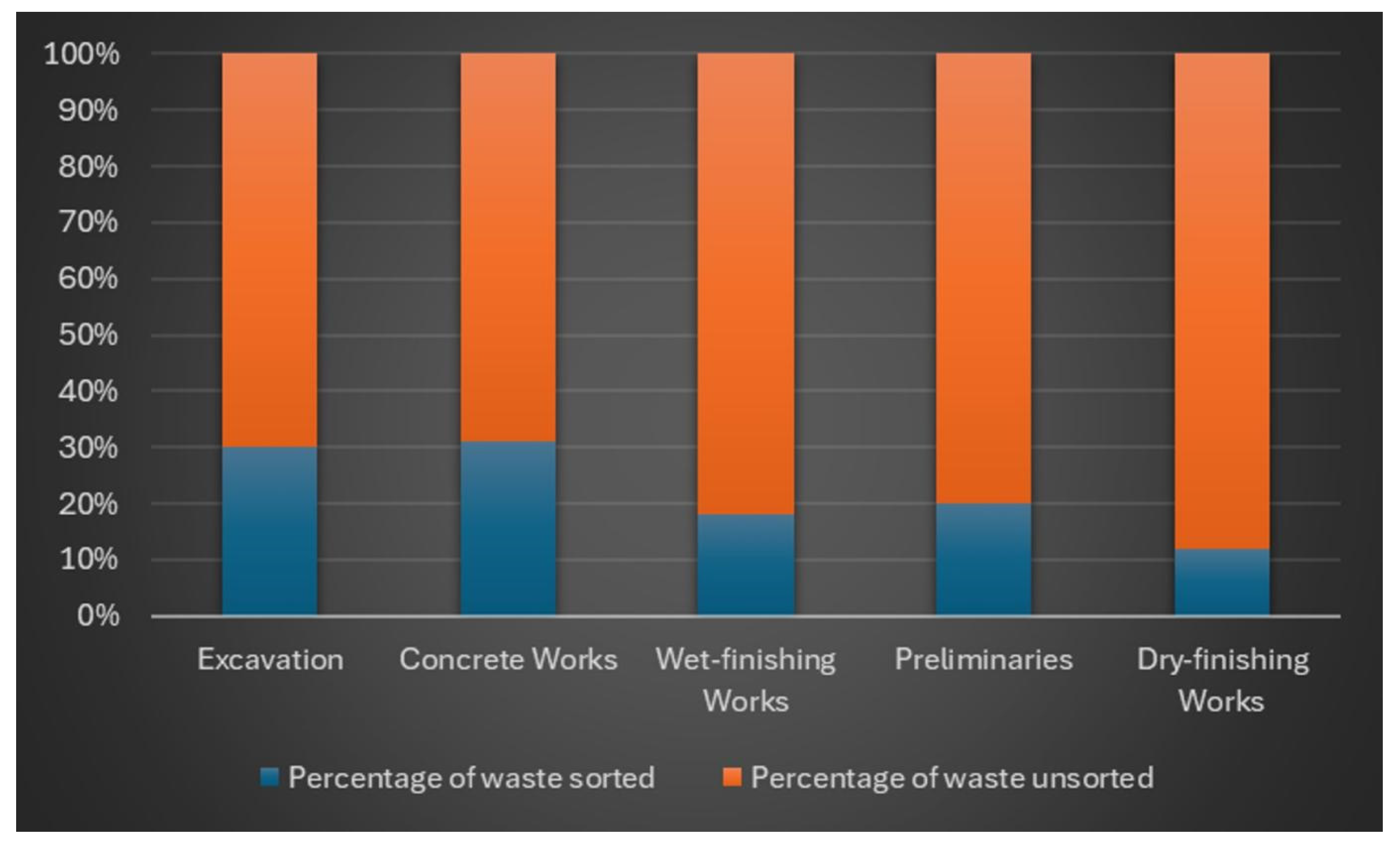

5.6. Regulatory Barriers and Challenges in CE Implementation

- Policy and Governance—A major challenge to reusing building waste—especially in Australasian contexts such as New Zealand and Australia—has been the limited implementation of policy-driven incentives for businesses. For instance, the Building Act (2004) and the Waste Management Act (2008) in New Zealand serve as primary regulatory frameworks on building waste. These Acts incorporate principles of sustainable material use and waste reduction during construction, supported by mechanisms such as a USD10 per ton landfill levy aimed at promoting recycling and funding new technologies. However, case studies indicate that this levy has exerted minimal influence on landfill behavior, and similar policy gaps or limited enforcement can also be observed in other countries, including China and France [114,127,135].

- Quality and Performance—A recurring issue in many countries is the difficulty of ensuring that recycled construction and demolition debris meets requisite quality standards. This often involves meticulous sorting, particularly for materials contaminated by hazardous substances. For example, effective timber separation requires distinguishing between contaminated and non-contaminated wood, a process demanding both time and labor. These costs are incurred globally, and insufficient separation can result in materials being unsuitable for recycling, as seen across multiple jurisdictions [128].

- Information—Industry-wide limitations in awareness regarding recycling benefits are not restricted to a single geography. Across developed and developing nations alike, the construction sector exhibits varying levels of engagement with recycling initiatives. Case studies from Brazil and Australia illustrate how a lack of awareness persists despite dynamic construction markets. Relevant organizations must invest in educational campaigns that leverage real-world case studies to foster behavioral change [133].

- Cost/Capital—Cost remains a pivotal barrier worldwide. In New Zealand, for example, the cost of recycling exceeds the cost of landfill disposal, thereby disincentivizing environmentally beneficial practices. Similar cost disparities have been reported in France, Italy, and Brazil [134]. Table 7, adopted from discussions in [127], illustrates recycling costs from a New Zealand context:

- Perception and Culture—Globally; the construction industry still struggles to recognize construction and demolition (C&D) waste as a resource. This mindset, observed in countries like Spain, Japan, and New Zealand, stems from entrenched linear economic practices. Sustainability-oriented strategies must reframe waste as a resource, aligning with global priorities on renewable and recyclable technologies to meet climate goals [128].

- Education and Awareness Deficit—A considerable portion of the global construction workforce lacks exposure to circular economy (CE) principles. This resistance to change, due to familiarity with traditional methods, is a barrier across countries. Governments and regulatory bodies should organize workshops, training, and awareness programs to build capacity for CE practices. The lack of advanced recycling infrastructure also results in poor-quality recycled products, which are costlier and often underperform [135].

- Permits and Specifications—Across various regions; rigid standards and outdated specifications hinder the acceptance of recycled materials. Regulatory approval for the use of such materials is frequently denied due to conservative practices or lack of precedent. This creates uncertainty in the market and discourages investment in recycled material supply chains, not only in Australasia but also in countries such as the UK, Germany, and the USA.

5.7. Strategic Frameworks and Models for CE Integration in C&D Waste Management

- Regenerate: Shifting the emphasis from conventional approaches to renewable technologies while preserving ecosystems.

- Share: Extending resource lifespans through maintenance and promoting shared use of reusable and recyclable materials.

- Optimize: Improving the efficiency of recycled products through waste minimization and green supply chains.

- Loop: Supplying technologies for effective waste recycling and reuse.

- Virtualize: Reducing material usage through direct and indirect methods.

- Exchange: Promoting the use of advanced construction materials and innovative methods.

- Preconstruction: Implementation of governmental restrictions, taxation on the acquisition of raw materials, utilization of economic tools, and prioritizing of waste management recovery alternatives.

- Construction and Renovation: Targeted demolition, an effective strategy for managing waste.

- Collection and Distribution: Practices involving collection, segregation, and on-site sorting; effective allocation of resources; transportation; and recycling of repurposed materials.

- Demolition (End of Life): Preference for selective deconstruction over conventional demolition, waste assessments, material reclamation, etc.

- Material Recovery and Production: Activities like reuse, recycling, backfilling, material or energy recovery, and waste treatment while considering environmental and economic factors.

6. Limitations, Research Gaps, and Practical Considerations for Circular Economy in Construction

6.1. Systemic Limitations and Theoretical Gaps

6.2. Practical Considerations for Enabling CE in Construction

- Design for Adaptability, Deconstruction, and Reuse (DfADR): Design-phase interventions must prioritize modularity, prefabrication, and reversible assembly. Design for disassembly (DfD) and design for reuse (DfR) principles should be embedded into building codes and professional training to ensure future resource recovery. Such approaches extend the usable life of materials, lower embodied carbon, and reduce end-of-life waste [150].

- Performance-Based Lifecycle Procurement: CE implementation requires rethinking procurement strategies. Contracts should incorporate lifecycle carbon analysis, resource circularity metrics, and provisions for material take-back. Performance guarantees for reused or recycled components must be supported by third-party certifications [163].

- Digital Innovation and Material Traceability: Technologies such as Building Information Modelling (BIM), Digital Twins, and Material Passports offer powerful tools for tracking material origins, composition, and lifecycle performance. Their use can facilitate recovery planning, on-site sorting logistics, and accurate carbon and cost modeling for circular projects [164].

- Standardization and Regulatory Alignment: A unified regulatory framework is necessary to create confidence in secondary materials. National and international standards should clearly define technical, health, and environmental criteria for recycled aggregates, polymers, metals, and hybrid composites used in construction [165].

- Policy Instruments and Fiscal Mechanisms: Governments must implement targeted incentives, including tax credits for circular designs, differential landfill fees, and green procurement policies that prioritize circular materials. Establishing extended producer responsibility (EPR) schemes for construction components can further institutionalize CE practices [165,166].

- Skills Development and Collaborative Ecosystems: The transition to CE requires a fundamental shift in industry culture. Educational institutions, certification bodies, and industry groups must collaborate to develop training programs in circular construction [167]. Stakeholder ecosystems, including clients, designers, contractors, recyclers, and policymakers, must work through collaborative platforms to share data, align objectives, and scale innovation.

6.3. Future Research Priorities

- Quantitative Modeling of CE Scenarios: Life Cycle Assessment (LCA), Material Flow Analysis (MFA), and Social Life Cycle Assessment (S-LCA) frameworks should be enhanced to capture long-term performance, economic trade-offs, and social outcomes of CE strategies.

- Circularity-Driven Design Optimization: Research should explore the co-optimization of modularity, recyclability, and performance in structural and non-structural elements. Material combinations and joint technologies that simplify future reuse and reprocessing must be rigorously tested.

- Circular Business Models in Construction: From leasing-based models for structural frames to digital product-service systems (PSS) for façade components, CE-aligned business innovations require testing for commercial scalability and consumer acceptance.

- Cross-Regional Policy Benchmarking: Comparative studies across developed and emerging markets can reveal effective regulatory mixes, institutional enablers, and cultural drivers for CE adoption.

- Integration of Bio-Based and Low-Impact Materials: Future work should investigate synergies between CE and the use of bio-composites, geopolymers, and other low-carbon alternatives to conventional Portland cement and virgin aggregates.

- Sustainability Index Development for CE Implementation: A comprehensive index combining environmental, economic, and social indicators is essential for benchmarking CE performance in construction. Data integration platforms powered by machine learning and AI may offer new ways to model complex sustainability trade-offs.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Giudici, H.; Bento, F.; Falk, K. Industrial Organizations Adapting to the Novel EU Taxonomy While Developing Socio-Technical Systems: A Literature Review. Systems 2024, 12, 485. [Google Scholar] [CrossRef]

- Soni, A.; Das, P.K.; Hashmi, A.W.; Yusuf, M.; Kamyab, H.; Chelliapan, S. Challenges and opportunities of utilizing municipal solid waste as alternative building materials for sustainable development goals: A review. Sustain. Chem. Pharm. 2022, 27, 100706. [Google Scholar] [CrossRef]

- Gounden, K.; Mwangi, F.M.; Mohan, T.P. A Perspective on Four Emerging Threats to Sustainability and Sustainable Development. Earth 2022, 3, 1207–1236. [Google Scholar] [CrossRef]

- George, A.S.; George, A.H. Towards a Super Smart Society 5.0: Opportunities and Challenges of Integrating Emerging Technologies for Social Innovation. Partners Univ. Int. Res. J. 2024, 3, 1–29. [Google Scholar]

- Dorfmüller, H.; Kimotho, W.; Ebert, I.; Dey, P.; Wettstein, F. Responsible Business Conduct in Commodity Trading—A Multidisciplinary Review. J. Bus. Ethics 2024, 195, 449–473. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy, COM (2015) 614. In Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Llorente-González, L.J.; Alberich, J.P.; Genovese, A.; Lowe, B.H. Towards radical circular economy futures: Addressing social relations of production. Technol. Forecast. Soc. Change 2025, 213, 123972. [Google Scholar] [CrossRef]

- Gautam, P.; Salunke, D.; Lad, D.; Gautam, A. Convergent synergy of carbon capture within the circular economy paradigm: A nexus for realizing multifaceted sustainable development goals. Carbon Res. 2025, 4, 3. [Google Scholar] [CrossRef]

- Kipping, M.; Clark, T. (Eds.) The Oxford Handbook of Management Consulting; Oxford University Press: Oxford, UK, 2012. [Google Scholar]

- Abu-Bakar, H.; Charnley, F. Developing a strategic methodology for circular economy roadmapping: A theoretical framework. Sustainability 2024, 16, 6682. [Google Scholar] [CrossRef]

- Cudečka-Puriņa, N.; Atstāja, D.; Koval, V.; Purviņš, M.; Nesenenko, P.; Tkach, O. Achievement of sustainable development goals through the implementation of circular economy and developing regional cooperation. Energies 2022, 15, 4072. [Google Scholar] [CrossRef]

- Ortiz-de-Montellano, C.G.S.; Samani, P.; van der Meer, Y. How can the circular economy support the advancement of the Sustainable Development Goals (SDGs)? A comprehensive analysis. Sustain. Prod. Consum. 2023, 40, 352–362. [Google Scholar] [CrossRef]

- Vann Yaroson, E.; Chowdhury, S.; Mangla, S.K.; Dey, P.; Chan, F.T.; Roux, M. A systematic literature review exploring and linking circular economy and sustainable development goals in the past three decades (1991–2022). Int. J. Prod. Res. 2024, 62, 1399–1433. [Google Scholar] [CrossRef]

- Engelman, R. Beyond Sustainababble. In State of the World 2013; Island Press: Washington, DC, USA, 2013; pp. 3–16. [Google Scholar] [CrossRef]

- UNEP. Towards a Green Economy: Pathways to Sustainable Development and Poverty Eradication; United Nations Environment Programme: Nairobi, Kenya, 2011. [Google Scholar]

- MacArthur, E. Towards the circular economy. J. Ind. Ecol. 2013, 2, 23–44. [Google Scholar]

- Federal Highway Administration (FHWA). Transportation Applications of Recycled Concrete Aggregate, 1st ed.; FHWA: Washington, DC, USA, 2004; pp. 1–38.

- Begum, R.A.; Satari, S.K.; Pereira, J.J. Waste generation and recycling: Comparison of conventional and industrialized building systems. Am. J. Environ. Sci. 2010, 6, 383–388. [Google Scholar] [CrossRef]

- Hassim, S.; Jaafar, M.S.; Sazalli, S.A. The contractor perception towards industrialised building system risk in construction projects in Malaysia. Am. J. Appl. Sci. 2009, 6, 937–942. [Google Scholar] [CrossRef]

- Nie, P.; Dahanayake, K.C.; Sumanarathna, N. Exploring UAE’s transition towards circular economy through construction and demolition waste management in the pre-construction stage–A case study approach. Smart Sustain. Built Environ. 2024, 13, 246–266. [Google Scholar] [CrossRef]

- James, M.N.; Choi, W.; Abu-Lebdeh, T. Use of recycled aggregate and fly ash in concrete pavement. Am. J. Eng. Appl. Sci. 2011, 4, 201–208. [Google Scholar] [CrossRef]

- Hamoush, S.; Abu-Lebdeh, T.; Picornell, M.; Amer, S. Development of sustainable engineered stone cladding for toughness, durability, and energy conservation. Constr. Build. Mater. 2011, 25, 4006–4016. [Google Scholar] [CrossRef]

- Batayneh, M.; Marie, I.; Asi, I. Use of selected waste materials in concrete mixes. Waste Manag. 2007, 27, 1870–1876. [Google Scholar] [CrossRef]

- Voukkali, I.; Papamichael, I.; Loizia, P.; Zorpas, A.A. Urbanization and solid waste production: Prospects and challenges. Environ. Sci. Pollut. Res. 2024, 31, 17678–17689. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Tang, J.T.; Zhang, S.; Dong, L.; Hu, L.; Meng, X.; Zhao, Y.; Feng, P. Carbon emissions of durable FRP composite structures in civil engineering. Eng. Struct. 2024, 315, 118482. [Google Scholar] [CrossRef]

- Rindl, J. Recycling Manager, Report by Recycling Manager; Dane County, Department of Public Works: Madison, WI, USA, 1998.

- Shayan, A.; Xu, A. Value-added utilisation of waste glass in concrete. Cem. Concr. Res. 2004, 34, 81–89. [Google Scholar] [CrossRef]

- Yang, S.; Kjartanson, B.H.; Lohnes, R.A. Structural performance of scrap tire culverts. Can. J. Civ. Eng. 2001, 28, 179–189. [Google Scholar] [CrossRef]

- Huang, B.; Li, G.; Pang, S.S.; Eggers, J. Investigation into waste tire rubber-filled concrete. J. Mater. Civ. Eng. 2004, 16, 187–194. [Google Scholar] [CrossRef]

- Atstaja, D.; Cudecka-Purina, N.; Koval, V.; Kuzmina, J.; Butkevics, J.; Hrinchenko, H. Waste-to-Energy in the Circular Economy Transition and Development of Resource-Efficient Business Models. Energies 2024, 17, 4188. [Google Scholar] [CrossRef]

- Zueva, S.; Ferella, F.; Corradini, V.; Vegliò, F. Review of Organic Waste-to-Energy (OWtE) Technologies as a Part of a Sustainable Circular Economy. Energies 2024, 17, 3797. [Google Scholar] [CrossRef]

- Schiller, G.; Gao, X.; Lanau, M.; Blum, A.; Zhang, N.; Çıdık, M.S. How does space matter? On the importance of embedding spatialities in industrial ecology frameworks for circularity in the built environment. J. Ind. Ecol. 2025, 29, 645–655. [Google Scholar] [CrossRef]

- Panda, U. Circular Economy: A Systematic Paradigm for Transition from ‘Soil to Silver’ toward a Sustainable Future. Circ. Econ. Sustain. 2024, 5, 1471–1482. [Google Scholar] [CrossRef]

- Genc, O. Harmony in industry and nature: Exploring the intersection of industrial symbiosis and food webs. Circ. Econ. Sustain. 2025, 5, 79–100. [Google Scholar] [CrossRef]

- Shamsuddoha, M.; Kashem, M.A.; Nasir, T.; Hossain, N.U.I. From Industry 4.0 to Industry 5.0: Transitioning to circular business paradigms—A review. In Handbook of Digital Innovation, Transformation, and Sustainable Development in a Post-Pandemic Era; CRC Press: Boca Raton, FL, USA, 2025; pp. 215–231. [Google Scholar]

- Paiva, T. A Systematic Review of Driving Sustainability Through Circular Economy Marketing: Insights and Strategies for Green Marketing Innovation. Encyclopedia 2025, 5, 61. [Google Scholar] [CrossRef]

- Afzal, M.A.; Rahman, S.U.; Aslam, M.T. Mapping the Nexus of Sustainability, Innovation, and Renewable Energy: A Bibliometric Analysis of Green Technology Research. Crit. Rev. Soc. Sci. Stud. 2025, 3, 1176–1200. [Google Scholar] [CrossRef]

- Chou, J.R. An integrative review exploring the development of sustainable product design in the technological context of Industry 4.0. Adv. Eng. Inform. 2024, 62, 102689. [Google Scholar] [CrossRef]

- Leong, T.H.; Zainordin, N.B.; Mohammad, N.A.; Rasdi, M.T.M. Defining Key Elements for Sustainable Interior Architectural Education via Systematic Literature Review. Future Cities Environ. 2024, 10, 11. [Google Scholar] [CrossRef]

- Raman, R.; Sreenivasan, A.; Suresh, M.; Nedungadi, P. Mapping biomimicry research to sustainable development goals. Sci. Rep. 2024, 14, 18613. [Google Scholar] [CrossRef]

- Jones, R.V.; Fuertes, A.; Scherer, R.; Clements-Croome, D. Opinion: Applications of and barriers to the use of biomimicry towards a sustainable architectural, engineering and construction industry based on interviews from experts and practitioners in the field. Biomimetics 2024, 9, 470. [Google Scholar] [CrossRef] [PubMed]

- Rodgers, V.L.; Deets, S.; Foster, S.; Schmitz, P.; Way, M. An interdisciplinary, co-teaching approach to a course in urban social-ecological systems. Urban Ecosyst. 2025, 28, 93. [Google Scholar] [CrossRef]

- Fischer, J.; Farny, S.; Abson, D.J.; Zuin Zeidler, V.; von Salisch, M.; Schaltegger, S.; Martín-López, B.; Temperton, V.M.; Kümmerer, K. Mainstreaming regenerative dynamics for sustainability. Nat. Sustain. 2024, 7, 964–972. [Google Scholar] [CrossRef]

- Yu, Y.; Junjan, V.; Yazan, D.M.; Iacob, M.E. A systematic literature review on Circular Economy implementation in the construction industry: A policy-making perspective. Resour. Conserv. Recycl. 2022, 183, 106359. [Google Scholar] [CrossRef]

- Schandl, H.; Boxall, N.J.; MacMillan, C.; Porter, N.; Terhorst, A.; Kong, T.; Walton, A.; Skidmore, M.; Muhlhausler, B.; Hodgkinson, J.; et al. Mission-Oriented Research and Theory of Change: Driving Australia’s Transition to a Circular Economy. Circ. Econ. Sustain. 2024, 5, 837–850. [Google Scholar] [CrossRef]

- Dzhengiz, T.; Miller, E.M.; Ovaska, J.P.; Patala, S. Unpacking the circular economy: A problematizing review. Int. J. Manag. Rev. 2023, 25, 270–296. [Google Scholar] [CrossRef]

- Sarkar, A. Minimalonomics: A novel economic model to address environmental sustainability and earth’s carrying capacity. J. Clean. Prod. 2022, 371, 133663. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: The concept and its limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Lahane, S.; Prajapati, H.; Kant, R. Emergence of circular economy research: A systematic literature review. Manag. Environ. Qual. 2021, 32, 575–595. [Google Scholar] [CrossRef]

- Sánchez-Ortiz, J.; Rodríguez-Cornejo, V.; Del Río-Sánchez, R.; García-Valderrama, T. Indicators to measure efficiency in circular economies. Sustainability 2020, 12, 4483. [Google Scholar] [CrossRef]

- Shpak, N.; Kuzmin, O.; Melnyk, O.; Ruda, M.; Sroka, W. Implementation of a circular economy in Ukraine: The context of European integration. Resources 2020, 9, 96. [Google Scholar] [CrossRef]

- Kristensen, H.S.; Mosgaard, M.A. A review of micro level indicators for a circular economy–moving away from the three dimensions of sustainability? J. Clean. Prod. 2020, 243, 118531. [Google Scholar] [CrossRef]

- Kravchenko, M.; Pigosso, D.C.; McAloone, T.C. Towards the ex-ante sustainability screening of circular economy initiatives in manufacturing companies: Consolidation of leading sustainability-related performance indicators. J. Clean. Prod. 2019, 241, 118318. [Google Scholar] [CrossRef]

- Alamerew, Y.A.; Brissaud, D. Circular economy assessment tool for end of life product recovery strategies. J. Remanuf. 2019, 9, 169–185. [Google Scholar] [CrossRef]

- Keles, C.; Cruz Rios, F.; Hoque, S. Digital technologies and circular economy in the construction sector: A review of lifecycle applications, integrations, potential, and limitations. Buildings 2025, 15, 553. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Núñez-Cacho Utrilla, P.; Górecki, J.; Maqueira, J.M. Simulation-based management of construction companies under the circular economy concept—Case study. Buildings 2020, 10, 94. [Google Scholar] [CrossRef]

- Lima, L.; Trindade, E.; Alencar, L.; Alencar, M.; Silva, L. Sustainability in the construction industry: A systematic review of the literature. J. Clean. Prod. 2021, 289, 125730. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Alhazmi, H.; Shah, S.A.R.; Anwar, M.K.; Raza, A.; Ullah, M.K.; Iqbal, F. Utilization of polymer concrete composites for a circular economy: A comparative review for assessment of recycling and waste utilization. Polymers 2021, 13, 2135. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Al-Kamaki, Y.S.S. State-of-the-art review: Concrete made of recycled waste PET as fine aggregate. J. Univ. Duhok. 2021, 23, 412–429. [Google Scholar] [CrossRef]

- EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mohamed, A.M. Eco-friendly concrete containing recycled plastic as partial replacement for sand. J. Mater. Res. Technol. 2020, 9, 4631–4643. [Google Scholar] [CrossRef]

- Sau, D.; Shiuly, A.; Hazra, T. Utilization of plastic waste as replacement of natural aggregates in sustainable concrete: Effects on mechanical and durability properties. Int. J. Environ. Sci. Technol. 2024, 21, 2085–2120. [Google Scholar] [CrossRef]

- Legese, A.M.; Mitiku, D.; Feyessa, F.F.; Urgessa, G.; Boru, Y.T. Experimental Study on the Suitability of Waste Plastics and Glass as Partial Replacement of Fine Aggregate in Concrete Production. Constr. Mater. 2024, 4, 581–596. [Google Scholar] [CrossRef]

- Fletcher, I.A.; Welch, S.; Torero, J.L.; Carvel, R.O.; Usmani, A. Behaviour of concrete structures in fire. Therm. Sci. 2007, 11, 37–52. [Google Scholar] [CrossRef]

- Aciu, C.; Ilutiu-Varvara, D.A.; Manea, D.L.; Orban, Y.A.; Babota, F. Recycling of plastic waste materials in the composition of ecological mortars. Procedia Manuf. 2018, 22, 274–279. [Google Scholar] [CrossRef]

- ACI 211.1; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. American Concrete Institute (ACI): Farmington Hills, MI, USA, 2002.

- ASTM C143/C143M; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- BS 1881; Testing Concrete. British Standards Institution (BSI): London, UK, 1983.

- ASTM C597; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C496/C496M; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C293/C293M; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading). ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C138/C138M; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C192/C192M; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2019.

- Pilipenets, O.; Gunawardena, T.; Hui, F.K.P.; Mendis, P.; Aye, L. A novel circular economy framework: Assessing process circularity through resource flow and emissions analysis. Resour. Conserv. Recycl. 2025, 215, 108083. [Google Scholar] [CrossRef]

- Bodnarova, L.; Valek, J.; Novosad, P. Testing of action of direct flame on concrete. Sci. World J. 2015, 2015, 371913. [Google Scholar] [CrossRef] [PubMed]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Velenturf, A.P.; Purnell, P. Principles for a sustainable circular economy. Sustain. Prod. Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

- Kremer, P.D.; Symmons, M.A. Mass timber construction as an alternative to concrete and steel in the Australia building industry: A PESTEL evaluation of the potential. Int. Wood Prod. J. 2015, 6, 138–147. [Google Scholar] [CrossRef]

- Turkyilmaz, A.; Guney, M.; Karaca, F.; Bagdatkyzy, Z.; Sandybayeva, A.; Sirenova, G. A comprehensive construction and demolition waste management model using PESTEL and 3R for construction companies operating in Central Asia. Sustainability 2019, 11, 1593. [Google Scholar] [CrossRef]

- Marsh, A.T.; Velenturf, A.P.; Bernal, S.A. Circular Economy strategies for concrete: Implementation and integration. J. Clean. Prod. 2022, 362, 132486. [Google Scholar] [CrossRef]

- Raza, M.S.; Kunal, R.A.I.; Kumar, D.; Mutahar, A.L.I. Experimental study of physical, fresh-state and strength parameters of concrete incorporating wood waste ash as a cementitious material. J. Mater. Eng. Struct. 2020, 7, 267–276. [Google Scholar]

- Ismail, Z.Z.; Al-Hashmi, E.A. Reuse of waste iron as a partial replacement of sand in concrete. Waste Manag. 2008, 28, 2048–2053. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Khoshnaw, G.; İpek, S. Abrasion and freezing–thawing resistance of pervious concretes containing waste rubbers. Constr. Build. Mater. 2014, 73, 19–24. [Google Scholar] [CrossRef]

- Shahidan, S.; Ranle, N.A.; Zuki, S.S.M.; Khalid, F.S.; Ridzuan, A.R.M.; Nazri, F.M. Concrete incorporated with optimum percentages of recycled polyethylene terephthalate (PET) bottle fiber. Int. J. Integr. Eng. 2018, 10, 1–8. [Google Scholar] [CrossRef]

- Tavakoli, D.; Hashempour, M.; Heidari, A. Use of waste materials in concrete: A review. Pertanika J. Sci. Technol. 2018, 26, 499–522. [Google Scholar]

- Awoyera, P.O.; Ndambuki, J.M.; Akinmusuru, J.O.; Omole, D.O. Characterization of ceramic waste aggregate concrete. HBRC J. 2018, 14, 282–287. [Google Scholar] [CrossRef]

- Qaidi, S.; Al-Kamaki, Y.; Hakeem, I.; Dulaimi, A.F.; Özkılıç, Y.; Sabri, M.; Sergeev, V. Investigation of the physical-mechanical properties and durability of high-strength concrete with recycled PET as a partial replacement for fine aggregates. Front. Mater. 2023, 10, 1101146. [Google Scholar] [CrossRef]

- Moolchandani, K.; Sharma, A.; Kishan, D. Enhancing concrete performance with crumb rubber and waste materials: A study on mechanical and durability properties. Buildings 2024, 14, 161. [Google Scholar] [CrossRef]

- Shukla, B.K.; Bharti, G.; Sharma, P.K.; Sharma, M.; Rawat, S.; Maurya, N.; Srivastava, R.; Srivastav, Y. Sustainable construction practices with recycled and waste materials for a circular economy. Asian J. Civ. Eng. 2024, 25, 5255–5276. [Google Scholar] [CrossRef]

- Hurukadli, P.; Parashar, B.; Shukla, B.K.; Sharma, P.K.; Sihag, P. Predictive modeling of crumb rubber-modified mortar: Insights from ANN, LR, RF, and M5P methods. Asian J. Civ. Eng. 2025, 26, 1621–1633. [Google Scholar] [CrossRef]

- Seifan, M.; Mendoza, S.; Berenjian, A. Mechanical properties and durability performance of fly ash based mortar containing nano-and micro-silica additives. Constr. Build. Mater. 2020, 252, 119121. [Google Scholar] [CrossRef]

- Gayake, S.B.; Desai, A.K. Innovative solutions for potential use of waste polyethylene terephthalate bottle cap as aggregates in concrete. Innov. Infrastruct. Solut. 2024, 9, 314. [Google Scholar] [CrossRef]

- Bhagat, G.V.; Savoikar, P.P. Durability related properties of cement composites containing thermoplastic aggregates—A review. J. Build. Eng. 2022, 53, 104565. [Google Scholar] [CrossRef]

- Hamada, H.M.; Al-Attar, A.; Abed, F.; Beddu, S.; Humada, A.M.; Majdi, A.; Yousif, S.T.; Thomas, B.S. Enhancing sustainability in concrete construction: A comprehensive review of plastic waste as an aggregate material. Sustain. Mater. Technol. 2024, 40, e00877. [Google Scholar] [CrossRef]

- Maurya, N.; Srivastav, Y.; Rawat, S.; Ranjan, Y.; Srivastava, R.; Shukla, B.K.; Varadharajan, S. Reinforcing civil infrastructure with waste glass-enhanced concrete: A comprehensive review of properties, performance and applications. Mater. Today Proc. 2023, 93, 239–248. [Google Scholar] [CrossRef]

- Buddhacosa, N.; Thevakumar, T.; Kandare, E.; Setunge, S.; Robert, D. Impact of manufacturing variables on the mechanical performance of recycled glass-enhanced composites. Clean. Mater. 2025, 15, 100297. [Google Scholar] [CrossRef]

- Bu, C.; Zhu, D.; Liu, L.; Lu, X.; Sun, Y.; Yu, L.; OuYang, Y.; Cao, X.; Wang, F. Research progress on rubber concrete properties: A review. J. Rubber Res. 2022, 25, 105–125. [Google Scholar] [CrossRef]

- Swilam, A.; Tahwia, A.M.; Youssf, O. Effect of rubber heat treatment on rubberized-concrete mechanical performance. J. Compos. Sci. 2022, 6, 290. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Hamada, H.M.; Almeshal, I.; Bakar, B.A. Durability and mechanical properties of cement concrete comprising pozzolanic materials with alkali-activated binder: A comprehensive review. Case Stud. Constr. Mater. 2022, 17, e01429. [Google Scholar] [CrossRef]

- Xu, K.; Yang, J.; He, H.; Wei, J.; Zhu, Y. Influences of Additives on the Rheological Properties of Cement Composites: A Review of Material Impacts. Mater. 2025, 18, 1753. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Letelier, V.; Tarela, E.; Moriconi, G. Mechanical properties of concretes with recycled aggregates and waste brick powder as cement replacement. Procedia Eng. 2017, 171, 627–632. [Google Scholar] [CrossRef]

- Oleynik, P.P.; Olejnik, S.P. Organization of Construction Waste Recycling System; Moscow State University of Civil Engineering: Moscow, Russia, 2009. [Google Scholar]

- VS, S.; Xavier, J.R. Effects of nanomaterials on mechanical properties in cementitious construction materials for high-strength concrete applications: A review. J. Adhes. Sci. Technol. 2024, 38, 3737–3768. [Google Scholar] [CrossRef]

- Anastasiades, K.; Blom, J.; Buyle, M.; Audenaert, A. Translating the circular economy to bridge construction: Lessons learnt from a critical literature review. Renew. Sustain. Energy Rev. 2020, 117, 109522. [Google Scholar] [CrossRef]

- Osmani, M.; Villoria-Sáez, P. Current and emerging construction waste management status, trends and approaches. In Waste; Academic Press: Cambridge, MA, USA, 2019; pp. 365–380. [Google Scholar]

- Abdolmaleki, H.; Ahmadi, Z.; Hashemi, E.; Talebi, S. A review of the circular economy approach to the construction and demolition wood waste: A 4R principle perspective. Clean. Waste Syst. 2025, 11, 100248. [Google Scholar] [CrossRef]

- Mak, T.M.; Chen, P.C.; Wang, L.; Tsang, D.C.; Hsu, S.C.; Poon, C.S. A system dynamics approach to determine construction waste disposal charge in Hong Kong. J. Clean. Prod. 2019, 241, 118309. [Google Scholar] [CrossRef]

- Begum, R.A.; Siwar, C.; Pereira, J.J.; Jaafar, A.H. A benefit–cost analysis on the economic feasibility of construction waste minimisation: The case of Malaysia. Resour. Conserv. Recycl. 2006, 48, 86–98. [Google Scholar] [CrossRef]

- Khahro, S.H.; Kumar, D.; Siddiqui, F.H.; Ali, T.H.; Raza, M.S.; Khoso, A.R. Optimizing energy use, cost and carbon emission through building information modelling and a sustainability approach: A case-study of a hospital building. Sustainability 2021, 13, 3675. [Google Scholar] [CrossRef]

- Guo, Z.; Sun, Q.; Zhou, L.; Jiang, T.; Dong, C.; Zhang, Q. Mechanical properties, durability and life-cycle assessment of waste plastic fiber reinforced sustainable recycled aggregate self-compacting concrete. J. Build. Eng. 2024, 91, 109683. [Google Scholar] [CrossRef]

- Alfahdawi, I.H.; Osman, S.A.; Hamid, R.; Al-Hadithi, A.I. Influence of PET wastes on the environment and high-strength concrete properties exposed to high temperatures. Constr. Build. Mater. 2019, 225, 358–370. [Google Scholar] [CrossRef]

- Singh, V.; SinghRana, A. Enhancing Sustainability in Concrete Construction: Utilizing LDPE and HDPE Plastics as Fine Aggregate Replacements. Rock Soil Mech. 2025, 4, 526–536. [Google Scholar] [CrossRef]

- Albsoul, H.; Doan, D.T.; GhaffarianHoseini, A. Estimating construction waste in New Zealand: A focus on urban areas, residential and non-residential building activities. Environ. Res. Commun. 2024, 6, 035009. [Google Scholar] [CrossRef]

- Zou, P.; Hardy, R.; Yang, R. Barriers to building and construction waste reduction, reuse and recycling: A case study of the Australian Capital Region. J. Constr. Dev. 2015, 5, 18–27. [Google Scholar]

- Cárcel-Carrasco, J.; Peñalvo-López, E.; Pascual-Guillamón, M.; Salas-Vicente, F. An overview about the current situation on C&D waste management in Italy: Achievements and challenges. Buildings 2021, 11, 284. [Google Scholar] [CrossRef]

- Ruiz, L.A.L.; Ramón, X.R.; Domingo, S.G. The circular economy in the construction and demolition waste sector–A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Gorak, P.; Postawa, P.; Trusilewicz, L.N.; Łagosz, A. Lightweight PET-based composite aggregates in Portland cement materials—Microstructure and physicochemical performance. J. Build. Eng. 2021, 34, 101882. [Google Scholar] [CrossRef]

- Meza, A.; Pujadas, P.; Meza, L.M.; Pardo-Bosch, F.; López-Carreño, R.D. Mechanical optimization of concrete with recycled PET fibres based on a statistical-experimental study. Materials 2021, 14, 240. [Google Scholar] [CrossRef] [PubMed]

- Alani, A.H.; Bunnori, N.M.; Noaman, A.T.; Majid, T.A. Durability performance of a novel ultra-high-performance PET green concrete (UHPPGC). Constr. Build. Mater. 2019, 209, 395–405. [Google Scholar] [CrossRef]

- Marchuk, J. Circular Economy in Construction Sector: Barriers for Scaling Up Construction Materials Reuse in Trondheim Region, Norway. Master’s Thesis, NTNU, Trondheim, Norway, 2020. [Google Scholar]

- Peisino, L.E.; del Mar Barbero-Barrera, M.; García-Castro, C.B.; Kreiker, J.; Gaggino, R. Assessment of the mechanical and physical characteristics of PET bricks with different aggregates. J. Environ. Manag. 2024, 357, 120720. [Google Scholar] [CrossRef] [PubMed]

- Shooshtarian, S.; Caldera, S.; Maqsood, T.; Ryley, T. Using recycled construction and demolition waste products: A review of stakeholders’ perceptions, decisions, and motivations. Recycling 2020, 5, 31. [Google Scholar] [CrossRef]

- Sáez, P.V.; Osmani, M. A diagnosis of construction and demolition waste generation and recovery practice in the European Union. J. Clean. Prod. 2019, 241, 118400. [Google Scholar] [CrossRef]

- Geng, Y.; Doberstein, B. Developing the circular economy in China: Challenges and opportunities for achieving ‘leapfrog development’. Int. J. Sustain. Dev. World Ecol. 2008, 15, 231–239. [Google Scholar] [CrossRef]

- Esa, M.R.; Halog, A.; Rigamonti, L. Developing strategies for managing construction and demolition wastes in Malaysia based on the concept of circular economy. J. Mater. Cycles Waste Manag. 2017, 19, 1144–1154. [Google Scholar] [CrossRef]

- Kok, L.; Wurpel, G.; Ten Wolde, A. Unleashing the Power of the Circular Economy; Circle Economy: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Esa, M.R.; Halog, A.; Rigamonti, L. Strategies for minimizing construction and demolition wastes in Malaysia. Resour. Conserv. Recycl. 2017, 120, 219–229. [Google Scholar] [CrossRef]

- Rohani, M.; Huang, T.; Hoffman, L.; Roberts, M.; Ribeiro, B. Cost Benefit Analysis of Construction And demolition Waste Diversion from Landfill. A Case Study Based on HLC Ltd. Development in Auckland; Auckland Council: Auckland, New Zealand, 2019; p. TR2019/012. [Google Scholar]

- Purchase, C.K.; Al Zulayq, D.M.; O’Brien, B.T.; Kowalewski, M.J.; Berenjian, A.; Tarighaleslami, A.H.; Seifan, M. Circular economy of construction and demolition waste: A literature review on lessons, challenges, and benefits. Materials 2021, 15, 76. [Google Scholar] [CrossRef]

- Yuan, Z.; Bi, J.; Moriguichi, Y. The circular economy: A new development strategy in China. J. Ind. Ecol. 2006, 10, 4–8. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Rahim, A.A.F. Experimental behavior and analysis of high-strength concrete beams reinforced with PET waste fiber. Constr. Build. Mater. 2020, 244, 118350. [Google Scholar] [CrossRef]

- Taghavi Parsa, M.H.; Adlparvar, M.R.; Esmaeili, M. Predicting the Mechanical Strengths of Steel Fiber–Reinforced Concrete Using Machine-Learning Methods and Feature Selection Techniques. J. Struct. Des. Constr. Pract. 2025, 30, 04025045. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Shahmansouri, A.A.; Fakoor, M. Post-fire compressive strength of recycled PET aggregate concrete reinforced with steel fibers: Optimization and prediction via RSM and GEP. Constr. Build. Mater. 2020, 252, 119057. [Google Scholar] [CrossRef]

- Sarde, B.; Patil, Y.D.; Dholakiya, B.; Pawar, V. Evaluation of effect of red mud and fly ash as filler on the properties of modified PET resin polymer mortar composite. Innov. Infrastruct. Solut. 2025, 10, 117. [Google Scholar] [CrossRef]

- Djamaluddin, A.R.; Pasra, M.; Arsyad, A. Strength and toughness characteristics of AC-WC mixture containing PET and PP plastic waste under static compression. GEOMATE J. 2021, 20, 20–27. [Google Scholar]

- Mishra, V.; Ror, C.K.; Negi, S.; Veeman, D. Recycling PET Waste into Functional 3D Printing Material: Effect of Printing Temperature on Physio-mechanical Properties of PET Parts. J. Mater. Eng. Perform. 2025. [Google Scholar] [CrossRef]

- Perera, S.; Arulrajah, A.; Wong, Y.C.; Horpibulsuk, S.; Maghool, F. Utilizing recycled PET blends with demolition wastes as construction materials. Constr. Build. Mater. 2019, 221, 200–209. [Google Scholar] [CrossRef]

- Nyah, E.; Onwuka, D.O.; Arimanwa, J.I.; Alaneme, G.U.; Nakkeeran, G.; Onwuka, U.S.; Okere, C.E. ANFIS modelling of the strength properties of natural rubber latex modified concrete. Discov. Appl. Sci. 2025, 7, 472. [Google Scholar] [CrossRef]

- Zapała-Sławeta, J.; Mazurek, G.; Woś, J. Analysis of the Influence of PET and Glass Packaging Waste Materials on the Physical and Mechanical Properties of Cementitious Composites. Appl. Sci. 2023, 13, 12409. [Google Scholar] [CrossRef]

- Karati, S.; Roy, T.K. Evaluation of Moisture Impact on Bituminous Mixtures Enhanced with Reclaimed Asphalt Pavement and Sawdust Ash. J. Mater. Civ. Eng. 2025, 37, 04025265. [Google Scholar] [CrossRef]

- Limami, H.; Manssouri, I.; Cherkaoui, K.; Khaldoun, A. Study of the suitability of unfired clay bricks with polymeric HDPE & PET wastes additives as a construction material. J. Build. Eng. 2020, 27, 100956. [Google Scholar] [CrossRef]

- Esfandabad, A.S.; Motevalizadeh, S.M.; Sedghi, R.; Ayar, P.; Asgharzadeh, S.M. Fracture and mechanical properties of asphalt mixtures containing granular polyethylene terephthalate (PET). Constr. Build. Mater. 2020, 259, 120410. [Google Scholar] [CrossRef]

- Yavaş, A.; Kalkan, Ş.O.; Sütçü, M.; Gündüz, L. Recycling waste polyethylene foam into fired clay bricks: A sustainable solution for lightweight and thermally efficient building materials. Constr. Build. Mater. 2025, 473, 140967. [Google Scholar] [CrossRef]

- Salim, A.; Tumpu, M.; Yunus, A.Y.; Yusuf, A.R.; Gusty, S. Accelerating Plastic Pollution Mitigation through Sustainable Urban Infrastructure Development. Eng. Technol. Appl. Sci. Res. 2024, 14, 17665–17671. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F. Design for adaptability and disassembly: Guidelines for building deconstruction. Constr. Innov. 2025, 25, 665–687. [Google Scholar] [CrossRef]

- Weiss, M.; Haufe, J.; Carus, M.; Brandão, M.; Bringezu, S.; Hermann, B.; Patel, M.K. A review of the environmental impacts of biobased materials. J. Ind. Ecol. 2012, 16, S169–S181. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Tseng, M.L.; Grybauskas, A.; Stefanini, A.; Amran, A. Behind the definition of Industry 5.0: A systematic review of technologies, principles, components, and values. J. Ind. Prod. Eng. 2023, 40, 432–447. [Google Scholar] [CrossRef]

- Robèrt, K.H.; Broman, G.I.; Basile, G. Analyzing the concept of planetary boundaries from a strategic sustainability perspective: How does humanity avoid tipping the planet? Ecol. Soc. 2013, 18, 5. [Google Scholar] [CrossRef]

- Berglund, E.Z.; Monroe, J.G.; Ahmed, I.; Noghabaei, M.; Do, J.; Pesantez, J.E.; Khaksar Fasaee, M.A.; Bardaka, E.; Han, K.; Proestos, G.T.; et al. Smart infrastructure: A vision for the role of the civil engineering profession in smart cities. J. Infrastruct. Syst. 2020, 26, 03120001. [Google Scholar] [CrossRef]

- Jansen, B.W.; van Stijn, A.; Eberhardt, L.C.M.; van Bortel, G.; Gruis, V. The technical or biological loop? Economic and environmental performance of circular building components. Sustain. Prod. Consum. 2022, 34, 476–489. [Google Scholar] [CrossRef]

- Rodias, E.; Aivazidou, E.; Achillas, C.; Aidonis, D.; Bochtis, D. Water-energy-nutrients synergies in the agrifood sector: A circular economy framework. Energies 2020, 14, 159. [Google Scholar] [CrossRef]

- Peng, X.; Jiang, Y.; Chen, Z.; Osman, A.I.; Farghali, M.; Rooney, D.W.; Yap, P.S. Recycling municipal, agricultural and industrial waste into energy, fertilizers, food and construction materials, and economic feasibility: A review. Environ. Chem. Lett. 2023, 21, 765–801. [Google Scholar] [CrossRef]

- Sáez-de-Guinoa, A.; Zambrana-Vasquez, D.; Fernández, V.; Bartolomé, C. Circular economy in the European construction sector: A review of strategies for implementation in building renovation. Energies 2022, 15, 4747. [Google Scholar] [CrossRef]

- Korhonen, J.; Snäkin, J.P. Quantifying the relationship of resilience and eco-efficiency in complex adaptive energy systems. Ecol. Econ. 2015, 120, 83–92. [Google Scholar] [CrossRef]

- Sparrevik, M.; De Boer, L.; Michelsen, O.; Skaar, C.; Knudson, H.; Fet, A.M. Circular economy in the construction sector: Advancing environmental performance through systemic and holistic thinking. Environ. Syst. Decis. 2021, 41, 392–400. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Implementing circular economy strategies in buildings—From theory to practice. Appl. Syst. Innov. 2021, 4, 26. [Google Scholar] [CrossRef]

- Fabbri, D.; Pizzol, R.; Calza, P.; Malandrino, M.; Gaggero, E.; Padoan, E.; Ajmone-Marsan, F. Constructed technosols: A strategy toward a circular economy. Appl. Sci. 2021, 11, 3432. [Google Scholar] [CrossRef]

- Demirbağ, A.T.; Aladağ, H.; Işık, Z.; Skibniewski, M.J. Circular Economy-Based Decision-Making Model for Contractor Selection. Buildings 2025, 15, 1665. [Google Scholar] [CrossRef]

- Markou, I.; Sinnott, D.; Thomas, K. Current methodologies of creating Material Passports: A Systematic Literature Review. Case Stud. Constr. Mater. 2025, 22, e04267. [Google Scholar] [CrossRef]

- Armistead, S.J.; Babaahmadi, A. Navigating regulatory challenges, technical performance and circular economy integration of mineral-based waste materials for sustainable construction: A mini review in the European context. Waste Manag. Res. 2025, 43, 674–683. [Google Scholar] [CrossRef]

- Espuny, M.; Reis, J.S.D.M.; Giupponi, E.C.B.; Rocha, A.B.T.; Costa, A.C.F.; Poltronieri, C.F.; Oliveira, O.J.D. The role of the triple helix model in promoting the circular economy: Government-led integration strategies and practical application. Recycling 2025, 10, 50. [Google Scholar] [CrossRef]

- Durdyev, S.; Koc, K.; Tleuken, A.; Budayan, C.; Ekmekcioğlu, Ö.; Karaca, F. Barriers to circular economy implementation in the construction industry: Causal assessment model. Environ. Dev. Sustain. 2025, 27, 4045–4081. [Google Scholar] [CrossRef]

| Types of Activities | Number of Enterprises | Solid Waste | Approaches for Solid Waste Disposal | |||||

|---|---|---|---|---|---|---|---|---|

| Quantity of Solid Wastes | Enterprises That Produce Wastes | Storage | Incineration | Collection | Selling | Burial | ||

| Site preparation | 22 | 8.1 | 18 | 0.0 | 0.0 | 8.1 | 0.0 | 0.0 |

| Building Installation | 422 | 226.6 | 172 | 0.0 | 0.0 | 225.3 | 1.3 | 0.0 |

| Buildings construction and civil eng. projects | 1049 | 1477.5 | 414 | 0.0 | 40.4 | 1333.0 | 6.8 | 97.3 |

| Building Completion | 6 | 9.6 | 59 | 0.0 | 0.0 | 8.5 | 1.1 | 0.0 |

| Total | 1559 | 1721.8 | 663 | 0.0 | 40.4 | 1574.9 | 9.2 | 97.3 |

| Polymer Type | Estimated No. of Studies (2015–2025) | Representative Sources/Methodology |

|---|---|---|

| PET (Polyethylene Terephthalate) | 80–120 | Scopus bibliometric query; validated in [60,61]; reviewed in [62] |

| HDPE (High-Density Polyethylene) | 15–25 | Bibliometric screening; limited coverage in [60] |

| LDPE (Low-Density Polyethylene) | 10–20 | Cited in niche applications in [61]; confirmed via Scopus [62] |

| PP (Polypropylene) | 10–15 | Noted as fiber reinforcement in [61]; supported by bibliometric screening |

| PVC (Polyvinyl Chloride) | 5–10 | Sparse mentions in [60]; few empirical studies in Scopus bibliometric screening |

| Other polymers (PS, PC, mixed) | <5 | Isolated reports; no consistent trend in Scopus bibliometric screening or reviews |

| Key Target Properties | Standard | Ref. |

|---|---|---|

| Slump | ASTM C 143 | [70] |

| Compressive Strength | BS 1881 | [71] |

| Pulse Velocity | ASTM C 597 | [72] |

| Fresh Concrete | ||

| Splitting Tensile Strength | ASTM C 496 | [73] |

| Hardened Concrete | ||

| Flexural Strength | ASTM C 293 | [74] |

| Unit Weight | ASTM C 138 | [75] |

| Recycled Material Type | Year | Replacement Level (%) | Key Findings | Target Property Studied | Ref. |

|---|---|---|---|---|---|

| Waste iron | 2008 | 10–20 | Increased compressive and flexural strength up to 17.4% and 27.9%, respectively, at 20%; increased fresh and dry density. | Compressive strength, Flexural strength, Density | [85] |

| Rubber aggregates | 2014 | 10–20 | Enhanced abrasion and freeze–thaw resistance; improved durability due to increased micro-pore content. | Durability, Abrasion, Freeze-thaw resistance | [86] |

| Waste PET (polymer bottles) | 2018 | 0.5–2.0 (volume %) | Workability reduced, optimum tensile strength observed at 1.0% replacement. | Mechanical strength, Workability | [87] |

| Glass powder | 2018 | 10–20 | Improved durability; enhanced compressive strength at 10% replacement. | Compressive strength, Durability | [88] |

| Mixed waste (polymer, Glass, Ceramics) | 2018 | 10–50 | Performance comparable to control at lower substitution ratios. | General performance | [87,88,89] |

| Shredded PET | 2023 | 10–40 | Compressive strength improved up to 10% replacement; reduced workability; density; lightweight concrete achieved. | Mechanical strength, Density, Workability | [90] |

| Tire rubber (TR) and fly ash (FA) | 2024 | TR: 10; FA: 15 | Durability improved; minor strength loss observed. | Durability, Compressive Strength | [91] |

| Recycled aggregate | 2024 | 20–50 | Effective up to 40%; quality depends on pre-treatment. | General strength and durability | [92] |

| Recycled polymer (as sand replacement) | 2024 | 5–30 | Up to 20% replacement led to ~8–10% reduction in density and comparable strength; good thermal resistance. | Workability, Strength, Sustainability | |

| Crumb rubber | 2025 | 2.5–7.5 | Reduced compressive strength; ductility and toughness enhanced, suitable for non-structural and plastering applications. | Compressive strength, Ductility | [93] |

| Material | Benefits | Ref. |

|---|---|---|

| Polymers | Enhanced ductility, minimized shrinkage cracks, and lightweight characteristics. | [94,95,96,97] |

| Glass | Pozzolanic characteristics, reduced shrinkage, high thermal conductivity, lower ecological impact, and better water absorption. | [98,99] |

| Rubber | Improved Heat Resistance and Strength Properties. | [86,100,101] |

| Concrete | Pozzolanic characteristics, reduced shrinkage, high thermal conductivity, lower ecological impact, and better water absorption. | [102,103] |

| Ceramics | Improved strength, optimal water absorption, reduced weight, and enhanced pozzolanic nature. | [87] |

| Coir and Almond Wastes | Improved mechanical strength, higher air content, and reduced air density. | [89,98] |

| Country | Concentration of Construction Waste in Total Waste (%) | C&D Waste Recycled (%) | Ref. |

|---|---|---|---|

| United Kingdom | 70 | 17 | [115,116] |

| United States of America | 50 | 40 | [117] |

| New Zealand | 50 | 28 | [118] |

| Australia | 44 | 51 | [114,119] |

| Italy | 36 | 65 | [120,121] |

| Netherlands | 30 | 10 | [122] |

| Spain | 30 | 7 | [123] |

| Finland | 29 | 25 | [124] |

| Norway | 26 | 75 | [125,126] |

| Denmark | 25–50 | 80 | [127,128,129] |

| Germany | 25 | 20–30 | [130,131] |

| Japan | 19 | 40–60 | [132] |

| Brazil | 15 | 8 | [133,134] |

| France | 14 | 40 | [135] |

| Expenditure | USD/Tonne |

|---|---|

| Wood chipping | 20 |

| Wood sorting | 40–126 |

| Concrete sorting | 7 |

| Concrete crushing | 8 |

| Concrete preparation | 4 |

| Types of Materials | Application Area | Composite/Mix Description | Key Outcomes/Performance Gains | Ref. |

|---|---|---|---|---|

| PET | Concrete | PET + fly ash-based aggregates | 10–25% replacement; improved strength; no PET degradation | [125] |

| PET fibers (up to 1%) in OPC concrete | +15% tensile toughness; improved shrinkage resistance | [123] | ||

| PET fibers with statistical optimization | Fiber dosage more dominant than aspect ratio; improved tensile strength | |||

| PET + recycled aggregate (self-compacting) | +41% compressive, +83% flexural, +19% tensile strength; −9.7% shrinkage; −73% environmental burdens | [115] | ||

| 0.25% PET + 30–40% FA | Improved ambient strength; reduced porosity by 50%; prevented spalling at 700 °C | [116] | ||

| PET + UPOFA blends (UHPPGC) | Lower porosity, improved chloride resistance; energy savings | [124] | ||

| PET + steel hybrid reinforced beams | Better crack control; ACI-compliant moment predictions | [136] | ||

| XGBoost model for fiber strength prediction | 30% higher accuracy over SVM; fiber geometry influences all strengths | [137] | ||

| 10% PET chip replacement under post-fire (600 °C) | Maintained strength without steel fibers; thermally resilient | [138] | ||

| Mortar | Hybrid PET–PVA strain-hardening mix | Enhanced tensile behavior with surface-treated PET | [87] | |

| PET + red mud/fly ash filler | +4.05% (compressive), +7.69% (tensile), +21.52% (flexural); thermal stability | [139] | ||

| PET/PP waste with Buton Asphalt | Improved compressive strength; Poisson’s ratio within standards | [140] | ||

| RPET-CF for 3D printable mortar | Tensile strength 47.3 MPa; low warpage; excellent bonding | [141] | ||

| Paving | PET + RCA + carbon black (3–5%) | Passed CBR and RLT standards for subbase; improved geo-environmental safety | [142] | |

| Bricks | PET + demolition waste (non-structural) | Achieved 2 MPa strength; good bulk density and hydric control | [126] | |

| Rubber | Concrete | Crumb rubber (10–20%) as aggregate | Abrasion and freeze–thaw resistance improved; compressive strength reduced | [86] |

| Engineered Stone | Crumb rubber + binder system | Toughness and energy dissipation improved | [23] | |

| Fiber-reinforced concrete | Crumb rubber + steel fibers | Enhanced flexural response and impact strength | [30] | |

| Asphalt | Rubber + PET + fly ash blends | Better fire resistance; reduced thermal diffusivity | [143] | |

| Glass | Concrete | Fine glass powder (10–20%) | Compressive strength and long-term durability improved | [88] |

| PET + glass powder | Comparable strength; reduced density | [144] | ||

| Pozzolanic concrete | Glass powder (75 µm) | Optimal reactivity and pozzolanic efficiency under 100 µm | [28] | |

| Mortar | Recycled glass as filler | Strength gains at 10–15%; good workability | [24] | |

| Asphalt | Ground glass + bitumen | Improved surface hardness; better high-temp performance | [145] | |

| LDPE/HDPE | Concrete | LDPE/HDPE as fine aggregate | Reduced environmental impact; improved sustainability and cost-efficiency | [146] |

| LDPE | Asphalt-Concrete | LDPE at 5.25% asphalt content | Improved Marshall properties and Cantabria durability; extended pavement life | [147] |

| Polymer Waste | Unfired Clay Brick | WPEF (up to 7.5%) | Density ↓ ~25%; thermal insulation ↑ ~70%; retained strength and durability | [148,149] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shukla, B.K.; Yadav, H.; Singh, S.; Verma, S.; Shukla, A.K.; Sharma, C. Sustainable Engineering of Recycled Aggregate Concrete: Structural Performance and Environmental Benefits Under Circular Economy Frameworks. Constr. Mater. 2025, 5, 67. https://doi.org/10.3390/constrmater5030067

Shukla BK, Yadav H, Singh S, Verma S, Shukla AK, Sharma C. Sustainable Engineering of Recycled Aggregate Concrete: Structural Performance and Environmental Benefits Under Circular Economy Frameworks. Construction Materials. 2025; 5(3):67. https://doi.org/10.3390/constrmater5030067

Chicago/Turabian StyleShukla, Bishnu Kant, Harshit Yadav, Satvik Singh, Shivam Verma, Anoop Kumar Shukla, and Chetan Sharma. 2025. "Sustainable Engineering of Recycled Aggregate Concrete: Structural Performance and Environmental Benefits Under Circular Economy Frameworks" Construction Materials 5, no. 3: 67. https://doi.org/10.3390/constrmater5030067

APA StyleShukla, B. K., Yadav, H., Singh, S., Verma, S., Shukla, A. K., & Sharma, C. (2025). Sustainable Engineering of Recycled Aggregate Concrete: Structural Performance and Environmental Benefits Under Circular Economy Frameworks. Construction Materials, 5(3), 67. https://doi.org/10.3390/constrmater5030067