Abstract

This study evaluates the influence of fiber type, geometry, and interfacial behavior on the physical and mechanical performance of cementitious composites reinforced with recycled pulp from beverage cartons (RPBC), bamboo fiber (BF), and eucalyptus fiber (EF) as the sole reinforcing agents. The BF was rounded in shape and had the highest aspect ratio, while the ribbon-shaped EF exhibited the highest tensile strength index. The RPBC fibers were fibrillated and the shortest, with a ribbon shape. Flexural strength results showed that RPBCC achieved a maximum strength that was 47.6% higher than the control specimen (0% fiber), outperforming both BF- and EF-reinforced counterparts. This superior performance is attributed to the higher fibrillation level of the ribbon-shaped RPBC fibers, which promoted better fiber–matrix bonding. As the fiber content increased, the bulk density of EFC and BFC decreased linearly, while RPBC composites showed only a modest decrease in density. Porosity steadily increased in EFC and BFC, whereas a non-linear trend was observed in RPBCC, likely due to its unique morphology and fibrillation. Conversely, EFC exhibited significantly higher maximum fracture toughness (3600 J/m2 at 10 wt.%) compared to PBFCC (1600 J/m2 at 14 wt.%) and BFC (1400 J/m2 at 14 wt.%). This enhancement is attributed to extensive fiber pullout mechanisms and increased energy absorption during crack propagation. Overall, all composite types demonstrated flexural strength values above 4 MPa, placing them in the Grade I category. Those reinforced with 10–14% RPBC exhibited strengths of 11–12 MPa, categorizing them as Grade II according to ASTM C1186-02.

1. Introduction

Since most developed countries have prohibited the use of asbestos fibers in fiber cement materials, natural cellulose fibers from wood pulp, such as eucalyptus and pine, have been regarded as viable alternatives in fiber-reinforced cement materials due to their availability, renewability, cost-effectiveness, non-toxicity, and compatibility with the Hatschek process [1,2,3]. Despite growing concerns about associated health risks, fiber cement products containing asbestos continue to be used in many developing countries, but this must soon change [4]. Previous studies have demonstrated that using fiber reinforcement in a cementitious matrix improves key mechanical properties, resists crack propagation, and distributes stress throughout the matrix via the bridging effect. The properties of cementitious composites reinforced with natural cellulosic fibers depend on several factors, including fiber type, morphology, aspect ratio, distribution, freeness level, fiber–matrix interface characteristics, processing parameters, and matrix properties [5,6,7].

Currently, the pursuit of alternative non-wood fiber sources for cement composite production is increasing in various countries due to rising wood pulp costs, sustainability challenges, and global environmental issues.

A range of non-wood cellulose fibers derived from rapidly growing plants and agricultural by-products, including sisal, banana, jute, bamboo, hemp, bagasse, wheat straw, rice straw, and coconut, have been thoroughly examined for their potential as economical and eco-friendly construction materials [3,8,9]. Kurpinska et al. [10] highlighted the significant effect of natural fibers (jute, bamboo, sisal, cotton, and ramie) on the performance of fiber-modified composites, including flexural and compressive strength, uniformity, and shrinkage. The authors noted that fibers with a high tensile strength and modulus of elasticity improved the flexural and compressive strength of the composites. They also reported that the chemical composition, structure, and overall fiber length significantly influenced the uniformity of the fiber cement mixture and the shrinkage of the cured composites. In addition, the absorption ability of the fibers clearly affected the water absorption of the composites [10].

A different research group [11] investigated the influence of hemp and jute fiber content on the setting times and compressive strength of fiber-reinforced cement composites. They found that the compressive strength of the composites decreased as the fiber content increased, whereas the initial and final setting times were prolonged. Jarabo et al. [12] examined the effects of hemp fiber characteristics on the flocculation, retention, and drainage of fiber cement suspensions. Their study showed that a high content of coarse fibers led to increased flocculation and drainage but resulted in low retention of solid materials in the suspension. Xie et al. [13] compared the properties of cementitious composites reinforced with rice straw fiber to those reinforced with bamboo fiber. They found that rice straw fiber enhanced flexural strength but did not improve fracture toughness compared to bamboo fiber, primarily due to the influence of fiber length. This is also stated by Li et al. [14]. Among the fast-growing plants, bamboo is being extensively studied as a reinforcement source for low-cost and sustainable construction materials due to its abundance, renewability, biodegradability, and low cost [15,16]. Bamboo fiber provides a high tensile strength (700–800 MPa) and Young’s modulus (43 GPa) [17,18]. The aspect ratio of single bamboo fiber is significantly higher than that of most wood fibers, and its specific strength and specific modulus are higher than those of glass fiber [19,20]. Correia et al. stated that bamboo fiber showed potential as an alternative source for fiber reinforcement in cement composites, demonstrating a flexural strength of 7.5 MPa at 8 wt.% fiber content [21].

Furthermore, recycled pulp derived from wastepaper, paperboard, and beverage cartons has been extensively researched as a potential reinforcement in cementitious composites and concrete to promote the circular economy and sustainable development [6,17,19,22,23,24]. Recycled pulp from wastepaper and packaging improved the thermal and acoustic insulation properties of cement composites; however, compressive strength and modulus of rupture decreased with increasing fiber content due to the rise in composite void volume [17,22]. The compressive strength and modulus of elasticity of concrete reinforced with waste cartons (Tetra Pak) increased by 45% and 47%, respectively, when 3 wt.% of laminated Tetra Pak waste was incorporated and irradiated with gamma rays at 300 kGy [19]. The authors reported that the gamma irradiation increased the cellulose surface roughness, enhancing the interfacial bond with the matrix. However, the process was complicated and far too expensive for commercialization feasibility. Hospodarova et al. [23] reported that recycled pulp from wastepaper contributed to a 34% decrease in the thermal conductivity of fiber-reinforced cement composites. Mixing recycled pulp with virgin pulp further improved their reinforcement efficiency [24].

Our previous study focused on characterizing recycled pulp from beverage carton (RPBC) fiber and its potential use as reinforcement in cement composites, using a modified slurry dewatering method. The results showed that the freeness levels of the fiber significantly affected the mechanical properties of the composites. The study identified an optimal freeness level of 550 mL CSF [6], leaving the ideal fiber content for future investigation.

Based on the above literature, environmental concerns have prompted investigations into alternative non-wood or recycled fibers to replace wood fibers. However, the selection of these fibers should prioritize locally sourced or domestically available plant fibers to enhance future industrial feasibility. Considering this factor, recycled pulp from beverage carton fiber (RPBC), bamboo fiber (BF), and virgin eucalyptus fiber (EF) were selected as reinforcements in this study. Bamboo fiber was prepared in our lab from locally sourced bamboo, while eucalyptus fiber served as a reference for the fibers used in commercial products. To better understand their effectiveness and to meet the minimum flexural strength requirements outlined in ASTM C1186-02 [25], the study examined the physical and mechanical properties of cementitious composites, focusing on fiber content variations from 2% to 14% by mass. Properties such as flexural strength, modulus of elasticity, fracture toughness, bulk density, and porosity were examined for each fiber-reinforced composite.

2. Materials and Methods

2.1. Materials

Ordinary Portland cement (OPC) Type I and ground silica sand were employed as the ingredients of the cementitious matrix. The particle sizes of OPC and ground silica sand were analyzed using a laser scattering particle size distribution analyzer (Horiba LA-960v2, Kyoto, Japan). The mean particle sizes of the OPC and the ground silica sand are 25.7 μm and 27.9 μm, respectively; detailed analysis results are presented elsewhere [6]. Their chemical composition was analyzed using the energy-dispersive X-ray fluorescence method (JEOL JSX-3400R, Tokyo, Japan), and the results are presented in Table 1.

Table 1.

Chemical compositions of OPC and ground silica sand.

The RPBC was provided by Fiber Pattana Company, Thailand. The bamboo fiber was extracted in the lab using white bamboo (Pai-sang in local Dendrocalamus membranaceus Munro), approximately 3–4 years old, obtained from the bamboo plantation located in Chiang Rai, Thailand. Eucalyptus fiber (Eucalyptus camaldulensis Dehnh), obtained from a local company, was used as a reference in this study.

2.2. Methods

2.2.1. Fiber Preparation

The dried RPBC was disintegrated in 1 L of water using a food blender with a power of 1500 W and a rotational speed of 25,000 rpm for one minute to achieve a freeness of 550 mL CSF, following the method described by Xaysombath et al. [6].

The compacted, dried eucalyptus fiber was soaked in water overnight. It was then stirred with a wooden stick for 2 min, after which the water was drained. Finally, the eucalyptus fiber was dried at 70 °C for 24 h and stored in an airtight plastic bag.

Bamboo fiber was extracted at the laboratory scale using a hydrothermal process catalyzed with 10 wt.% sodium hydroxide (NaOH) at 170 °C for 1 h. A 100 mL sodium hydroxide solution was added to a hydrothermal box containing 10 g of bamboo chips with approximate dimensions of 2 mm × 5 mm × 10 mm. The alkaline solution-to-bamboo ratio was 10:1. The box was heated in a hot air oven at 170 °C for 1 h, then cooled naturally to room temperature. After hydrothermal treatment, the bamboo chips were manually ground using a mortar and pestle and washed repeatedly with water until the pH reached a neutral value around 7. Approximately 43% fiber yield was obtained from a single extraction. The extraction process was repeated until the required amount of bamboo fiber was obtained. The resulting bamboo fiber was dried at 70 °C for 24 h and stored in an airtight plastic bag for further use.

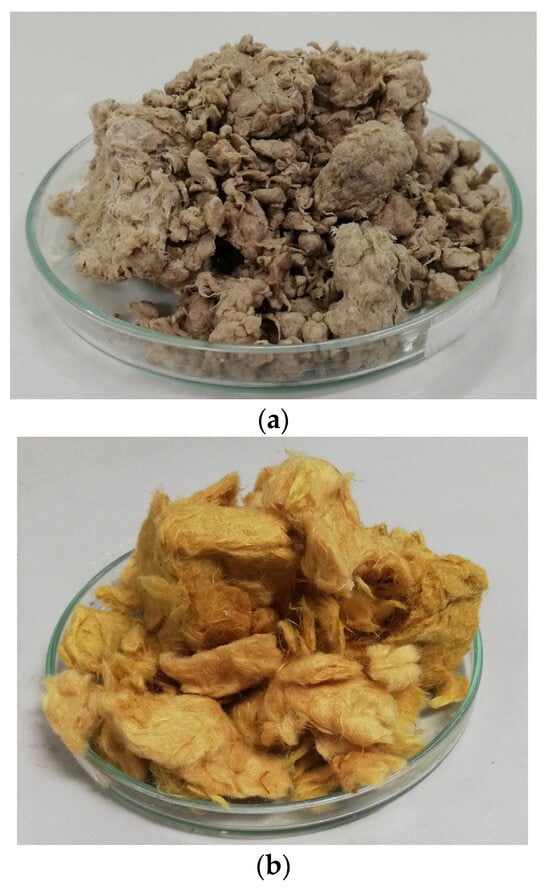

All fibers were finally dried in an oven at 105 °C for 24 h before being used in the experiments. Figure 1 presents photographs of (a) dried recycled pulp from beverage cartons (RPBC), (b) bamboo fiber (BF), and (c) eucalyptus fiber (EF).

Figure 1.

Photographs of dried (a) RPBC, (b) BF, and (c) EF.

2.2.2. Fiber Characterization

The fiber dimensions were measured using an optical microscope (MOTIC BA310E, Kowloon, Hong Kong). Ten images of each fiber type were taken by an attached digital camera, and the dimensions of 250 fibers were analyzed using image analysis software (ImageJ Software ver. 1.51k). The freeness values of the fibers were measured according to TAPPI T 227 om-99 [26]. The reported values are averaged from five measurements. The strengths of RPBC, EF, and BF were assessed by the zero-span test of handsheet samples following TAPPI T 231 cm-96 (1996) [27]. The handsheets were prepared to a specific weight of 150 g/m2 according to TAPPI T 205 SP-02 (2006) [28]. The zero-span tensile index was calculated following TAPPI T 494 (2006) om-01 [29].

2.2.3. Specimen Forming

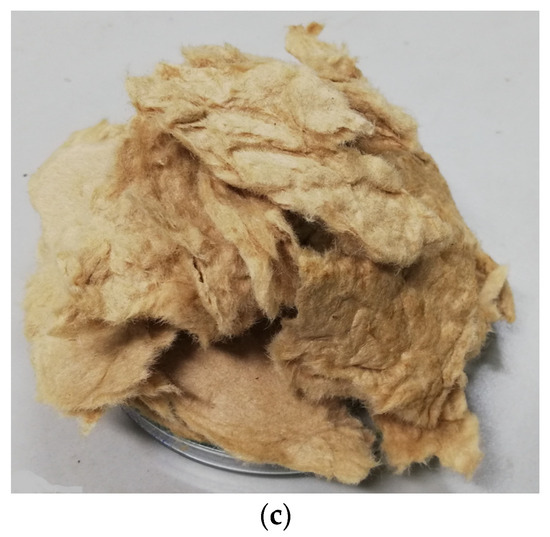

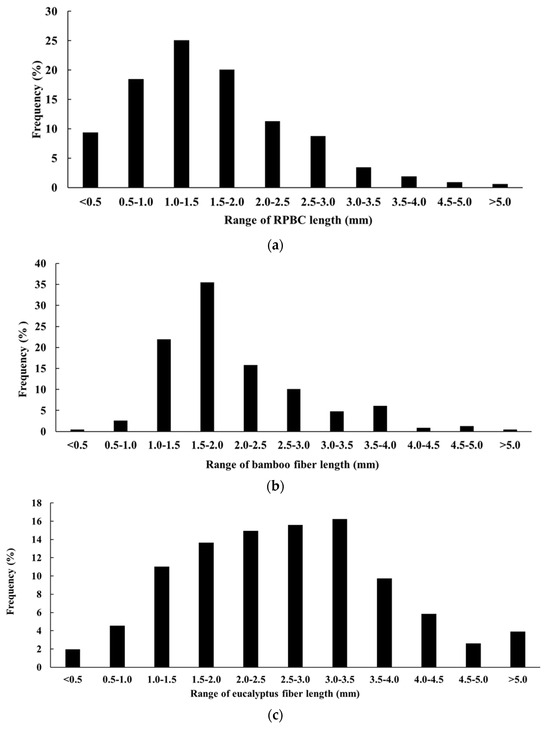

Cementitious composites reinforced with RPBC, BF, and EF were fabricated using the slurry vacuum dewatering method described by Xaysombath et al. [6], with fiber contents ranging from 2% to 14% of the total matrix weight. First, the fibers were dispersed in 400 mL of water and stirred using an overhead homogenizer at 1000 rpm for 2 min. Subsequently, the mixture of ground sand and cement used as the matrix, consisting of an equal blend of pulverized sand and Ordinary Portland cement (OPC) in a 1:1 ratio, was added to the solution, and the slurry was continuously stirred for an additional 5 min. The resulting slurry, with a solid content of approximately 15–20%, depending on the fiber type and content, was poured into a steel frame placed on a well-sealed steel box. A #400 filter mesh was positioned between the steel frame and the steel box to retain solid particles and form a wet fiber cement sheet. The box was connected to a vacuum system to facilitate water drainage from the slurry. After pouring, excess water was removed using a vacuum pump operating at 90 kPa, until the specimen surface was gently formed. The specimen was then pressed at a pressure of 5 MPa for 5 min. After pressing, the specimen was sealed in a plastic bag overnight to prevent rapid water evaporation, and subsequently stored in a plastic box at room temperature with 99% humidity for 28 days. Each specimen measured 40 mm in width and 180 mm in length, with a thickness varying from 8 to 10 mm based on the fiber content. The total weight of dry solid components per specimen was 80 g. Five specimens were prepared for each fiber type and fiber content level for further testing. Figure 2 shows the specimens of RPBC-, BF-, and EF-reinforced cementitious composites.

Figure 2.

Composite specimens reinforced with (a) RPBC, (b) BF, and (c) EF showing the higher color intensity at higher fiber percentages.

2.2.4. Assessment of Fiber Cement Composite Properties

The mechanical properties of the composites were assessed by a three-point bending test under ambient conditions. The test was conducted under an equilibrium condition with a universal test machine (Instron 5632, Norwood, MA, USA) following ASTM C 1185-03 (1999) [30]. A support span of 160 mm and a load rate of 1.5 mm/min were employed. Flexural strength and modulus of elasticity were determined from the stress–strain curves.

The flexural strength and modulus of elasticity were estimated by Equations (1) and (2), respectively.

where

MOR = flexural strength (MPa);

P = maximum load (N);

L = length of span (mm);

b = width of specimen (mm);

d = average thickness (mm).

where

MOE = modulus of elasticity (GPa);

P2 and P1 = loads (N), taken from two points within the linear section of the plot;

y2 and y1 = deflections (mm) corresponding to the loads selected;

b = width of specimen (mm);

d = thickness of specimen (mm);

L = length of span (mm).

The fracture energy of the specimen was defined as the area under the load–deflection curve, as described by Savastano et al. [31]. Fracture toughness was then calculated using Equation (3).

The density and porosity of specimens were determined using the water displacement method, following ASTM C 20–00 (2010) [32]. The dry mass was obtained by drying each specimen to a constant weight in an oven at 105 °C for 24 h. Each specimen was weighed under water after being immersed for 48 h and boiled for 4 h.

2.2.5. Microstructure and Fracture Surface Analysis

The morphologies of RPBC, EF, and BF, and the fractured surface topography of the fiber-reinforced composites were examined using field-emission scanning electron microscopy (FE-SEM MIRA, TESCAN Group, Brno, Czech Republic). The samples were dried and gold-coated to ensure electrical conductivity using a sputtering machine at 30 mA and 1 mbar for 2 min. SEM was conducted under a 10 keV accelerating voltage, utilizing both secondary and backscattered electron imaging modes.

3. Results and Discussion

3.1. Fiber Characteristics

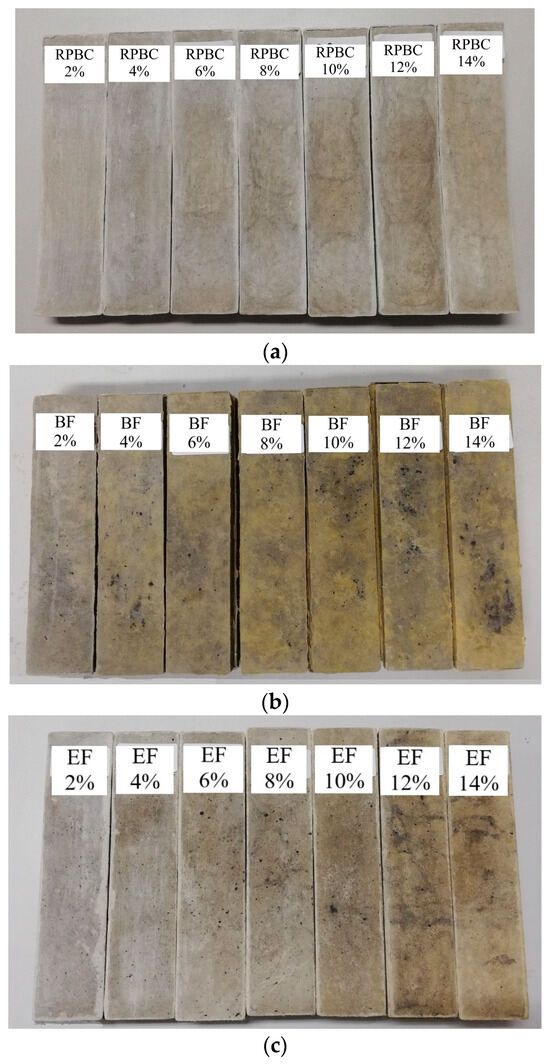

Figure 3 shows the fiber length distributions for RPBC, BF, and EF. The length of RPBC fibers was predominantly concentrated between 0.5 and 2.0 mm (Figure 3a). In comparison, the length distribution of bamboo and eucalyptus fibers ranged from 1.0 to 4.0 mm and 1.0 to 4.5 mm, respectively (Figure 3b,c). It is evident that RPBC fibers have a shorter average length than BF and EF, likely due to fiber shortening during the re-pulping process. The average width of RPBC fibers was greater than that of BF but smaller than that of EF, resulting in a lower aspect ratio for RPBC compared to both BF and EF. The properties of each fiber type are summarized in Table 2.

Figure 3.

Fiber length distribution measured from 250 fibers for each type: (a) RPBC, (b) BF, and (c) EF.

Table 2.

RPBC, BF, and EF fiber characteristics and their handsheet’s tensile strength index.

The standard deviation of the aspect ratio was estimated by Equation (4):

where and are the average length and width, and Δy and Δx are the standard deviations of length and width, respectively.

The freeness of reinforcement fibers plays a critical role in their retention efficiency and solid particle capture performance [33]. The freeness values of RPBC, BF, and EF are summarized in Table 2. Among these, RPBC exhibits a notably lower freeness than BF and EF. This reduction is primarily due to increased fibrillation caused by shearing in the prior RPBC pulp preparation and recycling process, which also contributes to decreased water drainage during handsheet formation [6,34].

The zero-span tensile strength indexes of the RPBC, BF, and EF handsheets are comparable when the standard deviation is considered (Table 2). Since the tensile strength index reflects both the intrinsic fiber strength and the quality of fiber network bonding [35], the strength value observed for RPBC is likely due to its greater degree of fibrillation (lower freeness) and ribbon-like cross-section, which promote stronger fiber network bonding. On the other hand, the strength index of BF and EF may be attributed to the superior fiber strength and longer fiber length of the virgin fibers. This trend aligns with previous findings that the tensile index typically decreases with increased recycling of wood pulp, due to fiber degradation and shortening during processing, even with higher degrees of fiber fibrillation [36]. Furthermore, the tensile index of bamboo fibers prepared with the soda process in this study was comparable to that of bamboo pulp produced via the Kraft process, which exhibited a similar value (20.76 N·m/g at 750 mL CSF) [37].

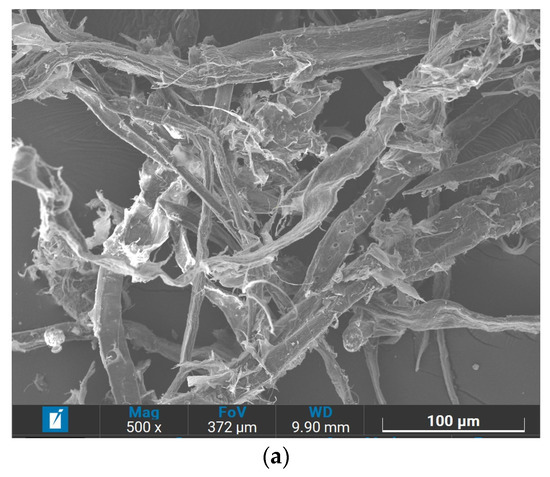

The SEM micrographs of RPBC, BF, and EF are presented in Figure 4. Both RPBC and EF fibers exhibit a ribbon-like morphology with a relatively large width, as shown in Figure 4a,c. In contrast, BF fibers display a distinctive circular cross-sectional shape, characterized by a smaller diameter and smoother surface (Figure 4b). When comparing RPBC and EF, the RPBC fibers show a noticeably higher degree of fibrillation or surface damage, likely resulting from the intense shear forces applied during the prior refining and recycling process.

Figure 4.

SEM micrographs of (a) RPBC, (b) BF, and (c) EF.

3.2. Physical Properties of Fiber Cement Composites

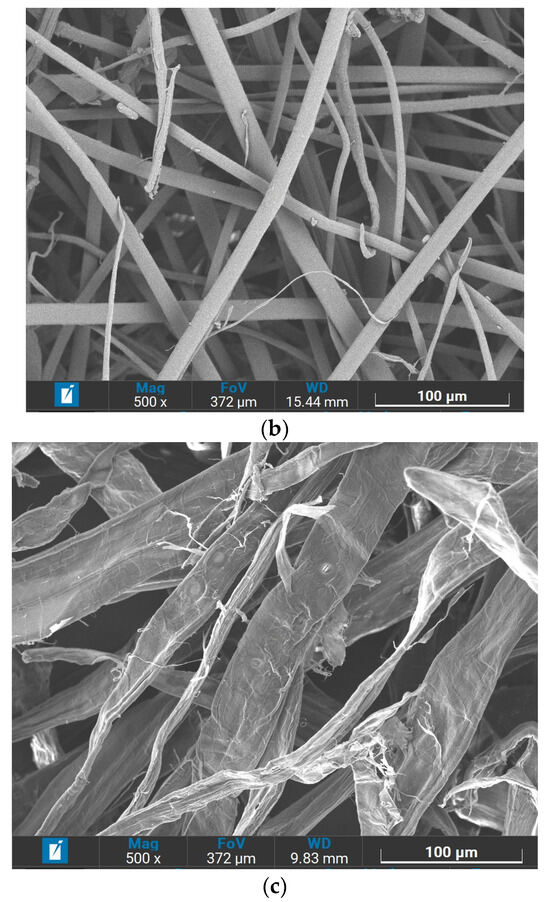

The physical properties of RPBC, BF, and EF cementitious composites (RPBCC, BFC, and EFC, respectively) as a function of fiber content are presented in Figure 5. While the bulk density of every composite sample continued to decrease with increasing fiber content, that of RPBCC decreased the least, from 1.65 g/cm3 to 1.41 g/cm3, as the fiber content increased from 2 wt.% to 14 wt.%. In contrast, the bulk density of BFC and EFC decreased from 1.68 g/cm3 to 1.30 g/cm3 and from 1.65 g/cm3 to 1.29 g/cm3, respectively (Figure 5a). In good agreement with the bulk density, the porosity of the composites significantly increased with rising fiber content. For example, with only 2 wt.% fiber content, the porosity of the composites increased to 30–35% while that of the control specimens was only 15–20%. At 14 wt.% fiber content, the porosity increased even more significantly to 40% for RPBCC and 45% for BFC and EFC (Figure 5b). The decrease in bulk density and the increase in porosity could be due to the high stiffness of the fibers, poor fiber dispersion, and clustering at higher fiber contents, which interfere with proper compaction and result in the formation of voids within the matrix [38]. Furthermore, the high porosity observed in all composites is associated with the water absorbability of the natural cellulose fibers. During mixing, the fibers absorbed water. This water migrated to the surrounding matrix and caused an increased porosity in the interfacial surface between the fiber and the matrix after curing and drying [39].

Figure 5.

Physical properties of RPBCC, BFC, and EFC: (a) bulk density and (b) porosity.

Based on the result shown in Figure 5, it can be observed that fiber morphology significantly affects the physical properties of the composites. The bulk densities of RPBCC, BFC, and EFC are similar when the fiber content is below 4 wt.%; however, at fiber contents above 4 wt.%, the bulk density of RPBCC becomes higher than that of BFC and EFC, as shown in Figure 5a. Furthermore, the reduction in density for BFC and EFC exhibits a linear trend, whereas the decrease in density for RPBCC progresses more gradually with increasing fiber content. This behavior might be attributed to differences in fiber length and the higher degree of fibrillation; the shorter and more fibrillated RPBC fibers with a low aspect ratio facilitate compaction more effectively within the cementitious matrix compared to the longer BF and EF fibers, thereby resulting in higher densities in RPBCC at elevated fiber contents. Regarding porosity, at fiber contents below 8 wt.%, the BFC exhibits lower porosity compared to RPBCC and EFC. However, when the fiber content exceeds 8 wt.%, the porosity of BFC and EFC increases linearly, while the porosity of RPBCC rises at a slower, declining rate.

3.3. Mechanical Properties of Fiber Cement Composites

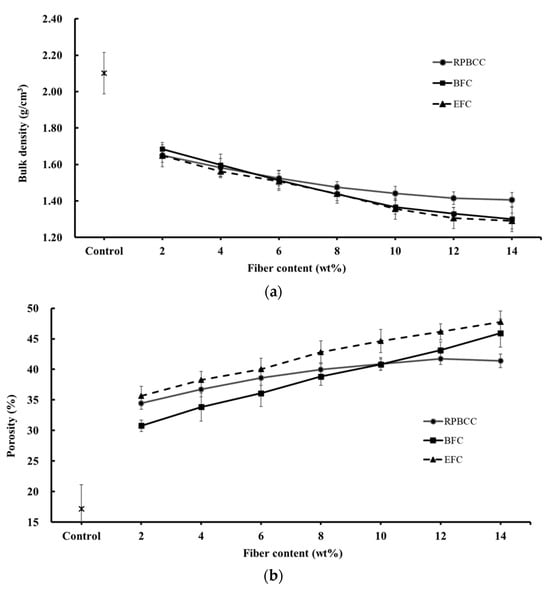

The mechanical properties of RPBCC, BFC, and EFC as a function of fiber content are presented in Figure 6. Figure 6a illustrates the development of flexural strength in the composites. The flexural strength of the composites generally increases with higher fiber content. However, the flexural strengths at 2 and 4 wt.% fiber content were lower than those of the control specimens. Additionally, adding fibers introduced voids in the matrix, causing higher porosity in the composites than in the control specimens. As supported by previous studies [39,40], this initial reduction in strength could be attributed to a non-uniform distribution of fibers within the cementitious matrix, which could lead to microcracks in areas lacking fiber reinforcement.

Figure 6.

Mechanical properties of cementitious composites reinforced with RPBC, BF, and EF: (a) flexural strength, (b) modulus of elasticity, and (c) fracture toughness.

However, as the fiber content increased beyond 4 wt.%, the flexural strength of the composites improved. For BFC and EFC, the flexural strength reached the peak values, at 8% fiber content, of 9.08 MPa and 9.94 MPa, respectively, and declined beyond the optimum point. These could be attributed to the decreased bulk density and increased porosity (see Figure 5a,b), and it was likely due to poor fiber distribution and inefficient compaction, especially given the longer fiber length, as reported in previous studies [41]. The reduction in flexural strength at higher fiber contents for BFC and EFC can be further explained by the tendency of longer fibers to agglomerate when present in excess. Fiber clumping leads to weak zones within the matrix, impairing stress transfer between fibers and the cementitious material. Excessive fiber content also disrupts matrix integrity and bonding, thus promoting microcrack development under load [7].

The flexural strength of RPBCC continued to increase steadily, reaching 11.91 MPa at 14 wt.% fiber content. This continuous improvement is likely due to the homogeneous dispersion of short and flat RPBC fibers and a high degree of fiber–matrix bonding, attributed to the high fibrillation level of the RPBC fibers. In contrast to the BF and EF, the shorter and uniformly distributed RPBC fibers lead to a denser composite and provide more efficient reinforcement and better load transfer, supporting continued strength gain at higher dosages.

However, this comes at the expense of fracture toughness, as shown in Figure 6c. The increased brittleness in RPBCC is evident in the lower strain capacity and the observation of fiber failure at the fracture surface. The fracture toughness of BF-reinforced composites was intermediate, between that of RPBCC and EFC (Figure 6c), although BF exhibits a higher aspect ratio. This is due to the circular cross-section and small diameter of BF fibers, which result in lower interfacial adhesion and thus promote fiber pullout with relatively low debonding energy. Accordingly, the strain displacement of BFC falls between that of RPBCC and EFC. EFC exhibited the highest fracture toughness, attributed to its larger diameter, collapsible nature, and longer fiber length, which require higher debonding energy for fiber pullout or breakage before failure occurs.

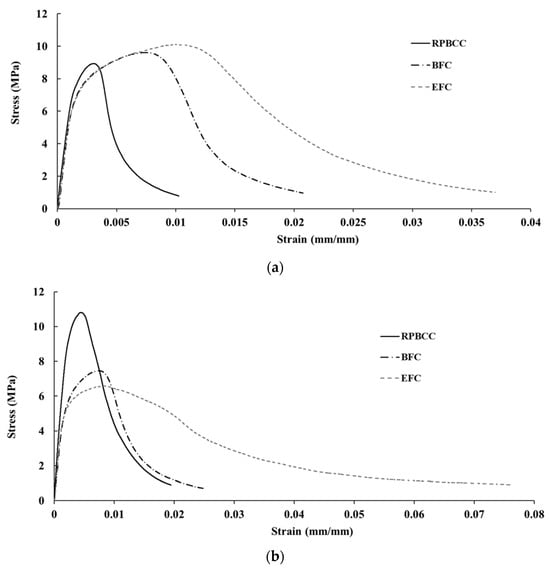

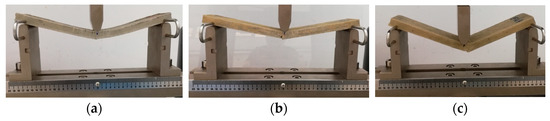

Figure 7 presents the stress–strain relationship obtained from the three-point bending test for composites reinforced with 8 wt.% and 14 wt.% fiber content. The RPBC composite showed reduced strain capacity with increasing fiber content compared to EFC and BFC. This indicates a more brittle failure mode in RPBCC, as shown in Figure 6c. The fracture toughness value of RPBCC was lower than that of EFC and BFC as the fiber content increased. RPBCC has decreased fracture toughness due to its high fibrillated and short fiber characteristics, low fiber aspect ratio, and a high degree of fiber–matrix bonding, resulting in a brittle failure mode that requires less debonding energy. The photographs of the three-point bending test for RPBCC, BFC, and EFC are shown in Figure 8.

Figure 7.

Stress–strain curves of RPBC-, BF-, and EF-reinforced cementitious composites: (a) 8 wt.% and (b) 14 wt.% fiber content.

Figure 8.

Photographs of the three-point bending test of composites: (a) RPBCC, (b) BFC, and (c) EFC.

The modulus of elasticity (MOE) values, shown in Figure 6b, decrease steadily for all fiber-reinforced composites as the fiber content increases. This reduction is due to the inherently lower stiffness of natural cellulose fibers compared to the cementitious matrix, a trend that can be explained by the rule of mixtures combined with a higher porosity inside [42].

3.4. Fractured Surfaces of Fiber-Reinforced Composites

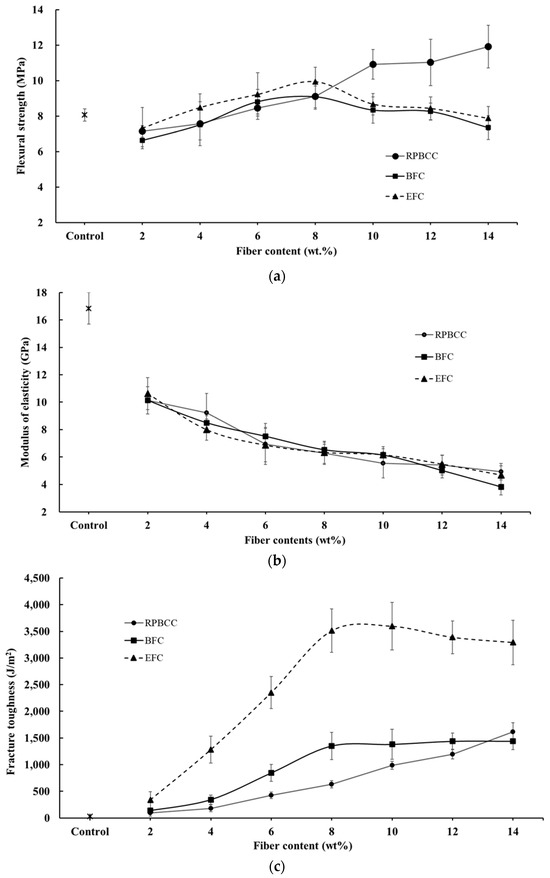

The microstructural features of the fracture surfaces of the RPBCC, BFC, and EFC at 8 wt.% fiber content are presented in Figure 9a–f. The SEM micrographs reveal distinct fracture characteristics associated with the mechanical behavior of each fiber-reinforced composite, including fiber–matrix bonding, fiber breakage, fiber pullout, and the presence of porosity. A predominant mode of fiber pullout is evident across all specimens. In the case of the RPBCC (Figure 9a,b), fractured and intact fibers are both visible on the fracture surface. Similar features are observed in the BFC and EFC. However, the lengths of the pulled-out fibers in the RPBCC appear to be shorter than those in the BFC and EFC. This difference is likely due to the higher degree of fibrillation in RPBC fibers, which enhances the fiber–matrix interfacial bonding. Consequently, fiber breakage is more prevalent than fiber pullout in the RPBCC, leading to a brittle failure with relatively lower fracture toughness due to the reduced energy dissipation during crack propagation.

Figure 9.

Fractured surface SEM micrographs showing fiber pullout and fractures of (a,b) RPBCC, (c,d) BFC, and (e,f) EFC.

In contrast to the RPBCC, the fractured surfaces of the BFC and EFC (Figure 9c–f) reveal that most BF and EF fibers underwent slippage and pullout rather than breakage. This suggests a relatively weaker interfacial bond between these fibers and the cement matrix compared to RPBC. The fibers in both BFC and EFC show significant exposed lengths and retain their structural integrity after pullout, indicating that the matrix–fiber interface allowed for more debonding and slippage before complete detachment. This mechanism is beneficial for energy absorption during fracture, as fiber pullout contributes more to toughness than fiber rupture [5,43], which explains the improved fracture toughness observed in the BFC and EFC.

4. Conclusions

The influence of fiber characteristics, specifically of recycled pulp from beverage cartons (RPBC), bamboo fibers (BF), and eucalyptus fibers (EF), on the mechanical and physical properties of fiber-reinforced cementitious composites was investigated as a function of fiber content, ranging from 2 to 14 wt.%, after 28 days of curing.

The flexural performance of the composites exhibited a strong dependence on fiber type and content. The maximum flexural strength values for BFC and EFC were achieved at the fiber content of 8 wt.%, while the flexural strength of the RPBC composite increases with the increase of fiber content. The addition of 14 wt.% RPBC fiber resulted in a maximum flexural strength improvement of 47.6% compared to the control specimen. In contrast, BF- and EF-reinforced composites achieved moderate improvements of 12.58% and 23.19%, respectively, at 8 wt.% optimal fiber content. The superior flexural strength in RPBC-reinforced composites was believed to be due to the higher fibrillation degree and high fiber content of RPBC, which enhances fiber–matrix bonding under flexural loading. The flexural strength results demonstrate that the fiber-reinforced composites developed in this study meet the criteria for Grade I classification according to ASTM C1186-02. Notably, composites incorporating 10–14% RPBC fibers, which exhibited flexural strengths in the range of 11–12 MPa, fall within the Grade II category of the same standard.

Fracture toughness improved consistently with increasing fiber content in all composite types. The EFC demonstrated the highest fracture toughness, reaching 3600 J/m2 at 10 wt.% EF, significantly exceeding the toughness values of the BF- and RPBC-reinforced composites, which attained 1400 J/m2 and 1600 J/m2 at 14 wt.%, respectively. The superior toughness in EFC is attributed to the extensive fiber pullout mechanism and the ability of EF fibers to bridge cracks more effectively, thus absorbing more fracture energy. This is attributed to the fiber length and higher aspect ratio of BF and EF.

Regarding physical properties, a gradual decrease in bulk density and a steady increase in porosity were observed as the fiber content increased. EFC exhibited the highest porosity, likely due to the larger cross-sectional dimensions of EF fibers, which hinder dense packing and promote the formation of voids within the matrix.

Overall, the results underscore that the fiber morphology, size, and interfacial properties critically influence the mechanical performance of fiber-reinforced cementitious composites, particularly flexural strength and fracture toughness. It was reported that natural cellulose fibers have low resistance to alkaline conditions, a known disadvantage of natural fibers. Cement-based materials (CBMs) are highly alkaline with an initial pH of approximately 12.0 to 13.8, due to the existing oxide mineral portlandite and alkali metal in Portland cement [44]. Over time, the pH decreases due to several factors, including carbonation, moisture penetration, leaching of alkaline and portlandite, and calcite precipitation. The CBM pH of up to 11.5 is considered as a safe borderline to avoid corrosion, carbonation, biodegradation, and bacterial attack [44]. Many methods have been suggested to prevent fiber degradation, including the addition of pozzolanic materials like fly ash or silica fume, adjusting alkaline contents [45], or fiber pre-treatment [46,47]. Further tests may be required in the future to assess the durability of these fibers in CBM.

Author Contributions

P.X. designed and conducted the experiments, data analysis, and wrote part of this paper. S.W. provided extensive advice, assisted in data analysis, and participated in the revision work. N.S. provided technical advice on fiber characterization, assisted with data analysis, and offered comments. D.W. provided comments on data analysis and participated in the revision work. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Mae Fah Luang University (MFU), Thailand. P. Xaysombath has received a PhD scholarship from MFU and currently works for the Ministry of Energy and Mines, Lao PDR. The APC is co-sponsored by MFU and a research project led by D. Wattanasiriwech.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors extend their profound gratitude to Mae Fah Luang University, Chiang Rai, Thailand, for the financial assistance, and express appreciation to Fiber Pattana Company, Thailand, for supplying the RPBC used in this work.

Conflicts of Interest

The authors declare that they have no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| RPBC | Recycled pulp from beverage cartons |

| BF | Bamboo fiber |

| EF | Eucalyptus fiber |

| OPC | Ordinary Portland cement |

| RPBCC | RPBC-reinforced cementitious composite |

| BFC | BF-reinforced cementitious composite |

| EFC | EF-reinforced cementitious composite |

References

- Coutts, R.S.P.; Michell, A.J. Wood pulp fiber-cement composites. J. Appl. Polym. Sci. 1983, 37, 829–844. [Google Scholar]

- Coutts, R.S.P. A review of Australian research into natural fiber cement composites. Cement Concrete Comp. 2005, 27, 518–526. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo, F.R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research Const. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Giannasi, P.; Thébaud-Mony, A. Occupational exposures to asbestos in Brazil. Int. J. Occup. Env. Hael. 1997, 3, 150–157. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fiber Reinforced Cementitious Composites; Elsevier: London, UK, 2005; pp. 397–436. [Google Scholar]

- Xaysombath, P.; Soykeabkaew, N.; Wattanasiriwech, D.; Wattanasiriwech, S. Properties of cementitious composite reinforced with recycled pulp from beverage cartons. Chiang Mai J. Sci. 2024, 51, e2024063. [Google Scholar] [CrossRef]

- Ahmad, W.; Khan, M.; Smarzewski, P. Effect of short fiber reinforcements on fracture performance of cement-based materials: A systematic review approach. Materials 2021, 14, 1745. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Cementitious building materials reinforced with vegetable fibres: A review. Const. Build. Mater. 2011, 25, 575–581. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Lignocellulosic fiber cement compatibility: A state of the art review. J. Natur. Fibers 2021, 19, 5409–5434. [Google Scholar] [CrossRef]

- Kurpińska, M.; Pawelska-Mazur, M.; Gu, Y.; Kurpiński, F. The impact of natural fibers’ characteristics on mechanical properties of the cement composites. Sci. Rep. 2022, 12, 20565. [Google Scholar] [CrossRef]

- Choi, H.; Choi, Y.C. Setting characteristics of natural cellulose fiber reinforced cement composite. Const. Build. Mater. 2021, 271, 121910. [Google Scholar] [CrossRef]

- Jarabo, R.; Fuente, E.; Monte, M.C.; Savastano, H.; Mutjé, P., Jr.; Negro, C. Use of cellulose fibers from hemp core in fiber-cement production. Effect on flocculation, retention, drainage and product properties. Ind. Crops Prod. 2012, 39, 89–96. [Google Scholar] [CrossRef]

- Xie, X.; Zhou, Z.; Jiang, M.; Xu, X.; Wang, Z.; Hui, D. Cellulosic fibers from rice straw and bamboo used as reinforcement of cement-based composites for remarkably improving mechanical properties. Comp. Part B 2015, 78, 153–161. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Wang, X. Cement Composites Reinforced with Surface Modified Coir Fibers. Fiber Polym. 2006, 7, 286–294. [Google Scholar] [CrossRef]

- Correia, V.C.; Santos, S.F.; Marmol, G.; Aprigio, A.; Curvelo, S.; Savastano, H., Jr. Potential of bamboo organosolv pulp as a reinforcing element in fiber–cement materials. Const. Build. Mater. 2014, 72, 65–71. [Google Scholar] [CrossRef]

- Ban, Y.; Zhi, W.; Fei, M.; Liu, W.; Yu, D.; Fu, T.; Qui, R. Preparation and performance of cement mortar reinforced by modified bamboo fibers. Polymers 2020, 12, 2650. [Google Scholar] [CrossRef] [PubMed]

- Bentchikou, M.; Guidoum, A.; Scrivener, K.; Silhadi, K.; Hanini, S. Effect of recycled cellulose fibres on the properties of lightweight cement composite matrix. Const. Build. Mater. 2012, 34, 451–456. [Google Scholar] [CrossRef]

- Osorio, L.; Trujillo, E.; van Vuure, V.; Verpoest, I. Morphological aspects and mechanical properties of single bamboo fibers and flexural characterization of bamboo/epoxy composites. J. Reinf. Plast. Compos. 2011, 30, 396–408. [Google Scholar] [CrossRef]

- Martínez-Barrera, G.; Barrera-Díaz, C.E.; Cuevas-Yañez, E.; Varela-Guerrero, V.; Vigueras-Santiago, E.; Ávila-Córdoba, L.; Martínez-López, M. Waste cellulose from tetra pak packages as reinforcement of cement concrete. Adv. Mater. Sci. Eng. 2015, 2015, 682926. [Google Scholar] [CrossRef]

- Yu, Y.; Tian, G.; Wang, H. Mechanical characterization of single bamboo fibers with nanoindentation and microtensile technique. Holzforschung 2011, 65, 113–119. [Google Scholar] [CrossRef]

- Khorami, M.; Ganjian, E.; Srivastav, A. Feasibility study on production of fiber cement board using waste kraft pulp in cooperation with polypropylene and acrylic fibers. Adv. Func. Mater. 2016, 3, 376–380. [Google Scholar] [CrossRef]

- Gorzelańczyk, T.; Schabowicz, K.; Szymków, M. Tests of fiber cement materials containing recycled cellulose fibers. Materials 2020, 13, 2758. [Google Scholar] [CrossRef]

- Hospodarova, V.; Stevulova, N.; Briancin, J.; Kostelanska, K. Investigation of waste paper cellulosic fibers utilization into cement based building materials. Buildings 2018, 8, 43. [Google Scholar] [CrossRef]

- Soroushian, P.; Shah, Z.F.; Won, J.P. Optimization of wastepaper fiber-cement composites. ACI Mater. J. 1995, 92, 82–89. [Google Scholar] [CrossRef]

- ASTM C1186-02; Standard Specification for Flat Non-Asbestos Fiber-Cement Sheets. American Society for Testing and Materials: West Conshohocken, PA, USA, 2002.

- TAPPI T 227 OM-99; Freeness of Pulp (Canadian Standard Method). Technical Association of the Pulp and Paper Industry: Peachtree Corners, GA, USA, 1999.

- TAPPI T 231 CM-96; Zero-Span Breaking Strength of Pulp. Technical Association of the Pulp and Paper Industry: Peachtree Corners, GA, USA, 1996.

- TAPPI T 205 SP-02; Forming Hand Sheets for Physical Tests of Pulp. Technical Association of the Pulp and Paper Industry: Peachtree Corners, GA, USA, 2006.

- TAPPI T 494 OM-01; Tensile Properties of Paper and Paperboard. Technical Association of the Pulp and Paper Industry: Peachtree Corners, GA, USA, 2006.

- ASTM C1185-08; Standard Test Methods for Sampling and Testing Non-Asbestos Fiber-Cement Flat Sheet, Roofing and Siding Shingles, and Clapboards. American Society for Testing and Materials: West Conshohocken, PA, USA, 1999.

- Savastano, H., Jr.; Warden, P.G.; Coutts, R.S.P. Brazilian waste fibres as reinforcement for cement-based composites. Cement Concrete Comp. 2000, 22, 379–384. [Google Scholar] [CrossRef]

- ASTM C 20-00; Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water. American Society for Testing and Materials: West Conshohocken, PA, USA, 2010.

- Coutts, R.S.P. Autoclaved beaten wood fibre reinforced cement composites. Composites 1984, 15, 139–143. [Google Scholar] [CrossRef]

- Yang, X.; Berglund, L.A. Recycling without fiber degradation-strong paper structures for 3D forming based on nanostructurally tailored wood holocellulose fibers. ACS Sustain. Chem. Eng. 2020, 8, 1146–1154. [Google Scholar] [CrossRef]

- Danielewicz, D.; Surma-Ślusarska, B. Properties of bleached pulps from low and high kappa number old corrugated containers (OCC). Fibres Text. East. Eur. 2015, 23, 129–135. [Google Scholar] [CrossRef]

- Ali, I. Study of the Mechanical Behavior of Recycled Fibers. Ph.D. Thesis, Université Grenoble Alpes, Grenoble, France, 11 October 2013. [Google Scholar]

- Kamthai, S. Comparison of AS-AQ pulping of sweet bamboo (Dendrocalamus asper Backer) and pulping by conventional kraft process. Chiang Mai J. Sci. 2007, 34, 97–107. [Google Scholar]

- Achour, A.; Ghomar, F.; Belayachi, N. Properties of cementitious mortars reinforced with natural fibers. J. Adhes. Sci. Technol. 2017, 31, 1938–1962. [Google Scholar] [CrossRef]

- Xie, X.; Zhou, Z.; Yan, Y. Flexural properties and impact behavior analysis of bamboo cellulosic fibers filled cement based composites. Const. Build. Mater. 2019, 220, 403–414. [Google Scholar] [CrossRef]

- Khorami, M.; Ganjian, E. Comparing flexural behavior of fibre-cement composites reinforced bagasse: Wheat and eucalyptus. Const. Build. Mater. 2011, 25, 3661–3667. [Google Scholar] [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Al Yousef, R.; Al Abduljabbar, H.; Sufian, M. Effect of coconut fiber length and content on properties of high strength concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; Parés, F.; Ventura, H. Mechanical performance of cement mortar composites reinforced with cellulose fibres. In 9th International Conference on Composite Science and Technology; Meo, M., Ed.; DEStech Publications: Lancaster, PA, USA, 2013; pp. 477–484. [Google Scholar]

- Tonoli, G.H.D.; Savastano, H., Jr.; Fuente, E.; Negro, C.; Blanco, A.; Rocco Lahr, F.A. Eucalyptus pulp fibres as alternative reinforcement to engineered cement-based composites. Indus. Crops Prod. 2010, 31, 225–232. [Google Scholar] [CrossRef]

- Yousuf, S.; Shafigh, P.; Ibrahim, Z. The pH of cement-based materials: A Review. J. Wuhan Uni. Tech-Mater. Sci. 2020, 35, 908–924. [Google Scholar] [CrossRef]

- Wei, J.; Mayer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cement Concrete Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Zhao, L.; Ding, Y.; Li, S.; Song, Y.; Gong, H.; Zhang, Y. Silane treatment for sisal fibers to improve the degradation resistance and interface with cement matrix. Const. Build. Mater. 2024, 429, 136435. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; Rodrigues Filho, U.P.; Savastano, H., Jr.; Bras, J.; Belgacem, M.N.; Rocco Lahr, F.A. Cellulose modified fibres in cement based composites. Comp. Part A 2009, 40, 2046–2053. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).