Foundry Sand in Sustainable Construction: A Systematic Review of Environmental Performance, Contamination Risks, and Regulatory Frameworks

Abstract

1. Introduction

2. Methods

3. Research Status and Emerging Directions

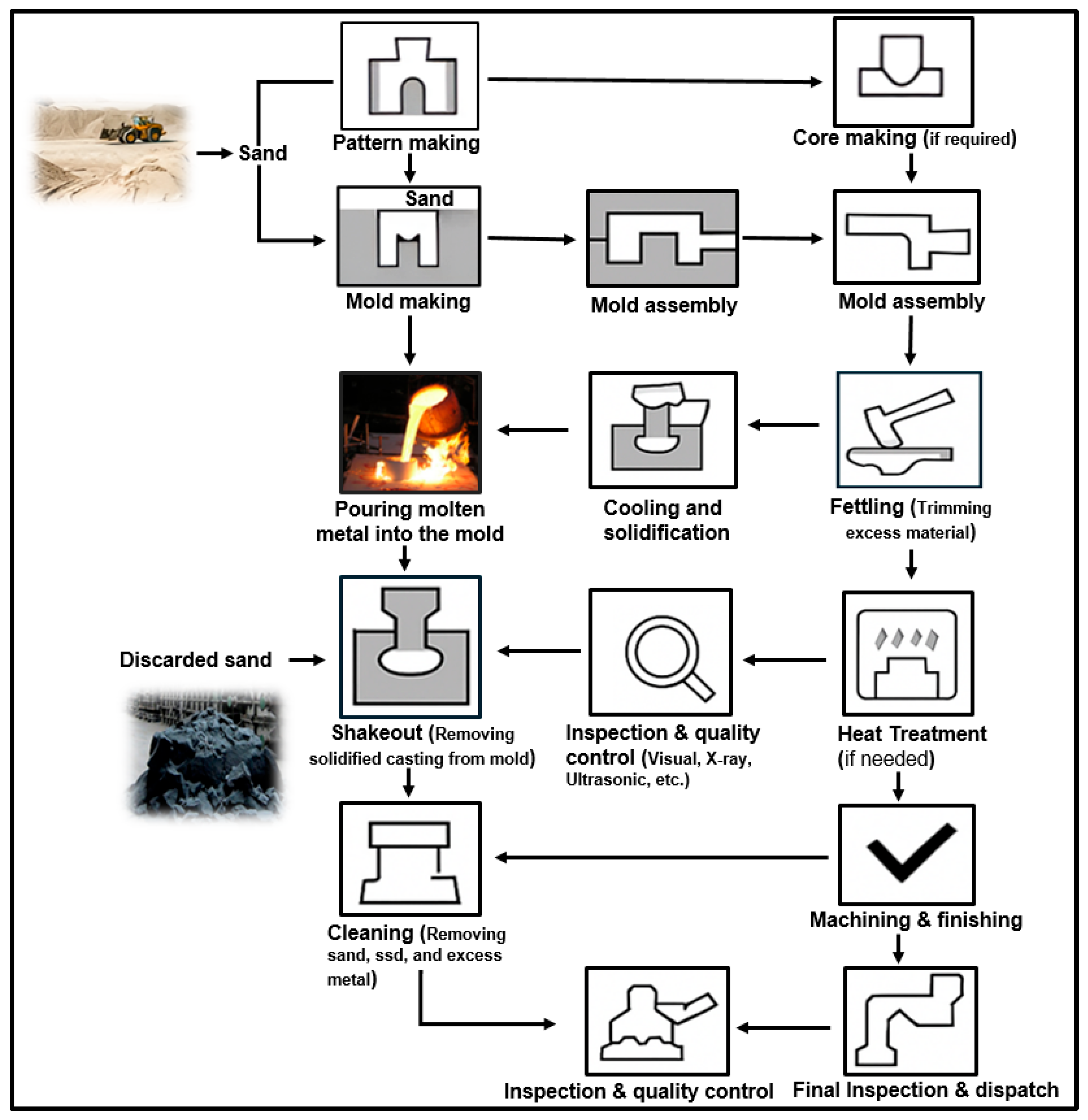

3.1. Sources and Compositions of WFS

3.1.1. Sources

3.1.2. Composition

Chemical Composition

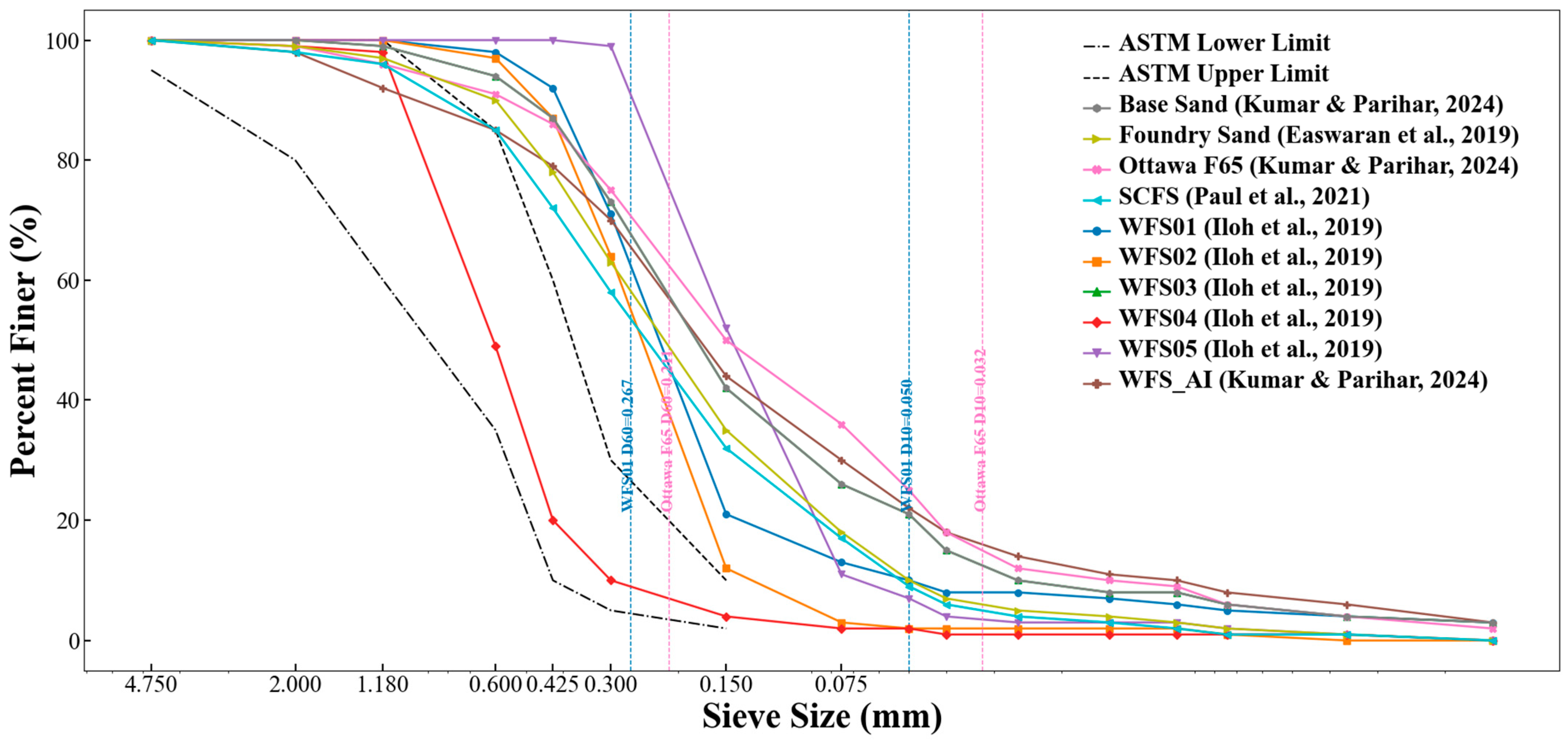

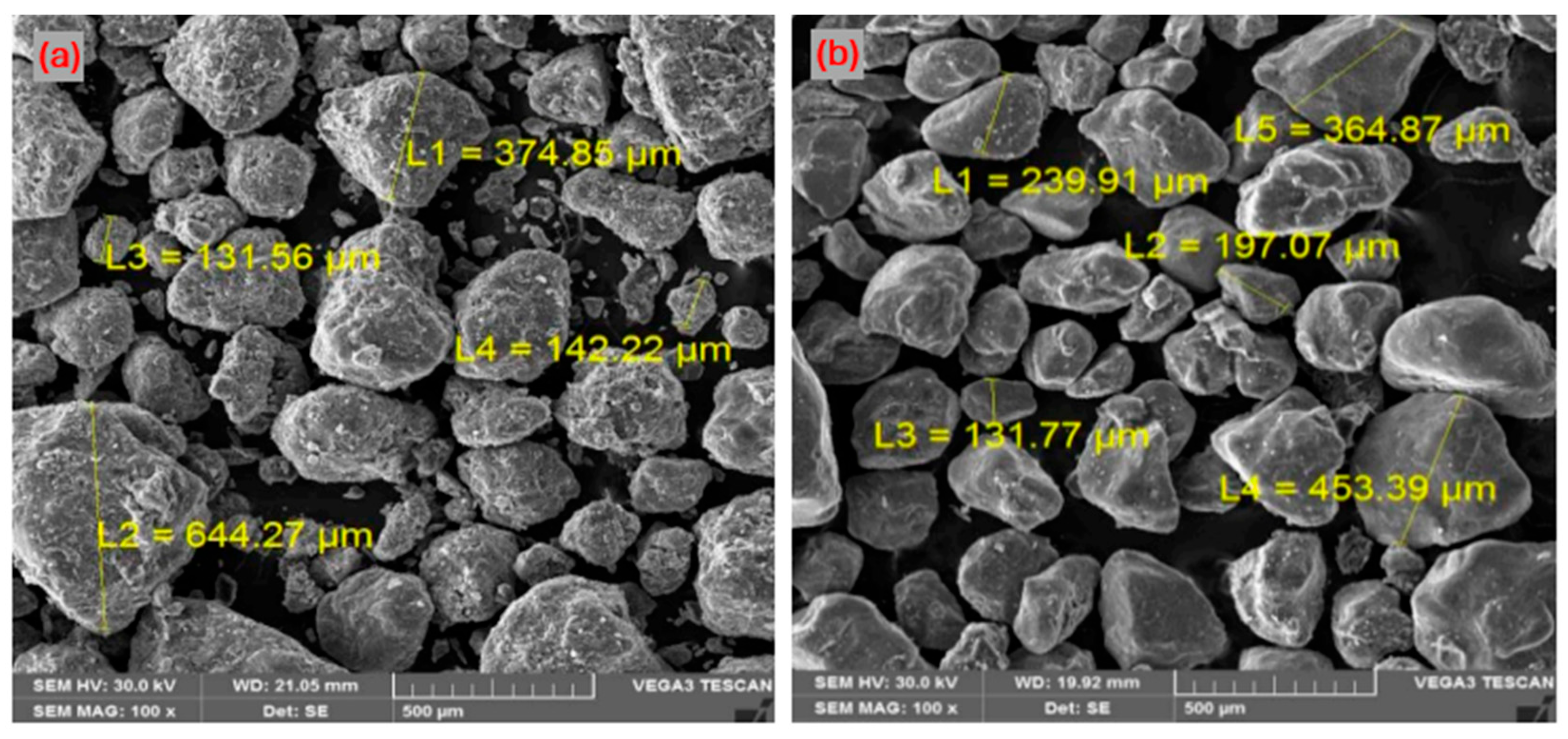

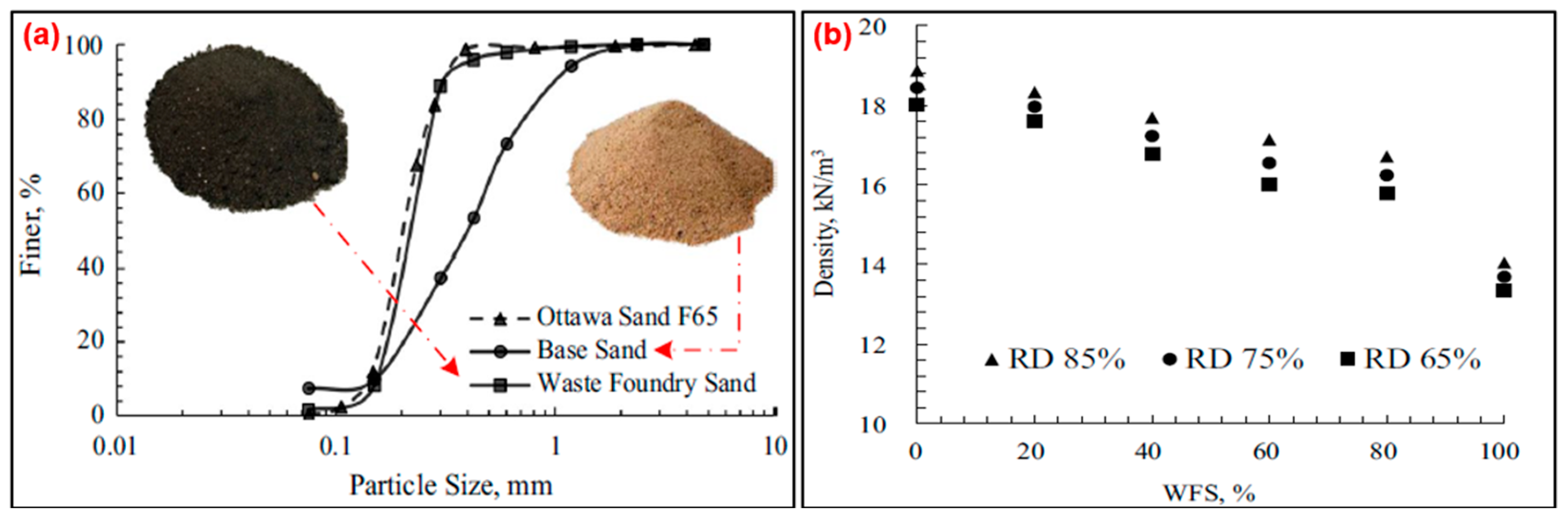

Physical Properties

3.2. Challenges and Environmental Impacts of WFS Disposal

3.3. WFS in Sustainable Construction Materials

3.3.1. Research Progress on the Reuse of WFS

3.3.2. Techno-Economic Analysis of WFS and Its Use in Concrete

3.3.3. Environmental and Durability Impacts of WFS in Sustainable Construction

Environmental Performance: CO2 Emissions and Resource Conservation

Long-Term Durability and Environmental Safety

Advanced Treatment and Quantitative Assessment of Waste Foundry Sand for Construction

3.3.4. Challenges of WFS Reuse

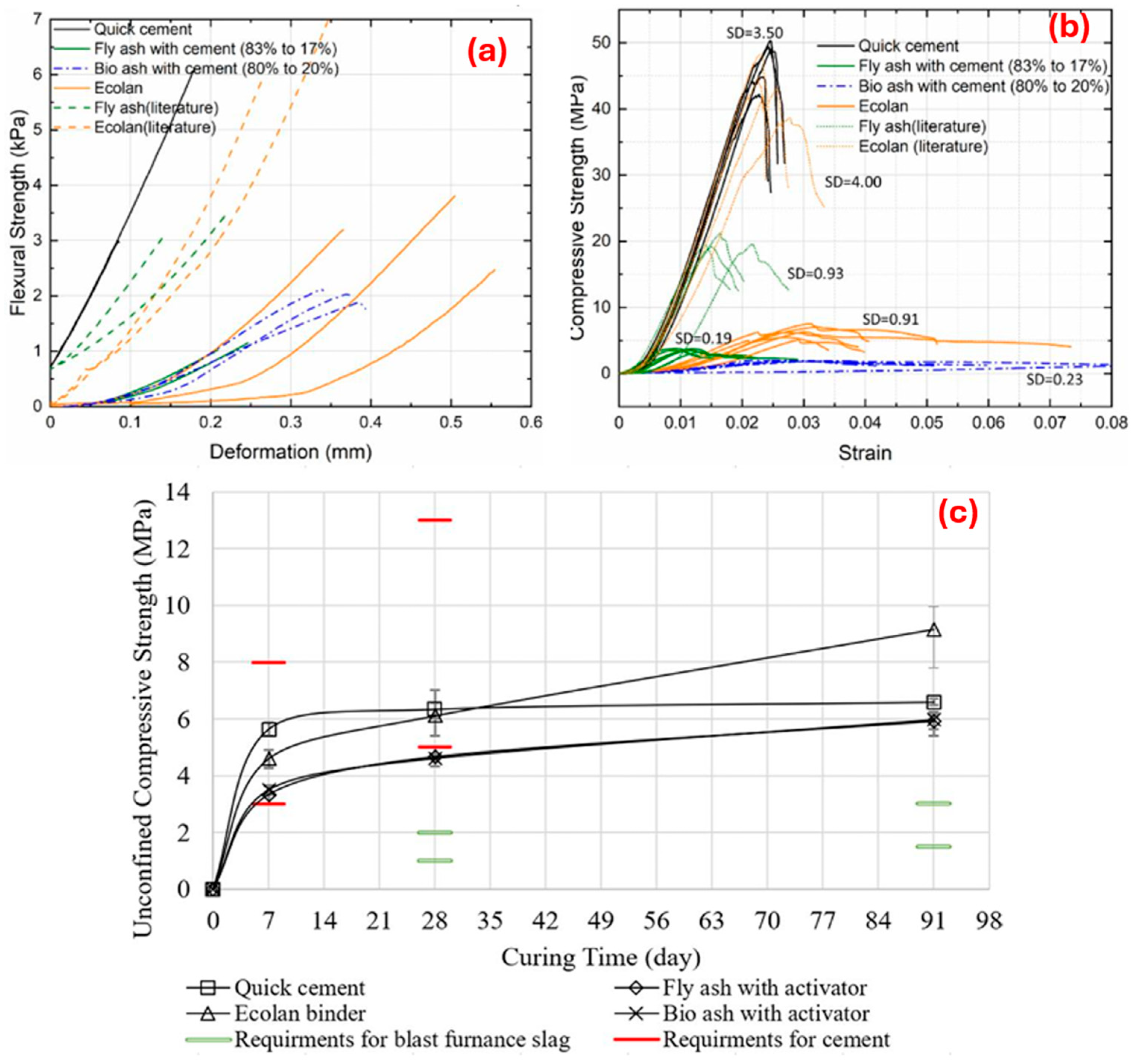

3.4. Binders for WFS Stabilization: Green vs. Non-Green

3.5. Environmental Benefits and Associated Challenges of WFS Reuse

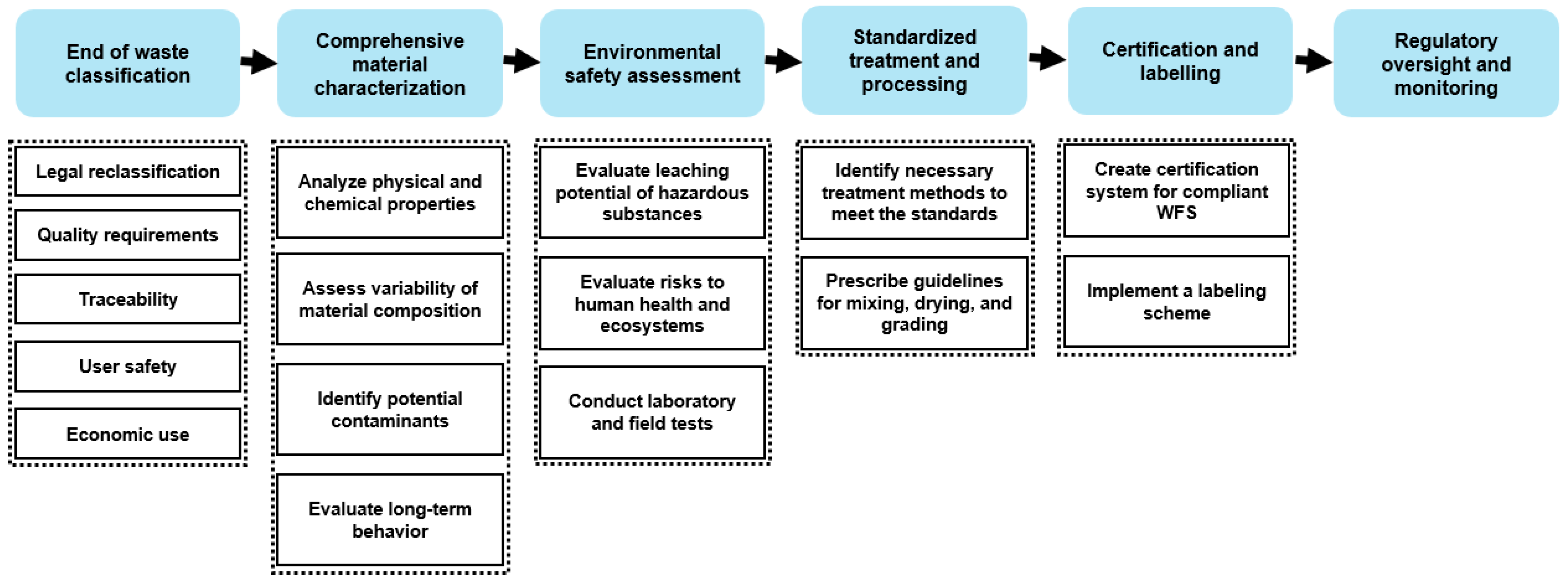

3.6. Regulatory Frameworks and Standards of WFS Reuse

3.7. Application of WFS in the Built Environment

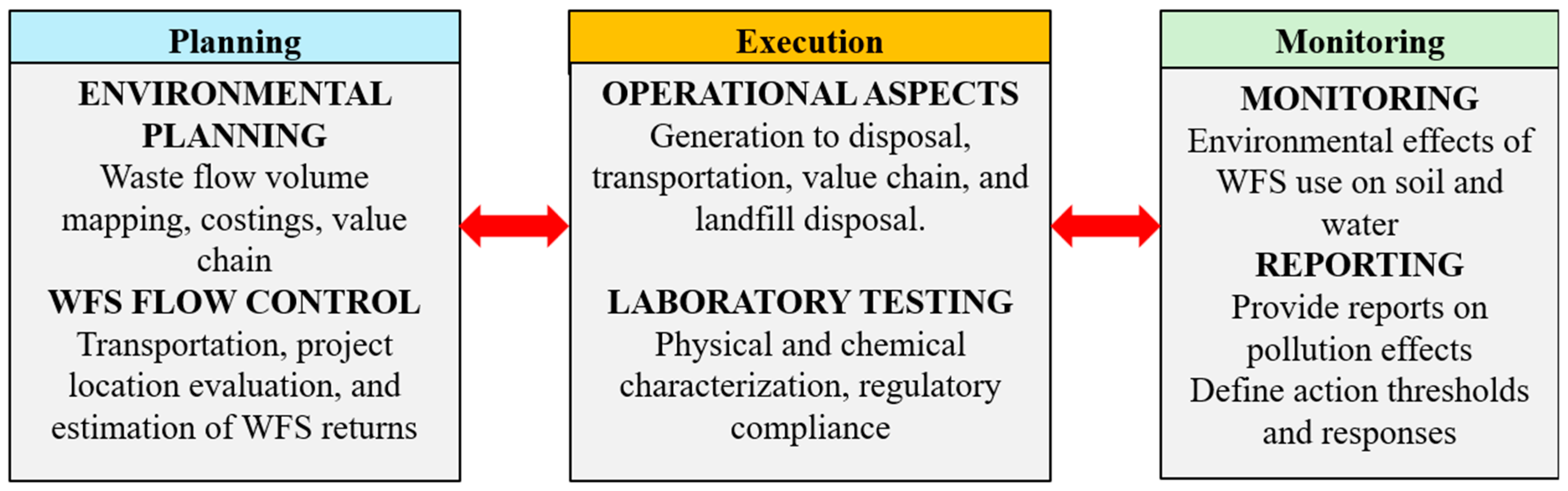

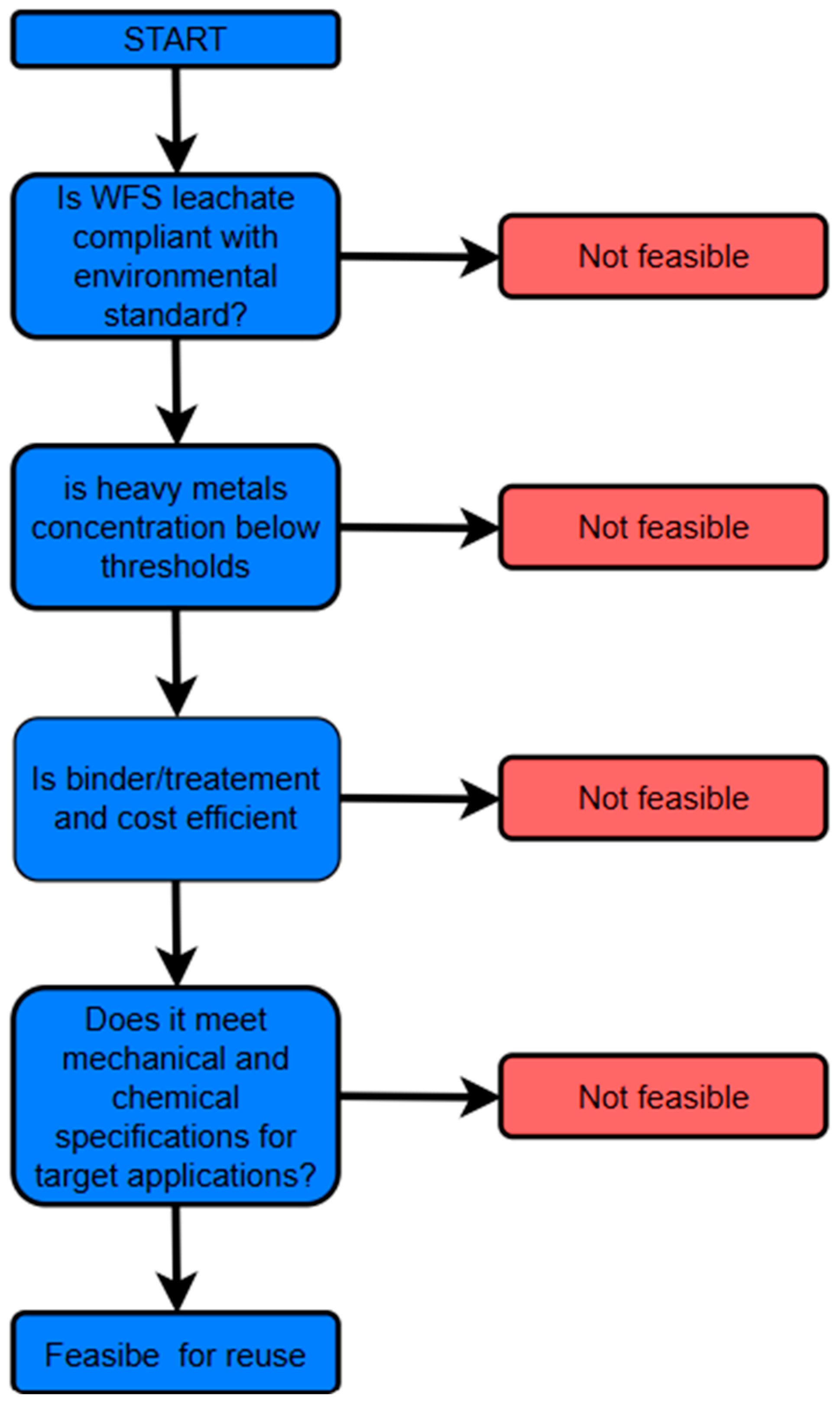

3.8. Hypothetical Application Scenario: Framework and Decision Tree Validation

Comparative Analysis of WFS Treatment and Reuse Policies: Europe, U.S., and South Africa

3.9. Challenges and Recommendations for Future Research

3.9.1. Key Knowledge Gaps Restricting WFS Reuse

3.9.2. Priority Areas for Future Research

3.9.3. Strategies for Enhancing WFS Reuse

3.9.4. Research Focus Areas in Sustainable Construction

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nature Editorial. Concrete needs to lose its colossal carbon footprint. Nature 2021, 597, 593–594. [Google Scholar] [CrossRef]

- Mehta, V. Sustainable approaches in concrete production: An in-depth review of waste foundry sand utilization and environmental considerations. Environ. Sci. Pollut. Res. 2024, 31, 23435–23461. [Google Scholar] [CrossRef]

- Abraham, E.; Abraham, G.M. Effect of Bacillus subtilis bacteria on waste foundry sand-containing concrete. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, G. Utilization of waste foundry sand (WFS) in concrete manufacturing. Resour. Conserv. Recycl. 2011, 55, 885–892. [Google Scholar] [CrossRef]

- Iloh, P.; Fanourakis, G.; Ogra, A. Evaluation of Physical and Chemical Properties of South African Waste Foundry Sand (WFS) for Concrete Use. Sustainability 2019, 11, 193. [Google Scholar] [CrossRef]

- Tavakoli, D.; Hashempour, M.; Heidari, A. Use of waste materials in concrete: A review. Pertanika J. Sci. Technol. 2018, 26, 499–522. [Google Scholar]

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Assessment of mechanical and durability properties of concrete containing waste rubber tire as fine aggregate. Constr. Build. Mater. 2014, 73, 562–574. [Google Scholar] [CrossRef]

- Iloh, P.I. The Effect of Waste Foundry Sand (WFS) on Concrete Properties. Master’s Dissertation, University of Johannesburg, Johannesburg, South Africa, 2018. Available online: https://hdl.handle.net/10210/297395 (accessed on 12 May 2025).

- Bożym, M. The study of heavy metals leaching from waste foundry sands using a one-step extraction. E3S Web Conf. 2017, 19, 02018. [Google Scholar] [CrossRef]

- Khan, M.M.; Singh, M.; Jadhav, G.N.; Mahajani, S.M.; Mandre, S. Characterization of waste and reclaimed green sand used in foundry processing. Silicon 2020, 12, 677–691. [Google Scholar] [CrossRef]

- Bhardwaj, B.; Kumar, P. Waste foundry sand in concrete: A review. Constr. Build. Mater. 2017, 156, 661–674. [Google Scholar] [CrossRef]

- Iloh, P.I.; Fanourakis, G.; Ogra, A. Characterisation of five different South African waste foundry sands to determine their suitability for use in concrete. In Proceedings of the 9th International Conference on Advances in Science, Engineering, Technology & Waste Management (ASETWM-17), Parys, South Africa, 27–28 November 2017; Available online: https://hdl.handle.net/10210/246219 (accessed on 22 July 2025).

- Kumar, S.; Silori, R.; Sethy, S.K. Insight into the perspectives of waste foundry sand as a partial or full replacement of fine aggregate in concrete. Total Environ. Res. Themes 2023, 6, 100048. [Google Scholar] [CrossRef]

- Tittarelli, F. Waste foundry sand. In Waste and Supplementary Cementitious Materials in Concrete; Siddique, R., Cachim, P., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Cambridge, UK, 2018; pp. 121–147. [Google Scholar] [CrossRef]

- Schwarz, M.; Salva, J.; Vanek, M.; Poništ, J.; Prepilková, V.; Lobotková, M.; Turčániová, E. Assessment of possibilities of using waste foundry sand—Review. Int. J. Miner. Res. 2022, 113, 549–559. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.; Martínez-García, R.; Vatin, N.I.; De-Prado-Gil, J.; El-Shorbagy, M.A. Waste Foundry Sand in Concrete Production Instead of Natural River Sand: A Review. Materials 2022, 15, 2365. [Google Scholar] [CrossRef] [PubMed]

- García, G.; Cabrera, R.; Rolón, J.; Pichardo, R.; Thomas, C. Systematic review on the use of waste foundry sand as a partial replacement of natural sand in concrete. Constr. Build. Mater. 2024, 430, 136460. [Google Scholar] [CrossRef]

- Chifflard, P.; Schütz, M.; Reiss, M.; Foroushani, M.A. Evaluating chemical properties and sustainable recycling of waste foundry sand in construction materials. Front. Built Environ. 2024, 10, 1386511. [Google Scholar] [CrossRef]

- Deng, A. Contaminants in waste foundry sand and its leachate. Int. J. Environ. Pollut. 2009, 38, 425–443. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Dayton, E.A.; Whitacre, S.D.; Dungan, R.S.; Basta, N.T. Characterization of physical and chemical properties of spent foundry sands pertinent to beneficial use in manufactured soils. Plant Soil. 2010, 329, 27–33. [Google Scholar] [CrossRef]

- Kumar, A.; Parihar, A. Quantifying suitability of waste foundry sands from different metal castings for geotechnical applications. Sadhana Acad. Proc. Eng. Sci. 2024, 49, 23. [Google Scholar] [CrossRef]

- Dungan, R.S.; Dees, N.H. The characterization of total and leachable metals in foundry molding sands. J. Environ. Manag. 2009, 90, 539–548. [Google Scholar] [CrossRef]

- Kaur, G.; Siddique, R.; Rajor, A. Micro-structural and metal leachate analysis of concrete made with fungal treated waste foundry sand. Constr. Build. Mater. 2013, 38, 94–100. [Google Scholar] [CrossRef]

- Siddique, R.; Kaur, G.; Rajor, A. Waste foundry sand and its leachate characteristics. Resour. Conserv. Recycl. 2010, 54, 1027–1036. [Google Scholar] [CrossRef]

- Ashish, D.K.; Verma, S.K. Robustness of self-compacting concrete containing waste foundry sand and metakaolin: A sustainable approach. J. Hazard. Mater. 2021, 401, 123329. [Google Scholar] [CrossRef]

- Shuaibu, A.A.; Otuoze, H.S.; Mohammed, A.; Lateef, M.A. Properties of asphalt concrete containing waste foundry sand (WFS) as filler material. Arid. Zo J. Eng. 2019, 15, 662–677. [Google Scholar]

- Liu, H.H.; Yang, H.H.; Chou, C.D.; Lin, M.H.; Chen, H.L. Risk assessment of gaseous/particulate phase PAH exposure in foundry industry. J. Hazard. Mater. 2010, 181, 105–111. [Google Scholar] [CrossRef]

- Dada, O.R. Characterization and Beneficiation of Foundry Greensand Waste from Ferrous Foundries. Master’s Thesis, University of Johannesburg, Johannesburg, South Africa, 2015. [Google Scholar]

- Xiang, R.; Li, Y.; Li, S.; Xue, Z.; He, Z.; Ouyang, S.; Xu, N. The potential usage of waste foundry sand from investment casting in refractory industry. J. Clean. Prod. 2019, 211, 1322–1327. [Google Scholar] [CrossRef]

- Martins, M.A.B.; da Silva, L.R.R.; Ranieri, M.G.A.; Barros, R.M.; Santos, V.C.; Gonçalves, P.C.; Rodrigues, M.R.B.; Lintz, R.C.C.; Gachet, L.A.; Martinez, C.B.; et al. Physical and chemical properties of waste foundry exhaust sand for use in self-compacting concrete. Materials 2021, 14, 5629. [Google Scholar] [CrossRef]

- Martins, M.A.B.; Barros, R.M.; Silva, G.; Santos, I.F.S. Study on waste foundry exhaust sand (WFES) as a partial substitute of fine aggregates in conventional concrete. Sustain. Cities Soc. 2019, 45, 187–196. [Google Scholar] [CrossRef]

- Mymrin, V.; Correia, R.A.M.; Alekseev, K.; Klitzke, W.; Avanci, M.A.; Rolim, P.H.B.; Argenta, M.A.; Carmo, J.B. Sustainable materials from hazardous lead ore flotation waste in composites with spent foundry sand and clay. Int. J. Adv. Manuf. Technol. 2020, 109, 1333–1344. [Google Scholar] [CrossRef]

- Cioli, F.; Abbà, A.; Alias, C.; Sorlini, S. Reuse or Disposal of Waste Foundry Sand: An Insight into Environmental Aspects. Appl. Sci. 2022, 12, 6420. [Google Scholar] [CrossRef]

- Miguel, R.E.; Ippolito, J.A.; Leytem, A.B.; Porta, A.A.; Banda Noriega, R.B.; Dungan, R.S. Analysis of total metals in waste molding and core sands from ferrous and non-ferrous foundries. J. Environ. Manag. 2012, 110, 77–81. [Google Scholar] [CrossRef]

- Basar, H.M.; Deveci Aksoy, N. The effect of waste foundry sand (WFS) as partial replacement of sand on the mechanical, leaching and micro-structural characteristics of ready-mixed concrete. Constr. Build. Mater. 2012, 35, 508–515. [Google Scholar] [CrossRef]

- Alias, C.; Cioli, F.; Abbà, A.; Feretti, D.; Sorlini, S. Ecotoxicological assessment of waste foundry sands and the application of different classification systems. Integr. Environ. Assess. Manag. 2024, 20, 2294–2311. [Google Scholar] [CrossRef]

- Díaz Pace, D.M.; Miguel, R.E.; Di Rocco, H.O.; Anabitarte García, F.; Pardini, L.; Legnaioli, S.; Lorenzetti, G.; Palleschi, V. Quantitative analysis of metals in waste foundry sands by calibration free-laser induced breakdown spectroscopy. Spectrochim. Acta B At. Spectrosc. 2017, 131, 58–65. [Google Scholar] [CrossRef]

- Waman, M.; Nagaraju, R.K.; Laware, S.L.; Raju, K. Physio-chemical and heavy metal analysis of waste foundry sand. Ecol. Environ. Conserv. 2022, 28, 1925–1930. [Google Scholar] [CrossRef]

- Paul, P.; Belhaj, E.; Diliberto, C.; Apedo, K.L.; Feugeas, F. Comprehensive characterization of spent chemical foundry sand for use in concrete. Sustainability 2021, 13, 12881. [Google Scholar] [CrossRef]

- Prasad, V.D.; Prakash, E.L.; Abishek, M.; Dev, K.U.; Kiran, C.K.S. Study on concrete containing waste foundry sand, fly ash and polypropylene fibre using Taguchi method. Mater. Today Proc. 2018, 5 Pt 3, 23964–23973. [Google Scholar] [CrossRef]

- Bilal, H.; Yaqub, M.; Rehman, S.K.U.; Abid, M.; Alyousef, R.; Alabduljabbar, H.; Aslam, F. Performance of foundry sand concrete under ambient and elevated temperatures. Materials 2019, 12, 2645. [Google Scholar] [CrossRef]

- Guney, Y.; Sari, Y.D.; Yalcin, M.; Tuncan, A.; Donmez, S. Re-usage of waste foundry sand in high-strength concrete. Waste Manag. 2010, 30, 1705–1713. [Google Scholar] [CrossRef]

- Easwaran, P.; Kalaivani, M.; Ramesh, S.; Ranjith, R. Study on strength properties of concrete by using bottom ash and foundry sand as a partial replacement of fine aggregate. Int. Res. J. Multidiscip. Technovation 2019, 1, 346–352. [Google Scholar] [CrossRef]

- Singh, G.; Siddique, R. Effect of waste foundry sand (WFS) as partial replacement of sand on the strength, ultrasonic pulse velocity and permeability of concrete. Constr. Build. Mater. 2012, 26, 416–422. [Google Scholar] [CrossRef]

- Prabhu, G.G.; Hyun, J.H.; Kim, Y.Y. Effects of foundry sand as a fine aggregate in concrete production. Constr. Build. Mater. 2014, 70, 514–521. [Google Scholar] [CrossRef]

- Kumar, A.; Parihar, A. Impact of waste foundry sand on drainage behavior of sandy soil: An experimental and machine learning study. AI Civ. Eng. 2024, 3, 1. [Google Scholar] [CrossRef]

- Sabour, M.R.; Derhamjani, G.; Akbari, M.; Hatami, A.M. Global trends and status in waste foundry sand management research during the years 1971–2020: A systematic analysis. Environ. Sci. Pollut. Res. 2021, 28, 37312–37321. [Google Scholar] [CrossRef]

- Vincevica-Gaile, Z.; Burlakovs, J.; Fonteina-Kazeka, M.; Wdowin, M.; Hanc, E.; Rudovica, V.; Krievans, M.; Grinfelde, I.; Siltumens, K.; Kriipsalu, M.; et al. Case study-based integrated assessment of former waste disposal sites transformed to green space in terms of ecosystem services and land assets recovery. Sustainability 2023, 15, 3256. [Google Scholar] [CrossRef]

- McKie, M. Research and Development of a Sustainable Technology Improvement Model for the Foundry Industry. Ph.D. Thesis, Teesside University, Middlesbrough, UK, 2015. [Google Scholar] [CrossRef]

- Usta Benli, A. Resource Efficient and Cleaner Production in Selected Foundries Through Environmental Performance Evaluation. Master’s Thesis, Middle East Technical University, Ankara, Turkey, 2017. Available online: https://hdl.handle.net/11511/26399 (accessed on 22 July 2025).

- Shukla, B.K.; Bharti, G.; Sharma, P.K.; Sharma, M.; Rawat, S.; Maurya, N.; Srivastava, R.; Srivastav, Y. Sustainable construction practices with recycled and waste materials for a circular economy. Asian J. Civ. Eng. 2024, 25, 5255–5276. [Google Scholar] [CrossRef]

- García Del Angel, G.; Sainz-Aja, J.A.; Tamayo, P.; Cimentada, A.; Cabrera, R.; Pestana, L.R.; Thomas, C. Effect of recycled foundry sand on the workability and mechanical properties of mortar. Appl. Sci. 2023, 13, 3436. [Google Scholar] [CrossRef]

- Sgarlata, C.; Ariza-Tarazona, M.C.; Paradisi, E.; Siligardi, C.; Lancellotti, I. Use of foundry sands in the production of ceramic and geopolymers for sustainable construction materials. Appl. Sci. 2023, 13, 5166. [Google Scholar] [CrossRef]

- Bakis, R.; Koyuncu, H.; Demirbas, A. An investigation of waste foundry sand in asphalt concrete mixtures. Waste Manag. Res. 2006, 24, 269–274. [Google Scholar] [CrossRef]

- Dyer, P.P.O.L.; de Lima, M.G. Waste foundry sand in hot mix asphalt: A review. Constr. Build. Mater. 2022, 359, 129342. [Google Scholar] [CrossRef]

- de Souza Campelo, N.; Sá da Costa, K.J.; Vieira, R.K.; Vieira, A.K. Use of waste foundry sand (WFS) as filler in hot-mixed asphalt concrete. In Sandy Materials in Civil Engineering—Usage and Management; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Dyer, P.P.O.L.; Gutierrez Klinsky, L.M.; Silva, S.A.; E Silva, R.A.; De Lima, M.G. Macro and Microstructural Characterisation of Waste Foundry Sand Reused as Aggregate. Road Mater. Pavement Des. 2021, 22, 464–477. [Google Scholar] [CrossRef]

- Fanourakis, G.; Ogra, A. Strength Properties of Concrete with Partial Utilization of South African Waste Foundry Sand. J. Res. Eng. Appl. Sci. 2024, 9, 791–800. [Google Scholar]

- Nabhani, F.; McKie, M.; Hodgson, S. A Case Study on a Sustainable Alternative to the Landfill Disposal of Spent Foundry Sand. Int. J. Sustain. Manuf. 2013, 3, 1–19. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, G.; Singh, M. Recycle Option for Metallurgical By-Product (Spent Foundry Sand) in Green Concrete for Sustainable Construction. J. Clean. Prod. 2018, 172, 1111–1120. [Google Scholar] [CrossRef]

- Yazoghli-Marzouk, O.; Vulcano-Greullet, N.; Cantegrit, L.; Friteyre, L.; Jullien, A. Recycling foundry sand in road construction—Field assessment. Constr. Build. Mater. 2014, 61, 69–78. [Google Scholar] [CrossRef]

- Cammelli, F.; Tameni, G.; Bernardo, E. Sustainable stabilization of waste foundry sands in alkali activated glass-based matrices. Case Stud. Constr. Mater. 2024, 21, e03538. [Google Scholar] [CrossRef]

- Mavroulidou, M.; Lawrence, D. Can waste foundry sand fully replace structural concrete sand? J. Mater. Cycles Waste Manag. 2019, 21, 594–605. [Google Scholar] [CrossRef]

- Anwar, N.; Jalava, K.; Orkas, J. Experimental study of inorganic foundry sand binders for mold and cast quality. Int. J. Met. 2023, 17, 1697–1714. [Google Scholar] [CrossRef]

- Branca, T.A.; Colla, V.; Algermissen, D.; Granbom, H.; Martini, U.; Morillon, A.; Pietruck, R.; Rosendahl, S. Reuse and recycling of by-products in the steel sector: Recent achievements paving the way to circular economy and industrial symbiosis in Europe. Metals 2020, 10, 345. [Google Scholar] [CrossRef]

- Owens, G. Development of Policies for the Handling, Disposal and/or Beneficial Reuse of Used Foundry Sands—A Literature Review; CRC CARE Technical Report No. 7; CRC for Contamination Assessment and Remediation of the Environment: Adelaide, Australia, 2008. [Google Scholar]

- Arulrajah, A.; Yaghoubi, E.; Imteaz, M.; Horpibulsuk, S. Recycled Waste Foundry Sand as a Sustainable Subgrade Fill and Pipe-Bedding Construction Material: Engineering and Environmental Evaluation. Sustain. Cities Soc. 2017, 28, 343–349. [Google Scholar] [CrossRef]

- Balulmath, A.B.; Sridhar, G.; Saranya, P. A Critical Review on Potential Use of Waste Foundry Sand in Geotechnical and Pavement Applications. In Proceedings of the Indian Geotechnical Conference 2022 Volume 8, Kerala, India, 15–17 December 2022; Jose, B.T., Sahoo, D.K., Shukla, S.K., Krishna, A.M., Thomas, J., Veena, V., Eds.; Lecture Notes in Civil Engineering. Springer: Singapore, 2024; Volume 492, pp. 309–320. [Google Scholar] [CrossRef]

- Aguiar, I.; Cunha, S.; Aguiar, J. Application of Foundry Wastes in Eco-Efficient Construction Materials: A Review. Appl. Sci. 2025, 15, 10. [Google Scholar] [CrossRef]

- Bardini, V.S.S.; Klinsky, L.M.; Albuquerque, A.; Andrade Pais, L.; Fiore, F.A. Waste foundry sand as an alternative material in road construction. Sustainability 2025, 17, 2370. [Google Scholar] [CrossRef]

- Fore, S.; Mbohwa, C.T. Cleaner production for environmental conscious manufacturing in the foundry industry. J. Eng. Des. Technol. 2010, 8, 314–333. [Google Scholar] [CrossRef]

- Zhang, Y.; Sappinen, T.; Korkiala-Tanttu, L.; Vilenius, M.; Juuti, E. Investigations into stabilized waste foundry sand for applications in pavement structures. Resour. Conserv. Recycl. 2021, 170, 105585. [Google Scholar] [CrossRef]

- Khan, M.M.; Mahajani, S.M. Chemical reclamation of waste green foundry sand and its application in core production. Sustain. Chem. Clim. Action. 2024, 4, 100038. [Google Scholar] [CrossRef]

- Kaur, G.; Siddique, R.; Rajor, A. Properties of Concrete Containing Fungal Treated Waste Foundry Sand. Constr. Build. Mater. 2012, 29, 82–87. [Google Scholar] [CrossRef]

- Seemantranon, N. Emission Reduction Potential in Thermal Reclamation of Waste Foundry Sand. Master’s Thesis, Aalto University, Espoo, Finland, 2023. Available online: https://urn.fi/URN:NBN:fi:aalto-202301291704 (accessed on 22 July 2025).

- Binti, Q.; Rudge, J.; Jin, F.; Maddalena, R. Waste Foundry Sand (WFS) as Aggregate Replacement for Green Concrete. In Proceedings of the Cardiff University Engineering Research Conference 2023, Cardiff, UK, 12–14 July 2023; Spezi, E., Bray, M., Eds.; Cardiff University Press: Cardiff, UK, 2024; pp. 52–54. [Google Scholar] [CrossRef]

- Gürkan, E.H.; Çoruh, S.; Elevli, S. Adsorption of Lead and Copper Using Waste Foundry Sand: Statistical Evaluation. Int. J. Glob. Warm. 2018, 14, 260–273. [Google Scholar] [CrossRef]

- Guleria, K.; Sharma, R.K. Improvement of Geotechnical Properties of Soil Using Calcium Carbide, Waste Foundry Sand and Polypropylene Fibre. J. Min. Environ. 2023, 14, 449–471. [Google Scholar] [CrossRef]

- Wan, Y.; Hui, X.; He, X.; Li, J.; Xue, J.; Feng, D.; Liu, X.; Wang, S. Performance of Green Binder Developed from Flue Gas Desulfurization Gypsum Incorporating Portland Cement and Large-Volume Fly Ash. Constr. Build. Mater. 2022, 348, 128679. [Google Scholar] [CrossRef]

- Omer Adam, M.G.; Koteng, D.O.; Thuo, J.N.; Anga, A.; Matallah, M. Effects of Acid Attack and Cassava Flour Dosage on the Interfacial Transition Zone Thickness, Durability and Mechanical Characteristics of High-Strength (HS) Concrete. Results Eng. 2023, 17, 100950. [Google Scholar] [CrossRef]

- Oni, D.; Mwero, J.; Kabubo, C. The Effect of Cassava Starch on the Durability Characteristics of Concrete. Open Civ. Eng. J. 2020, 14, 289–301. [Google Scholar] [CrossRef]

- Tran, T.Q.; Kim, Y.S.; Dang, L.C.; Do, T.M. A State-of-the-Art Review on the Utilization of New Green Binders in the Production of Controlled Low-Strength Materials. Constr. Build. Mater. 2023, 401, 132078. [Google Scholar] [CrossRef]

- Iro, U.I.; Alaneme, G.U.; Attah, I.C.; Ganasen, N.; Duru, S.C.; Olaiya, B.C. Optimization of Cassava Peel Ash Concrete Using Central Composite Design Method. Sci. Rep. 2024, 14, 7901. [Google Scholar] [CrossRef]

- Alsaed, M.M.; Al Mufti, R.L. The Effects of Rice Husk Ash as Bio-Cementitious Material in Concrete. Constr. Mater. 2024, 4, 629–639. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, B.; Liu, X.; Ruan, Z. Trends and Applications of Green Binder Materials for Cemented Paste Backfill Mining in China. Minerals 2025, 15, 97. [Google Scholar] [CrossRef]

- Al-Alwan, A.A.K.; Al-Bazoon, M.; Mussa, F.I.; Alalwan, H.A.; Shadhar, M.H.; Mohammed, M.M.; Mohammed, M.F. The Impact of Using Rice Husk Ash as a Replacement Material in Concrete: An Experimental Study. J. King Saud. Univ. Eng. Sci. 2024, 36, 249–255. [Google Scholar] [CrossRef]

- Thomas, B.S. Green Concrete Partially Comprised of Rice Husk Ash as a Supplementary Cementitious Material—A Comprehensive Review. Renew. Sustain. Energy Rev. 2018, 81, 3913–3923. [Google Scholar] [CrossRef]

- Zaid, O.; Ahmad, J.; Siddique, M.S.; Aslam, F. Effect of Incorporation of Rice Husk Ash Instead of Cement on the Performance of Steel Fibers Reinforced Concrete. Front. Mater. 2021, 8, 665625. [Google Scholar] [CrossRef]

- Khalaf, A.A.; Kopecskó, K.; Modhfar, S. Applicability of Waste Foundry Sand Stabilization by Fly Ash Geopolymer under Ambient Curing Conditions. Heliyon 2024, 10, e27784. [Google Scholar] [CrossRef] [PubMed]

- TS EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. Turkish Standards Institute: Ankara, Turkey, 2009.

- Kanagaraj, B.; Anand, N.; Andrushia, D.; Kodur, V. Residual Properties of Geopolymer Concrete for Post-Fire Evaluation of Structures. Materials 2023, 16, 6065. [Google Scholar] [CrossRef]

- Dacić, A.; Kopecskó, K.; Fenyvesi, O.; Merta, I. The Obstacles to a Broader Application of Alkali-Activated Binders as a Sustainable Alternative—A Review. Materials 2023, 16, 3121. [Google Scholar] [CrossRef] [PubMed]

- Hamid, R.; Owaid, H.M.; Taha, M.R. Elevated Temperature Performance of Multiple-Blended Binder Concretes. In High Performance Concrete Technology and Applications; Yilmaz, S., Baytan Özmen, H., Eds.; IntechOpen: Rijeka, Croatia, 2016. [Google Scholar] [CrossRef]

- Fox, J.T.; Cannon, F.S.; Brown, N.R.; Huang, H.; Furness, J.C. Comparison of a New, Green Foundry Binder with Conventional Foundry Binders. Int. J. Adhes. Adhes. 2012, 34, 38–45. [Google Scholar] [CrossRef]

- Iqbal, M.F.; Javed, M.F.; Rauf, M.; Azim, I.; Ashraf, M.; Yang, J.; Liu, Q.F. Sustainable Utilization of Foundry Waste: Forecasting Mechanical Properties of Foundry Sand Based Concrete Using Multi-Expression Programming. Sci. Total Environ. 2021, 780, 146524. [Google Scholar] [CrossRef]

- Altaf, S.; Sharma, A.; Singh, K. A Sustainable Utilization of Waste Foundry Sand in Soil Stabilization: A Review. Bull. Eng. Geol. Environ. 2024, 83, 143. [Google Scholar] [CrossRef]

- Deng, A.; Tikalsky, P.J. Geotechnical and Leaching Properties of Flowable Fill Incorporating Waste Foundry Sand. Waste Manag. 2008, 28, 2161–2170. [Google Scholar] [CrossRef]

- Batra, A.K.; Bhattacharjee, J.C.S. Using Foundry Sand in Green Infrastructure Construction. In Proceedings of the Green Streets and Highways 2010, Denver, CO, USA, 14–17 November 2010; American Society of Civil Engineers: Reston, VA, USA, 2010; pp. 280–298. [Google Scholar]

- Tangadagi, R.B.; Ravichandran, P.T. Performance Evaluation of Self-Compacting Concrete Prepared Using Waste Foundry Sand on Engineering Properties and Life Cycle Assessment. Recycling 2024, 9, 47. [Google Scholar] [CrossRef]

- Khalid, B.; Alshawmar, F. Comprehensive Review of Geotechnical Engineering Properties of Recycled Polyethylene Terephthalate Fibers and Strips for Soil Stabilization. Polymers 2024, 16, 1764. [Google Scholar] [CrossRef] [PubMed]

- Heidemann, M.; Nierwinski, H.; Hastenpflug, D.; Barra, B.; Perez, Y. Geotechnical Behavior of a Compacted Waste Foundry Sand. Constr. Build. Mater. 2021, 277, 122267. [Google Scholar] [CrossRef]

- Yin, J.; Soleimanbeigi, A.; Likos, W.J.; Edil, T.B. Compression Behavior of Foundry Sands. Geotech. Struct. Eng. Congr. 2016, 2016, 1392–1403. [Google Scholar] [CrossRef]

- Doğan-Sağlamtimur, N. Waste Foundry Sand Usage for Building Material Production: A First Geopolymer Record in Material Reuse. Adv. Civ. Eng. 2018, 2018, 1927135. [Google Scholar] [CrossRef]

- Gosk, E.; Kalinowska-Wichrowska, K.; Kosior-Kazberuk, M.; Yildiz, M.J.; Derpeński, Ł.; Zamojski, P.; Lipowicz, P. The Basic Properties of Lightweight Artificial Aggregates Made with Recycled Concrete Fines. Sustainability 2024, 16, 9134. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency (EPA). Beneficial Reuse of Foundry Sand: A Review of State Practices and Regulations. Sector Strategies Division, Office of Policy, Economics, and Innovation, Washington, DC, USA, in Partnership with American Foundry Society and ASTSWMO, December 2002. Available online: https://archive.epa.gov/sectors/web/pdf/reuse.pdf (accessed on 22 July 2025).

- Nyembwe, J.K.; Makhatha, M.E.; Madzivhandila, T.; Nyembwe, K.D. Characterisation of South African waste foundry moulding sand: Metallic contaminants. In Proceedings of the World Congress on Mechanical, Chemical, and Material Engineering (MCM 2015), Barcelona, Spain, 20–21 July 2015; pp. 1–8. [Google Scholar]

- Nyembwe, K.D.; Kabasele, J.K. Sustainability assessment of thermal and mechanical reclamation of foundry chromite sand. S Afr. J. Ind. Eng. 2022, 33, 29–39. [Google Scholar] [CrossRef]

- Econo Tek Recycling Ltd. The Processing of Current Waste Foundry Sand and Sand Previously Discarded to Landfill as a Total Recycling Service to the Foundry Industry and Other Users. LIFE Programme Project LIFE98 ENV/UK/000588; European Commission, Clay Cross, Chesterfield, UK, 1998–2000. Available online: https://webgate.ec.europa.eu/life/publicWebsite/project/LIFE98-ENV-UK-000588/the-processing-of-current-waste-foundry-sand-and-sand-previously-discarded-to-landfill-sand-as-a-total-recycling-service-to-the-foundry-industry-and-other-users (accessed on 22 July 2025).

- Madzivhandila, T. Waste Sand Management in South African Foundries. Ph.D. Thesis, University of Johannesburg, Johannesburg, South Africa, 2018. Available online: https://hdl.handle.net/10210/263158 (accessed on 22 July 2025).

- Bożym, M. Foundry waste as a raw material for agrotechnical applications. Gospod. Surowcami Min. Min. Resour. Manag. 2021, 37, 117–132. [Google Scholar] [CrossRef]

- European Commission. Re-Use of Surplus Foundry Sand by Composting. LIFE Project LIFE13 ENV/FI/000285 (LIFE-FOUNDRYSAND); European Commission, Brussels, Belgium, 2013–2017. Available online: https://webgate.ec.europa.eu/life/publicWebsite/project/LIFE13-ENV-FI-000285/re-use-of-surplus-foundry-sand-by-composting (accessed on 22 July 2025).

| Application | Considerations and Benefits | Applicable Foundry Sand Types | References |

|---|---|---|---|

| Aerated Concrete and Controlled Low-Strength Concrete | Up to the optimum of 30% of replacement of WFS increases the compressive and flexural strength, and up to 70% gives less but acceptable strength. | Greensand, alkaline phenolic, and resin shell sands. | [59] |

| Agriculture | It can be mixed with soils for agricultural benefits. Requires further testing for crop-specific suitability. | Greensand. | [22] |

| Hot Rolled Asphalt | The greensand clay content reduces bitumen bleed, and it has been proven successful in the UK and overseas. It is used as a partial replacement (50%). | Alkaline phenolic and resin shell sands. | [60] |

| Concrete Block Making | Suitable for both low-density (aerated) and dense blocks. Phenol leaching risks may require process adjustments. | Greensand and resin shell sands. | [61] |

| Road Base Construction | Unbound courses may risk contaminant leaching; testing is required to ensure environmental safety. | Most chemically bonded sands, including greensand. | [62] |

| Brick Manufacturing | Effective as an aggregate filler. Iron spotting may affect surface continuity but can be desirable for unique effects. | Greensand and chemically bonded sands. | [54] |

| Cement Production | Used in cement manufacturing. Strength reductions due to residual resin particles may occur. | Greensand, alkaline phenolic, and resin shell sands. | [63] |

| Soil Stabilization | Used to improve soil strength and durability in geotechnical applications like embankments and retaining walls. | Greensand and chemically bonded sands. | [64] |

| Landfill Cover Material | Acts as an alternative cover for landfills, reducing the cost of sourcing natural materials. | Spent greensand and resin shell sands. | [64] |

| Ceramic Production | Suitable as a filler material in ceramic products, improving durability and thermal resistance. | Greensand and chemically bonded sands. | [54] |

| Geopolymer Concrete | Used as a replacement aggregate in geopolymer concrete, enhancing mechanical properties and sustainability. | Greensand and resin shell sands. | [65] |

| Artificial Reefs | Incorporated into concrete structures for creating artificial reefs, providing marine habitat restoration. | Chemically bonded sands. | [66] |

| Potting Media and Topsoil Mix | Used as a component in horticulture for improving soil aeration and drainage. | Greensand (after leachate testing). | [67] |

| Pipe Bedding Material | Acts as a cushioning material for pipes, reducing reliance on natural aggregates. | Greensand and resin shell sands. | [68] |

| Paving and Tiles | Incorporated into concrete tiles and interlocking pavers, enhancing strength and aesthetics. | Greensand and resin shell sands. | [69] |

| Refractory Products | Utilized in refractory brick or lining production for high-temperature industrial applications. | Chemically bonded sands with high silica content. | [66] |

| Synthetic Aggregate Production | Processed into lightweight synthetic aggregates for construction, reducing the need for natural aggregate mining. | Chemically bonded sands. | [63] |

| Construction Material | Optimal WFS Content (% by Mass of Fine Aggregate) | Key Performance Criteria | Contamination Risk/Notes | References |

|---|---|---|---|---|

| Structural concrete | 10–30% | Maintains compressive strength and water absorption within ±5% of control; ensures workability and durability | Typically meets leaching limits for Cr, Cu, Zn at ≤30%; periodic tests advised | [17] |

| Mortar | 10–20% | Comparable workability and flexural strength with optimized ratios | Organic content and fines must be controlled | [17,70] |

| Aerated concrete | 10–15% | Required density, strength, and insulation properties were upheld | Strict monitoring of heavy metal leaching is required | [17] |

| Asphalt mixtures | Up to 15% | Maintains moisture resistance, rutting, and strength | Higher contents may increase stripping and moisture sensitivity | [71] |

| Flowable fill/controlled low-strength material | Up to 100% | Flow and strength criteria are easily met | Leaching below EPA regulatory limits for most WFS sources | [68] |

| Road embankment/fill | Up to 100% | Meets compaction, shear strength, and compressibility standards | Ensure contaminants are below soil reuse thresholds | [68] |

| Brick/block production | 10–30% | Preserves compressive strength, durability, and density | Fines and organic/metal content may affect firing/curing | [70] |

| Treatment Method | Description | Efficiency | Direct Cost | By-Product Management | Scalability | References |

|---|---|---|---|---|---|---|

| Physical | Sieving, washing, and mechanical separation to remove fines, binders, and clay | 30–60% (binders, organics) | 2–8 USD/ton | Fines, no hazardous waste | Highly scalable | [5,31] |

| Chemical | Acid/alkali washing (often using industrial effluent acids) | Up to 95% (metals, organics) | 5–15 USD/ton | Liquid effluents require neutralization | Industrial-scale effluent management is required | [18,74] |

| Microbial/Biological | Composting, fungi/bacterial inoculation for degradation and immobilization | 90–95% (metals, organics) | 3–10 USD/ton | Compost/sand, minimal hazardous residue | Pilot/demonstration scale, site-specific | [24,75] |

| Thermal (combined/advanced) | Controlled heating for binder/organic removal and sterilization | High (usually used in combination) | Higher (site/process-specific) | Volatilized organics, sterilized sand | Used as an integrated or advanced step | [76] |

| Aspect | Environmental Benefits | Challenges Associated with Benefits | References |

|---|---|---|---|

| Landfill and Resource Conservation | - Reduces landfill waste and conserves natural resources by substituting virgin sand. - Alleviates environmental strain caused by excessive sand mining. | - Requires effective collection and sorting to ensure quality for reuse. - Improperly treated WFS can still pose contamination risks if disposed of carelessly. | [62,64,68,99] |

| Energy and GHG Emission Reduction | - Lowers energy use and greenhouse gas emissions associated with traditional sand mining and transportation. | - Transporting WFS to distant construction sites can offset emission savings if not locally sourced. | [64,68] |

| Circular Economy and Material Reuse | - Promotes circular economy practices by transforming industrial by-products into construction resources. - Waste minimization. | - Ensuring consistent quality across different WFS batches can be challenging due to variability in industrial processes. | [62] |

| Safe Application | - Immobilizes harmful substances within concrete, minimizing leachate risks and ensuring safety for structural and non-structural uses. | - Leachate testing is required for each new source of WFS to confirm safety and compliance with environmental standards. | [65,68] |

| Economic and Sustainability Impact | - Reduces disposal costs and transportation emissions when WFS is sourced locally. - Increases the economic viability of sustainable construction by lowering material costs. | - Processing costs, especially for removing contaminants or optimizing performance, can limit its economic advantage. | [62,64] |

| Contaminants and Leachate | - Most WFS leachates, including heavy metals like cadmium, lead, and mercury, are below detection limits in controlled environments, reducing risks to groundwater contamination. - Provides opportunities for safe reuse in construction. | Some WFS, particularly from copper-based foundries, may have higher risks due to variability in contaminant levels, necessitating site-specific leachate management. | [19,25] |

| Concrete and Road Construction Applications | - Substituting 10–20% of natural sand with WFS in concrete offers economic advantages while maintaining acceptable mechanical properties. - WFS can replace clay in embankments, providing sufficient shear strength and erosion resistance. | - Limited substitution levels (10–20%) restrict broader adoption in concrete. - High-performance embankment applications require rigorous property testing. | [15] |

| Aspect | Key Points | Quantitative Specifications | Implications | Available Tools/Regulations |

|---|---|---|---|---|

| End-of-Waste (EoW) Criteria | Establishes legal classification for WFS as a secondary raw material rather than waste. | EU Directives 2008/98/EC and 2018/851/EC outline reuse conditions. | Provides a clear legal pathway for WFS utilization. | Directives and EoW Codes |

| Ecotoxicity Testing | Evaluates the toxic effects of WFS on aquatic and terrestrial organisms. | Acceptable WFS toxicity levels based on Vibrio fischeri and Daphnia magna bioassays. | Ensures safe environmental reuse of WFS in construction and agriculture. | Microtox, bioassay kits |

| Toxicity Characteristic Leaching Procedure (TCLP) | Assesses potential leaching of hazardous substances from WFS. | Acceptable Chromium (Cr) leaching limit: 114 mg/kg post-treatment. | Helps prevent groundwater contamination. | TCLP equipment, ICP-MS |

| Risk Assessment for Reuse | Evaluates exposure pathways, including inhalation, soil contamination, and water impact. | Defines regulatory thresholds for sub-base roads, potting media, and manufactured soils. | Ensures compliance with environmental and health standards. | USEPA protocols for construction reuse |

| Environmental Benefits Assessment | Reduces virgin raw material consumption and landfill waste. | CO2 emissions reduction. | Supports circular economy initiatives. | Life Cycle Assessment (LCA) tools (SimaPro, GaBi) |

| Life Cycle Assessment (LCA) | Evaluates the environmental impact of WFS across its reuse lifecycle. | Reduces landfill demand and saves disposal costs. | Identifies environmental hotspots and improvements. | SimaPro, GaBi |

| Mechanical Tests | Defines acceptable compressive, flexural, and tensile strength for WFS-based materials. | Compressive strength changes by substitution in concrete. | Ensures suitability for structural applications. | Strength-testing equipment |

| Chemical Tests | Evaluates silica content and heavy metal presence in WFS. | Silica (SiO2) content: 81.9–95.1%; heavy metal limits set by regulations. | Ensures material safety and suitability for reuse. | XRD, SEM, ICP-MS |

| Physical Tests | Determines particle size, density, and thermal resistance. | 84–93% of particles smaller than 100 μm; specific gravity: 2.35–2.60. | Influences workability and performance in construction materials. | Particle size analyzers (like sieve analysis) |

| Durability Tests | Measures long-term performance of WFS in various applications. | Water absorption and resistance to sulphate attack. | Ensures longevity of WFS-based materials in real-world conditions. | Durability testing equipment |

| Economic Benefits | Evaluates cost savings from WFS reuse. | Cost savings in material procurement for construction projects. | Encourages industry adoption and financial viability. | Cost-benefit analysis tools |

| Regulatory Challenges | Variability in regulations across regions. | No global standard; country-specific thresholds for leachate limits. | Standardized regulations would facilitate broader adoption. | Regional compliance tools |

| Framework Phase | Action in a Hypothetical Scenario | Outcome/Decision Point | References |

|---|---|---|---|

| 1. End-of-Waste Classification | Foundry applies to the classification of non-hazardous WFS and documenting source, traceability, and origin. | WFS provisionally approved for potential secondary use. | [5] |

| 2. Comprehensive Characterization | Lab analysis: specific gravity 2.5; fineness modulus 2.6; Cr 15 mg/kg, Cu 12 mg/kg—compliant with limits. | WFS was judged technically compatible; minor pre-treatment was recommended. | [5,47] |

| 3. Environmental Risk Assessment | TCLP and ecotoxicity tests on WFS-concrete confirm all values below thresholds. | Passed for downstream use in construction; move to preprocessing. | [24,34] |

| 4. Standardized Treatment and Processing | Sand is sieved and washed to optimize gradation and reduce LOI; record-keeping is implemented. | Physical and chemical properties conforming to the mix design; batch ready for certification. | [5,11] |

| 5. Certification and Labelling | An independent certified lab issues a compliance certificate and batch label. | The WFS batch was authorized for use as 30% replacement sand in a road project. | [4] |

| 6. Regulatory Oversight and Monitoring | Ongoing site audits and leachate spot-checks by the construction quality team and regulatory authorities. | Compliance is regularly verified; non-conforming material is excluded/remediated. | [34] |

| Decision Tree Checkpoints | At each phase, the decision tree ensures material failing criteria are halted, remediated, or redirected to landfill. | Only fully compliant WFS enters the construction stream, eliminating environmental or technical risks. | [5,18] |

| Aspect | Europe (EU and UK) | United States | South Africa |

|---|---|---|---|

| Regulatory classification | Generally, WFS is classified as non-hazardous if contaminant thresholds (EU Waste Directives) are met; individual member states may apply stricter criteria [14,34]. | It varies by state; some states classify it as an industrial by-product, with eligibility for beneficial reuse based on leachate and metals testing [106]. | Classified as hazardous by default unless proven otherwise, the SA Waste Management Act enforces stricter controls [107]. |

| Risk assessment and testing | Per EU directives, characterization is mandatory for heavy metals, organics, and leaching; ecotoxicity assessment is also required (yet methods are still evolving) [33,36]. | US EPA and USDA risk assessments provide national benchmarks; most states require TCLP or similar leachate and metals tests, with variable organics testing [106]. | Leachate, total metals content, and acid potential are tested; classification is generally stricter than EU/US, raising disposal costs [108]. |

| Reuse approval mechanisms | National and local permits; some countries (e.g., Finland, UK) are piloting ‘end-of-waste’ reclassification for geo-construction uses [109] | Combination of general permits, exemptions for qualified uses, and notification/approval schemes. | It requires a Waste Management License for storage and use outside the foundry; end-use in construction is possible but hindered by strict origin-based classification [110]. |

| Permissible reuse pathways | Geo-construction, green infrastructure, compost, cement, and asphalt. Some countries allow landfill mining and restoration of previously disposed WFS [109]. | Manufacturing, structural fill, road bases, manufactured soils, and landfill daily cover. Agricultural reuse is allowed if pollutant levels are low [111]. | Primarily limited to internal reuse or licensed projects; off-site reuse for construction requires full compliance and licensing, seldom permitted for direct land application [110]. |

| Examples of policy innovations | The Finnish MARA decree includes WFS in geo-construction, and pilot composting projects have produced national implementation guidelines [112]. | States like Illinois and Indiana exempt compliant WFS from some industrial waste regulations, and the EPA supports silica-based WFS for soil and road uses [106,111]. | Several reclamation initiatives respond to local pollution concerns, but broader regulatory harmonization with international practice is lacking [107,110]. |

| Key barriers/challenges | Harmonization of ecotoxicity protocols; member state variability. Some hesitation due to public perception and a lack of pan-European standards [34]. | State-by-state differences, lack of federal uniformity, and inconsistent organics regulation make it complex to approve higher-risk applications [111]. | High administrative burden; hazardous default classification raises costs and reduces incentive for proposed reuse; limited sector-specific standards [108,110]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niyonyungu, F.; Ogra, A.; Ngcobo, N. Foundry Sand in Sustainable Construction: A Systematic Review of Environmental Performance, Contamination Risks, and Regulatory Frameworks. Constr. Mater. 2025, 5, 57. https://doi.org/10.3390/constrmater5030057

Niyonyungu F, Ogra A, Ngcobo N. Foundry Sand in Sustainable Construction: A Systematic Review of Environmental Performance, Contamination Risks, and Regulatory Frameworks. Construction Materials. 2025; 5(3):57. https://doi.org/10.3390/constrmater5030057

Chicago/Turabian StyleNiyonyungu, Ferdinand, Aurobindo Ogra, and Ntebo Ngcobo. 2025. "Foundry Sand in Sustainable Construction: A Systematic Review of Environmental Performance, Contamination Risks, and Regulatory Frameworks" Construction Materials 5, no. 3: 57. https://doi.org/10.3390/constrmater5030057

APA StyleNiyonyungu, F., Ogra, A., & Ngcobo, N. (2025). Foundry Sand in Sustainable Construction: A Systematic Review of Environmental Performance, Contamination Risks, and Regulatory Frameworks. Construction Materials, 5(3), 57. https://doi.org/10.3390/constrmater5030057